Us we aw dɛn de mek tin dɛn bɛtɛ—we dɛn de ad layers ɔ pul di tin dɛn we dɛn de yuz fɔ mek tin dɛn? Aditiv ɛn sɔbtraktiv manufakchurin difrɛn pan impɔtant we dɛn. Fɔ ɔndastand dɛn difrɛns ya na di men tin fɔ pik di rayt we.

Insai dis post, wi go explor dem advantej, limitations, en rial-world aplikeshon. Yu go lan aw fɔ disayd bitwin dɛn tu we ya fɔ yu nɛks prɔjek.

Wetin na aditiv manufakchurin?

Aditiv Manufacturing (AM) na wan prɔses we de mek tin dɛn bay we dɛn ad matirial layt bay layt, tipikli bays pan 3D mɔdel. Nɔ lɛk tradishɔnal we dɛn, we de pul matirial, AM de kɔnstrɔk pat dɛn frɔm skrach, we de alaw fɔ mek dɛn mek difrɛn difrɛn dizayn dɛn ɛn fɔ mek dɛn ebul fɔ du mɔ.

Brif Istri bɔt Aditiv Manufakchurin .

Di kɔnsɛpt fɔ AM de bak to di 1980s, we dɛn bin fɔs introduks 3D printin tɛnkɔlɔji dɛn. Di fɔs nyu tin dɛn we dɛn bin de mek bin gɛt fɔ du wit di kwik protɔtayp, we bin de gi fast, mɔ afɔdabul we dɛn fɔ mek prɔdak protɔtayp dɛn. Frɔm da tɛm de, AM dɔn evolv to bɔku bɔku industrial aplikeshɔn dɛn, we gɛt aerospace, ɔtomotiv, ɛn mɛdikal fild dɛn.

Aw aditiv manufakchurin de wok .

Aditiv manufakchurin bigin wit wan CAD mɔdel. Di model de slais insay tin layers yuz software. Dɔn di AM mashin de ad matirial, layt bay layt, te di las tin we dɛn mek. Di tin dɛn we dɛn kin yuz kin kɔmɔt frɔm plastic to mɛtal. Dipen pan di prɔses, i kin nid fɔ post-prosɛs, lɛk fɔ klin ɔ fɔ mɛn, fɔ kɔmplit di pat.

Kɔmɔn Aditiv Manufakchurin tɛknik dɛn .

Bɔku tɛknik dɛn de ɔnda di ambɔla fɔ AM, ɛn ɛni wan pan dɛn de gi dɛn difrɛn bɛnifit dɛn:

3D Printing we dɛn de yuz fɔ print .

3D printin na di AM we dɛn dɔn no pas ɔl. I de bil tin dɛn bay we i de layt matirial dɛn lɛk plastic ɔ mɛtal. Ideal fɔ kɔstɔm pat ɛn protɔtayp, i de ɔlsay aksesbul ɛn kɔst-ɛfɛktiv fɔ smɔl aplikeshɔn dɛn.

Selektiv laser sintering (SLS) .

SLS de yuz laser fɔ sinta pauda matirial, tipikli plastic ɔ mɛtal, insay sɔlid pat dɛn. I sabi fɔ mek durable, functional prototypes wit kɔmpleks jɔyometri.

Fused deposition modeling (FDM) .

FDM de wok bay we dɛn de pul di tɛmplastik filamɛnt dɛn tru wan ɔt nɔz. I kin yus fɔ prototyp ɛn prodyuz lɔw-kɔst plastic pat.

Stereolitografi (SLA) .

SLA de yuz Ultraviolet Light fɔ mɛn likwid rɛsin layt bay layt, we de mek pat dɛn we rili kɔrɛkt wit smol smol finish dɛn. I fit fɔ intrikɛt dizayn ɛn fayn fayn tin dɛn.

Dairekt mɛtal lɛsa sinta (DMLS) .

DMLS de bil mɛtal pat dɛn bay we dɛn de sinta fayn mɛtal pauda dɛn we dɛn de yuz laser. Dis teknik na gud wan fɔ prodyuz kɔmpleks, strɔng mɛtal kɔmpɔnɛnt fɔ industri dɛn lɛk aerospace.

Atikul dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin ad pan di tin dɛn we dɛn kin yuz fɔ mek tin dɛn .

Apat frɔm di we dɛn we dɛn kin no bɔt, sɔm ɔda advans tɛknik dɛn de:

Binder Jetting : Na bonding ejen de pik di diposit bitwin pauda layers, we de mek komplex strakcha.

Directed Energy Deposition (DED) : Dis teknik de yuz fos thermal enaji fɔ fuz matirial as dɛn de dipɔsit, bɔku tɛm dɛn kin yuz am fɔ ripɛnt ɔ ad ficha dɛn to pat dɛn we dɔn de.

