Ilɛktrik dischaj mashin (EDM) de ple impɔtant pat pan di mɔdan manufakchurin, we de mek prɛsis pat dɛn na industri dɛn lɛk ɛrospɛs ɛn ɔtomotiv. Bɔt wetin mek Sinker EDM difrɛn frɔm waya EDM, ɛn uswan rayt fɔ yu prɔjek?

Insay dis post, yu go lan aw ɛni EDM tayp de wok, inklud dɛn pros, kɔns, ɛn di bɛst aplikeshɔn dɛn. Bay di ɛnd, yu go ɔndastand di men tin dɛn we de mek ɛni EDM tɛknik spɛshal ɛn ebul fɔ disayd uswan we go fayn fɔ yu manufakchurin nid dɛn.

Wetin na ilɛktrik dischaj mashin (EDM)?

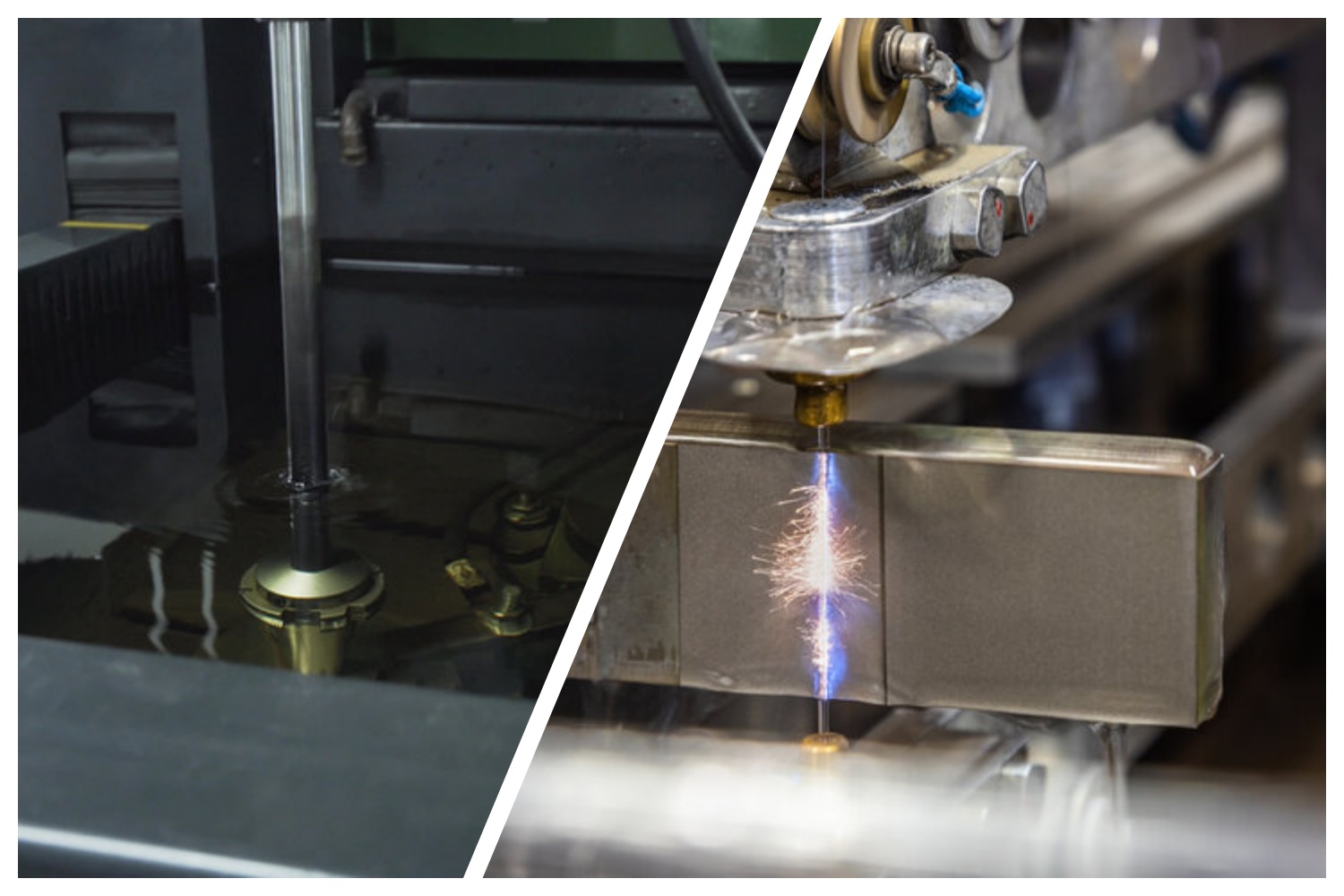

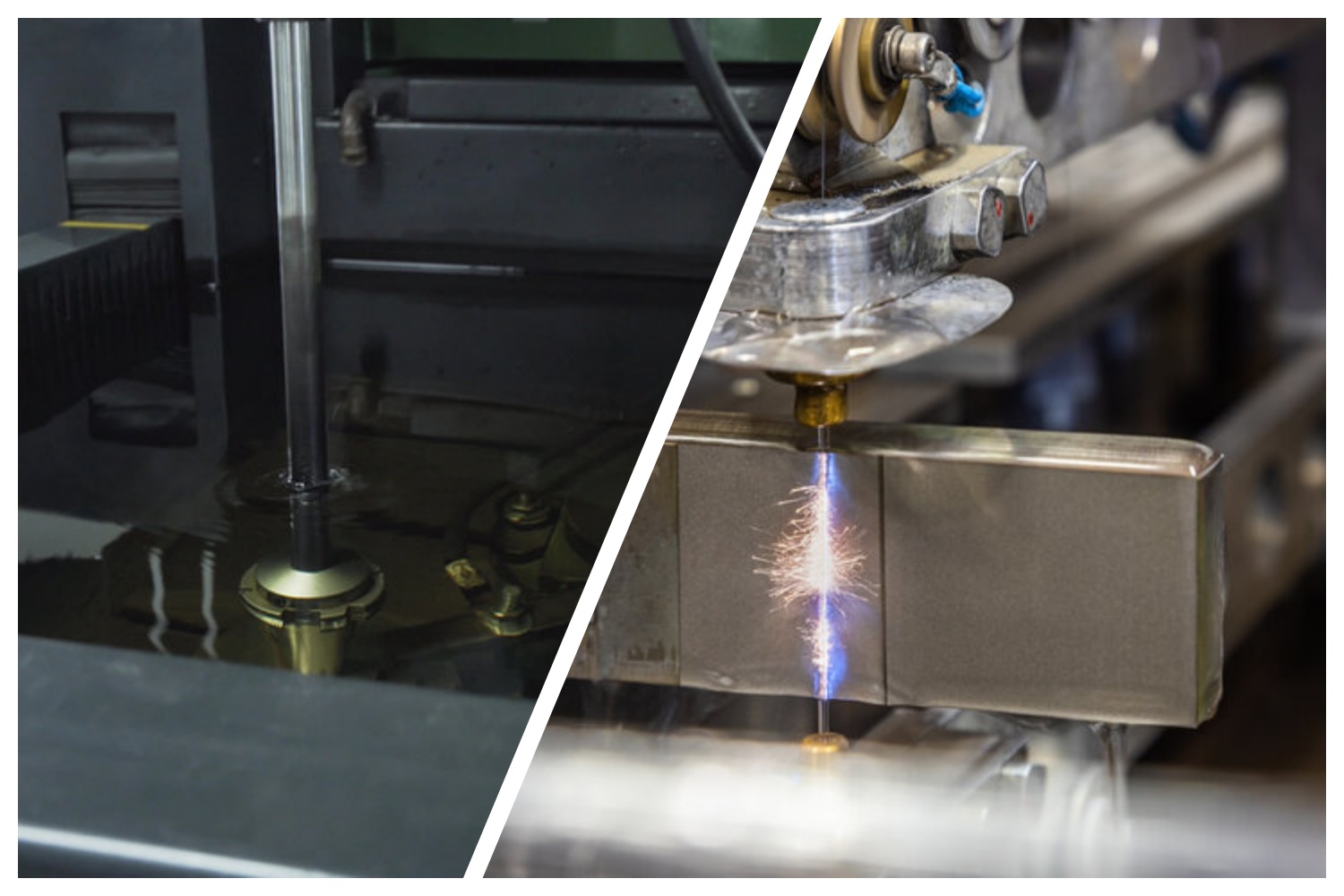

Ilɛktrikal dischaj we de mek mashin, ɔ EDM, na wan spɛshal we fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz ilɛktrik dischaj (spak) fɔ shep di tin dɛn we dɛn de yuz fɔ mek tin dɛn. Nɔ lɛk tradishɔnal mashin, we de abop pan fizik kɔt, EDM de abop pan kɔntrol spak fɔ pwɛl ɛn shep mɛtal prɛsishɔn. Dis yunik we de mek EDM fayn fɔ wok pan had mɛtal ɛn fɔ ajɔst ay prɛsishɔn insay intrikɛt dizayn dɛn.

Aw EDM de wok .

