Ni a bɛ fɔ nɛgɛw ma minnu bɛ kɛ fɛn dilanni n’u jɔli la, sɔsɔli min bɛ nɛgɛ ni nɛgɛ cɛ (o la, fɛn suguya caman bɛ yen i n’a fɔ nɛgɛ ni nɛgɛ min bɛ kɛ ni nɛgɛ ye ani nɛgɛ min bɛ kɛ ni nɛgɛ ye, n’o ye nɛgɛ ye, o bɛ to jateminɛba ye ɛntɛrinɛti injiniyɛriw ni fɛn dilannikɛlaw fɛ. Danfara min bɛ nɛgɛ ni nɛgɛ cɛ, o faamuyali nafa ka bon walasa ka kunnafoni sɔrɔ ka ɲɛsin latigɛw ma minnu bɛ kɛ ka ɲɛsin fɛnw sugandili ma.

Nɛgɛ min bɛ kɛ, o ye mun ye?

Nɛgɛdaga ye nɛgɛ ye min bɛ sɔrɔ karɔbɔni hakɛ la min ka ca ni 2% ye, a ka c’a la, a bɛ bɔ 2% la ka se 4% ma, ka fara siliyɔmu ni manganɛsi hakɛ caman kan. Nɛgɛ minnu bɛ bɔ, olu ni u jogo b’a to a bɛ danfara bɔ ni nɛgɛ ye, o bɛ mɔgɔ caman bila ka 'i ye nɛgɛ nɛgɛ ye wa?' k'a sɔrɔ nɛgɛ bɛ nɛgɛ la, a tɛ nɛgɛ ye fɛɛrɛko siratigɛ la k'a sababu kɛ a ka karɔbɔli hakɛ ka bon. Kabɔn hakɛ min bɛ nɛgɛ sɔgɔlen na, o bɛ jogo kɛrɛnkɛrɛnnenw di a ma, i n’a fɔ:

Fanga min bɛ se ka degun .

Excellent de donne resistance .

Vibration damping capacity .

A bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min tɛ se ka kɛ .

Machinability .

Nka, nɛgɛ min bɛ bɔ, o fana nafa dɔw bɛ yen, i n’a fɔ:

O dɛsɛw bɛɛ n’a ta, nɛgɛ min bɛ bɔ, o bɛ to ka kɛ sugandili ye min ka di kosɛbɛ baara suguya caman na k’a sababu kɛ a musaka ni a kɛcogo caman ye.

kemikɛli fɛnɲɛnamafagalan .

Nɛgɛ min bɛ kɛ, o ka kemikaliya jɔyɔrɔ ka bon kosɛbɛ a ka jogo dɔnni na. Fɛn fɔlɔ minnu bɛ nɛgɛ sɔgɔlen na olu ye:

| element | kɛmɛsarada la . |

| Carbone . | 2% - 4% . |

| Silicon . | 1% - 3% . |

| Manganɛsi . | 0,5% - 1% . |

| fosiforo . | ka se 1% ma . |

| Kibaruyaw . | ka se 0,1% ma . |

Karɔbɔli ni siliyɔmu hakɛ bɛ nɔba bila nɛgɛ fililenw ni u cogoyaw la. Kabon hakɛ caman bɛ dɔ fara grafite hakɛ kan min bɛ sɔrɔ solidification waati la, ka sɔrɔ siliyɔmu bɛ graphite sɔrɔli sabati ani ka a kɛ ka a fili.

Farikolo yɔrɔw .

Nɛgɛ min bɛ kɛ ka nɛgɛ kɛ, o bɛ farikolo cogoya caman jira:

Density (dansi) ka bon: nɛgɛ min bɛ kɛ, o ka density (dansi) bɛ se 7,2 g/cm⊃3 ma;, o b’a to a ka gɛlɛn ka tɛmɛ nɛgɛ kan.

A bɛ wuli yɔrɔ min na, o ka dɔgɔn: A bɛ wuli 1150°C fo 1250°C lamini na, o min ka dɔgɔn ni nɛgɛ ye, o bɛ kɛ sababu ye ka a filili nɔgɔya.

Sumaya-minɛn: nɛgɛ min bɛ kɛ, o bɛ se ka kɛ 50 W/m·k ɲɔgɔn ye, o min ka dɔgɔ ni nɛgɛ ye.

Kuranko : A ka kuran taabolo ka dɔgɔn ni nɛgɛ ye, o b’a to a bɛnnen don kuran baara ma yɔrɔ min na, fɛn minnu bɛ kɛ ka fɛnw tanga, olu ka kan ka kɛ.

Nɛgɛ suguya minnu bɛ kɛ .

Nɛgɛ min bɛ bɔ, o bɛ se ka tila suguya caman na ka da a ka mikrostruktɛri n’a jogo kan. Nɛgɛ suguya jɔnjɔnw ye:

Gris ka nɛgɛ .

Nɛgɛ bilenman ye suguya ye min ka ca, a bɛ dɔn ni grafite flakew bɛ a la a ka mikro-yɔrɔ la. A kɔnɔ:

Kabɔn: 2,5% - 4% .

Silicon: 1% - 3% .

Manganɛsi: 0,4% - 1% .

Nɛgɛ bilenman min bɛ kɛ ni gris ye, o bɛ fanga ɲuman di, a bɛ se ka kɛ ni masin ye, ani a bɛ se ka yɛrɛyɛrɛ kosɛbɛ. A bɛ kɛ ka caya baarakɛcogo la i n’a fɔ:

Nɛgɛ finmanw .

