Injɛkshɔn moldin de ple wan impɔtant pat fɔ prodyuz kɔmpleks plastic pat dɛn we dɛn de yuz akɔdin to difrɛn industri dɛn. Fɔ ɔndastand di kɔst fɔ injɛkshɔn mold impɔtant fɔ di wan dɛn we de mek di tin dɛn we dɛn want fɔ du fɔ kɔntrol di spɛns ɛn fɔ mek dɛn ebul fɔ wok fayn fayn wan. Dɛn kɔst ya kin kɔmɔt frɔm lɛk $100 fɔ 3D print mol to pas $100,000 fɔ di mɔlti-kaviti stɛl mol dɛn.

Insai dis post, yu go lan bɔt di men tin dɛm we de inflɔws injɛkshɔn mold kɔst ɛn aw fɔ ɛstimat dɛm fayn fayn wan. Wi go brok di matirial, dizayn fi, mashin, ɛn mɔ fɔ gi yu wan kɔmprɛhɛnsif gayd.

Factors we de afɛkt injɛkshɔn mold kɔst .

Di kɔst fɔ injɛkshɔn mold kin afɛkt difrɛn tin dɛn. We dɛn ɔndastand dɛn tin ya, dat kin ɛp fɔ mek dɛn ebul fɔ mek dizayn ɛn prodakshɔn wok fayn fayn wan, ɛn dis kin mek dɛn ebul fɔ mek tin dɛn we nɔ go tek bɔku mɔni.

Komplexity of pat dizayn .

Pat kɔmplisiti signifyant impaks mold kɔst:

Intrikɛt jɔyometri dɛn nid mɔ sofistikiet mashin .

Multiple Features Inkris Tul kɔmplisiti .

Tayt tolɛreshɔn dɛn de aks fɔ prɛsishɔn injinɛri .

Ɔndakɔt ɔ kɔmpleks sɔfays dɛn nid fɔ gɛt advans mold dizayn dɛn .

Bɔku tɛm, dɛn tin ya kin mek dɛn gɛt ay mashin tɛm, dɛn nid spɛshal ikwipmɛnt dɛn, ɛn dɛn kin spɛn mɔ mɔni fɔ wok.

Sayz fɔ di pat .

Big pat dɛn kin jɔs mek di mold kɔst go ɔp:

Big big mold dɛn nid mɔ raw matirial .

Inkris mashin tɛm fɔ big kaviti dɛn .

Ekstend prodakshɔn saykl dɛn bikɔs ɔf di lɔng tɛm we dɛn kin kol .

Di ay matirial kɔst fɔ ɛni pat we dɛn dɔn mol .

Balansin pat saiz wit prodakshɔn rikwaymɛnt na impɔtant tin fɔ kɔst ɔptimayzeshɔn.

Di we aw dɛn pik di tin dɛn we dɛn kin yuz fɔ mek di mold .

Tul stɛl de stil bi di bɛnchmak fɔ injɛkshɔn mold dɛn:

I de gi fɔ lɔng tɛm ɛn fɔ liv lɔng .

I fayn fɔ difrɛn plastic matirial dɛn .

Witstand ay prodakshɔn volyum dɛn .

Bɔt ɔda tin dɛn lɛk aluminiɔm ɔ 3D-printed opshɔn dɛn kin kɔst-ɛfɛktiv fɔ lɔwa volyum rɔn ɔ protɔtayp.

Di bɛst we fɔ du tin fɔ dizayn .

Implimentin dizayn fɔ manufakchurabiliti (DFM) prinsipul dɛn kin ridyus di kɔst dɛn bad bad wan:

Optimize wall tiknes fɔ yunifom kol .

Minimayz ɔnda-kɔt ɛn kɔmpleks ficha dɛn .

Disain aprupriet draft angles fɔ izi pat ɛjekshɔn .

Tink bɔt di say we di get de fɔ di bɛst matirial flɔ .

Mold Efisiɛns .

If yu maksimayz di mold efyushɔn, i kin mek di kɔst fɔ ɛni pat dɔŋ:

Multi-kaviti mold dɛn de inkrisayz autput fɔ ɛni saykl .

Famili mold dɛn de alaw fɔ mek bɔku bɔku pat dɛn we gɛt fɔ du wit am wan tɛm wan tɛm .

Hot Runner Systems Ridyus di west we dɛn de yuz fɔ mek tin dɛn .

Proper Cooling Channel Design Minimizes Cycle Times .

Di say we dɛn mek di mold

Di say we di pɔsin we mek di mol de, de ambɔg di ɔl di kɔst:

Shiping ɛn handlin fi fɔ fa fa manifakta dɛn .