Di spak erosion proses de fala wan prɛsis sikyud. Fɔs, tu ilɛktrɔd dɛn de na di pozishɔn nia dɛnsɛf, we di dayelɛktrik fluid de ful-ɔp di gap bitwin dɛn. Kɔmpyuta kɔntrol dɛn de mentɛn di rayt spays ɔlsay na di ɔpreshɔn.

We dɛn de pul di matirial, ay vɔltɛm de mek pawaful spak dɛn. Dɛn spak ya de mek lokal tɛmpracha rich 8,000-12,000°C, mɛlt mɛtal na kɔntakt pɔynt dɛn. Dɔn di dayelɛktrik fluid de was di dɔti we dɛn de yuz as di prɔses de ripit tawzin tɛm pan sɛkɔn.

Ki Point : Di dayelɛktrik fluid de ple tri impɔtant rol dɛn: insulɛta, kolant, debris rimova.

Wetin mek EDM difrɛn frɔm tradishɔnal mashin

| karakta | tradishɔnal mashin | EDM . |

| Di we aw yu fɔ kɔntak . | Dairekt Tul Kɔntakt . | Sparks we nɔ gɛt kɔntakt . |

| Fos dɛn we dɛn aplay . | Ay mɛkanikal strɛs . | Ziro Fizik Fos . |

| Material Rɛnj . | Limited by Hardness . | Eni konduktiv metal . |

| Prɛsishɔn lɛvɛl . | Tul-dipɛndent . | Maykro-Lɛvɛl Akkurat . |

| Impakt fɔ ɔt . | Mekanikal ɔt . | Kontroled tɛmral ifɛkt . |

