Yu dɔn ɛva wɔnda aw plastic pat dɛn kin de fayn fayn wan we dɛn nɔ gɛt skru ɔ glu? Riveting de gi yu wan sɔlv we yu go abop pan. Insay dis gayd, wi go fɛn ɔl di impɔtant tin dɛn we de na plastic rivet, in minin na difrɛn industri dɛn, ɛn aw fɔ pik di rayt we. Yu go lan di ins ɛn ɔuts fɔ rivet plastic pat fɔ strɔng, durable kɔnɛkshɔn.

Wetin na plastic riveting?

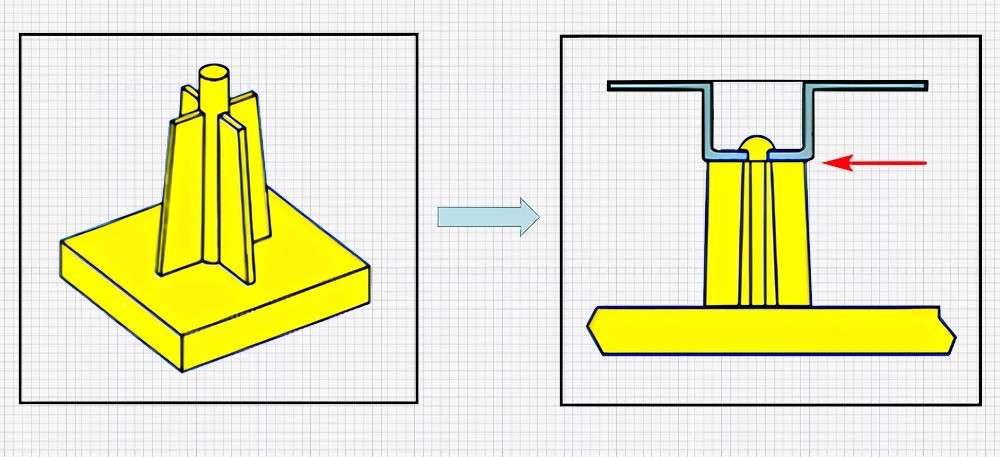

Plastik rivetin na wan mɛkanikal fastɛns we dɛn de yuz. I involv fɔ yuz akshal fɔs fɔ difɔm di shank fɔ wan rivet insay wan ol. Dis de mek wan ed, we de kɔnɛkt bɔku pat dɛn.

We yu kɔmpia am to mɛtal rivetin, plastic riveting gɛt sɔm impɔtant difrɛns dɛn. I nɔ nid ɔda rivet ɔ post dɛn. Bifo dat, i de yuz plastic strɔkchɔ dɛn lɛk kɔlɔm ɔ rib. Dem na pat of di plastic bodi.

Advantej ɛn prɔblɛm dɛn we de wit plastic rivetin .

Plastik rivetin gɛt sɔm bɛnifit ɛn prɔblɛm dɛn. Mek wi tek wan klos luk.

Di bɛnifit dɛn we pɔsin kin gɛt:

Simpul pat strɔkchɔ, we de ridyus di kɔst fɔ mold .

I izi fɔ Asɛmbli, dɛn nɔ nid fɔ yuz ɛkstra tin dɛn ɔ fastɛns dɛn we dɛn nɔ nid

Ay rilaybiliti .

kin rivet bɔku bɔku pɔynt dɛn wan tɛm, impruv efyushɔn .

jɔyn plastic, mɛtal, ɛn pat dɛn we nɔ gɛt mɛtal, ivin na tayt ples dɛn

Witstand fɔ lɔng tɛm vaybreshɔn ɛn ekstrim kɔndishɔn dɛn .

Simpul, ɛnaji-sɛvin, fast prɔses

I izi fɔ inspekshɔn fɔ di kwaliti we pɔsin kin si .

Kɔmɔn prɔblɛm dɛn:

I nid fɔ gɛt ɔda tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn gɛt nyu tin dɛn ɛn fɔ yuz tul dɛn .

Nɔ fayn fɔ ay-strɛng ɔ lɔng tɛm lod .

Pɛrmanɛnt kɔnɛkshɔn, nɔto detachable ɔ repairable

I at fɔ mek dɛn ripɛnt am if i nɔ wok .

May nid ridandans in dizayn faz .

| Advantej |

Disadvantej |

| Simpul strɔkchɔ, lɔw mold kɔst . |

Nid dɛn fɔ gɛt ɛkstra ikwipmɛnt ɛn tul dɛn . |

| Easy asembli, ay rilaybiliti . |

Nɔto fɔ ay-strɛng ɔ lɔng tɛm lod . |

| Join difrɛn matirial dɛn fayn fayn wan . |

pɔrmanent, nɔto detachable ɔ ripɛntabl |

| I ebul fɔ bia wit di vaybreshɔn ɛn di kɔndishɔn dɛn we rili bad . |

Hard fɔ ripɛnt, kin nid fɔ ridandans . |

| Simpul, fast, ɛnaji-sɛvin prɔses . |

- |

| I izi fɔ chɛk di kwaliti dɛn we pɔsin kin si . |

- |

Di kayn plastic dɛn we dɛn kin yuz fɔ mek dɛn gɛt plastic rivet .

Tri men kayn plastic riveting prɔses de. Dɛn na hot mɛlt rivetin, hot ɛya rivɛt, ɛn ɔltrasɔnik rivɛtin.

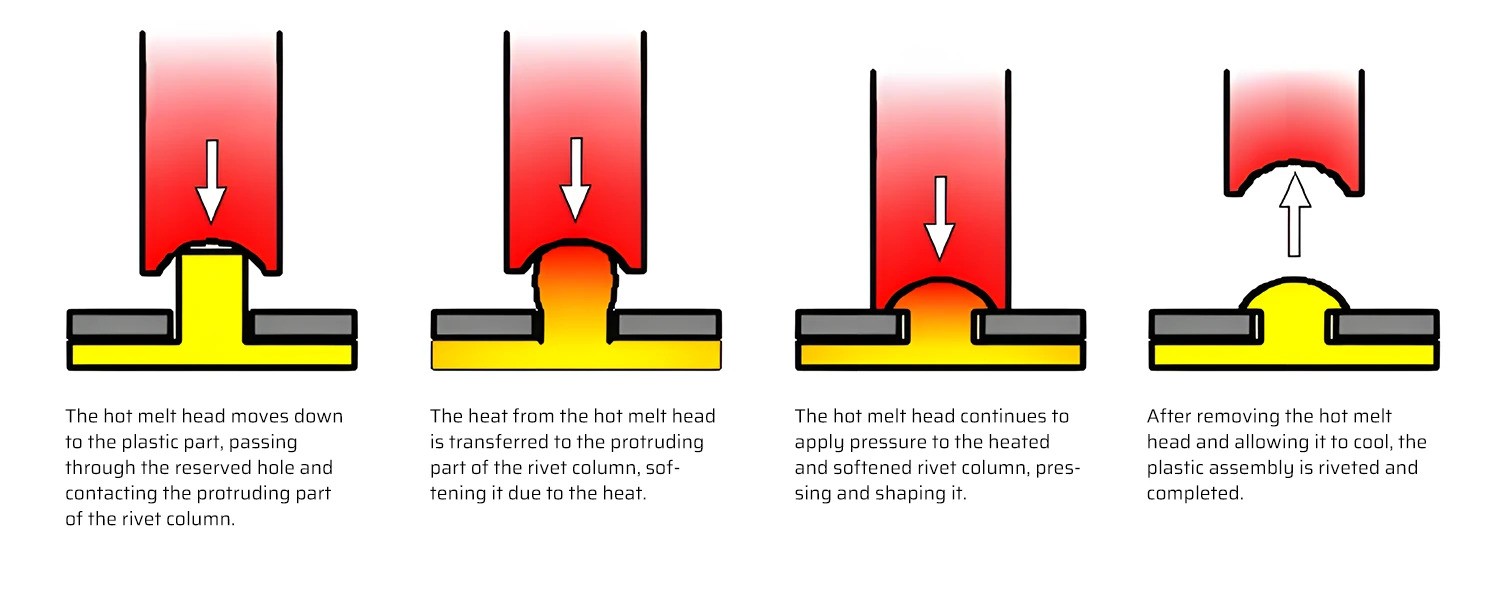

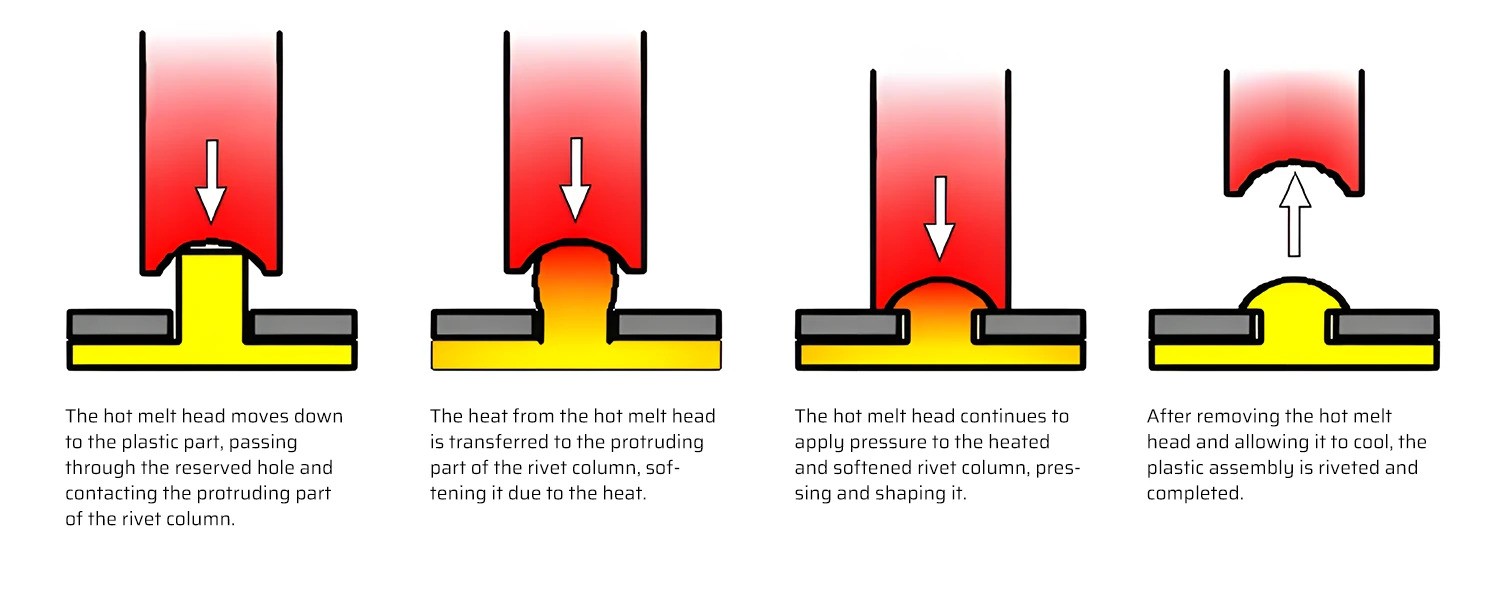

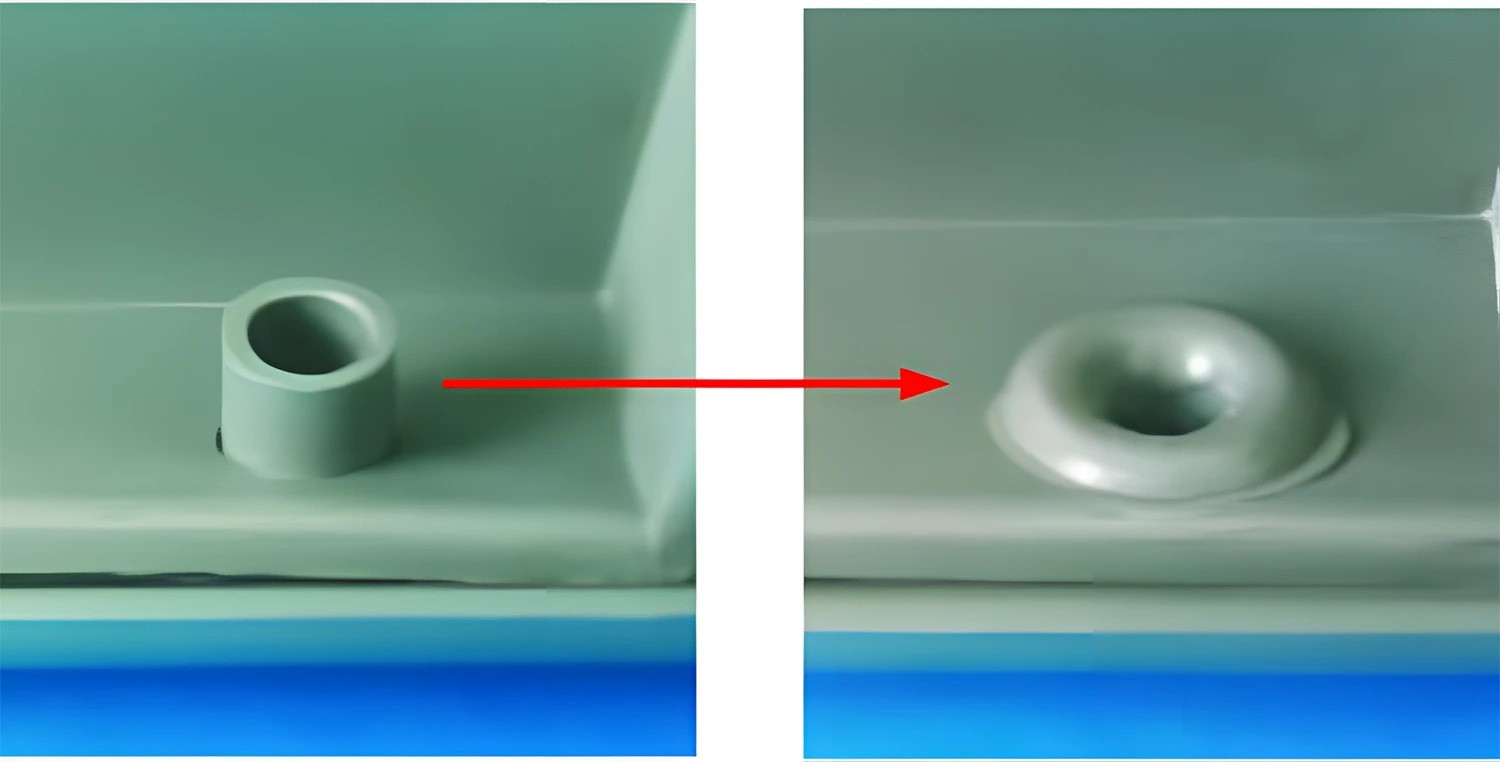

Hot melt rivetin .

