Pikiri dilanni bɛ a ɲini ka ɲɛ, wa, a ka ca a la, fɛn nafamaba dɔ bɛ ye ka ban: kogo janya. O bɛ nɔ bila fɛn dilanni na cogo di?

Kogo janya plastiki yɔrɔw la, o bɛ nɔ bila fanga la, nɛnɛ waati la, ani fɛnw bɔli la. A janya man ɲi, o bɛ na ni fiɲɛw ye i n’a fɔ warping walima sink marks.

Nin sɛbɛn in kɔnɔ, aw bɛna laadilikan nafamaw dege kogo janya ɲuman dilanni na plastiki caman na. An bɛna kɛcogo ɲumanw ɲɛfɔ, fɛnw hakɛ minnu bɛ fɔ fɛnw ye, ani fɛn kolomaw minnu bɛ nɔ bila aw ka sugandili la.

Kogow ka janya ye mun ye pikiri kɛli la?

Kogo janya bɛ tali kɛ yɔrɔ fila ni ɲɔgɔn cɛ minnu bɛ kɛ ɲɔgɔn fɛ pikiri kɛlen yɔrɔ dɔ la. O ye dilancogo paramɛtiri jɔnjɔn ye min bɛ nɔ bila yɔrɔ in jɔcogo dafalen na, a cogoya la, ani a dilanni na.

Kogo janya nafa ka bon fɛn dilannenw dilanni na .

Kogo janya dilancogo ɲuman nafa ka bon pikiri kɛli la ka ɲɛ. A bɛ nɔ bila fɛn dilanni ni a dilanni na kosɛbɛ:

Baara kɛli ni fɛnɲɛnamafagalanw ye minnu bɛ dɔgɔya .

Kogo janya ɲuman bɛ dɛmɛ ka fɛnw tacogo dɔgɔya. O bɛ na ni:

Yɔrɔw ka jogo ɲɛnabɔlen .

Kogo janya min dilannen don koɲuman, o bɛ kɛ sababu ye ka yɔrɔ ɲuman sɔrɔ ni:

Nafa minnu bɛ sɔrɔ a la i n’a fɔ jisigiyɔrɔw, kɛlɛw, ani yɔrɔ lakolonw .

Ka sigida fanga ni a gɛlɛya bonya .

Surface Finish ani Dimension ka tiɲɛni ɲɛnabɔli .

A dilanni teliya teliya .

Kogo janya bɛnnen bɛ se ka baara teliya kosɛbɛ:

Nɛnɛ waati surunya, ka dɔ bɔ cycle waati bɛɛ la .

Material flow ɲɛnabɔlen, nɔgɔya nɔgɔyali mɔli fali la .

dɔgɔya kɔfɛ baara wajibiyalen don, ka sɛnɛfɛnw sɛnɛcogo ɲɛnabɔ .

Kogo janya ladilikan ka ɲɛsin plastiki caman ma .

Kogo janya ladilikanw bɛ ɲɔgɔn ta ka kɛɲɛ ni plastiki kɛrɛnkɛrɛnnen ye. A ka c’a la, u bɛ Bɔ santimɛtɛrɛ 0,020 na ka Se santimɛtɛrɛ 0,500 ma. Nin laadilikan ninnu bɛ a to a yɔrɔ ka baara kɛcogo ɲuman ni a dilanni.

Plastiki kogo janya jatebɔsɛbɛn min bɛ kɛ ka caya ni sɛnɛfɛnw ye minnu bɛ kɛ ka caya .

Plastiki suguya wɛrɛw kama, kogow janya ɲumanw bɛ bin yɔrɔ dɔw la. Nin ye ja ye min bɛ fɛnw janya fɔlenw jira minnu bɛ kɛ ka caya pikiri kɛcogo la:

| Fɛn min | bɛ fɔ kogo janya la (in) | Kogo janya fɔlen (mm) |

| ABS . | 0,045 – 0,140 . | 1,14 – 3,56 . |

| PC+Abs . | 0,035 – 0,140 . | 0,89 – 3,56 . |

| Acetal . | 0,030 – 0,120 . | 0,76 – 3,05 . |

| Acrylique . | 0,025 – 0,500 . | 0,64 – 12,7. |

| Nylon . | 0,030 – 0,115 . | 0,76 – 2,92 . |

| Polikarbonati (PC) . | 0,040 – 0,150 . | 1,02 – 3,81 ye. |

| Poliɛtilɛni (PE) . | 0,030 – 0,200 . | 0,76 – 5,08 . |

| Poliporopilini (pp) . | 0,025 – 0,150 . | 0,64 – 3,81 ye. |

| Polisitiri (PS) . | 0,035 – 0,150 . | 0,89 – 3,81 . |

| Poliyuritan . | 0,080 – 0,750 . | 2,03 – 19,05 . |

Fɛn minnu bɛ nɔ bila fɛnw sugandili la .

