Plastik prodakt de evriwe, bot dizain dem no simpul. Aw injinia dɛn kin balans trɛnk, kɔst, ɛn prodakshɔn efyushɔn? Dis atikul go sho di kɔmplisiti dɛn biɛn di strɔkchɔral dizayn fɔ plastic prɔdak dɛn. Yu go lan di men tin dɛn, lɛk di tik we de na di wɔl, di rib dɛn we de mek yu gɛt mɔ trɛnk, ɛn ɔda tin dɛn, we de mek plastic pat dɛn we go de fɔ lɔng tɛm ɛn we nɔ go tek bɔku mɔni.

Karakta ɛn prosidyuz fɔ plastic pat strɔkchɔral dizayn .

Plastik matirial dɛn de gi yunik prɔpati ɛn versatile shep opshɔn dɛn, we de sɛt dɛn apat frɔm kɔvɛnshɔnal injinɛri matirial dɛn lɛk stɛl, kɔpa, aluminiɔm, ɛn wud. Dis difrɛn kɔmbaynshɔn fɔ matirial kɔmpɔzishɔn ɛn fɔmabiliti de gi plastic wan ay digri fɔ dizayn fleksibiliti kɔmpia to dɛn kɔmpin dɛn.

Yunik matiryal kompozishun ɛn versatile shep dɛn .

Di difrɛn difrɛn plastic matirial dɛn, ɛni wan wit in patikyula prɔpati dɛn, de alaw dizayna dɛn fɔ tayla dɛn chuk akɔdin to di prɔdak in rikwaymɛnt dɛn. Dis variety, kɔpl wit di abiliti fɔ mol plastic dɛn insay intrikɛt shep dɛn, de mek dɛn ebul fɔ mek kɔmpleks jɔyometri ɛn funkshɔn ficha dɛn we go chalenj ɔ nɔ prɛktikal wit ɔda matirial dɛn.

Jɛnɛral prosidur fɔ plastic pat dizayn .

Fɔ leva di advantej dɛm fɔ plastic ɛn mek shɔ se di bɛst strɔkchɔral dizayn, i impɔtant fɔ fala wan sistamɛtik apɔch. Di jenɛral prosidur fɔ plastic pat dizayn involv sɔm ki stej dɛn:

Ditarmin di funkshɔn rikwaymɛnt ɛn di we aw di prɔdak de luk:

Draw prɛliminari dizayn drɔin dɛn:

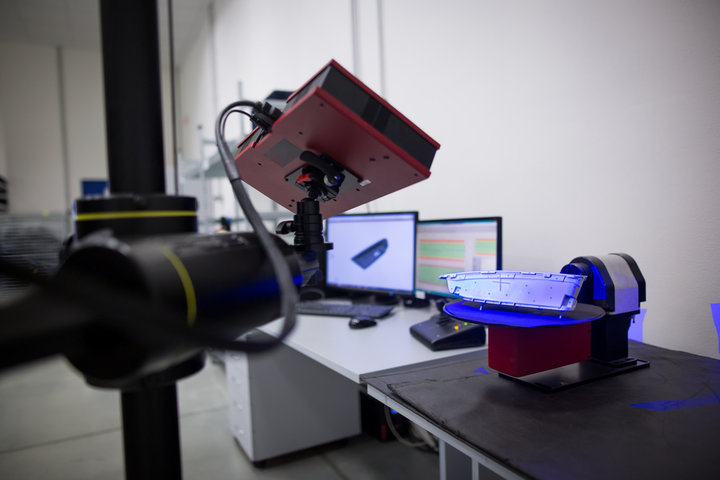

Protɔtayp:

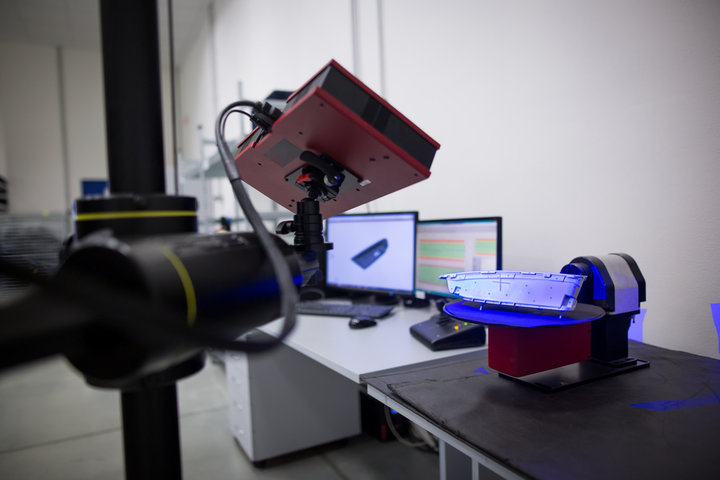

Prodyuz fyzikal protɔtayp dɛn we de yuz mɛtɔd dɛn lɛk 3D printin ɔ . CNC MACHINING .

Evaluate di prototype in funkshɔnaliti, ergonomics, ɛn ɔvalayn dizayn

Prodakt tɛst: .

Dizayn Rikalibreshɔn ɛn Rivishɔn:

Analayz di tɛst rizɔlt ɛn no di say dɛn we dɛn go impruv .

Mek nid fɔ ajɔst dizayn fɔ mek dɛn ebul fɔ du mɔ, fɔ mek dɛn ebul fɔ abop pan dɛn, ɔ fɔ mek dɛn ebul fɔ du tin fayn fayn wan.

Divɛlɔp impɔtant spɛsifikɛshɔn dɛn:

Krio ditayl spesifikeshɔn fɔ di fayn prodak, inklud dimɛnshɔn, tolɛreshɔn, ɛn matirial gred

Mek shɔ se di spɛsifikɛshɔn dɛn alaynɛd wit di manufakchurin prɔses ɛn kwaliti kɔntrol standad dɛn .

Opin mold prodakshɔn:

Disain ɛn fabrik di injɛkshɔn mold bays pan di faynlayz prodak spɛsifikɛshɔn dɛn .

Optimize di mold dizain fɔ efishɔnal matirial flɔ, kol, ɛn ejekshɔn

Kwaliti Kɔntrol:

fondamental factors in plastic prodakt strɔkchɔral dizayn .

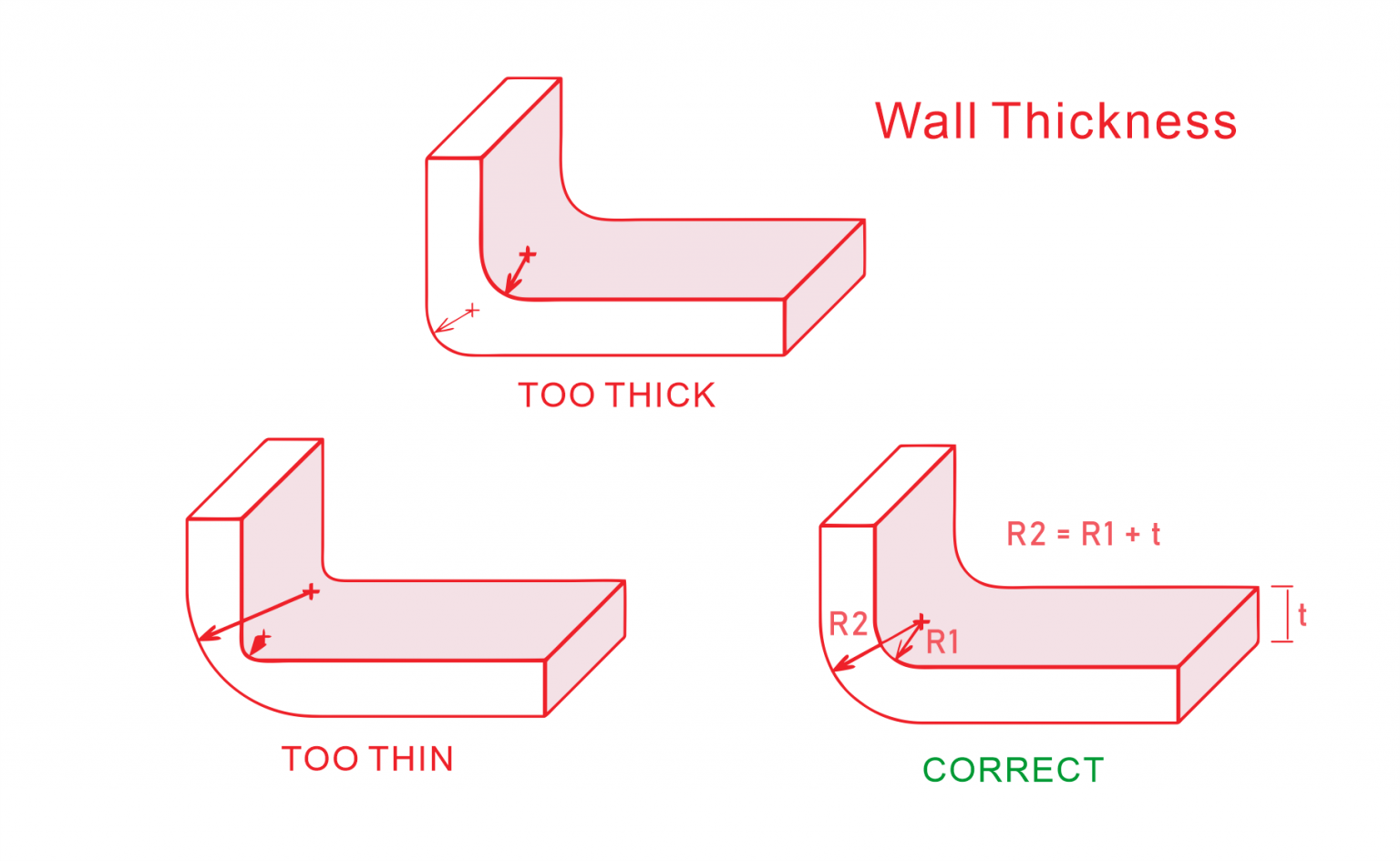

Tiknes fɔ di wɔl .

