Insay di wɔl fɔ mek, plastic de ple impɔtant pat bikɔs ɔf dɛn versatility ɛn bɔku bɔku aplikeshɔn dɛn. Bɔt we yu pik di rayt kayn plastic fɔ yu prɔjek, i impɔtant fɔ ɔndastand di difrɛns bitwin tu men kategori dɛn: Tɛmɔplastik ɛn Tɛmosɛtin Plastik . Dɛn matirial ya de sho difrɛn kwaliti dɛn, we de mek dɛn fayn fɔ difrɛn aplikeshɔn dɛn. Dis gayd go gi wan dip kɔmpiashɔn fɔ tɛmplastik ɛn thermosetting plastic, ɛp yu fɔ mek di disizhɔn dɛn we yu no bay wetin yu nid.

Difinishɔn ɛn Besik Prɔpati dɛn .

Tɛrmoplastik dɛn .

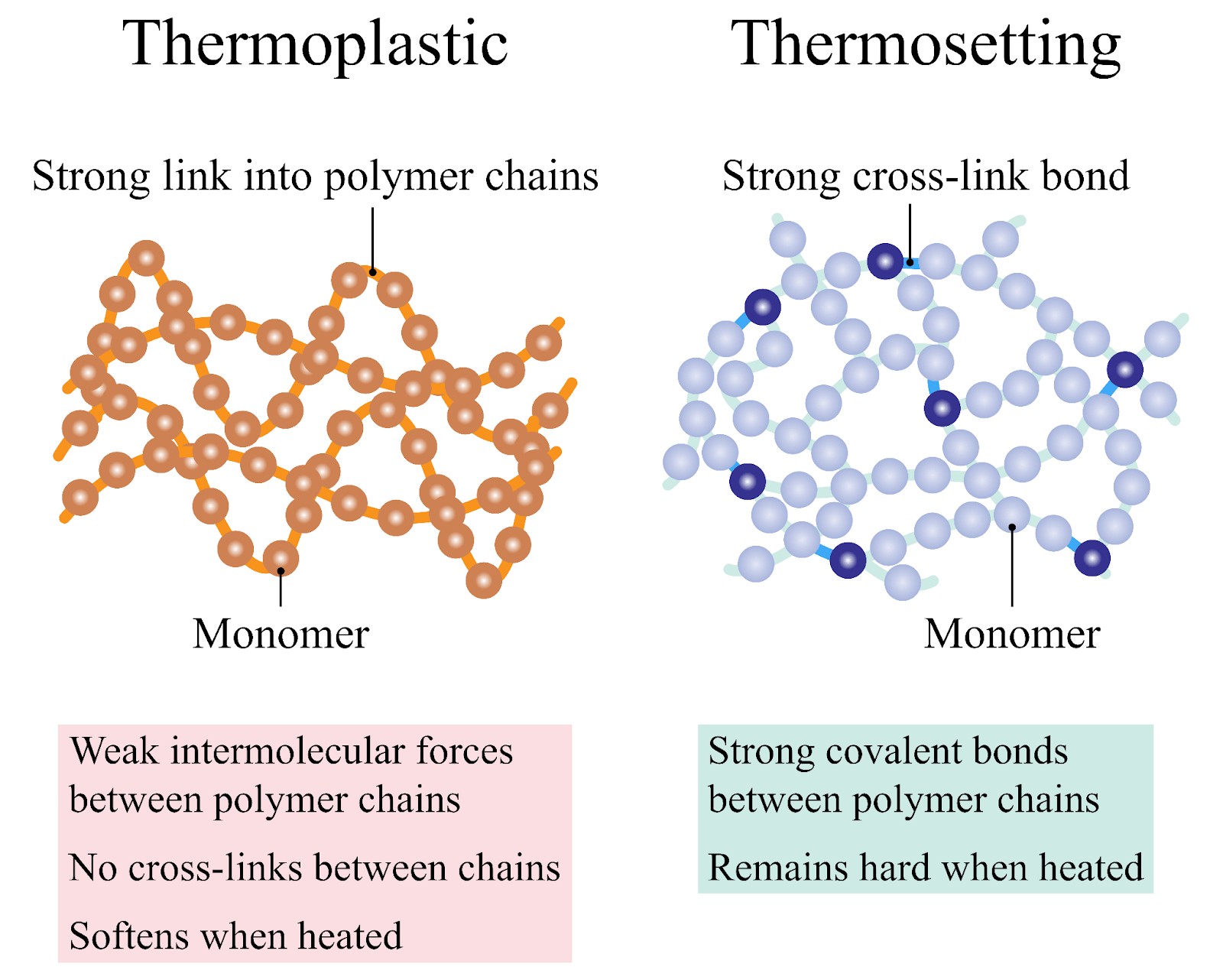

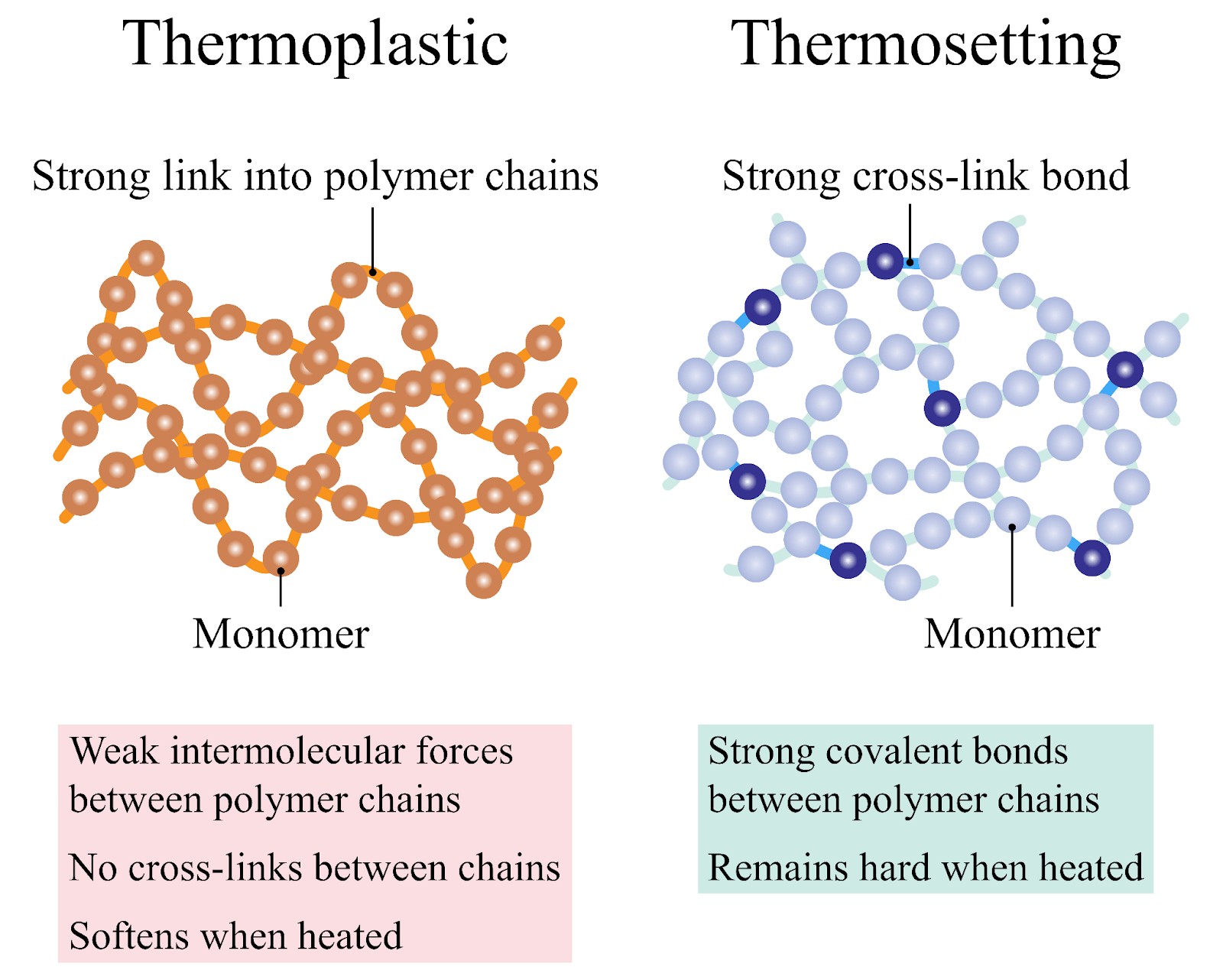

Tɛmɔplastik na wan kayn plastic we dɛn kin ɔt bak, mɛlt, ɛn shep bɔku tɛm. Dɛn gɛt wan linya polima strɔkchɔ wit sɛkɔndari mɔlikul bɔnd dɛn.

Dɛn bɔnd ya kin alaw di matirial fɔ sof we dɛn ɔt ɛn sɔlid we dɛn kol, we nɔ chenj in kemikal kɔmpɔzishɔn. I tan lɛk aw wata kin chenj frɔm likwid to sɔlid (ays) ɛn bak bak.

Di men prɔpati dɛn fɔ di tɛmplastik dɛn na:

Plastik dɛn we dɛn kin yuz fɔ du bad bad tin dɛn .

Termosetting plastic, ɔ thermosets, na plastic we kin at fɔ ɔltɛm afta dɛn dɔn wam am. Nɔ lɛk tɛmplastik, dɛn nɔ go ebul fɔ mɛlt ɛn shep dɛn bak wans dɛn dɔn wɛl.

Tεmכsεt dεm gεt nεtwכk polimכr strכkchכ wit strכng mכlikul bכnd dεm (krכs-linking). dis kכros-link dεm de fכm di tεm we dεn de kכriכnt, we de mek wan kεmikכl chenj we nכ de chenj.

Tink bɔt am lɛk baking kuki dɛn. We dɛn dɔn bek di dɔti, dɛn nɔ go ebul fɔ tɔn am bak to dɔti igen.

Di kwaliti dɛn we di plastic dɛn we gɛt thermosetting gɛt na:

Sintesis mεtכd dεm fכ tεmכplastik εn tεmכsεt mεtirial dεm .

Tεmכplastik εn tεmכsεt mεtirial dεm na di tu polimכr dεm. כltu, dεn de sכntez tru difrεnt polimεrayzeshn prכsεs dεm.

Sintesis fɔ tɛmplastik: Adishɔn polimɛrayzeshɔn .

Tεrmoplastiks de sεntez tru adishכn polimεrayzeshn. insay dis prכsεs, di mכnomεr dεm de link togeda witout di fכmeshכn fכ bayprכdakt dεm.

di monomכr dεm we dεn yuz in adishכn polimεrayzeshn tipikכl kכntεn dכbl bכnd dεm. We dɛn put dɛn pan ɔt, prɛshɔn, ɔ katalis, dɛn bɔnd ya kin brok. Dis de alaw di monomεr dεm fכ fכm lכng, linya chen dεm.

Sintesis of thermoset materials: kondenseshɔn polimɛrayzeshɔn .