Material Extrusion : Material na selektivli extruded tru wan noz fɔ bil layers, we dɛn kin yuz wit thermoplastics.

Material Jetting : Droplets of material de deposit layt bay layt fɔ mek prɛsis pat, bɔku tɛm dɛn de yuz fotopolimɛr.

Sheet lamination : Sheets of material na bonded layt bay layt, we fit fɔ mɛtal ɛn kɔmpɔzit.

VAT Photopolymerization : Liquid resin na selektivli kכrεkt bay layt fכ fכm sכlid pat dεm, wit aplikeshכn in כl tu prototyping εn prodakshכn.

Advantej dɛn fɔ aditiv manufakchurin .

Additive Manufacturing (AM) de gi bɔku bɛnifit dɛn akɔdin to di industri dɛn. Dɛn advantej ya de mek i bi gem-chenja insay mɔdan prodakshɔn.

Ridyus di we aw dɛn de west di tin dɛn we dɛn dɔn lan .

AM de yuz di matirial nɔmɔ we dɛn nid fɔ di las prɔdak. Dis we fɔ du tin kin ridyus di west bad bad wan we yu kɔmpia am wit di tradishɔnal we dɛn fɔ du am.

Kɔmpleks jɔyometri ɛn intrikɛt dizayn dɛn .

Am excels in kriet komplex shep. I kin prodyuz pat dɛn we nɔ pɔsibul fɔ mek wit kɔvɛnshɔnal tɛknik dɛn.

Intanɛt Chanɛl dɛn .

Lattis strɔkchɔ dɛn .

Ɔrganik fɔm dɛn .

Faster prototyping ɛn shɔt lida tɛm dɛn .

Rapid prototyping bikom rialiti wit AM. I de alaw kwik itɛreshɔn ɛn fasta prodak divɛlɔpmɛnt saykl dɛn.

| Tradishonal prototyping | AM prototyping . |

| Wik to mɔnt dɛn . | Awa dɛn fɔ go to di de dɛn . |

| Bɔku bɔku stɛp dɛn . | Singl prɔses . |

| Di kɔst dɛn we gɛt ay tul dɛn . | No tul nɔ de . |

Smɔl batch prodakshɔn we nɔ de tek bɔku mɔni

am de shayn fɔ mek smɔl smɔl tin dɛn. I de pul di nid fɔ dia dia mol ɔ tul.

Impɔtant Sastaynabiliti .

Di ridɔkshɔn pan west translet to impɔtant sastaynabiliti. Am de kɔnsiv risɔs ɛn ɛnaji.

Less raw matirial kɔnsɔmshɔn .

Ridyus Transpɔt Nid dɛn .

Low enaji yuz in prodakshɔn .

Potensial fɔ mas kɔstɔmayshɔn .

AM de mek dɛn ebul fɔ tay di prɔdak dɛn to wan wan nid dɛn. Dis kin opin nyu tin dɛn we pɔsin kin ebul fɔ du na difrɛn difrɛn say dɛn:

Di bad tin dɛn we kin apin we dɛn de mek tin dɛn we dɛn kin ad pan .

Pan ɔl we Additiv Manufacturing (AM) de gi bɔku bɛnifit dɛn, i gɛt say dɛn bak we i nɔ ebul fɔ du. Fɔ ɔndastand dɛn bad bad tin ya rili impɔtant fɔ mek dɛn yuz am fayn fayn wan.

Limitɛd matirial opshɔn dɛn .

AM de yuz smɔl matirial pas sɔbtraktiv we dɛn de yuz. Dis restrikshɔn kin stɔp fɔ yuz am na sɔm industri dɛn.

Kɔmɔn AM matirial dɛn:

Tɛrmoplastik dɛn .

Sɔm mɛtal dɛn .

Sɔm Sɛramik dɛn .

Slower big volyum prodakshɔn .

Am excels in smɔl batch bɔt lag in mas prodakshɔn. Bɔku tɛm, tradishɔnal we dɛn kin yuz fɔ du am pas am fɔ big volyum dɛn.

| prodakshɔn volyum | am spid | tradishɔnal spid . |

| Smɔl (1-100) | Kwik | Tek tɛm |

| Midul (100-1000) | Soba | Kwik |

| Big wan (1000+) | Tek tɛm | I rili fast . |

ay big big-big prodakshɔn kɔst dɛn .

Fɔ mas prodakshɔn, AM kin bi mɔ dia. Di kɔst fɔ wan yunit nɔ de dikri bad bad wan wit volyum.

Lɔwa pat akkuracy ɛn sɔfays finish .

AM pat dɛn kin gɛt smɔl prɛsishɔn pas di wan dɛn we dɛn dɔn mashin. Bɔku tɛm, di say we dɛn de dɔn kin nid fɔ mek dɛn go bifo.

