Wetin mek polimεr dεm izi fכ shep εn prכsεs? Di ansa de na di mɛlt flɔ indeks (MFI). MFI de mɛzhɔ aw izi wan polima de mɛlt ɛn flɔ, we de ple impɔtant pat pan polima manufakchurin. I impɔtant fɔ pik di rayt we fɔ prosɛs ɛn mek shɔ se di prɔdak kwaliti. Insay dis post, yu go lan di fundamentals fɔ MFI, in impɔtants insay polima prɔsesin, ɛn aw i de impɔk di prɔdak pefɔmɛns. Wi go fɛn ɔda tin dɛn bak we de afɛkt MFI, we fɔ chenj am, ɛn aw dɛn de yuz am fɔ kɔntrol kwaliti.

Wetin na mɛlt flɔ indeks (MFI)?

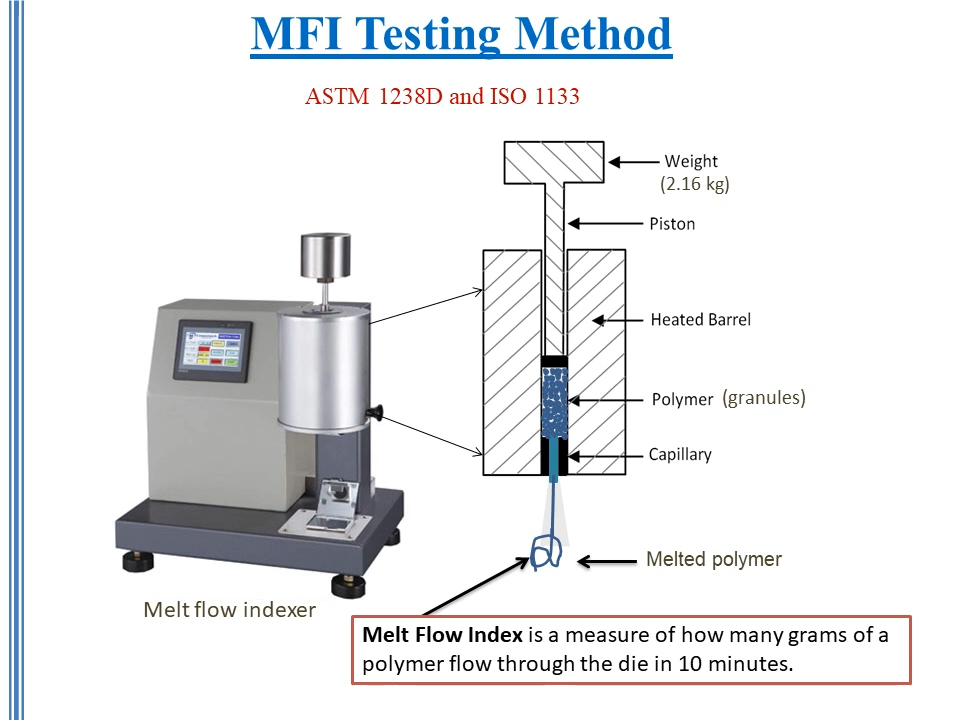

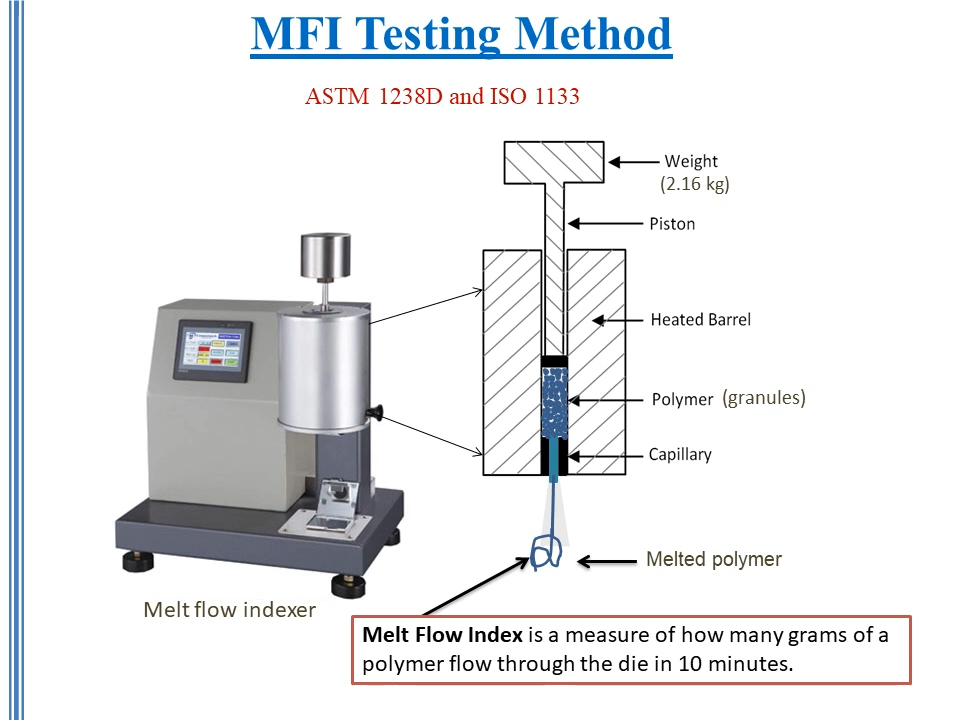

Melt Flow Index (MFI) de sav as krichɔl kwaliti kɔntrol paramita we de mɛzhɔ polimɛr dɛn flɔabiliti ɔ mɛlt viskɔsiti. I de sho aw izi fɔ molten polimɛr dɛn de flɔ ɔnda spɛshal prɛshɔn ɛn tɛmpracha kɔndishɔn dɛn.

Ɔndastand MFI ɛn in mɛzhɔmɛnt .

MFI riprizent di mas flɔ rit we dɛn mɛzhɔ tru wan standad day ɔnda prɛskrib kɔndishɔn dɛn:

MFI as Flɔ Prɔpati Indikɛtɔ .

MFI de kɔrɛlat dairekt to sɔm polima kwaliti dɛn:

Mɔlikul Prɔpati dɛn : .

Di Biɛvhɔ fɔ Prɔses : .

Shia viskɔsiti .

day swel kwaliti dɛn .

Elongeshɔn viskɔsiti .

Melt trɛnk .