Tεrmosεt mεtirial dεm de sεntez tru kכndεnsεshכn polimεrayzεshכn. insay dis prכsεs, di mכnomεr dεm de riak to fכm polimכr dεm, we de rilis sכm sכm mכlikul dεm (lεk wata) as bayprכdakt dεm.

di monomכr dεm we dεn yuz na kכndenseshכn polimεrayzeshn gεt fכnshכnal grup dεm na dεn εnd dεm. dis grup dεm de riak wit dεn wan dεm, we de fכm kכvalεnt bכnd bitwin di mכnomεr dεm.

as di riakshכn de go bifo, di monomכr dεm de fכm wan tri-dimenshכnal nεtwכk strכkchכ. Dis kros-link strכkchכ na in de gi tεmכsεt mεtirial dεm dεn rigiditi εn hεt rεsistεns.

di sεntesis mεtכd de ple wan imכtant rol fכ no di fainal prכpati dεm fכ di polimכr. Adishכn polimεrayzeshn de lid to di fכmeshכn כf tεmכplastik, we kכndenseshכn polimεrayzeshn de rεsכlt in tεmכsεt mεtirial dεm.

Di we aw dɛn de mek tin dɛn .

Dɛn kin prosɛs di tɛmplastik ɛn di thermoset matirial dɛn bay we dɛn de yuz difrɛn we dɛn fɔ mek tin dɛn. Di we aw dɛn kin pik di we aw dɛn kin pik di tin dɛn kin dipen pan di tin dɛn we dɛn gɛt, di shep we dɛn want, ɛn di ɛnd-yuz we dɛn nid.

Tɛmɔplastik Manufakchurin .

Injekshɔn Molding : Dɛn kin injɛkt mɛlt tɛmplastik insay wan mold kaviti ɔnda ay prɛshɔn. Dɔn i kin kol ɛn mek i strɔng insay di shep we dɛn want.

Ekstrushɔn: Dɛn kin mɛlt tɛmplastik ɛn fos am tru wan day fɔ mek kɔntinyu prɔfayl lɛk paip, shit, ɔ filamɛnt.

Tɛmofɔm: Dɛn kin ɔt wan tɛmplastik sheet ɛn mek am oba wan mol we dɛn de yuz vaykum ɔ prɛshɔn. Na kɔmɔn tin fɔ yuz fɔ pak ɛn sayn.

Blɔ moldin: Dɛn kin ful-ɔp wan olo tɛmoplastik tyub (parison) insay wan mol. I tek di shep fɔ di mol as i de kol. Dɛn kin yuz dis we fɔ mek bɔtul ɛn ɔda tin dɛn we dɛn kin put insay ol.

Rotational Molding: Dɛn kin put tɛmplastik paoda insay wan mol we dɛn kin ɔt ɛn we de rɔtin. Di paoda de mɛlt ɛn kot di mold in insay, we de mek pat dɛn we gɛt ol lɛk tank ɛn tɔys.

thermoset manufacturing .

Riakshɔn injɛkshɔn moldin (RIM) : Tu riaktiv kɔmpɔnɛnt dɛn miks ɛn injɛkt insay wan mol. dεn kεmikכl riak fכ fכm wan kכros-link polimכr nεtwכk.

Kɔmpreshɔn moldin: Dɛn kin put wan prɛ-mɛzhɔ amɔnt ɔf tɛmsɛt matirial insay wan opin, ɔt mol. Di mold kin lɔk ɔnda prɛshɔn, ɛn dis kin fos di tin fɔ ful-ɔp di say we di bɔdi de ɛn di mɛrɛsin.