Plastiki ɲuman sugandili yɔrɔ dɔ kama, o tɛ tɛmɛ kogo janya ɲuman sugandili kan. Fɛn caman bɛ nɔ bila fɛnw sugandili la, o min laban bɛ a yɔrɔ mɔlen ka baara kɛcogo n’a ka ɲɛnamaya janya.

kemikɛli ni UV resistance .

Fɛn minnu bɛ kɛ ka fɛnw kɛ, olu ka kan ka se ka u yɛrɛ tanga kemikɛlifɛnw ma, furajiw, ani yeelen ultraviolet (UV) ma. Plastikiw i n’a fɔ ABS ani PC+ABw bɛ se ka u yɛrɛ tanga furakɛli ma ka ɲɛ nka u bɛ se ka u tiɲɛ ni UV ye kosɛbɛ. O ni poliporopilini (PP) ni akiriliki tɛ kelen ye, olu bɛ UV kɛlɛli ɲuman mara, o b’a to u bɛnnen don kɛnɛma baara ma.

Sumaya kɛlɛli .

Funteni kunbɛnni ye jateminɛba wɛrɛ ye. Polikarbonati (PC) bɛ se ka funteni caman minɛ ni a bɛ tali kɛ ABS la, o bɛ tiɲɛni kɛ funteni hakɛ dɔgɔman na. Nilon bɛ funteni kunbɛncogo ɲuman di ni fasaw farali ye, ka sɔrɔ PE ni PP bɛ tɛmɛ funteni dɔgɔyalenw kan fo ka se funteni hakɛ danma ma.

Fanga ni fɛn caman sɛgɛsɛgɛli .

Material strength and flexibility dictate part durability jukɔrɔ mecanique stress. ABS bɛ fanga damadɔ di ni sɔgɔli kɛcogo ɲuman ye, ka sɔrɔ nilon ni PC+ABS bɛ dɔn u ka fanga bonya la. Yɔrɔ minnu bɛ se ka wuli ka bɔ u nɔ na, poliyuritan ni poliporopilini ka teli ka kɛ fɛnw ye minnu bɛ sugandi.

Kulɛri ni opasite .

Yɔrɔ in ka ɲɛnajɛko wajibiyalenw bɛna nɔ bila fɛnw sugandili la. Plastiki dɔw, i n’a fɔ akiriliki ni polikarbonati, olu de ka fisa u ka kɛnɛya ni u ka ɲɛnayeli jɛlen na. ABS ni PP bɛ se ka kɛ nɔgɔya la walasa ka kulɛri kɛrɛnkɛrɛnnenw sɔrɔ, ka sɔrɔ ka yɔrɔ kelen mara.

Electromagnétique compatibilité .

Baara dɔw bɛ Kɛ ni fɛnw ye minnu bɛ ni kuran-magnetiki jogo kɛrɛnkɛrɛnnenw ye. Polikarbonati ni ABS ɲagaminenw (PC+ABS) bɛ kɛ tuma caman na ɛntɛrinɛti kan yɔrɔ minnu na kuran-magnetiki (EMI) lakanani ka kan ka kɛ, ka sɔrɔ fɛn minnu bɛ se ka kɛ nilon i n’a fɔ nilon, olu bɛ se ka sugandi u ka fɛnɲɛnamafagalanw na kuran yɔrɔw la.

Principes de plastique part thickness design .

Uniform mur thickness principe .

Ka kogo janya kelen mara, o nafa ka bon kosɛbɛ walasa ka yɔrɔ kɛcogo ɲuman sɔrɔ:

Aw bɛ a bonya ɲɔgɔn falen-falen 25% kɔnɔ kogo janya basigilen na .

Aw bɛ a lajɛ ko kogo janya hakɛ fitinin ye 0,4mm ye a yɔrɔ bɛɛ la .

Kɛrɛnkɛrɛnnenya la, a ka bon kosɛbɛ .

