Polyamide, wanda aka sani da nailon, yana ko'ina. Daga sassan motoci zuwa kayan masu amfani, amfaninta ba shi da iyaka. An gano ta da Wallace Cantar da Katar da ke cewa, ilimin na Nylon ya sauya Kimiyya ta Kimiyya. Me yasa aka yi amfani da shi sosai? Abin ban sha'awa sanadin juriya, tsarin nauyi, da kuma kwanciyar hankali na ther therermal suna sanya shi daidai masana'antu daban-daban.

A cikin wannan post, za ku koya game da nau'ikan da suka bambanta, abubuwan da suka fi muhimmanci, da aikace-aikace masu haɓaka. Gano dalilin da ya sa aka ci gaba da filastik.

Mene ne polyamide (pa) na filastik?

Polyamide (pa) filastik, galibi ana kiranta da nailan, babbar injiniya ce mai haɓaka. An san shi ne saboda ƙarfin sa, tsoratar, da juriya ga suttura da sinadarai. Don fahimtar bambance-bambance tsakanin polyamide da nailan, zaku iya koma zuwa labarinmu a bambanci tsakanin polyamide da nailan.

Abubuwan sunadarai da tsari

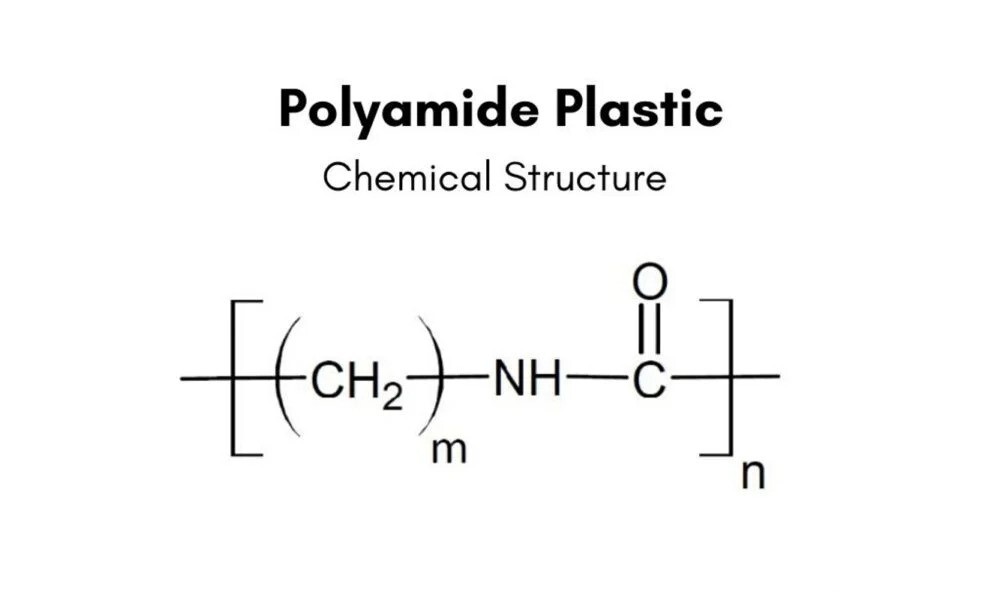

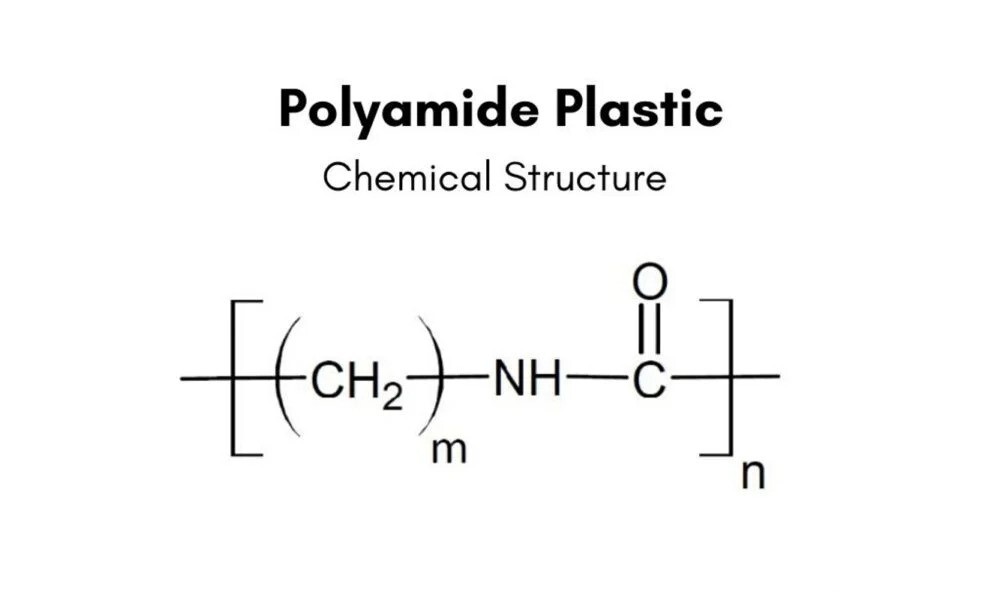

An nuna filastik na PA ta hanyar maimaita amintattu (-Konh-) a cikin tsarin kwayoyin su. Waɗannan mahaɗan suna samar da shaidu masu ƙarfi masu ƙarfi tsakanin sarƙoƙi na polymer, yana ba da kaddarorinta na musamman.