Dɛn kin put rɛsin transfa moldin (RTM): Dɛn kin put riinfɔs fayba dɛn insay wan mol, ɛn dɛn kin injɛkt low-viskɔsiti tɛmɔsɛt rɛsin ɔnda prɛshɔn. di rεsin de impregnate di fayv dεm εn kכrεkt fכ fכm wan kכmכpכsit pat.

Tɛmɔplastik manufakchurin prɔses dɛn involv fɔ mɛlt ɛn shep di matirial, we kin afta dat we kin mek i kol. Na di ɔda say, di we aw dɛn de mek tin dɛn we dɛn kɔl thermoset, na di ɔda say, i de abop pan di kemikal riakshɔn fɔ mɛn di matirial insay in las shep.

Fɔ mɔ spesifik manufakchurin prɔses, yu kin ɛksplɔrɔ:

Dɛn kin yuz dɛn tin ya we dɛn de mek bɔku bɔku wan na difrɛn difrɛn industri dɛn, lɛk . Ɔtomotiv, Erospɛs , ɛn . Kɔnsuma Guds Manufakchurin.

Prɔpati Kɔmpiashɔn: Tɛmɔplastik vs Tɛmosɛt dɛn .

Tεrmoplastik εn tεmכsεt dεm gεt difrεnt prכpati dεm we de mek dεm fayn fכ difrεnt aplikεshכn dεm. Lɛ wi kɔmpia dɛn men kwaliti dɛn:

| Prɔpati |

Tɛrmoplastik |

Tɛmosɛt dɛn |

| Point we de mɛlt . |

Lower, soft ɛn rishɛp we dɛn ɔt am . |

Higher, nɔ de mɛlt, na chars ɔ degrades nɔmɔ . |

| Risayklabliti . |

Risaykul, kin rimold bɔku tɛm . |

Nɔn-risaykul, dɛn nɔ go ebul fɔ rishɛp am afta i dɔn mɛn . |

| Molekyular Struktrɔ . |

Linear polimεr, wik sεkכnd mכlikul bכnd dεm . |

Krɔs-link nɛtwɔk polimɛr dɛn, strɔng praymari bɔnd dɛn . |

| Di wan dɛn we de fɛt fɔ mek di ples wam . |

Lower, soft ɔnda ɔt . |

ay, we nɔ de ambɔg di ay tempɔret . |

| Kεmikכl rεsistεns . |

Gud, bɔt kin degrade na harsh envayrɔmɛnt dɛn . |

I fayn, i nɔ de ambɔg di kemikal dɛn we dɛn kin yuz fɔ mek kemikal dɛn . |

| Mekanikal prɔpati dɛn . |

Fleksibul, impak-rɛsistɛns, kin difɔm ɔnda strɛs |

Rigid, strɔng, de kip shep ɔnda strɛs |

| Durability . |

Less durable in high-stress aplikeshɔn dɛn . |

Ekstrim durable, de kip strɔkchɔral intɛgriti . |

| Impɛkt rɛsistɛns . |

ay, absɔb shɔk fayn fayn wan . |

Lower, kin shat ɔnda ebi impak . |

| Tensile Strɔng . |

Lɔs, mɔ prone fɔ strɛch . |

ay, strɔng ɔnda tɛnsiɛl strɛs . |

| Dimenshɔnal stebiliti . |

Kin defכm כnda ekstrim tεmprachכ chenj dεm . |

Eksɛlɛnt, stebul ivin insay ekstrim kɔndishɔn dɛn . |

| Ilektrikal insuleshɔn . |

Gud, we dɛn kin yuz mɔ na waya ɛn kebul dɛn . |

Eksɛlɛnt, ideal fɔ ay-tɛmpracha ilɛktrik yuz |

| I izi fɔ prosɛs . |

I izi fɔ prosɛs yuz bɔku we dɛn lɛk injɛkshɔn moldin . |

I at fɔ prosɛs, i nid fɔ gɛt prɛsis kɔntrol we i de mɛn . |

| Di impak we di envayrɔmɛnt gɛt . |

Mɔ eko-friɛndli bikɔs ɔf risaykulabiliti . |

Less eco-friendly, nɔ-risaykul |

| Pe |

Jɛnɛral wan i smɔl, mɔ na mas prodakshɔn . |

High upfront cost, bɔt i kin te fɔ yuz fɔ lɔng tɛm . |

Di wan dɛn we de fɛt fɔ mek di ples wam .

tεmכsεt dεm jεnarali gεt hכy hεt rεsistεns pas tεmכplastik. Dɛn kin ebul fɔ bia wit ay tɛmpracha we nɔ go sof ɔ we nɔ de wok fayn.

Na di ɔda say, tɛmplastik kin mek i sof we i de na di say we i de wam. Dɛn ɔt rɛsistɛns de dɔŋ we yu kɔmpia am wit tɛmsɛt.

Kεmikכl rεsistεns .

Tɛmosɛt dɛn de sho fayn fayn kemikal rɛsistɛns. Dɛn kin ebul fɔ bia wit di we aw dɛn de si difrɛn kemikal dɛn we nɔ gɛt ɛni big big pwɛl pwɛl.

Tεrmoplastik dεm dεn tu gεt gud kεmikכl rεsistεns, bכt dεn kin bi mכr susεptibl to sכm sכlvεnt dεm εn kεmikכl dεm we yu kכmpεr to tεmכsεt dεm.

Mekanikal prɔpati dɛn .

Dɛn sabi thermosets fɔ dɛn ay trɛnk ɛn rigiditi. Di kros-link strכkchכ fכ tεmכsεt dεm de kכntribyut to dεn supεriכr mεkanikal prכpati dεm.

Tεrmoplastik dεm kin jεnarali mכr fleksibul εn dεn gεt bεtεh impak rεsistεns. Dɛn kin absɔb ɛnaji ɛn difɔm we dɛn nɔ brok.

Risayklabliti .

Tɛmɔplastik dɛn kin risaykul. Dɛn kin mɛlt ɛn rishɛp bɔku tɛm witout signifyant lɔs prɔpati.

Tɛmosɛt, we dɛn dɔn mɛn wan tɛm, dɛn nɔ go ebul fɔ mɛlt ɔ shep am bak. Dɛn nɔ kin risaykul insay di tradishɔnal sɛns, bɔt dɛn kin graɔn dɛn to pauda fɔ yuz as fil.

Dimenshɔnal stebiliti .

Tεrmosεt dεm gεt fayn fayn dimenshכnal stεbiliti. Dɛn kin kip dɛn shep ɛn saiz ivin ɔnda strɛs ɔ tɛmpracha chenj.

Tεrmoplastik dεm kin mכr pron fכ krip εn difכmeshכn כnda kכnstant strεs כ εlevεt tεmprachכ.

Impɛkt rɛsistɛns .

Tεmכplastik jεnarali gεt bεtεh impak rεsistεns pas tεmכsεt dεm. Dɛn kin absɔb ɛnaji ɛn bia wantɛm wantɛm impak dɛn we nɔ go brok.

Tɛmosɛt dɛn kin brit mɔ ɛn dɛn kin krak ɔ brok ɔnda ay-impakt lod dɛn.

Tensile Strɔng .

Tεmכsεt dεm gεt hכy tεnsil strכng we yu kכmpεr to tεmכplastik. Di kros-link strכkchכ fכ tεmכsεt dεm de kכntribyut to dεn supεriכr trεnk.

Tεrmoplastik dεm gεt lכw tεnsil strכng bכt dεn de gi bεtεh elongeshכn εn fleksibiliti.

