Pikiri dilanni jɔyɔrɔ ka bon kosɛbɛ plastiki yɔrɔ gɛlɛnw dilanni na minnu bɛ kɛ izini suguya caman kɔnɔ. Pikiriw musakaw faamuyali nafa ka bon dilanbagaw bolo minnu laɲini ye ka musakaw kunbɛn ani ka baarakɛcogo ɲuman caya. O musakaw bɛ se ka kɛ dɔrɔmɛ 100 ye 3D sɛbɛnnenw na ka se dɔrɔmɛ 100.000 ni kɔ ma, nɛgɛmugu caman na.

Nin sɛbɛn in kɔnɔ, aw bɛna fɛn kolomaw dɔn minnu bɛ nɔ bila pikirijikɛlan musakaw la ani u jateminɛcogo ɲuman na. An bɛna fɛnw, dilan sara, masinw, ani fɛn wɛrɛw tiɲɛ walasa ka gafe bɛɛ di aw ma.

Fɛn minnu bɛ pikirijikɛlan musaka nɔ na .

pikirijikɛlan musaka bɛ bɔ fɛn suguya caman na. Ninnu faamuyali bɛ se ka dɛmɛ don ka dilancogo ni fɛn dilanni taabolo ɲɛ, laban na, o bɛ na ni fɛn dilanni ye min musaka ka dɔgɔ.

complexité de part design .

A yɔrɔ gɛlɛya bɛ nɔba bila mɔli musaka la:

Geometries intricate bɛ machining caman de wajibiya .

Fɛn caman bɛ dɔ fara baarakɛminɛnw ka gɛlɛya kan .

Tight Tolerances Demand Precision Engineering .

Undercuts walima surfaces complexes (yɔrɔ minnu bɛ kɛ ka fɛnw tiɲɛ) bɛ kɛ sababu ye ka mɔli kɛcogo kɔrɔlenw wajibiya .

O kow bɛ kɛ sababu ye tuma caman na ka masinw ka waati caya, ka minɛnw mago kɛrɛnkɛrɛnnenw mago ɲɛ, ani ka baara musakaw caya.

A yɔrɔ bonya .

A ka c’a la, yɔrɔbaw bɛ na ni nɔgɔ musaka caman ye:

Molds belebelebaw bɛ materiel raw caman de wajibiya .

dɔ farala masinw ka waati kan ka ɲɛsin kɔnɔnabaw ma .

sɛnɛfɛnw bɔli waati janyalen ka da nɛnɛ waatiw kan .

Fɛn minnu musaka ka bon ni fɛn dilannen ye yɔrɔ kelen-kelen bɛɛ la .

Ka yɔrɔ hakɛ ni fɛn dilanni wajibiyalenw bɛn ɲɔgɔn ma, o nafa ka bon kosɛbɛ musaka ɲɛnabɔli la.

Sugandili kɛ mɔlifɛnw na .

Baarakɛminɛn nɛgɛ bɛ to pikirijikɛlanw ka dantigɛli ye:

A bɛ mɛnni kɛ ani ka ɲɛnamaya kɛ .

A bɛnnen don plastiki suguya caman ma .

A bɛ se ka fɛn dilanni hakɛ caman muɲu .

Nka, fɛn wɛrɛw i n’a fɔ aluminiyɔmu walima 3D sɛbɛnnenw bɛ se ka kɛ musaka dɔgɔyali ye hakɛ dɔgɔyali walima prototypes la.

A ka fisa ka baara kɛ ni fɛn dilanni ye .

Baara kɛli ni fɛn dilanni ye (DFM) sariyaw waleyali bɛ se ka musakaw dɔgɔya kosɛbɛ:

Optimiser kogo thickness for uniforme cooling .

Aw bɛ jukɔrɔlatigɛw ni fɛn gɛlɛnw dɔgɔya .

Dilan angles draft bɛnnenw walasa ka yɔrɔ dɔw bɔ nɔgɔya la .

Aw ye da yɔrɔ jateminɛ walasa ka fɛnw bolicogo ɲuman sɔrɔ .

Moule ka baarakɛcogo ɲuman .

Ni aw ye mɔni kɛcogo ɲuman bonya, o bɛ se ka yɔrɔ kelen-kelen bɛɛ musakaw dɔgɔya:

Multi-cavity molds bɛ dɔ fara bɔli kan cycle kelen kɔnɔ .

Denbaya ka mɔbiliw bɛ sira di yɔrɔ caman ma minnu bɛ tali kɛ ɲɔgɔn na waati kelen na .

Bololabaarakɛlaw ka sigida funteni bɛ dɔ bɔ fɛnw tiɲɛni na .

Fɔɔnɔ kanal dilancogo ɲuman bɛ cycle waatiw dɔgɔya .

Mold Manufacturer yɔrɔ .