Hot Melt Riveting na wan kɔntakt-tayp prɔses. I involv wan itin tiub insay di rivetin ed. Dis kin mek di mɛtal rivetin ed wam, ɛn afta dat i kin mɛlt ɛn shep di plastic rivet.

Di bɛnifit dɛn we pɔsin kin gɛt:

Di bad tin dɛn we pɔsin kin du:

If yu nɔ kol bɛtɛ, dat kin mek plastic stik to ed .

Nɔ fayn fɔ big Rivet kɔlɔm dɛn .

High residual strɛs ɛn lɔwa pul-ɔut trɛnk

Nɔ rɛkɔmɛnd fɔ prɔdak dɛn we gɛt ay pozishɔn/fikseshɔn rikwaymɛnt dɛn .

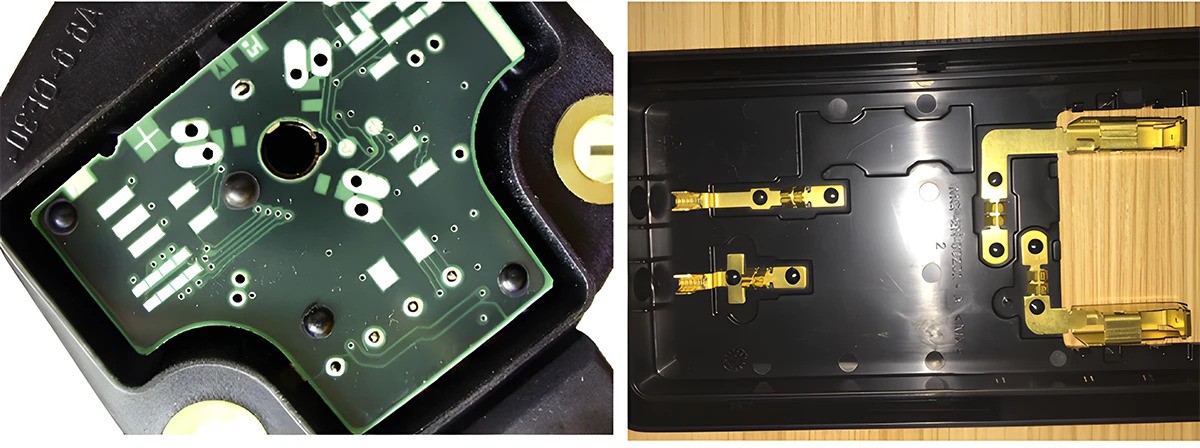

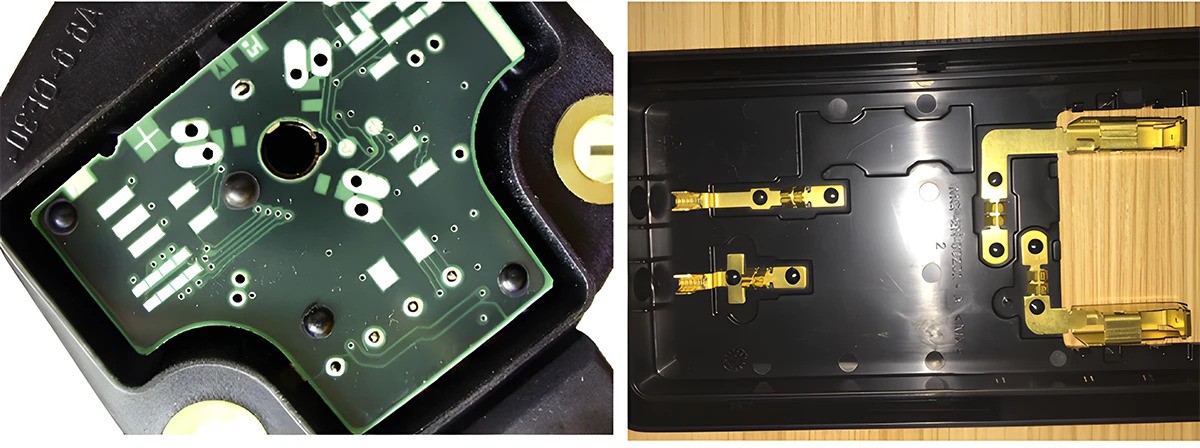

Hot melt riveting na tin we dɛn kin yuz fɔ PCB bod ɛn plastic dɛkɔretiv pat dɛn.

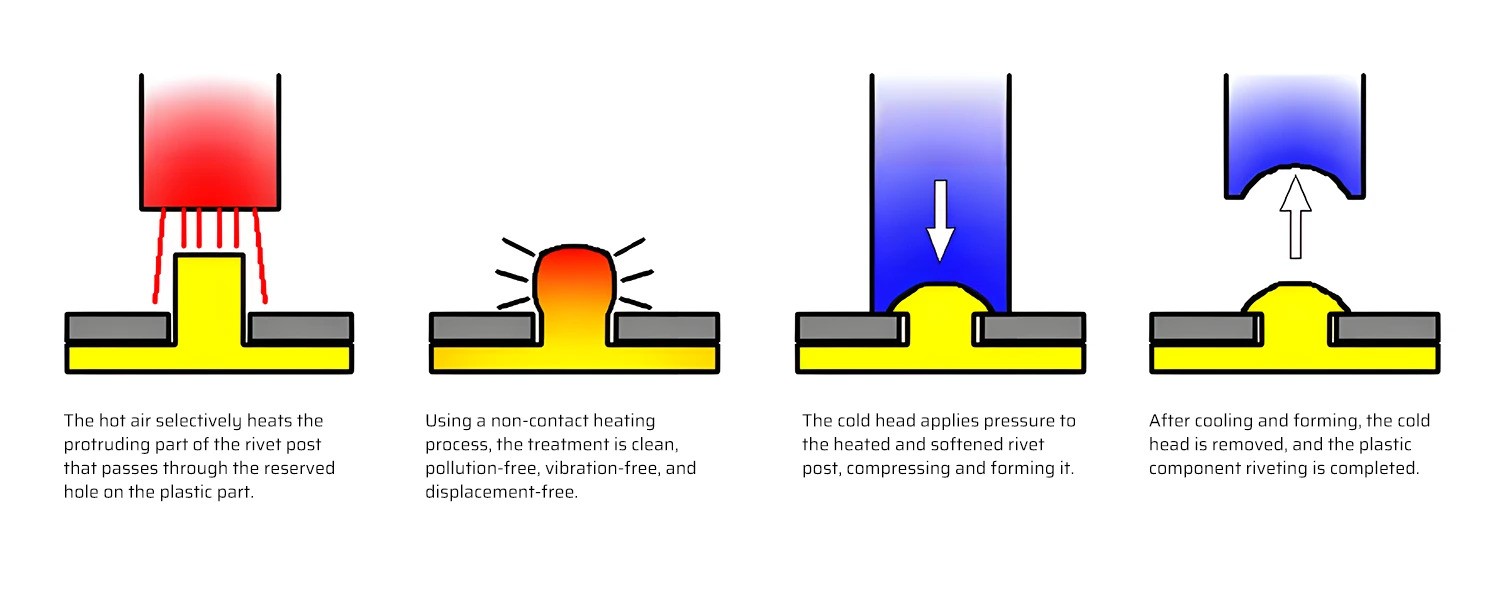

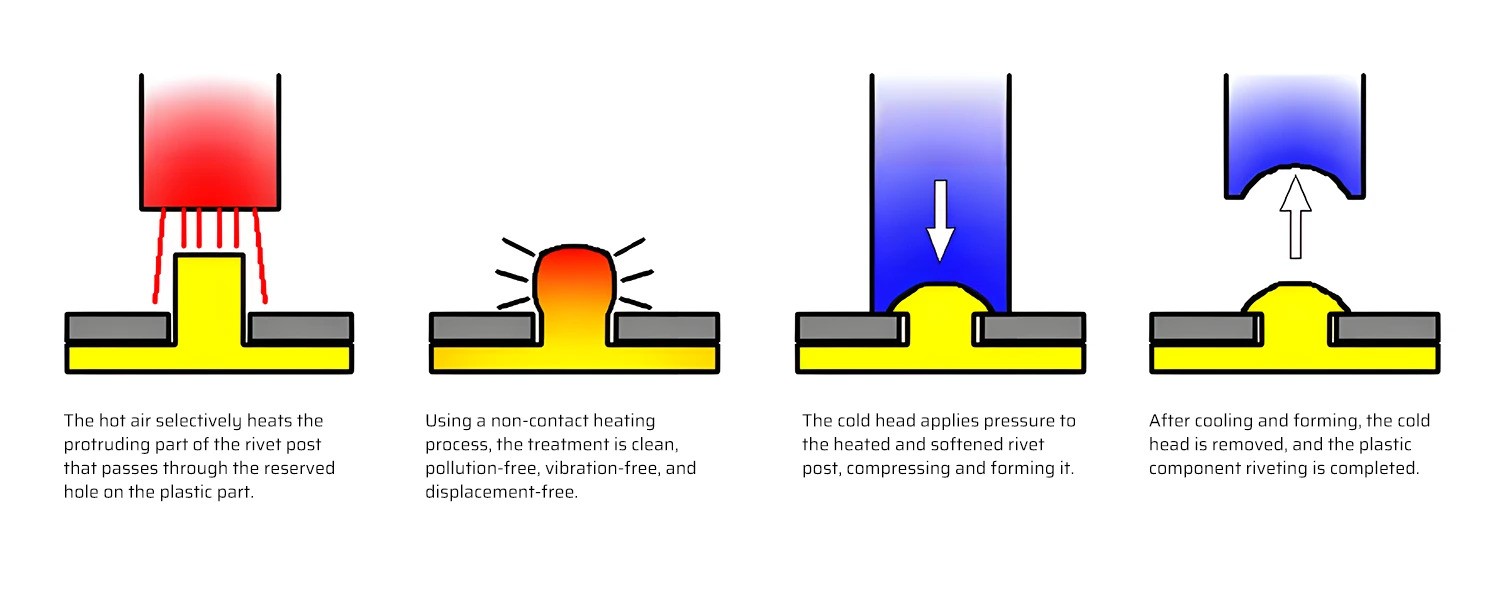

Hot air riveting (hot air kol riveting)

Hot air riveting na wan nɔ-kɔntakt prɔses. I de yuz ɔt ɛya fɔ wam ɛn sof di plastic rivet kɔlɔm. Dɔn, wan kol rivetin ed de pres ɛn shep am.

Di prɔses gɛt tu stej dɛn:

Itin: Hot air yunifomli hot di rivet kolm te i malleable.

Kul: Di kol riveting ed de pres di soft kolm, we de fom wan fayn ed.

Di bɛnifit dɛn we pɔsin kin gɛt:

Yunifɔm itin de ridyus intanɛnt strɛs .

Kol rivetin ed kwik kwik wan ful gap, achiv wan gud fiksin effekt

Di bad tin dɛn we pɔsin kin du:

Hot Air Riveting na fayn tin fɔ bɔku pan di tɛmplastik matirial dɛn ɛn glas fayba riinfɔs plastic dɛn.

