Yala aluminiyɔmu ye fɛn ye min bɛ kɛ ni fɛn ye wa? Aluminiyɔmu suguya wɛrɛw ye jumɛnw ye? Aluminiyɔmu kalasi bɛ se ka dɔn cogo di? Olu ye ɲininkaliw ye minnu bɛ kɛ tuma caman na fɛn dilanni ni fɛn dilanni na. Hali ni aluminiyɔmu saniyalen bɛ yen, baara fanba bɛ kɛ ni aluminiyɔmu bɔgɔlanw ye - fɛn minnu bɛ aluminiyɔmu ni fɛn wɛrɛw fara ɲɔgɔn kan walasa ka jogo kɛrɛnkɛrɛnnenw yiriwa.

Nin gafe in kɔnɔ min bɛ aluminiyɔmu suguyaw ni a nafaw jira, an bɛna aluminiyɔmu, aluminiyɔmu caman, aluminiyɔmu fɛn suguyaw, ani aliminiyɔmu ni alifɛnw cogoya suma ɲɔgɔn na. I mana sugandili kɛ manje alloy vs aluminum cɛ, ka aluminiyɔmu nɛgɛ barikama ɲini, walima ka aluminiyɔmu fɛnsɛbɛnniw faamuya, nin gafe in bɛ fɛn bɛɛ ɲɛfɔ k’a ta aliminiyɔmu seriyali jatebɔsɛbɛnw na ka se aliminiyɔmu gɛlɛya hakɛ ma .

Aluminiyɔmu bɔgɔlanw ye mun ye?

Aluminiyɔmu bɔgɔlanw ye fɛnw kulu ye minnu bɛ kɛ ni aluminiyɔmu saniyalen ye minnu faralen don ɲɔgɔn kan ni fɛn wɛrɛw ye walasa k’u ka nafaw n’u ka baara kɛcogo ɲɛ. O bɔgɔlanw bɛ Dabɔ ni aliminiyɔmu mɔlen ɲagamini ye ni fɛnw ye minnu sugandira koɲuman, o bɛ na ni furaji jɛlen ye nɛnɛ ni solidification (solidi) kan. Nin fɛn ninnu farali bɛ se ka aliminiyɔmu saniyalen fanga, a muɲuni ani a jogo wɛrɛw yiriwa kosɛbɛ, o b’a to a bɛnnen don baara caman ma.

Aluminiyɔmu bɔgɔlanw ka ɲɔgɔn sɔrɔli bɛ kɛ cogo min na:

Aluminiyɔmu saniyalen : nɛgɛ basigilen min bɛ kɛ nɛgɛ ye, a ka c’a la, o bɛ kɛ 85% fo 99% ye a girinya bɛɛ lajɛlen na.

Fɛn minnu bɛ kɛ ka fɛnw sɔgɔ: Nɛgɛ ni nɛgɛ tɛ minnu na, olu suguya caman bɛ fara aluminiyɔmu kan walasa ka alisi kɛrɛnkɛrɛnnenw dilan ni jogo ɲininenw ye. Fɛn minnu bɛ Kɛ ɲɔgɔn fɛ, olu ye nɛgɛ, manje, manganɛsi, silikon, zinki ani litiyamu ye.

Fɛn minnu bɛ kɛ ka fɛnw sɔgɔ aliminiyɔmu ka nafaw kan, olu nafa ka bon kosɛbɛ, wa u tɛ kelen ye:

Fanga : fɛn minnu bɛ kɛ i n’a fɔ nɛgɛ, manje ani zinki, olu bɛ se ka dɔ fara kosɛbɛ aluminiyɔmu bɔgɔlanw fanga kan ni i ye a suma ni aluminiyɔmu saniyalen ye.

Kɔnɔnatumuw kɛlɛli : fɛn dɔw, i n’a fɔ manje ni siliyɔmu, olu bɛ se ka aliminiyɔmu ka sɔgɔli kunbɛncogo ɲuman sabati ni oksizɛni lakananen dɔ jɔli ye.

Sumaya ni kuran taabolo : Hali ni aluminiyɔmu saniyalen ye funteni ni kuran ɲɛminɛbaga ɲumanba ye, fɛn dɔw farali bɛ se ka o jogo ninnu sɛmɛntiya walasa u ka bɛn baara kɛrɛnkɛrɛnnenw ma.

Formulabɛn ni masina sɔrɔcogo : fɛn minnu bɛ kɛ ka fɛnw sɔgɔ, olu bɛ se ka nɔ bila nɔgɔya la, aluminiyɔmu bɔgɔlanw bɛ se ka kɛ cogo min na, ka dilan, ani ka kɛ ni masin ye, o bɛ kɛ sababu ye u ka kɛ fɛn caman ye fɛn dilanni taabolo la.

Aluminiyɔmu sɛnɛfɛnw nafa ka bon kosɛbɛ izini suguya caman na, o tɛ se ka fɔ ka tɛmɛ:

Bololabaara : Aluminiyɔmu bɔgɔlanw bɛ baara kɛ kosɛbɛ mobili, aerospace, ani kɔgɔji baarakɛyɔrɔw la k’a sababu kɛ u fanga ni u girinya hakɛ ka bon, o min bɛ se ka kɛ sababu ye ka bolifɛnw ni awiyɔnw dilan minnu ka nɔgɔn ani minnu tɛ fɛn tiɲɛ.

A jɔli: Aluminiyɔmu bɔgɔlanw ka sɔgɔli ni u ka muɲuli b’a to u ka ɲi kosɛbɛ fɛnw dilanni na, i n’a fɔ finɛtiriw, so sanfɛla, ani finiw.

Elektroniki : Aluminiyɔmu fɛn dɔw ka funteni ni kuran taabolo ɲuman, n’u faralen don ɲɔgɔn kan, o bɛ kɛ sababu ye ka baara kɛ ni u ye ɛntɛrinɛti yɔrɔw la, funtenibɔlanw na, ani dakunw na.

Mɔgɔ minnu bɛ fɛnw feere: K’a ta du kɔnɔ minɛnw na ka se farikoloɲɛnajɛ minɛnw ma, aluminiyɔmu sɔgɔlenw bɛ kɛ fɛn caman na, k’a sababu kɛ u ka fɛn caman ye, u cɛɲi, ani u lasegincogo.

| fɛn minnu |

bɛ kɛ ka fɛnw falen . |

| Barika |

dɔ farala nɛgɛ, manje ani zinki kan . |

| Corrosion resistance . |

A bɛ bonya ni manje ni silimɔni ye . |

| Sumaya min bɛ kɛ ni funteni ye . |

modifié ka bɛn baarakɛcogo kɛrɛnkɛrɛnnenw ma . |

| Kuranko ɲɛnabɔli . |

Yɛlɛma donna a la ka da a kan fɛn minnu bɛ baara kɛ ni u ye . |

| Formulabilité . |

a bɛ nɔ bila fɛn kɛrɛnkɛrɛnnenw na minnu bɛ sɔrɔ . |

| Machinability . |

min tɔɔrɔla aluminiyɔmu sɔgɔlen in dilanni fɛ . |

Aluminiyɔmu Alloy tɔgɔw ani a dɔnni .

