Fɛn dilanni taabolo jumɛn ka fisa—ka layɛrɛw fara a kan walima ka fɛnw bɔ? Fɛn minnu bɛ fara ɲɔgɔn kan ani minnu bɛ bɔ ɲɔgɔn na, olu bɛ danfara don cogo nafamaw la. O danfara ninnu faamuyali ye fɛɛrɛ ɲuman sugandili kunba ye.

Nin sɛbɛn in kɔnɔ, an bɛna u ka nafaw, u ka danyɔrɔw, ani u ka baarakɛcogo lakikaw sɛgɛsɛgɛ. Aw bɛna a dɔn cogo min na aw bɛ se ka nin fɛɛrɛ fila ninnu latigɛ aw ka poroze nata kama.

Fɛn min bɛ fara ɲɔgɔn kan, o ye mun ye?

Additive Manufacturing (AM) ye wale ye min bɛ fɛnw dilan ni fɛnw layɛrɛ farali ye ɲɔgɔn kan, a ka c’a la, a sinsinnen bɛ 3D modɛli kan. A tɛ i n’a fɔ laadala fɛɛrɛw, minnu bɛ fɛnw bɔ, AM bɛ yɔrɔ dɔw jɔ ka bɔ fɛn fɔlɔ la, ka sira di dilancogo gɛlɛnw ma ani fɛnw ka baarakɛcogo ɲuman ma.

Tariku surun min bɛ fara fɛn dilanni kan .

AM hakilina bɛ segin san 1980 waatiw la, waati min na 3D sɛbɛnni fɛɛrɛw daminɛna. Kokura fɔlɔw tun ɲɛsinnen bɛ prototyping teliya ma, ka fɛɛrɛw di teliya la, minnu bɛ se ka sɔrɔ ka sɔrɔ ka fɛn dilannenw prototypes dilan. Kabini o waati, AM jiginna ka kɛ izini baara caman ye, i n’a fɔ aerospace, mobili ani furakɛli yɔrɔw.

Additive Manufacturing bɛ baara kɛ cogo min na .

Fàrafinna ka fɛn dilanni bɛ Daminɛ ni CAD modɛli ye. O modɛli bɛ tigɛ ka kɛ layɛrɛ finmanw ye ni porogaramuw ye. O kɔfɛ, AM masin bɛ fɛn dɔ fara a kan, layɛrɛ ni layɛrɛ, fo ka se fɛn laban ma. Fɛn minnu bɛ kɛ ka bɔ plastiki la ka taa a bila nɛgɛw la. Ka kɛɲɛ ni o kɛcogo ye, a bɛ se ka kɛ ko a bɛ kɛ ni baara kɔfɛta ye, i n’a fɔ saniya walima furakɛli, walasa ka a yɔrɔ dafa.

Fɛn minnu bɛ kɛ ka fara ɲɔgɔn kan, olu dilanni fɛɛrɛw .

Fɛɛrɛ caman bɛ bin AM ka parasol jukɔrɔ, u kelen-kelen bɛɛ bɛ nafa kɛrɛnkɛrɛnnenw di:

3D sɛbɛnni .

3D sɛbɛnni ye AM fɛɛrɛ ye min lakodɔnnen don kosɛbɛ. A bɛ fɛnw jɔ ni fɛnw layɛrɛli ye i n’a fɔ plastiki walima nɛgɛ. A ka ɲi kosɛbɛ ka ɲɛsin yɔrɔw ma minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye ani minnu bɛ kɛ ka kɛɲɛ ni fɛnw ye, a bɛ se ka sɔrɔ yɔrɔ bɛɛ ani a musaka ka dɔgɔ baara misɛnninw na.

Selective laser sintering (SLS) .

SLS bɛ laser kɛ ka sinter mugu kɛ, a ka c’a la, a bɛ kɛ plastiki walima nɛgɛ ye, a bɛ kɛ yɔrɔ gɛlɛnw ye. A bɛ Dɔn ka prototypes (daɲɛw) minnu bɛ Se ka Sɔ̀rɔ, olu Dabɔ ni jateminɛ gɛlɛnw ye.

Modèle de déposition fused (FDM) .

FDM bɛ baara kɛ ni filamanw ye minnu bɛ wele ko thermoplastic filaments through a heated nozzle. A bɛ kɛ ka caya walasa ka plastiki yɔrɔw prototyp ani ka u dilan.

Stereolithography (SLA) .

SLA bɛ baara kɛ ni yeelen ultraviolet ye walasa ka ji resin layɛrɛ furakɛ ni layɛrɛ ye, ka yɔrɔw dilan minnu bɛ tiɲɛ kosɛbɛ ni finiw ye minnu bɛ kɛ ka ɲɛ. A bɛnnen don dilancogo gɛlɛnw ma ani kunnafoni ɲumanw ma.

Laser de laser de laser de laser métallique (DMLS) .

DMLS bɛ nɛgɛ yɔrɔw jɔ ni nɛgɛmugu finmanw sintering ye ni laser ye. Nin fɛɛrɛ in ka ɲi kosɛbɛ walasa ka nɛgɛ yɔrɔ gɛlɛnw dilan, nɛgɛ barikamaw ka ɲɛsin iziniw ma i n’a fɔ aerospace.

