Plastiki fɛnw bɛ yɔrɔ bɛɛ, nka u dilanni man nɔgɔn. Ɛntɛrinɛti kalanbagaw bɛ fanga, musaka ani fɛn dilanni kɛcogo ɲuman balan cogo di? Nin barokun in bɛna gɛlɛyaw jira minnu bɛ plastiki fɛnw jɔcogo la. Aw bɛna fɛn kolomaw dege, i n’a fɔ kogo janya, kɔkiliw barika bonya, ani fɛn wɛrɛw, minnu bɛ kɛ plastiki yɔrɔw ye minnu bɛ mɛn, minnu musaka ka dɔgɔ.

Plastiki yɔrɔ sigicogo cogoya n’a kɛcogoyaw .

Plastiki fɛnw bɛ fɛnw di minnu tɛ kelen ye ani minnu bɛ se ka kɛ fɛn caman ye, k’u bɔ ɲɔgɔn na ni ɛntɛrinɛti fɛn kɔrɔw ye i n’a fɔ nɛgɛ, nɛgɛ, aliminiyɔmu ani jiri. O fɛnw labɛncogo ni u cogoya faralen ɲɔgɔn kan, o bɛ plastikiw di u dilanni sɛgɛsɛgɛli hakɛ caman ma n’i y’a suma n’u ɲɔgɔnnaw ye.

Fɛnw labɛncogo ɲɔgɔn tɛ minnu na ani u cogoya caman .

Plastiki fɛn suguya caman, u kelen-kelen bɛɛ n’a nafa kɛrɛnkɛrɛnnenw, olu bɛ se ka dilanbagaw bila u ka u ka sugandili kɛ ka kɛɲɛ ni fɛn dilannen ka ɲininiw ye. O suguya in, ka fara se kan ka plastikiw kɛ cogoya gɛlɛnw na, o bɛ kɛ sababu ye ka jateminɛ gɛlɛnw ni baarakɛcogo gɛlɛnw dilan minnu bɛna gɛlɛya walima ka kɛ fɛn wɛrɛw ye.

Procedure générale pour plastique part design .

Walasa ka plastiki nafa sɔrɔ ani ka a jɔcogo ɲuman sabati, a nafa ka bon ka tugu fɛɛrɛ sigilen na. Plastiki yɔrɔ dilanni taabolo bɛɛ lajɛlen bɛ tali kɛ dakun jɔnjɔn caman na:

A’ ye baarakɛcogo wajibiyalenw ni a bɔcogo dɔn:

Fɛn min bɛ kɛ ka baara kɛ n’a ye ani baarakɛcogo wajibiyalenw, olu dɔn .

Aesthetic appeal ani visual characteristics ɲininenw ɲɛfɔ .

Ja minnu bɛ kɛ ni ja fɔlɔw ye:

Prototyping:

ka farikolo-ɲɛnajɛ-fɛnw Bɔ ni fɛɛrɛw ye i n’a fɔ 3D sɛbɛnni walima . CNC Machining .

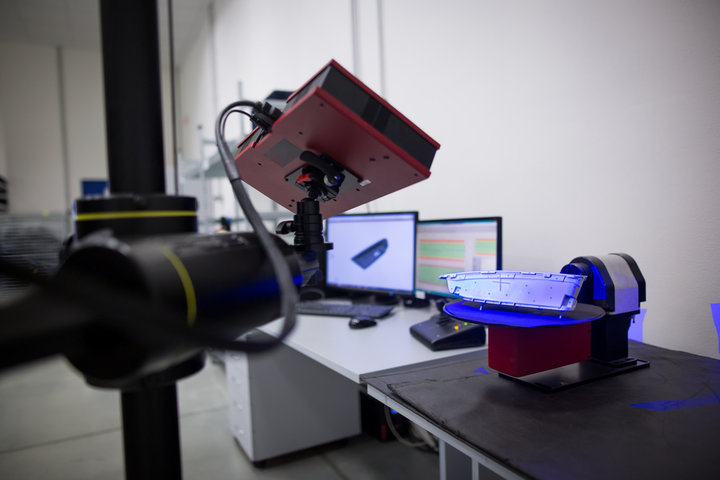

Prototype ka baarakɛcogo, a ka ergonomi, ani a ka dilancogo bɛɛ lajɛlen jateminɛ .

Fɛn minnu bɛ kɛ ka fɛnw sɛgɛsɛgɛ:

Design Recalibration and Revision:

Sɛgɛsɛgɛli jaabiw sɛgɛsɛgɛ ani ka yɔrɔw dɔn minnu ka kan ka ɲɛtaa sɔrɔ .

Aw bɛ fɛn dilanni ladilanni wajibiyalenw kɛ walasa ka baara kɛcogo ɲuman, dannaya, walima fɛn dilanni yiriwa .

Aw ye fɛn ɲɛfɔlen nafamaw labɛn:

Aw ye fɛn ɲɛfɔlenw ɲɛfɔ fɛn laban na, i n’a fɔ hakɛw, muɲuliw, ani fɛnw hakɛ .

Aw ye a lajɛ ko fɛn ɲɛfɔlenw bɛ bɛn fɛn dilanni taabolo ma ani jogoɲini sariyaw ma .

Open Mold Production:

Aw bɛ pikirijikɛlan dilan ani k’a dilan ka da a dilanni laban kan .

Optimiser the mold design for efficient material flow, cooling ani ejection .

Quality Control:

Fɛn jɔnjɔnw bɛ sɔrɔ plastiki fɛnw dilanni na .