Nɛgɛ finman bɛ kari finman yɔrɔ la ka da a kan grafite tɛ yen. A ka daɲɛw labɛncogo bɛ sɔrɔ:

Nɛgɛ finmanw bɛ dɔn a ka gɛlɛya ka bon ani a sɛgɛncogo ɲuman. A bɛ baarakɛminɛnw sɔrɔ:

Grinding Media .

Pompes de pompes .

Ball Mills .

Rolling Rolls .

nɛgɛ malleable .

Nɛgɛ min bɛ se ka sɔgɔ, o bɛ sɔrɔ nɛgɛ finmanw fɛ minnu bɛ funteni furakɛ walasa ka karɔti brittle structure (karɔti brittle) jɔcogo sɛmɛntiya ka kɛ feritiki matiriyali ye min bɛ kɛ ni ductile ye. A kɔnɔ:

Nɛgɛ malleable bɛ fanga, ductility ani toughness caman fara ɲɔgɔn kan. A bɛ baara kɛ ni nin ye:

Pipe fitininw .

Bolo baarakɛminɛnw .

Sɛnɛfɛnw ka minɛnw .

Mobili yɔrɔw .

Nɛgɛ min bɛ kɛ ka nɛgɛ bɔ (nodule) .

Nɛgɛ min bɛ wele ko nodular iron, o bɛ sɔrɔ ni manje walima cerium ye nɛgɛ wulilen na, o bɛ kɛ sababu ye ka grafite kɛ nodu sphériques ye flakes nɔ na. A dabɔcogo dɔw ye:

Kabɔn: 3,2% - 4% .

Silicon: 1,8% - 2,8% .

Manganɛsi: 0,1% - 1% .

Ductile cast iron bɛ fanga caman di, ka gɛlɛya, ani ka ductility di. A bɛ kɛ ka caya:

mansinw .

Gears .

Valves .

Suspension components .

Nɛgɛ min bɛ kɛ ni vermiculaire ye .

Vermicular cast iron, n’a bɛ fɔ fana ko graphite iron (CGI), o bɛ ni microstructure kɛrɛnkɛrɛnnen ye ni graphite particules ye a bɛ kɛ flakes surunw ye minnu ka bon. A bɛ cɛmancɛ-yɔrɔw Di nɛgɛ jɛman ni nɛgɛ-nɛgɛ-nɛgɛ-minɛnw cɛ, i n’a fɔ:

Fanga ni gɛlɛya ka bon ka tɛmɛ nɛgɛ bilenman kan .

A ka fisa ni funteni ye ka tɛmɛ ductile cast nɛgɛ kan .

A ka ca a la, a bɛ se ka kɛ ni a bɛ kɛ ka a suma ni ductile cast iron ye .

Vermicular nɛgɛ bɛ kɛ ka caya mobili baarakɛcogo la, i n’a fɔ:

Dizilɛri motɛri blokiw .

Manifolds exhaust .

Disiki freinw .

nɛgɛ min bɛ kɛ ni nɛgɛ ye .

Nɛgɛ min bɛ kɛ ni nɛgɛ ye, o bɛ sɔrɔ ni fɛn dɔw farala a kan i n’a fɔ nikɛri, chrome, molybdenum, walima kuran walasa ka jogo kɛrɛnkɛrɛnnenw sabati. Ka kɛɲɛ ni fɛnw ye minnu bɛ kɛ ka fɛnw sɔgɔ, nɛgɛ min bɛ kɛ ni nɛgɛ ye, o bɛ se ka kɛ:

Alloyed cast Iron bɛ baarakɛminɛnw sɔrɔ izini suguya caman na, i n’a fɔ:

Steel ye mun ye?

Nɛgɛ ye nɛgɛ ye min bɛ sɔrɔ nɛgɛ la, a bɛ sɔrɔ karɔbɔni ni fɛn wɛrɛw hakɛ fitininw na, i n’a fɔ manganɛsi, siliyɔmu, fosiporozɛni, kisɛ, ani oksizɛni. A bɛ dɔn a ka fanga bonya fɛ, a ka ductility (ductility) ani fɛn caman na, o b’a kɛ fɛn ye min bɛ kɛ ka caya izini suguya caman na. Steel ka nafaw bɛ se ka labɛn ni a labɛncogo ladilanni ye ani funteni furakɛli fɛɛrɛw fɛ.

kemikɛli fɛnɲɛnamafagalan .

Nɛgɛ ka kemikaliya jɔyɔrɔ ka bon kosɛbɛ a ka nafaw dɔnni na. Fɛn fɔlɔ minnu bɛ nɛgɛ la olu ye:

| element | kɛmɛsarada la . |

| Nɛgɛ | 90% - 99% . |

| Carbone . | 0,1% - 2% . |

| Manganɛsi . | 0,1% - 1% . |

| Silicon . | 0,1% - 0,5% . |

| Fɛn wɛrɛw . | < 1% . |

Kabon hakɛ ye fɛn nafamaba ye min bɛ nɔ bila Steel ka nafaw la. Kabon hakɛ caman bɛ fanga ni gɛlɛya bonya nka a bɛ dɔ bɔ ductility ni weldability la.

Farikolo yɔrɔw .

Nɛgɛ bɛ farikolo cogoya danfaralen caman jira:

Tensile fanga ka bon: Nɛgɛ bɛ se ka donibaw muɲu k’a sɔrɔ a ma kari walima ka a tiɲɛ kudayi.