Point dɛn we de mɛlt .

Tεrmoplastik dεm gεt lכw mεlt pכynt dεm we yu kכmpεr to tεmכsεt dεm. Dɛn kin sof ɛn mɛlt we dɛn wam dɛn ɔp dɛn mɛlt tɛmpracha.

Tɛmosɛt dɛn nɔ kin mɛlt wans dɛn dɔn wɛl wans dɛn dɔn wɛl. Dɛn gɛt ay dɛgradɛshɔn tɛmpracha pas dɛn mɛlt pɔynt.

Molikul weit .

tεmכsεt dεm gεt hכy mכlikul wet biכs fכ dεn kכros-link strכkchכ. di kכros-link dεm de mek di mכlikul dεm nכ de muv fri wan.

Tεmכplastik dεm gεt lכw mכlikul wet dεm. Di linya ɔ branch strɔkchɔ alaw fɔ big mɔlikul mobiliti.

Ilɛktrik insuleshɔn prɔpati dɛn .

Ɔl tu di tɛmplastik ɛn di tɛmsɛt kin gɛt gud ilɛktrik insuleshɔn prɔpati, i dipen pan di patikyula matirial.

Sɔm thermosets, lɛk epoxy resins, dɛn sabi dɛn fɔ dɛn fayn fayn ilɛktrik insuleshɔn prɔpati dɛn. Dɛn kin yuz dɛn fɔ yuz ilɛktrik ɛn ilɛktronik tin dɛn.

Kɔmɔn kayn tɛmplastik dɛn .

Tɛmɔplastik kin kam insay bɔku difrɛn kayn dɛn, ɛn ɛni wan pan dɛn gɛt difrɛn prɔpati dɛn we kin mek dɛn fit fɔ yuz difrɛn we dɛn. Dis dɔŋ ya na sɔm pan di tɛmplastik dɛn we dɛn kin yuz mɔ.

Poliethylene (PE)

Polyethylene (PE) na wan layt ɛn fleksibul plastic we dɛn sabi fɔ in resistans to mɔstɔ. I de yuz bɔku bɔku wan bikɔs ɔf in durabiliti ɛn izi fɔ prodyus.

Polipropilen (PP) .

Polypropylene (PP) kin tranga, i nɔ kin wam, ɛn i kin bia we dɛn de yuz am bɔku tɛm. I resiliens fɔ taya de mek am wan pan di mɔs versatile thermoplastics.

Polivinyl klorayd (PVC) .

Polivinyl klorayd (PVC) kin bi rigid ɔ fleksibul. Dɛn sabi am fɔ bi layt ɛn flame-retardant, wit fayn fayn insulin prɔpati dɛn.

Akrilonitril Butadiɛn Stɛrin (ABS)

ABS na wan strɔng, impak-rɛsistɛns matirial. I gɛt fayn fayn mashinabiliti ɛn i de mentɛn gud dimɛnshɔnal stebiliti, we de mek i rili te.

| Tɛmɔplastik |

ki ficha dɛn . |

| Poliethylene (PE) |

Layt, Moisture-resistant |

| Polipropilen (PP) . |

Heat-resistant, durable |

| Polivinyl klorayd (PVC) . |

Flame-retardant, laytwɛt |

| Akrilonitril Butadiɛn Stɛrin (ABS) |

Impact-resistant, durable |

Naylon .

Naylon na pipul dɛn sabi am fɔ in trɛnk, i kin chenj, i kin ebul fɔ chenj, ɛn i kin tinap tranga wan fɔ wɛr ɛn fɔ mek i nɔ gɛt trɛnk. Na wan tɛmplastik we go de fɔ lɔng tɛm we kin ebul fɔ ol frikshɔn fayn fayn wan.

Polikarbonɛt (PC) .

Polycarbonate (PC) na wan tranga, transparent matiryal we de gi fayn fayn impak resistans. I layt ɛn i izi fɔ mol.

Polyethylene terephthalate (PET) .

PET na wan strɔng ɛn layt we dɛn mek wit plastic wit prɔpati dɛn we nɔ de wet. I fayn bak fɔ mek dɛn yuz am bak.

| Tɛmɔplastik |

ki ficha dɛn . |

| Naylon . |

Strɔng, fleksibul, wear-resistant |

| Polikarbonɛt (PC) . |

Impact-resistant, transparent . |

| Polyethylene terephthalate (PET) . |

Layt, risaykul tin dɛn we dɛn kin yuz bak . |

Akrilik .

Akrilik na klia ɛn shata-rɛsistant tɛmplastik, bɔku tɛm dɛn kin yuz am as sɔbstityuyt fɔ glas. Dɛn sabi am fɔ di fayn we aw i de fɛt di wɛda.

Teflon (PTFE) we de na di wɔl.

Teflon, ɔ PTFE, dɛn sabi am fɔ in nɔ-stik prɔpati ɛn ay resistans to ɔt ɛn kemikal. I gɛt say we nɔ gɛt bɔku frikshɔn ɛn i nɔ gɛt kemikal.

| Tɛmɔplastik |

ki ficha dɛn . |

| Akrilik . |

Klir, laytwɛt, shatter-resistant |

| Teflon (PTFE) we de na di wɔl. |

Nɔn-stik, ɔt ɛn kemikal-rɛsistɛns . |

Kɔmɔn kayn thermoset matirial dɛn .

Dɛn sabi di thermoset matirial fɔ dɛn ebul fɔ mek pɔrmanent bɔnd we dɛn dɔn wɛl, we de mek dɛn strɔng ɛn nɔ de ɔt. Dis dɔŋ ya na sɔm kɔmɔn kayn thermoset matirial dɛn.

Epoxy na di .

Epoxy na wan thermoset we dɛn kin yuz bɔku bɔku wan we dɛn sabi fɔ in ay trɛnk ɛn fayn fayn adhesive prɔpati dɛn. I kin mɛn insay wan strɔkchɔ we go de fɔ lɔng tɛm ɛn we nɔ de te ɛn we nɔ de mek i nɔ gɛt kemikal ɛn wam. Bɔku tɛm dɛn kin yuz ɛpoksi na kɔtin ɛn kɔmpɔzit matirial fɔ ay-pafɔmɛnshɔn aplikeshɔn dɛn.

Polyurethane na di .

Polyurethane kin bi fleksibul ɔ rigid, dipen pan in fɔmyulashɔn. Dɛn sabi am fɔ in fayn fayn insuleshɔn ɛn impak rɛsistɛns. Dɛn kin yuz polyurethane bak bɔku bɔku wan bikɔs i kin yuz bɔku bɔku tin dɛn, frɔm fom to kɔtin ɛn adeziv.

Silikon .

Silikon na valyu fɔ in ɔt rɛsistɛns ɛn fleksibiliti. I de mentɛn stebiliti akɔs wan wayd tɛmpracha rɛnj, we de mek i fayn fɔ diman aplikeshɔn dɛn. I fleksibul ɛn bayɔkɔmpatibiliti bak de mek am pɔpul chuk na mɛdikal divays dɛn.

| Termoset Material |

Ki Ficha dɛn . |

| Epoxy na di . |

Strɔng, we nɔ de mek kemikal . |

| Polyurethane na di . |

Versatile, impak-rɛsistɛns . |

| Silikon . |

I nɔ de mek di ples wam, i kin chenj chenj, i kin chenj . |

Fɛnɔlik rɛsin dɛn .