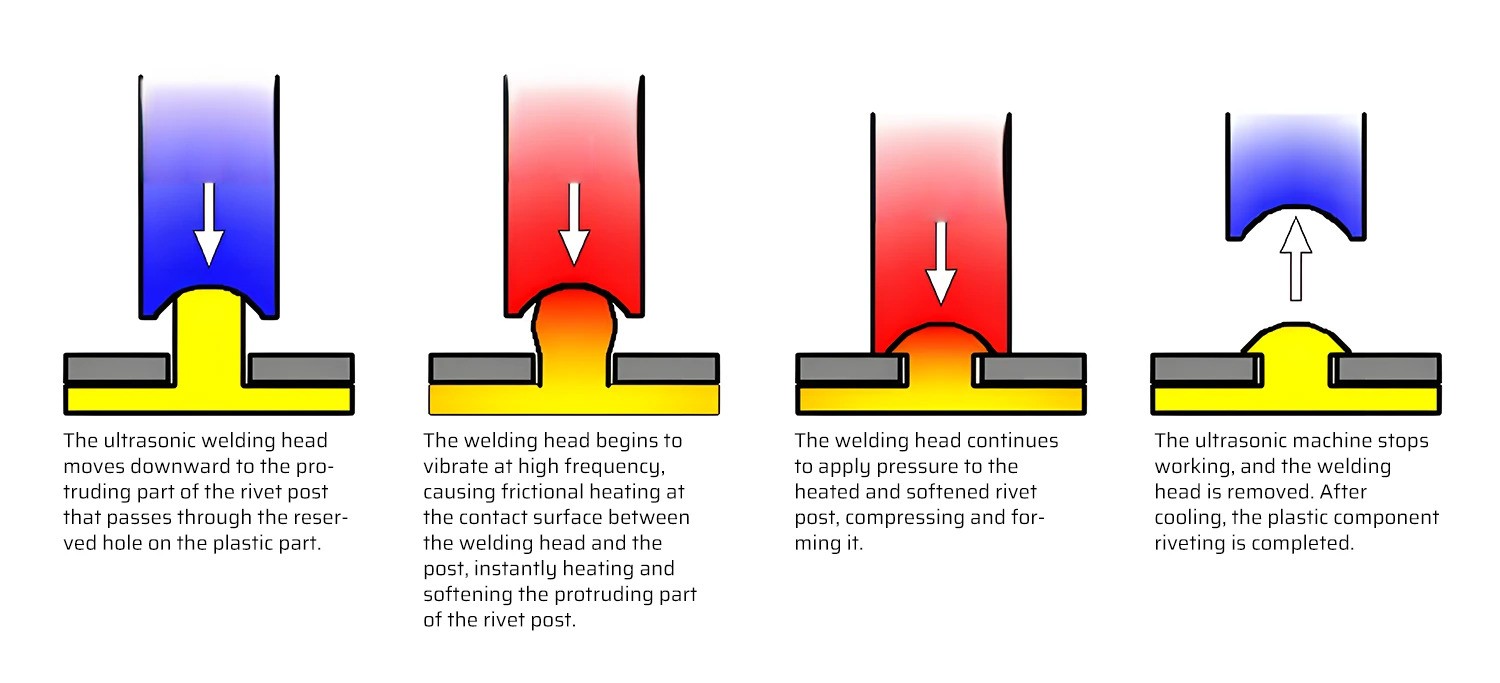

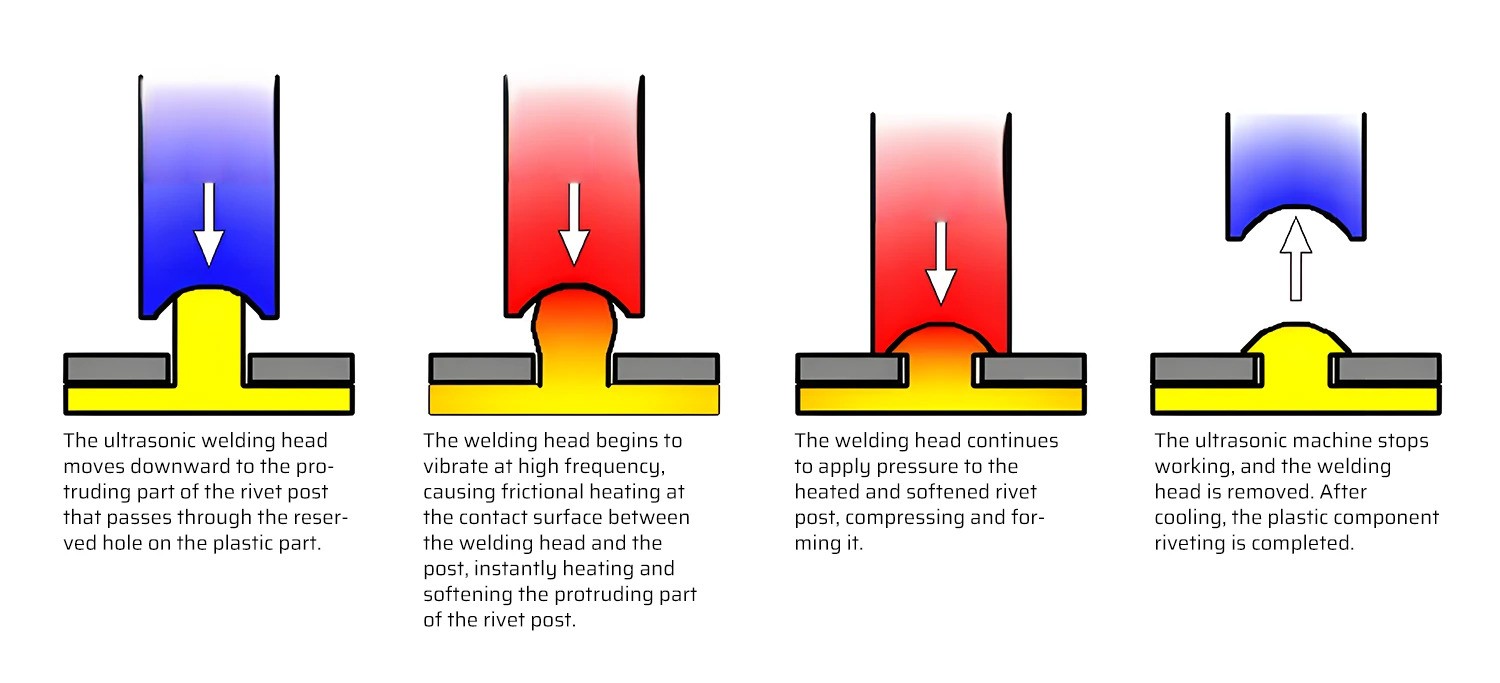

Ultrasonic rivetin na di .

Ultrasonic riveting na wan ɔda kɔntakt-tayp prɔses. I de yuz ay-frikyuɛnsi vaybreshɔn fɔ mek i gɛt ɔt ɛn mɛlt di plastic rivet kɔlɔm.

Di bɛnifit dɛn we pɔsin kin gɛt:

Di bad tin dɛn we pɔsin kin du:

If yu nɔ ivin ɔt, dat kin mek di kɔlɔm dɛn we nɔ gɛt ɔ we dɔn pwɛl ɔ we dɔn pwɛl .

Limited distribushɔn distans if yu de yuz wan singl wɛldin ed .

Vaybreshɔn kin pwɛl di kɔmpɔnɛnt dɛn to wan patikyula say .

Ultrasonic riveting nɔ fayn fɔ glas fayba matirial ɔ di wan dɛn we gɛt ay mɛlt pɔynt.

Na dis na wan kɔmpiashɔn tebul fɔ di tri prɔses dɛn:

| Prɔses |

Itin we |

Riveting Strength |

Fixing Effect |

Equipment |

Flexibility |

| Hot Melt we de na di . |

Kɔntakt (Mɛtal Ɛd) . |

Unreliable, sɛnsitiv to vaybreshɔn . |

Defective bikɔs ɔf inkɔmplit softin . |

6-60 dɛn |

Integreted, Kɔmpleks Chenj Ɔva . |

| Hot Air . |

Nɔn-kɔntakt (Hot Air) . |

ay, nɔ sɛnsitiv to vaybreshɔn . |

Eksɛlɛnt, kɔmplit wan ful-ɔp gap dɛn . |

8-12 dɛn |

Adjustable heating ɛn rivetin . |

| Ultrasonik we yu go yuz . |

Kɔntakt (vaybreshɔn) . |

Nɔbɔdi nɔ go abop pan am . |

Defective bikɔs ɔf inkɔmplit softin . |

<5s dɛn |

Limitɛd kɔntrol wit intagreted ed . |

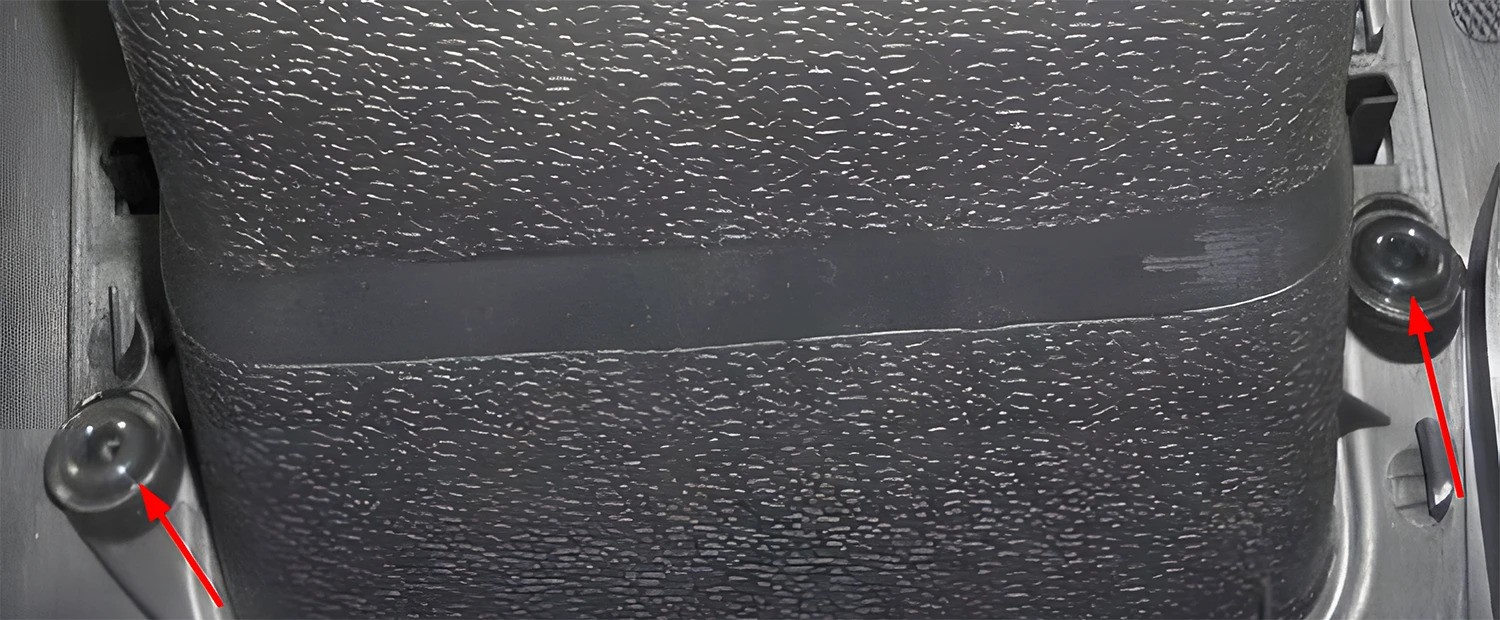

Kɔmɔn Rivet ed tayp fɔ plastic pat dɛn .