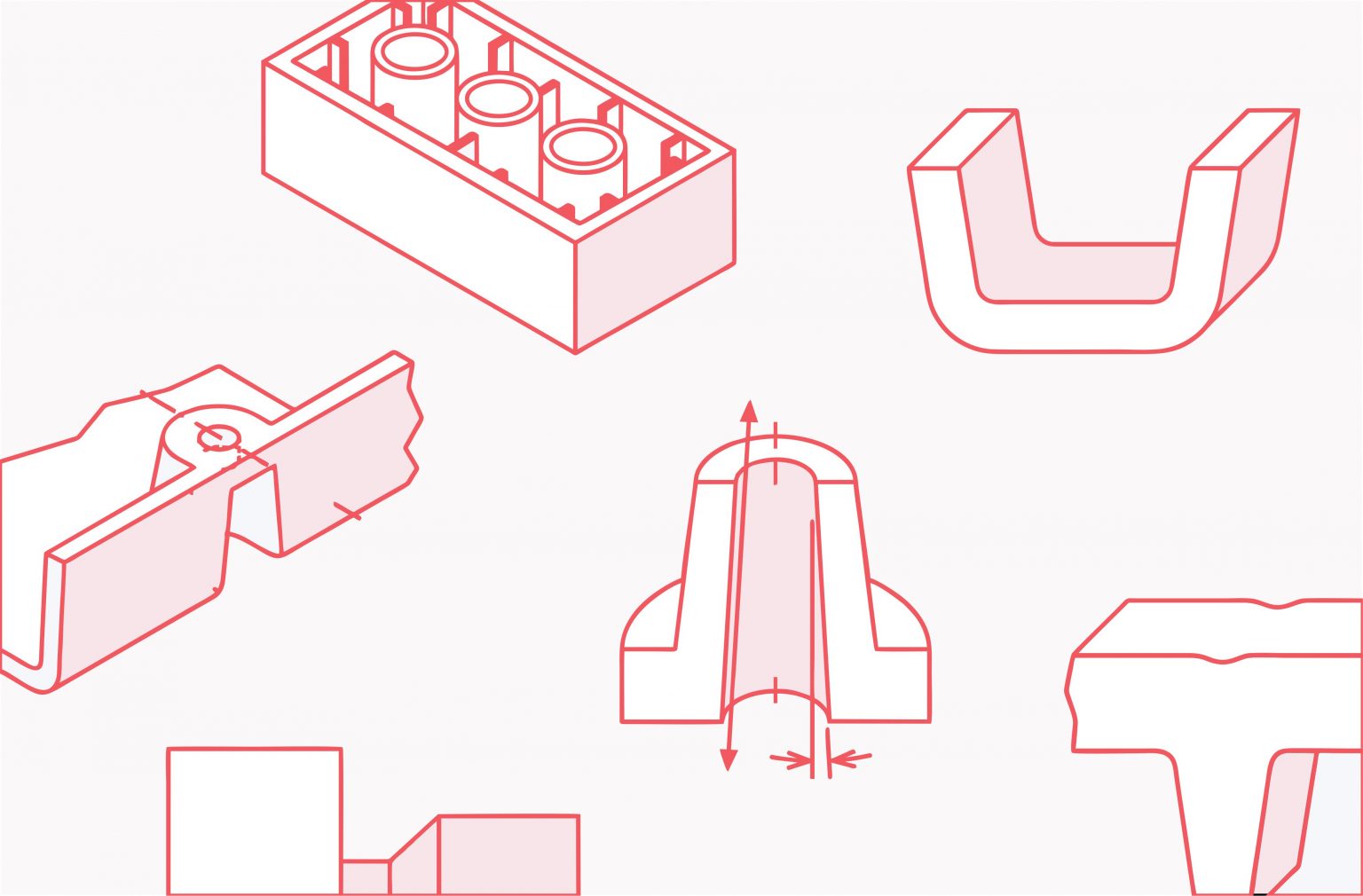

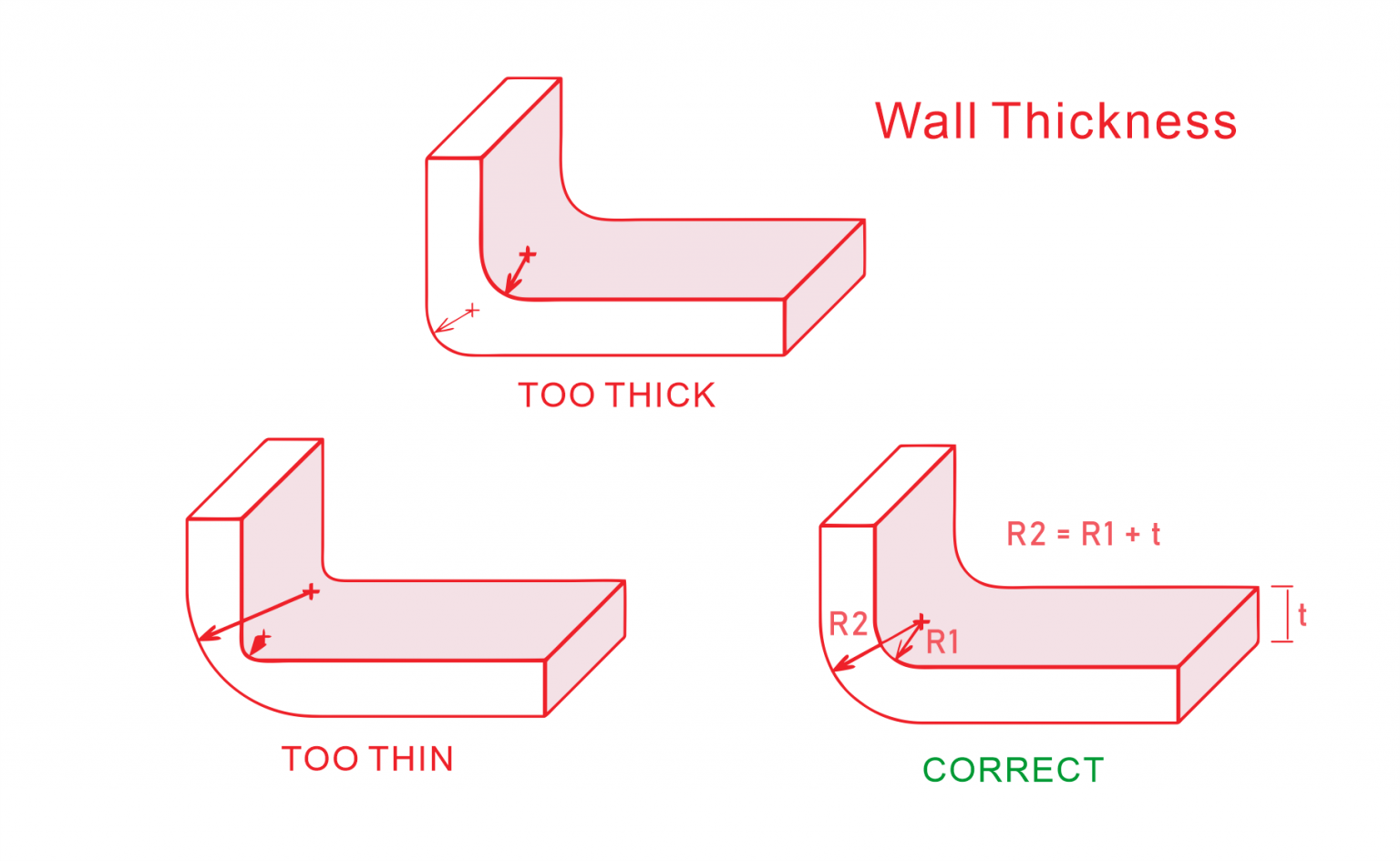

Kogo ka bon .

Kogo janya jɔyɔrɔ ka bon kosɛbɛ plastiki fɛnw dilanni na. A janya ka ɲɛ, o bɛ a to baara kɛcogo ɲuman, a dilanni, ani a musaka dɔgɔyali.

Kogow ka bonyali

| Nafaw Plastiki | Minimuma (mm) | Yɔrɔ fitininw (mm) | Yɔrɔ cɛmancɛw (mm) | Yɔrɔbaw (mm) |

| Nylon . | 0.45 | 0.76 | 1.5 | 2,4-3,2. |

| PE . | 0.6 | 1.25 | 1.6 | 2,4-3.2. |

| PS . | 0.75 | 1.25 | 1.6 | 3,2-5,4. |

| PMMA . | 0.8 | 1.5 | 2.2 | 4-6,5 ye. |

| PVC . | 1.2 | 1.6 | 1.8 | 3,2-5,8. |

| PP . | 0.85 | 1.54 | 1.75 | 2,4-3,2. |

| PC . | 0.95 | 1.8 | 2.3 | 3-4,5 ye. |

| Pom . | 0.8 | 1.4 | 1.6 | 3,2-5,4. |

| ABS . | 0.8 | 1 | 2.3 | 3,2-6 . |

Fɛn minnu bɛ nɔ bila kogo janya sugandili la .

Plastiki fɛnw nafa .

Kɛnɛma fanga ye muɲu .

Lakanali sariyaw .

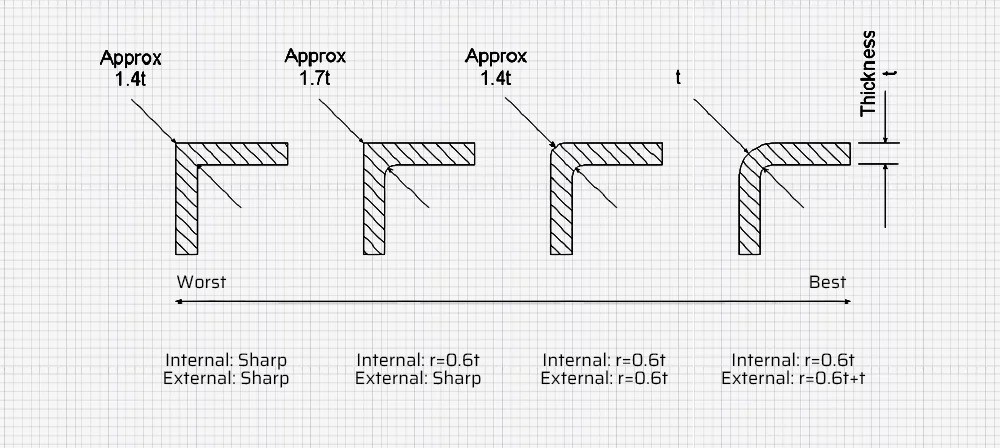

Aw bɛ kɔkiliw barika bonya .

Ka kɔkiliw barika bonya, o bɛ fanga bonya ka sɔrɔ ka kogo janya bɛɛ lajɛlen bonya, ka furaw tiɲɛni bali, ani ka sigicogo dafalen ɲɛ.

Dilancogo sariyaw ka ɲɛsin kɔkiliw barika bonya ma .

A janya: 0,5-0,75 siɲɛ kelen kogo janya (a bɛ fɔ a ma ko: <0,6 siɲɛ)

A janya: A tɛ se ka kɛ kogo janya ye siɲɛ 3 .

Yɔrɔ janya: a ka bon ni kogo janya ye siɲɛ 4 .

Fɛn minnu bɛ kɛ ka fanga di mɔgɔ ma, olu ka kan ka jateminɛ .

Aw bɛ aw yɛrɛ tanga fɛnw dalajɛli ma kɔkiliw ni ɲɔgɔn cɛ .

Aw bɛ perpendicularité mara kɛnɛma kogow la .

Aw bɛ kɔkiliw fanga dɔgɔya kuluw kan .

Aw ye jateminɛ kɛ ko sinkɔrɔ taamasiɲɛw bɛ nɔ min bila mɔgɔ la .