Mold Maker ka dugukolo yɔrɔ bɛ nɔ bila musaka bɛɛ lajɛlen na:

A bɛ ci ani a ka baara kɛ ni a ye ka ɲɛsin fɛn dilannikɛlaw ma minnu bɛ yɔrɔ jan .

Dugukolo kan fɛnw dondonni baara minnu bɛ se ka kɛ diɲɛ kɔnɔ .

Kumaɲɔgɔnya gɛlɛyaw ni kɔgɔjida la feerekɛlaw ye .

Ɲɛnabɔli waati jan minnu bɛ nɔ bila poroze waatiw la .

Pikiri mɔlifɛnw musaka .

Fɛnw sugandili jɔyɔrɔ ka bon kosɛbɛ pikiri kɛli la, o bɛ nɔba bila musaka ni fɛn dilannenw baaracogo la. Nin yɔrɔ in bɛ polimɛriw, musaka kɛcogo, ani sɔngɔko jateminɛw sɛgɛsɛgɛ.

Polimɛri minnu bɛ sɔrɔ pikiri kɛli la .

Polimɛri saba minnu bɛ kɛ ka caya, olu bɛ fanga sɔrɔ pikiri kɛcogo la:

Polietilɛni (PE): fɛn caman bɛ se ka kɛ fɛn caman na, k’a ta pakew dilanni na ka se fɛnw ma minnu bɛ kɛ ka fɛnw feere.

Poliporopilini (PP): A bɛ fanga ni fɛn caman sɛgɛsɛgɛli kɛ ɲɔgɔn fɛ, a ka ca a la, a bɛ kɛ mobili ni du kɔnɔ fɛnw na.

Polisitiri (PS): A bɛ dɔn a ka gɛlɛya n’a ka jɛya fɛ, a bɛ to ka baara kɛ dumuniw foroko kɔnɔ ani fɛn minnu bɛ kɛ siɲɛ kelen.

O fɛnw bɛ nafolo suguya caman di minnu bɛ fɛn suguya caman ɲini. U sugandili bɛ bɔ baara kɛcogo kɛrɛnkɛrɛnnenw na ani musaka jateminɛw la.

Fɛn minnu bɛ nɔ bila fɛnw musaka la .

Fɛn caman bɛ nɔ bila fɛn bɛɛ musaka la pikiri kɛli la:

Product Design Complexité .

Materiel suguya ani a kala .

Hakɛ wajibiyalen .

Suguda caman bεε bε bεn ni bεnkansεbεnw ye .

farankanw ka ɲɛsin fɛnw ma minnu bɛ bonya (misali la, UV stabilisateurs, tasumafagalanw) .

Dilanbagaw ka kan ka o kow jateminɛ koɲuman walasa ka fɛnw musakaw ɲɛ ka sɔrɔ u ma fɛn dilannenw cogoya tiɲɛ.

Peleti sɔngɔ min bɛ kɛ ka fɛnɲɛnamafagalanw sɔrɔ .

Peleti minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye, olu ye pikirijikɛlan ye, a ka c’a la, o bɛ bɔ dɔrɔmɛ 1 na ka se dɔrɔmɛ 5 ma kilogaramu kelen na. Nin sɔngɔ caman ɲɔgɔnna bɛ jira:

Material Grade ani a jogo .

Polimɛri suguya kɛrɛnkɛrɛnnen .

Sugu ɲinini ni a sɔrɔcogo sɛgɛsɛgɛli .

Hakɛ sanni (Bulk discounts bɛ se ka kɛ)

Walasa k’a jira, nin ye sɔngɔko tabali nɔgɔman ye min bɛ kɛ ka fɛnɲɛnamafagalanw sɔrɔ:

| Polimɛri suguya | sɔngɔ hakɛ ($/kg) |

| PE . | 1,00 - 2,50 . |

| PP . | 1,20 - 3,00 . |

| PS . | 1,50 - 3,50 . |

O sɔngɔw bɛ kɛ laadilikanw ye. Musaka lakikaw bɛ se ka ɲɔgɔn ta ka kɛɲɛ ni kalasi kɛrɛnkɛrɛnnenw ye, suguya cogoyaw, ani feerekɛlaw ka jɛɲɔgɔnyaw.

Pikirili mɔli baarakɛminɛnw musakaw .