Ductility: A bɛ se ka sama ka kɛ nɛgɛw ye walima ka a wuli ka kɛ sɛbɛnw ye k’a sɔrɔ a ma kari.

A bɛ wuli yɔrɔ min na, o ye nɛgɛ ye min bɛ wuli ni nɛgɛ ye 1370°C ni 1540°C cɛ, ka kɛɲɛ n’a kɛcogo ye.

Funteni-taama-cogo: A ka funteni-taama-cogo ka bon kosɛbɛ, o bɛ funteni Di a ma ka 'yɔrɔ wɛrɛ Kɛ.

Kuranko : nɛgɛ ye kuran ye min bɛ se ka kɛ, hali ni a tɛ baara kɛ kosɛbɛ i n’a fɔ nɛgɛ walima aliminiyɔmu.

Nafa minnu bɛ sɔrɔ nɛgɛ la .

Steel bɛ nafa caman di, o b’a to a bɛ kɛ sugandili ye min ka di kosɛbɛ baara suguya caman na:

Fanga ni girinya hakɛ caman: Nɛgɛ bɛ fanga ɲuman di ka sɔrɔ ka girinya dɔgɔya kosɛbɛ ni i ye a suma ni fɛn wɛrɛw ye.

A bɛ se ka muɲu: A bɛ se ka sigida gɛlɛnw muɲu, ka fɛnw tiɲɛ, ani ka sɛgɛn, o b’a to a bɛnnen don fɛnw ni fɛnw ma minnu bɛ mɛn.

Fɛn caman kɛli : nɛgɛ bɛ se ka kɛ cogo la, ka dilan, ka fara ɲɔgɔn kan ni fɛɛrɛ suguya caman ye, ka sira di dilancogo ni jɔcogo gɛlɛnw ma.

A bɛ se ka segin ka kɛ fɛn wɛrɛ ye: A bɛ se ka segin ka kɛ fɛn wɛrɛ ye 100%, o b’a to a bɛ kɛ fɛn ye min bɛ sigida lakana.

Musow ka musaka: Nɛgɛ sɔngɔ man gɛlɛn ni a bɛ tali kɛ fɛn wɛrɛw la minnu ka nafolo bɔlen don ɲɔgɔn fɛ.

Nafa minnu bɛ sɔrɔ nɛgɛ la .

Hali n’a nafa ka bon, nɛgɛso fana bɛ ni nafa dɔw ye:

Nɔgɔ : nɛgɛ bɛ se ka nɔgɔ ani ka nɔgɔ ni a bɛ kɛ ni ji ni ɔkisizɛni ye, o bɛ a to a bɛ se ka kɛ ka fɛnw tanga walima ka fɛnw kɛ fɛn wɛrɛw ye walasa ka nɔgɔw kunbɛncogo ɲɛ.

Sɛgɛn : doni min bɛ segin ka kɛ cyclique la, o bɛ se ka kɛ sababu ye ka nɛgɛ dɛsɛ degunw na a ka sɔrɔ fanga kɔrɔ, o ye ko ye min bɛ wele ko sɛgɛn.

density (dansi) ka bon : nɛgɛ ka ca ka tɛmɛ fɛnw kan i n’a fɔ aluminiyɔmu, o bɛ se ka kɛ dɛsɛ ye baarakɛcogo la, girinya dɔgɔyali nafa ka bon yɔrɔ minnu na.

Energy-intensive production (Sɔrɔli min bɛ fanga caman sɔrɔ): Nɛgɛ dilanni bɛ fanga donta caman de wajibiya, o bɛ kɛ sababu ye ka gaziw bɔ minnu bɛ bɔ kɛnɛ kan.

Nɛgɛ suguyaw .

Nɛgɛ bɛ se ka tila suguya caman na ka da a labɛncogo n’a jogo kan:

Karɔbɔni nɛgɛ .

Karɔbɔli nɛgɛ ye nɛgɛ suguya ye min ka ca, nɛgɛ ni karɔbɔli fɔlɔ bɛ min na. A bɛ tila ka caya ka da a ka karɔbɔli hakɛ kan:

Nɛgɛ karɔbɔlen dɔgɔman (< 0,25% carbone): A ka nɔgɔn, a ka kan ka kɛ fɛn ye, wa a bɛ se ka dilan nɔgɔya la, o b’a to a bɛnnen don baarakɛcogo ma i n’a fɔ mobili farikolo panɛriw ani nɛgɛw.

Nɛgɛ karɔbɔli cɛmancɛ (0,25% - 0,6% karɔbɔli): a bɛ fanga ni ductility balansi ɲuman di, o b’a to a bɛnnen don baarakɛcogo ma i n’a fɔ girinw, jirisunw, ani nɛgɛso siraw.

Nɛgɛ min bɛ bɔ karɔbɔli la (> 0,6% carbone): A ka gɛlɛn, a barika ka bon, a bɛ se ka sɛgɛn nka a tɛ se ka sɛgɛn, o b’a to a bɛnnen don baarakɛcogo ma i n’a fɔ tigɛminɛnw, jibolisiraw, ani birikiw.

Alizɔn .

Aloy steel bɛ sɔrɔ ni fɛn dɔw farali ye a kan i n’a fɔ manganɛsi, nikɛri, chrome walima molybdenum walasa ka jogo kɛrɛnkɛrɛnnenw sabati. Alloying elements minnu bɛ sɔrɔ ɲɔgɔn fɛ ani u nɔfɛkow ye:

Manganɛsi: A bɛ fanga, a gɛlɛya, ani a ka se ka a yɛrɛ tanga.