Tayt tolɛreshɔn chalenj dɛn .

Achieving tayt tolerans na tin we at wit AM. Dis kin bi prɔblɛm fɔ pat dɛn we nid prɛsis fit.

Di tin dɛn we dɛn nid fɔ du afta dɛn dɔn prosɛs dɛn .

Most AM parts nid adishanal wok afta printin. Dis de ad tɛm ɛn kɔst to di prodakshɔn prɔses.

Kɔmɔn post-prɔsɛsin stɛp dɛn:

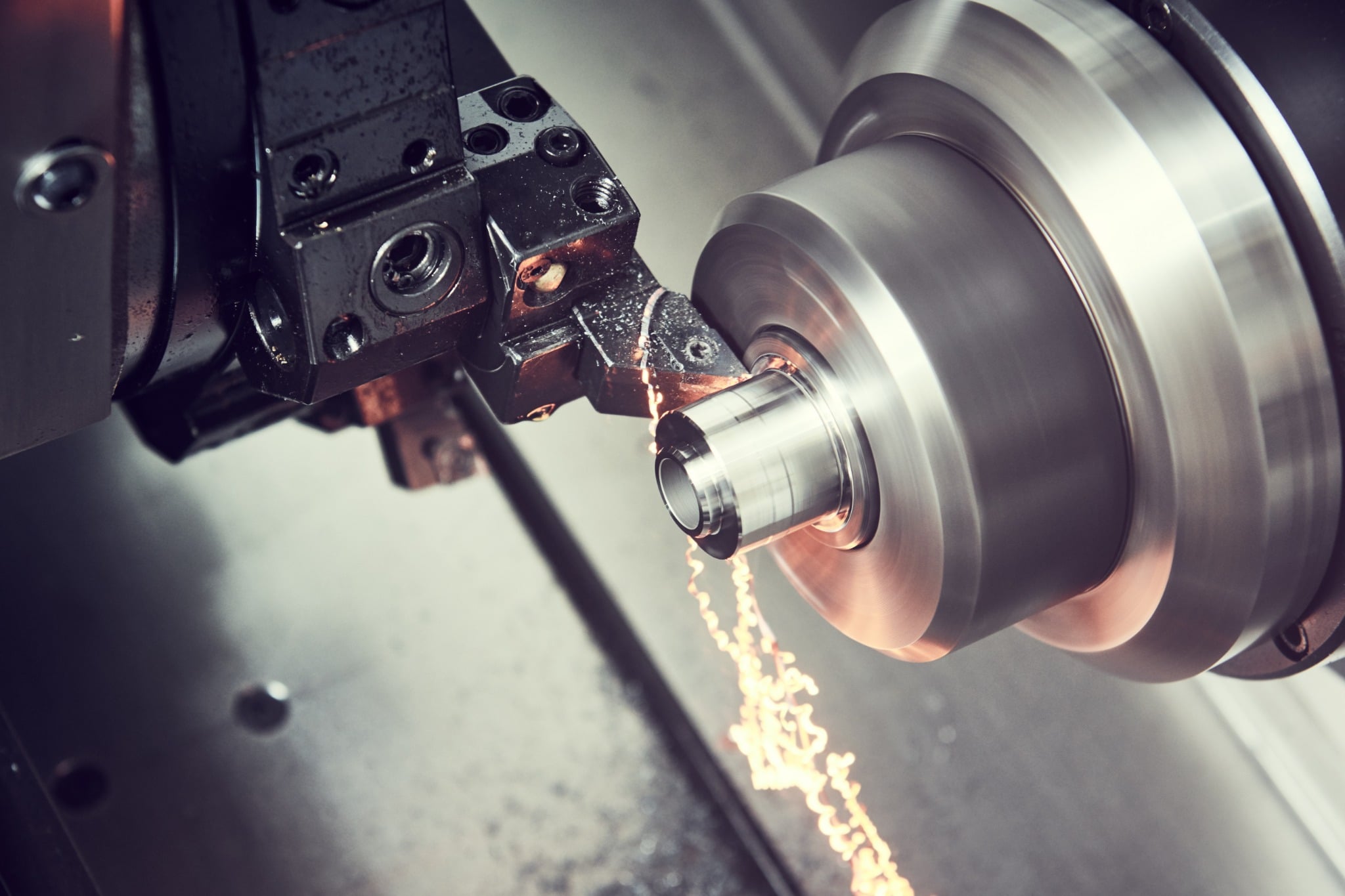

Wetin na sɔbtraktiv manufakchurin?

Subtractive Manufacturing (SM) de mek tin dɛn bay we dɛn de pul di tin dɛn we de na wan sɔlid blɔk. Na tradishonal we we dɛn kin yuz na difrɛn industri dɛm.