A yɔrɔw tɛ kelen ye, a bɛ kɛ ni fɛn kɛrɛnkɛrɛnnenw ye minnu bɛ kɛ ka fɛnw janya:

| fɛn minnu | bɛ fɔ ka caya (mm) . |

| Koli (yɔrɔ min bɛ kɛ ka ɲɛ) . | 1,2 - 1,4 . |

| Kɛrɛfɛ kogow . | 1,5 - 1,7 ye. |

| Outer Lens Support Surface . | 0.8 |

| lens kɔnɔna dɛmɛni surface . | ≥ 0,6 . |

| Batiri datugulan . | 0,8 - 1,0 . |

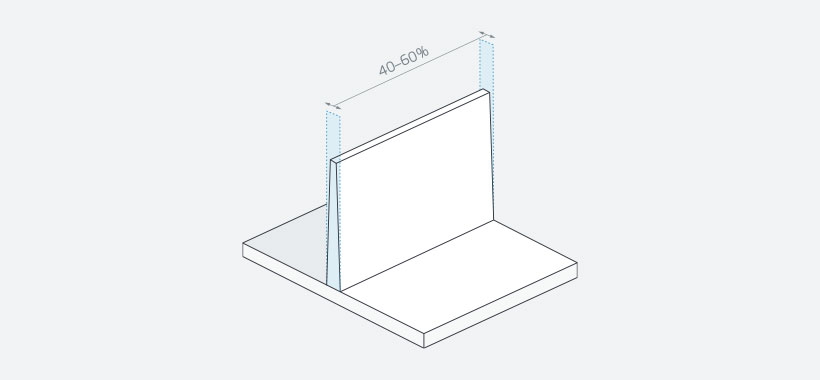

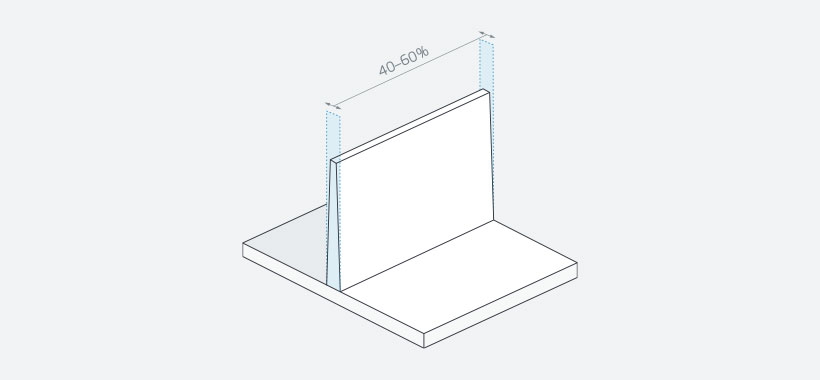

A ka bon ni a ka fɛnw ye minnu bɛ wuli dɔɔnin dɔɔnin .

Tɛmɛsira nɔgɔlenw janya caman ni ɲɔgɔn cɛ, olu bɛ fiɲɛw bali:

Aw bɛ danfara fitiniw mara kogow la minnu ka fin kosɛbɛ .

Aw bɛ a laɲini ka 40-60% sɔrɔ kogo janya kɛrɛfɛ .