Nikɛri: A bɛ gɛlɛya, ductility ani corrosion resistance ɲɛ.

Kɔrɔmu: A bɛ sɔgɔsɔgɔninjɛ kunbɛn, a gɛlɛya, ani a sɛgɛnbaliya.

Molibdɛni : a bɛ fanga, a gɛlɛya, ani a jiginni fanga bonya ni funteni kɔrɔtalen ye.

Alloy Steels bɛ baarakɛminɛnw sɔrɔ izini suguya caman na, i n’a fɔ:

Mobili yɔrɔw (Gears, Shafts, Springs)

aerospace structures .

Tubabu ni gazi pibilikiw .

Minɛnko minɛnw .

inox .

Inox ye nɛgɛ ye min bɛ kɛ ni nɛgɛ ye min ka dɔgɔn ni 10,5% ye, o bɛ kɛ ɔkisizɛni lakanani layɛrɛ ye a sanfɛla la, o bɛ kɛ sababu ye ka sɔgɔli kɛcogo ɲuman di. A ka ca a la, nɛgɛ minnu bɛ kɛ ni nɛgɛ ye, olu fana bɛ sɔrɔ ni nɛgɛ ye i n’a fɔ nikɛri, molibdɛni, ani titaniyɔmu walasa ka jogo kɛrɛnkɛrɛnnenw bonya.

Nɛgɛ minnu tɛ sɔgɔ, olu bɛ kɛ ka caya baarakɛcogo la minnu bɛ kɛ sababu ye ka fɛnw sɔgɔ, i n’a fɔ:

Baarakɛminɛn nɛgɛ .

Baarakɛminɛnw nɛgɛw ye nɛgɛ ye min ka bon kosɛbɛ, nɛgɛ minnu bɛ kɛ ni nɛgɛ ye, olu dilannen don walasa ka baarakɛminɛnw, sa ani mɔbiliw dilan. U bɛ dɔn u ka gɛlɛya ka bon, u bɛ se ka u yɛrɛ tanga, ani u bɛ se ka u ka jogo mara funteni kɔrɔtalenw na. A ka c’a la, baarakɛminɛnw nɛgɛw bɛ sɔrɔ fɛnw na minnu bɛ kɛ ka fɛnw sɔgɔ i n’a fɔ tungsten, molybdenum ani vanadium walasa k’u ka baara kɛcogo ɲɛ.

Baarakɛminɛn nɛgɛw bɛ baara kɛ ni u ye baara suguya caman na, i n’a fɔ:

Tigɛminɛnw (Drills, Taps, Dies)

Forming baarakɛminɛnw (punches, dies) .

Molds ka ɲɛsin plastiki pikiri kɛli ma .

Rolling Rolls .

Danfaraba minnu bɛ nɛgɛ ni nɛgɛ cɛ .

Hali ni nɛgɛ ni nɛgɛ ye nɛgɛ ye min bɛ sɔrɔ nɛgɛ kan, u ka jogo danfaralenw b’u la minnu b’u bɔ ɲɔgɔn na. O danfara ninnu faamuyali nafa ka bon kosɛbɛ walasa ka fɛn dɔ sugandi min bɛnnen don kosɛbɛ baarakɛcogo dilen dɔ kama. An ka danfara jɔnjɔnw sɛgɛsɛgɛ nɛgɛ ni nɛgɛ cɛ:

1. Kabon hakɛ .

Kabon hakɛ ye danfara fɔlɔ ye nɛgɛ ni nɛgɛ cɛ.

Nɛgɛ min bɛ kɛ ka bɔ, o bɛ ni karɔbɔli 2-4% ye, o bɛ jogo kɛrɛnkɛrɛnnenw di a ma i n’a fɔ fanga caman minɛcogo ani a filicogo ɲuman.

Nɛgɛ hakɛ tɛ 2% bɔ, o bɛ kɛ sababu ye ka fanga ni ductility (ductility) caya ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye.

2. Melting Point .

Nɛgɛ ni nɛgɛ min bɛ kɛ ka nɛgɛ kɛ, o ka wuliyɔrɔ bɛ danfaraba la, o bɛ nɔ bila u dilanni taabolo n’u kɛcogo la.

Nɛgɛ min bɛ bɔ, o ka dɔgɔn, a bɛ 2200°F (1204°C) lamini, o bɛ a nɔgɔya ka a wuli ka bɔn a kɔnɔ.

Nɛgɛ bɛ wuli yɔrɔ min na, o ka bon, a bɛ daminɛ 2500°F la ka se 2800°F ma (1371°C fo 1538°C), o bɛ fanga caman ɲini a wulicogo ni a sɔgɔli la.

3. Fanga .

Nɛgɛ ni nɛgɛ min bɛ kɛ, o bɛ fanga suguya wɛrɛw jira, o b’a to u bɛnnen don baara suguya caman ma.

Nɛgɛ min bɛ kɛ, o fanga ka bon kosɛbɛ, o b’a to a bɛ se ka doni girinmanw muɲu ani ka sɛgɛnbaliya kunbɛn ni a bɛ kɛ ni degun fanga ye.

Nɛgɛ fanga ka bon ni fanga ye, o b’a to a bɛ se ka fanga minɛ fanga la k’a sɔrɔ a ma kari walima k’a tiɲɛ kudayi.

4. Ductility ani brittleness .

Ductility ni brittleness ye fɛn nafamaw ye minnu bɛ nɔ bila fɛn dɔ ka kɛwalew la degun kɔrɔ.