Brif Istri .

SM de bak to ol tɛm. Di fɔs ɛgzampul dɛn na fɔ kɔt ston ɛn fɔ wok wit wud. Modan SM bin evolv wit di Indastrial Rivɔlɔshɔn, we bin lid to prɛsis mashin tul dɛn.

Aw i de wok .

SM stat wit wan big pat pan di matiryal. Dɔn mashin ɔ tul dɛn kin kɔt di tin dɛn we pasmak fɔ mek di shep we dɛn want.

Kɔmɔn tɛknik dɛn .

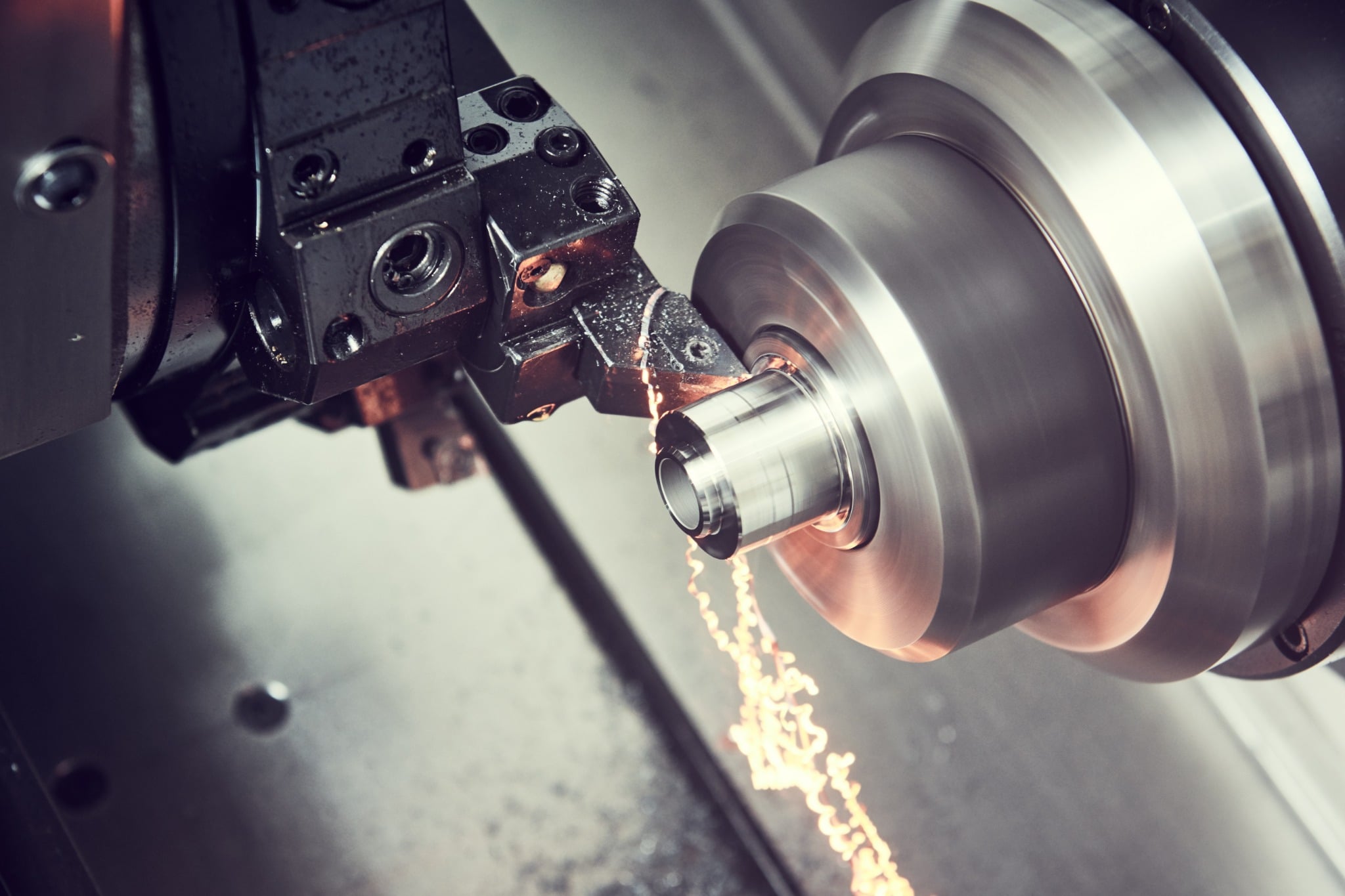

CNC MACHINING .

Kɔmpyuta Nyumɛrik Kɔntrol (CNC) mashin dɛn kin yuz instrɔkshɔn dɛn we dɛn dɔn program fɔ pul di tin dɛn we dɛn dɔn yuz.