Di tik we di wɔl tik de ple wan impɔtant pat pan di plastic prodak dizayn. Prɔpa tiknɛs de mek shɔ se di bɛst pefɔmɛns, manufakchurabiliti, ɛn kɔst-ɛfɛktiv.

Rekomendant wall tiknes valyu

| plastic material | minim (mm) | Smɔl pat (mm) | midul pat (mm) | Big pat (mm) |

| Naylon . | 0.45 | 0.76 | 1.5 | 2.4-3.2. |

| PE . | 0.6 | 1.25 | 1.6 | 2.4-3.2. |

| PS . | 0.75 | 1.25 | 1.6 | 3.2-5.4 Di wan dɛn we de wok. |

| PMMA . | 0.8 | 1.5 | 2.2 | 4-6.5. |

| PVC we de na di . | 1.2 | 1.6 | 1.8 | 3.2-5.8 Di wan dɛn we de wok. |

| PP we de na di . | 0.85 | 1.54 | 1.75 | 2.4-3.2. |

| PC . | 0.95 | 1.8 | 2.3 | 3-4.5. |

| Pom na di 1999. | 0.8 | 1.4 | 1.6 | 3.2-5.4 Di wan dɛn we de wok. |

| ABS na ABS | 0.8 | 1 | 2.3 | 3.2-6. |

Factors we de afɛkt di wɔl tiknes sɛlɛkshɔn .

Plastik Matirial Prɔpati dɛn .

Ekstanshal fos dɛn we dɛn dɔn bia wit .

Sefty Rigyuleshɔn .