Nɛgɛ min bɛ bɔ, o bɛ kari ani a bɛ kɛ ni ductility dɔgɔman ye, o kɔrɔ ye ko a bɛ se ka kari walima ka kari yɔrɔnin kelen ni fanga bɛ a la walima ni fanga bɛ a la.

Nɛgɛ ye ductile ye ani a ka dɔgɔn ka tɛmɛ nɛgɛ kan, o b’a to a bɛ se ka deform plastically sanni a ka kari, ka lakana yɔrɔ di a ma baarakɛcogo la.

5. castbilité .

casting nɔgɔya jɔyɔrɔ ka bon sɛnɛ taabolo la ani cogoyaw ka gɛlɛya min bɛ se ka sɔrɔ.

Nɛgɛ min bɛ bɔ, o ka nɔgɔn ka da a dɔgɔyali dɔgɔyali kan solidifiyeli waati la ani a bolicogo ɲuman na, o bɛ kɛ sababu ye ka cogoya gɛlɛnw ni cogoya gɛlɛnw dilan.

Nɛgɛ ka gɛlɛn ka tɛmɛ nɛgɛ kan, bawo a bɛ dɔgɔya ka tɛmɛ ani a ka jibɔ ka dɔgɔn, o bɛ kɛ sababu ye ka casting fɛɛrɛw ka ɲɛtaa sɔrɔ.

6. Masina sɔrɔcogo .

Masinaya bɛ tali kɛ fɛn dɔ bɛ se ka tigɛ, ka sɔgɔ, walima ka cogoya nɔgɔya ni masin baarakɛminɛnw ye.

A ka c’a la, nɛgɛ min bɛ kɛ ka nɛgɛ kɛ, o ka nɔgɔn ka tɛmɛ nɛgɛ kan, bawo grafite flakɛ minnu bɛ a ka mikrostruktɛri kɔnɔ, olu bɛ kɛ tulumafɛn ye, ka baarakɛminɛnw sɛgɛn dɔgɔya ani ka dugukolo sanfɛla finiko ɲɛ.

Nɛgɛ ka gɛlɛn masin na ni a bɛ tali kɛ nɛgɛ sɔgɔlen na, o bɛ kɛ sababu ye ka baarakɛminɛnw sɛgɛn ka caya ani ka tigɛminɛnw ni fɛɛrɛw caman wajibiya.

7. Ɲɛgɛnɛsiraw kɛlɛli .

Corrosion resistance nafa ka bon kosɛbɛ baarakɛcogo la minnu bɛ sɔrɔ sigida gɛlɛnw na walima minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye.

Nɛgɛ min bɛ kɛ, o bɛ se ka sɔgɔ ka ɲɛ fo ka se a dan na, o b’a to a bɛ se ka nɔgɔ ni nɔgɔya sɔrɔ ni a bɛ kɛ ni ji ni fɛn wɛrɛw ye minnu bɛ sɔgɔsɔgɔ.

Nɛgɛ bɛ se ka sɔgɔsɔgɔ ka tɛmɛ nɛgɛ kan, kɛrɛnkɛrɛnnenya la ni a kɛra fɛn ye min bɛ kɛ ni fɛnw ye i n’a fɔ chrome, nickel, walima ni nɛgɛ ye, o b’a to a bɛnnen don ka baara kɛ sigidaw la minnu falen don fɛn nɔgɔlenw na.

8. Aw bɛ resistance don .

sɛgɛnbaliya bɛ fɛn dɔ ka seko jira ka se ka yɔrɔ tiɲɛni muɲu min bɛ sɔrɔ sɔgɔli walima sɔgɔli fɛ.

Nɛgɛ min bɛ bɔ, o bɛ se ka masinw sɛgɛn ka ɲɛ, kɛrɛnkɛrɛnnenya la, fɛn minnu bɛ se ka sɔgɔsɔgɔ, k’a sababu kɛ grafite flakew bɛ yen minnu bɛ kɛ tulumafɛn gɛlɛn ye.

Nɛgɛ tɛ sɛgɛn kosɛbɛ ni a bɛ tali kɛ nɛgɛ sɔgɔlen na, nka a bɛ se ka ɲɛ ka tɛmɛ funteni furakɛli fɛ walima ka fara fɛnw kan minnu bɛ kɛ ka fɛnw sɔgɔ i n’a fɔ chromium walima molybdenum.

9. Impact resistance .

Impact resistance bɛ tali kɛ fɛn dɔ ka seko la ka fanga minɛ ani ka a jɛnsɛn ka bɔ fɛn barikamaw la k’a sɔrɔ a ma kari.

Nɛgɛ min bɛ bɔ, o bɛ se ka wuli ka bɔ a nɔ na kosɛbɛ ka a sababu kɛ a karicogo ye, o b’a to a bɛ se ka kari ni a bɛ se ka kɛ ni fɛn barikamaw ye walima ni a bɛ se ka wuli.

Nɛgɛ bɛ se ka wuli ka bɔ a nɔ na kosɛbɛ, wa a ka ɲi kosɛbɛ ni a bɛ se ka wuli ka bɔ a nɔ na, o min bɛ se ka kɛ sababu ye ka baara kɛ ni fɛnw ye minnu bɛ se ka kɛ sababu ye ka fɛnw don minnu bɛ se ka kɛ.

10. musaka .

Fɛn minnu bɛ kɛ, olu dilanni, ani u dilanni, o jɔyɔrɔ ka bon nɛgɛ walima nɛgɛ suguya dɔ sugandili la baara dilen dɔ kama.