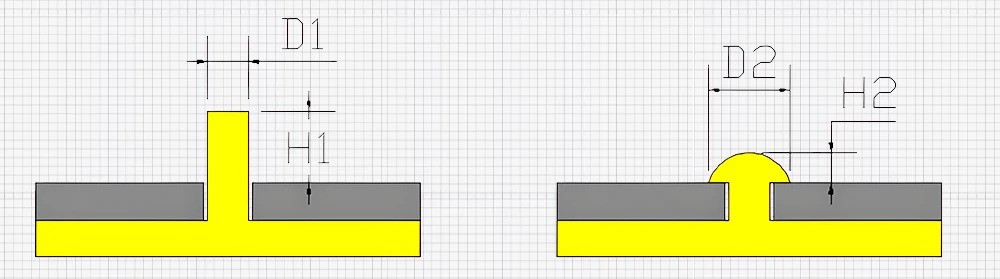

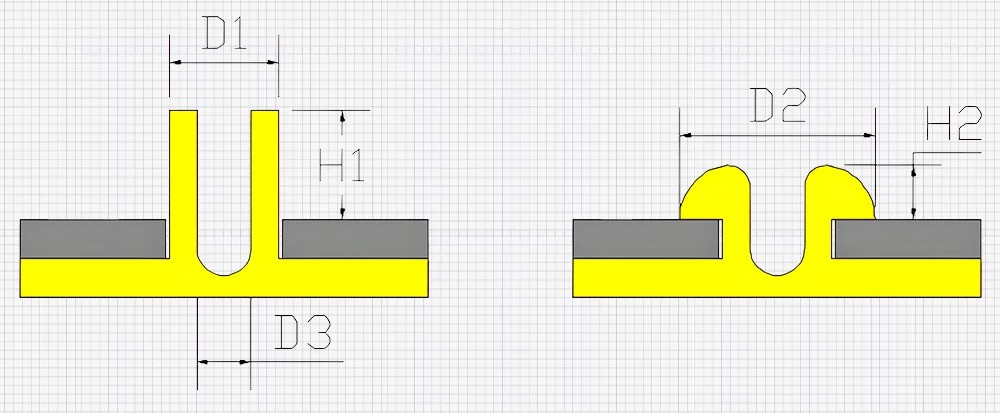

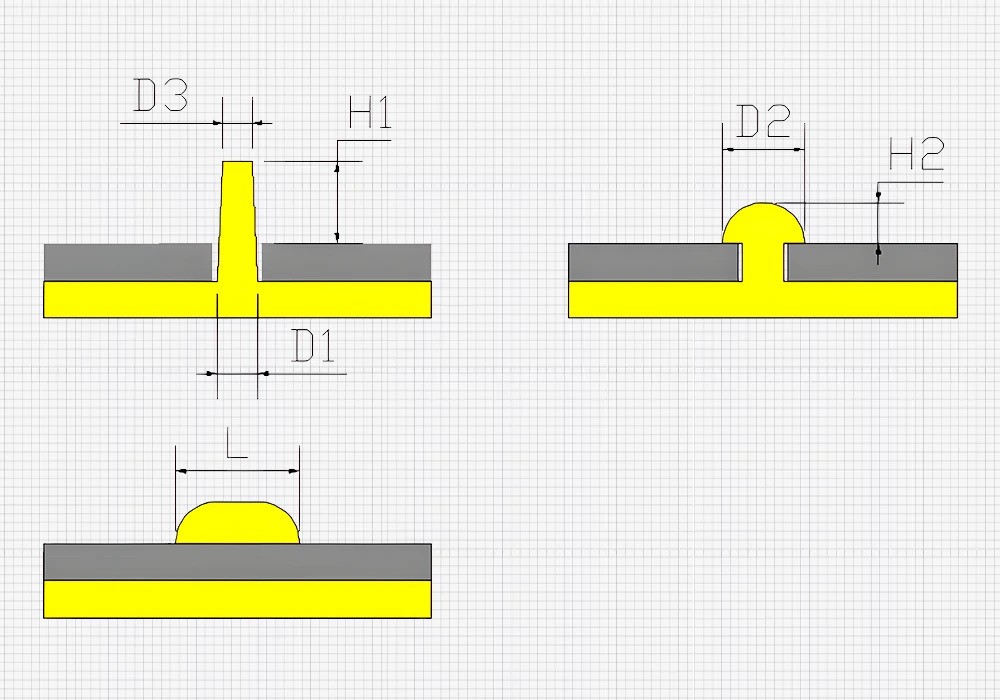

We i kam pan plastic riveting, di jɔyometri ɛn dimɛnshɔn fɔ rivet ed dɛn rili impɔtant. Lɛ wi tek wan luk pan sɔm kɔmɔn kayn dɛn.

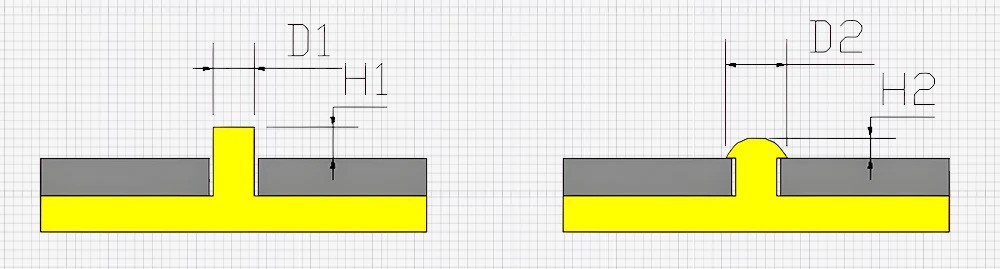

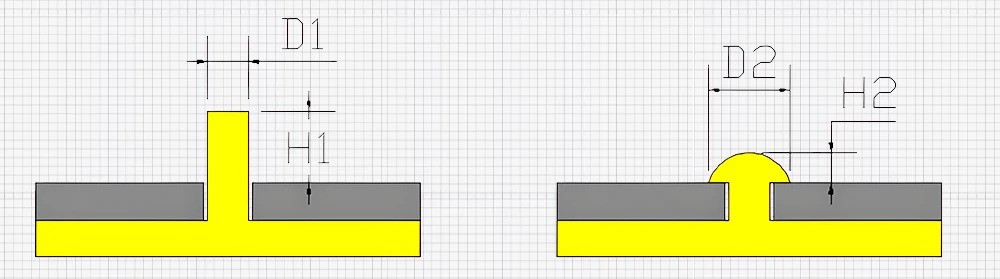

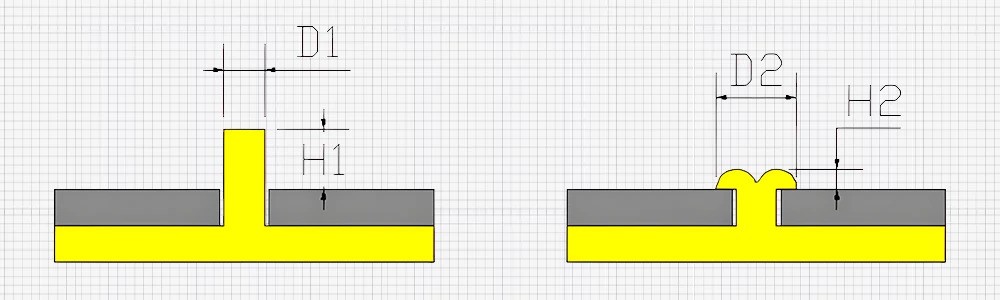

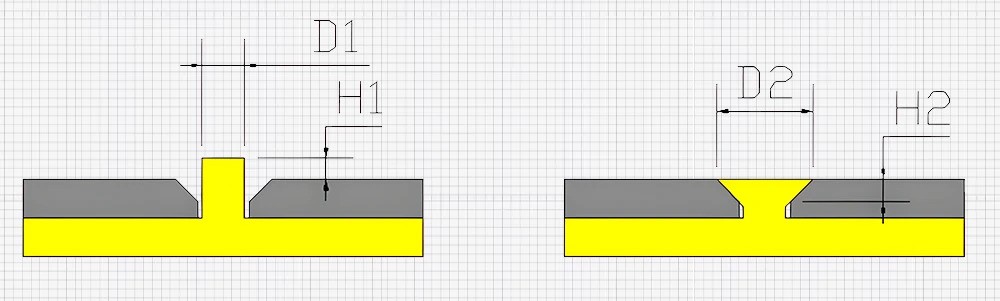

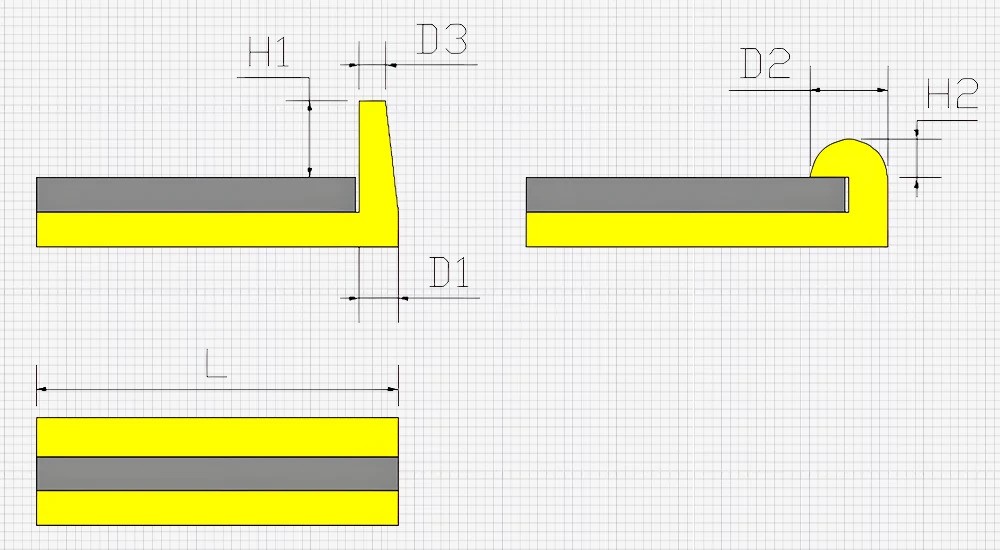

1. Semi-sɛkɔral rivet ed (big prɔfayl)

Dis na di kayn we we dɛn kin yuz mɔ. I de yuz we dɛn nɔ nid ay trɛnk, lɛk na PCB ɔ dekɔretiv pat.

Ki pɔynt dɛn:

Suitabl fɔ rivet kɔlɔm dɛn wit D1 < 3mm (ideally > 1mm fɔ mek dɛn nɔ brok)

H1 na jɔs (1.5-1.75) * D1.

D2 na arawnd 2 d1, H2 na lɛk 0.75 d1.

Spesifi k nɔmba dɛn we dɛn bays pan volyum kɔnvɛnshɔn: S_head = (85%-95%) * S_COLUMN

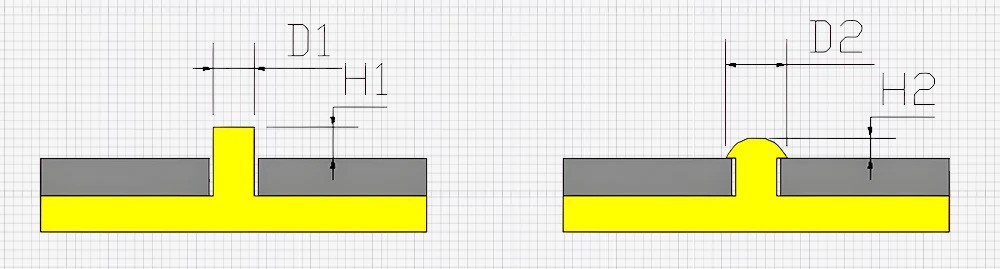

2. Semi-sɛkɔral rivet ed (smɔl prɔfayl)

Dis kayn gɛt shɔt tɛm fɔ rivet pas di big prɔfayl. I de bak fɔ lɔw-strɛng aplikeshɔn, lɛk FPC kebul ɔ mɛtal spring.

Dizayn Tin dɛn fɔ Tink bɔt:

D1 < 3mm, preferably > 1mm

H1 na nɔmal wan 1.0 * D1.

D2 na 1.5 d1, H2 na around 0.5 d1.