Aluminiyɔmu bɔgɔlanw bɛ danfara ni tɔgɔladoncogo ye min bɛ kunnafoni nafamaw di u labɛncogo n’u nafaw kan. Nin sigida in, min labɛnna Aluminiyɔmu tɔn fɛ, o bɛ kɛ ni jateden naani ye, o kɔfɛ, sɛbɛnni kɔfɛta bɛ a jira ko a bɛ dimi cogoya jira. An ka an yɛrɛ Dòn nin tɔgɔda-sɛbɛn in kɔnɔko fitininw na.

Tɔgɔdacogo min bɛ Kɛ ni nimɔrɔ naani ye .

Jateden naani min bɛ aluminiyɔmu bɔgɔlan tɔgɔ la, o bɛ nin kunnafoniw lase:

Nizɛri fɔlɔ bɛ a jira ko a bɛ kɛ ni fɛnba ye walima a bɛ kɛ ni fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye minnu bɛ se ka kɛ ka fɛnw ye.

Nizɛri filanan bɛ fɛn caman sɛmɛntiya walima nɔgɔya dantigɛliw:

Jateden sabanan ni naaninan kɔrɔ tɛ kelen ye ka da a kan a bɛ fɔ a ma ko alloy series:

1xxx seriyali : jateden laban fila bɛ aluminiyɔmu saniyalen hakɛ fitinin jira, misali la, 1060 bɛ ni aluminiyɔmu saniyalen 99,60% ye.

Seri wɛrɛw: jateden sabanan ni naaninan bɛ fɛn wɛrɛw jira o seri kɔnɔ, nka u nafa tɛ jatebɔ la.

Misali dɔw filɛ nin ye walasa ka tɔgɔdacogo jira:

1100: 99,00% aluminiyɔmu saniyalen hakɛ fitinin, a daminɛ na .

2024: Kupu i n'a fɔ alifɛnba, 2xxx seriyali fɛn caman ɲɔgɔnna .

6061: Manje ni silikon i n’a fɔ fɛn kolomaw, ɲɔgɔndan fɔlɔ 6xxx seriyali la .

bataki kɔfɛta minnu bɛ kɛ ka ɲɛsin funteni cogoyaw ma .

Ka fara jateden naani kan, aluminiyɔmu bɔgɔlanw tɔgɔladonw ka teli ka kɛ ni sɛbɛnnibolo ye min bɛ a jira ko a ka funteni cogoya walima a ka funteni furakɛli cogoya bɛ sɔrɔ. A ka c’a la, a ka ca ni tɔw bɛɛ ye:

F: i n’a fɔ a falen don cogo min na, k’a sɔrɔ a ma kɔrɔsi kɛrɛnkɛrɛnnen sɔrɔ funteni walima sɛgɛn gɛlɛya cogoyaw kan .

O: Annealed, o ye funteni cogoya nɔgɔman ye, min bɛ sɔrɔ funteni caman funteni fɛ ani nɛnɛ dɔɔnin dɔɔnin .

W: Solution funteni furakɛli, dimi basigibali dɔ bɛ kɛ ka a kɛ fɛn ye min bɛ kɛ a yɛrɛma so funteni na solution funteni furakɛli kɔfɛ .

T: funteni furakɛli sabatilen wɛrɛw, funteni furakɛli ni degunw faralen ɲɔgɔn kan cogo suguya caman na .

T temper bɛ tila ka taa a fɛ cogo kɛrɛnkɛrɛnnen caman na, i n’a fɔ:

T3: Solution min bɛ furakɛ ni funteni ye, min bɛ nɛnɛ, ani min bɛ kɛ a yɛrɛ la .

T4: Solution min bɛ furakɛ ni funteni ye ani min bɛ kɛ a yɛrɛ la .

T6: Solution min bɛ furakɛ ni funteni ye ani min kɔrɔlen don ni fɛn dilannen ye (precipitation hardened) .

Misali la, 6061-T6 bɛ manje ni silikoni sɔgɔlen jira min kɛra solution ye funteni na ani ka kɔrɔya ni artificiellement ye walasa ka dɔ fara a fanga kan.

| dimi |

ɲɛfɔli . |

| F . |

I n’a fɔ a falen bɛ fɛn min na, o tɛ se ka kɛ sababu ye ka funteni walima degun gɛlɛya kunbɛn . |

| o . |

Annealed, softest temper cogoya . |

| W . |

solution solution chaud-treated, unstable temper . |

| T . |

Funteni furakɛli cogoya sabatilen wɛrɛw, minnu bɛ kɛ ni kulu fitinin suguya caman ye . |

Aluminiyɔmu bɔgɔlan suguya wɛrɛw .

Aluminiyɔmu bɔgɔlanw tilalen don kuluba wolonwula ye ka da u ka ɲɔgɔndan fɔlɔw kan ani u ka nafolo sɔrɔlenw kan. Seri kelen-kelen bɛɛ bɛ jira ni jateden naani ye, ni jateden fɔlɔ bɛ a jira ko a ye fɛnba ye min bɛ kɛ ka fɛnw sɔgɔ. Nin ye nin aluminiyɔmu suguya ninnu ɲɛfɔli ye:

1xxx series (aluminiyɔmu saniyalen) .

1xxx seriyali bɛ kɛ ni aluminiyɔmu sɔgɔlenw ye minnu saniyalen don ni 99% ye. Fɛn wɛrɛw hakɛ dɔrɔn de bɛ u la, o bɛ nafa kɛrɛnkɛrɛnnenw Di u ma:

Sumaya ni kuran jiginni ka bon, o b’a to u ka ɲi kosɛbɛ funtenibɔlanw ni kuran baara kama .

A bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ .

Ductility (ductility) ka bon, o bɛ sira di a dilanni n’a cogoya nɔgɔyali ma .

1xxx series alloys (1xxx seriw) baarakɛcogo minnu bɛ kɛ tuma caman na, olu ye kemikɛlilanw, bisiw ani rivets ye.

2xxx Series (Copper) .

Kupu ye fɛn fɔlɔ ye min bɛ kɛ 2xxx seriyali la. O alloyw bɛ dɔn:

fanga ka bon, a ka c’a la, a bɛ se ka suma ni nɛgɛ ye .

Funteni-furakɛli, o bɛ dɔ Fàra u fanga kan ka Taa a fɛ .

Masinabilité ɲuman, nɔgɔya la fɛn dilanni tigitigi .

resistance de corrosion de corrosion étaisant à la alloys aluminiums .