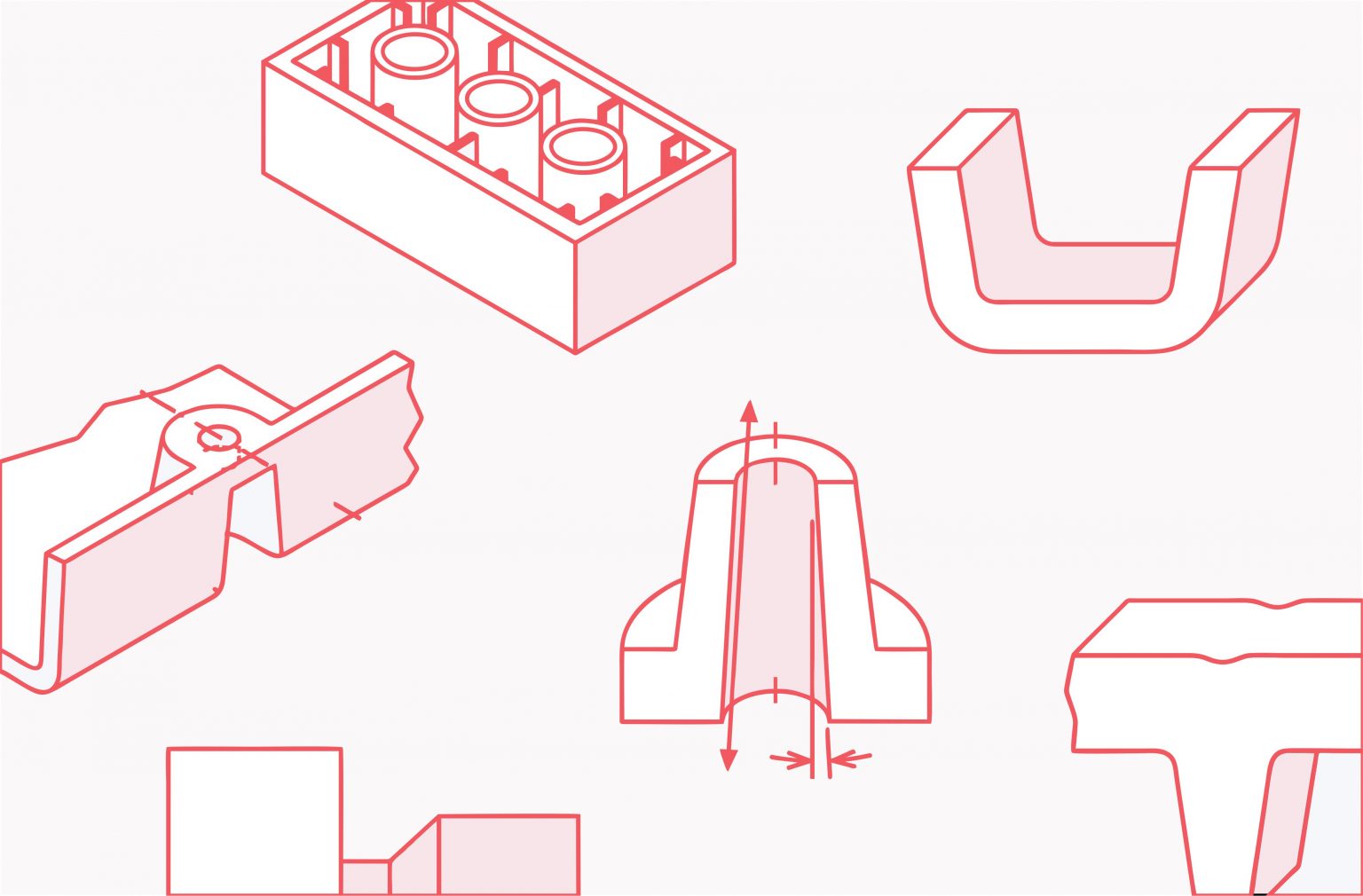

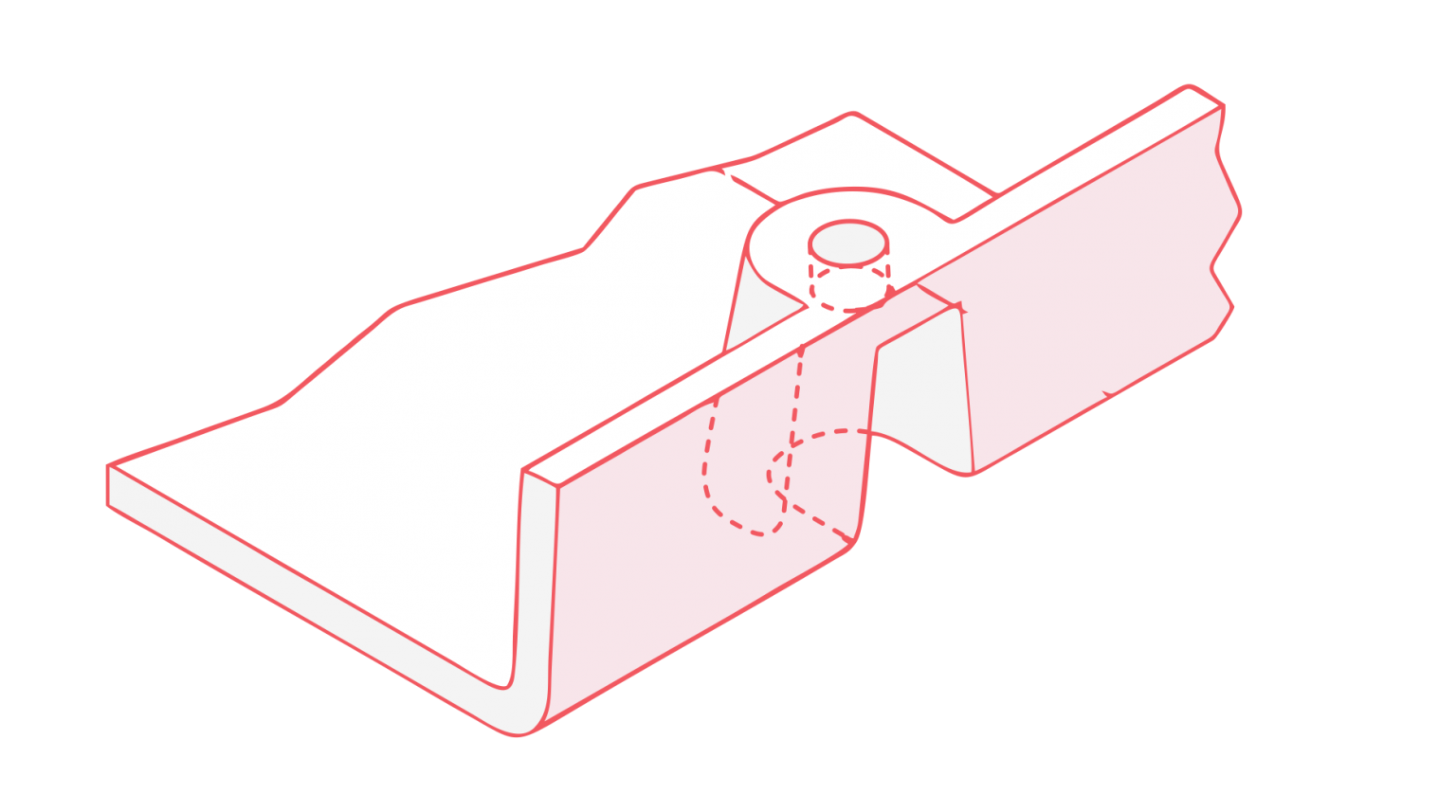

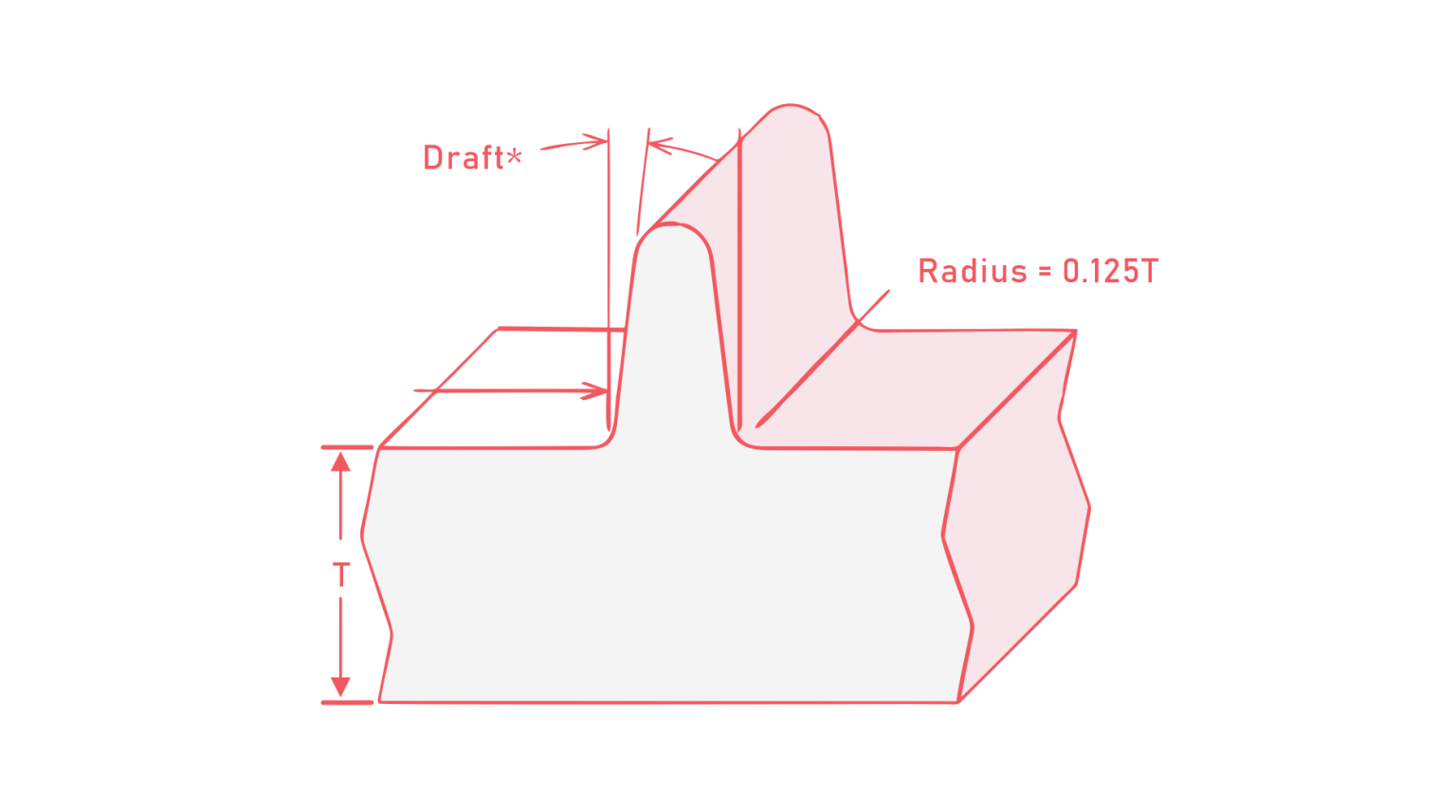

Rib dɛn we de mek pipul dɛn gɛt mɔ trɛnk .

Riinfɔs rib dɛn de ɛp fɔ mek trɛnk nɔ bɔku we dɛn nɔ de inkrisayz di ɔl di wɔl tik, i de mek di prɔdak difɔmeshɔn nɔ de, ɛn i de mek di strɔkchɔral intɛgriti bɛtɛ.

Dizayn Gaydlain fɔ Riinfɔs Rib dɛn .

Tik: 0.5-0.75 tɛm di ɔl di wɔl tik (dɛn kin tɔk bɔt am: <0.6 tɛm)

Ayt: I nɔ rich 3 tɛm tik tik .

Spays: Big pas 4 tɛm di wɔl tiknes

Aspek dɛm fɔ Riinfɔsmɛnt Dizayn we nid atɛnshɔn .

Avɔyd matirial akyumyuleshɔn na rib intasekshɔn .

Mentɛn pɔrpindikul to ɔda wɔl dɛn .

Minimize ribs we de riinfos pan stip slopes .

Tink bɔt di we aw di tin dɛn we de apin na di si we di sink mak dɛn de apin .

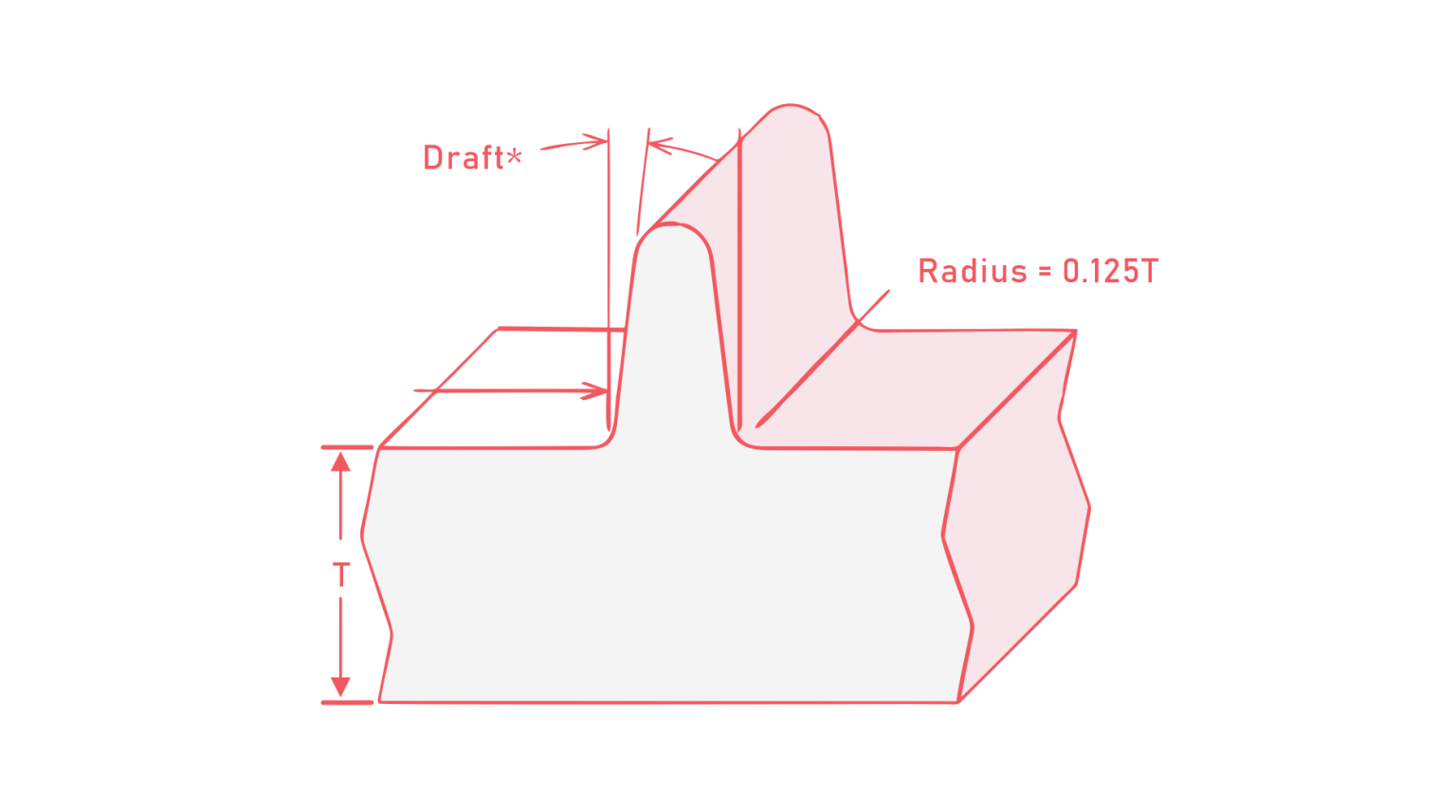

Draft angul dɛn .

Draft Angles Fasilitet izi pat rimobul frɔm mold, mek shɔ se smol prodakshɔn ɛn ay-kwaliti pat.

Rekomendant draft angles fɔ difrɛn matirial dɛn

| matirial | mold kor | mold cavity |

| ABS na ABS | 35'-1° Di wan dɛn we de na di wɔl. | 40'-1°20'. |

| PS . | 30'-1° we yu de | 35'-1°30'. |

| PC . | 30'-50'. | 35'-1° Di wan dɛn we de na di wɔl. |

| PP we de na di . | 25'-50'. | 30'-1° we yu de |

| PE . | 20'-45'. | 25'-45' |

| PMMA . | 30'-1° we yu de | 35'-1°30'. |

| Pom na di 1999. | 30'-1° we yu de | 35'-1°30'. |

| PA . | 20'-40'. | 25'-40'. |

| HPVC na di . | 50'-1°45' | 50'-2° we yu de |

| SPV . | 25'-50'. | 30'-1° we yu de |

| CP . | 20'-45'. | 25'-45' |

Aspek dɛm fɔ draft angul sɛlɛkshɔn nid fɔ pe atɛnshɔn .