Fɛn wɛrɛw dilanni fɛɛrɛ wɛrɛw .

Ka fara fɛɛrɛw kan minnu bɛ dɔn kosɛbɛ, fɛɛrɛ kɔrɔlen damadɔ wɛrɛw bɛ sɔrɔ:

Binder Jetting : A sirilan bɛ se ka kɛ sababu ye ka mugu layɛrɛw ni ɲɔgɔn cɛ, ka sigida gɛlɛnw dilan.

Directed Energy Deposition (DED) : Nin fɛɛrɛ in bɛ baara kɛ ni fanga ye min sinsinnen bɛ funteni kan walasa ka fɛnw fara ɲɔgɔn kan i n’a fɔ u bɛ bila cogo min na, a ka c’a la, u bɛ kɛ ka fɛnw dilan walima ka u fara yɔrɔw kan minnu bɛ yen.

Material Extrusion : Materiel bɛ bɔ ni sugandili ye nozzle la walasa ka layers (layɛrɛw) jɔ, minnu bɛ kɛ ka caya ni thermoplastiques (sɛnɛfɛnw) ye.

Material Jetting : Fɛn minnu bɛ kɛ fɛn ye, olu bɛ bila layini kelen-kelen bɛɛ la walasa ka yɔrɔ tigitigiw dilan, tuma caman na, u bɛ baara kɛ ni fotopolimɛriw ye.

Sheet Lamination : Sɛbɛnw bɛ siri ɲɔgɔn na ni layɛrɛ ye, u bɛnnen don nɛgɛw ni fɛnɲɛnamafagalanw ma.

VAT fotopolimɛri : jilama resin bɛ kɛnɛya ni yeelen ye walasa ka yɔrɔ gɛlɛnw dilan, ni a bɛ kɛ prototyping ni production fila bɛɛ la.

Nafa minnu bɛ sɔrɔ farankan dilanni na .

Additive Manufacturing (AM) bɛ nafa caman di iziniw kɔnɔ. O nafa ninnu b’a Kɛ tulonkɛ-yɔrɔ-ko ye bi-bi in na.

Materiel tiɲɛni dɔgɔyali .

AM bɛ baara kɛ ni fɛn ye min ka kan ka kɛ fɛn laban na. O fɛɛrɛ in bɛ dɔ bɔ tiɲɛni na kosɛbɛ ni i ye a suma ni laadala fɛɛrɛw ye.

Geometries complexes ani dilancogo gɛlɛnw .

Am ka fisa ni cogoya gɛlɛnw dabɔli ye. A bɛ se ka yɔrɔw dilan minnu tɛ se ka dilan ni fɛɛrɛ kɔrɔw ye.

Kɔnɔna kanw .

Lattice structures .

Foroko biologikiw .

Prototyping teliya ani a ka kan ka kɛ waati surun ye .

Prototyping rapide bɛ kɛ tiɲɛ ye ni AM ye. A bɛ sira Di iterasiyɔn teliyalenw ma ani ka fɛn dilanni teliya.

| laadala prototyping | am prototyping . |

| Dɔgɔkunw ka se kalow ma . | Lɛrɛw ka se tile ma . |

| Taabolo caman . | Taabolo kelen . |

| Baarakɛminɛnw musaka ka bon . | Baarakɛminɛnw tɛ yen . |

Batch petit de production cost-efficient .

Am bɛ yeelen bɔ hakɛ fitininw dilanni na. A tɛ mago bɔ fɛn sɔngɔ gɛlɛnw na walima baarakɛminɛnw na.

Sigida sabatili ɲɛtaa .

Nɔgɔ dɔgɔyali bɛ baara kɛ ni sabatili ye min bɛ ɲɛ. Am bɛ nafolo ni fanga mara.

Less raw materials consommation .

Bololabaara magow dɔgɔyali .

fanga dɔgɔyali baarakɛcogo la .

Seko ni dɔnko ka ɲɛsin jamanadenw ka ladamuni ma .

AM bɛ se ka fɛnw dilan ka kɛɲɛ ni mɔgɔ kelen-kelen bɛɛ magow ye. O bɛ seko kura da mɔgɔw ɲɛ na dakun suguya caman na:

farankanw dilanni nafa .

Hali ni farankan dilanni (AM) bɛ nafa caman di, dan bɛ a la fana. O dɛsɛw faamuyali nafa ka bon kosɛbɛ a kɛcogo ɲuman na.

Fɛn minnu bɛ kɛ ka fɛnw sugandi .

AM bɛ baara kɛ ni fɛnw ye minnu ka dɔgɔn ka tɛmɛ fɛnɲɛnamafagalanw kan. O dantigɛli bɛ se ka dan sigi a baara la izini dɔw la.

Volume caman bɔli ka dɔgɔ .

Am ka fisa ni batɛmu misɛnninw ye nka a bɛ to kɔfɛ mass production. Laadalata fɛɛrɛw ka teli ka tɛmɛ a hakɛ kan.

| Production volume | AM teliya | laadalata teliya . |

| A ka dɔgɔ (1-100) . | Teliman | Suma |

| Medium (100-1000) . | Ka bɛrɛbɛn | Teliman |

| belebele (1000+) . | Suma | Teliya kosɛbɛ . |

camanba bɛ sɔrɔ sɛnɛfɛnw na minnu bɛ kɛ ka caya .