Pɔtɛnɛshɛl import duties fɔ intanashɔnal sɔs .

Kɔmyunikeshɔn Chalenj dɛn wit Ɔfsho Suppliers .

Di tɛm we di lida dɛn kin gɛt lɔng tɛm pas di tɛm we dɛn kin afɛkt di prɔjek tɛmlayn dɛn .

Injekshɔn Mold Matirial Kɔst .

Matirial sɛlɛkshɔn de ple wan impɔtant pat pan injɛkshɔn moldin, we rili impɔk ɔl tu di kɔst ɛn prodak pefɔmɛns. Dis pat de ɛksplɔrɔ kɔmɔn polimɛr, kɔst faktɔ, ɛn prayz kɔnsidareshɔn.

Kɔmɔn polima dɛn na injɛkshɔn moldin .

Tri polimכr dεm we dεn yuz bכku bכku wan de dכmin di injεkshכn moldin indastri:

Polyethylene (PE): Versatile material we fit fɔ difrɛn aplikeshɔn dɛn, frɔm pak to kɔshɔma guds.

Polypropylene (PP): I de gi fayn fayn balans fɔ trɛnk ɛn fleksibiliti, bɔku tɛm dɛn kin yuz am na ɔtomotiv ɛn os prɔdak.

Polystyrene (PS): Dɛn sabi am fɔ in rigid ɛn klia, bɔku tɛm dɛn kin yuz am fɔ pak tin dɛn fɔ it ɛn tin dɛn we dɛn kin yuz wan tɛm nɔmɔ.

Dɛn matirial ya de gi wan rich prɔpati we de kech fɔ difrɛn prɔdak rikwaymɛnt dɛn. Dɛn sɛlɛkshɔn dipen pan spɛshal pefɔmɛns nid ɛn kɔst kɔnsidareshɔn.

Factors influence material cost .

Bɔku ɛlimɛnt dɛn de afɛkt di ɔvala matirial kɔst insay injɛkshɔn moldin:

Produk dizain Komplexiti .

Material tayp ɛn gred .

Kwantiti we dɛn nid .

Maket fluktueshɔn dɛn na raw matirial prayz dɛn .

Aditiv fɔ ɛnhans prɔpati dɛn (ɛgz., UV stebyulayza, flame retardants)

Di wan dɛn we de mek di tin dɛn fɔ tek tɛm wej dɛn tin ya fɔ mek dɛn ebul fɔ du mɔ di tin dɛn we dɛn nid fɔ pe fɔ di tin dɛn we dɛn nid we dɛn nɔ go ebul fɔ kɔmprɔmis di kwaliti fɔ di prɔdak.

Termoplastik pellet prayz .

Tεrmoplastik pεlεt dεm, di raw mεtirial fכ injεkshכn moldin, tipikכs de frכm $1 to $5 fכ wan kilogram. Dis prayz chenj de sho:

Matirial gred ɛn kwaliti .

Spesifi k polima tayp .

Maket Dimand ɛn Sapɔt Daynamiks .

Kwantiti we yu bay (bulk diskɔnt kin aplay)

Fɔ ɛgzampul, na wan simpul prayz tebul fɔ kɔmɔn tɛmplastik dɛn:

| Polima tayp | prays rɛnj ($/kg) |

| PE . | 1,00 - 2,50 |

| PP we de na di . | 1,20 - 3,00. |

| PS . | 1,50 - 3,50. |

Dɛn prayz ya de wok as jenɛral gaydlayn dɛn. Di rial kɔst kin difrɛn bay di patikyula gred dɛn, di kɔndishɔn dɛn na di makit, ɛn di rilayshɔnship dɛn we di saplay dɛn gɛt.

Injekshɔn Mold Tuling Kɔst .

Tul kɔst dɛn ripresent wan impɔtant pat pan injɛkshɔn moldin ɛkspɛns. Fɔ ɔndastand difrɛn we dɛn fɔ mek di mold ɛn di kɔst dɛn we dɛn gɛt fɔ mek dɛn gɛt mɔ mɔni na impɔtant tin fɔ mek dɛn plan ɛn badjɛt di prɔjek fayn fayn wan.

