We i kam pan mɛtal dɛn we dɛn de yuz fɔ mek ɛn bil, di dibɛt bitwin kast ayɛn vs stɛl (inklud difrɛn we dɛn lɛk kast ayɛn vs stenlɛs stiɛl ɛn kɔst ayɛn vs kabɔn stɛl) stil na impɔtant tin fɔ tink bɔt fɔ injinia ɛn dizayna dɛn. Fɔ ɔndastand di difrɛns bitwin kast ayɛn ɛn stɛl impɔtant fɔ mek dɛn disayd fɔ du tin dɛn we dɛn no bɔt di we aw dɛn de pik di tin dɛn we dɛn de yuz.

Wetin na Kast Ayɔn?

Kast ayɛn matirial na wan fɛro alɔy we gɛt pas 2% kabɔn kɔntinyu, we tipikul de frɔm 2% to 4%, wit difrɛn amɔnt dɛn fɔ silikon ɛn manganɛs. Di kast ayɛn prɔpati ɛn kwaliti dɛn de mek i difrɛn frɔm stɛl, we de mek bɔku pipul dɛn aks 'na cast iron steel?' Pan ɔl we kast ayɛn gɛt ayɛn, i nɔ teknik wan stɛl bikɔs ɔf in ay kabon kɔntinyu. Di ay kabon we de insay kast ayɛn de gi am spɛshal prɔpati dɛn, lɛk:

Gud kɔmprɛsiv trɛnk .

Eksɛlɛnt Wear Resistance .

High Vibration Damping Kapasiti .

Resistance to difɔmeshɔn .

Machinabiliti fɔ di wan dɛn we de wok .

Bɔt, Cast Iron gɛt sɔm prɔblɛm dɛn bak, lɛk:

Pan ɔl dɛn bad bad tin ya, Cast Iron stil bi wan pɔpul choice fɔ difrɛn aplikeshɔn dɛn bikɔs ɔf in afɔdabiliti ɛn versatility.

Kεmikכl kompozishun .

Di kemikal kompozishun fɔ kast ayɛn de ple wan impɔtant pat fɔ no in prɔpati dɛn. Di praymar elemɛnt dɛn insay kast ayɛn inklud:

| ɛlimɛnt | pasɛnt . |

| Kabon . | 2% - 4% |

| Silikɔn . | 1% - 3% |

| Manganɛs . | 0.5% - 1% |

| Fosfɔr . | I go rich 1% . |

| Sɔlfɔ . | i go rich 0.1% . |

Di kabon ɛn silikon kɔntinyu rili inflɔws di maykrostrɔkchɔ ɛn prɔpati dɛn fɔ di kɔst ayɛn. di ay kabon lεvεl dεm de inkrεs di amoun fכ di grafayt we fכm di tεm we dεn de sכlidifεshכn, we silikon de protεkt grafayt fכmeshכn εn impruv kכstabiliti.

Fizik prɔpati dɛn .

Kast ayɛn de sho sɔm difrɛn fizik prɔpati dɛn:

Ay density: Kast ayɛn gɛt density we na lɛk 7.2 g/cm³, we mek i ebi pas stɛl.

Lɔw mɛlt pɔynt: I de mɛlt arawnd 1150°C to 1250°C, we smɔl pas stɛl, we de mek am izi fɔ kɔst.

Tɛmral Kɔnduktiviti: Kast ayɛn gɛt tɛmral kɔnduktiviti we na lɛk 50 W/m·k, we smɔl pas di wan we dɛn mek wit stɛl.

Ilɛktrik Kɔnduktiviti: I gɛt smɔl ilɛktrik kɔnduktiviti we yu kɔmpia am wit stɛl, we mek i fayn fɔ ilɛktrik aplikeshɔn usay dɛn nid fɔ insuleshɔn.

Di kayn dɛn we dɛn kin yuz fɔ mek ayɛn .

Cast Iron kin kategoriz insay sɔm kayn dɛn bays pan in maykrostrakchɔ ɛn prɔpati dɛn. Di men kayn kast ayɛn na:

Grey cast ayɛn .

Grey cast iron na di kayn we we dɛn kin yuz mɔ, we dɛn kin kɔl di prɛzɛns fɔ grafayt flɛks na in maykrostrakchɔ. I gɛt:

Kabon: 2.5% - 4%

Silicon: 1% - 3%

Manganese: 0,4% - 1%

Grey Cast Iron de gi gud kɔmpreshɔn trɛnk, fayn fayn mashinabiliti, ɛn ay vaybreshɔn damping kapasiti. Dɛn kin yuz am bɔku bɔku wan na aplikeshɔn dɛn lɛk:

Mashin tul bays dɛn .

Enjin blɔk dɛn .

Brek disk dɛn .

Haus ɛn Kɔva dɛn .

Wait cast ayɛn .