Ni jamaba ye, AM bɛ se ka sɔngɔ gɛlɛya. A musaka hakɛ kelen-kelen bɛɛ tɛ dɔgɔya kosɛbɛ ni hakɛ ye.

Jiginni yɔrɔ tiɲɛni ani surface fini .

AM yɔrɔw bɛ se ka kɛ ni u tiɲɛni ye ka tɛmɛ masinw kan. Tuma caman na, u ka surface finish bɛ ɲɛtaa de wajibiya.

Tight Tolerance gɛlɛyaw .

Tolerances sirilenw sɔrɔli ka gɛlɛn ni AM ye. O bɛ se ka kɛ gɛlɛya ye yɔrɔw la minnu mago bɛ fitinin tigitigiw la.

Post-processing wajibiyalenw .

AM yɔrɔ fanba mago bɛ baara wɛrɛw la sɛbɛnni kɔfɛ. O bɛ waati ni musaka fara sɛnɛfɛnw dilanni kan.

A ka ca a la, a bɛ kɛ cogo min na, o ye ko:

Dɛmɛnanw bɔli .

Surface Smoothing .

Sumaya furakɛli .

Ja walima finimugu .

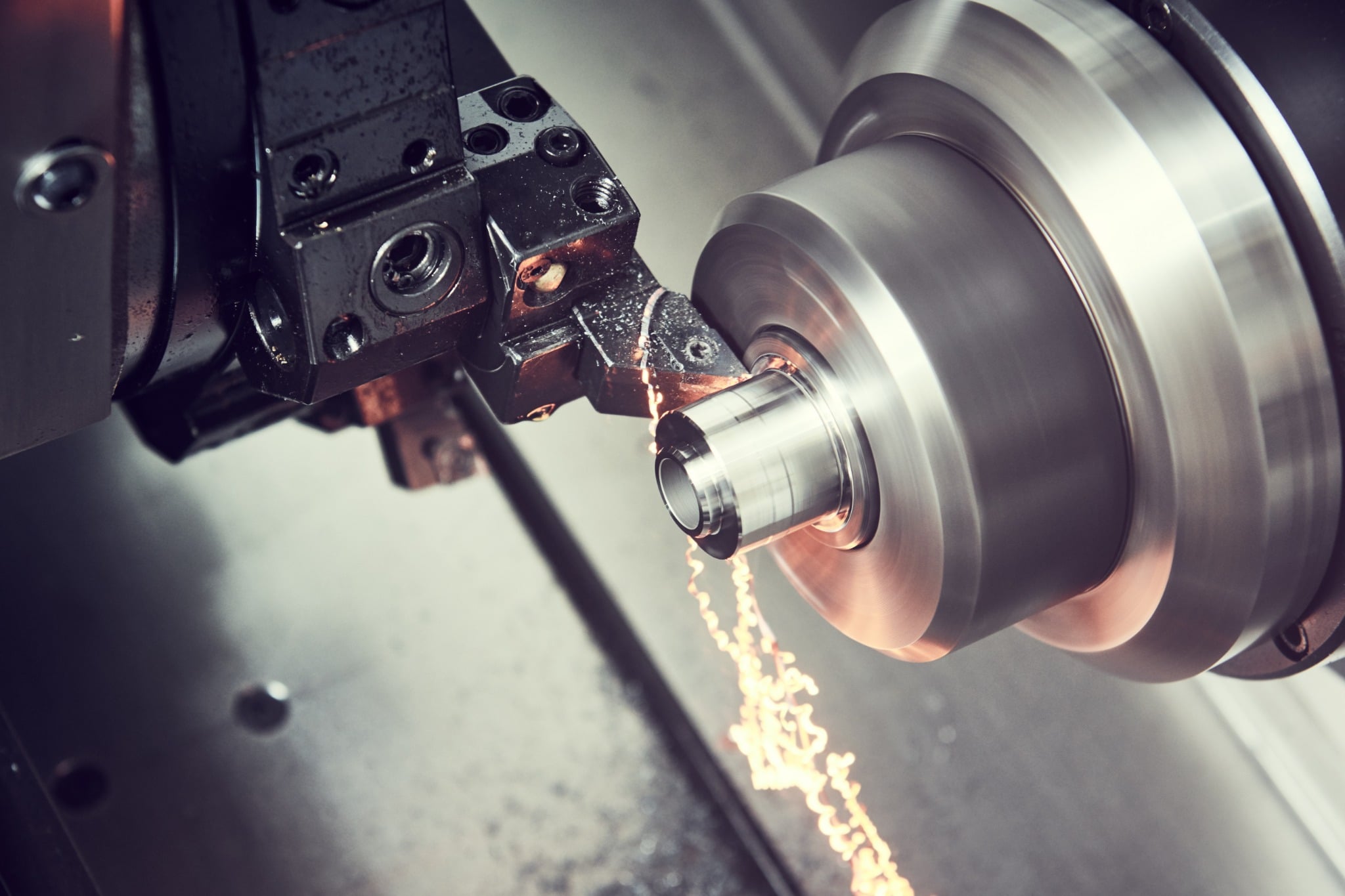

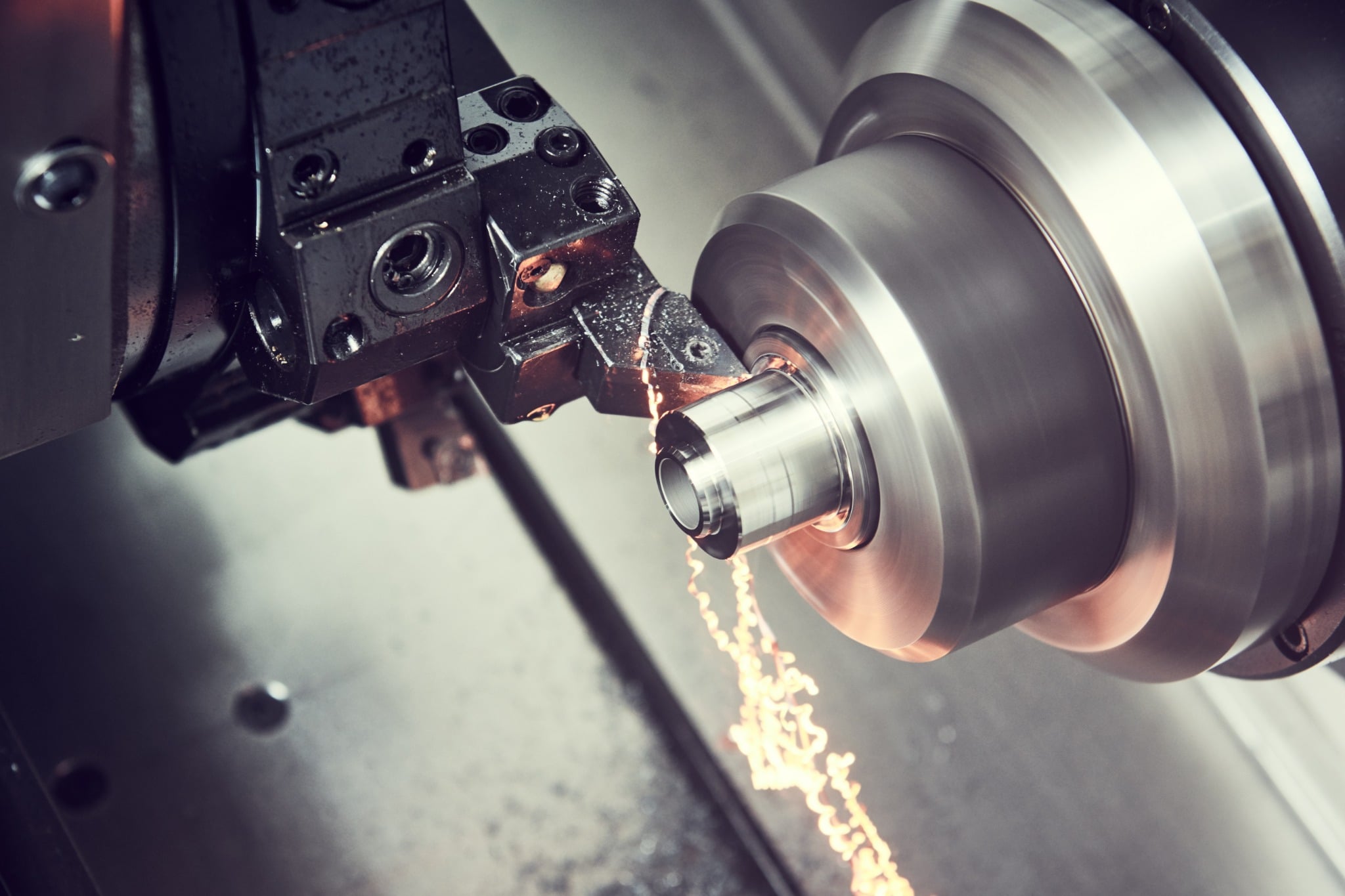

Subtractive manufacturing ye mun ye?