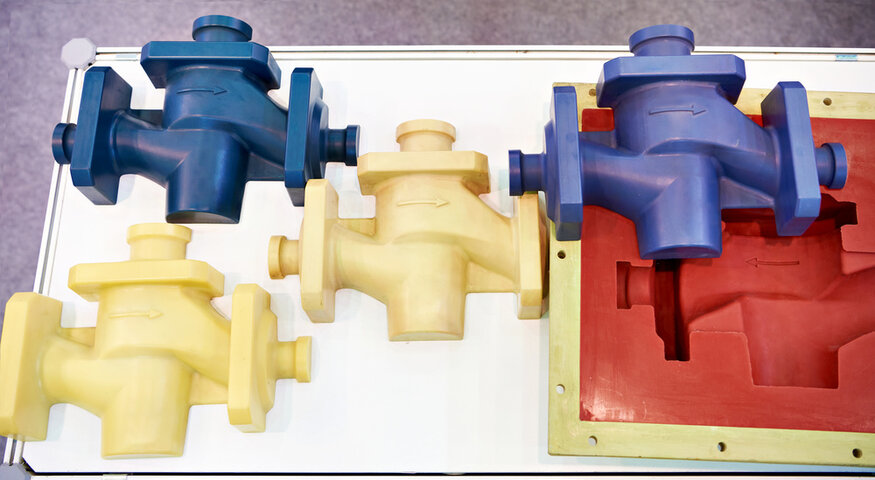

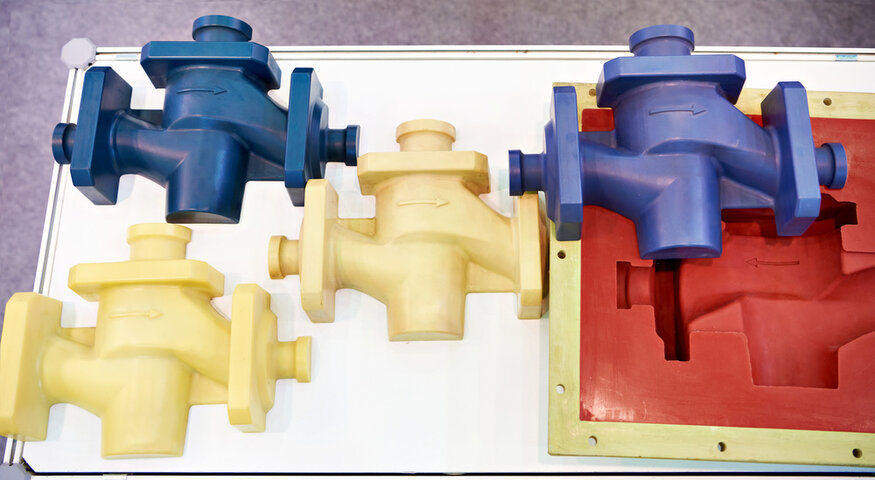

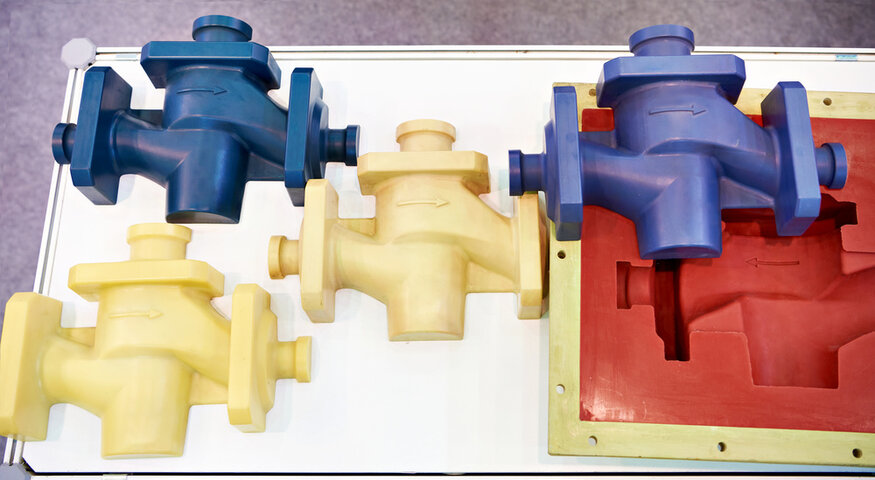

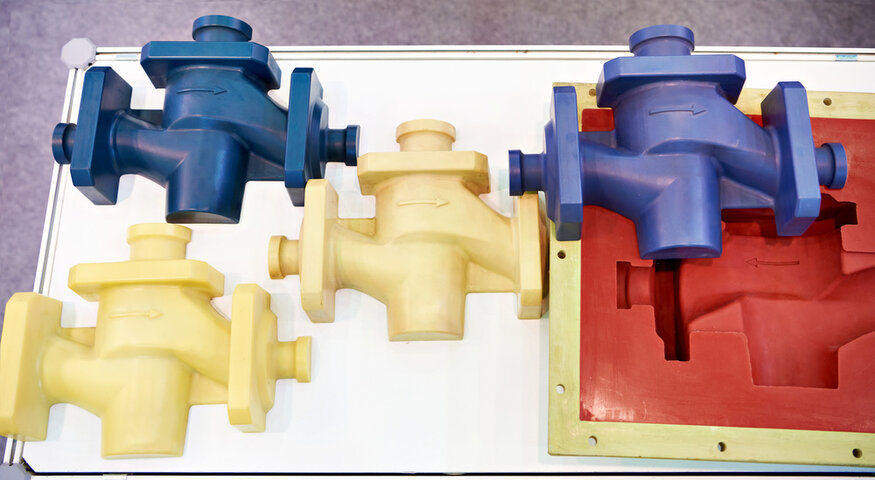

Praymari Mold Krieshɔn Mɛtɔd dɛn .

Tri men tɛknik dɛn de domin di injɛkshɔn mold manufakchurin land skay:

CNC MACHINING .

Ideal fɔ ay-prɛsishɔn aluminiɔm ɛn stenlɛs stiɛl mol dɛn .

Ofa fayn fayn akkuracy ɛn surface finish .

I fayn fɔ kɔmpleks jɔyometri dɛn we nid fɔ chenj bɔku bɔku tul dɛn .

Ilektrikal dischaj mashin (EDM) .

Speshal fɔ mek intrɛst mold patɛn .

Yuz ilɛktrik dischaj fɔ shep di mold kaviti .

I de prodyuz rili prɛsis rizɔlt dɛn we nɔ gɛt post-prɔsɛsin .

3D Printing we dɛn de yuz fɔ print .

Enables rapid ɛn kɔst-ɛfɛktiv mold prodakshɔn .

Perfekt fɔ prototyping ɛn lɔw-volyum prodakshɔn rɔn dɛn

Ridyus di lida tɛm ɛn alaw kwik dizayn itɛreshɔn dɛn .

Teknik Ɛkspɛriɛns Rikwaymɛnt dɛn .

Fɔ mek kɔmpleks mold dɛn de aks fɔ spɛshal no:

Advans CAD/CAM Softwea Proficiency .

Dip ɔndastandin fɔ matirial prɔpati ɛn flɔ dinamik .

Ɛkspɛriɛns insay Mɔld Dizayn Prinsipul ɛn Manufakchurin Prɔses .