Pik smɔl smɔl angul dɛn fɔ glos sɔfays ɛn ay-prɛsishɔn pat dɛn .

Yuz big angul fɔ pat dɛn we gɛt ay shrinkage rates

Inkris draft fɔ transparent pat dɛn fɔ mek dɛn nɔ skrach .

Adjɔst angul bays pan tɛkstɔr dip fɔ tɛkstɔr sɔfays dɛn .

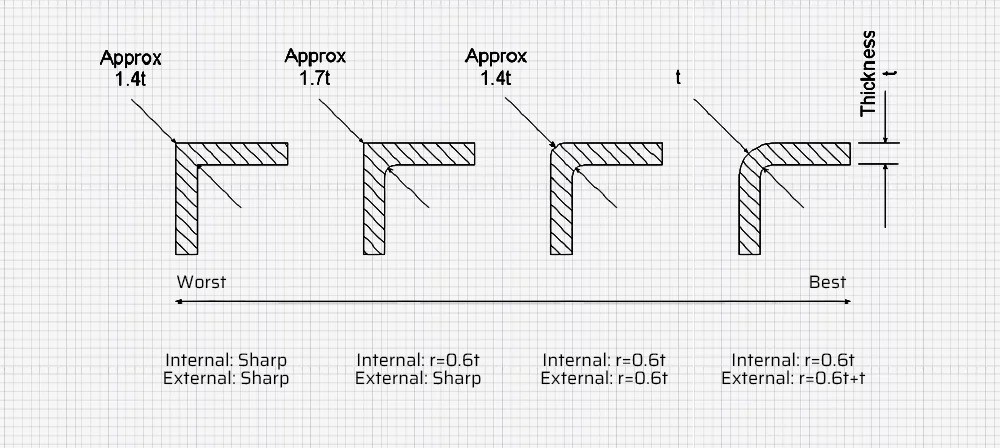

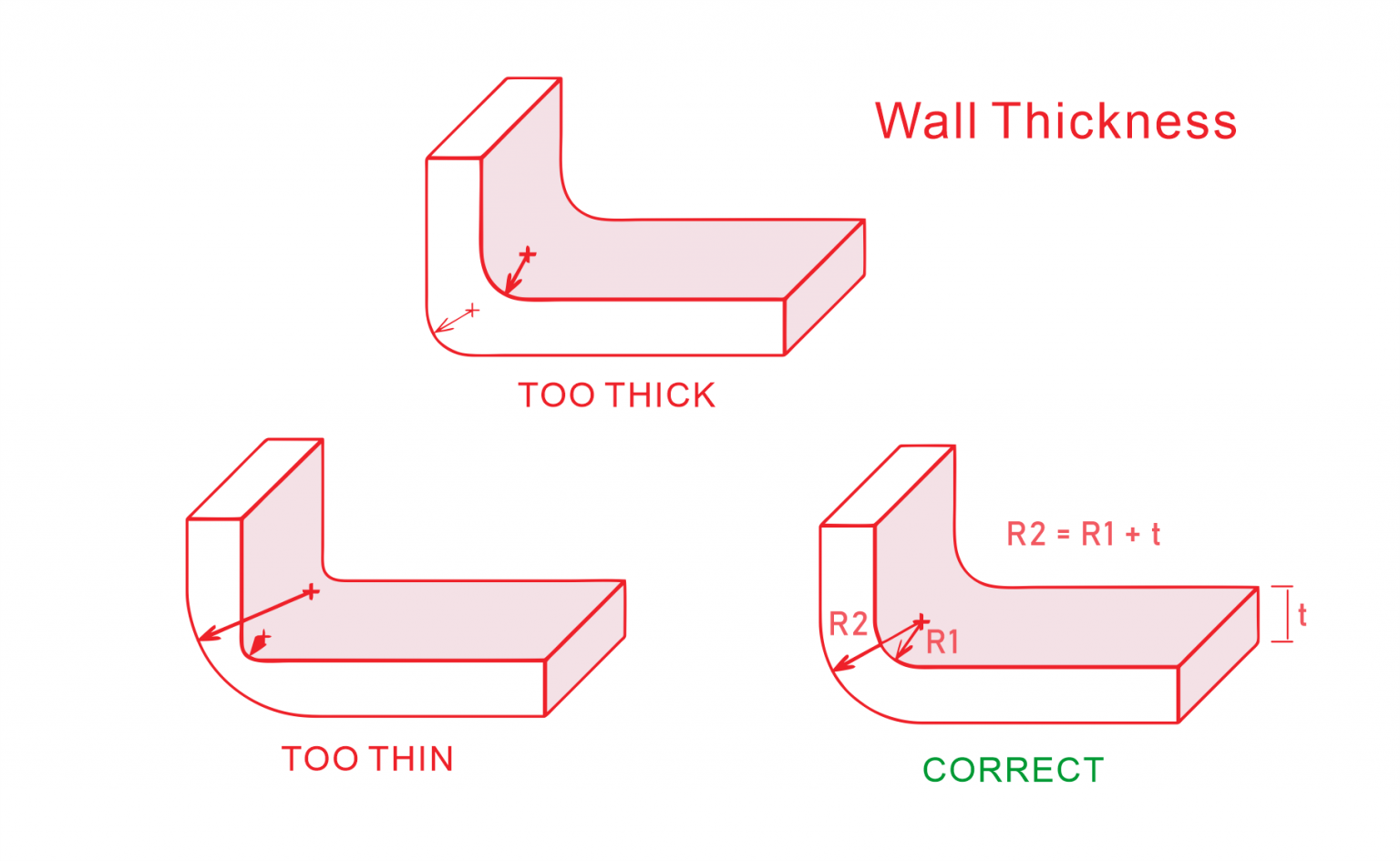

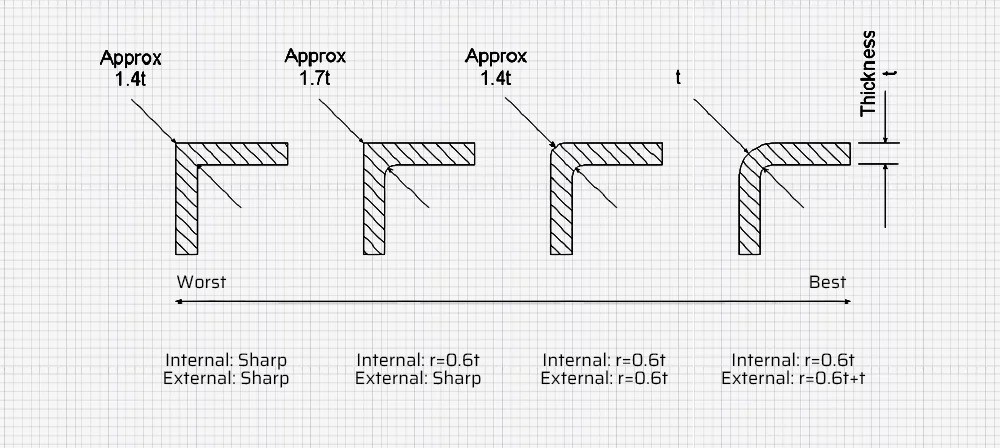

R Kɔna dɛn (we de rawnd di kɔna dɛn)

Raun kɔna dɛn kin ridyus di kɔnsɛntreshɔn fɔ strɛs, i kin mek am izi fɔ mek plastic flɔ, ɛn i kin izi fɔ pwɛl.

Dizayn Gaydlain fɔ R Kɔna dɛn .

Intanɛt Kɔna Radius: 0.50 to 1.50 tɛm matirial tiknes

Minimum radius: 0,30mm

Mentɛn yunifom wɔl tik we yu de disayn rawnd kɔna dɛn .

Avɔyd rawnd kɔna dɛn pan mold pating surfaces .

Yuz minimum 0.30mm radius fɔ edj fɔ mek yu nɔ skrach .