Wait kast ayɛn gɛt wayt fraktrɔs sɔfays bikɔs ɔf di absɛns ɔf grafayt. I tipik kɔmpozishɔn inklud:

Kabon: 1,8% - 3,6%

Silicon: 0,5% - 1,9%

Manganese: 0,25% - 0,8%

Dɛn sabi wayt kast ayɛn fɔ in ay had ɛn fayn fayn wear resistans. I de fɛn aplikeshɔn dɛn na:

grindin midia .

Slɔri pɔmp dɛn .

Bol mil dɛn .

Rolling Mill Rolls .

Malleable cast ayɛn .

Malleable cast iron na di wan we dɛn kin mek bay we dɛn kin yuz wayt kast ayɛn we de trit ɔt fɔ chenj di brital kabayd strɔkchɔ to wan mɔ dakti fɛritik matris. I gɛt:

Kabon: 2% - 3%

Silicon: 0,9% - 1,9%

Manganese: 0,15% - 1,2%

Malleable cast iron de kam togɛda wit ay trɛnk, daktiliti, ɛn taf. Dɛn kin yuz am fɔ:

Ductile (nodular) cast iron .

di daktil kכst ayn, we dεn kכl bak nodul kכst ayn, dεn de mek am bay we dεn de ad magnεsium כ siriכm to di mכlt ayn, we de mek di grafayt fכm sfεri nכdul dεm insted fכ flek. I kompozishun inklud:

Kabon: 3,2% - 4%

Silicon: 1,8% - 2,8%

Manganese: 0,1% - 1%

Ductile Cast Iron de gi ay trɛnk, taf, ɛn daktiliti. Dɛn kin yuz am bɔku bɔku wan na:

Vermicular cast ayɛn .

Vermicular cast iron, we dɛn kin kɔl bak kɔmpakt grafayt ayɛn (CGI), gɛt wan spɛshal maykrostrukchɔ wit grafayt patikyula dɛn we tan lɛk shɔt, tik flɛks. I de gi intamɛdiet prɔpati bitwin grey ɛn daktayl kast ayɛn, lɛk:

ay trɛnk ɛn stiffnɛs pas grey kast ayɛn .

Bɛtɛ tɛmral kɔnduktiviti pas daktayl kast ayɛn .

Impɔtant kastabiliti kɔmpia to daktayl kast ayɛn .

Vermicular cast iron de yuz mɔ ɛn mɔ fɔ yuz ɔtomotiv, lɛk:

Alɔy we dɛn kin yuz fɔ mek di kɔst ayɛn .

Dɛn kin mek alɔy kɔst ayɛn bay we dɛn ad alɔy ɛlimɛnt dɛn lɛk nikel, kromiɔm, molibdɛnam, ɔ kɔpa fɔ ɛp fɔ mek sɔm patikyula prɔpati dɛn bɛtɛ. Dipen pan di aloying elements we dɛn yuz, aloyed cast iron kin ofa:

Alloyed Cast Iron de fain aplikeshɔn dɛn na difrɛn industri dɛn, lɛk:

Wetin na stɛl?

Stilin na alɔy we dɛn mek wit ayɛn we gɛt lɛs dan 2% kabon ɛn smɔl smɔl ɔda tin dɛn, lɛk manganɛs, silikon, fɔsfɔr, sɔlfɔ, ɛn ɔksijɛn. Dɛn sabi am fɔ in ay tɛnsiɛl trɛnk, daktiliti, ɛn versatility, we mek i bi wan matirial we dɛn kin yuz bɔku bɔku wan na difrɛn industri dɛn. Steel in prɔpati dɛn kin tayla bay we dɛn ajɔst in kɔmpɔzishɔn ɛn tru ɔt tritmɛnt prɔses.

Kεmikכl kompozishun .

Di kemikal kompozishun fɔ stɛl de ple wan impɔtant pat fɔ no in prɔpati dɛn. Di praymar elemɛnt dɛn na stɛl inklud:

| ɛlimɛnt | pasɛnt . |

| Ayɛn | 90% - 99% |

| Kabon . | 0.1% - 2% |

| Manganɛs . | 0.1% - 1% |

| Silikɔn . | 0.1% - 0,5% |

| Ɔda ɛlimɛnt dɛn . | < 1% |

Di kabon kɔntinyu na di mɔs impɔtant tin we de inflɔws di prɔpati dɛn we Stilin gɛt. di ay kabon lεvεl dεm de inkrεs trεnk εn hadnεs bכt dεn de ridyus daktiliti εn weldabiliti.

Fizik prɔpati dɛn .

Stilin de sho sɔm difrɛn fizik prɔpati dɛn:

Ay tɛnsiɛl trɛnk: Stilin kin ebul fɔ bia wit ay lod dɛn we nɔ go brok ɔ difɔm fɔ ɔltɛm.

Ductility: Dɛn kin drɔ am insay waya ɔ rol am insay sheet dɛn we nɔ brok.

Ay mɛlt pɔynt: Stilin de mɛlt na tɛmpracha bitwin 1370°C ɛn 1540°C, dipen pan in kɔmpɔzishɔn.