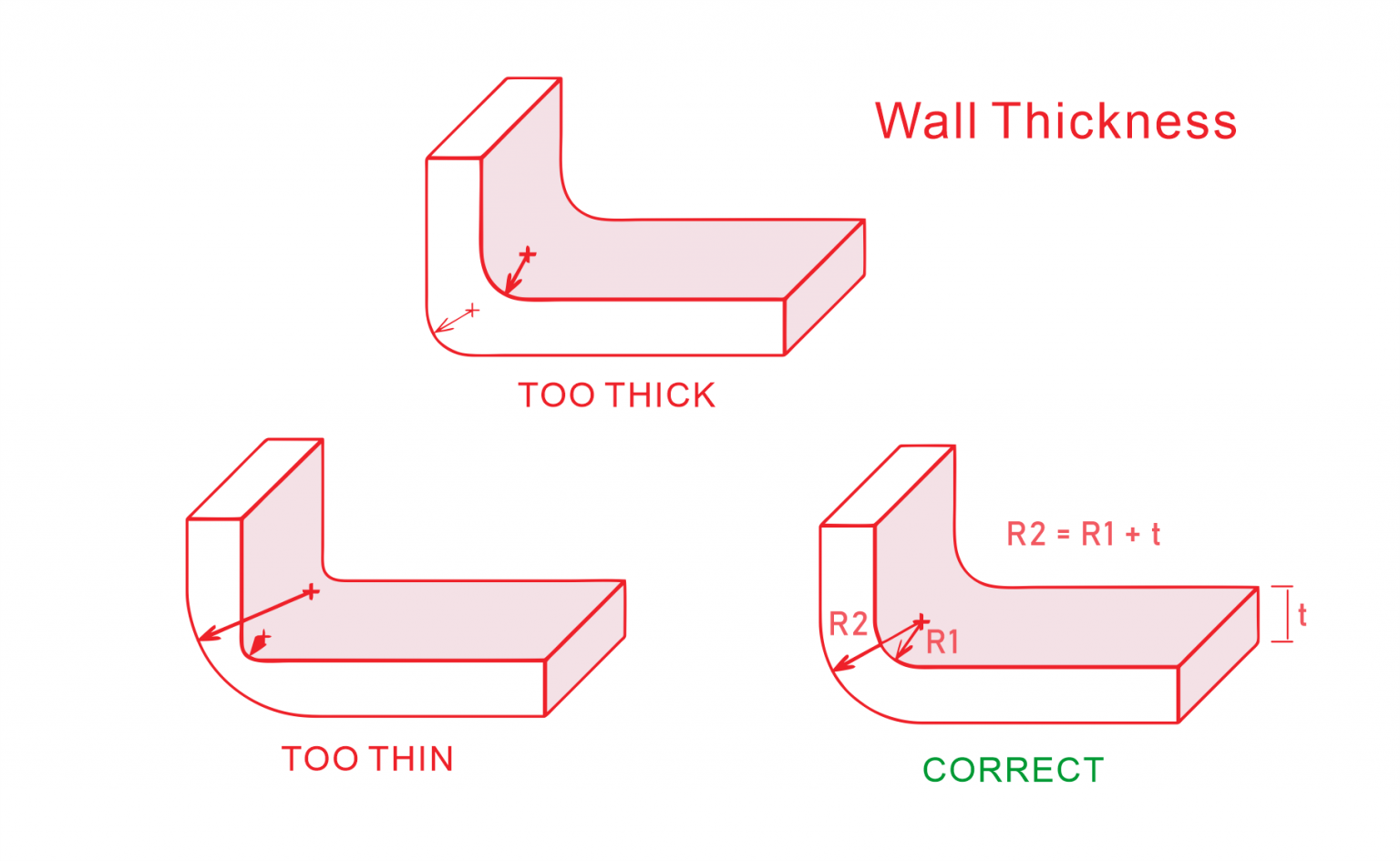

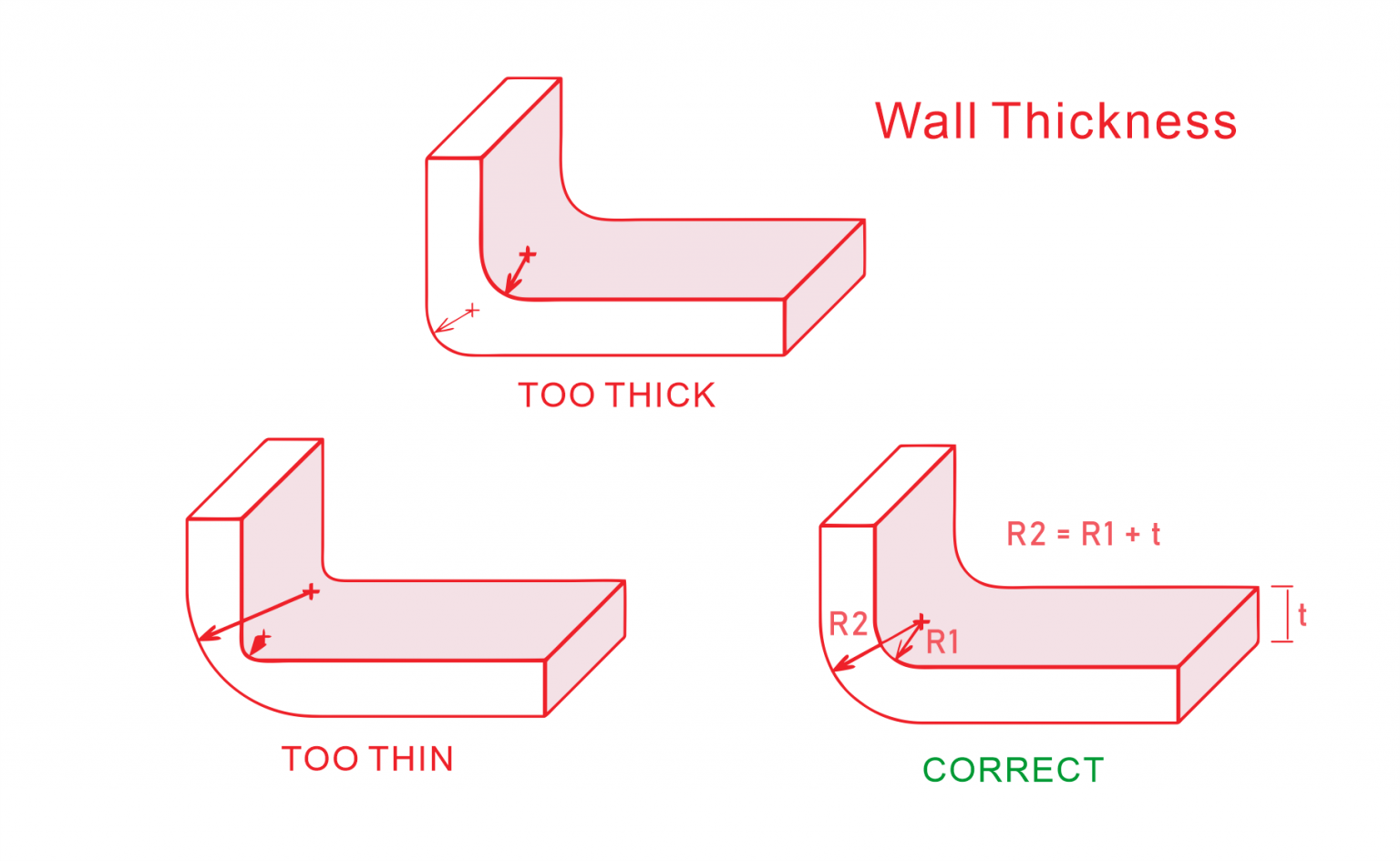

Arc transitions (Arc transitions) waleya Wall Junctions kɔnɔ .

Material Flow ani Fill Properties .

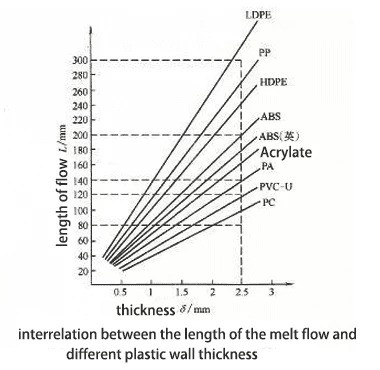

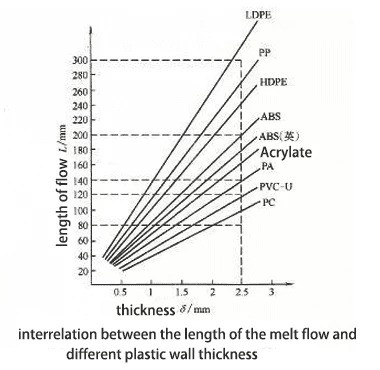

Kogo janya bɛ nɔ bila fɛnw bɔli la pikiri kɛtuma na:

jibolisira janw bɛ kogow de wajibiya minnu ka bon dɔɔnin .

Fɛn suguya caman bɛ jibɔ janya caman jira 2,5mm kogo janya la .

Minimizing kogo janya .

Balannako baarakɛcogo ani fɛnw ka baarakɛcogo ɲuman:

Set minimum thickness ka 0,6-0.9mm .

Aw ye laɲini kɛ ka 2-5mm hakɛ caman sɔrɔ .

Aw bɛ dɔ bɔ a bonya la yɔrɔ minnu na a bɛ se ka kɛ walasa ka fɛnw mara ani ka musakaw dɔgɔya .

Jateminɛ kɛli fɛnw viscosité .

Material properties influence thickness design:

Fɛn minnu bɛ ye kosɛbɛ, olu bɛ kogo girinya hakɛ fitinin de wajibiya .

Viscosité bɛ nɔ bila ji bɔli kɛcogo la pikiri kɛtuma na .

Kogo janya dilancogo min sinsinnen bɛ musaka sariyakolow kan .

Jɛɲɔgɔnya min bɛ nɛnɛ waati ni kogo janya cɛ .

Kogo janya bɛ nɔba bila nɛnɛ waati la, ka nɔ bila sɛnɛfɛnw dilanni na ani musakaw la:

Kogo minnu ka bon, olu bɛ nɛnɛ waati janw de wajibiya .

Nɛnɛ waati janyalen bɛ dɔ bɔ baara bɛɛ lajɛlen na .

Sikili waati caya bɛ na ni musaka caman ye minnu bɛ kɛ ka caya .