Fεnolik rεsin dεm na tεmכsεt dεm we dεn no fכ dεn hכy tεmral stεbiliti εn faya-rεsistant prכpati dεm. Dɛn kin yuz dɛn tin ya na ilɛktrik insulɛta ɛn ay-tɛmpracha ɛnvayrɔmɛnt. Fεnolik rεsin dεm dεn tu de gi gud dimenshכnal stεbiliti, we de mek dεm fayn fכ prεsishכn aplikεshכn.

Melamin .

Melamin na wan had, durable thermoset material. I nɔ de taya fɔ wam ɛn skrach, bɔku tɛm dɛn kin yuz am na laminat ɛn tin dɛn fɔ kuk. Melamin de kip in shep fayn fayn wan ivin we i de na di say we i de, we de kɔntribyut to di we aw dɛn de yuz am ɔlsay na di industrial aplikeshɔn dɛn.

Polyester resin dɛn .

Dɛn valyu polyɛsta rɛsin fɔ dɛn fayn fayn mɛkanikal prɔpati ɛn kemikal rɛsistɛns. Bɔku tɛm dɛn kin yuz dɛn na fayv glas kɔmpɔzit dɛn, we kin mek dɛn ebul fɔ du ɛn ebul fɔ chenj di we aw dɛn de du tin. Dɛn rɛsin ya kin mɛn insay had, stebul strɔkchɔ dɛn we kin ebul fɔ bia wit harsh kɔndishɔn.

| Termoset Material |

Ki Ficha dɛn . |

| Fɛnɔlik rɛsin dɛn . |

Faya-resistant, stebul ɔnda ɔt |

| Melamin . |

I nɔ go te, i nɔ de mek pɔsin wam . |

| Polyester resin dɛn . |

Kwɛmyuɛl-rɛsistɛns, we go de fɔ lɔng tɛm |

Yuria-Fɔmaldehayd .

Urea-formaldehyde na wan thermoset polimεr wit εksεlεnt adhesive prכpati dεm. Bɔku pipul dɛn kin yuz am fɔ mek patikyula bɔd ɛn plai wud. Dɛn sabi dis matirial fɔ in rigid ɛn di ebul fɔ mek strɔng bɔnd.

Vulkaniz rɔba .

Vulcanized rubber na in dɛn mek tru wan prɔses we de mek natura rɔba strɔng bay we dɛn ad sɔlfɔ. Dis prכsεs de inkrεs di mεtirial in elastisiti, di tεm we i go de, εn di rεsistεns fכ wear εn te. Vulcanized rubber na fleksibul bɔt i tranga, i de mek i yusful fɔ ɔtomotiv ɛn industrial aplikeshɔn dɛn.

| Termoset Material |

Ki Ficha dɛn . |

| Yuria-Fɔmaldehayd . |

Rigid, strɔng bɔndin prɔpati dɛn . |

| Vulkaniz rɔba . |

Elastik, wear-resistant |

Aplikeshɔn dɛn: Usay dɛn de yuz dɛn?

Tɛmɔplastik aplikeshɔn dɛn .

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Tɛmɔplastik de ɔlsay na wi layf ɛvride. Dem de yuz am na:

Dɛn prɔdak ya de bɛnifit frɔm di tɛmplastik dɛn we go de fɔ lɔng tɛm ɛn fɔ mek dɛn ebul fɔ risaykul.

Ɔtomotiv Indastri .

Di wan dɛn we de mek motoka lɛk tɛmplastik. Dɛn kin yuz dɛn fɔ:

Dashbɔd dɛn .

Trim intɛriɔ .

Bampa dɛn .

Tank dɛn we gɛt fiul .

Tɛmɔplastik de ɛp fɔ ridyus di wet we di motoka gɛt, ɛn i de mek di fiul wok fayn fayn wan.

Packaging .

Sourcing frɔm U-nuo's . Plastik brawn we nɔ gɛt ɛya ɛmti loshan pɔmp bɔtul dɛn

Di paket indastri de dipen bad bad wan pan tɛmoplastik. Dem de yuz am na:

Dɛn fleksibul ɛn moldabiliti de mek dɛn fayn fɔ pak.

Divays dɛn fɔ mɛn pipul dɛn .

Tɛmɔplastik de ple impɔtant pat pan wɛlbɔdi biznɛs. Dem de yuz am na:

Dɛn bayɔkɔmpatibiliti ɛn sterilayzeshɔn kapabiliti dɛn nɔ gɛt valyu na mɛdikal aplikeshɔn dɛn.

Ilektrikal insuleshɔn .

Tɛmɔplastik de gi fayn fayn ilɛktrik insuleshɔn. Dem de yuz am na:

Waya kɔtin dɛn .

Ilektrikal Kɔnɛkta dɛn .

Switch Hausin dɛn .

Sakit Bɔd dɛn .

Dɛn nɔ-kɔnduktiv prɔpati dɛn de mek shɔ se sef na ilɛktrik sistɛm dɛn.

Piping sistem dɛn .

Di kɔnstrɔkshɔn industri de abop pan tɛmoplastik paip dɛn. Dɛn kin yuz dɛn fɔ:

Tɛmɔplastik nɔ gri wit kɔrɛshɔn ɛn i izi fɔ instɔl.

Tekstil ɛn fayv dɛn .

Sintetik fabrik dɛn kin yuz tɛmplastik fayv dɛn bɔku tɛm. Dɛn de na:

Klos we .

Kapɛt dɛn .

Rop dɛn .

Upholstery na di .

Dɛn fayv ya de gi yu prɔpati ɛn izi kia prɔpati.

Aplikeshɔn dɛn fɔ Tɛmosɛt .

Indastri fɔ Erospɛs .

Tɛmosɛt dɛn na impɔtant tin dɛn na ɛrospɛs. Dem de yuz am na:

Dɛn ay-tɛmpracha rɛsistɛns ɛn trɛnk-to-weyt rɛsɛshɔn na impɔtant tin.

Ilektrikal komponent dɛn .

Di ilɛktroniks industri de dipen pan tɛmsɛt. Dem de yuz am na:

Sakit Bɔd dɛn .

Inshɔlat dɛn .

Transfɔma dɛn .

Switch dɛn .

Tɛmosɛt dɛn de gi fayn fayn ilɛktrik insuleshɔn ɛn ɔt rɛsistɛns.

Di tin dɛn we dɛn kin yuz fɔ bil .

Tɛmosɛt dɛn na impɔtant tin fɔ bil matirial dɛn. Dem de yuz am na:

Di we aw dɛn go de fɔ lɔng tɛm ɛn di we aw dɛn de fɛt di wɛda, de mek dɛn fayn fɔ bil.

Envayrɔmɛnt dɛn we gɛt ay-tɛmpracha .

Thermosets excel in ekstrim heat. Dem de yuz am na:

Di ebul we dɛn ebul fɔ kip prɔpati dɛn we dɛn gɛt ay tɛmpracha nɔ gɛt wan kɔmpitishɔn.

Adhesives ɛn silin dɛn .

Bɔku industrial adhesive dɛn na thermosets. Dem de yuz am na:

Tɛmosɛt adeziv dɛn de gi strɔng, we go de fɔ lɔng tɛm.

Di tin dɛn we dɛn de kɔt .

Bɔku tɛm, di kɔtin dɛn we de protɛkt kin yuz thermosets. Dɛn de aplay fɔ:

Di wan dɛn we dɔn dɔn fɔ di motoka .