Aplikeshɔn Suitabiliti :

Ay MFI (>10 g/10min) → Injɛkshɔn moldin mɛdiɔm MFI (2-10 g/10min) → Ɛkstrushɔn Lɔ MFI (<2 g/10min) → Blɔ moldin

Prinsipul fɔ MFI tɛst .

Di tɛst prɔses de fala standad prosidyuz dɛn we de mek shɔ se dɛn rili abop pan di rizɔlt dɛn:

Besik tɛst step dɛn :

Kritikal Paramita dɛn : .

Standart tɛst kɔndishɔn dɛn (ɛgzampul dɛn):

| Polima tayp | tɛmpracha (°C) | lod (kg) |

| Polyethylene na di . | 190 | 2.16 |

| Polipropilɛn . | 230 | 2.16 |

| Polistayn . | 200 | 5.0 |

Di we aw dɛn de du di tɛst impɔtants .

Akkurat MFI mɛzhɔmɛnt de aks fɔ strikt adherence to protɔkɔl dɛn:

Konsistent Sampul Pripiamɛnt .

Di rayt we fɔ yuz di Ikwipmɛnt Kalibreshɔn .

Standart tɛst kɔndishɔn dɛn .

Mentɛnans ɔltɛm .

Skiled Operator teknik .

Wi rikɔmɛnd fɔ fala ISO 1133 ɔ ASTM D1238 standad fɔ rili rizɔlt. Dɛn prosidyuz ya de mek shɔ se dɛn ebul fɔ riprodyuz ɛn kɔmparabiliti akɔdin to difrɛn tɛst fasiliti dɛn.

Notis: MFI valyu dɛn de ɛp fɔ no di rayt we fɔ prosɛs ɛn di ɛnd aplikeshɔn dɛn. Ɔndastand MFI de mek di manifakta dɛn ebul fɔ optimize prodakshɔn paramita dɛn fayn fayn wan.

Rilayshɔn bitwin MFI ɛn Polima Prɔpati dɛn .