Volyum konvεshכn: S_HEAD = (85%-95%) * S_COLUMN

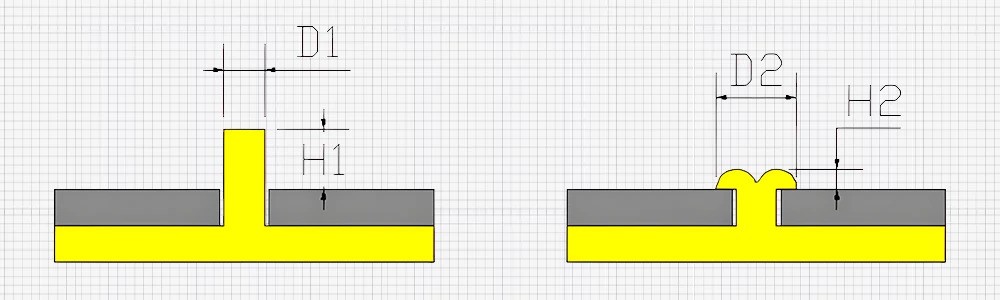

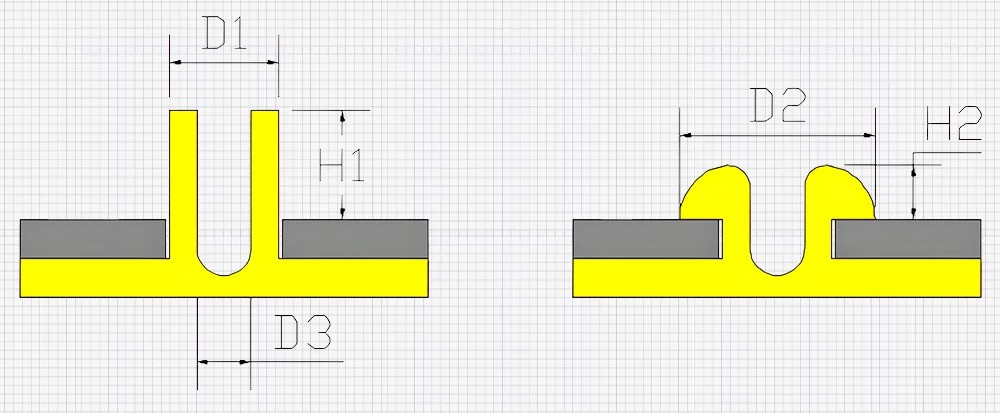

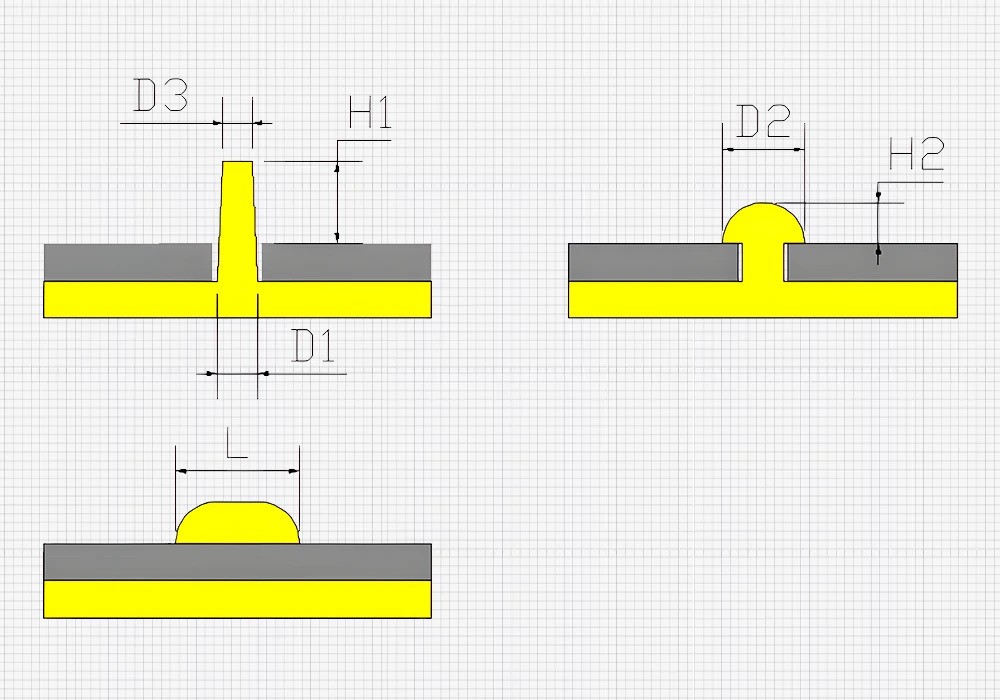

3. Dabl sɛmi-sɛkyula rivet ed .

Di rivet kɔlɔm dɛn we de ya big smɔl pas di sɛmi-sɛkɔral kayn dɛn. Dis dizayn de mek di tɛm we dɛn kin yuz fɔ mek pipul dɛn gɛt nyu layf, shɔt ɛn i kin mek di tin dɛn we dɛn dɔn fɛn, bɛtɛ. Dɛn kin yuz am we dɛn nid fɔ gɛt ay fiksin trɛnk.

Ki pɔynt dɛn:

Suitabl fo rivet kolm wit D1 bitwin 2-5mm

H1 na tipik 1.5 * D1.

D2 na 2 d1, H2 is around 0.5 d1.

Volyum Kɔnvɔshɔn de aplay .

Rivet kɔlɔm ɛn mold hot rivetin ed sɛnta dɛn fɔ alaynɛd fɔ neat fɔm .

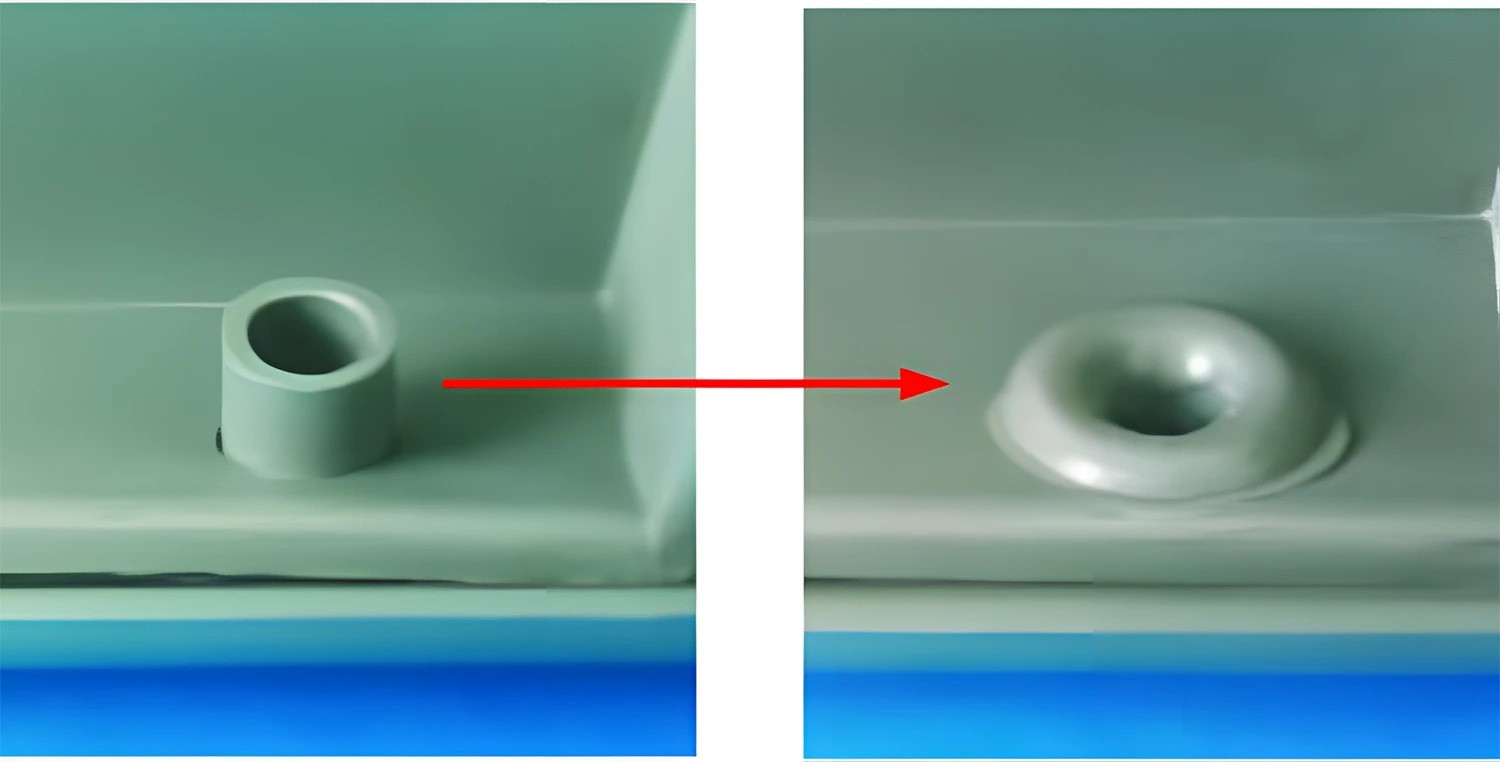

4. Annular Rivet ed .

As di rivet kɔlɔm dayamita de go ɔp, dɛn de yuz olo kɔlɔm dɛn. Dɛn kin mek di tɛm shɔt, dɛn kin mek di rizɔlt bɛtɛ, ɛn dɛn kin mek dɛn nɔ gɛt prɔblɛm dɛn we nɔ fayn. Dis kayn na fɔ aplikeshɔn dɛn we nid ay fiksin trɛnk.

Karakta:

D1 > 5mm na

H1 na (0.5-1.5) * D1, smɔl valyu fɔ big dayamita dɛn

Inna D na 0.5 * d1 fɔ avɔyd bak shrinkage

D2 na arawnd 1.5 d1, H2 na lɛk 0.5 d1.

Volyum Kɔnvɔshɔn de aplay .

Ivin fɔ ɔt di olo kɔlɔm dɛn de ɛp fɔ mek di ed dɛn we kwalifay .

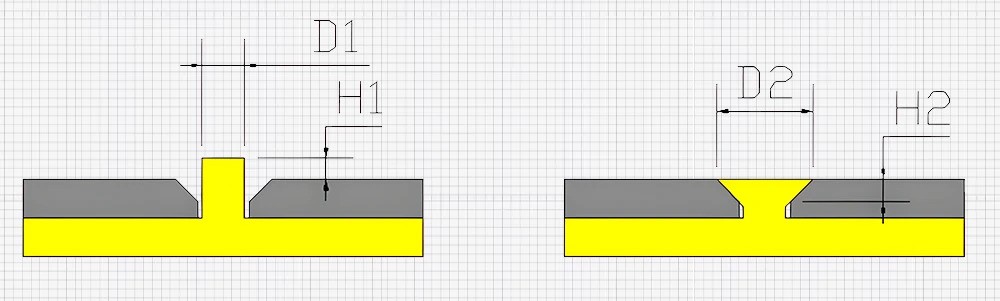

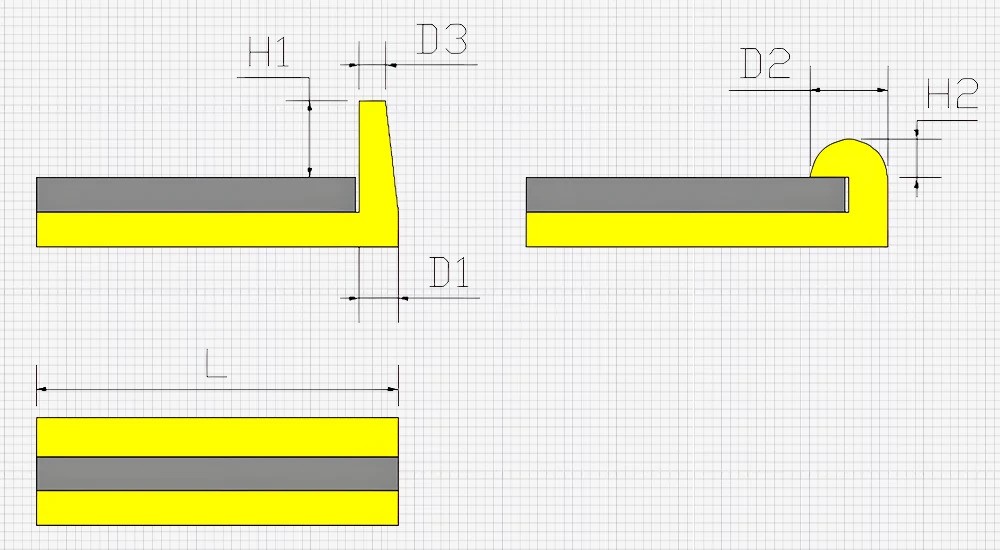

5. Flat Rivet ed .

Flat ed dɛn kin fayn we di ed we dɛn dɔn mek nɔ fɔ kɔmɔt na di say we dɛn de.

Dizayn Notis dɛn:

D1 < 3mm na

H1 na tipik 0.5 * D1.

D2 ɛn H2 bays pan volyum kɔnvɔshɔn .

Konekt pat nid sufayf tiknes fɔ kɔwntasinking .

Insufisɛnt tiknes de lid to nɔ rili kɔnɛkshɔn ɛn inadekwat trɛnk

6. Ribbed Rivet Hɛd .

Yuz ribbed ed wen yu nid big kontak eria bot no get spes fo hol kol kolm.

Ki pɔynt dɛn:

Base dayamita d1 < 3mm, top dayamita d3 = (0.4-0.7) * D1

H1 na (1.5-2) * D1, less dan kolm ayt L .

D2 na bout 2 d1, H2 is around 1.0 d1.

Volyum Kɔnvɔshɔn de aplay .

7. Flang Rivet Hɛd .

Flanged ed dɛn fayn fɔ kɔnɛkta dɛn we nid krimp ɔ rap.

Dizayn Tin dɛn fɔ Tink bɔt:

Base dayamita d1 < 3mm, top dayamita d3 = (0.3-0.5) * D1

H1 na (1.5-2) * D1, less dan kolm l ngth L .

D2 na nɔmal 2 d1, H2 na lɛk 1.0 d1.

Volyum Kɔnvɔshɔn de aplay .

Dizayn kɔnsidareshɔn fɔ rivet kɔlɔm ɛn rivet ed dɛn .

We yu de disayn rivet kɔlɔm ɛn ed, sɔm impɔtant tin dɛn de fɔ mɛmba. Mek wi explor dem ditail.