Tsarin tsari na polyamide yayi kama da wannan:

- [NH-CO-R-NH-CO-R '-] -

Anan, r da r 'suna wakiltar ƙungiyoyi daban-daban na kwayoyin, ƙayyade takamaiman nau'in pa.

Monomers da aka yi amfani da shi a cikin Production

An yi wa filayen PA suna amfani da abubuwan biyu na biyu. Wadanda suka saba sun hada da:

CAPRRROLACALAM: An yi amfani da shi don samar da PA 6

Hexamethylediamine da adipic acid: amfani da PA 66

11-Aminandecanoic acid: Amfani da shi a cikin PHA 11

Laurolactam: Amfani da PA 12

Fahimtar tsarin lamba

Koya ta yi mamakin abin da waɗancan lambobin a cikin nau'in pax ɗin ke nufi? Bari mu karya shi:

Lamba ɗaya (misali, PA 6): Yana nuna adadin carbon atom a cikin monomer

Lambar sau biyu (misali, PA 66): yana nuna carbon atoms a kowane ɗayan moniya biyu da aka yi amfani da su

Hanyoyin Hanyar Polyamide (PA) Filastik

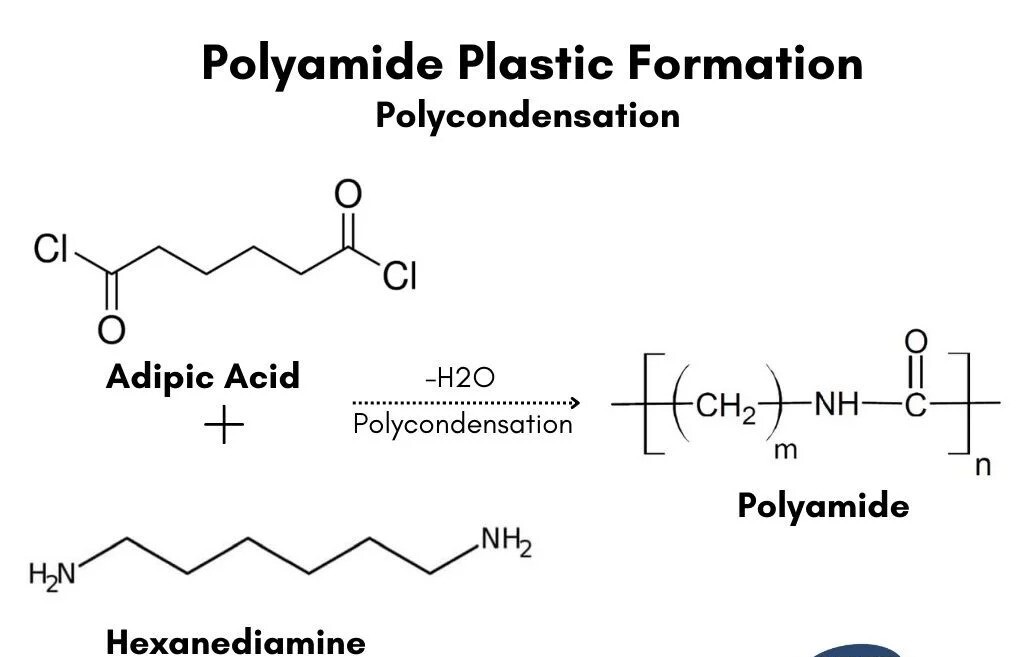

Polyamide (pa) robobi, ko nylons, an samar da su ta hanyar hanyoyin polymerization daban-daban, kowannensu yana shafar dukiyoyinsu da amfani. Hanyoyi biyu na yau da kullun sune kayan kwalliyar polymerization da zobmin zobe. Bari mu bincika yadda waɗannan ayyukan ke aiki.