2XXX seriyali bɛ kɛ ka caya aerospace, sɔrɔdasiw ani baara wɛrɛw la minnu bɛ se ka kɛ.

3xxx seriyali (Manganikan) .

Manganese ye 3xxx seriyali yɔrɔba ye. O alloyw bɛ dɔn ni:

Fanga hakɛ danmadɔ, min ka bon ni aluminiyɔmu saniyalen ye nka a ka dɔgɔ ni alifɛn tɔw ye .

Formulabilité ɲuman, min bɛ sira di a cogoya n’a kɔrɔtacogo nɔgɔya ma .

resistance de corrosion excellent, min bɛnnen don ka kɛ sigida gɛlɛnw na .

min tɛ funteni furakɛ, o kɔrɔ ye ko u ka jogo tɛ se ka Changé kosɛbɛ funteni furakɛli fɛ .

3xxx series alloys ka baarakɛcogo misaliw ye tobilikɛminɛnw, mobili yɔrɔw ani jɔli minɛnw ye.

4xxx Series (Silicon) .

Silicon ye fɛn fɔlɔ ye min bɛ 4xxx seriyali la. U bɛ dɔn:

A ka fisa ni fɛn bɛɛ ye, o b’a to u bɛnnen don cogoya ni dilancogo gɛlɛnw ma .

Masinaya ɲuman, min bɛ se ka kɛ sababu ye ka fɛn dilanni tigitigi kɛ .

Fanga hakɛ danmadɔ, min ka bon ni aluminiyɔmu saniyalen ye nka a ka dɔgɔ ni alifɛn tɔw ye .

Funteni jɛnsɛnni ɲuman, o b’a to u ka ɲi kosɛbɛ baarakɛcogo la minnu bɛ funteni jɛnsɛnni teliya wajibiya .

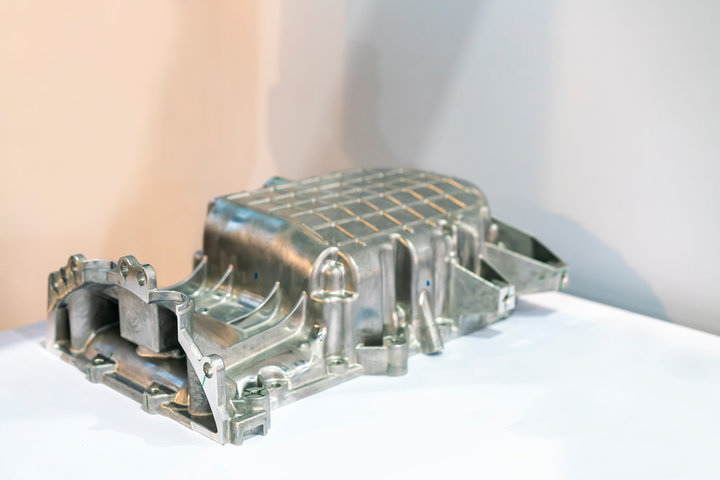

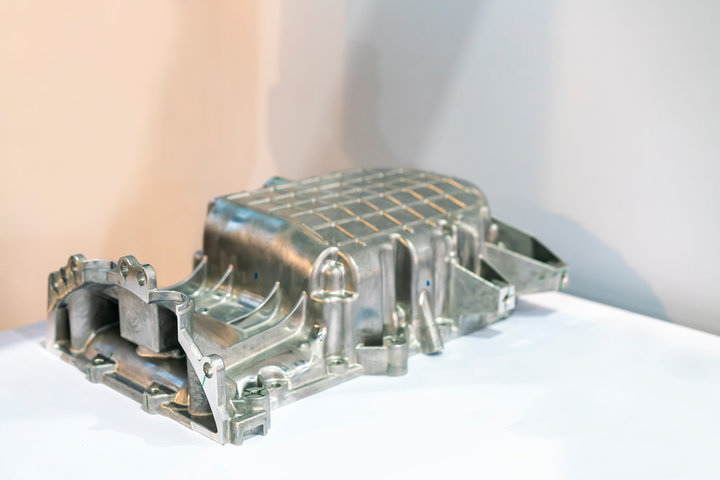

4xxx seriyali bɛ kɛ ka caya motɛri blokiw ni mobili yɔrɔ wɛrɛw la.

5xxx seriyali (magnesium) .

Magnesium ye fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ 5xxx seriyali la. O alloyw bɛ dɔn ni:

Fanga ɲuman, min bɛ kɛ ka caya baarakɛcogo la .

weldabilité excellent, min bɛ sira di ka don nɔgɔya la ani ka fɛn dilanni kɛ .

Kɔnɔnatumuw kɛlɛli ka bon, kɛrɛnkɛrɛnnenya la kɔgɔjida laminiw na .

min tɛ funteni furakɛ, o kɔrɔ ye ko u ka jogo tɛ se ka Changé kosɛbɛ funteni furakɛli fɛ .

5xxx seriyali aliziw ka baarakɛcogo minnu bɛ kɛ tuma caman na, olu ye kɔgɔji kɔnɔfɛnw ye, mobili yɔrɔw, ani degunminɛnw.

6xxx seriyali (magnesium ni silicon) .

6xxx seriyali kɔnɔ, manje ni siliyɔmu fila bɛɛ bɛ sɔrɔ a la i n’a fɔ fɛn fɔlɔw. U bɛ dɔn:

Fanga ɲuman, min bɛ kɛ ka caya baarakɛcogo la .

Formulabilité excellent, min bɛ sira di cogoya ni dilancogo gɛlɛnw ma .

Masinaya ɲuman, min bɛ se ka kɛ sababu ye ka fɛn dilanni tigitigi kɛ .

resistance de corrosion haute, min bɛnnen don ka baara kɛ ni a ye sigida gɛlɛnw na .

Funteni furakɛli, o bɛ se ka dɔ fara u fanga kan ani u ka jogo wɛrɛw kan .

6XXX seriyali bɛ baara kɛ kosɛbɛ aerospace, mobili, jɔli ani baarakɛcogo wɛrɛw la.

7xxx seriyali (zinc) .

Zɛnki ye fɛn fɔlɔ ye min bɛ 7xxx seriyali la, a ka c’a la, a bɛ fara ɲɔgɔn kan ni fɛn wɛrɛw hakɛ fitininw ye. U bɛ dɔn ni:

Fanga min ka bon kosɛbɛ aluminiyɔmu bɔgɔlanw bɛɛ cɛ .

Sɛgɛn kunbɛncogo ɲuman, o b’a to u bɛnnen don ka kɛ degunba ye .

Funteni furakɛli, o bɛ se ka dɔ fara u fanga kan ani u ka jogo wɛrɛw kan .

resistance de corrosion de corrosion étaisant à la alloys aluminiums .

weldability, nka ni fɛɛrɛ dɔw ye walasa ka i yɛrɛ tanga kari .