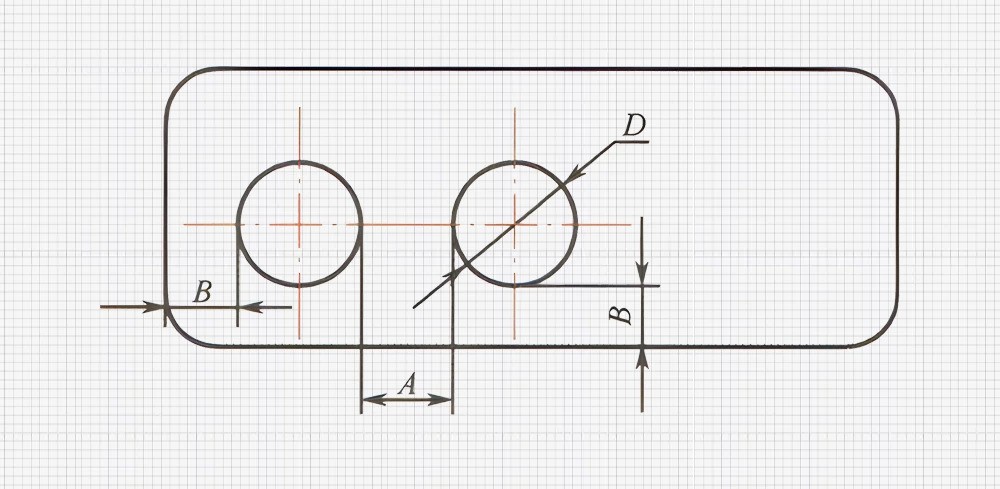

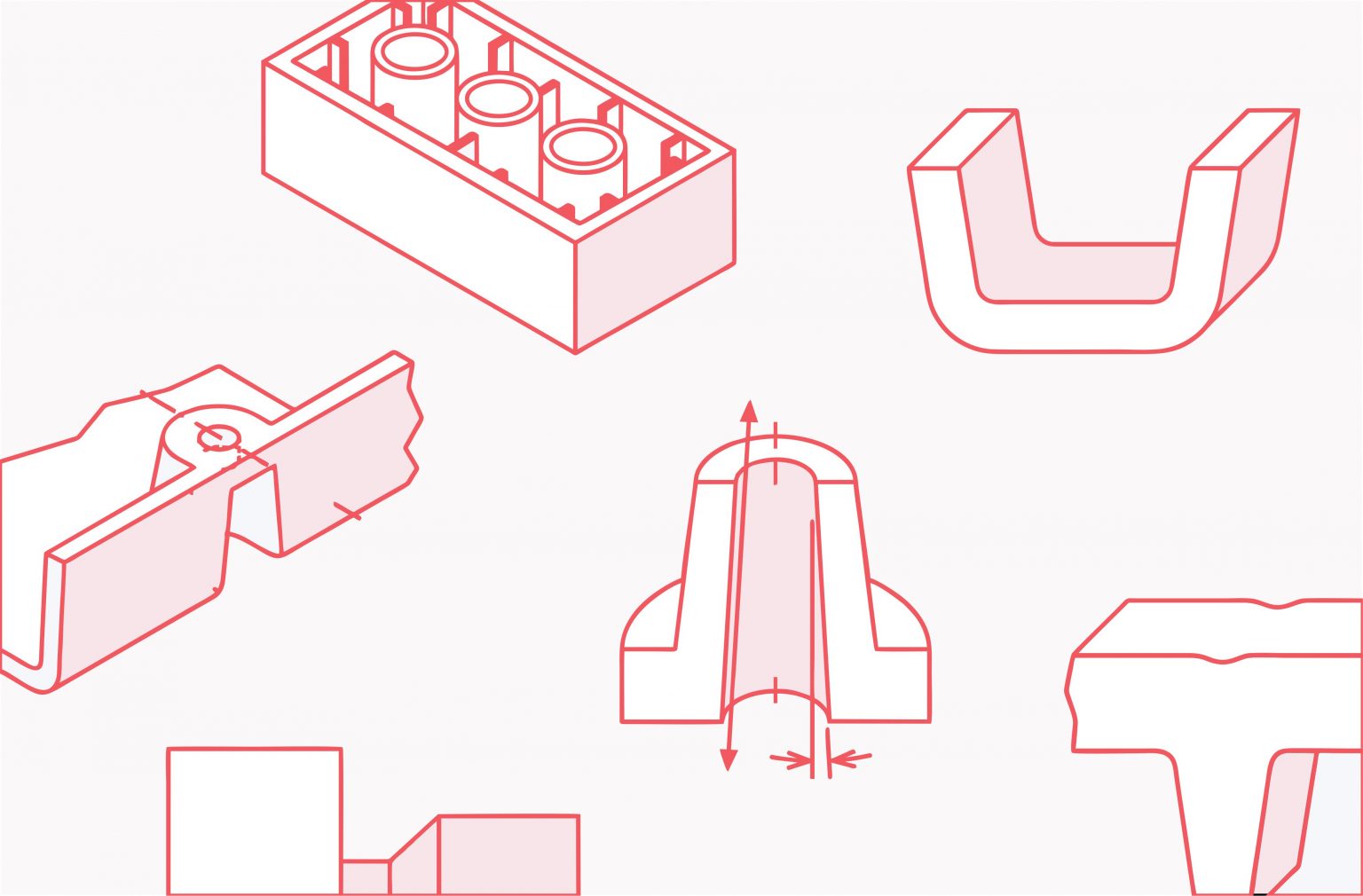

ol dɛn .

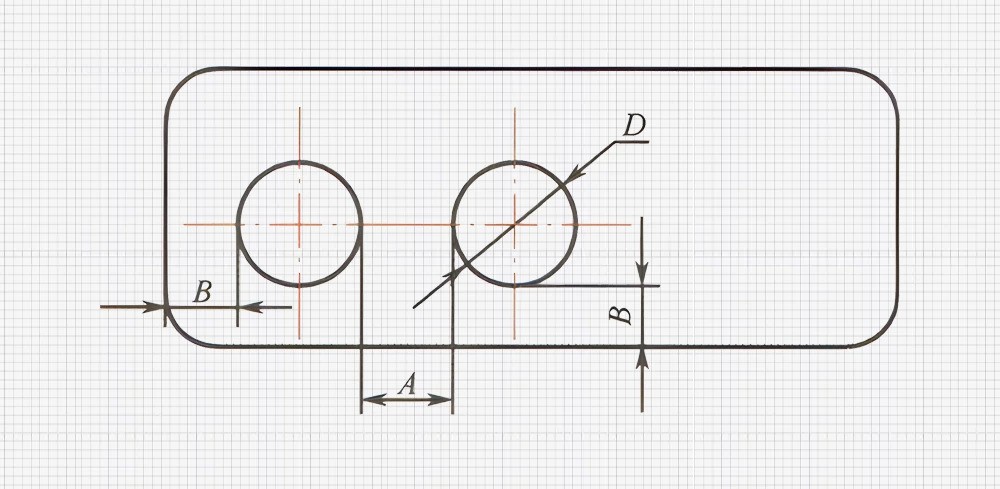

Ɔl dɛn de du difrɛn wok dɛn na plastic prɔdak ɛn dɛn nid fɔ tek tɛm tink bɔt aw fɔ disayn.

Dizayn rikwaymɛnt fɔ ol dɛn .

Distεns bitwin ol dεm (a): ≥ D (hol dayamita) if d < 3.00mm; ≥ 0,70d if d > 3,00mm

Distans frɔm ol to ɛj (b): ≥ D

Rilayshɔn bitwin ol dayamita ɛn dip .

Dizayn kɔnsidareshɔn fɔ spɛshal ol tayp dɛn .

Step Hols: Yuz bɔku bɔku koaksial kɔnɛkt ol dɛn we gɛt difrɛn dayamita dɛn .

Angled holes: Align aks wit mold opin direkshɔn we i pɔsibul we i pɔsibul

Sayd ol ɛn indenteshɔn: Tink bɔt di kɔr pul strɔkchɔ ɔ dizayn improvements

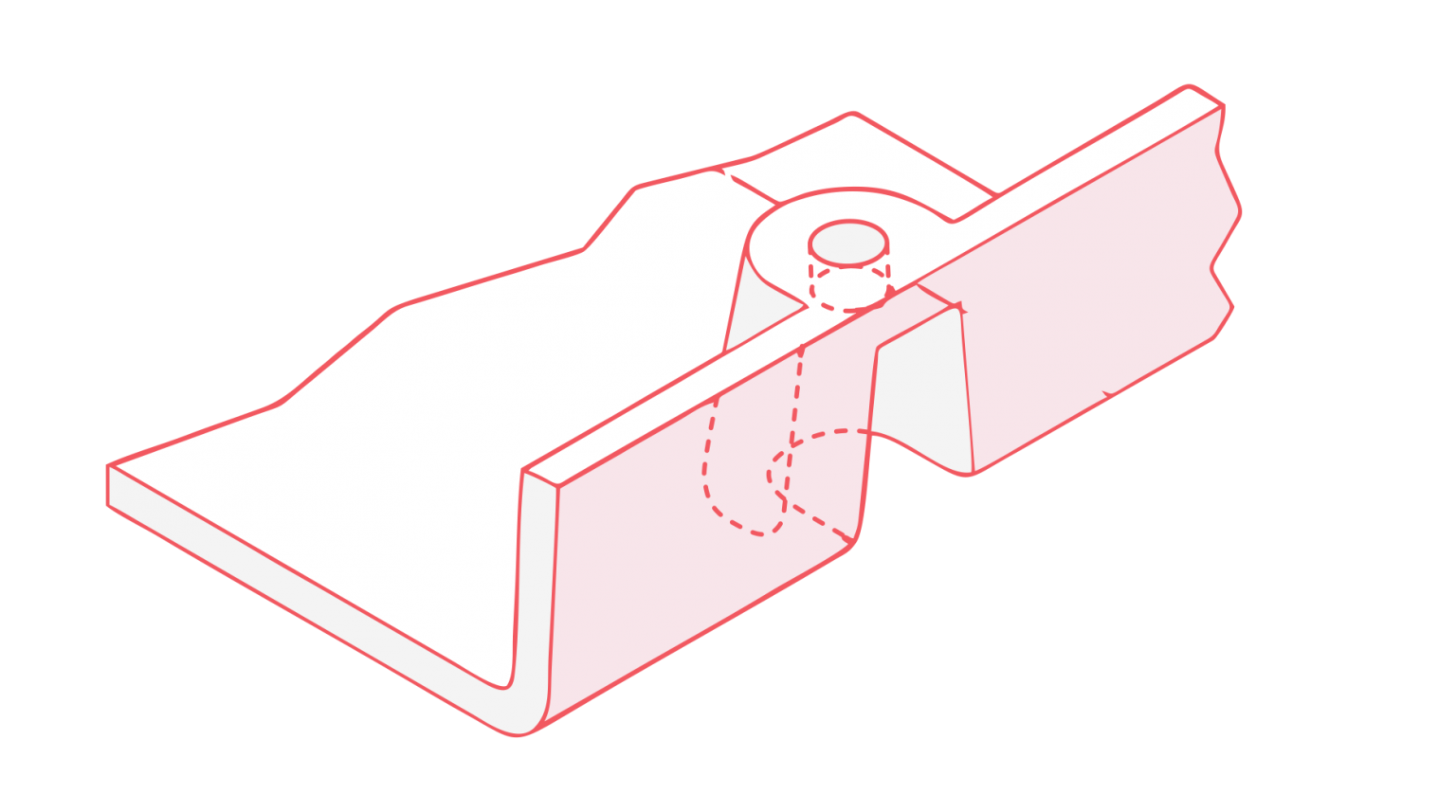

Bɔs dɛn

Bɔs dɛn kin gi asɛmbli pɔynt dɛn, sɔpɔt ɔda pat dɛn, ɛn ɛp fɔ mek di strɔkchɔral intɛgriti bɛtɛ.