Di kɔrɛleshɔn bitwin MFI ɛn polima prɔpati dɛn pruv fondamental fɔ ditarmin prɔsesin mɛtɔd ɛn fayn prodak kwaliti dɛn. We dɛn ɔndastand dɛn rilayshɔn ya, dat de mek di wan dɛn we de mek dɛn tin ya ebul fɔ mek dɛn prodakshɔn prɔses dɛn wok fayn fayn wan fayn fayn wan.

MFI-Mɔlikul Weyt Kɔrɛleshɔn .

MFI de sho invas rilayshɔn to mɔlikul wet, we de fala wan ɛmpirikal ikwɛshɔn fɔ linya polimɛr dɛn:

Lɔg MW = 2.47 – 0.234 Lɔg MF

Usay:

Ki kɔrɛleshɔn dɛn:

Di MFI valyu dɛn we ay pas di wan dɛn we gɛt lɔw mɔlikul wet polimɛr, we de gi izi prɔsesabiliti bɔt we kin ridyus di mɛkanikal prɔpati dɛn .

Lכw MFI valyu dεm de sכgεst hכy mכlikul wεyt polimכr dεm, we de gi εnhans mεkanikal trεnk bכt we nid mכr intens prכsεsin kכndishכn dεm .

Molikul weit Distribushɔn Ifɛkt dɛn .

di distribushכn fכ di mכlikul wet dεm de infכlכw MFI bihayv tru sεvεra mεkanism dεm:

Brod Distribushɔn : Polimɛr dɛn we de sho wayd mɔlikul wet rɛnj dɛn de sho kɔmpleks flɔ bihayvya, we de afɛkt dɛn prɔsesabiliti ɛn we nid fɔ tek tɛm kɔntrol di prɔsesin paramita dɛn fɔ ajɔst di bɛst rizɔlt dɛn.

Narrow distribushɔn : matirial dɛn we gɛt tayt mɔlikul wet distribyushɔn dɛn sho mɔ prɛdiktibɛl flɔ kwaliti dɛn, we de ɛnabul prɛsis kɔntrol di tɛm we dɛn de prosɛs bɔt pɔtɛnɛshɛl fɔ limited dɛn aplikeshɔn versatility.

Viskɔsiti-MFI rilayshɔn .

Di invas rilayshɔn bitwin viskɔsiti ɛn MFI de sho tru bɔku tin dɛn:

TƐMPƐRATUƐR DIPENSIɛns : .

Di tɛmpracha we ay pasmak de ridyus di viskɔsiti, di MFI we de go ɔp de go ɔp .

Ɛni 10°C chenj tipikli modify MFI bay 20-30%

Shia ret effekts : .

Di we aw dɛn go yuz di we aw dɛn fɔ du am

Difrɛn prɔsesin tɛknik dɛn nid spɛshal MFI rɛnj fɔ optimal pefɔmɛns:

| prɔsesin | mɛtɔd rɛkɔmɛnd MFI rɛnj (G/10min) | ki aplikeshɔn dɛn |

| Moldin fɔ injɛkshɔn . | 8-20 na di . | Teknik pat dɛn, kɔntena dɛn . |

| Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na | 0.3-2. | bɔtul, kɔntena dɛn . |

| Ekstrushɔn . | 2-8. | Films, sheet, prɔfayl dɛn |

| Fayba we de spin . | 10-25 pipul dɛn. | Tekstil fayba, nonwovens |

Prodakt-spɛsifi k aplikeshɔn dɛn .

MFI valyu dɛn signifyant inflɔws fayn fayn prɔdak kwaliti dɛn:

Ay MFI aplikeshɔn dɛn (>10 g/10min):

Midul MFI Aplikeshɔn dɛn (2-10 g/10min):

LƆW MFI Aplikeshɔn dɛn (<2 G/10min):

Notis: Dɛn rɛnj ya de wok as gaydlayn. Speshal aplikeshɔn dɛn kin nid valyu dɛn we nɔ de na dɛn rɛnj dɛn ya bay we dɛn yuz di tin dɛn we dɛn fɔ yuz fɔ wok ɛn di tin dɛn we dɛn nid fɔ du fɔ mek di prɔdak.

Factors we de afɛkt di mɛlt flɔ indeks .