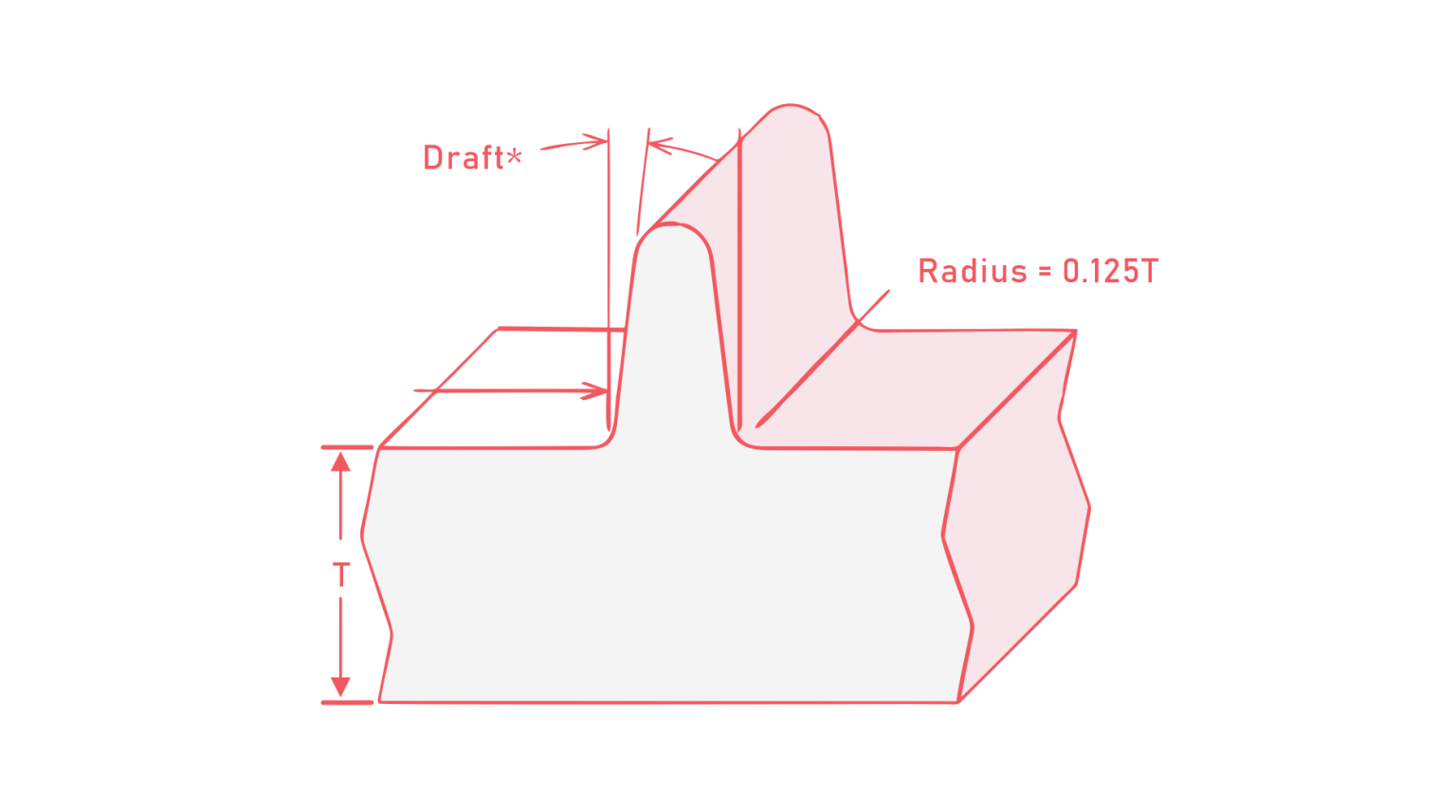

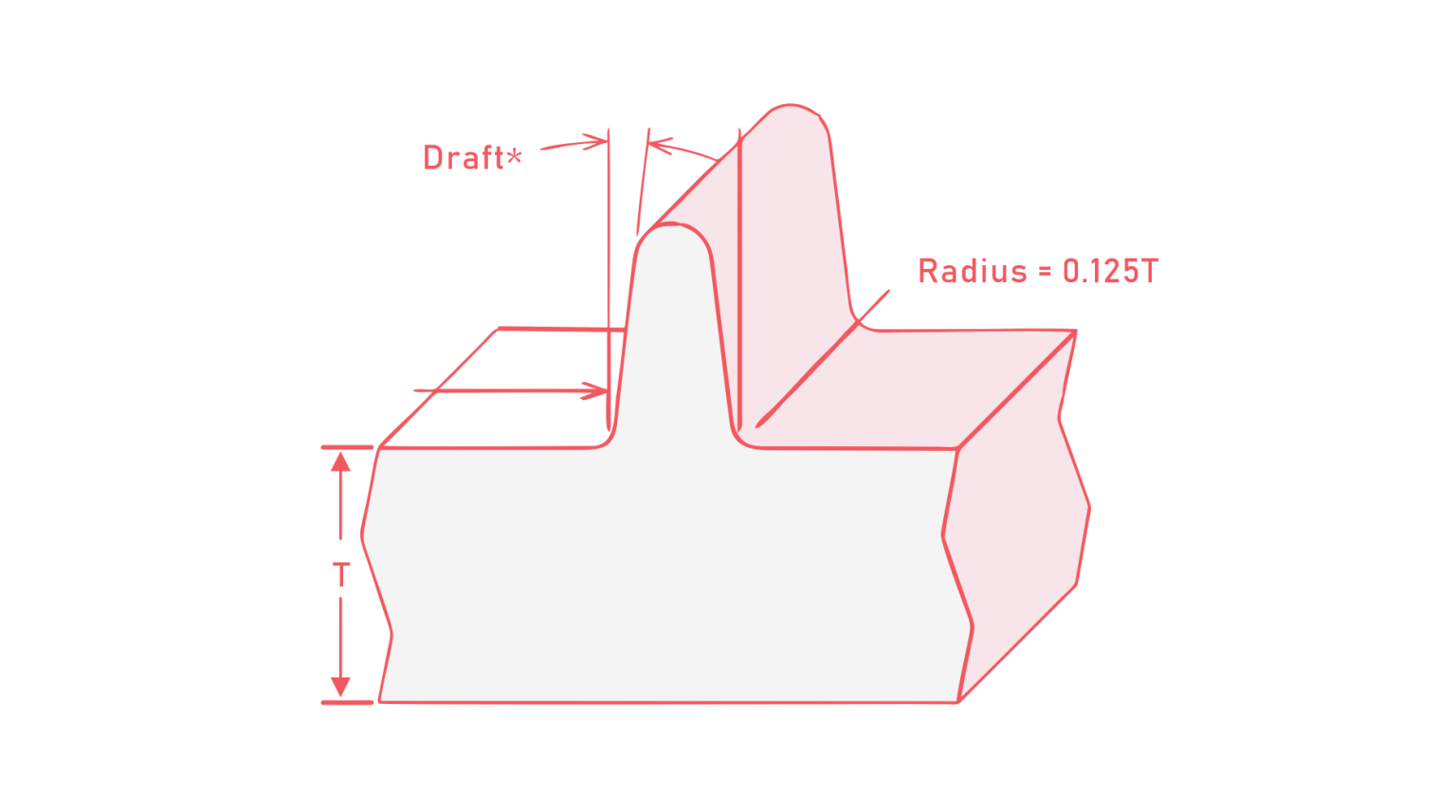

Angles de draft .

Angles draft bɛ nɔgɔya yɔrɔ bɔli nɔgɔya ka bɔ mɔni na, ka a sɔrɔ a dilanni bɛ ɲɛ ani a yɔrɔw ka ɲi kosɛbɛ.

Angles de draft recommended pour les matériaux différentes

| matériel | moule core | moule cavité . |

| ABS . | 35'-1° . | 40'-1°20'. |

| PS . | 30'-1° . | 35'-1°30'. |

| PC . | 30'-50'. | 35'-1° . |

| PP . | 25'-50'. | 30'-1° . |

| PE . | 20'-45'. | 25'-45'. |

| PMMA . | 30'-1° . | 35'-1°30'. |

| Pom . | 30'-1° . | 35'-1°30'. |

| PA . | 20'-40'. | 25'-40'. |

| HPVC ye . | 50'-1°45'. | 50'-2° . |

| SPV . | 25'-50'. | 30'-1° . |

| CP 1000 . | 20'-45'. | 25'-45'. |

A fanw ye draft angle sugandili ye min mago bɛ jateminɛ na .

Aw bɛ angle misɛnninw sugandi yɔrɔw la minnu bɛ yeelen bɔ ani yɔrɔ minnu bɛ kɛ ka ɲɛ kosɛbɛ .

Aw bɛ baara kɛ ni angle belebelebaw ye yɔrɔw la minnu ka dɔgɔyali hakɛ ka bon .

Aw bɛ dɔ fara a kan ka ɲɛsin yɔrɔw ma minnu bɛ ye kɛnɛ kan walasa ka sɔgɔsɔgɔninjɛw bali .

Angle ladilan ka da texture juguya kan textured surfaces .