7XXX seriyali bɛ kɛ ka caya aerospace la, farikoloɲɛnajɛ minɛnw na minnu bɛ baara kɛ kosɛbɛ, ani baarakɛminɛn wɛrɛw minnu bɛ baara caman kɛ.

8xxx series: alisi kɛrɛnkɛrɛnnenw .

8xxx seriyali aluminiyɔmu bɔgɔlanw kɔnɔ, fɛn minnu tɛ sɔrɔ kosɛbɛ i n’a fɔ tin ni nɛgɛ wɛrɛw, minnu dilannen don nisɛ baarakɛcogo ye minnu bɛ jogo kɛrɛnkɛrɛnnenw ɲini. Nin aliw tɛ baara kɛ kosɛbɛ i n’a fɔ seri fɔlɔ nka u nafa ka bon kosɛbɛ iziniw kɔnɔ minnu bɛ baarakɛcogo kɛrɛnkɛrɛnnenw ɲini.

Aluminiyɔmu Alloy ka jatebɔsɛbɛn ani a danfara .

Aluminiyɔmu seriyali jatebɔsɛbɛn min bɛ duguma, o bɛ aluminiyɔmu fɛn suguya wɛrɛw jira:

| aliyɛli seri |

fɔlɔ fɛn (w) |

key properties |

| 1xxx . |

None (aluminiyɔmu saniyalen) . |

Conductivité haute, resistance de corrosion, ductilité . |

| 2xxx . |

Nɛgɛ |

Fanga caman, funteni-furakɛli, masina ɲuman . |

| 3xxx . |

Manganɛsi . |

Fanga danma, cogoya ɲuman, resistance de corrosion . |

| 4xxx . |

Silicon . |

Castabilité excellent, machinable ɲuman, funteni jɛnsɛnni . |

| 5xxx . |

Magnesium . |

Fanga ɲuman, weldabilité, resistance de corrosion . |

| 6xxx . |

Manje ni Silicon . |

Fanga ɲuman, sigicogo, masina sɔrɔcogo, sɔgɔli resistance . |

| 7xxx . |

Zɛnki . |

Fanga min ka bon kosɛbɛ, sɛgɛnba bɛ se ka kɛ a la, funteni bɛ se ka furakɛ cogo min na . |

| 8xxx . |

Tin, nɛgɛ ani nikɛri, nɛgɛ wɛrɛw minnu man ca . |

Demande (ɲini) jogo kɛrɛnkɛrɛnnenw . |

Aluminiyɔmu aluminiyɔmu kilisi hakɛ n’u baarakɛcogo .

Aluminiyɔmu bɔgɔlanw bɛ sɔrɔ suguya caman na, u kelen-kelen bɛɛ bɛ labɛn ka kɛɲɛ ni baara kɛrɛnkɛrɛnnenw ye u kɛtɔ ka fɛnw balan i n’a fɔ fanga, sɔgɔli kunbɛncogo, ani sigicogo. Aluminiyɔmu sɛnɛfɛnw hakɛ jɔnjɔn dɔw bɛ duguma ani u bɛ dɛmɛ don izini minnu na.

Kalansen kɛrɛnkɛrɛnnenw ka ɲɛfɔli dafalen .

1100

Nin kala in ye jago siratigɛ la aluminiyɔmu ye , min lakodɔnnen don a ka sɔgɔli kɛcogo ɲuman fɛ ani a ka funteni ni kuran taabolo ka bon. Hali n’a ka nɔgɔn kosɛbɛ, a ka ɲi kosɛbɛ baarakɛcogo la yɔrɔ minnu na fanga tɛ wajibi fɔlɔ ye.

3003

Aluminiyɔmu min bɛ se ka kɛ fɛn caman ye, a tɛ se ka furakɛ, 3003 aluminiyɔmu bɛ sɔrɔ a la, manganɛsi bɛ sɔrɔ a la walasa a fanga ni a cogoya ka fara a kan, o b’a to a bɛnnen don fɛn caman ma.

Aplikasi : A bɛ kɛ tobilikɛminɛnw na, a marayɔrɔw la, a sanfɛla la, ani a ka baara la, a bɛ baara kɛ ni nɛgɛ ye, k’a sababu kɛ a ka baarakɛcogo n’a ka sɔgɔli ye.

5052

5052 aluminiyɔmu bɛ dɔn a ka sɔgɔli barikama fɛ, kɛrɛnkɛrɛnnenya la kɔgɔjida laminiw na, ka fara fanga danma kan ka se fanga ma. O b’a Kɛ sugandili ɲuman ye sigidaw la minnu bɛ Kɔgɔji la.

Baarakɛcogo : A bɛ kɛ ka caya kɔgɔjida la baarakɛminɛnw na, fɛnɲɛnamafagalanw na, degunminɛnw na, ani izini minɛnw na k’a sababu kɛ a bɛ mɛn ani a bɛ se ka wuli.

6061

A bɛ dɔn ko aluminiyɔmu suguya caman bɛ sɔrɔ a la, 6061 a bɛ fanga, sɔgɔli, ani masina sɔrɔcogo faralen ɲɔgɔn kan cogo dafalen na. A bɛ funteni furakɛ, o b’a to a bɛ se ka ladamu baarakɛcogo la.

Baarakɛcogo : A ka ɲi kosɛbɛ aerospace yɔrɔw la, mobili karamɔgɔya la, jɔlifɛnw na, ani fɛnw dɛmɛni fɛnw na.

7075

Ni fanga hakɛ caman bɛ aluminiyɔmuw cɛ, 7075 a bɛ kɛ fɔlɔ degunba la. A ka dɔgɔn ka kɛ fɛn ye min bɛ se ka sɔgɔsɔgɔ ka tɛmɛ suguya tɔw kan nka a bɛ tɛmɛ yɔrɔw kan, fanga ka bon yɔrɔ minnu na.

Aplikasi : A ka ca aerospace, lafasali, ani farikoloɲɛnajɛw la minnu bɛ baara kɛ kosɛbɛ, yɔrɔ minnu na, u ka nɔgɔn ani u ka muɲuli ka bon.