Subtractive Manufacturing (SM) bɛ fɛnw dilan ni fɛnw bɔli ye bloki solide kɔnɔ. O ye laadala fɛɛrɛ ye min bɛ Kɛ izini suguya caman na.

Tariku surun .

SM bɛ bɔ kɔrɔlenw na. Misali fɔlɔw ye kabakurunw dilanni ye ani jiriw dilanni. Modern SM jiginna ni Industrial Revolution ye, min kɛra sababu ye ka masinw dilan tigitigi.

A bɛ baara kɛ cogo min na .

SM bɛ daminɛ ni fɛn ye min ka bon kosɛbɛ. O kɔfɛ, masinw walima baarakɛminɛnw bɛ fɛn tɛmɛnenw tigɛ walasa ka cogoya ɲininen dilan.

Fɛɛrɛ minnu bɛ kɛ tuma bɛɛ .

CNC Machining .

Ɔridinatɛri Jateblaw (CNC) masinw bɛ baara kɛ ni cikanw ye minnu bolodara walasa ka fɛnw bɔ yen.

MILLING: A bɛ fɛn tigɛ ni baarakɛminɛnw ye minnu bɛ wuli .

Yɛlɛma: A yɔrɔw cogoya silindalenw ye ni baarakɛminɛn ye .

Drilling: A bɛ dingɛw da fɛn kɔnɔ .

laser tigɛ .