EDM de gi signifyant advantej pas tradishonal we. I de kɔt supa-had mɛtal dɛn lɛk titanium ɛn tungsten we i de mek intrɛst shep dɛn we nɔ pɔsibul tru kɔvɛnshɔnal mashin. Di prɔses de mentɛn tayt tolɛreshɔn, prodyuz nɔ mɛkanikal strɛs, ɛn wok pafɛkt wan pan dilikɛt kɔmpɔnɛnt dɛn.

Insay ɛvride sityueshɔn, tu praymar kayn EDM mashin dɛn de: Sinker EDM ɛn waya EDM.

Wetin na Sinker Edm?

Sinker EDM, we dɛn kin kɔl bak RAM EDM ɔ cavity EDM, na wan prɛsis mashin prɔses we dɛn kin yuz fɔ shep kɔmpleks 3D kaviti dɛn na kɔnduktiv matirial dɛn.

Sinker EDM Proses Ovaviu .

Sinker EDM de wok bay we i de put wan ilɛktrɔd ɛn di wokpies insay wan dayelɛktrik fluid. di ilektroyd, we dεn kin mek wit grafayt כ kכpa, dεn kin prε-shεp am fכ mach di kaviti shep we dεn want. We dɛn aplay vɔltɛm, di dayelɛktrik fluid de alaw spak fɔ jomp akɔdin to di smɔl gap bitwin di ilɛktrɔd ɛn wokpies. Ɛni spak de rɔtin smɔl smɔl tin dɛn, we de shep di wok we dɛn nɔ gɛt dairekt kɔntakt. Dis prɔses de minimiz mɛkanikal strɛs ɛn alaw fɔ ay prɛsishɔn insay kɔmpleks jɔyometri.