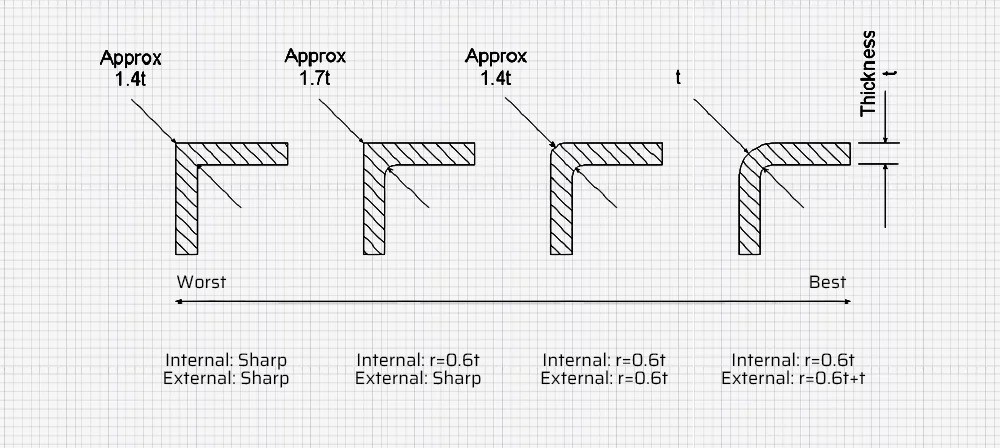

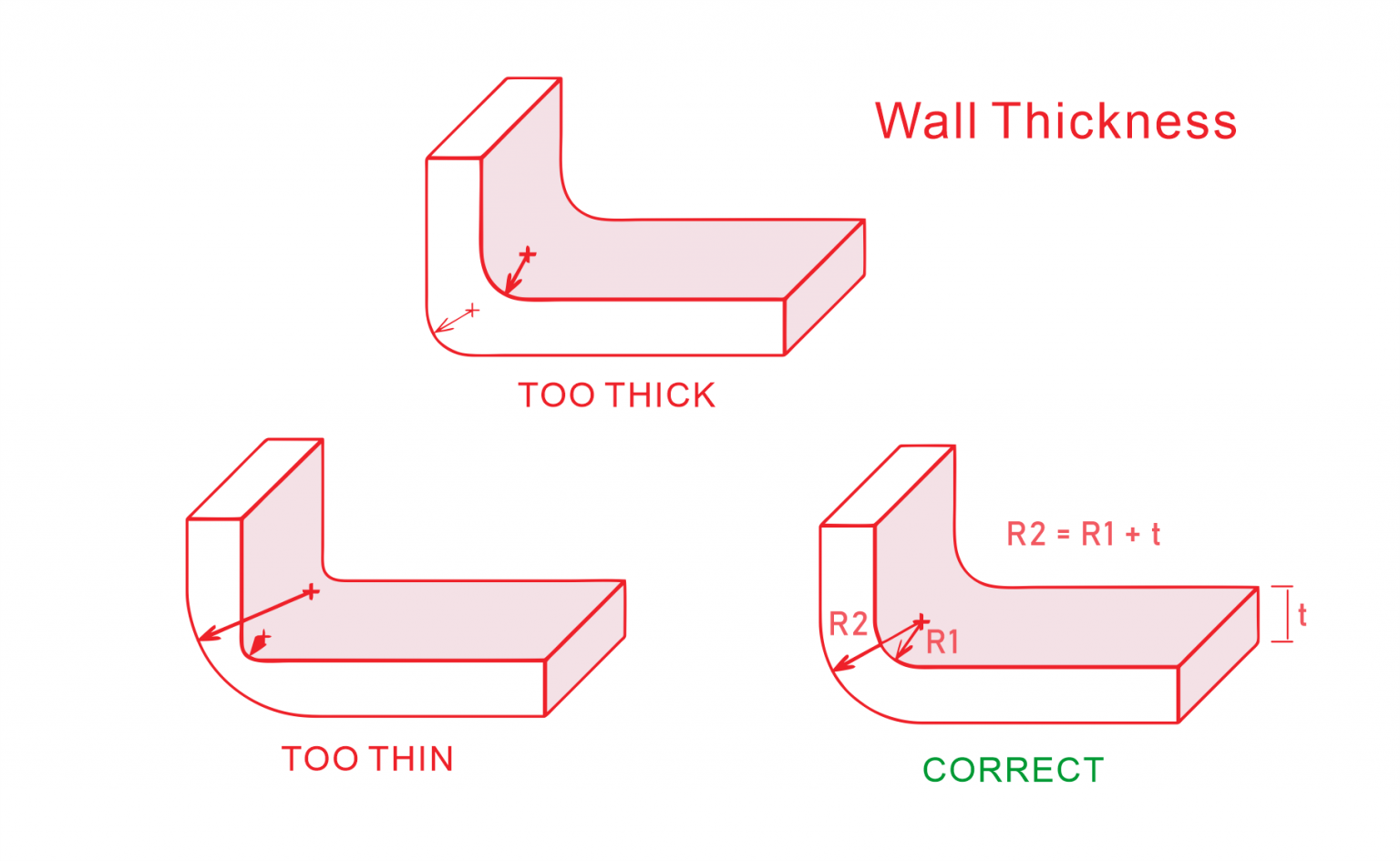

R Nkɔniw (Nkɔni lamininenw) .

Nkɔni bulama bɛ degunw hakɛ dɔgɔya, ka plastiki bolicogo nɔgɔya, ani ka a tiɲɛni nɔgɔya.

Dilancogo ɲɛfɔli R Corners .

Kɔnɔna kɔnɔna na: 0,50 ka se 1,50 ma, o ye fɛn ye .

A ka dɔgɔn kosɛbɛ: 0,30mm .

Aw bɛ kogo janya kelen mara ni aw bɛ nkɔni bulamaw dilan .

Aw bɛ aw yɛrɛ tanga nkɔni bulamaw ma minnu bɛ sɔrɔ nɔgɔw farali yɔrɔw kan .

Aw bɛ baara kɛ ni 0,30mm radius ye min ka dɔgɔn dakunw na walasa ka a bali ka sɔgɔsɔgɔ .

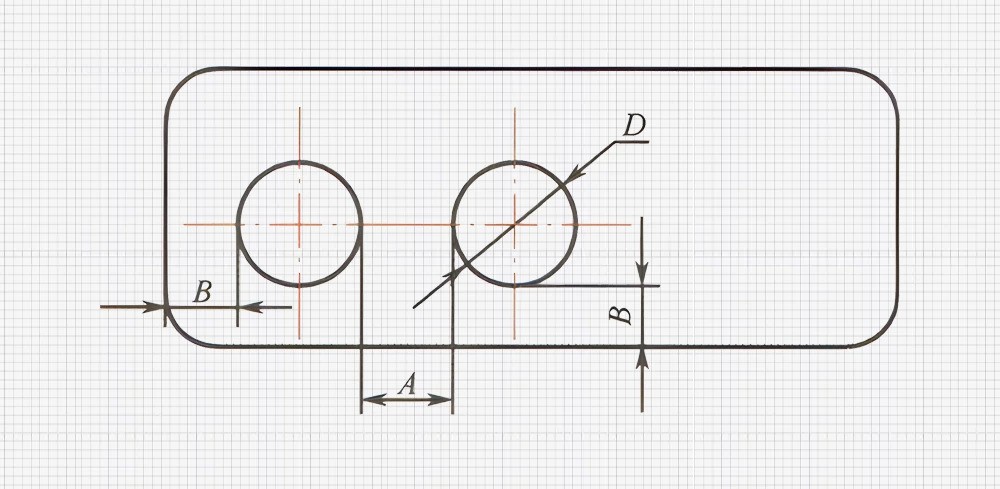

dingɛw .

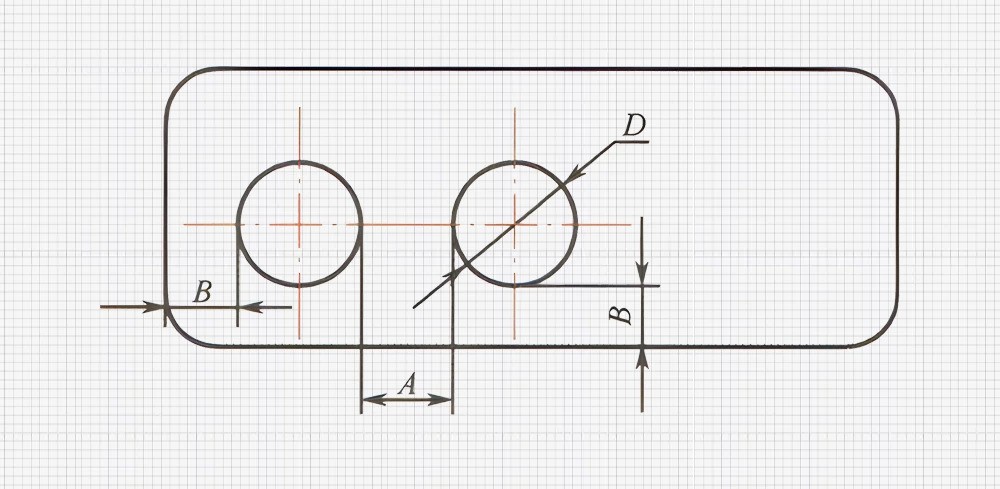

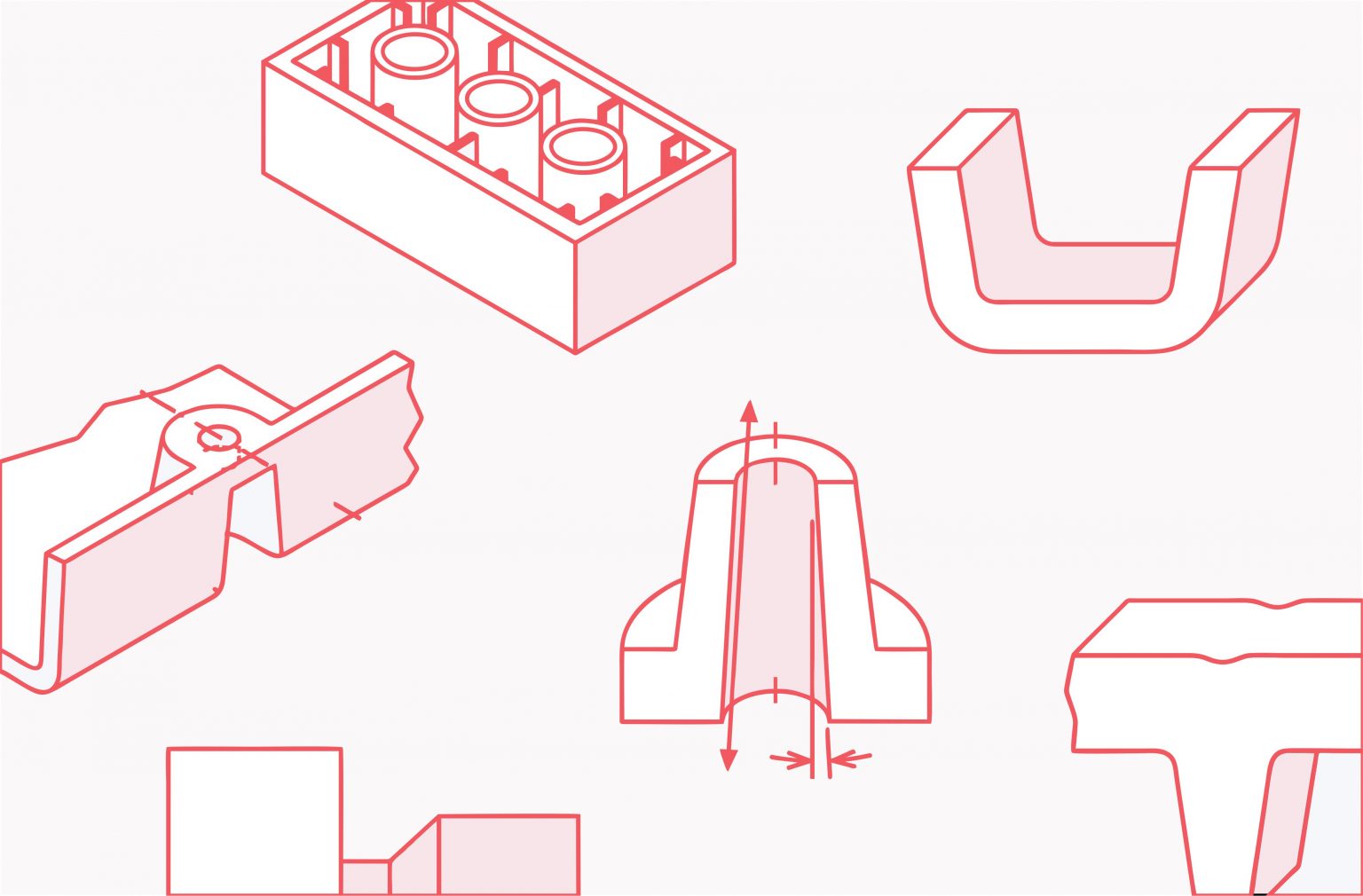

Dingɛw bɛ baara suguya caman kɛ plastiki fɛnw na ani u bɛ jateminɛ kɛ u dilanni na kosɛbɛ.

