Me ya sa polymers sauki da tsari? Amsar tana kwance a cikin narkewararrawa mai narkewa (MFI). MFI yana auna yadda cikin sauƙi polymer narke da gudana, yana wasa muhimmin matsayi a cikin masana'antar polymer. Yana da mahimmanci don zaɓin hanyar sarrafa dama da tabbatar da ingancin samfurin. A cikin wannan post, zaku koyi tushen MFI, mahimmancin sa a cikin sarrafa polymer, kuma yadda yake tasiri aikin samfurin. Za mu kuma bincika dalilai waɗanda ke tasiri MFI, hanyoyi don canza shi, da kuma yadda ake amfani da shi a cikin kulawa mai inganci.

Mene ne narkewar Nemo (MFI)?

Narke kwarara (MFI) yana aiki azaman muhimmin iko mai mahimmanci na ƙimar iko na ƙwaƙwalwar ƙwaƙwalwar ƙwaƙwalwar ƙwaƙwalwar ƙwaƙwalwar ƙwaƙwalwar ƙwaƙwalwa ko ƙwayar narkewa. Yana nuna yadda sauƙaƙen polymers yana gudana ƙarƙashin takamaiman yanayin matsin lamba da yanayin zafi.

Fahimtar MFI da ma'auninsa

MFI yana wakiltar yawan adadin kwararar da aka ambata ta hanyar daidaitawa a ƙarƙashin yanayin da aka wajabta:

MFI kamar yadda mai nuna kayan mallakar

MFI yana daidaita kai tsaye ga halaye na polymer:

Kayayyakin kwayoyin :

Matsakaicin nauyin kwaya

Rarraba nauyi

Fasali farawar sarkar

Halin sarrafa :

Hana danko

Halayen Halayen Ruwa

Danko na Elongation

Narke ƙarfi

Aikace-aikacen aikace-aikacen :

babban mfi (> 10 g / 10min) → allurar molding matsakaici mfi (2-10 g / 10min) → Version low mfi (<2 g / 10min) → Veryara molding