Komponent dɛn fɔ wan sinker EDM mashin .

Wan tipik sinker EDM mashin inklud dis impɔtant komponent dɛn:

Shaped Electrode : Na kɔstɔm-machin tul we de mirɔ di shep fɔ di kaviti we dɛn want. Dɛn kin mek am wit grafayt ɔ kɔpa, dɛn kin put am dɔŋ smɔl smɔl insay di wok we dɛn de du di wok.

Dielectric Oil : Na wan haydrokabon-based fluid we de insul di ilektroyd frɔm di wokpies, kɔntrol spak jenɛreshɔn ɛn kol di wokpies bay we i de flush away debris.

POWER SOURCE : I de gi di ilɛktrik ɛnaji we dɛn nid fɔ mek spak ɛn fɔ mek dɛn kɔntinyu fɔ kɔntrol di eroshɔn rit.

Aplikeshɔn dɛn fɔ Sinker EDM .

Sinker EDM na patikyula wan fɔ industri dɛn we nid prɛsishɔn kaviti ɛn kɔmpleks intanɛnt jɔyometri, lɛk:

Mold Making : Krio ditayli injɛkshɔn mold, ɛkstrushɔn day, ɛn stamp day.

Blind Cavities : Machining internal shapes we nɔ de pas tru di ɔl matirial tik.

Intrikɛt intanɛnt shep dɛn : I fayn fɔ dip rib dɛn, ki-we dɛn, ɛn splayn dɛn.

Tool & Die Manufacturing : Dɛn kin yuz am fɔ prodyuz ay-prɛsishɔn tul ɛn day fɔ industrial prodakshɔn.

Advantej dɛn fɔ Sinker Edm .

Sinker EDM de gi sɔm impɔtant bɛnifit dɛn, we mek i bi valyu tul fɔ kɔmpleks pat prodakshɔn:

Abiliti fɔ mek kɔmpleks 3D shep : pafɛkt fɔ intrɛstin dizayn usay kɔvɛnshɔnal tul dɛn fɔdɔm shɔt.

Low-Stress Machining : As wan nɔ-kɔntakt prɔses, i de avɔyd mɛkanikal strɛs pan ɔl tu di ilɛktrɔd ɛn wokpies.

Precision for Deep Cavities : Ideal fɔ kraft ditayla shep dɛn wit tayt tolɛreshɔn dɛn insay mɛtal dɛn we dɔn at.

Limiteshɔn dɛn fɔ Sinker Edm .

Pan ɔl we i gɛt trɛnk, Sinker EDM gɛt sɔm tin dɛn we i nɔ ebul fɔ du:

Slower Machining Speed : Di prɔses kin bi tɛm-intensif, mɔ fɔ ay-prɛsishɔn wok dɛn.

High Power Consumption : nid fɔ gɛt bɔku ɛnaji, we de mek i nɔ ebul fɔ wok fayn pas ɔda mashin opshɔn dɛn.

Limited to conductive materials : Sinker EDM de wok nɔmɔ pan kɔnduktiv mɛtal, we de limited in matirial versatility.

Wetin na waya EDM?