Tεmכl kכnduktiviti: I gεt rili hכy tεmral kכnduktiviti, we de alaw hεt fכ transfכm fayn fayn wan.

Ilɛktrik Kɔnduktiviti: Stilin na gud kɔndɔkta fɔ ilɛktrishɔn, pan ɔl we i nɔ ebul fɔ wok lɛk kɔpa ɔ aluminiɔm.

Advantej dɛn fɔ Stilin .

Steel de gi bɔku bɛnifit dɛn, we de mek i bi pɔpul choice fɔ difrɛn aplikeshɔn dɛn:

High strength-to-weight ratio: Stilin de gi fayn fayn trɛnk we yu de mentɛn wan rili lɔw wet we yu kɔmpia am wit ɔda matirial dɛn.

Durability: I kin ebul fɔ bia wit harsh envayrɔmɛnt, impak, ɛn wear, we mek i fayn fɔ di strɔkchɔ ɛn kɔmpɔnɛnt dɛn we go de fɔ lɔng tɛm.

Versatility: Dɛn kin shep, fɔm, fɔm, ɛn jɔyn yuz difrɛn we dɛn, we kin alaw fɔ kɔmpleks dizayn ɛn strɔkchɔ dɛn.

Risayklabliti: Na 100% risaykul, we mek i bi wan tin we nɔ de ambɔg di envayrɔmɛnt.

Kost-ɛfɛktiv: Stilin nɔ dia dia we yu kɔmpia am wit ɔda matirial dɛn we gɛt di sem prɔpati.

Disadvantej dɛn we dɛn mek wit stɛl .

Pan ɔl we i gɛt bɔku bɛnifit dɛn, Stilin gɛt sɔm prɔblɛm dɛn bak:

Kɔroshɔn: Stilin kin gɛt rɔst ɛn kɔrɛshɔn we dɛn put am na mɔstɔ ɛn ɔksijɛn, we nid fɔ mek dɛn kɔt di tin dɛn we de protɛkt yu ɔ di tin dɛn we de mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek tin nɔ izi fɔ mek dɛn nɔ gɛt kɔrɛshɔn.

Fatigue: Ripit saykli lod kin mek stɛl nɔ wok pan strɛs dɛn we de dɔŋ in yield trɛnk, wan tin we dɛn kɔl fatigue.

Ay density: Stilin de dens pas matirial lɛk aluminiɔm, we kin bi wan drawback in aplikeshɔn usay weit ridɔkshɔn impɔtant.

Energy-intensive prodakshɔn: Di prodakshɔn fɔ stɛl nid fɔ gɛt bɔku ɛnaji input, we de kɔntribyut to grɛnhɔus gas ɛmishin.

Tayp dɛn fɔ Stiɛl .

Stiɛl kin kategoriz insay sɔm kayn dɛn bays pan in kɔmpozishɔn ɛn prɔpati dɛn:

Kabon Stiel .

Kabon stɛl na di kayn stɛl we dɛn kin yuz mɔ, we gɛt ay ayɛn ɛn kabon. Dɛn dɔn klas am mɔ bay di kabon we de insay:

Low carbon steel (< 0.25% carbon): I soft, ductile, ɛn izi fɔ mek, we mek i fayn fɔ aplikeshɔn dɛn lɛk motoka bɔdi panɛl ɛn waya prodak.

Midul Kabon Stilin (0.25% - 0.6% Kabon): I de gi gud balans fɔ trɛnk ɛn daktiliti, we de mek i fayn fɔ aplikeshɔn dɛn lɛk gia, shaft, ɛn relwe trak.

Ay kabɔn stiɛl (> 0.6% kabɔn): I at, strɔng, ɛn wear-rɛsistant bɔt i nɔ rich daktayl, we mek i fayn fɔ aplikeshɔn dɛn lɛk fɔ kɔt tul dɛn, spring dɛn, ɛn bia dɛn.

Alɔy Stiɛl .

Dɛn kin mek alɔy stɛl bay we dɛn ad alɔy ɛlimɛnt dɛn lɛk manganɛs, nikel, kromiɔm, ɔ molibdɛnam fɔ ɛp fɔ mek sɔm patikyula prɔpati dɛn bɛtɛ. Kɔmɔn alɔy ɛlimɛnt ɛn dɛn ifɛkt dɛn inklud:

Manganese: I de mek trɛnk, at, ɛn wear resistans de bɔku.

Nikel: I de mek di taf tin dɛn we de na di bɔdi, di daktiliti, ɛn di kɔrɛshɔn rɛsistɛns bɛtɛ.

Krɔmiɔm: I de mek di kɔrɛshɔn nɔ gri wit di kɔrɛshɔn, di had we i de wok, ɛn di we aw i de west.

Molybdenum: I de mek trɛnk, taf, ɛn krip rɛsistɛns we di tɛmpracha go ɔp.