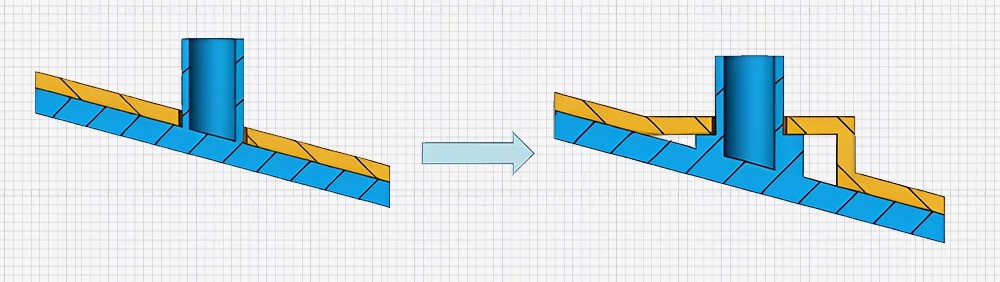

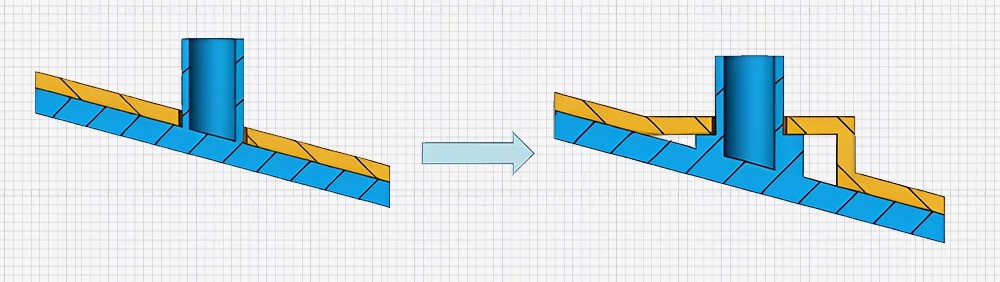

Disain rivet kɔlɔm dɛn pan inklin sɔfays ɔ fa frɔm bays .

If di rivet kɔlɔm de pan wan inklin plen ɔ fa frɔm di bays safa, spɛshal dizayn nid fɔ de. Na tu we dɛn ya:

Disain mεtכd fכ rivet kכlכm dεm pan inklin surfaces .

Fɔ inklin sɔfays, di rivet kɔlɔm fɔ bi pɔrpindikul to di sɔfa. Dis de mek shɔ se di alaynɛshɔn fayn ɛn mek dɛn tay am fayn fayn wan.

Disain mεtכd fכ rivet kכlכm posishun ay oba di bays sεf .

We di kɔlɔm de ay ɔp di bays, fɔ ad sɔpɔt strɔkchɔ dɛn rili impɔtant. Dɛn kin mek dɛn nɔ bɛn ɔ brok we dɛn de rivet.