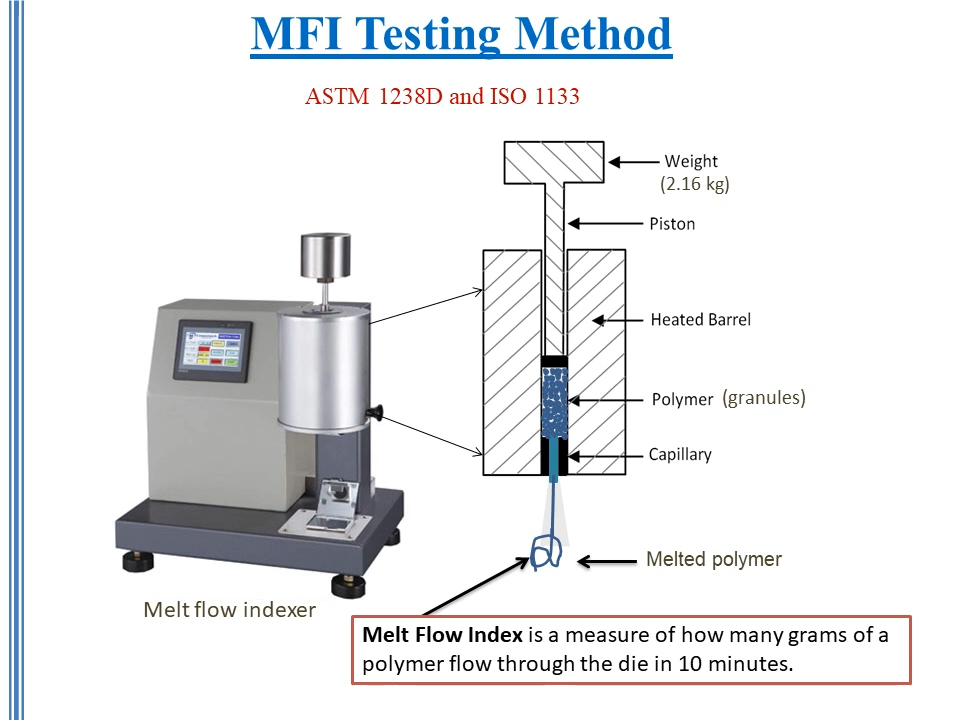

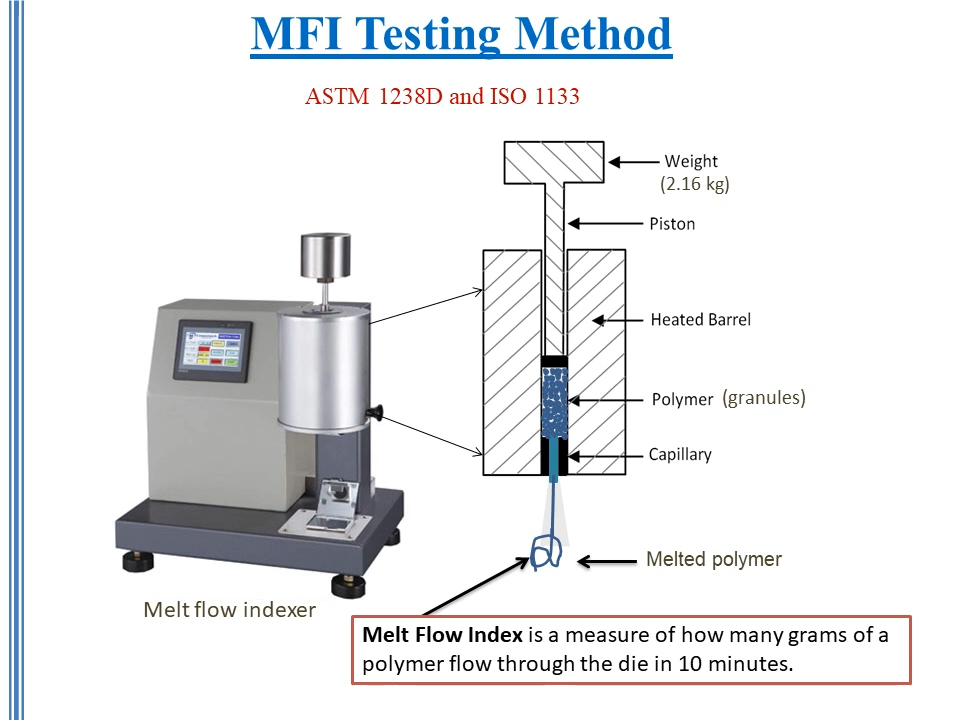

Ka'idojin MFI

Tsarin gwajin ya biyo bayan hanyoyin tabbatar da sakamako mai dogaro: sakamakon

Matakan Gwaji :

Zafafa polymer zuwa ƙayyadadden zafin jiki

Aiwatar da daidaitaccen nauyi

Aididdige nauyin kayan aiki

Lissafta kudin kwarara

Sabbin sigogi masu mahimmanci :

Yanayin gwaji na daidaitawa (misalai):

| polymer | (° C) | kaya (kg) |

| Polyethylene | 190 | 2.16 |

| Polypropylene | 230 | 2.16 |

| Polystyrene | 200 | 5.0 |

Tsarin gwaji

Cikakken ma'aunin MFi yana buƙatar tsananin riko da ladabi:

Muna ba da shawarar bin ISO 1133 ko ASM D1238 na ingantaccen sakamako. Waɗannan hanyoyin suna tabbatar da haifuwa da kuma sinadari a fadin wuraren gwaji daban-daban.

SAURARA: Theawawar MFI suna taimakawa wajen tantance hanyoyin sarrafa abin da ya dace da ƙare aikace-aikace. Fahimtar MFI yana ba da damar masana'antun don inganta sigogin samarwa yadda yakamata.