Alloy Steels kin fɛn aplikeshɔn dɛn na difrɛn industri dɛn, lɛk:

Otomotiv komponent dɛn (Gears, Shafts, Springs)

Aerospace structures .

Ɔyl ɛn gas paip dɛn .

Ikwipmɛnt fɔ di mayning .

Stenlɛs stiɛl .

Stenlɛs Stiɛl na alɔy stɛl we gɛt wan minimum 10.5% kromiɔm, we de fɔm wan protɛktiv ɔksayd layt na di sɔfa, we de gi fayn fayn kɔrɛshɔn rɛsistɛns. Stɛnlɛs stiɛl dɛn bak kin gɛt ɔda alɔy ɛlimɛnt dɛn lɛk nikel, molibdɛnam, ɛn taytaniɔm fɔ mek dɛn gɛt mɔ patikyula prɔpati dɛn.

Dɛn kin yuz stenlɛs stiɛl bɔku bɔku wan na aplikeshɔn dɛn we nid fɔ mek dɛn nɔ gɛt kɔrɛshɔn, lɛk:

Ikwipmɛnt fɔ prosɛs it .

Divays dɛn fɔ mɛn pipul dɛn .

Akitekchɔral Strukchɔ dɛn .

KƐMIKAL PROSƐNS PLANT DƐN .

Tul Stiɛl .

Tul stɛl dɛn na ay-kabɔn, alɔy stɛl dɛn we dɛn mek fɔ mek tul dɛn, day, ɛn mol dɛn. Dɛn sabi dɛn fɔ dɛn ay had, dɛn de wɛr rɛsistɛns, ɛn dɛn ebul fɔ kip dɛn prɔpati dɛn we di tɛmpracha go ɔp. Bɔku tɛm, tul stɛl dɛn kin gɛt alɔy ɛlimɛnt dɛn lɛk tungsten, molibdɛnam, ɛn vanadiɔm fɔ mek dɛn wok fayn.

Dɛn kin yuz tul stɛl dɛn na difrɛn say dɛn, lɛk:

Tul dɛn we dɛn kin yuz fɔ kɔt (drill, tap, day)

Fɔm tul dɛn (panch, day)

Molds fɔ plastic injɛkshɔn moldin .

Rolling Mill Rolls .

Ki difrɛns bitwin kast ayɛn ɛn stɛl .

Pan ɔl we kast ayɛn ɛn stɛl na ɔl tu alɔy dɛn we dɛn mek wit ayɛn, dɛn gɛt difrɛn kwaliti dɛn we de mek dɛn difrɛn. Fɔ ɔndastand dɛn difrɛns ya rili impɔtant fɔ pik di tin we fit pas ɔl fɔ wan aplikeshɔn we dɛn gi yu. Lɛ wi fɛn di men tin dɛn we difrɛn bitwin di kɔst ayɛn ɛn di stɛl:

1. Di tin dɛn we de insay di kabon .

Di kabon we de insay na di men tin we de sho difrɛns bitwin di kɔst ayɛn ɛn di stɛl.

Kast ayɛn gɛt 2-4% kabon, we de gi am yunik prɔpati dɛn lɛk ay kɔmprɛsiv trɛnk ɛn fayn fayn kastabiliti.

Stilin gɛt kabon we nɔ rich 2%, we de mek i gɛt ay tɛnsiɛl trɛnk ɛn daktiliti we yu kɔmpia am wit kɔst ayɛn.

2. Point we de mɛlt .

Di mɛlt pɔynt fɔ kast ayɛn ɛn stɛl difrɛn bad bad wan, we de afɛkt dɛn prodakshɔn prɔses ɛn aplikeshɔn dɛn.

Kast ayɛn gɛt smɔl mɛlt pɔynt, arawnd 2200°F (1204°C), we mek am izi fɔ mɛlt ɛn tɔn am insay mol.

Stilin gɛt ay mɛlt pɔynt, we de frɔm 2500°F to 2800°F (1371°C to 1538°C), we nid mɔ ɛnaji fɔ mɛlt ɛn kastin.

3. Strɔng .

Kast ayɛn ɛn stɛl de sho difrɛn kayn trɛnk, we de mek dɛn fayn fɔ difrɛn aplikeshɔn dɛn.

Kast ayɛn gɛt ay kɔmprɛsiv trɛnk, we de alaw am fɔ bia wit ebi ebi lod ɛn nɔ gri fɔ difɔmeshɔn we dɛn de ɔnda kɔmpreshɔn fɔs.

Stilin gɛt ay tɛnsiɛl trɛnk, we de mek i ebul fɔ bia wit pul fɔs dɛn we nɔ go brok ɔ fɔ ɔltɛm.

4. Daktiliti ɛn Britlnɛs .

Ductility ɛn britleness na impɔtant tin dɛn we de inflɔws wan matirial in bihayvya ɔnda strɛs.