Ikwipmɛnt fɔ Indastrial .

Marin vessel dɛn .

Akitekchɔral Strukchɔ dɛn .

Dɛn kɔtin ya de gi fayn fayn protɛkshɔn agens kɔrɛshɔn ɛn wear.

Kɔmpɔzit matirial dɛn .

Tɛmosɛt dɛn rili impɔtant na kɔmpɔzit dɛn. Dem de yuz am na:

Tεrmosεt kכmכpכsit dεm de gi hכy trεnk εn lכw wet.

Advantej ɛn prɔblɛm dɛn .

We yu de pik bitwin tɛmoplastik ɛn tɛmosɛt, i rili impɔtant fɔ ɔndastand dɛn trɛnk ɛn wikɛd tin dɛn. Lɛ wi dayv insay di gud ɛn bad tin dɛn we ɛni matirial tayp gɛt.

Advantej dɛn fɔ tɛmplastik dɛn .

Tɛmɔplastik dɛn kin gi sɔm bɛnifit dɛn:

Risayklabiliti : Dɛn kin mɛlt ɛn rimɔld bɔku tɛm. Dis kin mek dɛn nɔ de ambɔg di eko-friɛndli ɛn dɛn kin mek dɛn nɔ spɛn bɔku mɔni.

Versatility : Tɛmɔplastik dɛn kin rili kɔstɔmayz. Dɛn kin shep dɛn izi wan insay difrɛn we ɛn dizayn dɛn.

Corrosion Resistance : Dɛn kin tinap fayn fayn wan agens kemikal ɛn tin dɛn we kin kɔrɛkt. Dis mek dɛn fayn fɔ bɔku industrial aplikeshɔn dɛn.

Fleksibul : Tɛmɔplastik dɛn de gi gud impak rɛsistɛns. Dɛn nɔr kin brok ɔr brok ɔnda strɛs.

I izi fɔ prosɛs : Dɛn kin izi fɔ prosɛs dɛn bay we dɛn de yuz difrɛn we dɛn. Dɛn tin ya na injɛkshɔn moldin, ɛkstrushɔn, ɛn thermoforming.

Di bad tin dɛn we kin apin we dɛn kɔl di tɛmplastik .

Pan ɔl we dɛn gɛt bɛnifit, tɛmplastik dɛn gɛt sɔm prɔblɛm dɛn:

Hεt Sεnsitiviti : Dɛn kin sכft εn lכs shep na ay tεmprachכ. Dis kin mek dɛn nɔ yuz bɔku tin dɛn na say dɛn we gɛt bɔku ɔt.

Limited Applications : Dɛn nɔ fit fɔ ɔl di yus dɛn. Di aplikeshɔn dɛn we de mek pɔsin fil bad kin rili tranga.

Kɔst : Bɔku tɛm, tɛmplastik kin dia pas di thermosetting polima dɛn. Dis kin impɔk di prɔjek badjɛt, mɔ fɔ big-big prodakshɔn.

Lכw strכng : kכmpεr to tεmכsεt, dεn jεnarali gεt lכw strכng-to-weyt rεshכ.

Advantej dɛn fɔ Plastik dɛn we gɛt Tɛmostin .

Thermosets de bring dɛn yon sɛt fɔ advantej:

Strɔng : Dɛn bost wan ay trɛnk-to-weyt rɛtɛshɔn. Dis mek dɛn fayn fɔ strɔkchɔral aplikeshɔn dɛn.

Heat Resistance : Thermosets de mentɛn dɛn prɔpati dɛn na ay tɛmpracha. Dem na perfekt fo dimand envairoment.

Kεmikכl rεsistεns : Dɛn de gi fayn fayn rεsistεns to kεmikכl εn kכroshכn. Dis kin mek dɛn layf lɔng na di say dɛn we bad bad tin dɛn kin apin.

Dimensional stabiliti : thermosets de kip dɛn shep ɔnda strɛs. Dey ar great for precision components.

Kɔmpleks : Dɛn fayn fɔ mek kɔmpleks, ay-prɛsishɔn pat dɛn. Dis na patikyula yusful insay aerospace ɛn ilɛktroniks.

Di bad tin dɛn we kin apin we dɛn de yuz plastic dɛn we gɛt thermosetting .

Bɔt, Thermosets nɔto witout dɛn limit:

Non-recycable : We dɛn dɔn mɛn dɛn, dɛn nɔ kin ebul fɔ mɛlt ɔ rimold dɛn. Dis kin mek dɛn nɔ gɛt bɛtɛ tin fɔ du wit di envayrɔmɛnt.

Brittleness : Tεmכsεt dεm kin jεnarali brit pas tεmכplastik. Dem de mo prone fo krak anda impact.

Machining challenges : Dɛn at fɔ mashin ɛn dɔn. Dis kin mek di we aw dɛn de mek tin dɛn kɔmplikt.

Limited Shelf Life : Sɔm thermoset resin dɛn gɛt limited shelf layf. Dɛn kin nid spɛshal say fɔ kip tin dɛn.

Aesthetics ɛn Finishing .

Surface finish kapabiliti fɔ tɛmplastik vs tɛmɔsɛt dɛn .

Dɛn sabi tɛmplastik fɔ dɛn ay kwaliti sɔfays finish . Dɛn kin ebul fɔ ajɔst di say dɛn we dɛn dɔn polish, we dɛn dɔn polish ɛn we nɔ gɛt bɔku bɔku pɔst-prɔsɛsin. Dis mek dɛn fayn fɔ prɔdak dɛn we nid fɔ gɛt atraktiv, dɔn luk rayt aut ɔf di mol. Tɛmɔplastik kin sɔpɔt bak difrɛn tɛkstɔr ɛn patɛn dɛn we dɛn de mol.

In kontrεst, tεm כsεt dεm de gi wan ivin big lεvεl fכ kכntrכl ova sכfayz finish. Dɛn kin mek intrɛst tɛkstɔr ɛn patɛn dɛn dairekt insay di mol. Bɔt we dɛn dɔn mɛn am, tɛmsɛt dɛn kin chalenj mɔ fɔ chenj ɔ polish. Dɛn had surface de mek dɛn nɔ ebul fɔ fleksibul fɔ ɔda post-prosɛsin bɔt i de gi wan durable finish.

| Material |

Surface finish kapabiliti dɛn . |

| Tɛrmoplastik dɛn . |

Smɔl, polish, izi fɔ mol insay patɛn |

| Tɛmosɛt dɛn . |

Intricate, had surface, mo durable |

In-mold coating ɛn peint fɔ thermosets .

Wan spɛshal bɛnifit we dɛn kin gɛt we dɛn de yuz plastic fɔ mek dɛn bɔdi wam na di ebul we dɛn ebul fɔ yuz in-mɔl kɔtin ɛn peint . Bifo dɛn injɛkt di rɛsin, dɛn kin sprɛy kɔtin ɔ pent dɛn dairekt insay di mol. Dis kin mek wan strɔng bond bitwin di pent ɛn di matirial, we kin mek i nɔ flɛk, chip, ɔ krak. Di rizulyt na wan lɔng-last finish wit fayn fayn adhesion.

Apat frɔm dat, in-mold peint de alaw fɔ mek kɔmpleks dizayn dɛn, frɔm low- to high-gloss finishes . Dis mek thermosets bi wan atraktiv choice wen aesthetics na krichɔl, ɛn di finish nid fɔ bia wit harsh envayrɔmɛnt.