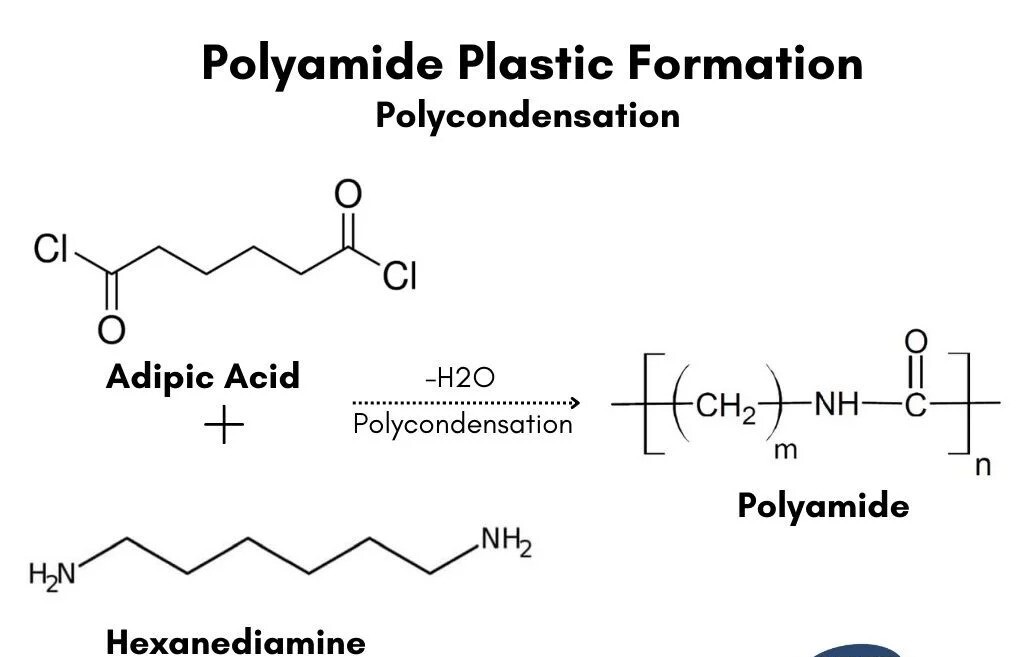

Polymerization polymerization

Wannan hanyar tana kama da rawar sunadarai tsakanin abokan hulɗa guda biyu: dicids da kuma kumburi. Suna amsawa ƙarƙashin takamaiman yanayi, rasa ruwa a cikin tsari. Sakamakon? Dogon sarkar polymers.

Ga yadda yake aiki:

Diacids da dialanis sun gauraye a sassa daidai.

Ana amfani da zafi, yana haifar da amsa.

Ana fito da kwayoyin da ruwa (bushewa).

Polymer sarƙoƙi da girma ya fi tsayi.

A dauki ci gaba har sai an sami tsawon sarkar da ake so.

Babban misali na wannan hanyar shine samar da PA 66. An yi shi ne ta hanyar hada Hexamethylediamine da adipic acid.

K.