Tabali min bɛ kɛ ka aluminiyɔmu sɔrɔ

| aluminiyɔmu gradew la, |

o bɛ kɛ sababu ye ka |

fɛnw jira minnu |

bɛ se ka kɛ fɛn ye . |

| 1100 |

99% aluminiyɔmu saniyalen . |

resistance de corrosion haute, ductile . |

HVAC, kemikɛli, dumuni dilanni . |

| 3003 |

Aluminiyɔmu ni manganɛsi . |

Fanga danma, baarakɛcogo ɲuman . |

Tobilikɛminɛnw, fɛn marayɔrɔw, so sanfɛla . |

| 5052 |

Aluminiyɔmu ni manje . |

resistance de corrosion barikama, weldable . |

Kɔgɔjida la, fɛnɲɛnamafagalan, tansiyɔn minɛnw . |

| 6061 |

Manje ni Silicon . |

Sumaya-furakɛli, a bɛ se ka kɛ fɛn caman ye kosɛbɛ . |

Fɛn minnu bɛ kɛ ka fɛnw jɔ, aerospace, mobili . |

| 7075 |

Zɛnki i n’a fɔ fɛn fɔlɔ min bɛ kɛ ka fɛnw kɛ . |

Fanga min ka bon, a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ . |

Aerospace, lafasali, farikoloɲɛnajɛ minɛnw . |

O aluminiyɔmu hakɛ ninnu bɛ sugandiliw di dilanbagaw ma minnu bɛ baara kɛcogo ni musakaw bɛn ɲɔgɔn ma, ka iziniw ka ɲininiw dafa k’a ta kɔgɔjida la ka se aerospace ma.

Funteni furakɛli taabolo minnu bɛ kɛ aluminiyɔmuw la .

Funteni furakɛli ye fɛɛrɛ jɔnjɔn ye aliminiyɔmu caman dilanni na, bawo a bɛ se k’u ka masinko nafaw bonya kosɛbɛ, i n’a fɔ fanga, gɛlɛya, ani ductility. Ni u bɛ funteni ni nɛnɛ waatiw kɔlɔsi kosɛbɛ, ka fara a kɔfɛta taabolo kan i n’a fɔ nɛnɛ baara ani kɔrɔya, ɛntɛrinɛti injiniyɛriw bɛ se ka aluminiyɔmu bɔgɔlanw nafaw labɛn walasa ka baarakɛcogo kɛrɛnkɛrɛnnenw wajibiyalenw dafa.

Funteni furakɛli taabolo minnu bɛ kɛ tuma caman na ani u tɔgɔw .

Funteni furakɛli kɛcogo caman bɛ yen minnu bɛ kɛ ka aluminiyɔmuw kɛ, u kelen-kelen bɛɛ n’a tɔgɔ kɛrɛnkɛrɛnnen don. O tɔgɔw bɛ di teliya ni sariya siratigɛ la walasa ka funteni furakɛli kɛrɛnkɛrɛnnen dɔ dɔn min kɛra ni bɔgɔ ye. An ka funteni furakɛli taabolo dɔw sɛgɛsɛgɛ minnu bɛ kɛ ka caya ani u tɔgɔw.

T3: Solution Chaud-Trated + Cold worked + Naturally Aged .

T3 funteni furakɛli taabolo bɛ nin wale ninnu senfɛ:

Solution Heat Treatment (Furakɛcogo funteni): A bɛ sumaya fo ka se funteni kɛrɛnkɛrɛnnen dɔ ma, ka a minɛ ka mɛn walasa ka a to a ka se ka fɛn dɔw kɛ ka a to a ka se ka wuli ka don aluminiyɔmu matiriyali kɔnɔ.

Nɛnɛ baara: O kɔfɛ, nɛnɛ bɛ baara kɛ, a ka c’a la, a bɛ kɛ ni sɔgɔli ye walima ka wuli, walasa k’a fanga n’a degun-sɔrɔcogo ɲɛ.

Kɔrɔya nafama: A laban na, a bɛ sɔn ka kɔrɔya a yɛrɛ la so funteni na, o bɛ dɔ fara a fanga n’a sabatili kan.

T3 funteni furakɛli bɛ kɛ ka caya alloyw la i n’a fɔ 2024 ani 7075, minnu bɛ kɛ aerospace ani baara wɛrɛw la minnu bɛ kɛ ni baara ye.

T4: Solution Chaud-Trated + Naturally Aged .

T4 funteni furakɛli taabolo bɛ kɛ ni fɛɛrɛba fila ye:

Solution Heat Treatment (Soli funteni furakɛli): A ni T3 bɛ tali kɛ ɲɔgɔn na, a bɛ sumaya fo ka se funteni kɛrɛnkɛrɛnnen dɔ ma, wa a bɛ minɛ yen walasa ka a to fɛn minnu bɛ kɛ ka fɛnw sɔgɔ, olu ka se ka wuli ka don aluminiyɔmu matiriyali kɔnɔ.

Kɔrɔya nafama : o kɔfɛ, a bɛ sɔn ka kɔrɔya a yɛrɛ la so funteni na, o bɛ dɔ fara a fanga n’a sabatili kan waati kɔnɔ.

T4 funteni furakɛli bɛ kɛ tuma caman na fɛnɲɛnamafagalanw na i n’a fɔ 6061, minnu bɛ baara sɔrɔ izini suguya caman na, i n’a fɔ mobili, jɔli ani ɲɛnajɛ.

T6: Solution Chaud-Trated + Artificially Aged .

T6 funteni furakɛli taabolo bɛ nin wale ninnu senfɛ:

Solution Heat Treatment (Soli funteni furakɛli): A bɛ sumaya fo ka se funteni kɛrɛnkɛrɛnnen dɔ ma, ka sɔrɔ ka a to a ka kɛ fɛn ye min bɛ se ka fɛn dɔw kɛ ka a to a ka se ka wuli ka don aluminiyɔmu matiriyali kɔnɔ.

Kɔrɔya kɛlen: O kɔ fɛ, a bɛ sumaya fo ka se funteni hakɛ kɔrɔtalen ma (a ka c’a la, a bɛ dɔgɔya ka tɛmɛ furaji funteni furakɛli funteni kan) ka sɔrɔ ka a minɛ waati kɛrɛnkɛrɛnnen dɔ la walasa ka fɛn minnu bɛ kɛ ka fɛnw sɔgɔ, olu ka sanjiko kɔrɔsilen sabati, o min bɛ dɔ fara kosɛbɛ nɛgɛmugu fanga ni a gɛlɛya kan.

T6 funteni furakɛli bɛ kɛ ka caya aliw la i n’a fɔ san 2024, 6061, ani 7075, minnu bɛ fanga ni gɛlɛya caman de wajibiya walasa ka baara ɲini.

T7: Solution Solution Chaud-Trated + Overaged .

T7 funteni furakɛli taabolo bɛ kɛ ni fɛɛrɛba fila ye:

Solution Heat Treatment (Soli funteni furakɛli): A bɛ sumaya fo ka se funteni kɛrɛnkɛrɛnnen dɔ ma, ka sɔrɔ ka a to a ka kɛ fɛn ye min bɛ se ka fɛn dɔw kɛ ka a to a ka se ka wuli ka don aluminiyɔmu matiriyali kɔnɔ.

Overaging: o kɔfɛ, a bɛ sumaya fo ka se funteni hakɛ ma min bɛ kɛ ka kɔrɔya ni T6 ye, ka sɔrɔ ka a minɛ yen waati jan kɔnɔ. O wale in bɛ fanga dɔw saraka walasa ka ductility, toughness ani dimension stabilité ɲɛnabɔ.