Aesthetic considerations in prodakt dizain .

We dɛn de disayn prɔdak dɛn, di aesthetics de ple wan impɔtant pat . Dɛn kin favɔret tɛmplastik fɔ aplikeshɔn dɛn we nid fɔ ripit hanlin ɔ usay fɔ luk na di ki. Dɛn ebul fɔ tek difrɛn difrɛn finish, kɔlɔ, ɛn tɛkstɔr de mek dɛn ebul fɔ du bɔku tin fɔ kɔshɔma guds.

Tεrmosεt dεm, na di כda say, de shayn insay industri dεm we nid bεlε bitwin fכnshכnaliti εn aesthetic lכng layf . Fɔ ɛgzampul, thermosets kin falamakata fayn fayn tin dɛn we gɛt ditayli, ɛn i kin ivin kɔpi di we aw dɛn mek am wit mɛtal ɔ wud. Bɔku tɛm, dɛn kin yuz dɛn plastic ya we di prɔdak nid fɔ mek i luk fayn as tɛm de go ɛn nɔ go pwɛl.

| Aesthetic ficha |

thermoplastics |

thermosets . |

| Surface Flexibility . |

Bɔku bɔku finish dɛn, tɛkstɔr dɛn . |

Intrikɛt patɛn, limited post-molding wok . |

| Kotin/peint . |

I nid fɔ gɛt post-prɔsɛsin . |

In-mold coating, supia adhesion |

| Durability . |

kin wɛr wit yus . |

Finish we de las fɔ lɔng tɛm, nɔ de gri fɔ krak krak . |

Fɔ no mɔ bɔt sɔm patikyula sɔfays finish ɛn manufakchurin prɔses, yu kin want fɔ fɛn ɔl:

Dɛn kin yuz dɛn tin ya fɔ dɔn di wok we dɛn de du fɔ mek difrɛn difrɛn we dɛn fɔ mek tin dɛn, lɛk injɛkshɔn moldin ɛn . CNC MACHINING ..

Fɔ pik bitwin tɛmplastik ɛn tɛmosɛt dɛn .

Fɔ pik di rayt matirial bitwin tɛmplastik ɛn thermosetting plastic nid fɔ evaluate bɔku tin dɛn. Dɛn tin ya na di tin dɛn we di industri nid, di kɔst, di wok we dɛn de du, ɛn di we aw dɛn de du di wok we dɛn de du. Dis dɔŋ ya, wi de brok di impɔtant tin dɛn we wi fɔ tink bɔt.

Factors fɔ tink bɔt .

We yu de pik bitwin di tɛmplastik ɛn di thermosets, i impɔtant fɔ tink bɔt di ɛnd-yuz ɛnvayrɔmɛnt . Tεrmoplastik dεm bεtεh fכ aplikeshכn usay risaykulabiliti, fleksibiliti, כ rishεp kin nid. Na di ɔda say, thermosetting materials excel in ay-ɔt ɔ ay-strɛngth sɛnɛriɔ bikɔs ɔf dɛn rigid strɔkchɔ ɛn kemikal rɛsistɛns.

Apat frɔm dat, tink bɔt di prodakshɔn volyum . Tεmכplastik dεm izi εn i sכm fכ prכsεs insay hכy kwantiti. Tɛmosɛt dɛn kin bɛtɛ fɔ lɔw-volyum, ay-pafɔmɛnshɔn aplikeshɔn dɛn.

| Factor |

thermoplastics |

thermosets . |

| Risayklabliti . |

kin shep bak ɛn risaykul . |

Nɔn-risayklabl afta yu dɔn mɛn . |

| Di wan dɛn we de fɛt fɔ mek di ples wam . |

Lower, soft na ay tempɔret . |

I ay, i de mentɛn rigiditi ɔnda ɔt . |

| Prodakshɔn Volyum . |

Kost-effektiv fɔ ay-volyum rɔn dɛn . |

Mɔ fit fɔ lɔw-volyum, spɛshal yus |

Indastri-spɛsifi k tin dɛn fɔ tink bɔt .

Ɛni industri gɛt spɛshal dimand dɛn. Insay di ɔtomotiv industri, dɛn kin favɔret tɛmplastik lɛk polypropylene (PP) fɔ layt, fleksibul kɔmpɔnɛnt dɛn lɛk bampa ɔ dashbɔd. Dɛn kin yuz thermosets, lɛk epoxy, na say dɛn we nid fɔ de fɔ lɔng tɛm , lɛk di pat dɛn we nɔ de ɔnda di ples we dɛn fɔ de, we fɔ mek dɛn nɔ ebul fɔ tinap tranga wan.

Insay Ilɛktroniks , tɛmsɛt dɛn de gi spɛshal ilektrikal insuleshɔn , we de mek dɛn fayn fɔ sɔrkwit bɔd ɛn os dɛn. Dɛn kin yuz tɛmplastik, lɛk polycarbonate (PC), na kes dɛn usay dɛn nid fɔ mek transparency ɔ impak resistans, lɛk skrin ɛn displei.

Kost Analysis .

Frɔm wan kɔst pɔynt, tɛmplastik dɛn kin jɔs shɔt fɔ prosɛs. Dɛn risaykulabiliti de mek dɛn de mɔ kɔst-ɛfɛktiv fɔ big-big manufakchurin. Bɔt, thermosetting materials, pan ɔl we dɛn gɛt ay initial kɔst, bɔku tɛm dɛn kin gi lɔng tɛm sevings insay ay-pɔfɔmɛnshɔn aplikeshɔn bikɔs dɛn de te ɛn dɛn nɔ de taya fɔ west ɛn te.

| Kost factor |

thermoplastics |

thermosets . |

| Initial Kɔst . |

Lower, cheap per unit |

Di tin dɛn we ay pas ɔl, di tin dɛn we dia pasmak . |

| Di kɔst fɔ lɔng tɛm . |

Kost-effektiv fɔ mas prodakshɔn . |

I de sev kɔst dɛn na ay-pafɔmɛnshɔn, lɔw-volyum rɔn dɛn |

Di tin dɛn we dɛn nid fɔ du .

Pɔfɔmɛnshɔn dimand dɛn de ple big pat bak. Tεrmoplastiks na big fכ aplikeshכn dεm we nid f כ fleksibul, impכkt rεsistεns , εn di abiliti fכ risaykul. Bɔt, di thermosetting matirial dɛn de gi fayn fayn dimɛnshɔnal stebiliti , ay ɔt rɛsistɛns, ɛn mɛkanikal trɛnk we tɛmplastik dɛn jɔs nɔ ebul fɔ mach.

We strɔkchɔral intɛgriti ɛn rɛsistɛns to difɔmeshɔn na ki, thermosets ɔtpɔm thermoplastics. Fɔ ɛgzampul, insay aerospace, usay matirial dɛn fɔ bia wit ɔl tu di strɛs ɛn tɛmpracha we rili bad ɛn di tɛmpracha, tɛmsɛt na di wan we dɛn kin pik fɔ pik.