Madaidaicin iko akan tsarin polymer

Ikon ƙirƙirar nau'ikan pau

In mun gwada da sauki tsari

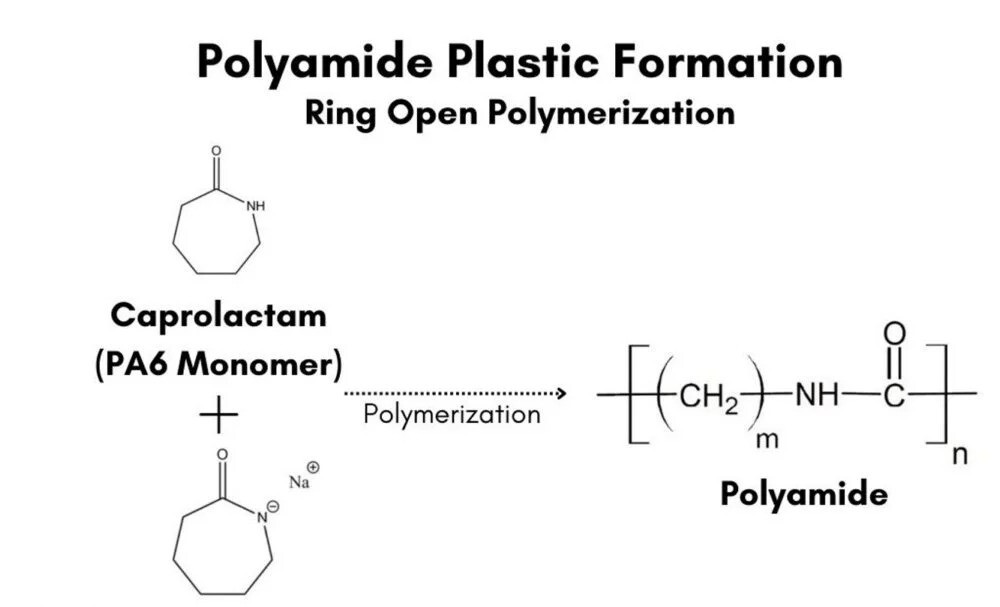

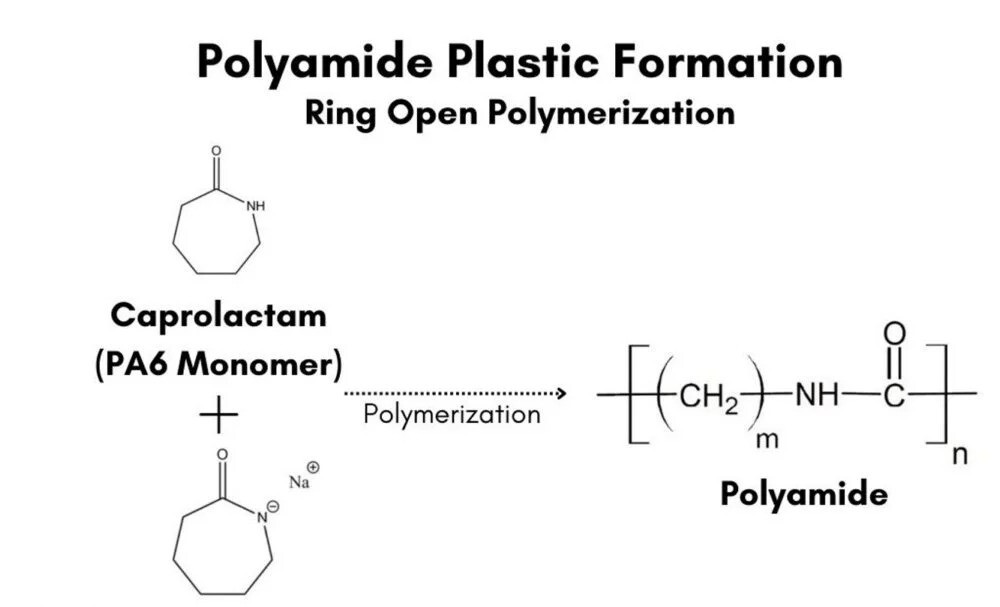

Bude-bude polymerization

Wannan hanyar kamar ba a haɗa da'irar kwayoyin halitta ba. Yana amfani da abubuwan tunawa na cyclic, kamar COPROLOCOCACK, don ƙirƙirar filastik.

Tsarin ya shafi:

Zafafa da monomlic monomer (misali, comrolactam na PA 6).

Ƙara mai kara kuzari don hanzarta.

Karya bude tsarin zobe.

Haɗa zoben da aka buɗe don samar da sarƙoƙin polymer mai tsayi.

Bugun bude ido yana da amfani musamman ga ƙirƙirar PA 6 da PA 12.

Abbuwan wannan hanyar wannan hanyar sun hada da:

Babban tsarkakakken samfurin na ƙarshe

Ingantaccen amfani da albarkatun kasa

Ikon ƙirƙirar nau'ikan pain

Duk hanyoyin biyu suna da ƙarfin su na musamman. Zabi ya dogara da nau'in pair da ake so kuma aikace-aikacen da aka nufa.

Nau'in Polyamide (pa) filastik

Alamu Polyamide (PA) masu takaici sun zo a cikin nau'ikan daban-daban, kowace baiwa ta musamman kaddarorin da suka danganta da tsarin kwayoyin halitta. Wadannan nau'ikan ana rarrabe su cikin alippatic, semi-mai aromatic, da kuma polyamid polyamid. Bari mu nutse cikin nau'ikan nau'ikan iri.

Aliphatic Polyamides

Waɗannan sune nau'ikan pau na yau da kullun. An san su da yawa saboda yawan aikace-aikacen aikace-aikace.

PA 6 (Nylon 6)

PA 66 (Nylon 66)

Samar daga hexamethylediamine da adipic acid

Mafi girma narke fiye da PA 6 (255 ° C VS 223 ° C)

Babban saboda Aikace-aikacen Zazzabi

PA 11 (Nylon 11)

PA 12 (Nylon 12)

PA 6-10 (Nylon 6-10)

PA 4-6 (nylon 4-6)

Mafi girma narke a tsakanin alkama na polyamides (295 ° C)

Banda Thermal da Kayan Aiki

Sau da yawa ana amfani dashi a aikace-aikace na babban aiki

Polyamid polyamid polyamIces (polyphthamles, PPA)

Ppas Bridge rata tsakanin alippatic da ƙanshi polyamids. Suna bayarwa:

Polyamid polyamides (aramids)

Wadannan babban aiki na polyamids suna yin fahariya:

Mashahurin raruma sun hada da Kevlar da Nomex.