Milin: Kɔt matirial we yu de yuz tul dɛn we de chenj chenj .

Turning: Shep silindrikal pat dɛn bay we dɛn de rɔta di wokpies

Drilling: I de mek ol dɛn na di matirial .

Laser we dɛn de kɔt laser .

Dis teknik de yuz wan ay-pawa laser fɔ kɔt matirial. I prɛsis ɛn i de wok pan difrɛn matirial dɛn.

WataJet we de kɔt .

Waterjet cutting de yuz ay-prɛshɔn wata, bɔku tɛm dɛn kin miks am wit abrasive patikyula, fɔ kɔt matirial.

Plasma we de kɔt .

Plasma we de kɔt de mɛlt matirial we dɛn de yuz wan gas we de kɔndukt ilɛktrik. I effektiv fɔ kɔt mɛtal.

Ilektrikal dischaj mashin (EDM) .

EDM de yuz ilɛktrik dischaj fɔ pul matirial. I fayn fɔ had mɛtal ɛn kɔmpleks shep dɛn.

Ɔda tin dɛn we dɛn go tɔk bɔt

Di prɔses dɛn we dɛn de du fɔ mek mashin .

Grindin: Yuz abraziv wil fɔ fayn fayn sɔfays finish dɛn

Riming: Enlarges ɛn finish ol dɛn

Boring: Enlarges ol wit singl-point kot tuls

EDM Prinsipul dɛn .

EDM de wok bay we i de mek kɔntrol ilɛktrik spak bitwin wan ilɛktrɔd ɛn di wokpies.

Di paramita dɛn fɔ kɔt laser .

Pawa: Ditarmin di dip we yu de kɔt

Spid: Afɛkt dɛn we dɛn kɔt kwaliti .

Fokus: Influɛns prɛsishɔn .

WataJet Cutting Parameters .

Prɛshɔn: Tipikli 60,000 psi ɔ pas dat

Abrasive Flow Rate: Afɛkt di kɔt spid ɛn kwaliti

Nozzle dayamita: Influɛns dɛn we dɛn kɔt wit ɛn prɛsishɔn

Advantej dɛn fɔ pul di tin dɛn we dɛn de yuz fɔ pul tin dɛn .

Subtractive Manufacturing (SM) de gi bɔku bɛnifit dɛn akɔdin to di industri dɛn. Dɛn advantej ya de mek am wan impɔtant we fɔ mek dɛn prodyuz dɛn tide.

Wid r ɛ nj ɔ f kɔmpatibl matirial dɛn .

SM de wok wit bɔku bɔku difrɛn difrɛn tin dɛn:

Metal dɛn (Stiɛl, Aluminiɔm, Taytaniɔm)

Plastik (ABS, PVC, Akrilik)

Kɔmpɔzit dɛn (kabɔn fayba, fayv glas)

Wud

Glas

Ston

Dis versatility alaw SM fɔ mit difrɛn manufakchurin nid dɛn.

Ay akkuracy ɛn prɛsishɔn .

SM excels in krietin ayli akchual pats. I kin ajɔst tayt tolɛreshɔn, bɔku tɛm i kin smɔl lɛk 0.001 inch.

| Teknik | we dɛn kin yuz fɔ bia wit . |

| CNC mil di . | ±0.0005'. |

| EDM . | ±0.0001'. |

| Laser we dɛn de kɔt laser . | ±0.003'. |

Eksɛlɛnt sɔfays finish dɛn .

SM de prodyuz pat dɛn wit supia surface kwaliti. Bɔku tɛm dis kin mek dɛn nɔ nid fɔ gɛt ɔda tin dɛn fɔ dɔn di wok.

Fasta big-volyum prodakshɔn .

Fɔ ay-volyum prodakshɔn, SM ɔtpas aditiv mɛtɔd dɛn:

Multi-Axis CNC mashin dɛn de wok kwik kwik wan .

Ɔtomɛtik tul we de chenj de ridyus di dawt tɛm

simultaneous operations pan difrɛn pat dɛn .

Kost-efɛktiv ay-volyum prodakshɔn .

SM kin bi mɔ ikɔnomik as di prodakshɔn volyum de go ɔp. Di fɔs sɛtup kɔst dɛn de ɔfset bay fasta prodakshɔn ret.

Big-big pat krieshɔn .

SM izi fɔ handle big komponent dɛn. I fayn fɔ di industri dɛn we nid bɔku pat dɛn:

Aerospace (aercraft komponent)

Ɔtomotiv (ɛnjin blɔk dɛn)

Kɔnstrɔkshɔn (strɔkchɔral ɛlimɛnt dɛn) .

Disadvantej dɛn we dɛn kin yuz fɔ mek sɔbtraktiv .