O fɛɛrɛ in bɛ baara Kɛ ni laser ye min fanga ka bòn walasa ka fɛnw Tigɛ. A bɛ tigitigi ani a bɛ baara kɛ fɛn suguya caman kan.

Waterjet tigɛ .

Waterjet tigɛ bɛ ji tansiyɔnba kɛ, a ka ca a la a bɛ ɲagami ni fɛn dɔw ye minnu bɛ fɛnw tigɛ, walasa ka fɛnw tigɛ.

Plasma tigɛcogo .

Plasma tigɛ bɛ fɛn dɔw wuli ni gazi ye min bɛ kuran ta. A bɛ nɔ bɔ nɛgɛ tigɛ la.

Kuran bɔli masin (EDM) .

EDM bɛ baara kɛ ni kuran bɔli ye walasa ka fɛnw bɔ yen. A ka ɲi nɛgɛ gɛlɛnw ni cogoya gɛlɛnw na.

kunnafoni wɛrɛw .

Masiniw ka baarakɛcogo .

Grinding: A bɛ baara kɛ ni abrasive wheels ye walasa ka fini ɲumanw kɛ .

Reaming: A bɛ dingɛw bonya ani ka u ban .

Boring: A bɛ dingɛw bonya ni tigɛminɛnw ye minnu bɛ kɛ yɔrɔ kelen na .

EDM sariyakolow .

EDM bɛ baara Kɛ ni kuran-sɔgɔli-minɛnw dabɔli ye elekitorode ni baarakɛminɛn cɛ.

Laser tigɛcogo paramɛtɛrɛw .

Fanga: A bɛ tigɛ juguya latigɛ .

Teliya: A bɛ nɔ bila tigɛcogo ɲuman na .

Sinsinnan: A bɛ nɔ bila tigitigi .

WaterJet tigɛcogo paramɛtɛrɛw .

Tansiyɔn: A ka ca a la 60 000 psi walima ka tɛmɛ o kan .

Abrasive flow rate: A bɛ nɔ bila tigɛ teliya ni a jogo la .

Nozzle diamètre: Influences Tigɛ bonya ni tiɲɛni .

Nafa minnu bɛ sɔrɔ fɛn dilanni na .

Subtractive Manufacturing (SM) bɛ nafa caman di iziniw kɔnɔ. O nafaw b’a kɛ fɛɛrɛ jɔnjɔn ye bi sɛnɛfɛnw dilanni na.

Fɛn caman minnu bɛ bɛn ɲɔgɔn ma .

SM bɛ baara kɛ ni fɛn suguya caman ye:

Nɛgɛw (Steel, Aluminiyɔmu, Titanium)

Plastikiw (ABS, PVC, acrylique) .

Composites (fibre carbone, fibre de fibre) .

Yiri

Wɛɛrɛ

Gabakurun

O fɛn caman kɛli bɛ sira di SM ma a ka se ka fɛn dilanni mago suguya caman ɲɛnabɔ.

Tiɲɛni ni tiɲɛniba .

SM ka fisa ni yɔrɔw dilanni ye minnu bɛ tiɲɛ kosɛbɛ. A bɛ muɲuli gɛlɛnw sɔrɔ, a ka ca a la a ka dɔgɔn fo ka se santimɛtɛrɛ 0,001 ma.

| Technique | typique tolerance . |

| CNC Milling . | ±0,0005'. |

| EDM . | ±0,0001'. |

| laser tigɛ . | ±0,003'. |

Fɛn minnu bɛ kɛ ka ɲɛ, olu ka ɲi kosɛbɛ .

SM bɛ yɔrɔw bɔ minnu ka bon ni u ɲɛda cogoya ka bon. O bɛ kɛ sababu ye tuma caman na ka finidoncogo wɛrɛw kɛ.

Teliya la, a bɛ sɔrɔ ka caya .

Walasa ka fɛn caman dilan, SM OutPaces farankan fɛɛrɛw:

CNC masin caman bɛ baara kɛ joona .

Baarakɛminɛnw caman cili otomatiki bɛ dɔ bɔ baarakɛbaliya la .

Baara minnu bɛ kɛ waati kelen na yɔrɔw kan .

A musaka ka bon kosɛbɛ fɛn caman na .

SM bɛ kɛ sɔrɔko ye ka taa a fɛ ni sɛnɛfɛnw bɔli hakɛ bɛ ka caya. Setup musaka fɔlɔw bɛ bɔ a la ni a dilanni hakɛ teliya ye.

Yɔrɔw dabɔli belebeleba .

SM bɛ yɔrɔbaw minɛ nɔgɔya la. A ka ɲi kosɛbɛ iziniw ma minnu bɛ yɔrɔ caman ɲini:

Nafa minnu bɛ sɔrɔ fɛn dilanni na .

Hali ni subtractive manufacturing (SM) bɛ nafa caman di, dan bɛ a la fana. O dɛsɛw faamuyali nafa ka bon walasa ka baara kɛ ka ɲɛ.

Fɛn minnu bɛ kɛ ka fɛnw tiɲɛ sanfɛ .

SM bɛ fɛnw bɔ yen walasa ka yɔrɔw dilan. Nin wale in bɛ tiɲɛniba lase mɔgɔ ma:

Fɛn minnu bɛ se ka kɛ fɛn tiɲɛnenw ye, olu bɛ se 90% ma ko dɔw la .