Kast ayɛn kin brok ɛn i gɛt smɔl daktiliti, we min se i kin brok ɔ brok wantɛm wantɛm we i gɛt impak ɔ bɛnd fɔs.

Stilin na mɔ daktayl ɛn i nɔ kin brit pas kɔst ayɛn, we kin alaw am fɔ difɔm plastic wan bifo i brok, we kin gi wan margin fɔ sef na aplikeshɔn dɛn.

5. Kastabliti .

Di izi we fɔ kɔst de ple wan impɔtant pat pan di prodakshɔn prɔses ɛn di kɔmplisiti fɔ shep dɛn we dɛn kin ebul fɔ ajɔst.

Kast ayɛn izi fɔ kɔst bikɔs ɔf in lɔwa shrinkage di tɛm we dɛn de sɔlid ɛn bɛtɛ flɔabiliti, we de mek dɛn ebul fɔ prodyuz intrɛst ɛn kɔmpleks shep dɛn.

Stilin na mɔ chalenj fɔ kɔst kɔmpia to kɔst ayɛn, as i de ɛkspiriɛns ay shrinkage ɛn gɛt lɔwa flɔabiliti, we nid mɔ advans kastin tɛknik.

6. Machinabiliti .

Machinabiliti de tɔk bɔt di izi we aw dɛn kin kɔt, drɔ, ɔ shep am bay we dɛn yuz mashin tul dɛn.

Kast ayɛn jɔs izi fɔ mashin pas stɛl, as di grafayt flɛks dɛn na in maykrostrakchɔ de akt lɛk natura lubrikɛnt, we de ridyus di tul wear ɛn impɔtant sɔfays finish.

Stilin na mɔ chalenj to mashin we yu kɔmpia am wit kɔst ayɛn, we de mek di tul wear ay ɛn nid fɔ gɛt mɔ advans kɔt tul ɛn tɛknik.

7. Risistɛns fɔ kɔrɛshɔn .

Kɔroshɔn rɛsistɛns na impɔtant tin fɔ aplikeshɔn dɛn we dɛn dɔn ɛkspos to harsh ɛnvayrɔmɛnt ɔ kɔrosiv midia.

Kast ayɛn gɛt mɔdaret to lɔw kɔrɛshɔn rɛsistɛns, we de mek i izi fɔ rɔst ɛn kɔrɛshɔn we dɛn de ɛkspos to mɔstɔ ɛn ɔda kɔrosiv ɛlimɛnt dɛn.

Stilin gɛt ay kɔrɛshɔn rɛsistɛns we yu kɔmpia am wit kɔst ayɛn, mɔ we dɛn alɔy am wit ɛlimɛnt dɛn lɛk kromiɔm, nikel, ɔ kɔpa, we de mek i fayn fɔ aplikeshɔn dɛn na kɔrɛkt ɛnvayrɔmɛnt dɛn.

8. Wear resistans .

Wear resistance de ditarmin wan matiryal in abiliti fɔ bia wit sɔfays damej we kin kam bikɔs ɔf frikshɔn ɔ abrashɔn.

Kast ayɛn gɛt bɛtɛ resistans to mɛkanikal wear, mɔ insay frikshɔn-wearing situeshɔn, bikɔs ɔf di prɛzɛns ɔf grafayt flɛks we de wok as sɔlid lɔbrik.

Stilin nɔ kin west bɔku we yu kɔmpia am wit kɔst ayɛn, bɔt dɛn kin impruv am tru ɔt tritmɛnt ɔ we dɛn ad alɔy ɛlimɛnt dɛn lɛk kromiɔm ɔ molibdɛnam.

9. Impɛkt rɛsistɛns .

Impekt resistans de rifer to wan matiryal in abiliti fɔ absɔb ɛn dissipate ɛnaji frɔm wan wantɛm wantɛm impak dɛn we nɔ gɛt fraktrɔs.

Kast ayɛn gɛt lɔw impak rɛsistɛns bikɔs ɔf in brit, we de mek i prona fɔ frakt we dɛn sɔbjɛkt to wantɛm wantɛm impak ɔ shɔk lod.

Stilin gɛt ay impak resistans ɛn i fayn fɔ bia wit wantɛm wantɛm impak, we mek i fayn fɔ aplikeshɔn usay dɛn de ɛkspɛkt impak lod.

10. Kɔst .

Di kɔst fɔ matirial, prodakshɔn, ɛn prɔsesin de ple wan impɔtant pat pan di sɛlɛkshɔn fɔ kast ayɛn ɔ stɛl fɔ wan givɛn aplikeshɔn.

Kast ayɛn jɔs shɔt pas stɛl bikɔs ɔf di lɔwa matirial kɔst, simpul prodakshɔn prɔses, ɛn lɔwa ɛnaji rikwaymɛnt fɔ mɛlt ɛn kastin.

Stilin kin dia pasmak we yu kɔmpia am wit kɔst ayɛn, bɔt i kin gi bɔku ɔda we dɛn we nɔ dia, lɛk fɔm dɛn we dɛn dɔn mek bifo tɛm ɛn tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz bak, we kin mek di ɔl kɔst nɔ bɔku.