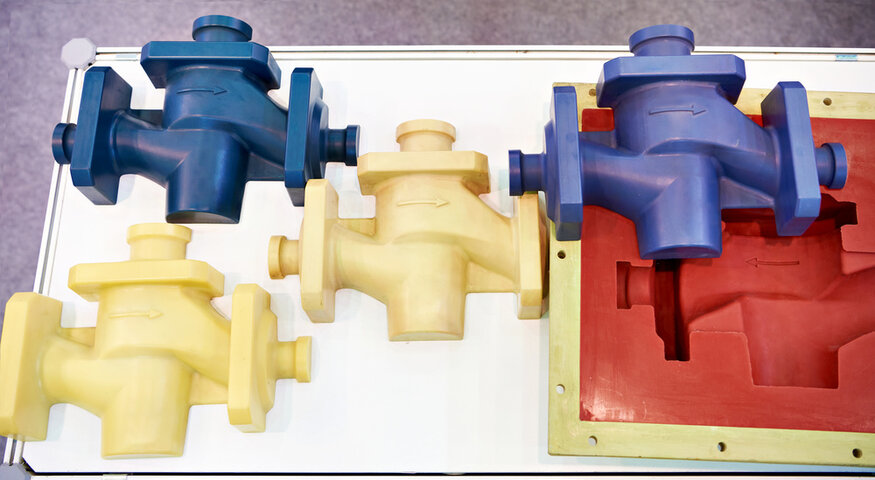

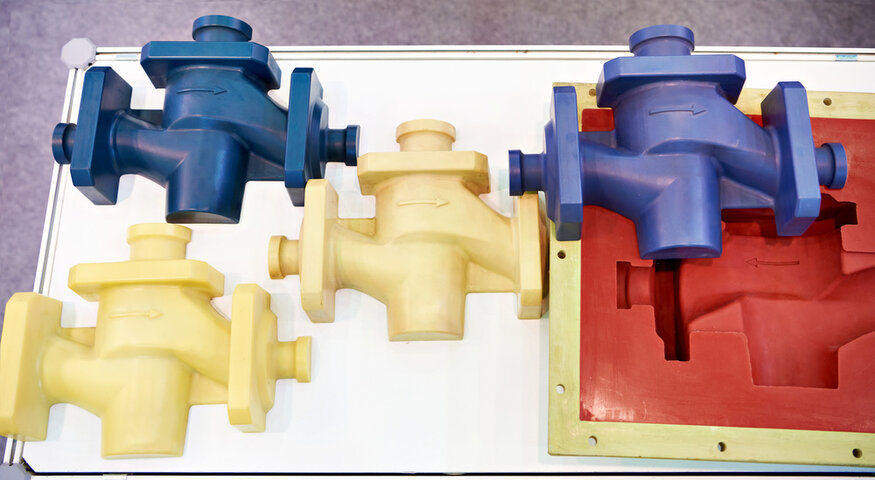

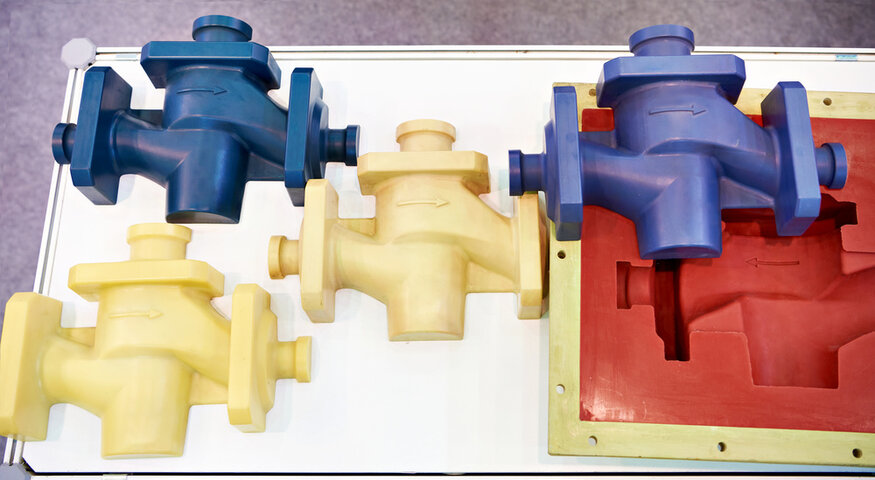

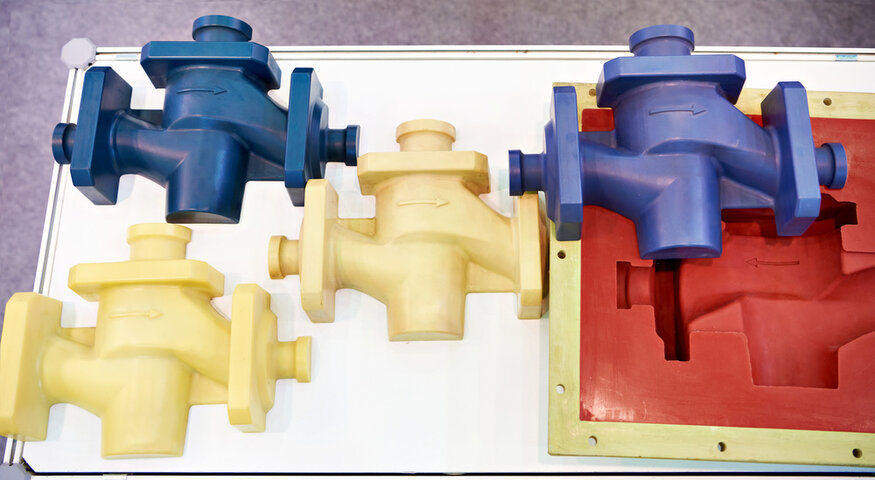

Baarakɛminɛnw musakaw bɛ pikiri musaka tilayɔrɔba dɔ jira. Mold dabɔcogo suguya caman faamuyali n’u musaka minnu bɛ tali kɛ u la, o nafa ka bon kosɛbɛ poroze bolodacogo ɲuman ni baarakɛnafolo labɛnni na.