Nɛgɛ min bɛ bɔ, a ka c’a la, a sɔngɔ ka dɔgɔ ni nɛgɛ ye ka da fɛnw musakaw dɔgɔyali kan, a dilanni nɔgɔyali, ani a fanga hakɛ dɔgɔyali ka ɲɛsin fɛnw wulicogo n’u filili ma.

Nɛgɛ sɔngɔ ka gɛlɛn ni nɛgɛ ye, nka a bɛ fɛn caman di minnu sɔngɔ ka dɔgɔ, i n’a fɔ a dilannen don ka kɔn, ani fɛnw minnu bɛ segin ka kɛ fɛn wɛrɛw ye, minnu bɛ se ka dɔ bɔ musakaw bɛɛ lajɛlen na.

Nɛgɛ ni nɛgɛ min bɛ kɛ ka fɛnw kɛ .

Nɛgɛ ni nɛgɛ fila bɛɛ bɛ baara caman kɛ iziniw kɔnɔ, minnu sugandira u ka nafolo danfaralenw kama walasa ka baarakɛcogo mago kɛrɛnkɛrɛnnenw ɲɛnabɔ.

cast iron applications .

Nɛgɛ min bɛ kɛ ka nɛgɛ kɛ, o fanga, a dilanni, ani a musaka dɔgɔyali b’a kɛ sugandili ye min ka di kosɛbɛ baarakɛcogo gɛlɛnw na, yɔrɔ minnu na muɲuli ye fɛnba ye.

Mobili industry : nɛgɛ min bɛ kɛ ka a kɛ, o ka ɲi kosɛbɛ yɔrɔw la minnu bɛ funteni kunbɛn ani ka yɛrɛyɛrɛ. Baara minnu bɛ kɛ tuma caman na, olu dɔw ye:

A jɔli : A nafa ka bon a ka barika la, nɛgɛ min bɛ kɛ ka fɛnw dilan, o bɛ kɛ ka caya boonw kɔnɔ i n’a fɔ:

Pibilikiw ni fɛnw bɛ kɛ ka ɲɛsin pɔmpiw ni jibolisiraw ma, o bɛ kɛ sababu ye ka fɛnw tiɲɛ minnu bɛ se ka kɛ sababu ye ka fɛnw sɔgɔ .

Fɛn masirilenw, i n’a fɔ fencing ani nbɛdaw la minɛnw, k’a sababu kɛ a filili n’a muɲuni ye .

Fɛn dilanni : Industriw ka sigida la, nɛgɛ min bɛ kɛ ka fɛnw lamaga, o ka bon kosɛbɛ:

Masina baarakɛminɛnw farikolow ni basigiw minnu bɛ sabatili de wajibiya walasa ka u ɲɛfɔ .

Sow bɛ kɛ masinbaw ye, yɔrɔ minnu na, u jɔcogo dafalen don .

A bɛ baara kɛ ni nɛgɛ ye .

Steel ka fanga, a ka se ka fɛn caman kɛ, ani a bɛ se ka fɛnw sɔgɔ, o b’a to a nafa ka bon kosɛbɛ izini suguya caman kɔnɔ, kɛrɛnkɛrɛnnenya la, yɔrɔ minnu na, nɔ bilali kunbɛncogo ka bon kosɛbɛ.

Sow jɔli : Nɛgɛ jɔyɔrɔ jɔnjɔn bɛ boonw jɔli la ani a bɛ dɛmɛ nafama di:

Jɛkuluw ka yɔrɔw i n’a fɔ jirisunw, jɔw, ani sigidaw ka ɲɛsin sow ni dankanw ma .

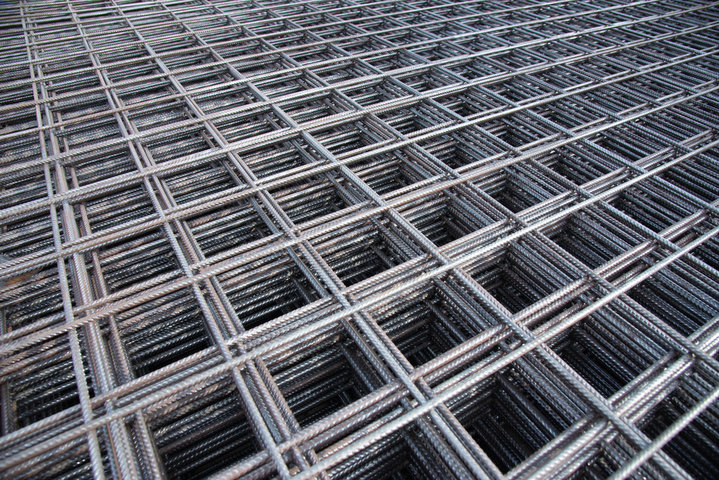

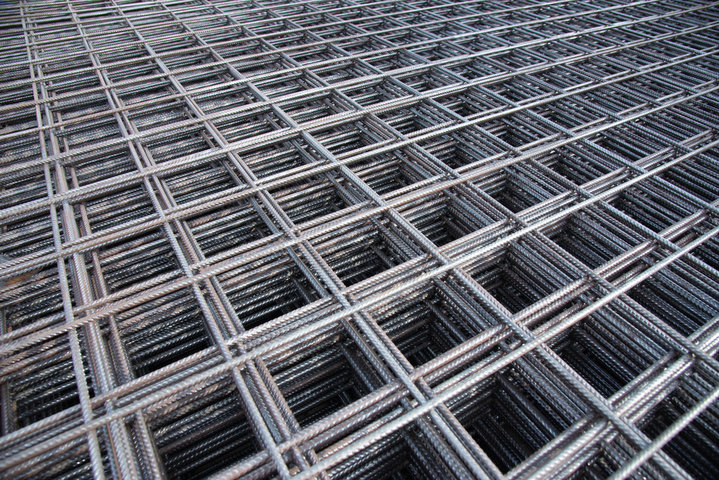

barika don bɛtonw jɔli la walasa ka tension fanga yiriwa .