T7 funteni furakɛli bɛ kɛ tuma caman na fɛnɲɛnamafagalanw na i n’a fɔ 7075, minnu bɛ kɛ aerospace la ani baara wɛrɛw la minnu bɛ kɛ ni fanga ni gɛlɛya balansi ye.

T8: Solution Chaud-Trated + Cold worked + artificially aged .

T8 funteni furakɛli taabolo bɛ nɛnɛ baara ni kɔrɔya kɛcogo ɲumanw fara ɲɔgɔn kan:

Solution Heat Treatment (Soli funteni furakɛli): A bɛ sumaya fo ka se funteni kɛrɛnkɛrɛnnen dɔ ma, ka sɔrɔ ka a to a ka kɛ fɛn ye min bɛ se ka fɛn dɔw kɛ ka a to a ka se ka wuli ka don aluminiyɔmu matiriyali kɔnɔ.

Nɛnɛ baara: O kɔfɛ, nɛnɛ bɛ baara kɛ, a ka c’a la, a bɛ kɛ ni sɔgɔli ye walima ka wuli, walasa k’a fanga n’a degun-sɔrɔcogo ɲɛ.

Kɔrɔya kɛlen: A laban na, nɛgɛ bɛ sumaya fo ka se funteni kɔrɔtalen ma, wa a bɛ minɛ yen waati kɛrɛnkɛrɛnnen dɔ la walasa ka fɛnw falen-falenw sanjiko kɔrɔsilen sabati, k’a fanga n’a gɛlɛya bonya ka taa a fɛ.

T8 Funteni furakɛli bɛ kɛ ka caya alloyiw la i n’a fɔ san 2024 ani 7075, minnu bɛ fanga, gɛlɛya ani degun-sɔrɔcogo caman fara ɲɔgɔn kan.

Secondaires de produits spéciales pour les réseau de stress walima kɔrɔya hakɛ .

Ka fara funteni furakɛli fɔlɔw kan, taamasiyɛn filanan kɛrɛnkɛrɛnnenw fana bɛ yen minnu bɛ kɛ walasa ka degun kɛrɛnkɛrɛnnenw walima kɔrɔya cogoyaw jira. O tɔgɔw bɛ fara funteni furakɛli tɔgɔ fɔlɔ kan, i n’a fɔ T7351 walima T6511. Fɛn filanan minnu bɛ kɛ tuma caman na, olu dɔw ye:

51: Degun bɛ lafiya ni sɛgɛn ye .

511: Degun bɛ lafiya ni sɔgɔli ni tilennen misɛnni ye a jiginni kɔfɛ .

52: Degun bɛ lafiya ni degun ye .

54: Degun bɛ lafiya ni a sɔgɔli ni a sɔgɔli faralen ye ɲɔgɔn kan .

Misali la, 7075-T7351 b’a jira ko nɛgɛ in kɛra solution ye min furakɛra ni funteni ye, a si bɛ san hakɛ la, a degunna ni a sɔgɔli ye, ani a tilennen don a jiginni kɔfɛ.

cast vs. aluminium aluminiyɔmuw .

Aluminiyɔmu bɔgɔlanw bɛ se ka tila ka caya ka kɛ kuluba fila ye: alloy cast ani wrought alloys. Hali ni aluminiyɔmu nafa jɔnjɔnw bɛ ɲɔgɔn na, u bɛ danfara don u cogoya la, u dilanni fɛɛrɛw la, ani u kɛcogo laban na. An ka o danfara ninnu sɛgɛsɛgɛ ka ɲɛ.

Danfara minnu bɛ a ni ɲɔgɔn cɛ aloy (alloy) la .

Danfara fɔlɔ minnu bɛ aluminiyɔmu bɔgɔlanw ni ɲɔgɔn cɛ, olu dɔ ye u ka kemikaliya ye, kɛrɛnkɛrɛnnenya la, fɛn minnu bɛ sɔrɔ fɛnw na, olu bɛ sɔrɔ kɛmɛsarada la.

Die casting alloys (die casting alloys) bɛ sɔrɔ a ka c’a la, a ka ca a la, a bɛ tɛmɛ 5% kan a girinya bɛɛ lajɛlen na. O kɛmɛsarada la, fɛn minnu bɛ ɲɔgɔn sɔrɔ, olu bɛ se ka kɛ sababu ye ka fɛnw fili, ka fɛnw falen, ani ka fɛnw falen-falen seko kɛ fɛn dilanni na.

Faan wɛrɛ fɛ, a ka c’a la, fɛn minnu bɛ kɛ ka fɛnw sɔgɔ, olu ka fɛn dilannenw hakɛ bɛ dɔgɔya, a ka c’a la, u bɛ 5% duguma. Alloying hakɛ dɔgɔman minnu bɛ sɔrɔ sɛnɛfɛnw na minnu bɛ baara kɛ, olu bɛ dɛmɛ ka cogoya ɲuman mara, ka baara kɛ, ani ka ductility (ductility) mara, o min nafa ka bon walasa ka fɛnw cogoya ni u dilanni taabolo nataw kɛ.

Danfara minnu bɛ fɛn labanw na, olu bɛ se ka nɔba bila fɛn labanw ka masinko ni u ka kemikaliya cogoyaw la:

Fanga : a ka c’a la, nɛgɛw fanga ka bon ni u ye ni u bɛ tali kɛ fɛnɲɛnamafagalanw na ka da u ka fɛnɲɛnamafagalanw hakɛ kan. Nka, o fanga bonya in bɛ na ni ductility (ductility) dɔgɔyali ni gɛlɛya dɔgɔyali ye.

Ductility (ductility): A ka c’a la, alloys wrought bɛ ductility ni formability ɲuman jira ka tɛmɛ cast alloys kan, k’a sababu kɛ u ka alloying element kɛmɛsarada la dɔgɔya ye. O b’a to u bɛnnen don kosɛbɛ baarakɛcogo ma minnu bɛ kɛ ni u cogoya walima u dilanni caman ye.

resistance de corrosion : aluminiyɔmu sɔgɔlenw ka sɔgɔli bɛ se ka ɲɔgɔn ta ka kɛɲɛ ni fɛn kɛrɛnkɛrɛnnenw ye minnu bɛ sɔrɔ. Alloy dɔw minnu bɛ baara kɛ, i n’a fɔ 5xxx series ni manje ye, olu bɛ sɔgɔli kɛcogo ɲuman di, ka sɔrɔ fɛn dɔw bɛ se ka kɛ fɛn ye min bɛ se ka sɔgɔ sigida gɛlɛnw na.

Fabrication Techniques .

Danfaraba wɛrɛ min bɛ aluminiyɔmu bɔgɔlanw ni ɲɔgɔn cɛ, o ye u dilanni n’u cogoya ye ka kɛ fɛn labanw ye.