Nɔgɔ fɔlɔ dabɔcogo .

Fɛɛrɛba saba de bɛ pikirijikɛlan dilanni cogoya de kan:

CNC Machining .

A ka ɲi kosɛbɛ aluminiyɔmu ni nɛgɛmafɛnw dilanni na .

A bɛ tiɲɛni kɛcogo ɲuman di ani ka fini don .

A bɛnnen don jateminɛ gɛlɛnw ma minnu bɛ baarakɛminɛn caman caman cili wajibiya .

Kuran bɔli masin (EDM) .

Kɛrɛnkɛrɛnnenya la, a bɛ kɛ ka mɔli kɛcogo gɛlɛnw dilan .

A bɛ baara kɛ ni kuran bɔli ye walasa ka nɔgɔbɔlan cogoya .

A bɛ jaabi tigitigiw Bɔ k'a sɔrɔ a ma baara Kɛ ni a ye .

3D sɛbɛnni .

A bɛ se ka kɛ sababu ye ka mɔni teliya ni musaka dɔgɔya .

Dafalen don prototyping ni low-volume production runs .

A bɛ dɔ bɔ ɲɛminɛ waatiw la ani ka a to a ka se ka kɛ teliya la dilancogo iterations .

Tekniki dɔnniya wajibiyalenw .

Ka mɔli gɛlɛnw dilan, olu bɛ dɔnniya kɛrɛnkɛrɛnnenw ɲini:

CAD/CAM porogaramu ɲɛtaa ɲɛtaa .

Faamuyali jugu min bɛ kɛ fɛnw cogoyaw la ani u ka jibɔcogo la .

Dɔnniya min bɛ sɔrɔ mɔli dilanni sariyakolow ni a dilanni taabolo la .

O wajibiw ka teli ka kɛ sababu ye ka tɔnw bila ka baara kɛ ni u ka baara ye ka ɲɛsin fɛnw dilanni n’u dilanni ma, ka ɲɛsin izini kɛrɛnkɛrɛnnenw ma.

Outsourcing vs. in-house production .

Nafa minnu bɛ sɔrɔ baara la .

Sɔrɔli dɔnniya ni minɛnw na .

A musaka ka dɔgɔ ka ɲɛsin mɔli gɛlɛnw ma walima minnu ka bon kosɛbɛ .

Kapitali wari bilali masinw na .

Nafa minnu bɛ sɔrɔ so kɔnɔ .

Kɔrɔsiliba kɛra sɛnɛfɛnw dilanni taabolo kan .

Yɛlɛma teliya ka ɲɛsin mɔli nɔgɔmanw ma .

A musaka ka dɔgɔn ka ɲɛsin mouliw ma minnu ka dɔgɔn walima minnu bɛ kɛ ni prototype ye ni 3D sɛbɛnni ye .

Mold Cost Ranges .

Mɔbili musakaw bɛ danfara kosɛbɛ ka da a gɛlɛya, a hakɛ ani a dilanni fɛɛrɛ kan:

| Mold type | production volume | cost range |

| 3d imprimé . | A ka dɔgɔn (< 100 unité) . | $100 - $1000 |

| Nɛgɛ (Boli-yɔrɔ) . | 1000 - 5000 ye . | $2000 - $5000 |

| complexe (hakɛ caman) . | 10.000+ Unités . | $5,000 - $100.000+ |

Fɛn minnu bɛ nɔ bila o musakaw la, olu dɔw ye:

Multé matériel (aluminum, steel, etc.) .

Cavities hakɛ .

Surface Finish wajibiyalenw .

Gɛlɛya min bɛ sɔrɔ yɔrɔ jateminɛ .

pikiri kɛli ni pikirijikɛlan musaka ye .

Pikiri musaka musakaw tiɲɛni faamuyali nafa ka bon kosɛbɛ baarakɛnafolo bolodacogo ɲuman na ani musakaw ɲɛnabɔli la. Nin yɔrɔ in bɛ fɛn suguya caman sɛgɛsɛgɛ minnu bɛ kɛ sababu ye ka fɛnw musaka bɛɛ lajɛlen musaka kɛ ani ka hakilinaw di fɛnw musakaw kan minnu bɛ kɛ ka ɲɛsin fɛn kɛrɛnkɛrɛnnenw ma.

Cost Component tiɲɛni .

A ka c’a la, pikirijikɛlan musakaw bɛ kɛ suguya duuru ye:

Materiel musakaw: 20-35% .

Masini musakaw: 25-40% .