Mobili industry : Mobili dilanni na, Steel ka fanga ni a girinya hakɛ ka bon, o b’a kɛ sugandili ɲuman ye:

Mobili farikolow ani chassis, o bɛ muɲu ani ka nɔ bila mɔgɔ la lakana kama .

wotoro ni aksidanw, o bɛ baara kɛcogo ɲuman ni sɛgɛnba di .

Fɛn dilanni : nɛgɛ nafa ka bon baarakɛminɛnw dilanni na minnu bɛ mɛn ani minnu bɛ baara kɛ kosɛbɛ, olu dɔw ye :

So kɔnɔ minɛnw ni tobilikɛminɛnw : Inox ka sɔgɔli ni ɲɛnajɛw b’a kɛ fɛn ye min bɛ diya du kɔnɔ baarakɛminɛnw na:

Cuisini minɛnw, i n’a fɔ frigow ani forow, walasa u ladonni ka nɔgɔn .

Tobilikɛminɛnw, dagaw ni bɔgɔdagaw sen bɛ minnu na, olu nafa ka bon u ka muɲuli n’u ka funteni marali la .

Fɛn minnu ka kan ka jateminɛ ni aw bɛ nɛgɛ ni nɛgɛ cɛ sugandi .

Fɛn ɲuman sugandili nɛgɛ ni nɛgɛ cɛ, o bɛ fɛn caman jateminɛ koɲuman. Porozɛ kelen-kelen bɛɛ bɛ gɛlɛya ni wajibi kɛrɛnkɛrɛnnenw jira. Nin jateminɛ kolomaw faamuyali bɛ dɛmɛ don ka latigɛw kɛ minnu bɛ kɛ ni kunnafoniw ye.

Fanga wajibiyalenw .

I ka poroze ka kan ka muɲu fanga sugu min na, o bɛ i ka fɛnw sugandili latigɛ. Nɛgɛ min bɛ bɔ, o ka fisa ni degun ye, o b’a to a ka ɲi kosɛbɛ jusigilanw ni masinw jɔli kama. Steel bɛ tension fanga fisaman di, min dafalen don jɔli kama minnu mago bɛ resistance la ka ɲɛsin samali walima stretching forces ma.

Corrosion resistance .

Sigida laminiko jɔyɔrɔ ka bon kosɛbɛ fɛnw sugandili la. Nɛgɛ min bɛ kɛ, o bɛ patina lakana waati kɔnɔ, o bɛ a jira ko a bɛ se ka sɔgɔsɔgɔ. Nɛgɛ, kɛrɛnkɛrɛnnenya la, fɛn minnu tɛ sɔgɔ, olu bɛ mɔgɔ tanga ka ɲɛ nɔgɔ ni kemikɛli sɔgɔli ma. Aw bɛ a jateminɛ ko fɛn in bɛ ji, kemikaliw walima kɔgɔji la.

Impact resistance .

Aw ka poroze ka fanga barikamaw ka dɛsɛ bɛ nɔ bila fɛnw sugandili la. Nɛgɛ bɛ a jira ko a bɛ se ka fɛnw minɛ ka ɲɛ ani ka doni barikamaw ta. Nɛgɛ min bɛ kɛ, o bɛ tiɲɛni jira impact jukɔrɔ, hali ni a bɛ doni jɔlenw minɛ ka ɲɛ.

A dilanni gɛlɛya .

Nin yɔrɔ ninnu bɛ nɔ bila sɛnɛfɛnw dilanni seko la:

Nɛgɛ min bɛ kɛ ka fɛnw dilan, o bɛ a to a ka kɛ fɛn gɛlɛnw ye a ka fɛn dilanni cogoya ɲumanw fɛ ani a ka jibɔcogo fɛ .

Steel bɛ fɛn caman di fɛn caman sɛgɛsɛgɛli la, fɛn minnu bɛ se ka kɛ sababu ye ka fɛnw caman sɛmɛntiya ani ka u fara ɲɔgɔn kan .

Siginiden gɛlɛnw bɛ machining dɔgɔya ni u bɛ baara kɛ ni nɛgɛ ye min bɛ kɛ ka a sababu kɛ u filili ka ɲi .

Steel bɛ sugandi caman di welding ni mechanical sirili ma lajɛ kɛcogo la .

musaka jateminɛ

| factor | cast nɛgɛ | nɛgɛ . |

| Matériel raw . | musaka dɔgɔyali . | A musaka ka bon . |

| Baarakɛcogo . | casting processus nɔgɔman . | Ka tɛmɛn fɛn dilanni kan . |

| Baara | A ka dɔgɔ kosɛbɛ . | Baara caman wɛrɛw wajibiyalen don . |

| Labɛn | Lakanali tuma bɛɛ mago bɛ a la . | A bɛ danfara ka kɛɲɛ ni a suguya ye . |

Sigidako koɲɛw .

Funteni ni sigida cogoyaw bɛ nɔ bila fɛnw ka baarakɛcogo la:

Nɛgɛ min bɛ kɛ ka nɛgɛ kɛ, o bɛ sabatili mara funteni hakɛ caman cɛ .