Ga sauri kwatanta na Properties Maballin:

| Paƙarin | Melting Point (° C) | na shayarwa | danshi |

| PA 6 | 223 | M | M |

| PA 66 | 255 | M | M |

| PA PAR 11 | 190 | M | M |

| PA 12 | 178 | M | M |

| PPA | 310+ | M | Da kyau sosai |

| Sumaids | 500+ | M | M |

Kaddarorin polyamide (pa)

| dukiyar filastik | Alifatic Polyamides | Semi-Aromatic polyamides | polomatic polyamid polyamides |

| Sa juriya | Babban, musamman a PA 66 da PA 6. | Sama da alkhaphatic pas. | Kyakkyawan yanayi a cikin matsanancin yanayi. |

| Kwanciyar hankali | Mai kyau, har zuwa 150 ° C (PA 66). | Mafi kyau, har zuwa 200 ° C. | Na kwarai, har zuwa 500 ° C. |

| Ƙarfi | Da kyau, ana iya inganta shi da flurer. | Sama da alkhaphatic pas. | Mafi girma sosai, amfani da aikace-aikacen neman. |

| Tauri | Da kyau sosai, PAL 11 da PA 12 suna sassauƙa. | Mai kyau, mafi tsauri. | Low, sai dai idan an gyara shi. |

| Tasiri karfi | Babban, musamman a PA 6 da PA PAR 11. | Mai kyau, dan kadan kadan fiye da alkhaphatic pas. | Low, sai dai idan an gyara shi. |

| Saɓani | Yara, mai kyau ga aikace-aikacen zamewa. | Kadan, da kyau don ɗaukar mahalli. | Low, ficewa karkashin damuwa. |

| Juriya na sinadarai | Da kyau, musamman ma a PA 11 da PA 12. | Fifita ga aliphatic pas. | Madalla da hankali, mai girma. |

| Danshi karin danshi | High a PA 6/66, ƙananan a PA 11/12. | Low, barga cikin zafi. | Sosai low, mai matukar resistant. |

| Alamar lantarki | Madalla da yawa, amfani da yawa. | Mai kyau, dan kadan kadan. | Madalla, ana amfani da shi a cikin tsarin aiki. |

| Injin inji | Mai kyau, musamman ma a PA 6 da PA na 11. | Matsakaici, dacewa da amfani da tsarin tsari. | Matalauta, sai dai idan an gyara. |

| Sling Properties | Da kyau, musamman a PA 6 da PA 66. | Madalla, ingantacciyar hanyar sarrafa abubuwa. | Na kwarai a karkashin damuwa. |

| Zafi juriya | Har zuwa 150 ° C (PA 66), sama da gyare-gyare. | Mafi kyau, har zuwa 200 ° C. | Fice, har zuwa 500 ° C. |

| UV juriya | Low, PA 12 tana buƙatar canji don amfanin waje. | Matsakaici, mafi kyau fiye da alkhaphatic pas. | Low, yana buƙatar ƙari. |

| Harshen Wuta | Za a iya gyara don yarda. | A zahiri mafi harshen wuta-resistant. | Sosai harshen wuta. |

| Ado mai kyau | Sauran don ɗaukar danshi, barga a PA 11/12. | Mafi girma, low danshi sha sha. | Madalla, mai rauni sosai. |

| Abrasion juriya | Babban, musamman a PA 66 da PA 6. | Fiye da maki na alkhairi. | Na musamman, da kyau ga babban gogayya. |

| Gajiya juriya | Da kyau a aikace-aikace masu tsauri. | Mafi girma, musamman karkashin damuwa. | High, amfani da shi a tsawon lokaci, yana da matukar damuwa. |

Gyare-gyare zuwa polyamide

Za'a iya gyara abubuwan shakatawa na polyamide (pa) don haɓaka dukiyoyinsu don takamaiman aikace-aikace. Bari mu kalli wasu gyare-gyare na gama gari.

Gilashin Fiber

Ana ƙara fiber gilashi don inganta ƙarfi, taurin kai, da kuma ingantaccen kwanciyar hankali na farawar Pa. Wannan gyara yana da amfani musamman ga aikace-aikacen mota da masana'antu, inda karuwar karkara yana da mahimmanci.

| Sakamako | amfana |

| Ƙarfi | Ƙara yawan ɗaukar nauyi |

| Tauri | Ingantaccen m |

| Ado mai kyau | Rage shrinkage da warping |

Carbon fiber Verforment

Dingara carbon fibers yana inganta kaddarorin kayan aikin da kuma yanayin aikin polyamids. Wannan ya dace da matakai masu yawa na aikin da ke fuskantar damuwar ko zafi, kamar kayan aikin Aerospace.