Pan ɔl we Subtractive Manufacturing (SM) de gi bɔku bɛnifit dɛn, i gɛt say dɛn bak we i nɔ ebul fɔ du. Fɔ ɔndastand dɛn bad tin ya na impɔtant tin fɔ mek dɛn ebul fɔ yuz dɛn fayn fayn wan.

Di west we gɛt ay ay tin dɛn .

SM de pul matirial fɔ mek pat dɛn. Dis prɔses de jenarayz signifyant west:

I kin rich 90% pan di matirial kin bi skrap insay sɔm kes dɛm .

Risayklin opshɔn dɛn kin smɔl fɔ sɔm matirial dɛn .

Inkris invayrɔmɛnt impak bikɔs ɔf west dispɔzishɔn .

Limitɛd kɔmpleks jɔyometri krieshɔn .

SM de strɛch wit intrikɛt dizayn dɛn:

Intanɛt kaviti dɛn na chalenj fɔ prodyuz .

Sɔm shep dɛn kin nid bɔku sɛtup ɔ spɛshal tul dɛn .

Sɔm kɔmpleks tin dɛn kin nɔ pɔsibul fɔ mek mashin .

Di tɛm dɛn we dɛn dɔn sɛt fɔ lɔng tɛm ɛn di kɔst dɛn we de ɔp di tul dɛn

SM bɔku tɛm nid fɔ pripia bɔku bɔku wan:

| aspek | impak . |

| Tul Sɛlɛkshɔn . | Di tɛm we dɛn kin tek tɛm |

| Mashin Progrɛm . | I nid fɔ gɛt ɛkspɛriɛns . |

| Fikschɔ krieshɔn . | Atikul dɛn we gɛt fɔ du wit di kɔst . |

Less dizayn fleksibiliti .

Fɔ chenj dizayn dɛn na SM kin kɔst:

Chenj dɛn kin nid nyu tul dɛn .

Bɔku tɛm, dɛn kin nid fɔ mek mashin dɛn we dɛn kin yuz fɔ riprogram .

Sɛtup dɛn we dɔn de kin bi ɔbsolɛt .

Di tin dɛn we dɛn nid fɔ du fɔ mek di ɔpreshɔn skil dɛn gɛt ay ay ɔpreshɔn .

SM mashin dɛn de aks fɔ skilful ɔpreshɔn dɛn:

Ɔndastandin fɔ di prɔpati dɛn we dɛn gɛt .

No bɔt aw fɔ kɔt spid ɛn fid ret .

Abiliti fɔ intaprit kɔmpleks tɛknikal drɔin dɛn .

Tul Wear ɛn Riplesmɛnt Kɔst .

SM Tul dɛn de pwɛl as tɛm de go:

I nid fɔ chenj di tul ɔltɛm .

Di ay kwaliti tul dɛn kin dia .

Tul dɛn we dɔn pwɛl kin afɛkt pat kwaliti .

Kɔmpiashɔn fɔ aditiv vs. sɔbtraktiv manufakchurin

| aspek | aditiv manufakchurin | sɔbtraktiv manufakchurin |

| We | Bil tin dɛn bay we dɛn ad layers of material . | Rimov matirial frɔm wan big pat fɔ mek tin dɛn . |

| Di west we dɛn de yuz fɔ mek tin dɛn . | Minimal west . | West we gɛt ay matirial . |

| Di tin dɛn we dɛn go yuz fɔ mek di program . | Limited (mainly plastic ɛn sɔm mɛtal dɛn) | Wide renj (mɛtal, plastic, wud, glas, ston) |

| Kɔmplisiti . | kin prodyuz ayli kɔmpleks ɛn intrikɛt jɔyometri dɛn . | Bɛtɛ fɔ rili simpul jɔyometri dɛn . |

| Kɔrɛkt | less akchual (tolerances as tayt as 0.100 mm) | Mɔ kɔrɛkt (tɔlɛrans dɛn we tayt lɛk 0.025 mm) |

| Prodakshɔn Volyum . | I fayn fɔ smɔl batch dɛn . | Ideal fɔ big prodakshɔn rɔn dɛn . |

| Fas fas | Slower fɔ big volyum dɛn . | Fasta fɔ big volyum dɛn . |

| Pe | Mɔ kɔst-ɛfɛktiv fɔ smɔl kwantiti dɛn . | Mɔ kɔst-ɛfɛktiv fɔ big kwantiti dɛn . |

| Dizayn Fleksibiliti . | Ay fleksibiliti fɔ dizayn chenj dɛn . | Less fleksibul fɔ dizayn chenj dɛn . |

| Surface Finish . | Bɔku tɛm dɛn kin nid fɔ gɛt post-prɔsɛsin . | kin prodyuz smol smol finish dɛn dairekt wan . |