Design wajibiyalenw ka ɲɛsin dingɛw ma .

Yɔrɔ min bɛ dingɛ (a) ni ɲɔgɔn cɛ: ≥ D (hole diameter) ni d < 3.00mm; ≥ 0,70d ni d > 3,00mm .

Janya ka bɔ dingɛ la ka taa da la (b): ≥ d .

Jɛɲɔgɔnya min bɛ dingɛ cɛmancɛ ni a juguya cɛ .

Fiyentɔw ka dingɛ dunba (A): ≤ 5D (a bɛ fɔ a ma ko < 2d) .

A ka ca a la, a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ .

Dilanko jateminɛw dingɛ suguya kɛrɛnkɛrɛnnenw kan .

Step Holes: Aw bɛ dingɛ caman kɛ minnu ni ɲɔgɔn cɛ bɛ tali kɛ ɲɔgɔn na, minnu janya tɛ kelen ye .

Dingɛ minnu bɛ kɛ kɛrɛ fɛ: Aw bɛ aksidan ni mɔli da wuli ni a bɛ se ka kɛ .

Kɛrɛfɛ dingɛw ni indentations: Aw ye jateminɛ kɛ core samali yɔrɔw la walima dilancogo ɲɛnabɔli .

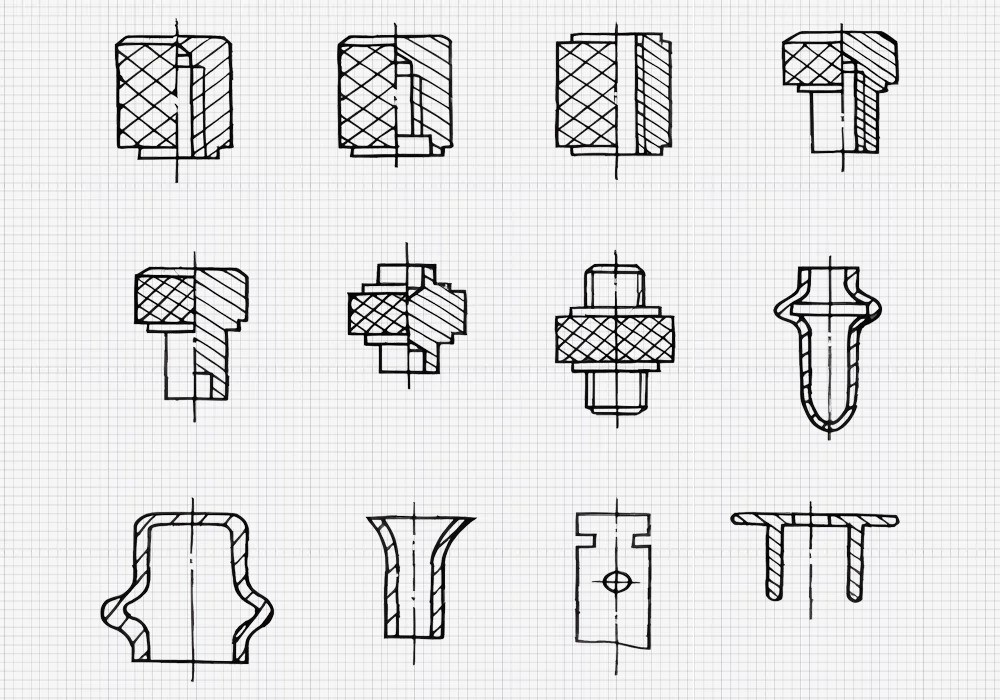

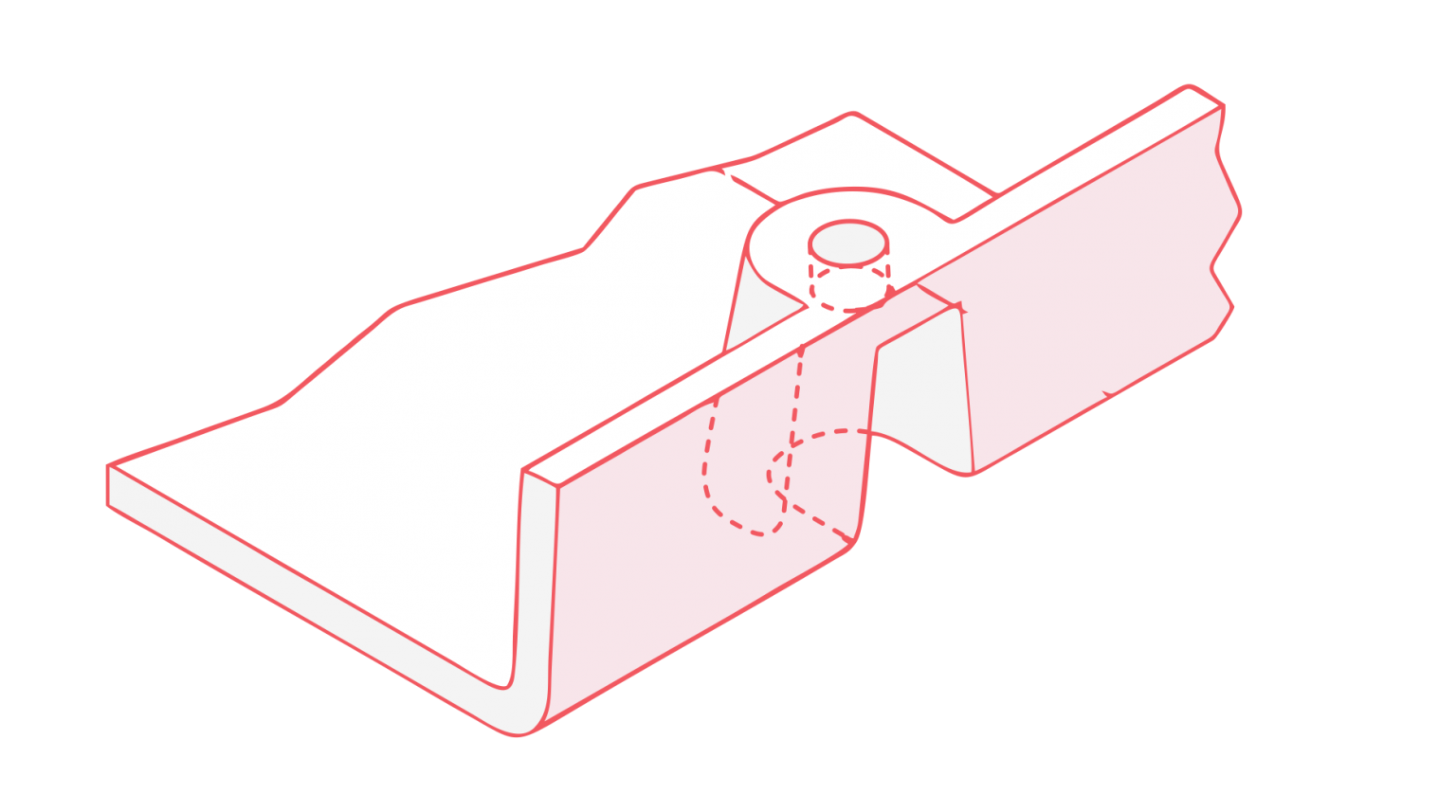

Bosses .

Patɔrɔnw bɛ lajɛyɔrɔw di, ka yɔrɔ wɛrɛw dɛmɛ, ani ka sigicogo dafalen sabati.

Basic design guidelines ka ɲɛsin patɔrɔnw ma .

A janya: ≤ 2,5 siɲɛ Boss Diamètre .

Aw bɛ baara kɛ ni barikalanw ye walima ka u siri kɛnɛma kogow la ni a bɛ se ka kɛ .

Design for smooth plastic flow ani demolding nɔgɔya .

Design Points ka ɲɛsin fɛn suguya caman ma .

ABS: kɛnɛma cɛmancɛ ≈ 2x kɔnɔna cɛmancɛ; Aw bɛ kɔkiliw kɛ ka barika don u la walasa ka barika don u la .

PBT: Basi dilancogo kan rib hakilina kan; Aw bɛ ɲɔgɔn sɔrɔ kɛrɛfɛ kogow la ni aw bɛ se .

PC: interlock side bosses ni kɔkiliw; Aw bɛ a kɛ ka mɔgɔw lajɛ ani ka u dɛmɛ .

PS: Aw bɛ kɔkiliw fara a kan walasa ka barika sɔrɔ; Aw bɛ ɲɔgɔn sɔrɔ kɛrɛfɛ kogow la ni aw bɛ a kɛrɛfɛ .

PSU: kɛnɛma cɛmancɛ ≈ 2x kɔnɔna cɛmancɛ; Janya ≤ 2x kɛnɛma cɛmancɛ .