Besik dizayn gaydlayn fɔ bɔs dɛn .

Ayt: ≤ 2.5 tɛm di bɔs dayamita

Yuz riinfɔsmɛnt rib ɔ ataya to ɔta wɔl dɛn we i pɔsibul .

Disain fɔ smol plastic flɔ ɛn izi fɔ pwɛl .

Disain Point fɔ difrɛn matirial dɛn .

ABS: Ɔta dayamita ≈ 2x insay dayamita; Yuz Beveled Ribs fɔ Strɔng .

PBT: bays dizayn pan rib kɔnsɛpt; Kɔnekt to saydwɔl dɛn we i pɔsibul .

PC: Intalɔk sayd bɔs dɛn wit rib; Yuz fɔ Asɛmbli ɛn Sɔpɔt .

PS: Ad ribs fɔ mek i strɔng; Kɔnekt to saydwɔl dɛn we de nia de

PSU: Ɔta dayamita ≈ 2x insay dayamita; Ayt ≤ 2x ɔda dayamita .

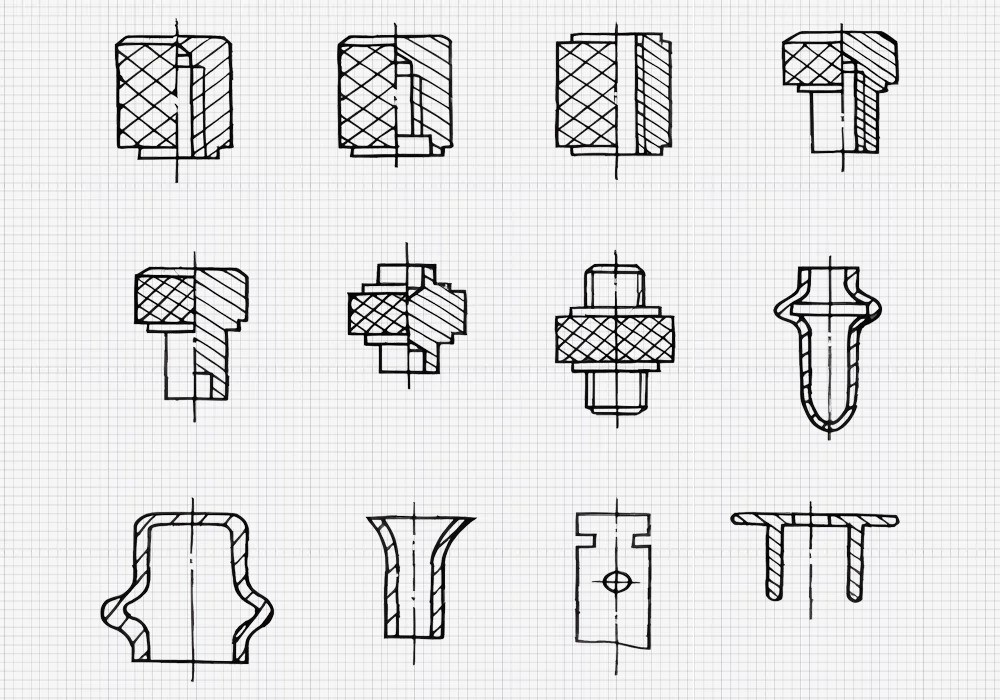

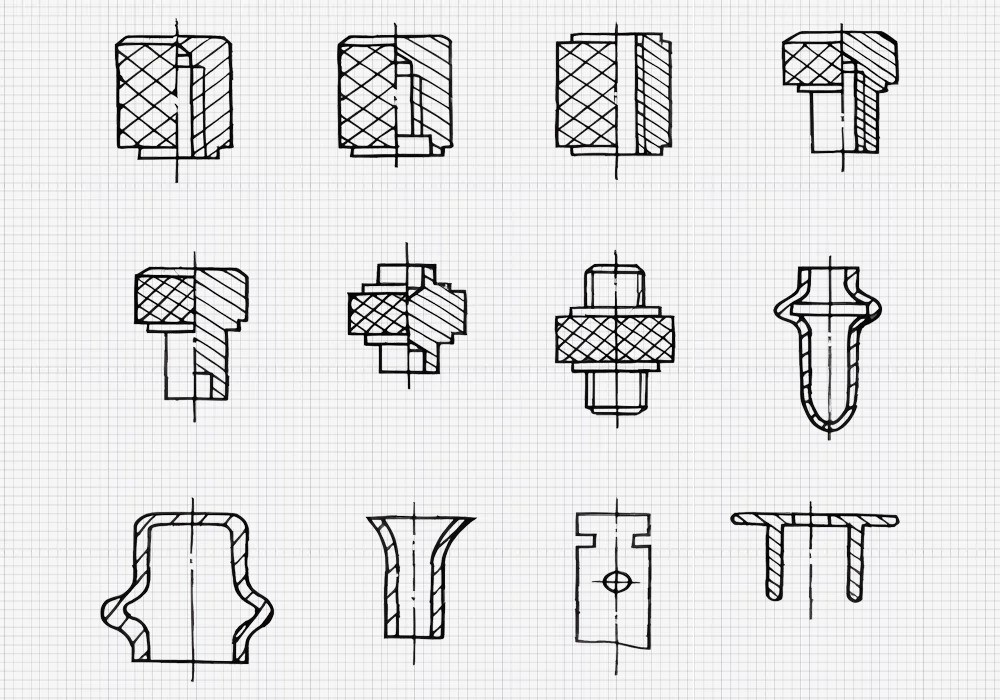

Insɛt dɛn .

Inserts Enhans functionality, gi decorative elements, ɛn impruv assembly options in plastic parts.

Shep ɛn strɔkchɔral rikwaymɛnt fɔ insɛt dɛn .

Manufacturability: Kompatibl wit kot ɔ stamp prɔses .

Mekanikal Strɔng: Naf Matirial ɛn Dimɛnshɔn dɛn .

Bɔndin Strɔng: Adekwat sɔfayz ficha fɔ sikyuɔr atakshɔn .

Pozishɔn: Silindrikal ɛkstend pat fɔ izi mold plesmɛnt

Flash Prevention: Inklud silin Boss strɔkchɔ dɛn .

Pɔst-prɔsɛsin: Dizayn fɔ sɛkɔndari ɔpreshɔn (thrɛd, kɔt, flanging)

dizayn kɔnsidareshɔn dɛn we yu de yuz insɛt dɛn .

Mek shɔ se yu put di rayt pozishɔn insay di mold dɛn .

Krio strɔng kɔnɛkshɔn wit pat dɛn we dɛn dɔn mol .

Prɛvent plastic lik arawnd insɛt .

Tink bɔt di difrɛns bitwin di tɛmal ɛkspɛnshɔn bitwin di insɛt ɛn di plastic matirial .

Produk surface texture ɛn tɛks/patna dizayn .

Surface textures fɔ plastic prodakt dɛn .

Dɛn kin mek plastic prodak sɔfays dɛn wit difrɛn tɛkstɔr dɛn fɔ mek dɛn ebul fɔ du mɔ fayn fayn tin dɛn, fɔ wok fayn fayn wan, ɛn fɔ mek dɛn ebul fɔ yuz di tin dɛn we dɛn de yuz. Kɔmɔn sɔfays tɛkstɔr dɛn inklud:

Fayn

Spark-eched .

Patterned etched na

Engraved .

Smayt surfaces .

Smɔl smɔl tin dɛn we de ɔp di grɔn kin kɔmɔt frɔm di polish mold sɔfays dɛn. Dɛn kin gi:

Spark-ɛt di sɔfays dɛn .

Krio tru kɔpa EDM prɔsesin fɔ di mold kaviti, spak-ɛt sɔfays dɛn de gi:

Patterned etched surface dɛn .

Dɛn sɔfays ya gɛt difrɛn patɛn dɛn we dɛn etch insay di mold kaviti, we de gi:

Dizayn dɛn we dɛn kin kɔstɔmayz .

Enhansed prodakt difrɛns .

Impɔtant Taktil Prɔpati dɛn .

Surface dɛn we dɛn rayt wit engrav .

Dɛn kin mek sɔfays dɛn we dɛn rayt bay we dɛn de mek dɛn bay dairekt mashin patɛn dɛn insay di mol, we de alaw fɔ:

Draft angle kɔnsidareshɔn fɔ tɛkstɔr sɔfays dɛn .

We yu de disayn tɛkstɔr sɔfays dɛn, tink bɔt fɔ inkrisayz draft angul dɛn fɔ mek i izi fɔ mek dɛn ebul fɔ pul pat pan di tin dɛn we dɛn de yuz fɔ mek pat:

| di dip we | dɛn tek di tɛkstɔr we dɛn kin yuz fɔ mek dɛn gɛt ɔda draft angul . |

| 0,025 mm | 1° . |

| 0,050 mm | 2° . |

| 0,075 mm | 3° . |

| > 0,100 mm | 4-5° . |

Teks ɛn Pɔtn Dizayn .