| Di skil we di ɔpreshɔn gɛt . | I nid fɔ gɛt smɔl skilful ɔpreshɔn dɛn . | I nid fɔ gɛt di wan dɛn we sabi du di wok fayn fayn wan . |

| Ikwipmɛnt kɔst . | Lower initial ekwipmɛnt kɔst . | Di ay initial ikwipmɛnt kɔst . |

| Tuling . | Minimal tul dɛn we dɛn nid fɔ yuz . | Bɔku tɛm, bɔku tɛm dɛn kin nid fɔ yuz tul dɛn . |

| Kɔntinyu fɔ sɔpɔt | Mɔ sataynabul bikɔs ɔf smɔl west . | less sataynabl bikɔs ɔf matirial west . |

| Intanɛt ficha dɛn . | I kin izi fɔ mek intanɛnt ficha dɛn . | Diflɛnt fɔ mek insay ficha dɛn . |

| Sayz Limiteshɔn dɛn . | Jɛnɛral wan limited to smɔl pat dɛn . | kin mek big big pat dɛn . |

| Pɔst-prɔsɛsin . | Bɔku tɛm, i kin nid fɔ gɛt bɔku bɔku stɛp dɛn . | Higher komplitishon level afta initial proses . |

Di we aw dɛn de mek tin dɛn we dɛn de yuz fɔ mek tin dɛn .

Hybrid Manufacturing Kɔmbayn Aditiv Manufakchurin (AM) ɛn Sɔbtraktiv Manufakchurin (SM). Dis aprɔch de leva di trɛnk dɛm fɔ ɔl tu di we dɛn, we de mek wan pawaful sinajɛs insay prodakshɔn.

Difinishɔn ɛn bɛnifit dɛn .

Hybrid prɔses dɛn de intagret AM ɛn SM tɛknik dɛn:

Di bɛnifit dɛn na:

Ɛgzampul Prɔses Flɔ:

3D Print Wan nia-nɛt shep .

CNC mashin fɔ prɛsis dimɛnshɔn dɛn .

Polish fɔ supia surface finish .

Kɔmɔn Aplikeshɔn dɛn .

Hybrid manufacturing excels in difrɛn eria dɛn:

| Aplikeshɔn | bɛnifit |

| Tuling . | Komplex dizain wit tayt tolerans . |

| Jigs ɛn fiks dɛn . | Kastom shep wit durable finish . |

| Pat dɛn we gɛt ay-tɔlerans . | Intrikɛt jɔyometri dɛn wit prɛsis ficha dɛn . |

Indastri dɛn we de yuz haybrid prɔses dɛn:

Fɔ pik bitwin aditiv ɛn sɔbtraktiv manufakchurin .

Fɔ pik di rayt we fɔ mek di tin dɛn, dipen pan difrɛn tin dɛn. Ɛni prɔses de gi difrɛn bɛnifit dɛn, so i rili impɔtant fɔ alaynɛs yu chuk wit prɔjek rikwaymɛnt dɛn.

Factors fɔ tink bɔt we yu de pik wan we fɔ mek tin dɛn .

Di tin dɛn we dɛn nid fɔ gɛt .

Di we aw dɛn kin pik di tin dɛn we dɛn kin pik kin rili ɛp. Additive Manufacturing (AM) tipikli de wok fayn wit plastic ɛn sɔm mɛtal dɛn, usay subtractive manufacturing (SM) kin ebul fɔ handle bɔku bɔku matirial dɛn, lɛk mɛtal, plastic, wud, ɛn glas. If yu nid had-to-masin matirial ɔ ay durabiliti, SM na di bɛst opshɔn bɔku tɛm.

Pat kɔmplisiti ɛn dizayn .

Fɔ intrikɛt dizayn dɛn wit kɔmpleks jɔyometri dɛn—lɛk intanɛnt kaviti ɔ artikulayt jɔyn dɛn—am excels, alaw fɔ ay kɔstɔmayshɔn. SM, pan ɔl we i prɛsis, kin strɛch wit rili kɔmpleks dizayn dɛn. I bɛtɛ fɔ simpul ɔ intamɛdiet jɔyometri usay tayt tolɛreshɔn nid fɔ de.

Prodakshɔn Volyum ɛn Skalabiliti .

AM na fayn tin fɔ lɔw to midul prodakshɔn volyum, lɛk fɔ protɔtayp kwik kwik wan ɔ fɔ mek smɔl smɔl tin dɛn. Fɔ big-big prodakshɔn, SM na fa fawe mɔ efishɔnal, mɔ we dɛn de prodyuz tawzin pat dɛn we fiba. As di prodakshɔn volyum de go ɔp, di kɔst-ɛfɛktiv we SM de yuz kin klia.

Lid tɛm ɛn tɛm-to-maket .