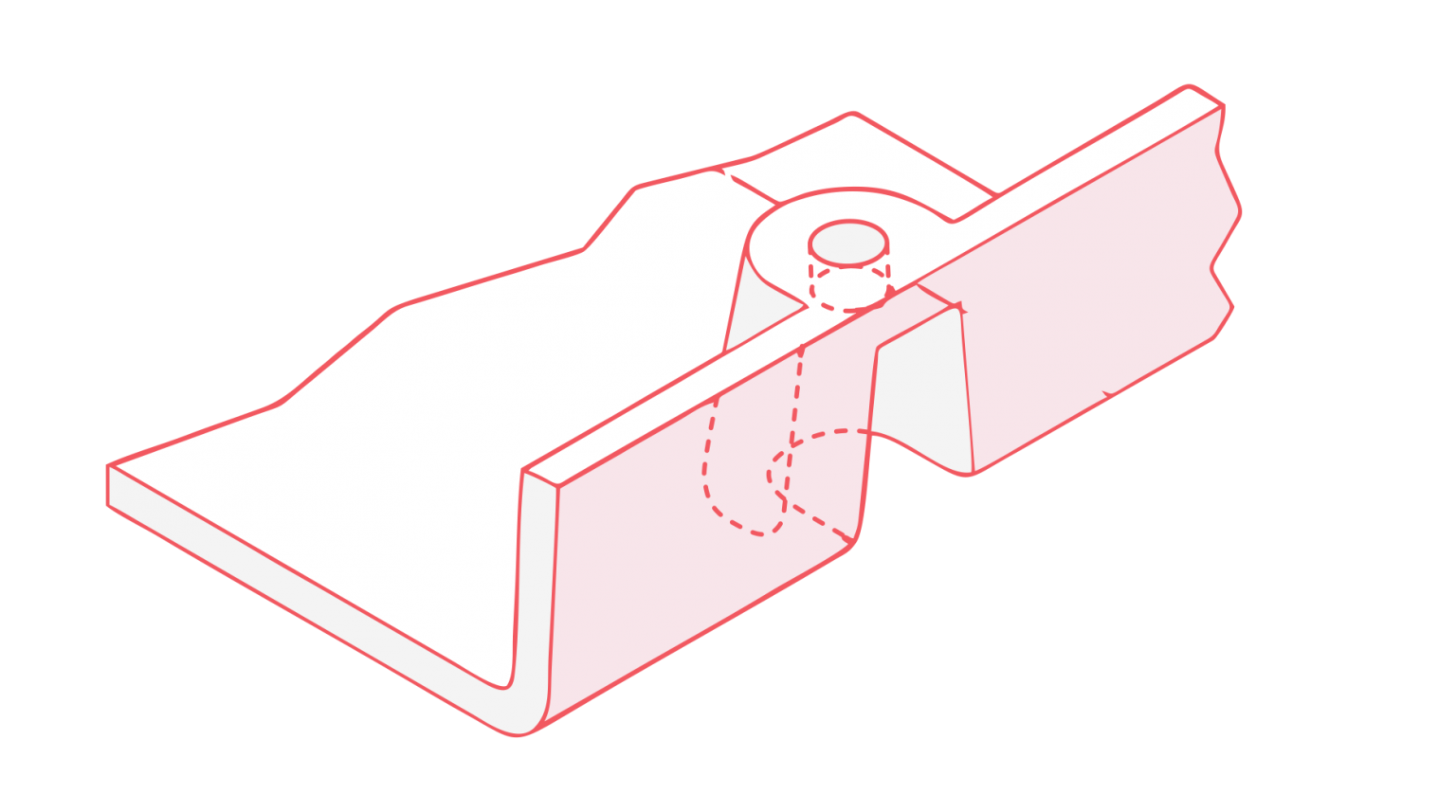

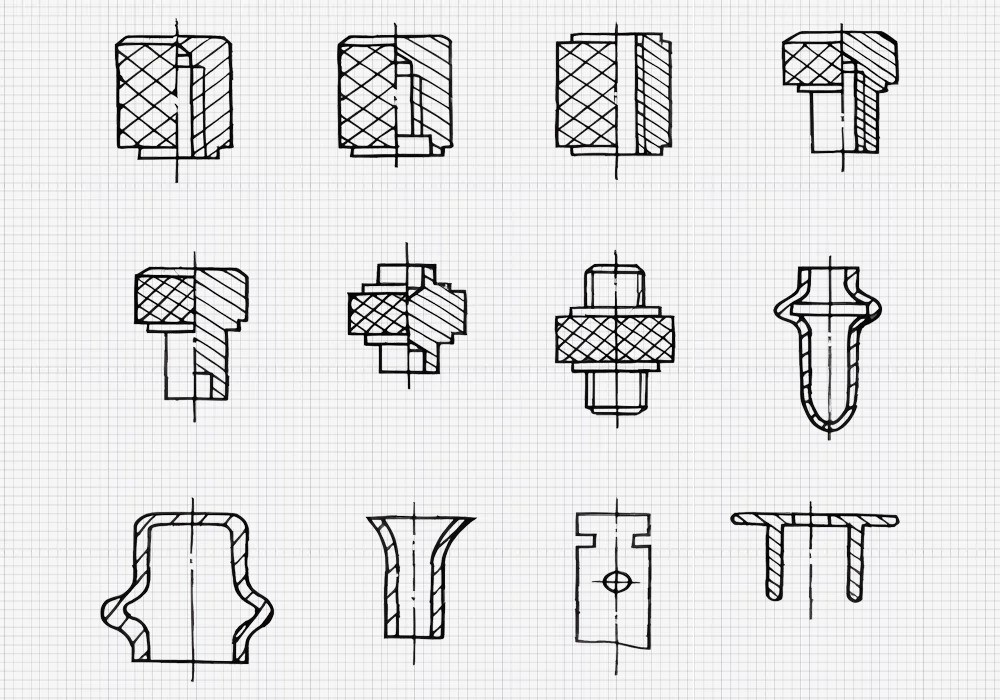

Inserts .

Inserts bɛ baarakɛcogo ɲɛ, ka decorative elements di, ani ka ɲɔgɔnjɛ sugandiliw ɲɛ ka ɲɛ plastiki yɔrɔw la.

Siginidenw ni u jɔcogo wajibiyalenw doncogo la .

Manufacturability: A bɛ se ka kɛ tigɛcogo walima taamasiyɛn kɛcogo ye .

Mekaniki fanga: Fɛnw ni hakɛw bɛrɛbɛn .

Bonding strength: Surface features bɛnnenw ka ɲɛsin a nɔrɔli ma .

JIGISƐN: Silinda janya yɔrɔw walasa ka mɔli nɔgɔya walasa ka u bila nɔgɔya la .

Flash Prevention: A bɛ se ka kɛ ni sealing boss structures ye .

Baara kɔfɛ: dilancogo filananw kama (Tɔgɔ tigɛ, tigɛ, flanging) .

Aw bɛ jateminɛ kɛ ni aw bɛ baara kɛ ni donnakow ye .

Aw ye aw jija ka jɔyɔrɔ tigitigi sɔrɔ mɔliw kɔnɔ .

Aw bɛ jɛɲɔgɔnya barikamaw da ni yɔrɔw ye minnu dilannen don .

Aw bɛ plastiki bɔli bali dondaw lamini na .

Aw ye danfara minnu bɛ funteni bonya la, olu jateminɛ fɛnw doncogo ni u plastiki cɛ .

Product Surface Texture ani Text/Pattern Design .

Surface textures ka ɲɛsin plastiki fɛnw ma .

Plastiki fɛnw bɛ se ka dilan ni fɛn suguya caman ye walasa ka ɲɛnajɛko, baarakɛcogo ani baarakɛcogo ɲɛ. Surface textures minnu bɛ sɔrɔ ɲɔgɔn fɛ, olu dɔw ye:

Nugu

Spark-Etched .

Etched min bɛ kɛ ni misali ye .

Gravée .

Surfaces smooths .

Yɔrɔ nɔgɔlenw bɛ bɔ nɔgɔbɔlanw na minnu bɛ sɔgɔ. U bɛ nin fɛn ninnu di:

A yecogo saniyalen don, a ɲɛ ka ɲi .

Yɔrɔ bɔli nɔgɔya ka bɔ mɔli la .

Lower draft angle wajibiyalenw .

Surfaces spark-etch .

A dabɔra nɛgɛ EDM baarakɛcogo fɛ nɔgɔbɔlan kɔnɔ, yɔrɔ minnu bɛ sɔgɔ, olu bɛ:

Surfaces étchés motifs .

O yɔrɔw bɛ ni misali suguya caman ye minnu sɛbɛnnen bɛ nɔgɔbɔlan kɔnɔ, minnu bɛ dilan:

Dilancogo minnu bɛ se ka kɛ ka kɛɲɛ ni mɔgɔw sago ye .

Produit différentielle de produits

Tactile Properties (Tactile Properties) ɲɛtaa .

Surfaces gravés .

Surfaces gravés (yɔrɔ jalenw) bɛ Dabɔ ni masinw ye k’u Kɛ ‘fɛn ye min bɛ Kɛ ‘fɛn ye, o bɛ sira Di:

draft angle jateminɛw ka ɲɛsin textured surfaces ma .

Ni aw bɛ yɔrɔw dilan minnu bɛ sɛbɛnni kɛ, aw bɛ jateminɛ kɛ ka dɔ fara draft angles kan walasa ka yɔrɔ dɔw bɔli nɔgɔya:

| texture depth | recommended angle draft additional |

| 0,025 mm . | 1° . |

| 0,050 mm . | 2° . |

| 0,075 mm . | 3° . |

| > 0,100 mm . | 4-5° . |

Text ani Pattern Design .

Tuma caman na, plastiki fɛnw bɛ sɛbɛnniw ni misaliw don u kɔnɔ walasa ka u tɔgɔw sɛbɛn, ka cikanw walima ka u masiri. O fɛnw bɛ se ka kɔrɔta walima ka don u kɔnɔ.

Kɔrɔlen vs.

Ladilikan: Aw bɛ baara kɛ ni yɔrɔ kɔrɔtalenw ye sɛbɛnniw ni misaliw kama ni aw bɛ se.