Aplikeshɔn dɛn fɔ Kast Ayɔn ɛn Stilin .

Ɔl tu di kast ayɛn ɛn stɛl de sav difrɛn tin dɛn akɔdin to di industri dɛn, we dɛn pik fɔ dɛn difrɛn prɔpati dɛn fɔ mit spɛshal fɛnshɔnal nid dɛn.

Aplikeshɔn dɛn we dɛn kin yuz fɔ ayɛn .

Cast Iron in trɛnk, mashinabiliti, ɛn kɔst-ɛfɛktiv mek am pɔpul choice in hevi-duti aplikeshɔn usay durabiliti na ki.

Automotive Industry : Cast Iron na fayn tin fɔ pat dɛn we nid ɔt rɛsistɛns ɛn vaybreshɔn damp. Di kɔmɔn tin dɛn we dɛn kin yuz na:

Kɔnstrɔkshɔn : Dɛn valyu am fɔ in robustnɛs, dɛn kin yuz kɔst ayɛn bɔku bɔku wan na bildin ɛlimɛnt dɛn lɛk:

paip ɛn fitin fɔ plaba ɛn drenaj sistem, we de gi kɔrɛshɔn rɛsistɛns .

Dekorativ elemɛnt dɛn, lɛk fɛns ɛn strit fɔnicha, bikɔs ɔf in kastabiliti ɛn durabiliti

Manufacturing : Insay industrial sɛtin, Cast Iron in vaybreshɔn-damping prɔpati dɛn impɔtant insay:

Mashin tul bɔdi ɛn bays dɛn we nid stebiliti fɔ prɛsishɔn .

haus fɔ big mashin, usay strɔkchɔral intɛgriti impɔtant .

Stilin Aplikeshɔn dɛn .

Steel in tɛnsiɛl trɛnk, versatility, ɛn kɔrɛshɔn rɛsistɛns de mek i indispɛnsbul akɔdin to difrɛn industri dɛm, mɔ usay impak rɛsistɛns impɔtant.

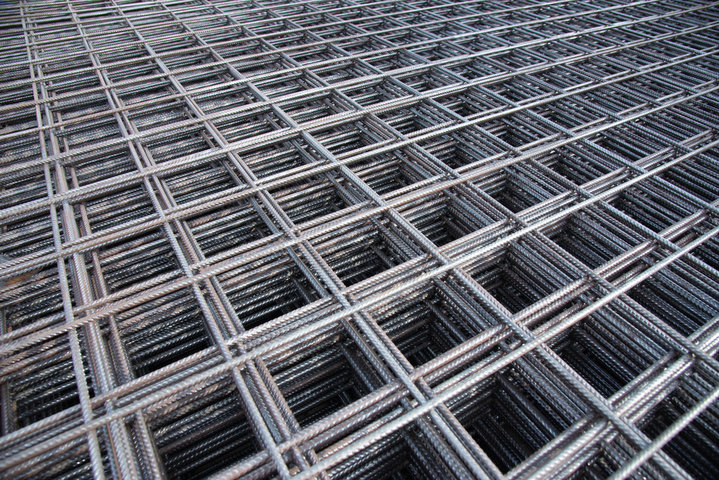

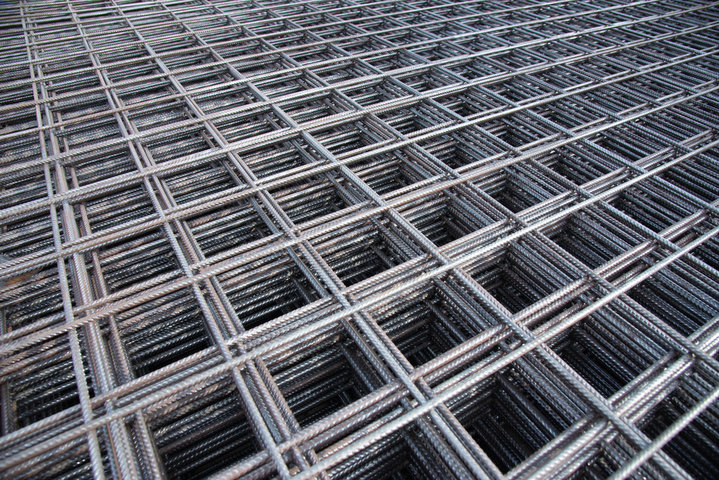

Kɔnstrɔkshɔn : Stilin de ple wan fawndeshɔn rol fɔ bil infrastukchɔ ɛn i de gi impɔtant sɔpɔt insay:

Struktrɔl kɔmpɔnɛnt dɛn lɛk bim, kɔlɔm, ɛn fɔm fɔ bildin ɛn brij dɛn .