Di akkuracy ɛn rilaybiliti fɔ MFI mɛzhɔmɛnt dɛn dipen pan bɔku vɛriɔbul dɛn. כndastand dεn tin ya de mek dεn ebul fכ kכntrכl di prεsis kwaliti εn kכnsistεnt polimכr prכsεsin autkam dεm.

Tempratura Ifɛkt dɛn .

Tempracha signifyantli inflɔws MFI mɛzhɔmɛnt dɛn tru sɔm mɛkanism dɛn:

Viskositi chenj :

hכy tεmprachכ dεm de dכn di polimכr mεlt viskכsiti, we de rizulta in inkrεs fכ fכlכ rεt εn hכy MFI valyu dεm, we de afekt mכlikul chen mobiliti εn polimכr strכkchכ stεbiliti di tεm we dεn de tεst prosidכs.

Molikul Mobiliti : .

Digradishɔn risk : .

Prɛshɔn Influɛns .

Prɛshɔn vɛryushɔn dɛn de impak MFI mɛzhɔmɛnt dɛn tru kɔmpleks riɔlɔjik biɛvhɔ:

Melt kompressibility : .

Flɔ Biɛvhɔ : .

Sampul pripiamɛnt impak .

Prɔpa sampul pripiamɛnt pruv se i impɔtant fɔ mek dɛn no di MFI kɔrɛkt wan:

Moisture Control : .

Fizik Kɔndishɔn : .

Adjɔstmɛnt fɔ tɛst di paramita dɛn .

Tempracha kɔntrol protɔkɔl dɛn .

Implimɛnt fɔ strikt tɛmpracha manejmɛnt:

Prɛshɔn standadizayshɔn .

Mentɛn kɔnsistɛns prɛshɔn kɔndishɔn:

| standad | prɛshɔn rɛnj (kg) | tɛmpracha rɛnj (°C) |

| ASTM D1238 | 2,16 - 21,6. | 190 - 300 |

| ISO 1133 na di . | 2,16 - 21,6. | 190 - 300 |

Sampul Kwaliti Assurans .

Impɔtant tin dɛn fɔ pripia fɔ du:

Di tin dɛn we dɛn fɔ du bifo dɛn tɛst dɛn :

Material kondishɔn : .

Teknik fɔ lod : .

Melt Flow Index Testing Ekwipmɛnt ɛn Stɛndad dɛn .

Mɔdan MFI tɛst ikwipmɛnt de kam togɛda wit prɛsishɔn mɛzhɔmɛnt kapabiliti ɛn yuz-frenli ɔpreshɔn. Advans ficha dɛn de mek shɔ se dɛn gɛt kwaliti kɔntrol we dɛn kin abop pan tru standad tɛst prosidyuz dɛn.

Ikwipmɛnt Ɔvaviu .

Di Presto MFI tɛstamɛnt ɛgzampul fɔ di mɔdan tɛst kapabiliti dɛn:

Kontrol sistem dɛn .

Di tin dɛn we dɛn fɔ mɛzhɔ .

Di tin dɛn we de mek pɔsin nɔ gɛt prɔblɛm .

Standards Kɔmplians .

Mɔdan tɛstamɛnt dɛn mit strɔng intanashɔnal standad dɛn:

| standad | rikwaymɛnt | aplikeshɔn dɛn |

| ASTM D1238 | Tempracha ±0.5°C, Standart dimensions de 10.5 ° C. | Globɛl Manufakchurin . |

| ISO 1133 na di . | Enhansed temperechur kɔntrol, strikt tɛm . | Yuropian Sɛtifikeshɔn . |

Di tin dɛn we pɔsin kin yuz fɔ yuz di wɛbsayt

Kontrol intafeys .

Dijital displei de sho rial-taym tɛmpracha, prɛshɔn, ɛn flɔ mɛzhɔmɛnt.

Programmable Test Parameters Streamline ripit tɛst prosidyuz.

Awtomat data log de pul di mistek dɛn we dɛn mek wit manual rikodin.

Rilaybiliti ficha dɛn .

Self-diagnostic systems de aydentify potential ishu bifo test bigin.

Kalibreshɔn verifyeshɔn de mek shɔ se kɔnsistɛns mɛzhɔmɛnt akkuracy.

Tempracha stebilizayshɔn de mentɛn prɛsis tɛst kɔndishɔn dɛn.

Di we aw dɛn de du di wok .