Nafa minnu bɛ sɔrɔ yɔrɔ kɔrɔtalenw na:

Walasa ka dilanw kɛ minnu bɛ fɛn dɔw wajibiya minnu bɛ kɛ ni ji ye walima minnu bɛ don u kɔnɔ:

Aw bɛ yɔrɔ dɔ labɛn min bɛ se ka don .

Aw bɛ sɛbɛnni walima misali kɔrɔta recess kɔnɔ .

Aw bɛ to ka fɛn bɛɛ kɛ ka ɲɛ ka sɔrɔ ka mɔli kɛcogo nɔgɔya .

Text and pattern dimensions

| feature | recommended dimensions . |

| A janya/a juguya . | 0,15 - 0,30 mm (La lamɔ) . |

| 0,15 - 0,25 mm (a bɛ bɔ a la) . |

Text Size Specifications .

Aw ye nin laadilikanw labato walasa ka sɛbɛnni kɛcogo ɲuman sɔrɔ:

A bɛ se ka fɔ ko a bɛ se ka kɛ 0,25 mm ye .

Yɔrɔ janya (b): ≥ 0,40 mm .

Janya min bɛ mɔgɔ dɔw la ka taa dakun na (C, D): ≥ 0,60 mm .

Sɛbɛnni/pattern dilancogo jateminɛ wɛrɛw .

Aw bɛ aw yɛrɛ tanga kɛrɛw ma minnu bɛ sɛbɛnni walima misaliw la .

Aw ye a lajɛ ko bonya bɛ bɛn molding process ma .

Aw ye a lajɛ sɛbɛnni/cogo bɛ nɔ min bila a yɔrɔ bɛɛ fanga la .

Text/Pattern bɛ nɔ min bila fɛnw bolicogo la molding waati la .

Fɛn wɛrɛw minnu bɛ kɛ ka ɲɛsin sigicogo ma .

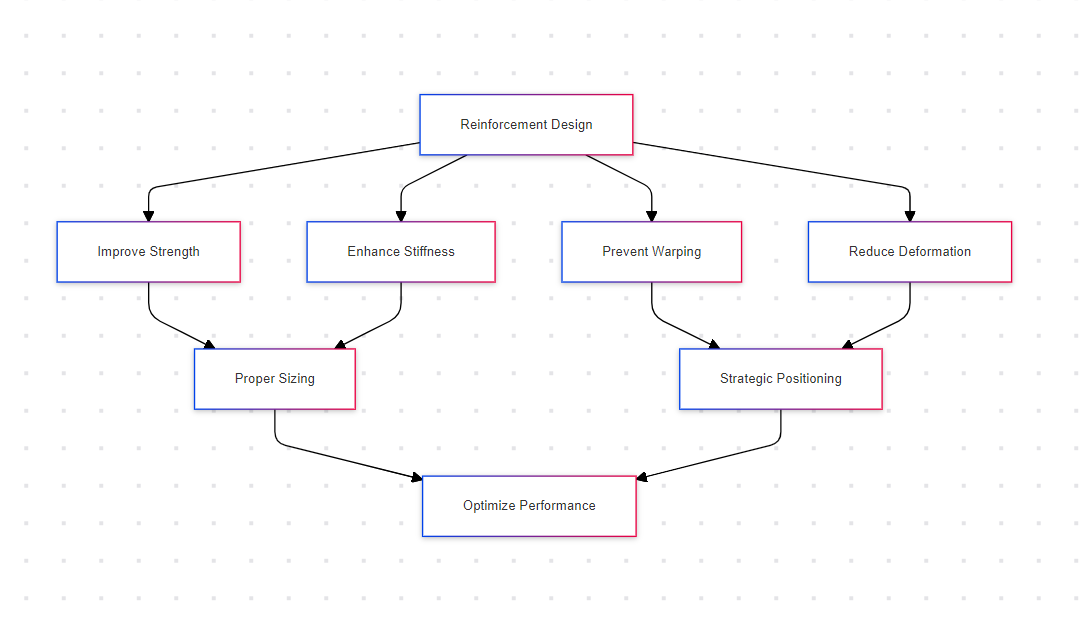

Baracture structure design principes .

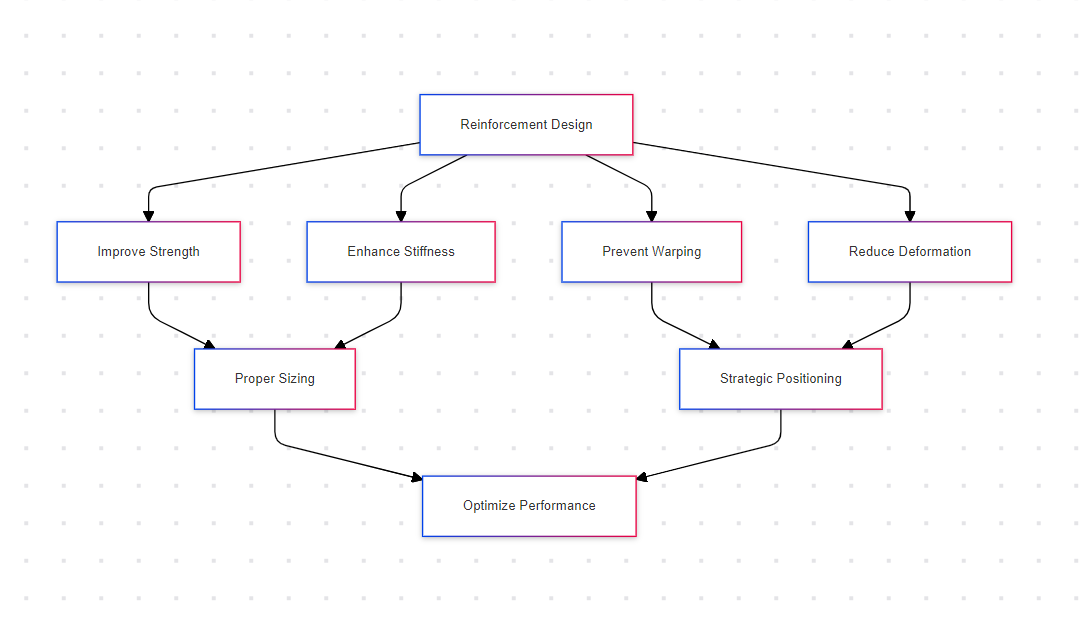

Barikadoncogo jɔyɔrɔ ka bon kosɛbɛ plastiki fɛnw baara bɛɛ lajɛlen yiriwali la. U bɛ fanga, gɛlɛya ani hakɛ sabatili ɲɛ kosɛbɛ.

Laɲini jɔnjɔnw ye fanga dilancogo ye:

Fanga bonya .

gɛlɛya ɲɛtaa .

Warping kunbɛnni .

Deformation dɔgɔyali .

A jɔyɔrɔ ka ɲi ani a bonya ka ɲɛsin barikalanw ma:

Kogo janya: 0,4-0,6 siɲɛ kunba farikolo janya .

Yɔrɔ janya: > siɲɛ 4 farikolo girinya kunba .

A janya: < 3 siɲɛ farikolo bonya .

Screw Column Reinforcement: A ka dɔgɔn 1.0mm Column surface jukɔrɔ .

Jɛkuluba ka barikalan: A ka dɔgɔn 1.0mm yɔrɔ min bɛ a yɔrɔ la walima a tilacogo la .

Fɛɛrɛw minnu bɛ se ka kɛ sababu ye ka fanga di u ma:

Baro minnu bɛ kɛ ni fanga ye minnu tɛ bɛn ɲɔgɔn ma walasa ka fɛnw camanba bali .

Jiriw kɔnɔna na, barikalanw cɛtigɛyɔrɔw la .

tension-based designs for slender riveringments .

Ka i yɛrɛ tanga degunw ma .

Degun hakɛ bɛ se ka nɔba bila plastiki fɛnw jɔcogo dafalen na ani u ka ɲɛnamaya janya la. Dilancogo ɲumanw bɛ se ka o ko ninnu nɔgɔya.

Nafa min b’a la ka i yɛrɛ tanga nkɔni nɔgɔlenw ma:

Fɛɛrɛ minnu bɛ kɛ walasa ka degunw hakɛ dɔgɔya:

Chamfers .

Nkɔni lamininenw .

Slopes gents pour transitions .

Kɔnɔnatumuw bɛ don kɔnɔna na ni nɛgɛberew ye .

| Fɛɛrɛ | ɲɛfɔli | nafa . |

| Chamfers . | Edges beveled . | Degunw tilatilali dɔɔni dɔɔni . |

| Nkɔni lamininenw . | Tɛmɛsira kurulenw . | A bɛ degunw bɔ yen minnu ka gɛlɛn . |

| Slopes gents . | Yɛlɛma dɔɔnin dɔɔnin . | Hali degunw tilatilali . |

| Kɔnɔnatumuw . | Material Removal at Corners . | Sigidaw ka degunw dɔgɔyali . |

Angles de draft bɛnnenw dilanni .

Draft angles nafa ka bon walasa ka yɔrɔ dɔw bɔ nɔgɔw la. U bɛ nɔba bila a yɔrɔ ɲuman ni a dilanni nafama na.

Sariyasen minnu bɛ kɛ ka ɲɛfɔli kɛ anglɛw kan:

Aw bɛ baara kɛ ni jateden dafalenw ye (misali la, 0,5°, 1°, 1,5°)

Angles extérieur > Angles kɔnɔna .

Angles (angles) caman kɛ ka sɔrɔ u ma kɛ cogo la min bɛ ɲɔgɔn tiɲɛ .

Fɛn minnu bɛ nɔ bila draft angle size la:

Yɔrɔ juguya .

Surface Finish .

Matériel shrinkage .

Texture juguya .