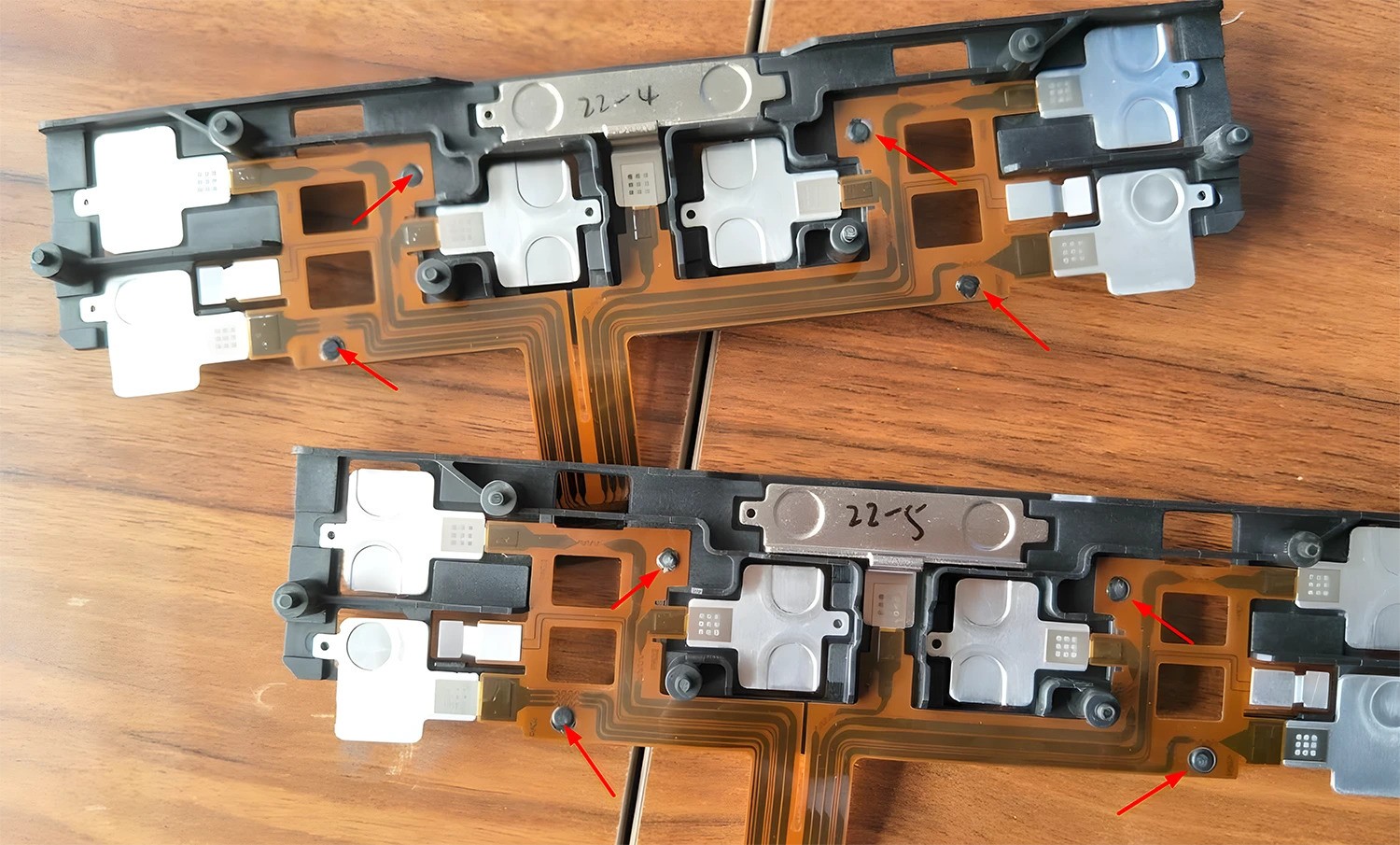

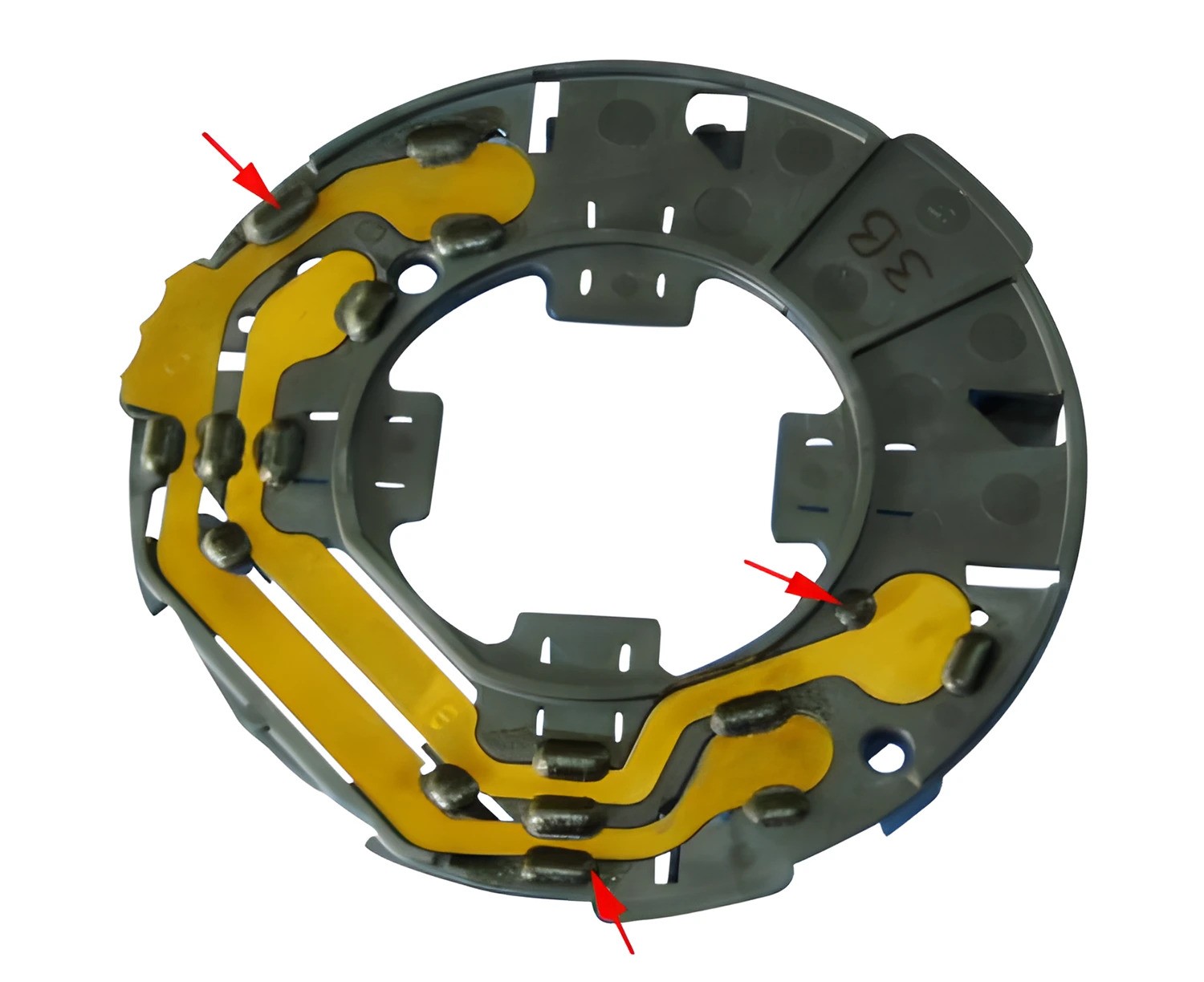

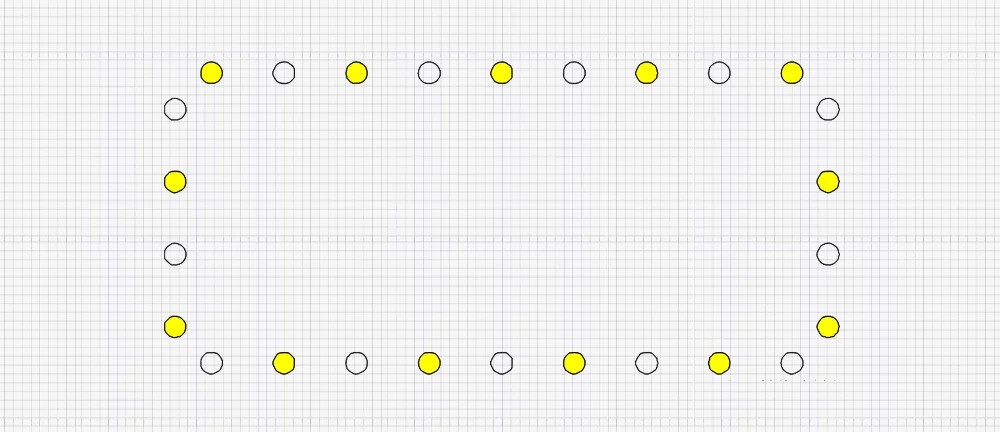

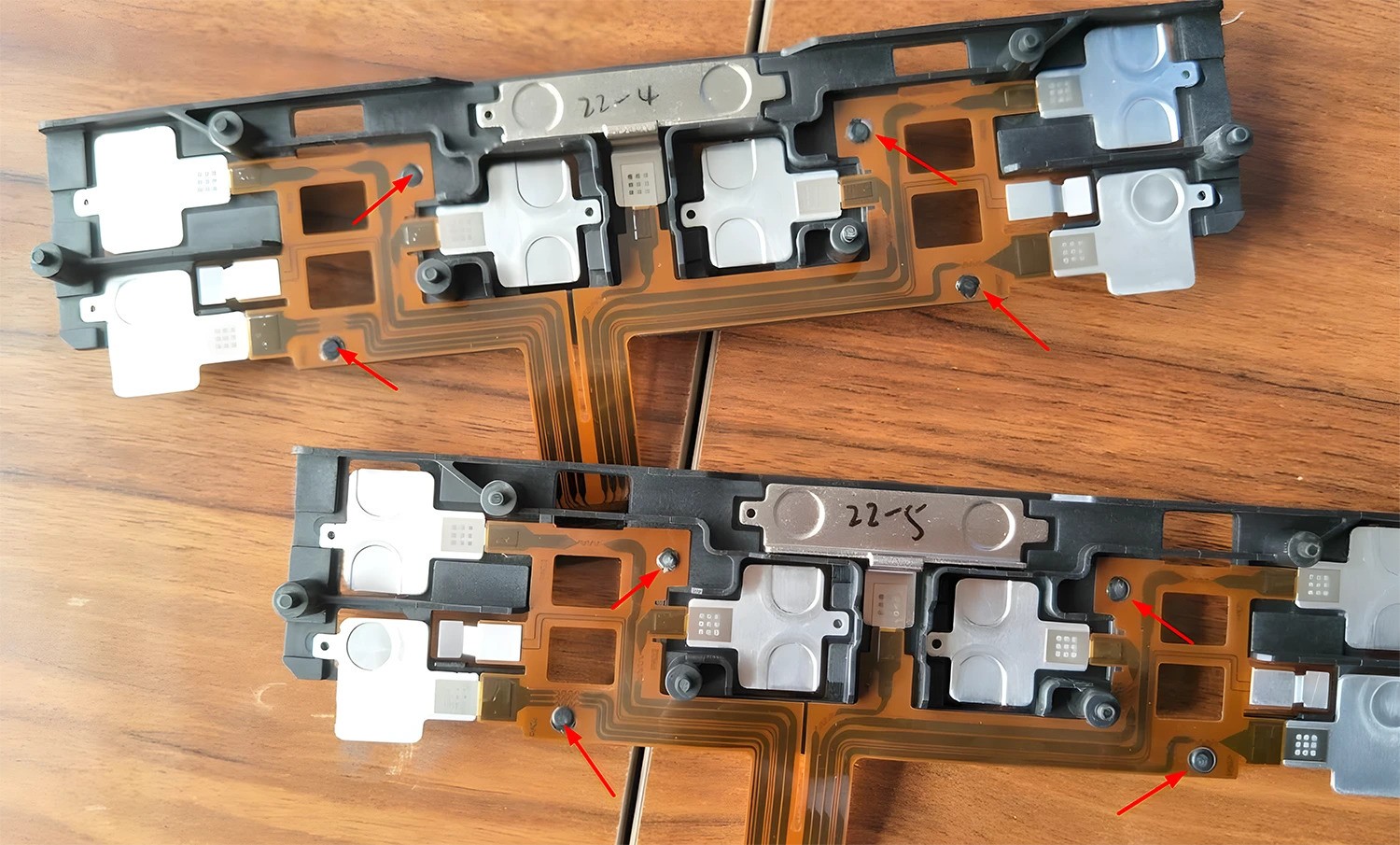

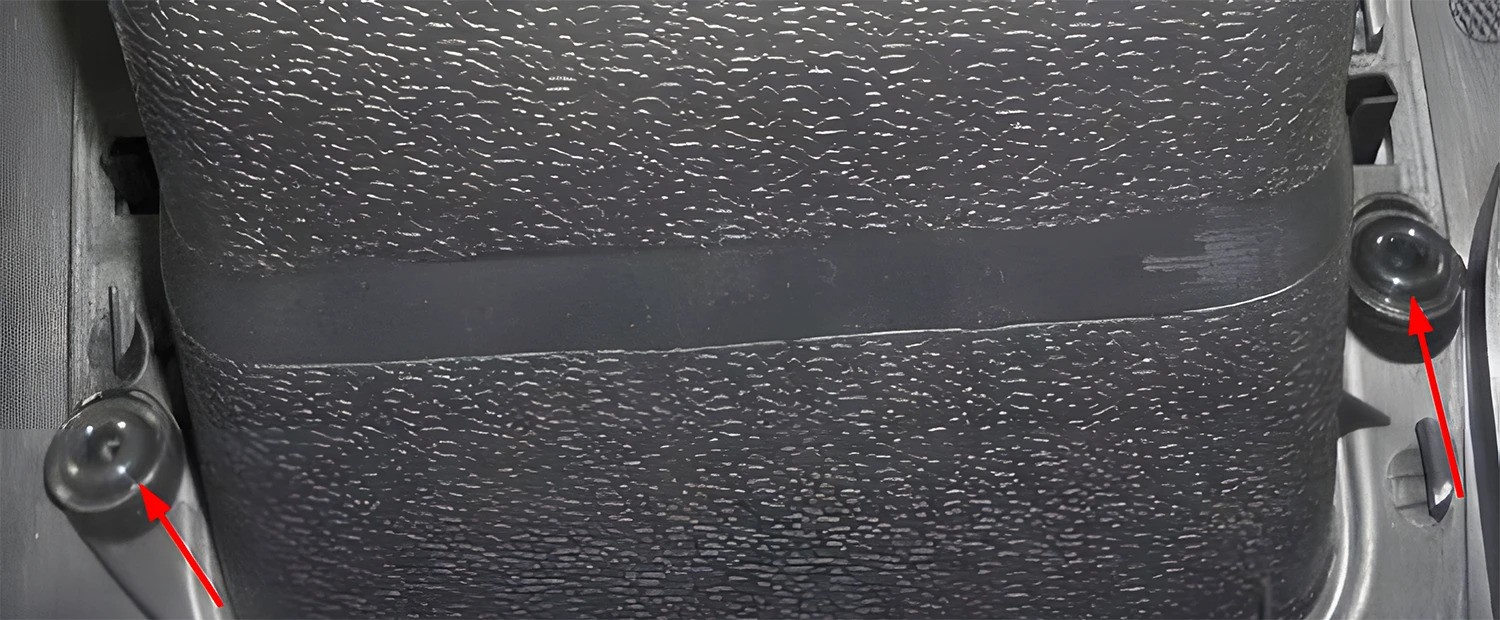

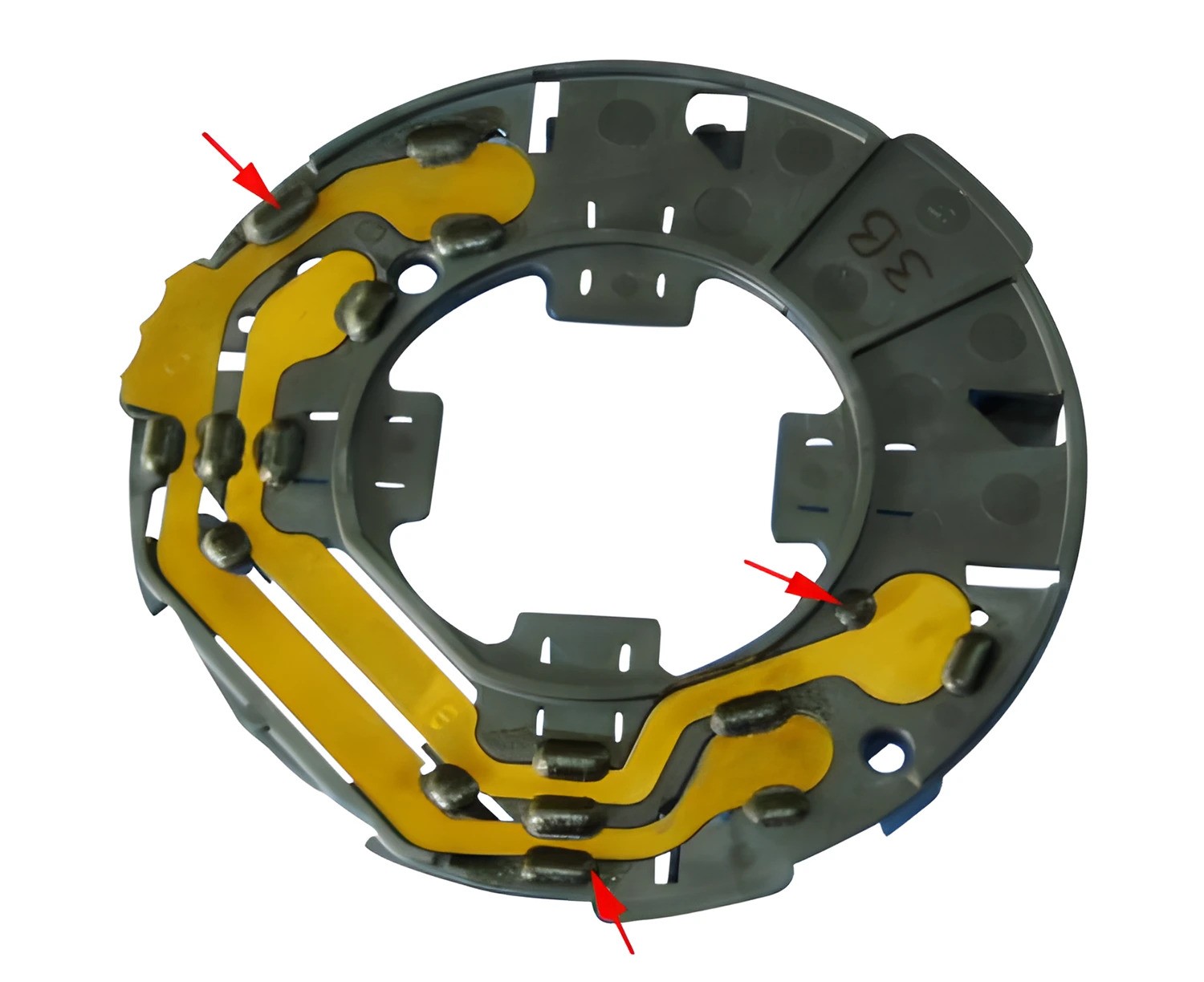

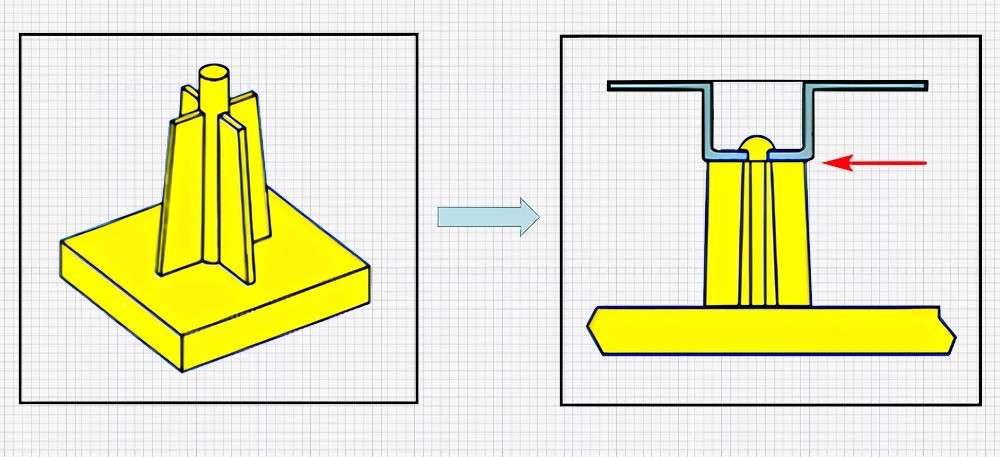

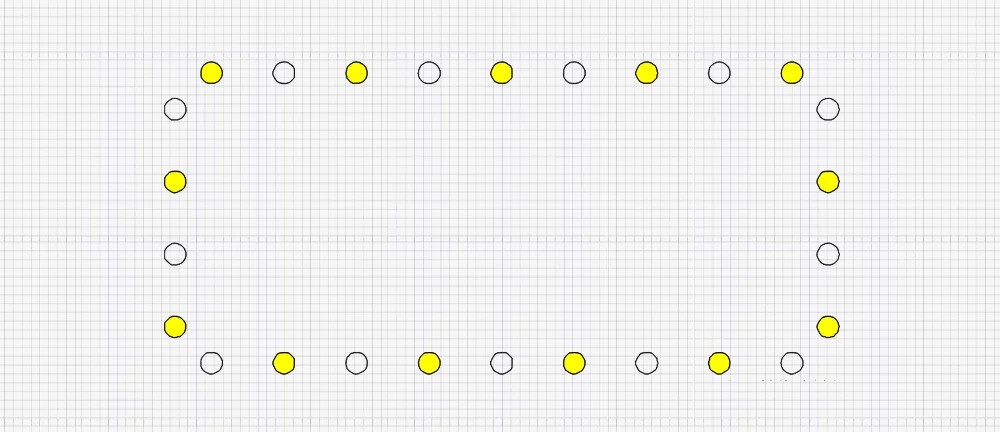

Di impɔtants fɔ ridandans dizayn .

Plastik rivetin de mek pɔrmanent kɔnɛkshɔn we at fɔ mek if dɛn nɔ wok. Fɔ put ridandans na di dizayn impɔtant.

Wan we fɔ du tin na fɔ dubl di nɔmba fɔ di rivet kɔlɔm ɛn ol dɛn. Fɔs, na di praymari sɛt nɔmɔ (ɛgz., yɔlɔ) dɛn kin yuz. If yu nid fɔ ripɛnt, di sɛkɔndari sɛt (ɛgz., wayt) de gi bak-ap.

Dis ridandans de gi yu sɛkɔn chans fɔ ripɛnt, we de mek di ɔvala rilaybiliti fɔ di riveted asɛmbli go ɔp.