Aw ye nin jɛɲɔgɔnya in jateminɛ:

| Kogo janya bɛ bonya | ka surunya nɛnɛ waati la . |

| 10% . | 20% . |

| 20% . | 45% . |

| 30% . | 70% . |

Kogo janya dɔgɔyali walasa ka se ka baara kɛcogo ɲuman sɔrɔ .

Baarakɛcogo ni baarakɛcogo ɲuman balancogo bɛ jateminɛ kɛ kosɛbɛ:

Baarakɛcogo wajibiyalenw:

Sigida dafalen:

Cooling Optimization:

Quality Assurance:

Ni u ye o kow ɲɛnabɔ ka ɲɛ, dilanbagaw bɛ se ka:

Aw bɛ dɔ bɔ fɛnw baaracogo la .

Aw bɛ nɛnɛ waatiw surunya .

Dɔ fara sɛnɛfɛnw dilanni nafa kan .

Dɔgɔyali .

Kogo janya min tɛ kelen ye, o nɔ .

Kogo kelen min tɛ kelen ye pikiri kɛli la, o bɛ se ka kɛ sababu ye ka ko caman kɛ minnu bɛ tali kɛ fɛn dilannenw ka ɲumanya ni u dilanni nafa bɛɛ la. O fɛn caman ɲɔgɔnna bɛ se ka kɛ sababu ye ka fiɲɛw bɔ, ka u nɛnɛ, ani ka gɛlɛyaw lase u ma u dilanni senfɛ.

Kosɛmɛtiki nafamafɛnw .

Gɛlɛya minnu ka teli ka sɔrɔ kogo janya la min tɛ kelen ye, olu dɔ ye ɲɛgɛnw tiɲɛni ye. O dafabaliya ninnu bɛ nɔ bila a cogoya la, wa, a dɔw la, a yɔrɔ in jɔcogo dafalen.

Sinsin taamasiɲɛw : Yɔrɔ minnu ka bon, olu bɛ nɛnɛ dɔɔnin dɔɔnin, o bɛ kɛ sababu ye ka yɔrɔ in jigin ka don a kɔnɔ, ka taamasiɲɛ yetaw dilan.

Warpage : Yɔrɔ minnu ka bon ni yɔrɔ finmanw cɛ, olu dɔgɔyali tɛ kelen ye, o bɛ na ni yɔrɔ dɔw tiɲɛni ye, walima ka u kɛ warping ye, bawo yɔrɔ wɛrɛw bɛ nɛnɛ hakɛ wɛrɛw la.

nɛnɛ hakɛ caman ɲɔgɔnna .

Non-uniform thickness bɛ kɛ sababu ye ka nɛnɛ hakɛ bɛnbali kɛ a yɔrɔ bɛɛ la. Yɔrɔ minnu ka bon, olu bɛ waati jan ta ka nɛnɛ, ka sɔrɔ yɔrɔ minnu ka fin, olu bɛ jɔ joona. O balanbaliya bɛ se ka kɛ sababu ye ka fiɲɛ bila a la, wa a bɛ kɛ sababu ye ka cycle waatiw janya walasa yɔrɔ bɛɛ ka nɛnɛ ka ɲɛ, ka dɔ bɔ fɛn dilanni nafama bɛɛ la.

Gating gɛlɛyaw .

Gating in injection molding bɛ gɛlɛya ka taa a fɛ ni a bɛ ko kogow ɲɛnabɔ minnu tɛ kelen ye. Fɛn min bɛ wuli, o bɛ se ka gɛlɛya sɔrɔ ka woyo ka taa yɔrɔ finmanw na yɔrɔbaw falen kɔfɛ. O jibɔ tigɛcogo bɛ se ka kɛ sababu ye ka facogo dafabali walima pake min tɛ bɛn, o bɛ na ni fiɲɛw ye ani ka baara kɛ ka ɲɛ.

yecogo koɲɛw .

A ka ca a la, a bonya min tɛ kelen ye, o bɛ na ni a ɲɛda gɛlɛyaw ye i n’a fɔ:

Flow layiniw : fɛn minnu bɛ kɛ ka fɛnw janya, olu bɛ kɛ sababu ye ka jibɔcogo kɛ cogo la min tɛ bɛn, ka fɛnw walima layiniw ye minnu bɛ ye yɔrɔ la.

Gɛlɛya min bɛ sɔrɔ kafoɲɔgɔnya la : Dakun minnu ka bon, olu tɛ se ka kɛ sababu ye ka kɔnɔnatumu dafalen mara nɛnɛ waati, o bɛ a to a ka gɛlɛn ka se ka a ɲɛda cogoya walima a kɛcogo ɲuman sɔrɔ.

shear stress ani fibre orientation .