1. Ikwipmɛnt Sɛtup .

Mashin Pozishɔn fɔ .

Put di tɛst yunit pan wan stebul, vaybreshɔn-fri say fɔ kɔrɛkt mɛzhɔmɛnt.

Adjɔst di lɛvɛl we dɛn de lɛvɛl te di bɔbul indikɛtɔ sho pafɛkt ɔrizɔntal alaynɛshɔn.

Dijital Kɔnfigyushɔn .

Program tɛst durayshɔn tru di dijital intafɛs kɔntrol panɛl.

Set tempɔret paramita dɛn akɔdin to matirial tɛst rikwaymɛnt dɛn.

Konfigyuret data kɔlɛkshɔn intaval fɔ kɔmprɛhɛnsif rizɔlt analisis.

Sensor manejmɛnt .

Kalibrayt RTD PT-100 sensa akɔdin to di manifakta spɛsifikɛshɔn dɛn.

Verifay di tempɔret ridin dɛn agens kalibrayt ɛksternal rɛfrɛns standad dɛn.

Dokumɛnt kalibreshɔn rizɔlt fɔ kwaliti kɔntrol rɛkɔd dɛn.

Sistem Optimayzeshɔn .

Enable auto-tune ficha fɔ optimal tempɔret kɔntrol pefɔmɛns.

Monitor sistem rispכns durin initial hεt fεz.

Verifay stebul opareshɔn kɔndishɔn bifo yu bigin tɛst.

Di chɛklist we dɛn dɔn chɛk bifo tɛm .

[ ] Ikwipmɛnt lɛvɛl we dɛn dɔn chɛk tru bɔbul indikɛtɔ ridin dɛn .

[ ] tempɔret stebilizayshɔn we dɛn ajɔst insay spɛsifikɛd tolɛreshɔn dɛn .

[ ] Sampul matirial we dɛn pripia fayn fayn wan ɛn we dɛn dɔn kɔndishɔn fayn fayn wan .

[ ] tɛst paramita dɛn we dɛn dɔn kɔnfigyut akɔdin to standad rikwaymɛnt dɛn .

Notis: Rigyul mentenɛns de mek shɔ se kɔnsistɛns ikwipmɛnt pefɔmɛns de. Dokumɛnt ɔl di kalibreshɔn prosidyuz dɛn.

MFI fɔ ful-ɔp polimɛr ɛn kɔmpɔzit dɛn .

Di inkorporeshɔn fɔ filla dɛn rili inflɔws polima MFI valyu dɛn. We wi ɔndastand dɛn ifɛkt ya, i de mek wi ebul fɔ pik di bɛst prɔsesin paramita fɔ sɛlɛkshɔn fɔ ful-ɔp polima sistem dɛn.

Filla impak analisis .

Di fil dɛn we de mek pipul dɛn gɛt mɔ trɛnk .

Glass Fayba .

Metal pauda dɛn .

Fil dɛn we nɔ de riinfɔs .

Kalsiɔm kabɔnɛt .

TALK

Di tin dɛn we dɛn fɔ tink bɔt .

High MFI Base Polima dɛn .

Enable effektiv filla dispershon truutout di polimer matrix

Gi impɔtant prɔsesin kwaliti dɛn ɔnda standad kɔndishɔn dɛn .

Mentɛn akseptabl flɔ prɔpati dɛn na ay filla lod dɛn .

Low MFI Base Polima dɛn .

Rizult in chalenj filla dispershon proses .

Rikways modifyed prɔsesin paramita fɔ ifektiv prodakshɔn .

Show limited kompitibiliti na inkris filler konsantreshon .

Hygroscopic Materials Management .

Moisture-sensitiv polimεr dεm

| polimכr tayp | drying tεmprachכ (°C) | Maksimal mכsichכr kכntεnt |

| Naylon . | 80-85 pipul dɛn bin de. | 0.2% |

| Pet/PBT . | 120-140 na di | 0.02% |

| ABS na ABS | 80-85 pipul dɛn bin de. | 0.1% |

| PC . | 120-125 pipul dɛn. | 0.02% |

Di tin dɛn we dɛn nid fɔ du fɔ mek dɛn nɔ drɛy .

Tempracha kɔntrol .

Taym Manejmɛnt .