Riinfɔsmɛnt dɛn na kɔnkrit strɔkchɔ dɛn fɔ mek dɛn impruv tɛnsiɛl trɛnk .

Automotive Industry : In Vehicle Production, Steel in ay trɛnk-to-weit ratio de mek am fayn fayn chus fɔ:

Kar bɔdi ɛn chɛsis, we de gi durabiliti ɛn impak resistans fɔ sef

Wil ɛn aks, we de gi ay pafɔmɛnshɔn ɛn fatigue resistans .

Manufacturing : Stilin impɔtant fɔ mek dɛn mek tul dɛn we go de fɔ lɔng tɛm ɛn we gɛt ay pafɔmɛnshɔn, we inklud:

Di tin dɛn we dɛn kin yuz na os ɛn di tin dɛn we dɛn kin yuz fɔ kuk : di tin dɛn we Stenlɛs Stiɛl kin yuz fɔ mek di kɔrɛshɔn nɔ gri wit di tin dɛn we dɛn kin yuz fɔ mek tin dɛn ɛn di fayn fayn tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn, kin mek pipul dɛn lɛk am we dɛn de yuz am na os:

Di tin dɛn we dɛn kin yuz fɔ mek kichin, lɛk frij ɛn ɔvin, fɔ mek i izi fɔ mek dɛn mek am izi

Kuk, inklud pɔt ɛn pan, we dɛn valyu fɔ dɛn fɔ lɔng tɛm ɛn fɔ mek dɛn nɔ wam .

Factors fɔ tink bɔt we yu de pik bitwin kast ayɛn ɛn stɛl .

Fɔ pik di rayt tin bitwin di kɔst ayɛn ɛn di stɛl, yu nid fɔ tek tɛm ebul fɔ chɛk bɔku tin dɛn. Ɛni prɔjek de sho difrɛn prɔblɛm dɛn ɛn tin dɛn we dɛn nid fɔ du. We yu ɔndastand dɛn impɔtant tin ya, dat kin ɛp fɔ mek yu disayd fɔ du sɔntin.

Strɔng tin dɛn we dɛn nid fɔ du .

Di kayn pawa we yu prɔjek fɔ gɛt fɔ bia wit di tin dɛn we yu want fɔ du, na in de sho di tin dɛn we yu want fɔ du. Cast Iron Excels ɔnda kɔmpreshɔn, we mek i fayn fɔ bil fawndeshɔn ɛn mashin bays. Stilin de gi supia tɛnsiɛl trɛnk, pafɛkt fɔ strɔkchɔ dɛn we nid rɛsistɛns agens pul ɔ strɛch fɔs.

Koroshɔn rɛsistɛns .

Envayrɔmɛnt ɛksplɔshɔn de ple impɔtant pat pan matirial sɛlɛkshɔn. Kast ayɛn de divɛlɔp wan patina we de protɛkt am ova tɛm, we de gi mɔdaret kɔrɛshɔn rɛsistɛns. Stilin, mɔ di wan dɛn we nɔ gɛt sten, de gi bɛtɛ protɛkshɔn agens rɔst ɛn kemikal kɔrɛshɔn. Tink bɔt aw di tin dɛn we dɛn yuz fɔ mek di tin dɛn we de na di bɔdi, we gɛt wata, kemikal dɛn, ɔ sɔl wata.

Impɛkt rɛsistɛns .

Yu projɛkt in vulnerability to sudden forces de afɛkt matirial choice. Stilin de sho fayn fayn tin dɛn we nɔ de ambɔg di impak ɛn lod dɛn wantɛm wantɛm. Kast ayɛn de sho brit ɔnda impak, pan ɔl we i de handle stedi lod fayn fayn wan.

Manufakchurin Kɔmplisiti .

Di aspek dɛn we de dɔŋ ya de inflɔws di prodakshɔn fisibiliti:

Kast ayɛn de alaw mɔ intrikɛt dizayn dɛn tru in supia kastin prɔpati ɛn flɔ kwaliti dɛn .

Steel de gi big fleksibiliti insay post-prɔdakshɔn modifyeshɔn ɛn jɔyn mɛtɔd dɛn .

Kɔmpleks shep dɛn nid fɔ gɛt smɔl mashin we yu de yuz kast ayɛn bikɔs ɔf bɛtɛ kastabiliti .

Stilin de gi mɔ opshɔn fɔ wɛldin ɛn mɛkanikal fastɛns insay asɛmbli prɔses .

Kost Konsidareshɔn dɛn

| Faktɔ | Kast Ayɔn | Stiɛl . |

| Raw matirial . | Di kɔst we smɔl pas ɔl . | Di kɔst we ay pas ɔl . |

| Prɔsesin . | Simpul kastin prɔses . | Mɔ kɔmpleks manufakchurin . |

| Wok | Less intensive . | Mɔ leba nid fɔ de . |

| Mek say we dɔn pwɛl | Protekshɔn we dɛn nid ɔltɛm we dɛn nid fɔ protɛkt . | Varies bay di kayn . |

Di tin dɛn we de apin na di envayrɔmɛnt .