Bɔku tɛm, plastic prɔdak dɛn kin put tɛks ɛn pɔtn fɔ mek dɛn gɛt brand, instrɔkshɔn, ɔ tin dɛn we dɛn kin yuz fɔ mek di ples fayn. Dɛn kin rayz dɛn ɛlimɛnt ya ɔ dɛn kin rayz dɛn.

rayz vs. recessed surfaces .

Rikɔmɛndishɔn: Yuz di say dɛn we dɛn rayz fɔ tɛks ɛn patɛn we i pɔsibul.

Di bɛnifit dɛn we di say dɛn we dɛn dɔn rayz de gi:

Fɔ dizayn dɛn we nid fɔ gɛt flush ɔ recessed ficha dɛn:

Krio wan eria we dɛn dɔn rɛs .

rayz tɛks ɔ patɛn insay di rɛs .

Mentɛn ɔl di flush apinans we yu de simpul mold dizayn .

Teks ɛn Patɛn Dimɛnshɔn dɛn

| Ficha | Rikɔmɛnd Dimɛnshɔn |

| Ayt/dipth . | 0,15 - 0,30 mm (raised) |

| 0.15 - 0,25 mm (we dɛn gi di mɔni) |

Teks saiz spesifikeshɔn dɛn .

Fɔ fala dɛn gaydlain ya fɔ di bɛst tɛks dizayn:

Stroke wit (a): ≥ 0,25 mm

Spays bitwin aks (b): ≥ 0.40 mm

Distans frɔm aks to ɛj (c, d): ≥ 0.60 mm

Atikul dɛn we dɛn kin tink bɔt fɔ mek tɛks/patna dizayn .

Avɔyd shap angul dɛn na tɛks ɔ patɛn .

Mek shɔ se saiz fayn fɔ moldin prɔses .

Tink bɔt di impak we tɛks/patna gɛt pan ɔl di pat trɛnk

Evaluate di effekt we tɛks/patna gɛt pan matirial flɔ di tɛm we dɛn de mol di moldin .

Atikul dɛn we dɛn dɔn tink bɔt fɔ mek dɛn gɛt strɔkchɔral dizayn .

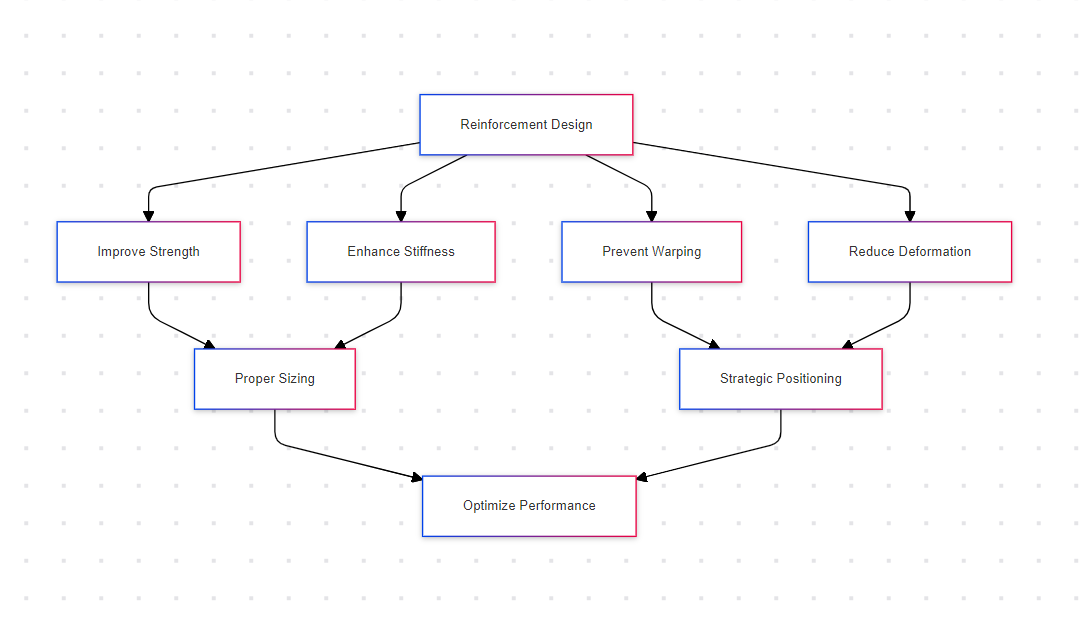

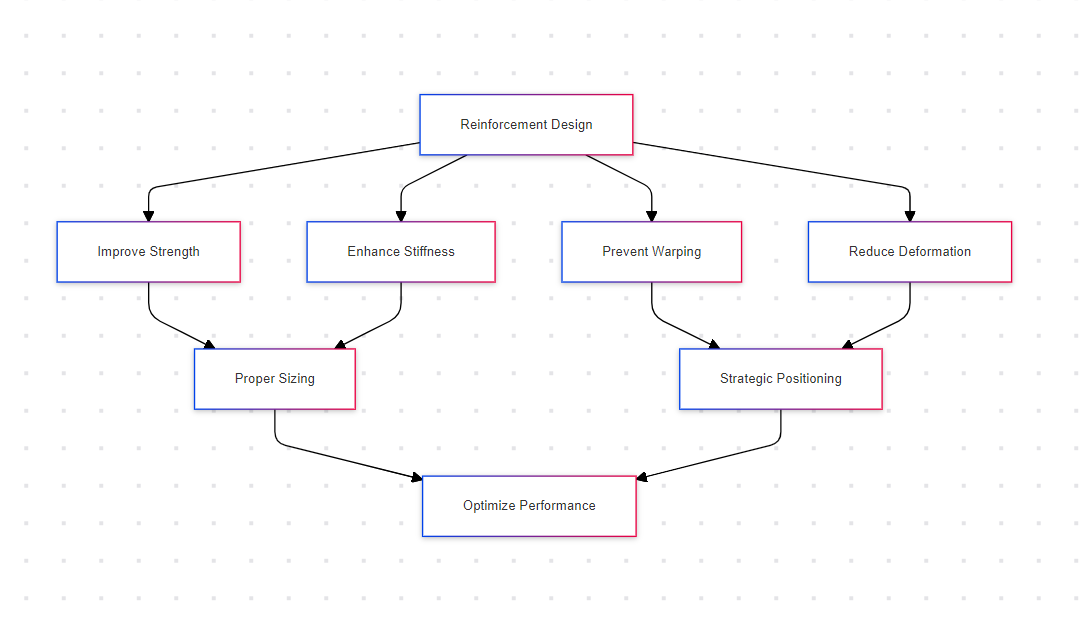

Riinfɔsmɛnt Struktrɔ Dizayn Prinsipul dɛn .

Riinfɔsmɛnt strɔkchɔ dɛn de ple wan impɔtant pat fɔ ɛp fɔ mek di ɔl di wok we dɛn de du fɔ di plastic prɔdak dɛn, go bifo. Dɛn kin rili ɛp fɔ mek trɛnk, stiffnɛs, ɛn dimɛnshɔnal stebiliti.

Di men tin dɛn we dɛn want fɔ du fɔ mek dɛn gɛt mɔ trɛnk fɔ mek dɛn strɔng:

Strɔng ɛnhansmɛnt .

Stifnɛs Improvement .

Di we aw dɛn de mek pipul dɛn nɔ gɛt wɔpin .

Difɔmeshɔn ridyushɔn .

Prɔpa pozishɔn ɛn sayzin fɔ riinfɔsmɛnt dɛn:

Di tik we di wɔl tik: 0.4-0.6 tɛm di men bɔdi tiknes

Spays: > 4 tɛm men bɔdi tiknes

Ayt: < 3 tɛm men bɔdi tiknes

Skru Kɔlɔm Riinfɔsmɛnt: at le 1.0mm dɔŋ di kɔlɔm sɔfays

Jɛnɛral riinfɔsmɛnt: Minimum 1.0mm dɔŋ pat sɔfa ɔ pat layn

Advans Riinfɔsmɛnt Tɛknik dɛn:

Misaligned reinforcement bars fɔ mek dɛn nɔ bil bɔku bɔku tin dɛn .

Holo strɔkchɔ dɛn na riinfɔsmɛnt intasekshɔn dɛn .

Tɛnshɔn-bɛs dizayn fɔ slɛnd riinfɔsmɛnt dɛn .

Fɔ avɔyd di kɔnsɛntreshɔn fɔ strɛs .

Stret konsantreshɔn kin rili impɔk di strɔkchɔral intɛgriti ɛn lɔng layf fɔ plastic prɔdak dɛm. Di rayt we aw dɛn mek di dizayn kin mek dɛn tin ya stɔp dɛn tin ya.

Impɔtant fɔ avɔyd shap kɔna dɛn:

Measures fɔ ridyus strɛs kɔnsɛntreshɔn:

Chamfers na di .

Raun Kɔna dɛn .

Gentle slopes fɔ transishɔn dɛn .

Inward hollowing na shap kɔna dɛn .

| Tɛknik | Diskripshɔn bɛnifit | bɛnifit . |

| Chamfers na di . | Ej dɛn we dɛn dɔn bɛvɛl . | smɔl smɔl strɛs distribyushɔn . |

| Raun Kɔna dɛn . | Kerv transishɔn dɛn . | I de pul shap strɛs pɔynt dɛn . |

| Slɔp dɛn we nɔ gɛt saful saful . | Smɔl smɔl tik dɛn de chenj . | Ivin strɛs distribyushɔn . |

| Inward Hollowing . | Material removal na kɔna dɛn . | Localized strɛs ridɔkshɔn . |

Disain fayn fayn draft angul dɛn .

Draft angles na impɔtant tin fɔ saksesful pat ɛjekshɔn frɔm mold. Dɛn signifyantli impɔk pat kwaliti ɛn prodakshɔn efyushɔn.