Segin-ka-bɔnye sugandiliw bɛ se ka dan kɛ fɛn dɔw la .

Sigida laminiko gɛlɛya ka da a kan a bɛ se ka kɛ sababu ye ka bɔgɔ bɔ a la .

Dantigɛli dafalen dantigɛli .

SM bɛ kɛlɛ kɛ ni dilan gɛlɛnw ye:

Kɔnɔnatumuw dilanni gɛlɛya .

Siginiden dɔw bɛ se ka kɛ sigicogo caman walima baarakɛminɛn kɛrɛnkɛrɛnnenw ye .

Fɛn gɛlɛn dɔw bɛ se ka kɛ masin ye .

Segin waati janw ani baarakɛminɛnw musaka minnu ka ca .

SM ka teli ka labɛn caman kɛ:

| Aspect | Impact . |

| Baarakɛminɛnw sugandili . | Waati-dafalen . |

| Masina porogaramu . | A bɛ dɔnniya de wajibiya . |

| fixture (fixture) dabɔli . | musaka wɛrɛw . |

A ka ca a la, a bɛ se ka kɛ ko a bɛ se ka kɛ .

Yɛlɛma minnu bɛ kɛ SM kɔnɔ, olu bɛ se ka kɛ musakabaw ye:

Yɛlɛma bɛ se ka kɛ baarakɛminɛn kura de ye .

Programming machines ka teli ka kɛ wajibi ye .

Setup minnu bɛ yen, olu bɛ se ka kɛ fɛn kɔrɔlenw ye .

Operatɛri ka seko wajibiyalenw ka bon .

SM masinw bɛ baarakɛlaw ɲini minnu bɛ se kosɛbɛ:

Faamuyali min bɛ kɛ fɛnw nafa kan .

Tigɛ teliya ni balo hakɛw dɔnni .

Se ka ja gɛlɛnw kɔrɔ fɔ .

Baarakɛminɛnw doncogo ani u falenni musakaw .

SM baarakɛminɛnw bɛ dɔgɔya waati kɔnɔ:

Baarakɛminɛn minnu bɛ kɛ tuma bɛɛ, olu nɔnabila ye wajibi ye .

Baarakɛminɛn minnu ka ɲi kosɛbɛ, olu bɛ se ka kɛ sɔngɔba ye .

Baarakɛminɛn minnu bɛ don, olu bɛ se ka nɔ bila yɔrɔ jogo la .

farankan ni fɛn dilanni

| aspect aspect aspect di manufacturing | subtractive | manufacturing . |

| Ka tɛmɛ | A bɛ fɛnw jɔ ni fɛnw layɛrɛw farali ye . | A bɛ fɛnw bɔ fɛn belebeleba dɔ la walasa ka fɛnw dilan . |

| Fɛnw tiɲɛni . | Minimal tiɲɛni . | Materiel haute . |

| Fɛn minnu bɛ bɛn ɲɔgɔn ma . | Limited (kɛrɛnkɛrɛnnenya la plastiki ni nɛgɛ dɔw) . | A ka bon (nɛgɛw, plastiki, jiri, gilasi, kabakurun) . |

| complexité . | A bɛ se ka jateminɛ kɛlenw dilan minnu ka gɛlɛn kosɛbɛ ani minnu ka gɛlɛn kosɛbɛ . | A bɛnnen don kosɛbɛ jateminɛ nɔgɔmanw ma . |

| Fáranfasiya | A ka dɔgɔn kosɛbɛ (a muɲuni ka gɛlɛn i n’a fɔ milimɛtɛrɛ 0,100) . | A ka ɲi kosɛbɛ (a muɲuni ka gɛlɛn i n’a fɔ milimɛtɛrɛ 0,025) . |

| Production Volume . | A bɛnnen don batch misɛnninw ma . | A ka ɲi kosɛbɛ ka ɲɛsin fɛn dilanni bolibaw ma . |

| Teliya | Slower ka ɲɛsin volumes caman ma . | Teliya ka ɲɛsin volumes caman ma . |

| Sɔngɔ | A musaka ka dɔgɔ hakɛ fitininw na . | A musaka ka dɔgɔ hakɛ caman na . |

| Dilancogo sɛgɛsɛgɛli . | Flexibilité (Flexibilité) caman bɛ sɔrɔ dilancogo caman na . | Less Flexible ka ɲɛsin dilancogo caman ma . |

| Surface Finish . | Tuma caman na, a bɛ kɛ ni baara kɔfɛta ye . | bɛ se ka fini nɔgɔlenw dilan k' u ɲɛsin . |

| Operator ka seko . | A bɛ baarakɛlaw wajibiya minnu tɛ se kosɛbɛ . | A bɛ baarakɛlaw de wajibiya minnu bɛ se kosɛbɛ . |

| Minɛnw musaka . | Minɛn fɔlɔw musaka dɔgɔyali . | Minɛn fɔlɔw musaka ka bon . |

| Baarakɛminɛnw . | Baarakɛminɛn fitininw wajibiyalen don . | Baarakɛminɛn caman minnu ka kan ka kɛ tuma caman na . |

| Mɛli | A bɛ sabati ka tɛmɛ tiɲɛni dɔgɔyali kan . | A ka dɔgɔ kosɛbɛ ka da fɛnw tiɲɛni kan . |

| Kɔnɔnafɛnw . | Ka se ka kɔnɔnafɛnw dilan nɔgɔya la . | A ka gɛlɛn ka kɔnɔnafɛnw dilan . |

| Bonya dantigɛli . | A ka c’a la, a dan ye yɔrɔ fitininw ye . | A bɛ se ka yɔrɔbaw dilan . |

| Post-processing . | Tuma caman na, a bɛ taabolo caman de wajibiya . | Dafalen hakɛ ka bon a daminɛ kɔfɛ . |

hybride de manufacturing processes .