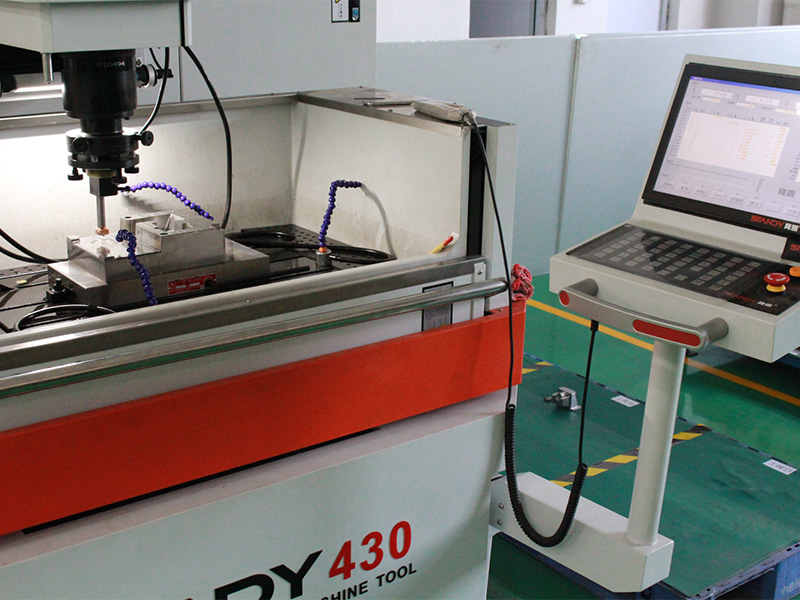

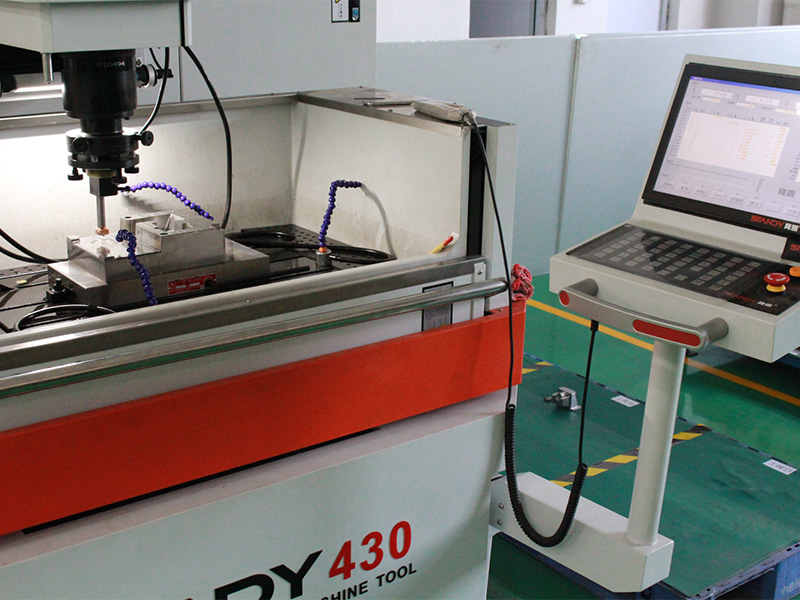

Waya ilɛktrik dischaj mashin (EDM) na wan prɛsis, nɔ-kɔntakt we fɔ kɔt kɔnduktiv matirial. I de yuz wan chaj waya, we CNC teknɔlɔji de gayd, fɔ mek intrɛst shep dɛn we nɔ tɔch di wokpies.

Waya EDM prɔses ɔvaviu .

Insay waya EDM, wan tin we dɛn mek wit mɛtal waya—bɔku tɛm dɛn kin gi bras—dɛn kin gi dɛn tin fɔ it tru wan sistɛm we gɛt CNC. Dis waya, we dɛn chaj wit ilɛktrik kɔrɛnt, de mek spak bitwin insɛf ɛn di wokpies. Ɛni spak de rɔtin smɔl smɔl tin dɛn, we de shep di wok we dɛn nɔ gɛt bɔdi kɔntakt. Deionized wata de akt lɛk dayelɛktrik fluid, kɔntrol di spak gap, kol di wokpies, ɛn pul di dɔti. Dis prɔses de mek waya EDM ebul fɔ kɔt kɔmpleks kɔnto ɛn ajɔst tayt tolɛreshɔn.

Komponent dɛn fɔ wan waya EDM mashin .

Wan waya EDM mashin inklud sɔm impɔtant kɔmpɔnɛnt dɛn we de mek shɔ se prɛsishɔn ɛn kɔntrol:

Brass Wire : Di tul we dɛn de kɔt, we dɛn kin kɔntinyu fɔ gi fɔ mek dɛn kɔntinyu fɔ shap ɛn kɔrɛkt.