Steel bɛ baara kɛcogo ɲuman di nɛnɛba la .

O fɛn fila bɛɛ mago bɛ lakanani na ka bɔ waati gɛlɛnw na .

So kɔnɔ baarakɛminɛnw bɛ gɛlɛya caman sɔrɔ sigida la ka tɛmɛ kɛnɛma fɛnw kan .

Farankan

Kuma surun na, nɛgɛ ni nɛgɛ min bɛ kɛ, olu ni ɲɔgɔn cɛ, u fanga ani u musaka tɛ kelen ye. Nɛgɛ min bɛ kɛ, o bɛ fanga caman di min bɛ se ka degun ani a dilanni musakaw ka dɔgɔn, ka sɔrɔ nɛgɛ bɛ fanga ni sɔgɔli fanga bonya. Fɛn ɲumanw sugandili minnu bɛ bɛn a ka nafaw ma ka bɛn i ka baarakɛminɛnw magow ma. Ni aw ye o danfara jɔnjɔnw faamuya, aw bɛ se ka sugandili kɛ ni kunnafoni ye minnu bɛ aw ka porozew muɲuni ni u kɛcogo ɲuman ɲɛ.

Reference sources .

Nɛgɛ

Nɛgɛ

A ka fisa ka die casting factory .

Ɲininkali minnu bɛ kɛ tuma caman na (FAQ) .

J: Nɛgɛ min bɛ kɛ, o ye mun ye, ani a bɛ kɛ cogo di?

Nɛgɛ min bɛ kɛ ka nɛgɛ kɛ, o ye nɛgɛ-karɔbɔni ye min kɔnɔna na, a hakɛ bɛ se 2% ma, o bɛ sɔrɔ sɔgɔli ni sɔgɔli fɛ.

J: Nɛgɛ ye mun ye, ani a ni nɛgɛ sɔgɔlen tɛ kelen ye cogo di?

Nɛgɛ ye nɛgɛ-karɔbɔni ye min tɛ 2% bɔ kabɔri la, a bɛ fanga caman di ka tɛmɛ nɛgɛ kan.

J: Mun na nɛgɛ min bɛ kɛ ka nɛgɛ kɛ, o fanga ka fisa ni nɛgɛ ye?

Nɛgɛ min bɛ kɛ ni karɔbɔli ye, o bɛ a degun fanga bonya, o b’a to a bɛnnen don doni girinmanw tali ma.

J: Nɛgɛ ni nɛgɛ kalali bɛ se ka suma cogo di sɔgɔli kɛlɛli siratigɛ la?

Nɛgɛ, kɛrɛnkɛrɛnnenya la nɛgɛ min tɛ sɔgɔ, a ka c’a la, a bɛ sɔgɔli kɛ ka ɲɛ, ka sɔrɔ nɛgɛ min bɛ kɛ, o bɛ se ka nɔgɔ ni finimugu tɛ a la.

J: Ne ka kan ka fɛɛrɛ jumɛnw jateminɛ ni n bɛ nɛgɛ ni nɛgɛ cɛ?

Aw ye fɛnw jateminɛ i n’a fɔ tension fanga, degun fanga, masinw ka se ka kɛ, u bɛ se ka fɛnw sɔgɔ, ani u bɛ se ka nɔ bila u la walasa ka ɲɛtaa ɲuman sɔrɔ.

J: Nɛgɛ sɔgɔlenw ka masinako bɛ tali kɛ nɛgɛ la cogo di?

Nɛgɛ min bɛ Bɔ, o ka nɔgɔn ka Kɛ a ka grafite jɔcogo ye, o min bɛ dɔ Bɔ tigɛminɛnw sɛgɛnni na n’i y’a suma ni nɛgɛ ye.

J: Mun na nɛgɛ min bɛ kɛ, o bɛnnen don kosɛbɛ casting designs complexes ma?

Nɛgɛ min bɛ bɔ, o bɛ se ka woyo ka ɲɛ ani ka dɔgɔya, o bɛ a to cogoya gɛlɛnw bɛ kɛ ni fɛn caman tigɛli ye nɛnɛ waati.

J: Ne bɛ se ka gɛlɛyaw ɲɛnabɔ cogo di ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye min bɛ se ka kɛ ni fanga ye?

Ni nɛgɛ karilenw bɛ nɔ bila u la, aw bɛ nɛgɛ jateminɛ walasa ka a dɔn ni a bɛ se ka a yɛrɛ tanga walima ka dɛmɛnan wɛrɛw kɛ a la.

J: Ne ka kan ka lakana fɛɛrɛ jumɛnw tigɛ ni nɛgɛ ni nɛgɛ ye min bɛ kɛ ka nɛgɛ tigɛ?

Aw bɛ aw tangalanw don, ka fiɲɛ bila u la ka ɲɛ tigɛ walima welding waati la, ani ka baarakɛminɛnw kɛ minnu jateminɛna fɛnw kama minnu ka bon kosɛbɛ.

J: Nɛgɛ ni nɛgɛ min bɛ kɛ ka ɲɛ, o bɛ kɛ min ka fisa ni izini baarakɛcogo ye?

Nɛgɛ min dilannen don, o bɛ baara kɛ ka ɲɛ yɔrɔ girinmanw na, yɔrɔ jɔlenw na i n’a fɔ motɛri blokiw, k’a sɔrɔ nɛgɛ ka ɲi kosɛbɛ a jɔcogo, a doni-ta, ani a baarakɛcogo la.