Dilan sara: 5-10%

Lajɛ musakaw: 15-20% .

Takisiw ni tɔnɔw: 20-30% .

Walasa ka nin jatebɔ in ye, aw bɛ nin ja in jateminɛ:

Pie Title Injection Mold Cost Composition 'Material Costs' : 27.5 'Machining Costs' : 32.5 'Design fees' : 7.5 'Assembly Costs' : 17.5 'taxes and profits' :

Material Cost misaliw .

Fɛnw musakaw bɛ danfara kosɛbɛ ka kɛɲɛ ni mɔli yɔrɔ ye ani a ka gɛlɛn. Nin ye fɛnw musaka danma-danma tiɲɛni ye mɔlifɛn suguya caman na:

| bɛ | fɛn minnu | kɛ ka fɛnw mara musaka jateminɛlenw . |

| Locating rings . | Baarakɛminɛn nɛgɛ . | $50 - $200 |

| Sliders . | Nɛgɛ gɛlɛn . | $200 - $1000 |

| Lifters . | inox . | $150 - $500 |

| Bololabaarakɛlaw ka funteni . | Alloy suguya caman . | $1000 - $5000 |

O yɔrɔw bɛ kɛ bilasiralikanw ye. Musaka lakikaw bɛ se ka wuli ka bɔ u nɔ na ka da:

Fɛn minnu bɛ nɔ bila musaka tilali la .

Fɛn caman bɛ se ka nɔ bila musakaw tilatilali kɛmɛsarada la:

Mold Complexity: Dilancogo gɛlɛnw bɛ se ka dɔ fara masinw ni ɲɔgɔnjɛ hakɛ kan kɛmɛsarada la .

Material Selection: Alloys minnu bɛ baara kɛ kosɛbɛ, olu bɛ se ka fɛnw musaka kɛmɛsarada la kɔrɔta .

Production Volume: Ka caya, o bɛ se ka dɔ bɔ dilancogo sara nɔ na min bɛ se ka kɛ .

Fɛɛrɛ minnu bɛ kɛ ka pikirijikɛlanw fɔ .

Kumaɲɔgɔnya tigitigi nafa ka bon kosɛbɛ pikirijikɛlan dilannikɛlaw ni sannikɛlaw bɛɛ la. Nin yɔrɔ in bɛ fɛɛrɛ fɔlɔ saba sɛgɛsɛgɛ minnu bɛ kɛ baara in na walasa ka nɔgɔ musakaw jateminɛ.

Material Cost Multiplier Method .

O fɛɛrɛ tilennen in bɛ tali kɛ:

Jatebɔ kɛli fɛnw musaka bɛɛ lajɛlen na .

Ka sɔngɔ jateminɛ kɛ walasa ka mɔli laban musaka dɔn .

A ka c’a la, sɔngɔko hakɛ bɛ daminɛ 2,5 na ka se 5 ma, a bɛ ɲɔgɔn ta ka da:

Moli hakɛ: A ka c’a la, nɔgɔw bɛ kɛ ni fɛnw ye minnu ka dɔgɔn .

Gɛlɛya: Dilancogo gɛlɛnw bɛ fɛn caman de wajibiya .

Production Volume: Molds de la haute-volume bɛ se ka kɛ sababu ye ka fɛn caman kɛ .

Misali jateminɛ:

Fɛnw musaka: $10,000 Sɔngɔko: 3,5 Modɛli musaka jateminɛlen: $10,000 x 3,5 = $35.000

Component-Wise Estimation .

Nin fɛɛrɛ ɲɛfɔlen in bɛ tali kɛ:

musaka yɔrɔ kelen-kelen bɛɛ jateminɛni danfaralen .

Mɔgɔ kelen-kelen bɛɛ ka jateminɛw lajɛlenw ka ɲɛsin quote comprehensive quote ma .

A yɔrɔ kolomaw ye:

Material musakaw .

Masini musakaw .

Design sara .

Ɲɛnabɔli sanfɛ .

Lajɛba musakaw .

A ka c’a la, fɛn dilannikɛlaw bɛ tɔnɔ sɔrɔta hakɛ 15-30% fara musaka jateminɛlen bɛɛ kan.

| musaka yɔrɔ | kɛmɛsarada la | hakɛ hakɛ . |

| Fɛn minnu bɛ kɛ . | 25% . | $8,750 ye. |

| Machining . | 35% . | $12,250 ye. |

| Desɛn | 10% . | $3,500 |

| Mara kɛ cogo | 10% . | $3,500 |

| Asanbile | 20% . | $7000 |

| Kasabi | 100% . | $35.000 |

| Tɔnɔ (20%) . | - | $7000 |

| quote laban . | - | $42.000 |

Jatebɔcogo kɔfɛta .

O fɛɛrɛ in bɛ daminɛ ni laɲini yɔrɔ sɔngɔ ye, wa a bɛ baara kɛ kɔfɛ:

Yɔrɔ kelen musaka hakɛ sɛgɛsɛgɛ .