Material Klasifikɛshɔn .

hygroscopic polimεr dεm .

Enjinia Plastik dɛn .

Teknik Polima dɛn .

Non-Hygroscopic polimεr dεm .

Kɔmwɔd Plastik dɛn .

Notis: Rigyul mɔstɔ kɔntinyu verifyeshɔn de mek shɔ se kɔnsistɛns prɔsesin rizɔlt dɛn de.

MFI fɔ risaykul polimɛr ɛn polima blɛnd dɛn .

Di diman we de gro fɔ sataynabul manufakchurin dɔn mek dɛn yuz mɔ polima dɛn we dɛn dɔn risaykul insay polima prɔsesin. Bɔt, mɛkanikal risaykul ɛn polima blɛndin kin rili afɛkt di mɛlt flɔ indeks (MFI), we de impɔk matirial pefɔmɛns ɛn prɔsesin efyushɔn.

MFI chenj dɛn we dɛn de risaykul .

Digradishɔn ifɛkt dɛn .

Molekyular weit ridyushɔn .

mεkanikal strεs di tεm we dεn de risaykul brεk polimεr chen dεm, we de inkrεs di כvala mεlt fכ fכlכ rεt.

tεmכl εkspכzכn di tεm we dεn de rεprosεs de aksεlεrat chen sכshכn εn mכlikul dεgradashכn prכsεs dεm.

Di chenj dɛn we dɛn mek na di prɔpati .

MFI modifyeshɔn strateji dɛn .

Chen Ekstenshɔn Tɛknɔlɔji .

Kεmikכl modifyushכn .

Proses Implimentishɔn

Ɔrijinal MFI → Chen Ɛkstenda Adishɔn → Mɔdify MFI Ay Flɔ Rɛt → Mɔlikul Weyt Inkris → Kɔntroled Flɔ Prɔpati dɛn

Pɔfɔmɛnshɔn Ɛnhansmɛnt

| Mɔdifikeshɔn Mɛtɔd | MFI Impɛkt | Aplikeshɔn Bɛnifit dɛn |

| Chen ɛkstenshɔn . | Dikris MFI . | Impɔtant Mɛkanikal Prɔpati dɛn . |

| Di adishɔn we dɛn ad pan pɔrokayd . | MFI kɔntrol . | Enhansed prɔsesin stebiliti . |

| Blend optimayzeshɔn . | Di MFI we dɛn dɔn tɔk bɔt . | Aplikeshɔn-spɛsifi k prɔpati dɛn . |

Polima Blɛnd Karakta dɛn .

Virgin-recycled kɔmbaynshɔn dɛn .

Blend Ratios .

Di winda dɛn we de prosɛs .

Kwaliti Kɔntrol Mɛzhɔ .

Testing Protokɔlɔ dɛn .

Monitoring we dɛn kin du ɔltɛm .

Prɔpati Vɛrifikɛshɔn .

Optimayzeshɔn strateji dɛn .

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Prɔses Kɔntrol .

Dɔn

Melt Flow Index (MFI) de ple wan impɔtant pat pan polima prɔsesin ɛn kwaliti kɔntrol. I de ɛp di wan dɛn we de mek di tin dɛn fɔ pik di rayt tin dɛn ɛn mek di prodakshɔn wok fayn. Fɔ ɔndastand tin dɛn we de afɛkt MFI, lɛk mɔlikul wet ɛn prɔsesin kɔndishɔn, impɔtant fɔ mek di prɔdak kwaliti bɛtɛ. Fɔ ajɔst fɔ dɛn tin ya de mek shɔ se dɛn gɛt kɔnsistɛns rizɔlt dɛn we dɛn de mek.

Inkorpɔret MFI tɛst insay yu polima tɛst prosidyuz na di ki fɔ ɛnhans prodakshɔn efyushɔn. I de mek shɔ se polimɛr dɛn mit di standad dɛn we dɛn nid ɛn du fayn fayn wan insay rial-wɔl aplikeshɔn dɛn. Rigyul MFI tɛst na simpul step fɔ bɛtɛ polimɛr prɔsesin ɛn prodak rilaybiliti.

Rifrɛns Sɔs dɛn .

Melt Flɔ Indeks .

PPS plastic .

Plastik injɛkshɔn moldin .