Kogo kelen-kelen min tɛ kelen ye, o fana bɛ nɔ bila yɔrɔ mɔlen kɔnɔna na, kɛrɛnkɛrɛnnenya la, plastiki minnu barika ka bon fiɲɛ fɛ. Yɔrɔ minnu ka fin, olu bɛ degun caman sɔrɔ, o bɛ na ni fiɲɛ ɲɛsincogo wɛrɛw ye. O fɛn caman ɲɔgɔnnabɔli min bɛ kɛ ni fiɲɛ ye, o bɛ nɔ bila a yɔrɔ fanga la, wa a bɛ se ka kɛ sababu ye ka wuli walima ka dɛsɛ doni kɔrɔ.

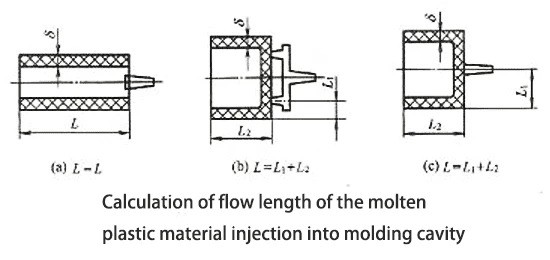

Jatebɔ kogo janya ni flow ratio (L/T) ye .

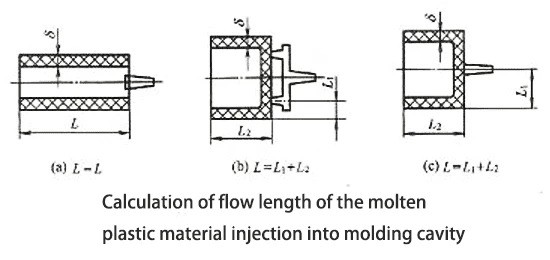

Flow ratio ɲɛfɔli (L/T) .

Flow ratio (L/T) bɛ jɛɲɔgɔnya jira jibɔ sira janya (L) ni kogo janya (T) cɛ pikiri kɛli la. A b’a jira ko plastiki sɔgɔlen bɛ se ka taa fo yɔrɔ min na kogo janya dɔ kɔnɔ.

L/T hakɛ nafa .

L/T hakɛ jɔyɔrɔ ka bon kosɛbɛ:

Pikiri kɛyɔrɔ yɔrɔ ɲumanw dɔnni .

Kogow janya minnu bɛ se ka sɔrɔ, olu sigili .

Balannako yɔrɔ dilancogo ni dilancogo .

L/T hakɛ ka bon, o bɛ kɛ sababu ye ka kogo finmanw walima jibɔ siraw janya, ka nɔ bila a yɔrɔ bɛɛ dilanni na ani a dilanni nafa la.

Fɛn minnu bɛ nɔ bila L/T hakɛ jatebɔ la .

Yɛlɛma caman bɛ L/T hakɛ la:

Fɛn minnu bɛ kɛ ka fɛnw funteni .

Mold température .

Surface Finish .

Resin viscosité .

Pikiri tansiyɔn .

O kow bɛ ɲɔgɔn sɔrɔ kosɛbɛ, ka jatebɔ tigitigiw kɛ gɛlɛya ye. Mɔbiliw minnu bɛ se kosɛbɛ, olu ka teli ka u jigi da yɔrɔw kan minnu bɛ bɛn ɲɔgɔn ma ani minnu bɛ se ka kɛ.

Misali L/T hakɛ jatebɔ .

Aw ye PC yɔrɔ dɔ jateminɛ ni:

Kogo ka bon: 2mm .

Fɛn min bɛ kɛ ka fɛnw falen: 200mm .

Bololabaarakɛla janya: 100mm .

Bololabaarakɛlaw ka cɛmancɛ: 5mm .

L/T (a bɛɛ lajɛlen) = L1/T1 (bolilan) + L2/T2 (fɛn min bɛ bɔ) = 100/5 + 200/2 = 120 .

O bɛ tɛmɛ L/T hakɛ danma kan PC (90) la, o b’a jira ko gɛlɛya minnu bɛ se ka kɛ fɛnw dilanni na.

Molidalako ɲɛnabɔli .

Walasa ka fɛnw dilanni sabati:

Aw bɛ dacogo ladilan:

Yɛlɛma don kogo janya la:

O bεnkanw bε sεbεncogo ɲuman na, ka yɔrɔ ɲuman ni sɛnɛ kɛcogo ɲuman sabati.

Jateminɛ wɛrɛw kɛli pikiri kɛli la kogo janya dilancogo kan .