CNC Gayd Sistem : de gayd di waya along programmed paths fɔ mek prɛsis kɔt.

Deionized Water : I de wok as di dayelɛktrik fluid, we de gi kɔntrol kɔnduktiviti, kol, ɛn dɔti flashin.

Aplikeshɔn dɛn fɔ waya EDM .

Waya EDM impɔtant fɔ industri dɛn we nid ay-prɛsishɔn pat dɛn. Tipik aplikeshɔn dɛn na:

Ekstrushɔn day ɛn panch : Dɛn kin yuz am fɔ ay-prɛsishɔn tul dɛn na manufakchurin.

Medikal Divays : I fayn fɔ smɔl, intrikɛt kɔmpɔnɛnt dɛn na ɔspitul ikwipmɛnt.

Aerospace Components : Ideal fɔ ay-prɛsishɔn pat dɛn we nid tayt tolɛreshɔn.

Kɔmpleks gia ɛn pat : de prodyuz dilikɛt, ditayl pat dɛn we kɔvɛnshɔnal tul dɛn nɔ ebul fɔ handle.

Advantej dɛn fɔ waya EDM .

Waya EDM de gi sɔm bɛnifit dɛn we de mek i rili valyu fɔ prɛsishɔn mashin:

High Precision : kin ajɔst ɛksɛpshɔnali tayt tolɛreshɔn, we fayn fɔ intrikɛt dizayn dɛn.

Klin Edges : Cuts wit no mechanical force, ridyus di nid fɔ additional finishing.

Versatile for delicate cuts : I de wok fayn fɔ fayn, ditayla profayl ɛn pat dɛn wit tayt tolɛreshɔn.

Limiteshɔn dɛn fɔ waya EDM .

Pan ɔl we waya EDM na ifɛktiv, i gɛt limiteshɔn:

Material restrictions : Na onli wok pan konduktiv matiryal, limitin versatility.

High Initial Cost : Ikwipmɛnt ɛn sɛtup kin dia, mɔ fɔ kɔmpleks aplikeshɔn dɛn.

Oxide Layer Formation : I kin nid fɔ gɛt ɔda tin dɛn fɔ dɔn di wok fɔ pul di sɔfays ɔksayd pan sɔm mɛtal dɛn.

Sinker edm vs waya edm: ki difrɛns aspek

| sink | EDM | waya EDM |

| Tul tayp . | Ilektroyd we shep lɛk kɔstɔm | Tin waya ilɛktrɔd . |

| Dielektrik fluid . | Haydrokabon Ɔyl dɛn . | Diaionized wata . |

| Fɔ muv | Ilɛktrod sink dɛn insay di wokpies . | Waya muv along x ɛn y aks dɛn . |

| Ideal aplikeshɔn dɛn . | Molds, Dies, Blind Cavities | Prɛsishɔn prɔfayl dɛn, panch dɛn, pat dɛn we nɔ izi fɔ ɔndastand |

| Machining Proses . | Yuz wan shep ilɛktrɔd fɔ mek kɔmpleks 3D kaviti dɛn . | Yuz wan kɔntinyu fɔ muv waya fɔ 2D prɔfayl kɔt |

| Ilɛktrod tayp . | Kastɔm ilɛktrɔd we dɛn mek wit grafayt ɔ kɔpa . | Tin bras ɔ waya we dɛn kɔt . |

| Jɔyometri ɛn di tin dɛn we dɛn ebul fɔ du . | Best fɔ 3D shep ɛn blaynd kaviti | Ideal fɔ 2D profayl ɛn fayn kɔt |

| Surface finish kwaliti . | I de lɛf smɔl rɔf say, i kin nid fɔ gɛt ɔda tin dɛn fɔ dɔn | Produces smooth edges wit minimal finishing needed |

| Spid ɛn efyushɔn . | Slower bɔt prɛsis fɔ kɔmpleks shep dɛn . | Fasta fɔ tin profayl, kɔntinyu fɔ kɔt matirial . |