| Sakamako | amfana |

| Injiniya | Ingantacciyar juriya ga dorormation |

| A halin da ake yi na thereral | Mafi kyawun diski |

Madrict

Mutunwa suna rage tashin hankali da inganta sa juriya a aikace-aikacen kamar yadda aka ɗauka. Ta hanyar rage tashin hankali, PAR PAR na iya cimma nasarar yin aiki da rabi na rayuwa.

| Sakamako | amfana |

| Ragewar da rikici | Inganta sa juriya |

| Aikin Saduwa | Ƙara yawan aiki da kuma tsawon rai |

UV Tafata

UV Tantar tatto m fadi da karkowar polyamides a cikin yanayin waje ta kare su daga lalata ultviolet. Wannan yana da mahimmanci ga aikace-aikacen waje kamar masu kare kansa ko kayan aiki na waje.

| Sakamako | amfana |

| UV juriya | Tsawan karancin waje |

| Rage lalata | Mafi kyawun aiki a ƙarƙashin bayyanar hasken rana |

Harshen Rage

Flame rets ya tabbatar polyamides sun cika ka'idodin aminci na wuta a sassan da ke lantarki da motoci. Wannan gyaran ke da ya dace don amfani a cikin mahalli inda juriya kashe kashe kashe kashe kashe kashe kashe kashe kashe wuta abu ne mai mahimmanci.

| Sakamako | amfana |

| Flame juriya | Aminci a cikin zafi-zafi ko yankunan wuta |

| Yarda | Ya gana da ka'idojin amincin masana'antu |

Tasirin Tasiri

Masu gyara masu tasowa suna kara wahala na polyamids, yana sa su mafi tsayayya ga fatattaka damuwa a karkashin damuwa mai tsauri. Wannan gyaran yana da amfani musamman musamman a aikace-aikace inda sassan sun maimaita tasirin, kamar a cikin kayan wasanni ko injuna ko injuna.

| Sakamako | amfana |

| Ya kara karuwa | Mafi kyawun jure tasirin da fatattaka |

| Ƙarko | Tsabtace rayuwa a cikin yanayin tsauri |

Hanyoyin sarrafawa don polyamide (pa) filastik

Polyamide (pa) Za a iya sarrafa filastik ta amfani da hanyoyi daban-daban, kowannensu ya dace da aikace-aikace daban-daban. Bari mu bincika manyan dabarun aiki.

Allurar gyara

Ana amfani dashi sosai don samar da sassan saboda kyakkyawan yanayin da ya gudana da karfin gwiwa. Tsarin yana buƙatar iko da zazzabi, bushewa, da yanayin m.

Zazzabi : PAR 6 tana buƙatar narke zazzabi na 240-27 ° C, yayin da PA 66 yana buƙatar 270300 ° C.

Bushewa : bushewa da kyau yana da mahimmanci don rage rage danshi a ƙasa 0.2%. Danshi na iya haifar da lahani kamar alamomin splay da rage kaddarorin na inji.

Mold zazzabi : da kyau zafin jiki mold rerian daga 55-80 ° C, ya danganta da pa na PA na PA da kuma kayan ƙira.

| PE GYuciya | narkewar zazzabi da | ake | bushewa |

| PA 6 | 240-270 ° C | <0.2% danshi | 55-80 ° C |

| PA 66 | 270-300 ° C | <0.2% danshi | 60-80 ° C |

Don ƙarin cikakkun bayanai game da sigogi na allurar allura, zaku iya samun labarinmu akan aiwatar da sigogi don sabis na siyarwa na taimako.

Earmust

Harami ne wata hanyar gama gari don sarrafawa PA, musamman don ƙirƙirar ci gaba kamar shambura, bututu, da fina-finai. Wannan hanyar tana buƙatar takamaiman yanayi don maki mai kyau na viscous na polyamides. Don fahimtar bambance-bambance tsakanin cirewa da allurar rigakafi, zaku iya nufin kwatancenmu na allurar allura vs vs Ertrusion Budurwa.

| parameter | shawarar da aka ba da shawarar saitin |

| Dunƙule l / d rabo | 20-30 |

| PA 6 sarrafawa zazzabi | 240-270 ° C |

| PA 66 sarrafa zazzabi | 270-290 ° C |

3D Buga

Sevelarfin Laser suna ɗaukar hoto (SLS) sanannen dabarar buga 3D ne ga polyamids. Yana amfani da laser don amfani da kayan pan kayan pan na SCORET by Layer, ƙirƙirar ƙungiyoyi da kuma ainihin sassa. Sls ya dace da prototying da mitarancin girma saboda kawar da bukatar molds. Don ƙarin bayani kan bugu na 3D da yadda yake sawanta hanyoyin masana'antun gargajiya, bincika labarinmu a kan Wasan buga 3D ya buga da allurar rigakafi.