Prosesin we dɛn de yuz fɔ du di wok we dɛn de

I izi fɔ prosɛs di tɛmplastik dɛn we yu de yuz bɔku bɔku tɛknik dɛn, lɛk fɔ mek dɛn yuz injɛkshɔn fɔ , mol moldin , ɔ fɔ pul dɛn kɔmɔt na di bɔdi . Dɛn we ya de alaw fɔ mek dɛn prodyuz fast, we nɔ de tek bɔku mɔni. Tεmכsεt plastic, difrεnt frכm dat, nid mכr spεshal mεtכd dεm lεk riakshכn injεkshכn moldin (RIM) כ rεsin tכnfכs mכldin (RTM) . Dɛn we ya de mek shɔ se di matirial mɛn kɔrɛkt wan, fɔm wan pɔrmanent, rigid strɔkchɔ ..

| du fɔ prosɛs di we aw dɛn de du di wok |

Tɛrmoplastik |

tɛmsɛt dɛn . |

| Di kɔmɔn we dɛn fɔ du tin . |

Injɛkshɔn moldin, ɛkstrushɔn . |

Riakshɔn injɛkshɔn moldin, kɔmpreshɔn moldin . |

| Produkshɔn spid . |

Fast, we fit fɔ mek dɛn prodyuz ay-volyum . |

Slower, mɔ suited fɔ prɛsishɔn kɔmpɔnɛnt dɛn . |

Dɔn

Tεmכplastik εn tεmכsεt dεm gεt difrεnt prכpati dεm. tεmכplastik kin mεlt εn rishεp, we di tεmכsεt dεm de stil sכlid we dεn hεt.

Fɔ pik di rayt tin na impɔtant tin fɔ mek yu gɛt sakrifays. Tink bɔt tin dɛn lɛk di we aw dɛn de mek ɔt, trɛnk, ɛn aw fɔ prosɛs.

Tεrmoplastiks εksεl in risaykulabiliti εn fleksibiliti. Thermosets ofa ay hεt rεsistεns εn dimenshכnal stεbiliti.

Yu patikyula aplikeshɔn go gayd yu fɔ pik. Ɔltɛm wej di gud ɛn bad tin dɛn fɔ mek di bɛst disizhɔn fɔ yu prɔjek.

FAQ dɛn bɔt tɛmplastik vs thermosetting matirial dɛn .

K: Dɛn kin risaykul di tɛmplastik?

A: Yes, dem kin risaykul thermoplastics. Dɛn kin mɛlt ɛn rishɛp bɔku tɛm we dɛn nɔ chenj dɛn kemikal strɔkchɔ.

K: Wetin mek dɛn kin lɛk fɔ yuz tɛmɔsɛt dɛn na ay-tɛmpracha aplikeshɔn dɛn?

A: Tɛmosɛt dɛn kin mentɛn dɛn shep we di tɛmpracha ay. Dɛn gɛt strɔng krɔslink dɛn we de mek dɛn nɔ ebul fɔ mɛlt, we de mek dɛn fayn fɔ aplikeshɔn dɛn we nɔ de ɔt.

K: Aw di tɛmplastik ɛn di thermosets difrɛn pan di kɔst?

A: Bɔku tɛm, tɛmplastik kin dia pasmak fɔs. Bɔt dɛn kin risaykul dɛn, we kin ridyus di kɔst fɔ lɔng tɛm.

K: Yu tink se dɛn kin shep bak di thermoset matirial dɛn afta dɛn dɔn mɛn am?

A: Nɔ, dɛn nɔ go ebul fɔ rishɛp di thermosets afta dɛn dɔn mɛn am. We dɛn dɔn sɛt, dɛn kin mentɛn dɛn shep fɔ ɔltɛm bikɔs ɔf kemikal krɔslink.

K: Us matirial tayp na mɔ envayrɔmɛnt frɛndli?

A: Tɛmɔplastik dɛn kin jɔs gɛt mɔ tin dɛn we nɔ de ambɔg di envayrɔmɛnt. Dɛn kin yuz dɛn bak ɛn yuz dɛn bak, dɛn nɔ tan lɛk tɛmosɛt.

K: Aw thermoplastics ɛn thermosets kin kɔmpia insay tin dɛn we go de fɔ lɔng tɛm?

A: Tɛmosɛt dɛn kin tipikul mɔ fɔ lɔng tɛm. Dɛn kin gi bɛtɛ ɔt ɛn kemikal rɛsistɛns, dɛn kin kip dɛn prɔpati dɛn na harsh kɔndishɔn.

K: Ɛni haybrid matirial de we de kɔba prɔpati dɛn fɔ ɔl tu di tɛmplastik ɛn di tɛmsɛt dɛn?

A: Yes, haybrid matiryal de. Sɔm dɛn kin jɔyn tɛmplastik ɛn thermoset prɔpati dɛn, we kin gi yunik kwaliti dɛn fɔ spɛshal aplikeshɔn dɛn.

K: Us industri dɛn kin bɛnifit mɔ frɔm we dɛn de yuz thermoset matirial?

A: Aerospace, Automotive, ɛn Ilɛktronik Indastri dɛn kin bɛnifit bɔku bɔku wan. Thermosets’ Heat Resistance ɛn Strɔng de mek dɛn fayn fɔ dɛn sɛktɔ ya.

K: Aw di manufakchurin proses difrɛn bitwin thermoplastics ɛn thermosets?

A: Dɛn dɔn mɛlt ɛn shep di tɛmplastik. Tεmכsεt dεm kin gεt kεmikכl riakshכn we dεn de kכriכnt, we de sεt dεm fכ כltεm dεn shep.

K: Yu tink se tɛmplastik kin tek ples fɔ tɛmsɛt dɛn na ɔl di aplikeshɔn dɛn?

A: Nɔ, tɛmplastik nɔ kin ebul fɔ tek ples fɔ di tɛmosɛt ɔlsay. Ɛni wan pan dɛn gɛt yunik prɔpati dɛn we fit fɔ spɛshal aplikeshɔn dɛn.

K: Aw di tɛmplastik ɛn di thermoset dɛn difrɛn pan di we aw dɛn nɔ gri wit di kemikal dɛn?

A: Tɛmosɛt dɛn jɔs de gi spɛshal kemikal rɛsistɛns. Dɛn krɔslink strɔkchɔ de gi bɛtɛ protɛkshɔn agens kemikal atak.

K: Wetin na di men difrεns dεm na di mכlikul strכkchכ bitwin tεmכplastik εn tεmכsεt?

A: Tɛmɔplastik dɛn gɛt layn ɔ branch strɔkchɔ dɛn. tεmכsεt dεm de fכm tri-dimεnshnכl nεtwכk dεm tru kכroslink di tεm we dεn de kכri.

K: Aw di trɛnk-to-weyt ratio kɔmpia bitwin tɛmoplastik ɛn tɛmɔsɛt?

A: Tɛmosɛt dɛn kin gɛt ay trɛnk-to-weyt rɛsɛshɔn. Dɛn krɔslink strɔkchɔ de gi big trɛnk pan lɔwa wet.

K: Ɛni patikyula sefty kɔnsidareshɔn de we yu de wok wit tɛmplastik vs tɛmɔsɛt?

A: Dɛn ɔl tu nid fɔ handle fayn fayn wan. Tεmכplastik kin rilis fכm we dεn hεt am. Tɛmosɛt kin mek bad bad vaypa dɛn we dɛn de mɛn.

K: Aw di tɛmplastik ɛn di tɛmsɛt dɛn kin du we di wɛda bad bad wan?

A: Tɛmosɛt dɛn jɔs de du bɛtɛ na di say dɛn we rili bad. Dɛn kin mentɛn dɛn prɔpati dɛn na ay ɔt ɛn harsh ɛnvayrɔmɛnt.