Draft angle design points for différents:

| Matériel | recommandé angle range |

| ABS . | 0,5° - 1° . |

| PC . | 1° - 1,5° . |

| PP . | 0,5° - 1° . |

| PS . | 0,5° - 1° . |

| SOKƆBAGAN MISƐNI | 1° - 1,5° . |

structurel design ka bɔ mold structure perspective .

Nɔgɔ dilanni ɲuman nafa ka bon kosɛbɛ plastiki yɔrɔ dilanni na min bɛ ɲɛ. Aw ye o fanw jateminɛ walasa ka a yɔrɔ ni a dilanni kɛcogo ɲɛ.

Ka i yɛrɛ tanga sigicogo gɛlɛnw ma:

A yɔrɔ jateminɛcogo nɔgɔya .

Aw bɛ dɔ bɔ u jukɔrɔla tigɛcogo la .

Aw bɛ kɛrɛfɛwalew dɔgɔya .

Ka i yɛrɛ tanga kɔnɔna tigɛcogo ma:

Fɛn minnu bɛ se ka kɛ, olu bɔ yen minnu bɛ core pulls complexew de wajibiya .

Design for split-line accessibilité .

Ni an bɛ jateminɛ kɛ lateral bɔli wajibiyalenw na:

Aw bɛ yɔrɔ caman di slider lamagacogo ma .

A bɛ dakunw dacogo bɛnnenw dilan .

Optimiser part orientation dans la moule .

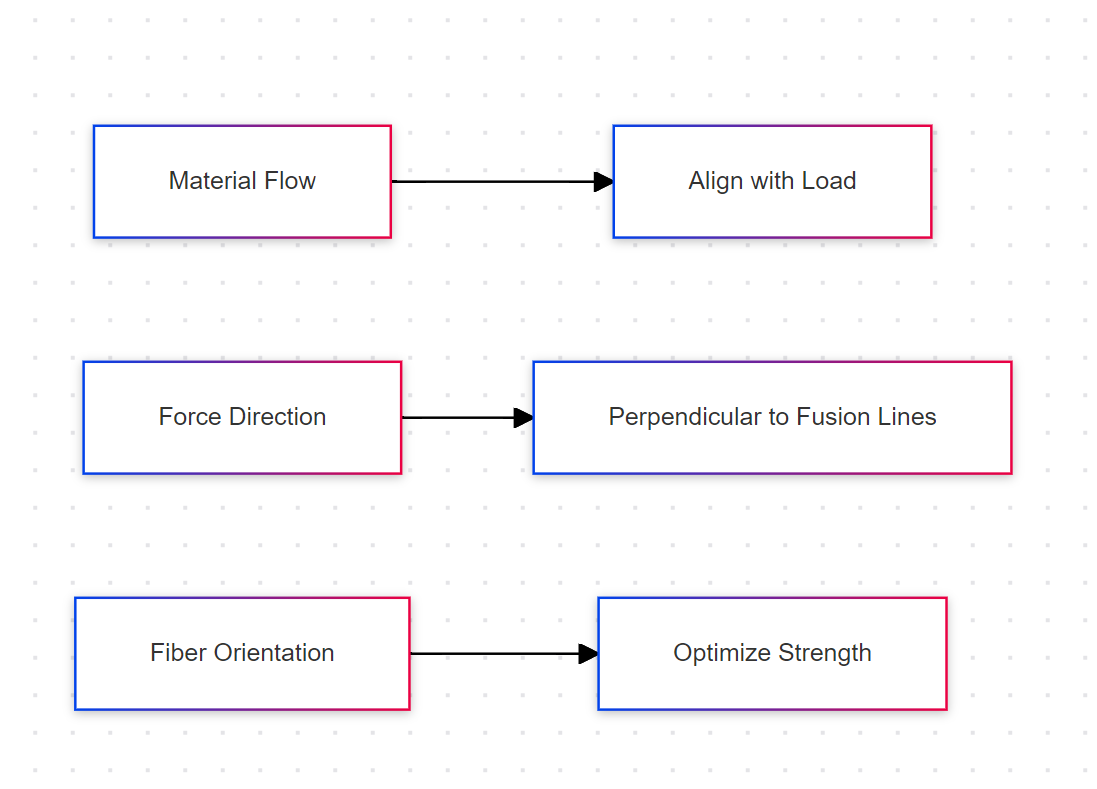

dilancogo ka ɲɛsin plastikiw ma minnu tɛ isotropiki ye .

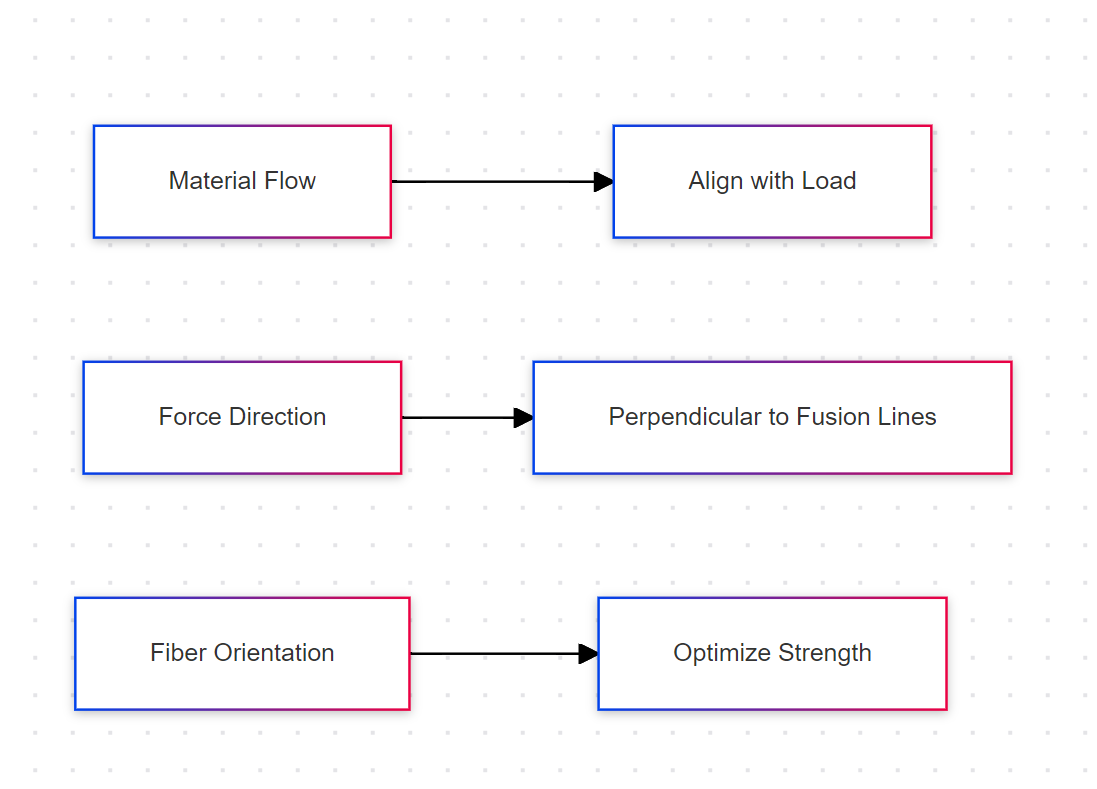

Plastiki caman bɛ fɛnw jira minnu tɛ isotropi ye, minnu bɛ jateminɛ kɛrɛnkɛrɛnnenw wajibiya walasa ka baara kɛcogo caya.

Material flow direction ni doni-ta-sira-yɔrɔ-yɔrɔ-ko:

Force direction relative to fusion lines:

Dilan ka ɲɛsin fanga ma min bɛ kɛ ka ɲɛsin fɛnw ma minnu bɛ se ka kɛ fɛn ye walima minnu bɛ kɛ ka u kɛ fɛn ye .

Aw bɛ aw yɛrɛ tanga fanga paralɛliw ma minnu bɛ kɛ ɲɔgɔn fɛ walasa ka fanga dɔgɔya walasa ka barika dɔgɔya .

structurel design from assembly perspective .

Lajɛ kɛcogo ɲuman bɛ fɛn dilannenw baarakɛcogo, u ka ɲɛnamaya jan ani u dilanni nɔgɔya.

Ka i yɛrɛ tanga hakɛba ma ni muɲuli misɛnninw ye:

Bonding interface design:

Aw bɛ se ka fanga sɔrɔ min bɛ se ka kɛ ni fanga ye min bɛ se ka kɛ sababu ye .

Aw bɛ dɔ fara bondingɛ yɔrɔ kan .

Aw ye a lajɛ ni nɛgɛw bɛ bɛn kemikɛli ma .

Bolt connection jateminɛw ka ɲɛsin plastiki yɔrɔw ma:

Baara kɛ ni Inserts ye walasa ka jɛgɛnsira caman sɔrɔ .

Design boss structures bɛnnenw .

Aw ye jateminɛ kɛ danfara minnu bɛ funteni bonya la .

Farankan

Plastiki fɛn dilanni na, fɛn jɔnjɔnw i n’a fɔ kogo janya, kɔkiliw barika bonya, ani fɛnw minnu bɛ kɛ ka fɛnw sɔgɔ, olu nafa ka bon walasa u ka se ka muɲu ani ka baara kɛ. A nafa ka bon kosɛbɛ ka fɛnw cogoyaw, u jɔcogo, ani u lajɛcogo magow jateminɛ o baara bɛɛ la. Jatebɔcogo ɲuman tɛ dɔrɔn ka fɛn dilannenw baaracogo ɲɛ, nka a bɛ dɔ bɔ fana fiɲɛw ni fɛn dilanni musakaw la. Ni u bɛ u sinsin nin dilanfɛnw kan, fɛn dilannikɛlaw bɛ se ka plastiki yɔrɔw lajɛ minnu ka ɲi, minnu musaka ka dɔgɔ, minnu bɛ baarakɛcogo ni ɲɛnajɛko wajibiyalenw bɛɛ dafa.