Aw bɛ mɔli musaka jateminɛ yɔrɔ kelen na .

Jate kɛ mɔli musaka bɛɛ lajɛlen na ka da a dilanni hakɛ makɔnɔnen kan .

Misali:

Target Part Price: $1.00 Materiel Cost kelen-kelen bɛɛ: $0.30 A dilanni musaka tilayɔrɔba kelen na: $0.40 Mold Amortisation Part er: $0.20 A ka baara hakɛ makɔnɔnen hakɛ: 100.000 Unit

Nin fɛɛrɛ in bɛ dɛmɛ don walasa mɔli musaka ka bɛn poroze bɛɛ lajɛlen sɔrɔko ma.

Fɛɛrɛ minnu bɛ kɛ ka pikirijikɛlan musakaw dɔgɔya .

Cost Optimisation in Injection Molding bɛ fɛɛrɛ bɛɛjɛfanga de wajibiya, ka baara kɛcogo suguya caman ɲɛnabɔ. Nin yɔrɔ in bɛ fɛɛrɛ jɔnjɔnw sɛgɛsɛgɛ walasa ka musakaw dɔgɔya k’a sɔrɔ u ma jogo tiɲɛ.

Product Design Optimisation .

Fɛn dilannenw dilanni ɲuman bɛ nɔba bila mɔbili musakaw la:

Kogo janya kelen: A bɛ a to a ka nɛnɛ ani ka Warpage dɔgɔya ani ka dɔ bɔ .

Filɛli ɲuman ani angles draft: A bɛ nɔgɔya yɔrɔ bɔli nɔgɔya ani ka mɔli jan sɔrɔ .

Fɛn minnu bɛ se ka kɛ fɛn gɛlɛnw ye: o bɛ dɔ bɔ masinw dilanni waati la ani u dilanni gɛlɛya la .

Mold Design Cost Control .

Mold design optimising bɛ se ka kɛ sababu ye ka wari caman bɔ:

Maximiser standard component usage .

Ka fɛn dilanni ɲɛfɔ ka ɲɛ .

Optimiser gate location ani runner design .

Design Efficient Cooling Systems .

O fɛɛrɛw bɛ dɔ bɔ masinw ka waati la, u ka ɲɔgɔn lajɛ gɛlɛyaw la, ani fɛnw tiɲɛni na.

Mold Material Selection .

Ka mɔli kɛcogo ɲuman sugandi Balannako musaka ni baarakɛcogo:

| Mɔle ka ɲɛnamaya kɔnɔfɛn | Ladilikanw |

| < 10.000 ye . | Aluminiyɔmu . |

| 10.000 - 100.000 . | P20 . |

| > 100.000 shots . | H13 walima S7 nɛgɛ . |

Surface furakɛli bɛ se ka sɛgɛnbaliya ni polisiya sabati ni a mago bɛ a la.

Masini kɛcogo ɲɛnabɔli .

Masini kɛcogo ɲumanw bɛ dɔ bɔ fɛn dilanni waati ni a musakaw la:

Fɛɛrɛ bɛnnenw sugandi minnu sinsinnen bɛ mɔli jɔcogo kan .

Baara kɛ ni CNC minɛnw ye minnu bɛ taa ɲɛ walasa ka baarakɛcogo ɲɛ .

Aw bɛ taabolo kɛrɛnkɛrɛnnenw dɔgɔya i n’a fɔ EDM .

Pikiri molding paramɛtiri optimisation .

Fine-tuning process parameters bɛ baarakɛcogo ɲuman sabati:

Kɔlɔsili pikiri teliya, tansiyɔn ani funteni .

Aw bɛ nɛnɛ waati dɔgɔya ni mɔli kɛcogo ɲuman ye .

Baara kɛ ni dɛmɛnanw ye yɔrɔ gɛlɛnw na .

Pikirili mɔli musakaw ɲɛnabɔli .

Muɲu maracogo ɲuman pikiri kɛli la, o bɛ taabolo sigilen de wajibiya. Nin yɔrɔ in bɛ fɛɛrɛw jira minnu bɛ kɛ ka musakaw kunbɛn mɔli ɲɛnamaya bɛɛ kɔnɔ.

musaka jatebɔcogo bɛɛ lajɛlen .

Jatebɔ sira barikama waleyali nafa ka bon kosɛbɛ mɔli musakaw nɔfɛtaama n’u ɲɛnabɔli la. A ka kan ka lamini:

Matériel Cost Control .

Negotiate Bulk Purchase Discounts .

A’ ye fɛnw maracogo ɲɛnabɔ min bɛ kɛ waati dɔrɔn kɔnɔ .

Aw bɛ fɛnw tiɲɛnenw kɔlɔsi ani ka baarakɛcogo ɲuman sɔrɔ .

Masini musaka ɲɛnabɔli min bɛ kɛ ni masinw ye minnu bɛ bɔ kɛnɛ kan .