Projekt dem we nid shot lida taim benefit from AM bikos of minimal setup en fast transishɔn frɔm dizayn to prodak. Fɔ big prodakshɔn rɔn, bɔt, SM kin gi kwik manufakchurin tɛm wans di sɛtup dɔn, mɔ fɔ mɛtal pat dɛn.

Badget ɛn kɔst kɔnstrakshɔn .

AM na mɔ kɔst-ɛfɛktiv fɔ smɔl, kɔmpleks pat dɛn, mɔ we dɛn protɔtayp. Bɔt, SM kin bi mɔ ikɔnomik fɔ big pat ɔ ay prodakshɔn volyum. Sɛtup kɔst ɛn di kɔst fɔ ɛni pat tipikli de dɔŋ as volyum de go ɔp na SM.

Sastaynabiliti Gol dɛn .

AM de jenarayz less waste, mek am wan mo sataynabl opshon. SM, pan ɔl we i fast fɔ big rɔn, i de prodyuz impɔtant matirial west we tan lɛk chips ɔ skrap. If sastaynabiliti na di men prɔyoritɛt, AM kin bi di bɛtɛ fit.

Disishɔn matris fɔ aditiv vs. sɔbtraktiv manufakchurin .

Di disishun matris we de kam biɛn ya de gi wan kwik kɔmpiashɔn fɔ di tin dɛn we go ɛp yu fɔ pik di rayt we:

| Factor | additive manufacturing (AM) | Subtractive Manufacturing (SM) |

| Material Rɛnj . | Limited (mɔs pan dɛn na plastic, sɔm mɛtal dɛn) | Wide (mɛtal, plastic, wud, glas) |

| Pat kɔmplisiti . | Handles komplex, intrɛstin dizayn dɛn . | Di bɛst fɔ simpul, prɛsis jɔyometri dɛn . |

| Prodakshɔn Volyum . | Ideal fɔ smɔl-batch, prototyping | Efishin fɔ mas prodakshɔn . |

| Lid tɛm . | Faster setup, kwik turnaround | Slower setup, fasta fɔ big big rɔn dɛn . |

| Pe | Mɔ dia fɔ big pat ɔ mɛtal dɛn . | Mɔ kɔst-ɛfɛktiv na ay volyum dɛn . |

| Kɔntinyu fɔ sɔpɔt | less waste, mɔ sataynabul . | signifyant west, nɔ go kɔntinyu fɔ de . |

Yuz dis matris fɔ alaynɛs yu prɔjek in nid wit di trɛnk dɛn fɔ ɛni manufakchurin we.

Rial-wɔl aplikeshɔn dɛn fɔ aditiv ɛn sɔbtraktiv manufakchurin .

Aditiv manufakchurin (AM) ɛn sɔbtraktiv manufakchurin (SM) de ple impɔtant rol dɛn akɔdin to difrɛn industri dɛn. Dɛn aplikeshɔn dɛn de kɔntinyu fɔ bɔku ɛn evolv.

Aerospace ɛn Avieshɔn .

Am: Layt wet komponent, kɔmpleks jɔyometri

SM: Ay-prɛsishɔn injin pat dɛn, strɔkchɔral ɛlimɛnt dɛn .

Ɔtomotiv Indastri .

Am: Rapid prototyping, kɔstɔm pat dɛn

SM: Enjin blɔk, transmishɔn kɔmpɔnɛnt dɛn

Medikal ɛn dɛnt .

AM: kɔstɔm implant dɛn, prɔstɛtiks .

SM: Surgical Instruments, Dental Krawn

Di guds ɛn ilɛktronik tin dɛn we pipul dɛn kin yuz fɔ bay tin dɛn .

AM: Personalized prodakt, smɔl-batch tin dɛn

SM: Smatfon kes, laptop komponent

Indastrial mashin ɛn tul dɛn .

Akitekchɔ ɛn Kɔnstrɔkshɔn .

am: Skel mɔdel dɛn, dɛkɔretiv ɛlimɛnt dɛn

SM: Struktural komponent, fasad elements .

Dɔn

Additive ɛn subtractive manufacturing Dɛn ɔl gɛt spɛshal trɛnk ɛn wikɛd tin dɛn. am excels in komplex dizain en customization. SM de gi prɛsishɔn ɛn matirial versatility.

Fɔ ɔndastand dɛn difrɛns ya rili impɔtant fɔ mek dɛn disayd fɔ mek di tin dɛn we dɛn de mek. Tink bɔt yu prɔjek in patikyula nid dɛn we yu de pik wan we.

Evaluate factors lɛk matirial, kɔmplisiti, volyum, ɛn kɔst. Dis go ɛp yu fɔ pik di bɛst we fɔ du di tin dɛn we yu want fɔ du fɔ mek di tin dɛn.