Dangantaka tsakanin MFI da Polymer Polymer

Gyara tsakanin MFI da kayan kwalliyar polymer sun tabbatar da asali wajen tantance hanyoyin sarrafawa da halaye na kayan aikin ƙarshe. Fahimtar wadannan dangantakar tana sa masana'antun don inganta hanyoyin samarwa yadda yakamata.

MFI-kwayoyin halitta nauyi

MFI ta nuna kyakkyawar dangantakar kwayoyin halitta ga nauyin kwayar halitta, bayan daidaituwa mai lalacewa don layin polymer:

log MW = 2.47 - 0.234 LOG MF

A ina:

Key daidaito:

Darajojin MFi mafi girma suna nuna ƙananan ƙananan ƙwayoyin cuta na ƙwararraki, suna ba da sauki mai sauƙi amma rage yawan kayan aikin

Darajojin MFi suna ba da shawarar mafi girman nauyin ƙwayoyin cuta, samar da haɓaka haɓaka injiniyoyi amma yana buƙatar ƙarin yanayin aiki

Kwayar cutar kwayoyin halitta

Rarraba kayan aikin kwayoyin halitta muhimmanci yana tasiri halaye na MFI ta hanyoyi da yawa:

Rarraba Rarraba : Polymers suna nuna kewayon nauyin kwayoyin halitta masu yawa suna nuna tsarin kwarangwal na nuna halaye na kwarara, wanda ya shafi ikon aiwatar da sigogin aiki don cimma kyakkyawan sakamako.

Rarraba rarrabe : kayan da ke da girman halayen da ake iri na kwayoyin halitta, yana iya sarrafa halayen da suka shafi amfani da su yayin aiki amma yiwuwar iyakance aikace-aikacen su.

Dangantakar kula-mfi

Dangantaka ta Cinta tsakanin danko da MFI ta bayyana ta hanyar dalilai da yawa:

Dubawar Zama :

Matsakaici mafi girma suna rage danko, ƙara yawan mfi

Kowace 10 ° C ya canza yawanci yana inganta MFI da 20-30%

Tasirin Sharar Adali :

Yarjejeniyar Hanyar aiki

Tasirin sarrafawa daban- na buƙatar takamaiman jerin MFI don ingantaccen aiki:

| Hanyar sarrafawa | shawarar da aka ba da shawarar MFI Range (G / 10min) | daban |

| Allurar gyara | 8-20 | Sassan fasaha, kwantena |

| Bude molding | 0.3-2 | Kwalabe, kwantena |

| Hawa | 2-8 | Fim, zanen gado, bayanan martaba |

| Fiber Zagi | 10-25 | Rubutun FIBERS, Norwwovens |

Aikace-aikacen takamaiman aikace-aikace

Halittar MFI suna da muhimmanci tasiri halaye kayan aikin ƙarshe:

Babban aikace-aikacen MFI (> 10 g / 10min):

Aikace-aikacen MFi Matsakaici (2-10 g / 10min):

Aikace-aikacen MFI low (<2 g / 10min):

SAURARA: Waɗannan taruruwan suna aiki da jagorori. Takamaiman aikace-aikace na iya buƙatar dabi'u a bayan waɗannan kewayon dangane da damar kayan aiki da buƙatun samfur.

Dalilai da suka shafi fadada na narkewa

Daidai da amincin mfi suna dogara da masu canji da yawa. Fahimtar wadannan dalilai suna ba da tabbacin ingancin kulawa da ingantaccen tsari na polymer.

Tasirin zazzabi

Zazzabi yana tasiri yana tasiri a kan ma'aunai na MFI ta hanyar da yawa:

Tabbatarwa yana canzawa :

Motrafukan kwayoyin halitta :

Rashin haɗarin lalata :

Tasiri matsa lamba

Matsalar matsin lamba na matsin lamba na MFi ta hanyar halayyar Hancin Hiolom:

Narke compressity :

Halin gudana :

Sample shiri tasiri

Shiri mai kyau ya dace da mahimmanci don mahimmanci na MFI:

Ikon danshi :

Yanayin jiki :

Daidaita sigogi na gwaji

Ikon kula da zazzabi

Aiwatar da m sarrafa zazzabi:

Matsakaicin Matsayi

Kulawa da yanayin matsin lamba: kewayon matsin

| lamba | (kg) | kewayon zafin jiki (keway) |

| Astm D1238 | 2.16 - 21.6 | 190 - 300 |

| ISO 1133 | 2.16 - 21.6 | 190 - 300 |

Tabbacin samfuri

Matakan shirye-shiryen shiri:

Hanyoyi na gwaji :

Kayan aiki :

Loading dabara :

Narke kayan gwaji na gwaji da ka'idoji

Kayan aiki na MFI na zamani suna haɗu da ikon daidaitawa da kuma aikin sada zumunta. Abubuwan da ke gaba sun tabbatar da ingantaccen ingancin iko ta hanyar daidaitattun hanyoyin gwaji.

Kayan aiki

Presto MFI GWAMNATI HUKUNCIN SAUKI:

Tsarin sarrafawa

Abubuwan ma'auni

Fasalolin aminci

Daidaitattun ka'idoji

Testerters na zamani suna haɗuwa da ka'idodi na duniya:

| Aikace- aikace na | Buƙatun Aikace | -aikace |

| Astm D1238 | Zazzabi ± 0.5 ° C, daidaitaccen mutu ya dace | Yanayin duniya |

| ISO 1133 | Ingantaccen sarrafa zazzabi, tsayayyen lokaci | Takaddun shaida na Turai |

Mai amfani-mai amfani

Gudanarwa

Nunin dijital yana nuna zazzabi na gaske, matsa lamba, da ma'aunin gudana.

Tsarin gwajin shirye-shirye na shirye-shirye yana maimaita hanyoyin gwaji.

Shiga Laja mai sarrafa kansa yana kawar da kurakurai na ainihi.

Abubuwan da ke dogaro

Tsarin bincike na kai gano matsaloli kafin gwaji ya fara.

Tabbatar da inganci yana tabbatar da daidaito mai daidaitaccen ma'auni.

Ingantaccen zazzabi yana kiyaye yanayin gwajin.

Hanyoyin aiki

1. Saitin kayan aiki

Madadin injin

Sanya sashin gwaji a kan barga, m farfajiya don daidaitattun ma'auni.

Daidaita ƙafafun ƙafa har sai mai nuna alama mai ban sha'awa yana nuna cikakkun jeri na kwance.

Tsarin dijital

Tsawon gwajin shirin ta hanyar Tsarin Kulawa na Digital.

Saita sigogin zafin jiki gwargwadon bukatun gwaji.

Sanya taƙaitaccen bayanan bayanai don cikakken bincike.

Gudanar da Sensor

Halittar RTD PTD PTD PTD PT-100 a cewar bayani dalla-dalla.

Tabbatar da karatun zazzabi a kan daidaito matsayin nunawa na waje.

Bayanin daidaituwa na daidaitawa don bayanan sarrafa inganci.

Tsarin ingantawa

Sanya fasalin Auto-tuni don mafi kyawun yanayin zafin jiki.

Saka saka idanu na tsarin yayin yawan lokuta.

Tabbatar da yanayin aiki mai tsayayye kafin fara gwaji.

Binciken gwaji na gwaji

[] Tsarin kayan aiki ta hanyar karatun mai nuna alama

[] Zazzabin zazzabi ya samu a cikin yarda

[] Kayan abu daidai da aka shirya yadda yakamata aka shirya

[] Ana tsara sigogi na gwaji gwargwadon daidaitattun bukatun

SAURARA: Kulawa na yau da kullun yana tabbatar da aikin kayan aiki. Yi dadin duk hanyoyin daidaitawa.

MFI na cika polymers da kuma kayan aiki

Haɗin 'yan wasan masu yawa suna tasiri da ƙimar Polymer MFI. Fahimtar wadannan tasirin suna ba da damar mafi kyawun tsari na zaɓin tsari don cike tsarin polymer.