Prinsipul fɔ no di draft angul dɛn:

Yuz wan ol nɔmba angul dɛn (ɛgz., 0.5°, 1°, 1.5°)

Ekstirian angles > intɛriɔ angul dɛn .

Maksimayz angul dɛn we nɔ gɛt kɔmprɔmis apinans .

Fakta dɛn we de inflɔws di draft angul saiz:

pat dip .

Surface Finish .

Material Shrinkage Rɛt .

Tekstura dip .

Draft Angle Design Points fɔ difrɛn matirial dɛn:

| Material | Recommended Draft Angle Rɛnj |

| ABS na ABS | 0,5° - 1° |

| PC . | 1° - 1,5° . |

| PP we de na di . | 0,5° - 1° |

| PS . | 0,5° - 1° |

| ANIMAL WE YU GI NEM | 1° - 1,5° . |

Structural dizain frɔm mold strɔkchɔ pɔsitiv .

Efisiɛns mold dizayn impɔtant fɔ saksesful plastic pat prodakshɔn. Tink bɔt dɛn aspek ya fɔ mek ɔl tu di pat ɛn di mold dizayn fayn.

Fɔ avɔyd kɔmpleks strɔkchɔ dɛn:

Fɔ avɔyd di strɔkchɔ dɛn we de insay di intanɛt:

We yu tink bɔt di tin dɛn we dɛn fɔ du fɔ mek di lateral rilis:

Alaw inof ples fɔ mek di slayd dɛn muv .

Disain di rayt say dɛn we dɛn kin stɔp fɔ wok .

Optimize pat orientation in di mold .

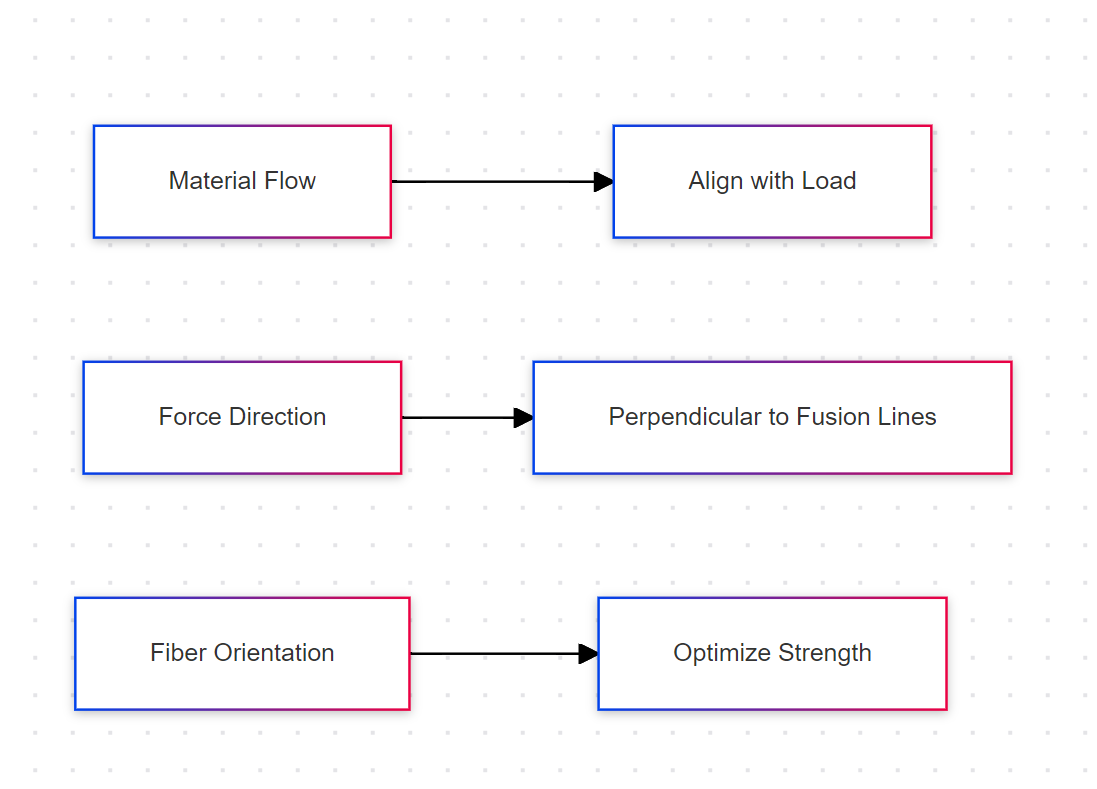

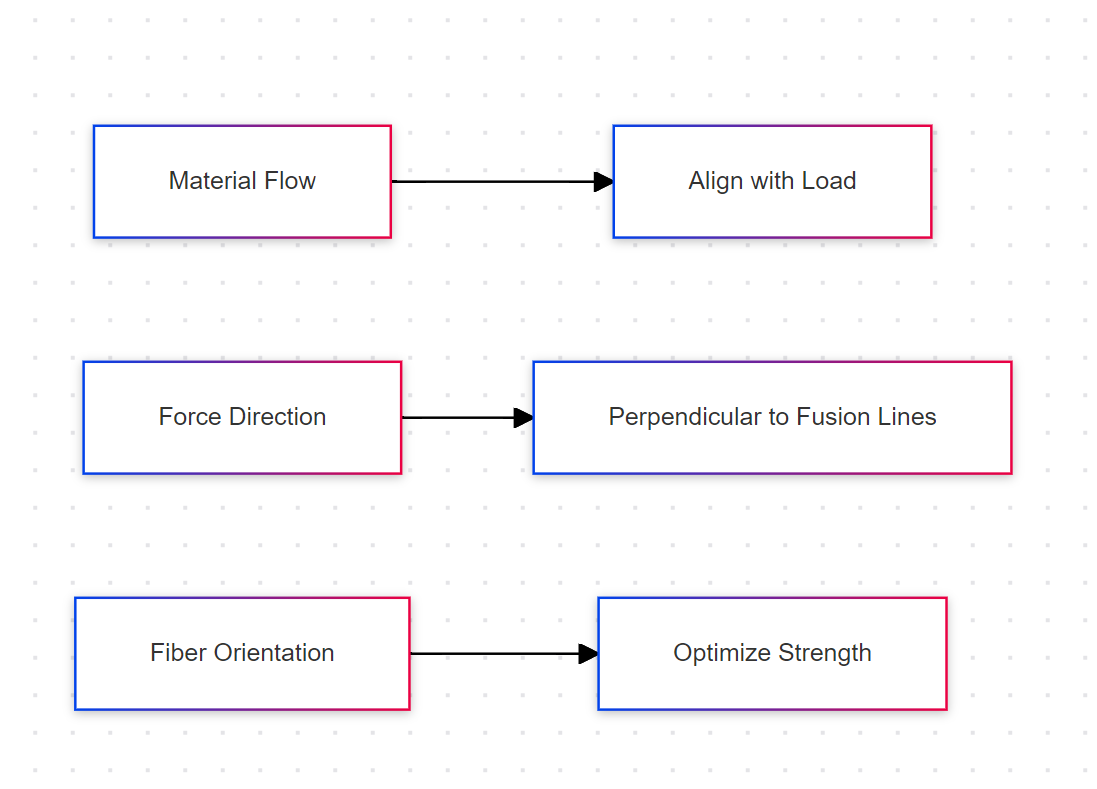

Disain fɔ nɔ-isotropik kwaliti dɛn fɔ plastic dɛn .

Bɔku plastic dɛn de sho nɔ-isotropik prɔpati dɛn, we nid spɛshal dizayn kɔnsidareshɔn fɔ maksimayz pefɔmɛns.

Aligning Material Flow Direkshɔn wit lod-bearing dairekshɔn:

Fos dairekshɔn rilitiv to fushɔn layn dɛn:

Struktural dizain frɔm asɛmbli pɔynt .

Ifɛktiv asɛmbli dizayn de mek shɔ se di prɔdak de wok, i go liv lɔng, ɛn i izi fɔ mek am.

Fɔ avɔyd big big saiz dɛn wit smɔl smɔl tolɛreshɔn dɛn:

Bonding intafeys dizayn: .

Prioritize shear force ova tearing tension .

Inkris di Bonding Surface Eria .

Tink bɔt aw fɔ yuz di kemikal dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kɔl adhesives .

Bolt kɔnɛkshɔn kɔnsidareshɔn fɔ plastic pat dɛn:

Yuz Inserts fɔ gɛt ay-stress kɔnɛkshɔn .

Dizayn aprɔpriet bɔs strɔkchɔ dɛn .

Tink bɔt di difrɛns bitwin di tɛmal ɛkspɛnshɔn .

Ɛksplen

Insay plastic prodakt dizayn, ki strɔkchɔral factor dɛm lɛk wɔl tik, riinfɔs rib dɛm, ɛn draft angul dɛm impɔtant fɔ durabiliti ɛn pefɔmɛns. I impɔtant fɔ tink bɔt matirial prɔpati, mold strɔkchɔ, ɛn asɛmbli nid ɔlsay na di prɔses. Prɔpa strɔkchɔral dizayn nɔ jɔs de ɛp fɔ mek di prɔdak wok fayn bɔt i de ridyus di prɔblɛm dɛn ɛn di kɔst fɔ mek tin dɛn. Bay we dɛn de pe atɛnshɔn pan dɛn dizayn ɛlimɛnt dɛn ya, di wan dɛn we de mek dɛn kin mek shɔ se dɛn gɛt ay kwaliti, kɔst-ɛfɛktiv plastic pat dɛn we de mit ɔl tu di funkshɔnal ɛn aestɛtik rikwaymɛnt dɛn.