Aluminiyɔmu sɔgɔlenw bɛ dilan ni casting fɛɛrɛ suguya caman ye, i n’a fɔ:

Cɛmancɛlabɔli: Aluminiyɔmu mɔlen bɛ bɔn cɛncɛn foroko kɔnɔ, o min bɛ dilan ni cogoya ɲininen cogoya ye. Cɛmancɛlabɔli bɛ se ka kɛ fɛn caman na ani a musaka ka dɔgɔ walasa ka fɛn caman dilan walima yɔrɔbaw, yɔrɔ minnu ka gɛlɛn.

Die casting: Aluminiyɔmu mɔlen bɛ pikiri kɛ ni tansiyɔnba ye nɛgɛ die kɔnɔ. Die casting bɛnnen don yɔrɔw dilanni ma minnu bɛ se ka kɛ ni kunnafoni gɛlɛnw ye ani muɲuli gɛlɛnw.

Investissement casting: Wax pattern bɛ da ni seramiki slurry ye, o kɔfɛ, a bɛ sumaya walasa ka sizo bɔ, ka seramiki bɔgɔlan dɔ to a kɔnɔ. Aluminiyɔmu mɔlen bɛ bɔn ka don bɔgɔdaga kɔnɔ walasa ka a yɔrɔ laban dilan. Investissement casting bɛ surface fini ɲuman ni dimensional tiɲɛni di.

Aluminiyɔmu sɔgɔlenw, o ni ɲɔgɔn cɛ, u dilannen don ni fɛnw dilanni ni u cogoya suguya caman ye, i n’a fɔ:

Extrusion: Aluminiyɔmu bilɛtiw bɛ Gɛn ka Tɛmɛ die da la walasa ka profile janw, minnu bɛ Taa ‘ɲɛ ni cross-section constant ye. Extrusion (bɔli) bɛ kɛ ka caya walasa ka baraw, tubabukanw ani cogoya gɛlɛnw dilan.

Rolling: Aluminiyɔmu sɔgɔlanw walima ingots bɛ tɛmɛ ni wulilanw ye minnu bɛ tugu ɲɔgɔn na walasa ka dɔ bɔ u bonya la ani ka sɛbɛn fla walima tasaw dilan. Rolling bɛ se ka kɛ funteni na walima nɛnɛ na, ka kɛɲɛ ni alloy ani a ɲininenw ye.

BEND: Aluminiyɔmu sɛbɛnw walima profile minnu dilannen don, olu bɛ kɔrɔta walima u bɛ kɛ cogo la min b’a fɛ ka kɛ ni presse freinw ye, roll fɔlɔw, walima bending minɛn wɛrɛw. Binging bɛ sira di yɔrɔw dabɔli ma minnu bɛ kurukuru walima minnu bɛ kɛ kɛrɛ fɛ.

Aplikasi ni a ka nafaw .

Danfara minnu bɛ danfara ni fɛn dilanni fɛɛrɛw cɛ aluminiyɔmu sɔgɔlenw ni ɲɔgɔn cɛ, olu bɛ na ni baarakɛcogo ni jogo wɛrɛw ye.

Aluminiyɔmu sɔgɔlenw nafalanw cogoya dɔw ye:

Mobili yɔrɔw, i n’a fɔ motɛri blokiw, silinda kunkolow, ani fɛnw cicogo, yɔrɔ minnu na, cogoya gɛlɛnw ni fanga caman bɛ sɔrɔ yen.

Tobilikɛminɛnw ni bakew, k’a sababu kɛ u ka funteni jiginni ɲuman ye ani u dilanni nɔgɔyali ye.

Fɛn minnu bɛ kɛ ka fɛnw masiri ani minnu bɛ mɔgɔ ɲɛnajɛ, i n’a fɔ minɛnw ni yeelenbɔlanw, k’a sababu kɛ u ka se ka cogoyaw dilan minnu bɛ fɛn caman ɲɛfɔ ani minnu bɛ mɔgɔ ɲɛnajɛ.

A ka c’a la, a ka fisa ni fɛn dɔw ye minnu bɛ kɛ ka fɛnw kɛ:

Geometries complexes walima kunnafoni gɛlɛnw minnu sɔrɔli ka gɛlɛn ni alloy wrought ye .

Fanga ni girinya hakɛ caman, kɛrɛnkɛrɛnnenya la doni-ta-yɔrɔw la .

Sumayako ɲuman ka ɲɛsin funteni bɔli ma walima funteni jiginni baarakɛcogo ma .

Faan wɛrɛ fɛ, aluminiyɔmu sɛnɛfɛnw baaracogo minnu bɛ kɛ cogoya la, olu dɔw ye:

Sow jɔli sow, bɔlɔnw, ani bolifɛnw kɔnɔ, fanga caman ni cogoya ɲuman nafa ka bon yɔrɔ minnu na .

Aerospace yɔrɔw, i n’a fɔ fuselage ani wing components, k’a sababu kɛ u fanga ni u girinya hakɛ ɲuman ye ani u ka sɛgɛn .

Elektɔriki dakunw ni funteni-minɛnw, k'a sababu kɛ u ka funteni-taama ɲuman ye ani u ka se ka dilan cogo tigitigiw la .

Baara minnu bɛ kɛ ni fɛnw ye, olu bɛ sugandi caman na sɛbɛnw kama minnu bɛ ɲini:

Ductility (ductilité) caman ani formation (dafalen) ka ɲɛsin shaping (sɔgɔli) ni biding (bɔgɔ) ma .

Fanga ni girinya hakɛ ɲumanba ka ɲɛsin fɛnw ma minnu bɛ se ka kɛ fɛn ye .

resistance de corrosion ɲuman bɛ sɔrɔ sigida gɛlɛnw na walima kɛnɛma baarakɛcogo la .

| Property |

Cast Alloys |

Wrought Alloys |

| Alloying element % . |

sanfɛ (>5%) . |

A ka dɔgɔn (<5%) . |

| Barika |

Fanga ka bon, ductility dɔgɔyali . |

Fanga dɔgɔyali, ductility ka bon . |

| Corrosion resistance . |

A bɛ danfara ka kɛɲɛ ni fɛnw ye minnu bɛ ɲɔgɔn sɔrɔ . |

Jɛnkulu ka ɲi, kɛrɛnkɛrɛnnenya la 5xxx seriyali . |

| Fabrication typique . |

cɛncɛn casting, die casting, investissement casting . |

extrusion, rolling, bind . |

| Aplikasi minnu bɛ kɛ tuma bɛɛ . |

Mobili yɔrɔw, tobilikɛminɛnw, fɛnw masirilenw . |

Fɛn minnu bɛ kɛ ka fɛnw jɔ, aerospace yɔrɔw, ɛntɛrinɛti . |

Jateminɛw kɛra ka ɲɛsin aluminiyɔmu bɔgɔlanw sugandili ma .