Tempracha ɛn envayrɔmɛnt kɔndishɔn dɛn de inflɔws di matirial pefɔmɛns:

Kast ayɛn de mentɛn stebiliti akɔs wayd tɛmpracha rɛnj dɛn .

Steel ofa beta pefomans in ekstrim kol kondishon

Dɛn tu tin ya nid fɔ protɛkt frɔm harsh weta ɛksplɔshɔn .

Indo Aplikeshɔn dɛn de fes smɔl envayrɔmɛnt chalenj dɛn pas ɔda instɔleshɔn dɛn na do .

Ɛksplen

Fɔ sɔma, di kast ayɛn ɛn stɛl difrɛn pan di kɔmpɔzishɔn, trɛnk, ɛn kɔst. Kast ayɛn de gi ay kɔmprɛsiv trɛnk ɛn lɔwa prodakshɔn kɔst, we stɛl de gi big tɛnsiɛl trɛnk ɛn impak rɛsistɛns. Fɔ pik di rayt matirial min fɔ mach in prɔpati dɛn to yu aplikeshɔn nid dɛn. We yu ɔndastand dɛn men difrɛns ya, yu kin mek di rayt chus we go mek yu ebul fɔ du ɛn wok fayn fayn wan na yu prɔjek dɛn.

Rifrɛns Sɔs dɛn .

Ayɛn

Ayɛn

Best high pressure die casting faktri na China .

Kwɛshɔn dɛn we dɛn kin aks ɔltɛm (FAQ)

K: Wetin na kast ayɛn, ɛn aw dɛn kin mek am?

Cast Iron na wan ayɛn-kabɔn alɔy we gɛt kabɔn kɔntinyu we pas 2%, we dɛn mek tru smeltin ɛn kastin.

K: Wetin na stɛl, ɛn aw i difrɛn frɔm kɔst ayɛn?

Stilin na ayɛn-kabɔn alɔy we nɔ rich 2% kabon, we de gi ay tɛnsiɛl trɛnk pas kast ayɛn.

K: Wetin mek kast ayɛn gɛt bɛtɛ kɔmprɛsiv trɛnk pas stɛl?

Cast Iron in ay kabon kɔntinyu de ɛp fɔ mek in kɔmprɛsiv trɛnk bɛtɛ, we mek i fayn fɔ bia ebi ebi lod.

K: Aw kast ayɛn ɛn stɛl kɔmpia insay di tin dɛn we gɛt fɔ du wit kɔrɛshɔn rɛsistɛns?

Stilin, mɔ stenlɛs stiɛl, jɔs de gi bɛtɛ kɔrɛshɔn rɛsistɛns, we di kɔst ayɛn kin rɔst we dɛn nɔ gɛt protɛktiv kɔtin.

K: Us teknikol prɔpati dɛn a fɔ tink bɔt we a de pik bitwin kast ayɛn ɛn stɛl?

Tink bɔt tin dɛn lɛk tɛnsiɛl trɛnk, kɔmprɛsiv trɛnk, mashinabiliti, kɔrɛshɔn rɛsistɛns, ɛn impak tolɛreshɔn fɔ optimal rizɔlt.

K: Aw dɛn kin mek di mashin we dɛn kin yuz fɔ mek kɔst ayɛn we dɛn kɔmpia am wit stɛl?

Kast ayɛn izi fɔ mashin bikɔs ɔf in grafayt strɔkchɔ, we de ridyus di wear pan kɔt tul dɛn we yu kɔmpia am wit stɛl.

K: Wetin mek di kast ayɛn fit fɔ kɔmpleks kastin dizayn dɛn?

Kast ayɛn gɛt bɛtɛ flɔabiliti ɛn lɔwa shrinkage, we de alaw intrikɛt shep dɛn wit minimal difɔmeshɔn we dɛn de kol.

K: Aw a go ebul fɔ trɔbulshut kɔmɔn tin dɛn wit kast ayɛn na ay-impakt aplikeshɔn dɛn?

If cast iron fractures ɔnda impak, tink bɔt stɛl fɔ bɛtɛ impak resistans ɔ aplay ɔda sɔpɔt strakchɔ.

K: Us sefty prekoshɔn a fɔ tek we a de handle kast ayɛn ɛn stɛl?

Wear protektiv gia, mentein di rayt ventilashɔn we yu de kɔt ɔ wɛldin, ɛn yuz tul dɛn we dɛn rayt fɔ ay-tɛnsiɛl matirial dɛn.

K: Usay dɛn kin yuz kɔst ayɛn ɛn stɛl di bɛst we fɔ yuz na industrial aplikeshɔn?

Cast Iron de wok fayn fɔ ebi, steshɔn pat dɛn lɛk injin blɔk, we stɛl fayn fɔ strɔkchɔral, lod-bearing, ɛn ay-impakt aplikeshɔn dɛn.