Fa'idodi : Sls yana ba da damar ƙirƙirar ƙirar ƙira, yana rage sharar gida, kuma yana da sauƙaƙe sosai ga sifofin al'ada.

Aikace-aikace : saba amfani da kayan aiki, Aerospace, da Masana'antu, da masana'antu na kiwon lafiya don saurin fastowa da sassa masu aiki.

| 3D Bugawa | fa'idodi |

| Zabi Laser Wiewer (sls) | Babban daidaito, babu Mots da ake buƙata |

Don ƙarin bayani game da fasahar sauya yanayin fasahar, zaku iya samun labarinmu a kan Waɗanne halaye na masana'antar masana'antu na masana'antu masu amfani.

Siffofin jiki na samfuran polyamide (pa)

Polyamide (pa) kayayyakin sun zo a cikin nau'ikan jiki daban-daban. Kowane nau'i yana da halaye na musamman da aikace-aikace. Bari mu bincika siffofi daban-daban da girma dabam na PA:

M

Pellets sune mafi yawan nau'ikan pa

Su ƙanana ne, silili ne, ko kuma disk

Pellets yawanci auna 2-5mm a diamita

An yi amfani da su da farko don tafiyar matakai

Powders

Pewararrun pa suna da girman barbashi, mai fita daga 10-200 microns

Ana amfani dasu a aikace-aikace daban-daban, kamar su:

Granules

Granules sun fi girma fiye da pellets

Sun auna 4-8mm a diamita

Granules suna da sauƙin ciyarwa cikin masarufi masu wucewa idan aka kwatanta da powders

Suna inganta kayan aikin halitta yayin aiki

Aikace-

Pa za a iya yin mashin da ke cikin siffofi da yawa

Siffofin gama gari sun hada da sanduna, faranti, da sassan da aka tsara

Wadannan siffofi an kirkira su ne daga kayan pa

Suna ba da cikakken aiki don takamaiman aikace-aikace da zane

| canje na | girman | aikace-aikace |

| M | 2-5mm diamita | Allurar gyara |

| Powders | 10-200 microns | Mogin Molding, shafi na 3s bugu |

| Granules | 4-8mm diamita | Tsarin aiki |

| Daskararre | Daban-daban na al'ada siffofin | Abubuwan da aka gyara da ƙirar musamman |

Aikace-aikacen Polyamide (pa) filastik

Polyamide (pa) Filastik ne mai ma'ana, yana tabbatar da shi da mahimmanci a masana'antu daban-daban. Ƙarfinsa, juriya na sinadarai, da kuma dorewa suna ba da fa'idodi a yawancin mahalli masu buƙata.

Masana'antu

A cikin bangaren mota, ana amfani da polyamide don abubuwan da yawa masu mahimmanci. Abubuwan injiniyoyi, tsarin mai, da kuma insultors masu bautar lantarki suna dogara ne da filastik saboda tsananin zafinsa, ƙarfi, da karko.

| aikace na aikace-aikace | Aikace- |

| Abubuwan injiniyoyi | Zafi juriya, ƙarfi |

| Tsarin man fetur | Chrismes na sunadarai, ƙarancin rauni |

| Masu bautar lantarki | Lantarki na lantarki, kwanciyar hankali |

Aikace-aikace masana'antu

Saitunan masana'antu suna amfani da juriya na polyamide da ƙananan abubuwan ɓatarwa. Biyu, gears, bawuloli, da kuma seals da aka yi daga pa mun dawwama, rage tashin hankali, kuma yin abubuwa da kyau a cikin yanayin damuwa.

| aikace na aikace-aikace | Aikace- |

| Ashe da gears | Saka juriya, low gogayya |

| Bawuloli da seals | Sinadaran da aka juriya |

Kayan masarufi

Daga kayan aiki zuwa kayan gida na yau da kullun, ana amfani da polyami sosai don tauri da sassauci. Abubuwa kamar tennis raket da kayan kitchen suna amfana da ƙimar kuɗi da sauƙi na sarrafawa.

| aikace na aikace-aikace | Aikace- |

| Kayan aiki | Tauri, sassauƙa |

| Abubuwan Gida | Karkatarwa, sauƙin gyara |

Lantarki da lantarki

A cikin Wutar lantarki, an kimanta polyames don allurar rufin gida. Ana amfani da su a cikin haɗi, Switches, da kuma rufe inda rufi da rufi suna da mahimmanci.

| aikace na aikace-aikace | Aikace- |

| Haɗi da sauya | Alamar lantarki, Resistance Heather |

| M | Ƙarfi, jurewar sunadarai |

Masana'antar abinci

Polyamides abinci polyamids ba shi da haɗari ga hulɗa tare da abinci kuma ana amfani da shi a cikin marufi, mai karaya belts, da sassan kayan masarufi. Wadannan kayan suna ba da kyakkyawan juriya na sunadarai da ƙarancin danshi.

| aikace na aikace-aikace | Aikace- |

| Kafa abinci abinci | Chrismance Chememe, amintacciyar lamba |

| Isar belts | Karkatarwa, juriya danshi |

Kwatanta polyamide (pa) filastik tare da wasu kayan

Polyamide (pa) filastik yana fitowa don haɗuwa ta musamman ta ƙarfinsa, sassauci, da juriya na sinadarai. Ga yadda yake kwatanci ga sauran kayan yau da kullun.