Aluminiyɔmu sɔgɔlen ɲuman sugandili porozɛ dɔ kama, o bɛ a ɲini k’a ka masina, a musaka, ani a ni funteni furakɛli bɛncogo faamuya. O kow bɛ nɔ bila fɛn dilanni na, musakaw la, ani fɛn dilanni na.

Masina sɔrɔcogo jatebɔ .

Aluminiyɔmu bɔgɔlan dɔ bɛ ka masina hakɛ nɔ bila a cogoya la nɔgɔya la ni CNC masin ye. Fɛn minnu bɛ kɛ ni masinw ye, olu bɛ waati caman bɔ ani ka baarakɛminɛnw sɛgɛn dɔgɔya, ka baara kɛcogo ɲɛ ka taa a fɛ fɛn dilanni gɛlɛn na.

Material Cost ani a sɔrɔcogo .

fɛnw sugandili bɛ nɔba bila porozew ka baarakɛnafolo ni u dilanni teliya la . Alloy minnu musaka ka bon, olu bɛ se ka nafolo ɲumanw di nka u tɛ se ka sɔrɔ walima u tɛ sabati porozebaw kama.

Funteni furakɛli baarakɛcogo ɲuman .

Funteni furakɛli bɛ a to aluminiyɔmu fɛn kɛrɛnkɛrɛnnenw bɛ se ka dɔ fara u fanga kan, u ka muɲuli kan, ani u ka baara kɛcogo kan. Alloy bɛɛ tɛ jaabi ɲuman di funteni furakɛli ma, o la faamuyali bɛnkan nafa ka bon kosɛbɛ baarakɛcogo la min fanga ka bon.

Sumaya furakɛli nafa : .

A bɛ se ka kɛ sababu ye ka gɛlɛya ni fanga fisaya ni 2xxx, 6xxx, ani 7xxx series ye.

A bɛ ɲɛ baara kɛcogo ni ɲɛnamaya kɛcogo ka ɲɛsin fɛnw ma minnu bɛ degunba la.

A bɛ sira di fɛn caman sɛgɛsɛgɛli ma, a ka baara kɛlen kɔfɛ, a nafa ka bon kosɛbɛ aerospace ani industrie gɛlɛnw na.

| Jateminɛ |

nafaw sugandili |

key alloys . |

| Masina sɔrɔcogo jatebɔ . |

Machining teliya, baarakɛminɛnw doncogo ka dɔgɔ . |

6061, 2011, 7075 |

| Materiel Cost & Disponibilité . |

Budjet-friendly, steady supply . |

3003, 5052 . |

| Funteni furakɛli baarakɛcogo ɲuman . |

Fanga ni gɛlɛya min bɛ bonya . |

2024, 6061, 7075 . |

Nin ko ninnu jateminɛni b’a to aliminiyɔmu suguya sugandilen bɛ poroze ka baarakɛcogo, a ka baarakɛnafolo, ani a ka baarakɛcogo magow ɲɛ, o bɛ na ni fɛn dilanni ni fɛn dilannenw dannaya ɲuman ye.

Farankan

Aluminiyɔmu bɔgɔlan suguyaw faamuyali nafa ka bon walasa ka fɛn dilanni ni a dilanni baara kɛcogo ɲɛ. Ni aw ye fɛn kɛrɛnkɛrɛnnenw sugandi minnu bɛ se ka kɛ ka fɛn kɛrɛnkɛrɛnnenw kɛ—a kɛra fanga ye, a kɛra fɛn ye min bɛ se ka fɛnw tiɲɛ, walima a kɛra masinw ye—o bɛ se ka nɔba bila jogo ni musaka la kosɛbɛ. K’a ta fɛn nɔgɔmanw na minnu bɛ aerospace kɔnɔ ka taa a bila fɛnw na minnu bɛ mɛn kɔgɔjida la, fɛn kelen-kelen bɛɛ bɛ baara kɛ ni kuntilenna kɛrɛnkɛrɛnnen ye. Nin gafe in bɛ jusigilan di sugandili ma min bɛ kɛ ni kunnafoniw ye. Aw ye nafolo wɛrɛw ɲini walasa ka aw ka dɔnniya juguya ani ka fɛn o fɛn latigɛ ka ɲɛ poroze o poroze la.

Reference sources .

Aluminiyɔmu .

Aluminiyɔmu aliman .

6061 ni 7075 aluminiyɔmu .

Top Aluminum Process Manufacturer .

Ɲininkali minnu bɛ kɛ tuma caman na (FAQ) .

J: Aluminiyɔmu bɔgɔlan ye mun ye?

Aluminiyɔmu sɔgɔli ye nɛgɛ ye min bɛ sɔrɔ aliminiyɔmu saniyalen ni fɛn wɛrɛw ɲagamini fɛ i n’a fɔ manje, nɛgɛ, walima zinki walasa ka fanga, sɔgɔli kunbɛn, ani a muɲuni sabati.

J: Aluminiyɔmu bɔgɔlanw bɛ se ka suma ni nɛgɛ ye cogo di fanga ni girinya siratigɛ la?

Aluminiyɔmu bɔgɔlanw ka nɔgɔn ka tɛmɛ nɛgɛ kan, o bɛ fanga ni girinya hakɛ caman di. U bɛ kɛ tuma caman na yɔrɔ minnu na girinya dɔgɔyali nafa ka bon, i n’a fɔ aerospace ani mobili baarakɛcogo.

J: Fɛn jumɛnw bɛ se ka kɛ aluminiyɔmuw ka masinako la?

Masina sɔrɔcogo aluminiyɔmu bɔgɔlanw na, o bɛ nɔ bila fɛnw dilanni na, funteni furakɛli la, ani gɛlɛya la. Misali la, 6061 ani 7075 alloy bɛ masina sɔrɔcogo ɲuman di CNC masinw na.

J: Ne bɛ se ka sɔgɔsɔgɔninjɛ bali cogo di ni aw bɛ baara kɛ ni aluminiyɔmu ye?

Walasa ka sɔgɔsɔgɔninjɛ kunbɛn ka ɲɛ, aw bɛ aliziw sugandi ni manje ye (i n’a fɔ 5052) walima ka u tangalanw kɛ u la. Saniya tuma bɛɛ, o fana bɛ sigida laminiw bali minnu bɛ se ka kɛ sababu ye ka u nɔgɔ.

J: Aluminiyɔmu bɔgɔlanw bɛ kɛ yɔrɔ jumɛn na?

Aluminiyɔmu bɔgɔlanw bɛ kɛ ka caya aerospace, mobili, jɔli ani ɛntɛrinɛti kan. Industri kelen-kelen bɛɛ bɛ fɛn kɛrɛnkɛrɛnnenw sugandi ka da magow kan i n’a fɔ fanga, girinya, ani sɔgɔli kɛlɛli.