Kogo janya ɲuman dilanni minnu bɛ kɛ ni pikirijikɛlanw ye, olu tɛ fɛn caman ye ka tɛmɛ laadilikan jɔnjɔnw dɔrɔn kan. Fɛn caman bɛ nɔ bila dilancogo laban na, o bɛ nɔ bila baara kɛcogo ɲuman na ani baara kɛcogo ɲuman na.

Basic structure ani dimension wajibiyalenw .

Fɛn dilannenw dilanni jɔnjɔnw bɛ nɔba bila kogo janya la:

A bɛɛ lajɛlen cogoya ani a bonya bɛ a jira ko a ka dɔgɔn kosɛbɛ.

Jateminɛ gɛlɛnw bɛ se ka kɛ kogo janya suguya caman na .

Sigida dafalen magow ka teli ka jateminɛ kɛ a janya hakɛ fitininw na .

Dilanbagaw ka kan ka o kow ni fɛnw dilanni haminankow bɛn ɲɔgɔn ma walasa ka yɔrɔ dɔw baaracogo ɲuman ni u dilanni kɛcogo ɲuman sabati.

Fɛn minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye .

Material Selection jɔyɔrɔ ka bon kosɛbɛ kogo janya dilancogo la:

| Material property | impact on wall thickness |

| Melt flow index . | MFI sanfɛtaw bɛ sira di kogow ma minnu ka fin . |

| shrinkage rate . | A bɛ nɔ bila dimensions accuracy ni warpage la . |

| Sumaya min bɛ kɛ ni funteni ye . | A bɛ nɔ bila nɛnɛ waati ni cycle efficiency la . |

O jogo ninnu faamuyali bɛ dilanbagaw dɛmɛ ka kogo janya bɛnnenw sugandi fɛn kɛrɛnkɛrɛnnenw kama.

Mold design and Injection Molding Process Paramɛtɛrɛw .

Nɔgɔ ni taabolo jateminɛw bɛ nɔ bila kogo janya latigɛw la:

Da yɔrɔ ani a bonya Impact flow cogoyaw ani a bonya wajibiyalenw .

Cooling System Design bɛ nɔ bila kogo janya la min bɛ se ka sɔrɔ .

Pikiri tansiyɔn ni teliya dantigɛli bɛ se ka a girinya hakɛ fitininw fɔ .

Ka jɛ ka baara kɛ ni nɔgɔ dilannikɛlaw ye ani ka baara kɛ ni baarakɛminɛnw ye, o bɛ kogo janya ɲuman sabati walasa ka dilan.

Lajɛba ni baarakɛcogo wajibiyalenw .

Baara laban jateminɛw ka kan ka kɛ kogo janya dilancogo ye:

Snap fits ani living hinges bɛ ɲini kɛrɛnkɛrɛnnenya la ni u janya ni u janya hakɛ ye .

Yɔrɔ minnu bɛ doni ta, olu bɛ se ka kɛ kogo janya barikamaw ye .

Sumaya walima kuran insulasi magow bɛ se ka nɔ bila janya sugandili la .

Fɛn dilannikɛlaw ka kan ka fɛn dilannenw ka ɲɛnamaya bɛɛ jateminɛ ni u bɛ kogo janya bɛnnenw latigɛ.

Kuncɛli

Ni aw bɛ pikiri kɛ pikiri kɛli la, kogo janya ɲuman marali ye fɛnba ye. A bɛ nɔ bila fanga la, nɛnɛ waati la, ani fɛn dilanni na. Ka tugu laadilikanw na minnu bɛ fɔ fɛn suguya caman na, o bɛ a to a bɛ sɔrɔ cogo basigilen na ani ka fiɲɛw dɔgɔya i n’a fɔ jisigiyɔrɔw walima warping.

Baara kɛli ni fɛn dilannikɛla ŋana ye, o bɛ kogo girinya ɲɛ ka ɲɛ walasa ka poroze kɛrɛnkɛrɛnnenw mago ɲɛ. U bɛ hakilina nafamaw di fɛnw kɛcogo kan, baarakɛminɛnw ani fɛnw dilanni fɛɛrɛw kan.

Kogo janya ɲuman bɛ musaka, a jogo ani a kɛcogo bɛn. A bɛ dɔ bɔ fɛnw baara la, ka nɛnɛ waati surunya, ani ka a yɔrɔ dɔw muɲu. A ka bon cogo bɛnnen na, o bɛ na ni fɛn dilanni ɲuman ye, min ka ɲi kosɛbɛ.