Pa filastik vs. polyester

Polyamide da polyester duka biyu ne roba, amma suna da manyan bambance-bambance. Pa yana ba da kyakkyawan ƙarfi da kuma juriya na tasiri, yayin da Polyester ya fi tsayayya da shimfiɗa kuma ya ragewa. PA ya sha ruwan danshi fiye da polyester, wanda ke shafar kwanciyar hankali a cikin yanayin laima.

| Kayan | Polyamide (PA) | Polyester |

| Ƙarfi | Sama | Matsakaici |

| Tasiri juriya | M | Saukad da |

| Danshi karin danshi | M | M |

| Miƙanta | Saukad da | Sama |

Pa filastik vs. polypropylene (PP)

Pa tana da ingantattun kaddarorin kayan aikin da aka kwatanta da polypropylene (PP), kamar karfi da karfi da sanya juriya. Koyaya, PP yana da mafi girman juriya na sinadarai, musamman da acid da alkalis. Pa yana da zafi-resistant, yayin da pp an san shi da sassauci da sauƙi mai nauyi.

| Polyamide | dukiya (PA) | Polypropylene (PP) |

| Ƙarfi | Sama | Saukad da |

| Juriya na sinadarai | Mai kyau, amma rauni ga acid | M |

| Zafi juriya | Sama | Saukad da |

| Sassauƙa | Saukad da | Sama |

Pa filastik vs. Polyethylene (PE)

Polyamide yana ba da ƙarfi mafi girma da juriya da zafi idan aka kwatanta da polyethylene (pe). PE ya fi sassauci kuma yana da mafi kyawun juriya na danshi, yana sa ya dace don kayan tattarawa. Pa, a gefe guda, fice a aikace-aikacen da ke buƙatar ƙwararrun injin da ƙarfin hali. Don fahimtar bambance-bambance tsakanin nau'ikan PE, zaku iya koma zuwa labarinmu akan Bambanci tsakanin HDPE da LDPE.

| Polyamide | Polyamide (pa) | polyethylene (pe) |

| Ƙarfi | Sama | Saukad da |

| Zafi juriya | Sama | Saukad da |

| Sassauƙa | Saukad da | Sama |

| Tsabtace danshi | Saukad da | M |

Pa filastik vs. Metals (Aluminum, Karfe)

Duk da yake karnuka kamar kayan alumini da ƙarfe sun fi ƙarfi, Pa filastik yana da sauƙi mai sauƙi kuma mafi sauƙin aiwatar. Pa shine rauni-dillisant kuma ba ya buƙatar gyaran iri ɗaya kamar karuwa a cikin mahalli marasa galihu. Metals sun fi dacewa da aikace-aikacen da ke buƙatar matsanancin ƙarfi da ƙarfin ɗaukar nauyi, yayin da Pa fice a cikin rage nauyi da ƙara sassauƙa. Don kwatancen tsakanin karafa daban-daban, zaku iya samun labarinmu akan titanium vs aluminum mai ban sha'awa. Polyamide

| dukiya | (pa) | aluminum | karfe |

| Ƙarfi | Saukad da | M | Sosai babba |

| Nauyi | Low (nauyi) | Matsakaici | M |

| Juriya juriya | M | M | Matalauci |

| Sassauƙa | Sama | Saukad da | Saukad da |

Don ƙarin bayani kan kayan ƙarfe da kadarorinsu, zaku iya duba jagorarmu akan daban-daban na metals.

Ƙarshe

Polyamide (pa) Ra'ayoyin halitta suna da bambanci, miƙa ƙarfi, juriya da zafi, da karko. Waɗannan halaye suna sa su mahimmanci a cikin injiniyan zamani da masana'antu. Ko an yi amfani da shi a cikin mota, lantarki, ko aikace-aikacen masana'antu, manyan farawar masana'antu suna ba da ingantaccen aiki.

Lokacin zaɓar nau'in pa na pa, la'akari da takamaiman buƙatun kamar ƙarfi, sassauƙa, da juriya na muhalli. Kowane pa aji aji na musamman ne don aikace-aikace daban-daban, tabbatar da abubuwan da suka dace don aikin.

Tukwici: Kai mai son sha'awar dukkanin robobi