hybride manufacturing bɛ farankanw dilanni (AM) ani subtractive manufacturing (SM) fara ɲɔgɔn kan. O fɛɛrɛ in bɛ fɛɛrɛ fila bɛɛ fanga bonya, ka jɛɲɔgɔnya barikama dɔ Dabɔ a dilanni na.

ɲɛfɔli ni nafaw .

Fɛɛrɛw minnu bɛ kɛ ɲɔgɔn fɛ, olu bɛ AM ni SM fɛɛrɛw fara ɲɔgɔn kan:

Nafa minnu bɛ sɔrɔ a la, olu ye:

Misali la baara kɛcogo:

3d Print A Near-Net cogoya .

CNC Machining ka ɲɛsin dimensions tigitigiw ma .

Pologne ka ɲɛsin surface fini sanfɛla ma .

Aplikasi minnu bɛ kɛ tuma bɛɛ .

hybride manufacturing bɛ tɛmɛ yɔrɔ caman kan:

| a kɛcogo | nafa . |

| Baarakɛminɛnw . | Designs complexes ni tolerances sirilenw . |

| Jigw ni fixtures . | ladamu cogoya ni fini sabatilenw . |

| Yɔrɔ minnu bɛ muɲu kosɛbɛ . | Geometries intricate ni fɛn tigitigiw ye . |

Industries minnu bɛ baara kɛ ni taabolo suguya caman ye:

Aerospace .

Mobili .

Furakɛcogo minɛnw .

Custom Manufacturing .

Sugandili bɛ kɛ fɛn dilanni faralen ni fɛn wɛrɛ dilanni cɛ .

Fɛn dilanni fɛɛrɛ ɲuman sugandili bɛ bɔ fɛn suguya caman na. Taabolo kelen-kelen bɛɛ bɛ nafa danfaralenw di, o la a nafa ka bon kosɛbɛ ka i ka sugandili bɛn ni poroze wajibiyalenw ye.

Fɛn minnu ka kan ka jateminɛ ni u bɛ fɛn dilanni fɛɛrɛ dɔ sugandi .

Materiel (Matɛriw ka wajibiyalenw) .

Fɛn minnu bɛ se ka kɛ, olu sugandili jɔyɔrɔ ka bon kosɛbɛ. A ka c’a la, fɛn dilanni (AM) bɛ baara kɛ ka ɲɛ ni plastiki ni nɛgɛ dɔw ye, k’a sɔrɔ fɛnw dilanni (SM) bɛ se ka fɛn caman ɲɛnabɔ, i n’a fɔ nɛgɛw, plastikiw, jiriw, ani gilasi. Ni aw mago bɛ fɛnw na minnu ka gɛlɛn walima ni u bɛ mɛn ka tɛmɛ, SM de ka teli ka kɛ fɛɛrɛ ɲuman ye.

Yɔrɔw ka gɛlɛya ni u ka dilancogo .

Walasa ka dilan gɛlɛnw sɔrɔ ni jateminɛ gɛlɛnw ye—i n’a fɔ kɔnɔna kɔnɔnatumuw walima joli-sira-funu-kɔnɔ-fɛnw—am excels, minnu bɛ sira di ka kɛɲɛ ni mɔgɔw sago ye kosɛbɛ. SM, hali n’a y’a sɔrɔ tigitigi, a bɛ se ka kɛlɛ kɛ ni dilanw ye minnu ka gɛlɛn kosɛbɛ. A bɛnnen don kosɛbɛ jateminɛ nɔgɔmanw walima cɛmancɛw ma yɔrɔ minnu na muɲuli sirilenw ka kan.

Production volume ani scalability .

AM ka ɲi kosɛbɛ sɛnɛfɛnw bɔli hakɛw la minnu ka dɔgɔn fo ka se u cɛmancɛ ma, i n’a fɔ prototyping rapide walima small-batch production. Walasa ka fɛn caman dilan, SM bɛ baara kɛ ka ɲɛ kosɛbɛ, kɛrɛnkɛrɛnnenya la ni a yɔrɔ ba caman bɛ bɔ ɲɔgɔn na. Ni sɛnɛfɛnw bɔli hakɛ bɛ ka caya, SM musaka dɔgɔyali bɛ jɛya.

ɲɛminɛ waati ni waati-ni-waati .

Porozɛ minnu bɛ nafa surun sɔrɔ ɲɛtaa waati la AM fɛ k’a sababu kɛ sigicogo fitinin ye ani ka wuli teliya la ka bɔ dilancogo la ka taa fɛn dilannen na. Nka, ka ɲɛsin fɛn dilanni boliw ma, SM bɛ se ka fɛn dilanni waati teliyalenw di ni a sigicogo dafara, kɛrɛnkɛrɛnnenya la nɛgɛ yɔrɔw kama.