Dɛn tin ya we dɛn nid kin mek di kɔmni dɛn go na ɔtsɔs mold dizayn ɛn prodakshɔn to spɛshal fam dɛn.

Outsɔsing vs. in-haus prodakshɔn .

Outsɔsing bɛnifit dɛn .

Akses to spɛshal ɛkspɛriɛns ɛn ikwipmɛnt .

Kost-ɛfɛktiv fɔ kɔmpleks ɔ ay-volyum mold dɛn .

Ridyus kapital invɛstmɛnt na mashin dɛn .

In-haus prodakshɔn advantej dɛn .

Greater Control ova di prodakshɔn prɔses .

Faster turnaround fɔ simpul mold dɛn .

Kost-effektiv fɔ lɔw-volyum ɔ protɔtayp mold dɛn we de yuz 3D printin

Mold Kost Renj dɛn .

Mold kɔst dɛn kin difrɛn bad bad wan bay di kɔmplisiti, volyum, ɛn di we aw dɛn de mek tin dɛn:

| Mold tayp | prodakshɔn volyum | kɔst rɛnj |

| 3d we dɛn print . | Low (< 100 yunit) | $100 - $1,000 |

| Metal (mid-volyum) . | 1,000 - 5,000 yunit dɛn | $2,000 - $5,000 |

| Kɔmpleks (hay-vɔlyum) . | 10,000+ yunit dɛn . | $5,000 - $100,000+ |

Di tin dɛn we de ambɔg dɛn kɔst ya na:

Mold matirial (aluminum, stɛl, ɛn ɔda wan dɛn)

Nɔmba fɔ di kaviti dɛn .

Di tin dɛn we dɛn nid fɔ dɔn di say we dɛn dɔn .

Komplexiti fɔ pat jɔyometri .

Kɔmpozishɔn fɔ injɛkshɔn mold kɔst dɛn .