| Di kayn tin dɛn we dɛn kin yuz fɔ mek di tin dɛn . | I fayn fɔ tik, mɔ rigid pis dɛn | I bɛtɛ fɔ mek dɛn mek sɛkshɔn dɛn we tan lɛk tin dɛn ɛn ay-prɛsishɔn matirial dɛn . |

| Tolerance ɛn prɛsishɔn . | prɛsis, mɔ fɔ dip kaviti dɛn . | High tolerance, ideal fɔ intrɛstin ɛn tayt-prɔfayl kɔt |

| Di tin dɛn we dɛn nid fɔ du fɔ tul dɛn . | kɔstɔm ilɛktrɔd dɛn nid fɔ de, we de mek dɛn wɛr lokaliz wear . | Yuz wan kɔntinyu waya fid, mek shɔ se yunifom wear distribyushɔn |

| Kost ɛn ɔpreshɔnal impak . | Higher cost bikɔs ɔf kɔstɔm ilɛktrɔd dɛn, we fayn fɔ lɔw-volyum, kɔmpleks dizayn dɛn | Higher initial setup cost bɔt efishɔnal fɔ ay-prɛsishɔn aplikeshɔn dɛn . |

Aw fɔ pik bitwin Sinker EDM ɛn waya EDM .

Factors fɔ tink bɔt .

Prodakshɔn Volyum : Fɔ smɔl batch ɔ kɔstɔm pat dɛn, Sinker EDM kin fayn bɔku tɛm, we waya EDM kin suit ay-prɛsishɔn mas prodakshɔn.

Material type and thickness : Sinker EDM de handle tik, rigid matirial, we waya EDM excel wit tin profayl ɛn dilikat pat.

Badget : Di fɔs sɛtup kɔst fɔ waya EDM kin ay pas dat, bɔt i kin ridyus di kɔst dɛn na ay-prɛsishɔn aplikeshɔn dɛn.

Surface Finish : Waya EDM jɔs de gi wan smol smol finish, we de ridyus di nid fɔ post-prosɛsin.

Pat Jɔyometri : Kɔmpleks 3D shep ɔ intanɛnt kaviti dɛn kin fayn fɔ sink EDM, we waya EDM fayn fɔ 2D profayl ɛn intrikɛt kɔt.

Tolerance requirements : Fɔ rili tayt tolɛreshɔn, waya EDM na tipikli di prɛferɛd chuk.

Wen yu go yuz Sinker Edm .

Sinker EDM na fayn tin fɔ prɔjek dɛn we nid kɔmpleks 3D shep dɛn, lɛk:

Mold and Die Making : I fayn fɔ mek dɛn mek injɛkshɔn mold ɛn fɔm day.

Blind Cavities : Di bɛst fɔ dip kaviti ɛn intanɛnt ficha dɛn we nɔ de go tru di wokpies.

Tooling for Industrial Use : Dɛn kin lɛk fɔ mek tin dɛn we go de fɔ lɔng tɛm, ditayli tul dɛn usay tik ɛn strɔkchɔral intɛgriti impɔtant.

Wen yu go yuz Wire EDM .

Waya EDM na di wan we dɛn kin lɛk fɔ yuz na aplikeshɔn dɛn we nid ay prɛsishɔn ɛn klin kɔt, lɛk:

High-precision parts : Ideal fɔ aerospace ɛn medikal komponent usay akkuracy impɔtant.

Tin profayl : fit tin ɔ dilik pat, mek shɔ se nɔ mɛkanikal strɛs ɔ difɔmeshɔn nɔ de.

Kɔmpleks, tayt-tɔlerans kɔt : pafɛkt fɔ intrikɛt profayl ɛn fayn kɔt we de aks fɔ strikt tolɛreshɔn.