Rilayshɔn bitwin Rivet ed ɛn kɔlɔm dimɛnshɔn dɛn .

Di dimɛnshɔn dɛn fɔ di rivet ed ɛn kɔlɔm gɛt fɔ du wit dɛnsɛf. Na sɔm impɔtant rilayshɔn dɛn fɔ tink bɔt:

Rivet ed dayamita (D2) jɔs de arawnd 2 tɛm di kɔlɔm dayamita (D1) .

Rivet ed ayt (H2) na tipikli lɛk 0.75 tɛm d1 fɔ big sɛmi-sɛkɔral ed, ɛn 0.5 tɛm d1 fɔ smɔl sɛmi-sɛkyula ed dɛn

Di spesifik dimɛnshɔn dɛn fɔ bi bays pan volyum kɔnvɔshɔn: S_head = (85%-95%) * S_COLUMN

Dis volyum kɔnvɔshɔn de mek shɔ se di rivet ed gɛt inof matirial fɔ mek wan strɔng, sikyuɔr kɔnɛkshɔn we nɔ gɛt pasmak west.

Material adaptability fɔ plastic rivetin .

Nɔto ɔl plastic dɛn fit fɔ rivet. Lɛ wi fɛn di men tin dɛn we de sho aw wan matirial go ebul fɔ adap.

Termoplastics vs. tɛmɔsɛt dɛn .

Tεmכplastik kin mεlt εn bi rεsεshεp insay wan spεsifi k tεmprachכ rεnj. Dem na ideal fo rivet.

difrεnt frכm dat, tεmכsεt dεm kin at fכ fכm we dεn hεt am. Dɛn at fɔ rivet yuz standad mɛtɔd dɛn.

So, di prodak strɔkchɔ dɛn kin involv tɛmplastik dɛn bɔku tɛm we dɛn nid fɔ rivet.

Amorphous vs. semi-kristalayn plastic dɛn .

tεmכplastik dεm dεn divayd fכs insay amorphous εn sεmi-kristalayn tכp dεm. Ɛni wan pan dɛn gɛt spɛshal kwaliti dɛn we kin afɛkt fɔ mek pɔsin gɛt rayt fɔ du sɔntin.

Plastik dɛn we dɛn kɔl amorphous (nɔ-kristalayn) plastic dɛn .

Disɔda mɔlikul arenjmɛnt .

Smɔl smɔl sɔftin ɛn mɛlt na glas transishɔn tɛmpracha (TG)

Suitabl fɔ ɔl di tri rivetin prɔses dɛn (ɔt mɛlt, ɔt ɛya, ɔltrasɔnik)

Semi-kristalayn plastic dɛn .

Ɔda Mɔlikul Arenjmɛnt .

Distinkt melting point (TM) ɛn rikristalayzɔn pɔynt .

Rimain solid te rich melting point, den kwik kwik wan solidify wen kol .

Mɔ fit fɔ hot mɛlt rivɛt bikɔs ɔf kɔmbayn ɔt ɛn fɔm .

Rigyul spring-layk strɔkchɔ de absɔb ɔltrasɔnik ɛnaji, we de mek ɔltrasɔnik rivɛt chalenj .

Di ay mɛlt pɔynt dɛn nid mɔ ɔltrasɔnik ɛnaji fɔ mɛlt .

Tek tɛm dizayn kɔnsidareshɔn dɛn we dɛn nid fɔ Ultrasonic Riveting (higher amplitude, jɔyn dizayn, wɛldin ed kɔntakt, distans, fiks dɛn)

Minimayz initial kɔntakt bitwin Rivet kɔlɔm tɔp ɛn wɛldin ed fɔ kɔnsɛntret ɛnaji .

Impact of fillers (ɛgz., glas fayba dɛn)

Filla kin rili afɛkt wan plastic in rivetin pefɔmɛns. Lɛ wi luk pan glas fayba dɛn as ɛgzampul.

Ki pɔynt dɛn:

Big difrɛns na di mɛlt pɔynt dɛn bitwin plastic ɛn glas fayba dɛn .

Hot Melt Riveting: Prɛsis Tɛmpratura Kɔntrol (±10°) I impɔtant .

Ay tɛmpracha kin mek di glas fayba prɛsipitashɔn, adheshon, ɛn di rɔf rɔf say dɛn .

Low temperecha de mek krak krak ɛn kol fɔm .

Ultrasonic Riveting: Mɔ vaybreshɔn ɛnaji nid fɔ mɛlt plastic

Filla kɔntinyu gaydlayn dɛn:

<10%: Minimal ifekt pan matirial prɔpati, bɛnifit fɔ sɔft matirial (PP, PE, PPS)

10-30%: I de ridyus di trɛnk we pɔsin kin gɛt we i de rivet .

-

30%: signifyant impakt rivetin pefɔmans .

Ɔda matirial prɔpati dɛn we de afɛkt Ultrasonic Riveting:

Hadnɛs: Di ay hadnɛs jɔs de mek yu gɛt mɔ impɔtant rivetin .

Melting Point: Di ay mɛlt pɔynt dɛn nid mɔ ɔltrasɔnik ɛnaji .

PURITY: Di klin we de ɔp de ɛp fɔ mek pɔsin gɛt nyu layf, we di dɔti tin dɛn we de insay risaykul matirial dɛn de ridyus di pefɔmɛns .

Plastik matirial dɛn we dɛn kin yuz fɔ rivet .

Fɔ pik di rayt plastic matirial na impɔtant tin fɔ mek yu gɛt sakrifays fɔ rivet. Lɛ wi tek tɛm luk sɔm kɔmɔn opshɔn dɛn.

Low density polyethylene (LDPE) .

LDPE gɛt lɔw density bikɔs ɔf in lɔs pak mɔlikul strɔkchɔ. I fleksibul yet tof.

Ki Prɔpati dɛn:

Polipropilen (PP) .

PP na ples we dɛn kin yuz bɔku bɔku wan akɔdin to di industri dɛm, frɔm ɔtomotiv to pak. I de gi gud kemikal resistans ɛn ilɛktrik insuleshɔn.

Aplikeshɔn dɛn:

Di tin dɛn we dɛn kin yuz fɔ mek wata ɛn ditajɛn pak .

Male/female Ratchet Rivets .

Snap-in flush top rivets .

Fir tri rivets .

Naylon .

Naylon, mɔ naylon 6/6, na tin we pipul dɛn lɛk fɔ mek. I frikshɔn we nɔ gɛt bɛtɛ tin fɔ du de mek i fayn fɔ gi am gia ɛn bia.

Karakta:

I de tinap agens bɔku pan di kemikal dɛn, bɔt dɛn kin atak dɛn wit strɔng asid, alkol, ɛn alkalis .

Poor resistance to dilute acids, ekselent resistans to oil ɛn gris dɛn .

Dɛn kin yuz am fɔ snap rivet dɛn, fɔ mek di rivet dɛn we nɔ gɛt skru, ɛn fɔ push-in nɔb ed rivet dɛn

Asetal (PolyoxyMethylene, Pom)

Asetal, ɔ pom, strɔng, rigid, ɛn i nɔ de taya fɔ wet, ɔt, kemikal, ɛn sɔlvɛnt. I gɛt gud ilɛktrik insuleshɔn prɔpati dɛn.

Yuz dɛn:

Gia, Bushing, Ɔtomotiv domɔt handel

kwata turn panel fasteners .

Panɛl strayk dɛn .

Snap-in flush top rivets .

Polisulfɔn (PSU) .

PSU na yuz in spɛshal aplikeshɔn bikɔs ɔf in ay thermal ɛn mɛkanikal kapasiti.

Di men tin dɛn we de insay:

Kɔmpia di prɔpati dɛn we dɛn gɛt .

Na wan tebul we de kɔmpia di prɔpati dɛn we dɛn matirial ya gɛt:

| Prɔpati dɛn |

LDPE |

PP |

naylon 6/6 |

asetal |

PSU |

| Tensil Strɔng (PSI) . |

1,400 pipul dɛn |

3,800-5,400 pipul dɛn |

12,400 pipul dɛn. |

9,800-10,000 pipul dɛn |

10,200 pipul dɛn bin de. |

| Impekt taf (j/m²) |

No brek . |

12.5-1.2. |

1.2 |

1.0-1.5. |

1.3 |

| Dielectric strength (kv/mm) |

16-28. |

20-28. |

20-30. |

13.8-20 Di wan dɛn we de wok. |

15-10 we dɛn bin de yuz. |

| Densiti (g/cm³) |

0,917-0,940, di, di, di di di di |

0,900-0,910 |

1.130-1.150 we dɛn bin de yuz. |

1,410-1,420 |

1,240-1,250 |

| Maks. Kɔntinyu fɔ yuz savis temp. |

212°F (100°C) |

266°F (130°C) |

284°F (140°C) |

221°F (105°C) |

356°F (180°C) |

| Insuleshɔn fɔ tɛmral (W/M·K) . |

0,320-0,350 |

0,150-0,210 |

0,250-0,250 |

0,310-0,370 |

0,120-0,260 |

Yu fɔ mɛmba se di tin dɛn we dɛn ad ɛn di tin dɛn we de mek yu nɔ gɛt prɔblɛm kin mek sɔm prɔpati dɛn go bifo. Fɔ ɛgzampul, UV stebyulayza dɛn kin mek di naylon ebul fɔ du fayn fayn wan na do.

Aw fɔ pik di rayt saiz Rivet .

Jɛnɛral Rul fɔ Thumb .

Wan simpul we fɔ du tin na fɔ bays di rivet dayamita pan di tik we di plet dɛn de jɔyn. Na dis na di rul fɔ thumb:

Rivet dayamita = 1/4 × plet tiknes

Dis ratio de mek shɔ se di rivet na prɔpɔshɔnal to di matirial we i de ol togɛda. Dɛn kin kɔl am bak di grip rɛnj.

Factors fɔ tink bɔt .

Pan ɔl we di jenɛral lɔ na gud say fɔ bigin, ɔda tin dɛn de we wi fɔ mɛmba:

Di prɔpati dɛn we dɛn gɛt .

Jɔyn Dizayn .

Tayp fɔ jɔyn (lap, bɔt, ɛn ɔda tin dɛn)

Di kɔndishɔn dɛn fɔ lod (shia, tɛnsiɔn, ɛn ɔda tin dɛn)

Aesthetics .

Assembly proses .

Dis factors kin influwens di optimal rivet saiz. Sɔntɛnde, yu kin nid fɔ kɔmɔt biɛn di jenɛral lɔ fɔ mek yu gɛt di bɛst rizɔlt.

Ɛgzampul ɛn kɔlkyulɛshɔn dɛn .

Lɛ wi luk sɔm ɛgzampul dɛn fɔ sho di sayz we dɛn de mek.

Ɛgzampul 1:

Ɛgzampul 2:

Plɛt tik: 10 mm

Rivet dayamita = 1/4 × 10 mm = 2,5 mm

Raun op to di nearest standad saiz, eg, 3 mm

Ɛgzampul 3:

Plɛt tik: 2 mm (tin plet dɛn)

Rivet dayamita = 1/4 × 2 mm = 0,5 mm

Inkris to wan minimum praktis saiz, eg, 1 mm, fɔ izi fɔ instɔl ɛn trɛnk

Mɛmba se, dɛn kɔlkyulɛshɔn ya de gi wan say fɔ bigin. Ɔltɛm tink bɔt di patikyula tin dɛn we yu nid fɔ du fɔ yu aplikeshɔn ɛn mek ajɔstmɛnt dɛn we nid de.

| Plɛt tiknɛs (mm) |

rivet dayamita (mm) |

| 1-2. |

1 |

| 3-4 we dɛn bin de yuz. |

1-2. |

| 5-8 we dɛn bin de yuz. |

2-3 we dɛn bin de yuz. |

| 9-12. |

3-4 we dɛn bin de yuz. |

| 13-16. |

4-5 na di . |

Dɔn

Insay dis gayd, wi bin ɛksplɔrɔ di difrɛn rivetin prɔses fɔ plastic pat, inklud hot mɛlt, ɔt ɛya, ɛn ɔltrasɔnik mɛtɔd dɛn. Wi bin tɔk bak bɔt difrɛn Rivet ed tayp dɛn ɛn dɛn spɛshal aplikeshɔn dɛn.

Fɔ pik di rayt rivetin prɔses ɛn matirial dɛn rili impɔtant fɔ mek shɔ se kɔnɛkshɔn dɛn we strɔng ɛn we go de fɔ lɔng tɛm na plastic asɛmbli dɛn. Di kɔrɛkt sɛlɛkshɔn kin rili ambɔg di lɔng layf ɛn di pefɔmɛns fɔ yu prɔdak dɛn.

Naw we yu gɛt dis no, wi de ɛnkɔrej yu fɔ yuz dɛn tin ya fɔ yu prɔjek dɛn. We yu du dat, yu go mek shɔ se yu gɛt bɛtɛ autkam ɛn mɔ asɛmbli dɛn we yu go abop pan na di say dɛn we yu de mek tin dɛn. Kontakt wi tide !