Ɔndastand di brekdɔwn fɔ injɛkshɔn mold kɔst na impɔtant tin fɔ ifektiv badjɛt ɛn kɔst ɔptimayzeshɔn. Dis pat de eksplor di difrɛn komponent dɛn we de kɔntribyut to di ɔvala mold kɔst ɛn i de gi insayt fɔ matirial ɛkspɛns fɔ spɛshal mold ɛlimɛnt dɛn.

Kost komponent brekdaun .

Injekshɔn mold kɔst tipikli kɔmprɛs fayv men kategori:

Di kɔst fɔ di matirial: 20-35%

Di kɔst fɔ mashin: 25-40%

Dizayn fi dɛn: 5-10%

Assembly kos: 15-20%

Taks ɛn prɔfit: 20-30%

Fɔ si dis distribyushɔn, tink bɔt di chɔt we de dɔŋ ya:

Pie taytul injɛkshɔn mold kɔst kɔmpɔzishɔn 'Material Kɔst' : 27.5 'Mashin Kɔst' : 32.5 'dizayn fi dɛn' : 7.5 'assembly kɔst' : 17.5 'taxes ɛn prɔfit' : 25

Material Kost Ɛgzampul dɛn .

Matirial kɔst dɛn kin difrɛn bad bad wan dipen pan di mold kɔmpɔnɛnt ɛn in kɔmplisiti. Na dis na di brekdaun fɔ di tipik matirial ɛkspɛns fɔ difrɛn mold ɛlimɛnt dɛn:

| Kɔmpɔnɛnt | matirial | ɛstimat kɔst rɛnj |

| Fɔ fɛn ring dɛn . | Tul Stiɛl . | $50 - $200 fɔ di mɔni. |

| Slayd dɛn . | stɛl we dɛn dɔn mek tranga wan . | $200 - $1,000 |

| Di wan dɛn we de lif . | Stenlɛs stiɛl . | $150 - $500 |

| Hot Runners . | Difrɛn alɔy dɛn . | $1,000 - $5,000 |

Dɛn rɛnj ya de wok as jenɛral gaydlayn. Di rial kɔst dɛn kin chenj chenj bay we dɛn yuz:

Speshal matirial gred dɛn .

Komponent saiz ɛn kɔmplisiti .

Di kɔndishɔn dɛn na di makit .

Kwantiti we dɛn dɔn ɔda .

Fakta dɛn we de inflɔws di kɔst distribyushɔn .

Bɔku tin dɛn kin ambɔg di pasɛnt alɔkayshɔn fɔ di kɔst dɛn:

Mold kɔmplisiti: Intrikɛt dizayn dɛn kin mek di mashin ɛn di asɛmbli pasɛnt dɛn bɔku .

Material Selection: Ay-perfomans alɔy dɛn kin ɛlevɛt matirial kɔst pasɛnt

Prodakshɔn Volyum: Di volyum dɛn we ay kin ridyus di rilitiv impak we dizayn fi dɛn gɛt

Di we dɛn fɔ kot injɛkshɔn mold dɛn .

Fɔ kot kɔrɛkt wan na impɔtant tin fɔ di wan dɛn we de mek injɛkshɔn mold ɛn di wan dɛn we de bay. Dis pat de tɔk bɔt tri men we dɛn we dɛn yuz na di industri fɔ ɛstimat di kɔst fɔ di mold.

Matirial Kost Multiplier Method .

Dis we aw dɛn de du tin stret involv:

Kalkul di totɛl matirial kɔst .

Aplaying a Price Factor fɔ no di fayn fayn mold kɔst .

Di prayz factor tipikli de frɔm 2.5 to 5, we de difrɛn bay we dɛn de bay:

Mold Size: Big big mold dɛn jɔs gɛt smɔl tin dɛn we nɔ gɛt bɛtɛ tin fɔ du .

Kɔmplisiti: Intrikɛt dizayn dɛn nid fɔ gɛt ay faktɔ dɛn .

Prodakshɔn volyum: ay-volyum mold dɛn kin jɔstify ay faktɔ dɛn .

Example Calculation:

Material Kost: $10,000 Prays Fakta: 3.5 Estimated Mold Kost: $10,000 x 3.5 = $35,000

Komponent-ways ɛstimɛshɔn .

Dis ditayli we fɔ du tin involv:

Ɛstimat ɛni kɔst kɔmpɔnɛnt sɛpret wan .

Summing individyual ɛstimat fɔ wan kɔmprɛhɛnsif kot .