Aw ye fɛnw dilanbagaw ka rezow labɛn minnu bɛ se ka da u kan .

Aw bɛ sɛgɛsɛgɛli kɛcogo ɲumanw waleya .

Aw ye jɛɲɔgɔnya kuntaalajanw sigi sen kan ka ɲɛsin hakɛ dɔgɔyali ma .

Kɔnɔna masinw musaka tilali .

Track Machine utilization rates .

Baara kɛcogo musakabɔ baara musaka tigitigiw waleya .

Aw bɛ wari bila bana kunbɛnni na walasa ka dɔ bɔ a jɔli waati la .

Dilancogo ani fɛn dilanni taabolo ɲɛnabɔli .

Dilancogo ni fɛn dilanni taabolo kɔlɔsili barika bonya bɛ se ka musakaw dɔgɔya kosɛbɛ:

Design Review ani Optimisation .

Aw ye jateminɛ kɛ tuma bɛɛ dilancogo la ni jɛkuluw ye minnu bɛ baara kɛ ɲɔgɔn fɛ .

Baara kɛ ni simulatigɛ porogaramuw ye walasa ka ko minnu bɛ se ka kɛ , olu dɔn joona .

Standardize Design Elements ka fɛn dilannenw siraw cɛ .

Taabolo ka jogoɲini .

Jateminɛ kɛcogo kɔlɔsili (SPC) fɛɛrɛw waleya .

Aw bɛ baarakɛlaw ka kalanw kɛ tuma bɛɛ.

Aw ye jogoɲumanya dantigɛli jɛlenw ni kɔlɔsili taabolo sigi sen kan .

Mold Reparation ani Modification Cost Control .

ladonni min bɛ kɛ ka ɲɛ ani dilan waati bɛnnen na, o nafa ka bon walasa ka waatijan kɔnɔ musaka musakaw ɲɛnabɔ:

| fɛɛrɛw | nafaw | waleyali . |

| Ladonni tuma bɛɛ . | A bɛ mɔli ɲɛnamaya janya, ka dɔ bɔ baarakɛbaliya la min ma labɛn . | Aw bɛ sɛgɛsɛgɛliw kɛ minnu bɛ kɛ tuma bɛɛ, ka ladonni kunbɛn baaraw kɛ . |

| A bɛ dilan waati bɛnnen na . | A bɛ fɛn dilanni tiɲɛniw dɔgɔya, a bɛ koɲɛw caya bali . | Aw bɛ jaabi teliyacogo dɔ sigi sen kan nɔgɔko koɲɛw kama, ka yɔrɔw mara minnu bɛ sɔrɔ fɛnw na |

| Yɛlɛma dɔw kɛra . | Adresses kɛrɛnkɛrɛnnenw don, a musaka ka dɔgɔ ka tɛmɛ a falenni dafalen kan . | Aw bɛ sɛgɛn yɔrɔw dɔn minnu bɛ sɔrɔ tuma bɛɛ, ka fɛn caman sɛmɛntiyacogo fɛɛrɛw labɛn . |

Pikirili mɔli jateminɛ musaka: A tiɲɛni .

Pikiriw musaka jateminɛ tigitigi nafa ka bon kosɛbɛ walasa ka baara kɛ ka ɲɛ fɛn dilanni porozɛ o porozɛ la. Nin yɔrɔ in bɛ fɛn kolomaw tilatilali caman di minnu bɛ nɔ bila musakaw la ani cogo min na fɛn dilannikɛlaw bɛ se ka o musakaw jateminɛ.

fɛnw sugandili n' a nɔfɛkow musaka kan .

Fɛn suguya min sugandira, o jɔyɔrɔ ka bon kosɛbɛ mɔli musaka bɛɛ lajɛlen na. Plastiki suguya caman bɛ ni fɛnw ye minnu bɛ ɲɔgɔn ta, suguya sɔngɔw, ani u bɛnnen don baara kɛrɛnkɛrɛnnenw kama. Fɛn minnu bɛ fara a kan i n’a fɔ UV sabatili walima tasumafagalanw, olu bɛ se ka baara kɛcogo ɲɛ nka u bɛ dɔ fara u sɔngɔ kan fana.

Fɛn minnu ka kan ka jateminɛ ka ɲɛsin fɛnw sugandili ma:

Fɛnw nafa : A bɛ mɛn, a bɛ se ka funteni kunbɛn, a bɛ se ka a yɛrɛ tanga.

Sugu sɔngɔ : fɛnɲɛnamafagalanw sɔngɔw bɛ wuli ka bɔ u nɔ na ani ka nɔ bila mɔli musakaw la.

Fɛn minnu bɛ fara ɲɔgɔn kan : Ka baara kɛcogo ɲɛ nka ka musakaw kɔrɔta ka kɛɲɛ ni ɲɛtaa ɲininenw ye.

musaka minnu bɛ kɛ pikiri kɛli la .