Dɔn

Sinker EDM ɛn waya EDM difrɛn siriɔs wan pan di prɔses, aplikeshɔn, ɛn bɛnifit dɛn. Fɔ ɔndastand ɛni we aw dɛn de du tin ɛn di tin dɛn we dɛn nɔ ebul fɔ du, impɔtant fɔ mek dɛn ebul fɔ du di rayt tin dɛn we go apin. Sinker EDM na gud tin fɔ mek kɔmpleks 3D shep dɛn, we waya EDM ɛksɛl dɛn na ay-prɛsishɔn, 2D prɔfayl kɔt. Kɔnsultin EDM ɛkspɛkt dɛn kin ɛp fɔ no di bɛst sɔlvishɔn fɔ spɛshal aplikeshɔn dɛn, mɔ na kɔmpleks manufakchurin. Tink bɔt tin dɛn lɛk pat jɔyometri, matirial tayp, tolɛreshɔn rikwaymɛnt, ɛn prodakshɔn volyum we yu de pik bitwin sinker EDM ɛn waya EDM fɔ mek shɔ se dɛn ebul fɔ wok fayn ɛn prɛsishɔn.

Rifrɛns Sɔs dɛn .

Ilektrikal dischaj we de mek mashin fɔ mek mashin .

Sinker edm vs. waya edm .

Faqs about sinker edm en wire EDM

K: Sinker EDM ɔ waya EDM dia mɔ?

A: Initial sɛtup kɔst dɛn rɔn ay fɔ Sinker EDM bikɔs ɔf kɔstɔm ilɛktrɔd rikwaymɛnt dɛn. Waya EDM de gi lɔwa sɛtup kɔst bɔt nid kɔntinyu waya riplesmɛnt. Ɔl di kɔst fɔ di prɔjek dipen pan:

Pat kɔmplisiti .

Prodakshɔn Volyum .

Material tayp .

Prɛsishɔn we dɛn nid .

K: Yu tink se dɛn go ebul fɔ mek mashin tin dɛn we nɔto mɛtal bay we dɛn de yuz EDM?

A: Nɔ, EDM na limited to ilɛktrik kɔnduktiv matirial, we mek i nɔ fayn fɔ mɔs plastic ɛn sɛramik. Fɔ di wan dɛn we nɔto mɛtal, tink bɔt:

K: Wetin na di akkuracy levul of EDM proses?

WAN:

| Proses | Standard Tolerance | Best Achievable . |

| Sinker Edm we de na di . | ±0.0001 na di . | ±0,00008 |

| Waya EDM . | ±0.0001 na di . | ±0.00005 na di |

K: Us industri dɛn de yuz Sinker EDM ɛn Waya EDM pas ɔlman?

A: Indastri dɛn we nid prɛsishɔn kɔmpɔnɛnt dɛn kin yuz EDM bɔku tɛm. Aerospace ɛn Medical Device Industries de abop pan waya EDM fɔ intrikɛt, ay-tɔlerans pat dɛn. Otomotiv ɛn tul industri dɛn de yuz Sinker EDM fɔ mol, day, ɛn tul dɛn we go de fɔ lɔng tɛm wit kɔmpleks intanɛnt shep dɛn.

K: Us EDM tayp de fast?

A: Waya EDM tipikli de wok fast pas sinker EDM, mɔ fɔ tin profayl ɔ 2D kɔt. Sinker EDM na slo bɔt dɛn kin lɛk am fɔ dip, kɔmpleks kaviti dɛn. Opareshɔnal spid fɔ ɔl tu di dipen pan tin dɛn lɛk matirial tik, pat jɔyometri, ɛn rikwayd finish.

Yu de luk fɔ EDM manufakchurin sɔlvishɔn dɛn? Tim MFG de deliver ɔl tu di waya EDM ɛn sinker EDM savis fɔ yu prodakshɔn nid dɛn.

Wi de sɔpɔt:

Protɔtayp Divɛlɔpmɛnt .

Smɔl batch prodakshɔn .

Mas manufakchurin .

Kastɔm Projɛkt dɛn .

Wi injinɛri tim de briŋ 10+ ia EDM ɛkspiriɛns to ɛvri prɔjek. Wi de pe atɛnshɔn pan kwaliti, spid, ɛn kɔst efyushɔn.

Start yu projɛkt tide. Kontakt wi ɔ kɔl +86-0760-88508730.