Di men tin dɛn we dɛn fɔ du na:

Di wan dɛn we de mek di tin dɛn kin ad prɔfit margin we na 15-30% to di ɔl di kɔst we dɛn dɔn ɛstimat.

| Kost Komponent | Pasɛnt | Ɛgzampul Amaunt . |

| Di tin dɛn we dɛn yuz fɔ mek di tin dɛn . | 25% | $8,750 pipul dɛn. |

| Machining . | 35% | $12,250 pipul dɛn. |

| Dizayn | 10% | $3,500 pipul dɛn. |

| Fɔ manɛj | 10% | $3,500 pipul dɛn. |

| Asɛmbli | 20% | $7,000 |

| Ɔl | 100% | $35,000 |

| prɔfit (20%) . | - | $7,000 |

| Faynal kot . | - | $42,000 |

Di we aw dɛn de kɔl di kɔlkyulɛshɔn .

Dis aprɔch bigin wit di target pat prays ɛn wok bak:

Analayz di kɔst kɔmpozishɔn fɔ wan pat pan .

Ɛstimat di mold amortizayshɔn kɔst fɔ ɛni pat .

Kalkul di totɛl mold kɔst bays pan ɛkspɛkt prodakshɔn volyum .

Example:

Target Part Price: $1.00 Matirial Kost fɔ wan pat: $0.30 Prodakshɔn Kɔst fɔ wan pat: $0.40 mold amortayzeshɔn fɔ wan pat: $0.20 Ɛkspɛkt Prodakshɔn Volyum: 100,000 yunit Ɛstimat Mɔld Kɔst: $0.20 x 100,000 = $20,000

Dis we ya de ɛp fɔ mek shɔ se di mold kɔst alayns wit di ɔvala prɔjek ikɔmiks.

Di we dɛn fɔ ridyus di kɔst fɔ injɛkshɔn mold .

Kost optimayzeshɔn in injɛkshɔn moldin nid fɔ gɛt ɔlistik apɔch, we de adrɛs difrɛn stej dɛn na di prodakshɔn prɔses. Dis pat de fɛn ɔl di men strateji dɛn fɔ mek dɛn nɔ spɛn bɔku mɔni we dɛn nɔ go kɔmprɔmis di kwaliti.

Produkt dizain optimizayshɔn .

Efisiɛns Prodakt Dizayn signifyant impaks mold kɔst:

Yunifɔm wɔl tik: I de mek shɔ se ivin kol ɛn ridyus wɔpej

Prɔpa filɛt ɛn draft angul dɛn: I de mek am izi fɔ mek i izi fɔ mek dɛn pul pat pan di pat ɛn fɔ mek di mold liv lɔng .

Minimizing Kɔmpleks Ficha dɛn: I de ridyus di tɛm we di mashin de ɛn di kɔmplisiti fɔ mek di mold kɔmplikt

Mold dizayn kɔst kɔntrol .

Optimizing mold design kin mek yu sev bɔku mɔni:

Maksimayz standad komponent yuz .

Impruv di manufakchurin prɛsishɔn .

Optimize Gate Location ɛn Runner Design .

Disain Efisiɛns Kɔling Sistɛm dɛn .

Dɛn strateji ya de ridyus di tɛm we dɛn de yuz mashin fɔ mek mashin, di prɔblɛm dɛn we de wit di asɛmbli, ɛn di west we dɛn de west.

Mold Matirial Sɛlɛkshɔn .

Fɔ pik di rayt mold matirial balans kɔst ɛn pefɔmɛns:

| mold layf ɛkspɛkteshɔn | rɛkɔmɛnd matirial |

| < 10,000 shot | Aluminium na di . |

| 10,000 - 100,000 shot dɛn | P20 stiel . |

| > 100,000 shot dɛn | H13 ɔ S7 stɛl . |

Surface tritment kin enhans wear resistance en polishbility wen e nid.

Machining Proses Optimayzeshɔn .

Efisiɛns mashin prɔses dɛn de ridyus di prodakshɔn tɛm ɛn kɔst:

Selekt di rayt we dɛn we de bays pan mold strɔkchɔ .

Yuz Advans CNC Ikwipmɛnt fɔ Impɔtant Efisiɛns .

Minimayz spɛshal prɔses dɛn lɛk EDM .

Injekshɔn moldin paramita ɔptimayzeshɔn .

Fayn-tyunin prɔses paramita dɛn de ɛp fɔ mek di wok go bifo:

Kontrol injɛkshɔn spid, prɛshɔn, ɛn tɛmpracha .

Ridyus di tɛm fɔ kol tru di optimized mold dizayn .

Employ Auxiliary Processes fɔ Kɔmpleks Pat dɛn .

Manejin injekshɔn mold kɔst .