Fɛn caman bɛ pikiri kɛli musaka bɛɛ lajɛlen bila sen kan. Ninnu faamuyali bɛ se k’aw dɛmɛ ka latigɛ ɲumanw kɛ u dilanni n’u dilanni dakunw na:

Mold complexity and size : Yɔrɔ gɛlɛnw bɛ mɔli caman de wajibiya, ka dɔ fara masinw ni u lajɛ waati kan.

Fɛnw sugandili : Fɛn minnu ka ɲi kosɛbɛ i n’a fɔ baarakɛminɛn nɛgɛ bɛ dɔ fara u ka mɔni musakaw kan ka kɔn o ɲɛ nka u bɛ mɛn ka ɲɛ.

Sɛnɛfɛnw bɔli hakɛ : Sɛnɛfɛnw bolicogo belebelebaw bɛ dɔ bɔ yɔrɔ kelen-kelen bɛɛ musaka la ka da sɔrɔko kan.

Baara musakaw : Baara minnu bɛ se ka kɛ, olu ka kan ka kɛ walasa ka mɔli dilanni ni a dilanni kɛ; Hakɛ caman bɛ dɔ fara musakaw kan.

Layidu talenw : Moli dilannikɛla sigiyɔrɔ bɛ nɔ bila kurunbokari sara la, kɛrɛnkɛrɛnnenya la diɲɛ kɔnɔ komandiw kama.

Hakɛ, cycle waati, ani sɛnɛfɛnw bɔli hakɛw .

Yɔrɔ minnu bɛ bɔ boli kelen-kelen bɛɛ la ani cycle waati min bɛ kɛ yɔrɔ kelen na, olu hakɛ bɛ nɔba bila musaka bɛɛ lajɛlen na:

Hakɛ ni musaka yɔrɔ kelen na : sɛnɛfɛnw bɔli hakɛ caman bɛ mɔli musaka jɛnsɛn unit caman kɔnɔ, ka yɔrɔ kelen-kelen bɛɛ musaka dɔgɔya.

Sikili waati fɛnw : A yɔrɔ ka gɛlɛn, a ka fɛnw cogoya, ani a dilanni bɛɛ bɛ nɔ bila a yɔrɔ kelen-kelen bɛɛ la waati hakɛ la.

Fɛn dilanni hakɛ fɛɛrɛw : Ka baara kɛ ni fɛn caman ye , ka fɛn ɲumanw sugandi, ani ka fɛnw dilanni nɔgɔya, o bɛ se ka dɔ fara fɛn dilanni hakɛ kan, ka baara kɛcogo bɛɛ lajɛlen ɲɛ.

musakaw jateminɛni ni u jateminɛni .

Ni pikiri kɛli musaka bɛɛ lajɛlen jateminɛna, a dilannikɛlaw ka kan ka jateminɛ kɛ a yɔrɔ caman na:

Yɔrɔ musakaw : A bɛ danfara ka kɛɲɛ ni a yɔrɔ ka gɛlɛya ni a bonya ye.

Baarakɛminɛnw musakaw : musaka min bɛ kɛ ka mɔni yɛrɛ dilan ani k’a dilan.

Fɛnw musakaw : Ka da plastiki suguya kan ani fɛn o fɛn bɛ fara a kan.

Production volume : A ka bon ka boli yɔrɔ kelen-kelen bɛɛ musakaw la, ka sɔrɔ batch misɛnninw bɛ se ka musaka caman sɔrɔ ka da a sigili fɔlɔ kan.

Baara kɛli ni musaka jateminɛ ye : Dilanbaga caman bɛ baara kɛ ni pikirijikɛlan musaka jateminɛnanw ye walasa ka baara nɔgɔya ani ka baarakɛnafolo bolodacogo ɲuman sabati.

Kuncɛli

Pikiriw musaka faamuyali nafa ka bon kosɛbɛ dilanbagaw bolo walasa u ka musakaw ɲɛnabɔ ani ka u dilanni nafa bonya. Fɛn kolomaw i n’a fɔ a yɔrɔ ka gɛlɛn, a bonya, a fɛnw sugandili, a dilanni, ani a sigiyɔrɔ, o bɛɛ bɛ nɔ bila musakaw la. Ni u bɛ dilanw kɛ ka ɲɛ ka ɲɛsin fɛnw dilanni ma, ka fɛn bɛnnenw sugandi, ani ka mɔni kɛcogo ɲɛ, u dilannikɛlaw bɛ se ka musakaw dɔgɔya. Ka fara o kan, yɔrɔko nɔfɛta ɲuman ni a sugandili tɛ sɔngɔko dɔrɔn ye, nka a bɛ kɛ fana a dilanni cogoya ɲuman na. Ka sinsin nin fɛɛrɛ ninnu kan, o b’a to fɛn dilannikɛlaw bɛ se ka balansi sɔrɔ musaka ni jogo ɲuman cɛ, ka pikiri kɛcogo ɲɛ.