Budjet ni musaka gɛlɛyaw .

AM bɛ musaka bɔ yɔrɔ misɛnniw na, yɔrɔ gɛlɛnw na, kɛrɛnkɛrɛnnenya la ni a bɛ kɛ prototyp ye. Nka, SM bɛ kɛ sɔrɔko ye yɔrɔbaw la walima sɛnɛfɛnw bɔli hakɛ caman na. Setup musakaw ni a yɔrɔ kelen musaka bɛ dɔgɔya a ka c’a la ni hakɛ bɛ caya SM la.

Sigida sabatili kuntilenna .

AM bɛ tiɲɛni dɔgɔya, o b’a to a bɛ kɛ sugandili ye min bɛ sabati. SM, hali n’a teliyalen don bolibaw la, a bɛ fɛn tiɲɛnenbaw bɔ chips walima scraps cogo la. Ni sabatili ye ɲɛtaa kunba ye, AM bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka ɲɛ.

Desizɔn matirizi min bɛ kɛ ka fara a kan, o ye fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye .

Nin latigɛ matiriyali bɛ fɛnw suma teliya la walasa k’aw dɛmɛ ka fɛɛrɛ ɲuman sugandi:

| Factor | Additive Manufacturing (AM) | Subtractive Manufacturing (SM) . |

| Materiel range . | Limited (a fanba ye plastiki ye, nɛgɛ dɔw) . | A ka bon (nɛgɛw, plastiki, jiri, gilasi) . |

| part complexité . | Handles complexes, designs intricates . | A ka fisa ni jateminɛ nɔgɔmanw ye, minnu bɛ kɛ ka ɲɛ. |

| Production Volume . | A ka ɲi kosɛbɛ ka kɛ fɛn fitininw ye, prototyping . | A bɛ baara kɛ ka ɲɛ jamana kɔnɔ . |

| Waati min bɛ kɛ ka baara kɛ . | Setup teliya, teliya jiginni . | Setup slow, teliya la bolibaw kama . |

| Sɔngɔ | A sɔngɔ ka bon yɔrɔbaw walima nɛgɛw la . | A musaka ka dɔgɔ ni hakɛ caman ye . |

| Mɛli | Nɔgɔ dɔgɔyali, ka sabati ka taa a fɛ . | tiɲɛni nafama, min tɛ sabati kosɛbɛ . |

Aw bɛ baara kɛ ni nin matiriyali in ye walasa ka aw ka poroze magow ɲɛ ni fɛn dilanni fɛɛrɛ kelen-kelen bɛɛ fanga ye.

Diɲɛ kɔnɔ, fɛn minnu bɛ kɛ ka fɛn dɔw fara ɲɔgɔn kan ani minnu bɛ bɔ .

Fɛn min bɛ kɛ ka fɛnw dilan (AM) ani ka fɛn dilanni (SM) kɛ, o jɔyɔrɔ ka bon kosɛbɛ izini suguya caman kɔnɔ. U ka baarakɛminɛnw bɛ ka taa ɲɛ ani ka wuli ka taa ɲɛ.

aerospace ani aviation .

AM: Yɔrɔ nɔgɔmanw, jateminɛ gɛlɛnw .

SM: Motɛri yɔrɔ minnu ka ɲi kosɛbɛ, fɛnw jɔcogo .

Mobili industrie .

AM: Prototyping rapide, parts customs .

SM: Motɛri blokiw, transmission yɔrɔw .

Dɔgɔtɔrɔso ni denso .

AM: Custom Implants, Prothètiques .

SM: Opereli minɛnw, ɲinw koronawirisi .

Kunnafoni-falen-falen-fɛnw ni ɛntɛrinɛti-fɛnw .

AM: Fɛn minnu bɛ kɛ mɔgɔ kelen-kelen bɛɛ ye, fɛn minnu bɛ kɛ fɛn fitininw ye .

SM: Smartphone Casings, Components ordinateurs .

Industriw ka masinw ni baarakɛminɛnw .

Architecture ani jɔli .

AM: Modèles de scale, elements decoratifs .

SM: fɛnw jɔcogo, fasokanw yɔrɔw .

Kuncɛli

Fɛn minnu bɛ fara ɲɔgɔn kan ani minnu bɛ bɔ u la, olu kelen-kelen bɛɛ fanga ni u barika tɛ kelen ye. Am ka fisa ni dilancogo gɛlɛnw ye ani ka kɛɲɛ ni mɔgɔw sago ye. SM bɛ fɛn caman ɲɛfɔ ani ka fɛnw caman kɛ.

O danfara ninnu faamuyali nafa ka bon kosɛbɛ walasa ka kunnafoni di fɛn dilanni latigɛw kan. Aw ye aw ka poroze mago kɛrɛnkɛrɛnnenw jateminɛ ni aw bɛ fɛɛrɛ dɔ sugandi.

Aw bɛ fɛnw jateminɛ i n’a fɔ fɛnw, gɛlɛya, hakɛ ani musaka. O bɛna aw dɛmɛ ka fɛɛrɛ ɲuman sugandi aw ka fɛn dilanni kuntilenna na.