Effective cost management in injection molding nid fɔ gɛt wan sistamɛtik we fɔ du tin. Dis pat de sho di men strateji fɔ kɔntrol di ɛkspɛns dɛn ɔlsay na di mold layfsaykl.

Kɔmprɛhɛnsif kɔst akauntin sistem .

Fɔ impruv wan strɔng akauntin sistɛm na impɔtant tin fɔ trak ɛn manej mold kɔst. I fɔ gɛt kɔmpas:

Material Kost Kɔntrol .

Negotiate Bulk Purchase Diskɔnt dɛn .

Impliment jɔs-in-taym invɛntari manejmɛnt .

Monitor matirial west ɛn optimize usage .

Outsourced Machining Kost Manejmɛnt .

Divɛlɔp wan nɛtwɔk fɔ di wan dɛn we yu go abop pan

Impliment kɔmpitishɔn bidding prɔses dɛn .

Establish long-tem patnaship fɔ volyum diskɔnt .

Intanɛt Machining Kɔst Alɔkeshɔn .

Trak mashin yutilizeshɔn ret .

Impliment aktiviti-bez kostin fɔ kɔrɛkt wok kɔsting .

Invest in preventive maintenance fɔ ridyus di dawt tɛm .

Dizayn ɛn Manufakchurin Prɔses Manejmɛnt .

Fɔ mek di ovasayt fɔ dizayn ɛn di we aw dɛn de mek tin dɛn strɔng kin ridyus di kɔst dɛn bad bad wan:

Dizayn Rivyu ɛn Optimayzeshɔn .

Kɔndɔkt rɛgyula dizayn rivyu wit krɔs-fɔnshɔn tim dɛn

Yuz simulshɔn softwe fɔ no di prɔblɛm dɛn we kin apin kwik kwik wan kwik kwik wan .

Standardize Design Elements across Prodakt Layn dɛn .

Proses Kwaliti Kɔntrol .

Impliment Statistikal Prɔses Kɔntrol (SPC) Mɛtɔd dɛn .

Kɔndɔkt rɛgyula ɔpreshɔn trenin sɛshɔn dɛn .

Establish klia kwaliti bɛnchmakɛt ɛn monitarin prosidyuz .

Mold ripa ɛn modifyeshɔn kɔst kɔntrol .

Proactive maintenance ɛn repairs we de kam di rayt tɛm impɔtant fɔ manej fɔ lɔng tɛm mold kɔst:

| strateji | bɛnifit | implimɛnt |

| Mentɛnans ɔltɛm . | Ekstend mold layf, de ridyus di dawt tɛm we dɛn nɔ plan fɔ du | Schedule routine inspections, impliment preventive maintenance tasks . |

| Ripair dɛn we dɛn dɔn mek di rayt tɛm . | Minimizes prodakshɔn intarapshɔn, de mek dɛn nɔ ebul fɔ go ɔp di prɔblɛm dɛn we de apin . | Establish wan rapid rispɔns sistɛm fɔ mold ishu dɛm, mentein spay pat dɛm invɛntari |

| Patɛl modifyeshɔn dɛn . | Adrɛs Speshal Wear Points, we nɔ go tek bɔku mɔni pas fɔ mek dɛn chenj am ful wan | Identify kɔmɔn wear eria, divɛlɔp targeted modifyeshɔn strateji . |

Estimating Injection Mold Costs: Wan Breakdown

Akchuali estimat injekshɔn mold kɔst na impɔtant tin fɔ ifektiv badjɛt insay ɛni manufakchurin projɛkt. Dis pat de gi wan ditayl brekdaun fɔ di men tin dɛn we de inflɔws di kɔst ɛn aw di wan dɛn we de mek dɛn kin ebul fɔ ɛstimat dɛn ɛkspɛns ya.

Material Selection ɛn di impak we i gɛt pan di kɔst .

Di kayn matirial we dɛn pik de ple wan impɔtant pat pan di ɔvala mold kɔst. Difrɛn plastic dɛn gɛt difrɛn prɔpati dɛn, di prayz fɔ di makit, ɛn di fit we dɛn fit fɔ sɔm patikyula aplikeshɔn dɛn. Aditiv dɛm lɛk UV stebyulayza ɔ flame retardants kin ɛp fɔ mek di wok fayn bɔt i kin mek bak di prayz go ɔp.

Factors fɔ tink bɔt fɔ pik di tin dɛn we yu nid:

Material Properties : Durability, temperechur resistans, kemikal resistans.

Maket Prays : Raw matirial prayz de chenj chenj ɛn impak mold kɔst.

Aditiv : Impruv pefɔmɛns bɔt rayz kɔst dipen pan di ɛnhansmɛnt dɛn we dɛn want.