Binciken Tsarin Filer

Maido da fasali

Zare na gilashi

M Karfe

Ba a sake kunna filayen ba

Alli carbonate

Talc

Aiwatar da aiki

Babban mfi tushe

Yana ba da ingantaccen watsawa a cikin matrix na polymer

Bayar da ingantattun halaye na aiki a karkashin yanayin yanayi

Kula da kayan da aka yarda da shi a mafi girman nauyin filler

Mfi bitar mfi

Haifar da kalubale filler

Na buƙatar sigogi na gyara don samar da ingantaccen tsari

Nuna iyakataccen karɓuwa a karuwar farji na filler

Hygroscopic kayan sarrafawa

Danshi-m polymers

| polymer rubuta | bushewa zazzabi (° C) | mafi girman danshi abun ciki |

| Nail | 80-85 | 0.2% |

| Pet / pbt | 120-140 | 0.02% |

| Abin da | 80-85 | 0.1% |

| PC | 120-125 | 0.02% |

Abubuwan bushewa

Sarrafa zazzabi

Ajiyan lokaci

Tsarin kayan aiki

Sojan ruwa na hygroscopic

Filayen injiniya

Polymers na fasaha

Ba-hygroscopic polymers

Rikicin kayayyaki

SAURARA: Tabbatarwar danshi na yau da kullun yana tabbatar da sakamakon sarrafa sarrafawa.

Mfi na polymers da aka sake amfani da polymer

Bukatar cigaban masana'antu ta haifar da ƙara yawan amfani da polymers a cikin sarrafa polymer. Koyaya, sake amfani da kayan aiki da kuma haɗawa na polymer na iya shafar narkewar frowx (MFI), wanda ke haifar da aikin kayan aiki da ƙarfin aiki.

Canjin MFI a lokacin sake sarrafawa

Lalata illa

Rage nauyi mai nauyi

Damuwa na inji yayin sake amfani da sarƙoƙi na polymer, yana ƙaruwa gaba ɗaya ragi na ruwa.

Fitar da Therrmal a lokacin da ake zargi da yanke hukunci game da darajar sarkar da lalata hanyoyin lalata kwayoyin halitta.

Canje-canje canje-canje

Dabarun canji na MFI

Fasahar fadama sarkar

Canjin sunadarai

Tsarin aiwatar da

sarkar asali MFI → sarkar sarkar → gyara MFI babbar yawan kwarara → ƙwayoyin kwarara

Hanyar Inganta

| Hanyar | MFI | Inganta |

| Sarkar tsawo | Rage mfi | Ingantattun kayan aikin injin |

| Peroxide Bugu da kari | Sarrafa mfi | Ingantaccen Tsarin aiki |

| Haske | Mfi | Aikace-aikacen-takamaiman kaddarorin |

Polymer hade da halaye

Hadawar Virgin

Hukumar Ruwa

Sarrafa windows

Matakan sarrafawa mai inganci

Gwajin ladabi

Kulawa na yau da kullun

Tabbatar da dukiya

Dabarun ingantawa

Zabin Abinci

Sarrafawa

Ƙarshe

Narke kwarara (MFI) yana taka muhimmiyar rawa a cikin sarrafa polymer da kuma kulawa mai inganci. Yana taimaka wa masu kera zaɓi kayan da dama da ingantawa. Fahimtar dalilai waɗanda ke shafar MFI, kamar nauyin kwayoyin da sarrafawa, yana da mahimmanci don inganta ingancin samfurin. Daidaita ga waɗannan abubuwan suna tabbatar da sakamako mai mahimmanci yayin masana'antu.

Yin gwajin MFI a cikin hanyoyin gwajin polymer dinku shine mabuɗin don inganta ingancin samarwa. Yana tabbatar da cewa polymers sun hadu ka'idodi da kuma yin aiki sosai a aikace-aikacen duniya. Gwajin MFI na yau da kullun abu ne mai sauki zuwa mafi kyawun sarrafa polymer da amincin samfurin.

Takamatsu

Narke kwarara

PPS filastik

Filastik allurar motsa jiki