Kost factors in injekshɔn moldin .

Bɔku tin dɛn de mek di ɔl di kɔst fɔ injɛkshɔn moldin. We yu ɔndastand dɛn tin ya, dat kin ɛp yu fɔ disayd fɔ du bɛtɛ tin dɛn na di dizayn ɛn prodakshɔn faz dɛn:

Mold kɔmplisiti ɛn saiz : Kɔmpleks pat dɛn nid mɔ ditayla mol, ad to mashin ɛn asɛmbli tɛm.

Material Selection : Ay-kwaliti matirial dɛn lɛk tul stɛl inkris apfrɔnt mold kɔst bɔt dɛn de gi bɛtɛ lɔng layf.

Prodakshɔn Volyum : Big prodakshɔn rɔn dɛn de ridyus di pe-pat kɔst bikɔs ɔf di ikɔnomi dɛn fɔ skel.

Leba kɔst : skilful leba nid fɔ de fɔ mek ɛn prodyuz mold; Di ay ret dɛn de mek di kɔst dɛn go ɔp.

Shiping Costs : Di say we di mold manifakta de afɛkt di shiping fi, mɔ fɔ intanashɔnal ɔda.

Kwantiti, Saykl Tɛm, ɛn Prodakshɔn Rɛt .

di kwantiti fכ pat dεm we dεn prodyuz insay εvri rכn εn di saykl tεm pan wan pat de infכlכw di כvala kכst sכmtεm:

Kwantiti ɛn kɔst fɔ wan pat : Di ay prodakshɔn volyum dɛn de spre di mold kɔst akɔdin to mɔ yunit dɛn, we de mek di ɛkspɛns we dɛn gɛt fɔ ɛni pat, go dɔŋ.

Saykl tɛm Faktɔ : Pat kɔmplisiti, matirial prɔpati, ɛn mold dizayn ɔl de inflɔws aw lɔng i tek fɔ prodyuz ɛni pat.

Prodakshɔn Rɛt Strateji : Yuz Multi-Cavity Molds , pik efyushɔn matirial, ɛn strimlayn mold dizayn kin mek di prodakshɔn ret go ɔp, impruv ɔl di efyushɔn.

Evalueshɔn ɛn Ɛstimat ɔf Kɔst .

We dɛn de ɛstimat di ɔl kɔst fɔ injɛkshɔn moldin, di wan dɛn we de mek di tin dɛn fɔ tink bɔt sɔm pat dɛn:

Pat kɔst : kin difrɛn bay we dɛn tek pat kɔmplisiti ɛn saiz.

Tooling Costs : Di ɛkspɛns fɔ disayn ɛn mek di mol insɛf.

Material Costs : Bays pan di kayn plastic ɛn ɛni aditiv we dɛn yuz.

Prodakshɔn Volyum : Big rɔn dɛn lɔwa fɔ ɛni pat kɔst, we smɔl batch dɛn kin gɛt ay kɔst bikɔs ɔf di fɔs sɛtup.

Yuz Kɔst Ɛstimatɔ : Bɔku manifakta dɛn de yuz injɛkshɔn moldin kɔst ɛstimat fɔ mek di prɔses simpul ɛn mek shɔ se dɛn gɛt kɔrɛkt badjɛt.

Dɔn

Fɔ ɔndastand injɛkshɔn mold kɔst na impɔtant tin fɔ mek di wan dɛn we de mek di tin dɛn fɔ manej di spɛns ɛn mek shɔ se dɛn ebul fɔ mek di prodakshɔn wok fayn fayn wan. Ki tin dɛm lɛk pat kɔmplisiti, saiz, matirial chuk, mold dizayn, ɛn ples ɔl de inflɔws kɔst. We dɛn mek di dizayn dɛn fayn fayn wan fɔ mek dɛn ebul fɔ mek di tin dɛn we dɛn nid, fɔ pik di rayt tin dɛn, ɛn fɔ mek di mold dɛn wok fayn, di wan dɛn we de mek di tin dɛn kin ridyus di kɔst. Apat frɔm dat, ɔtsɔsing ɛn pik di rayt ples impak nɔto jɔs prayz bɔt bak prodakshɔn kwaliti. Fɔ pe atɛnshɔn pan dɛn strateji ya de alaw di wan dɛn we de mek di tin dɛn fɔ mek dɛn gɛt balans bitwin di kɔst ɛn di kwaliti, fɔ mek shɔ se dɛn gɛt saksesful injɛkshɔn moldin prɔjek dɛn.