Kayan samfuran filastik suna ko'ina, amma suna tsara su ba sauki. Ta yaya Injinin Injiniya, farashi ne, da kuma ingancin samarwa? Wannan talifin zai buɗe rikicin a bayan tsarin tsarin filastik. Za ku iya koyan mahimman abubuwan, kamar kauri na bango, yana ƙarfafa haƙarƙari, kuma mafi, waɗanda ke da dorewa, sassan filastik masu tsada.

Halaye da hanyoyin kirkirar filastik filastik

Kayan kayan filastik suna ba da kaddarorin musamman da zaɓuɓɓukan gyaran gyara da zaɓuɓɓukansu na al'ada kamar ƙarfe, jan ƙarfe, da katako. Wannan haɗakar kayan haɗin abu da kuma ƙirar tallafin tallafin filaye ne na sassauci mai sassauci idan aka kwatanta da takwarorinsu.

Keɓaɓɓen kayan abu da fasalin m

Abubuwan da ke kewayon kayan filastik, kowannensu yana da takamaiman kaddarorin, yana ba da damar masu tsara su don dacewa da zaɓin su gwargwadon bukatun samfurin. Wannan iri-iri, hada kai da ikon murkushe makullai cikin sifofi masu kayatarwa, yana ba da kalubalantar da abubuwan da ke tattare da wasu kayan aiki da zasu zama kalubale ko kuma m da sauran kayan.

Janar hanya don tsara filastik

Don yin fa'idar matsalolin matsalolin da kuma tabbatar da ingantaccen tsarin tsari, yana da mahimmanci a bi tsarin tsarin. Janar hanya don ƙirar ɓangare na filastik ya ƙunshi matakai da yawa na maɓalli:

Eterayyade bukatun aiki da bayyanar samfurin:

Zana zane na farko na farko:

Bayanin:

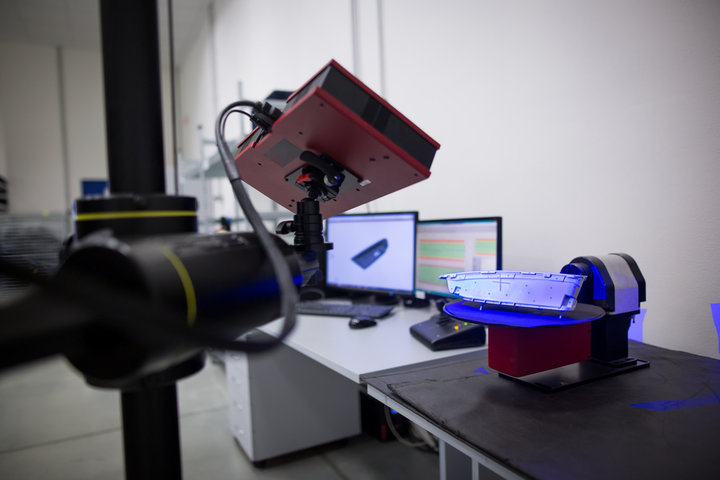

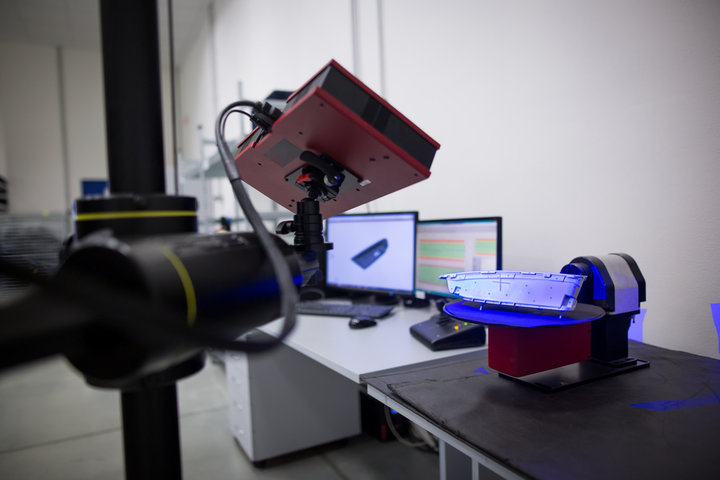

Samar da prototypes na zahiri ta amfani da hanyoyi kamar bugu na 3D ko Cnc Mactining

Kimanta aikin prototype, Ergonomics, da kuma ƙirar gaba

Gwajin Samfurin:

Tsara Tsara da Bita:

Bincika sakamakon gwaji da gano wuraren don cigaba

Yi daidaitattun kayan zane don haɓaka aiki, aminci, ko ƙwarewa

Inganta mahimman bayanai:

Ciktar cikakken bayani don samfurin ƙarshe, gami da yanayi, haƙuri, da sa na kayan

Tabbatar da bayanai dalla-dalla tare da tsarin masana'antu da ka'idojin kulawa mai inganci

Bude samarwa na:

Designer da ƙirƙira da allurar rigakafi sun dogara da bayanan samfuran da suka gabata

Inganta ƙirar ƙirar don ingantaccen abu na gudana, sanyaya, da ƙin

Ikon ingancin:

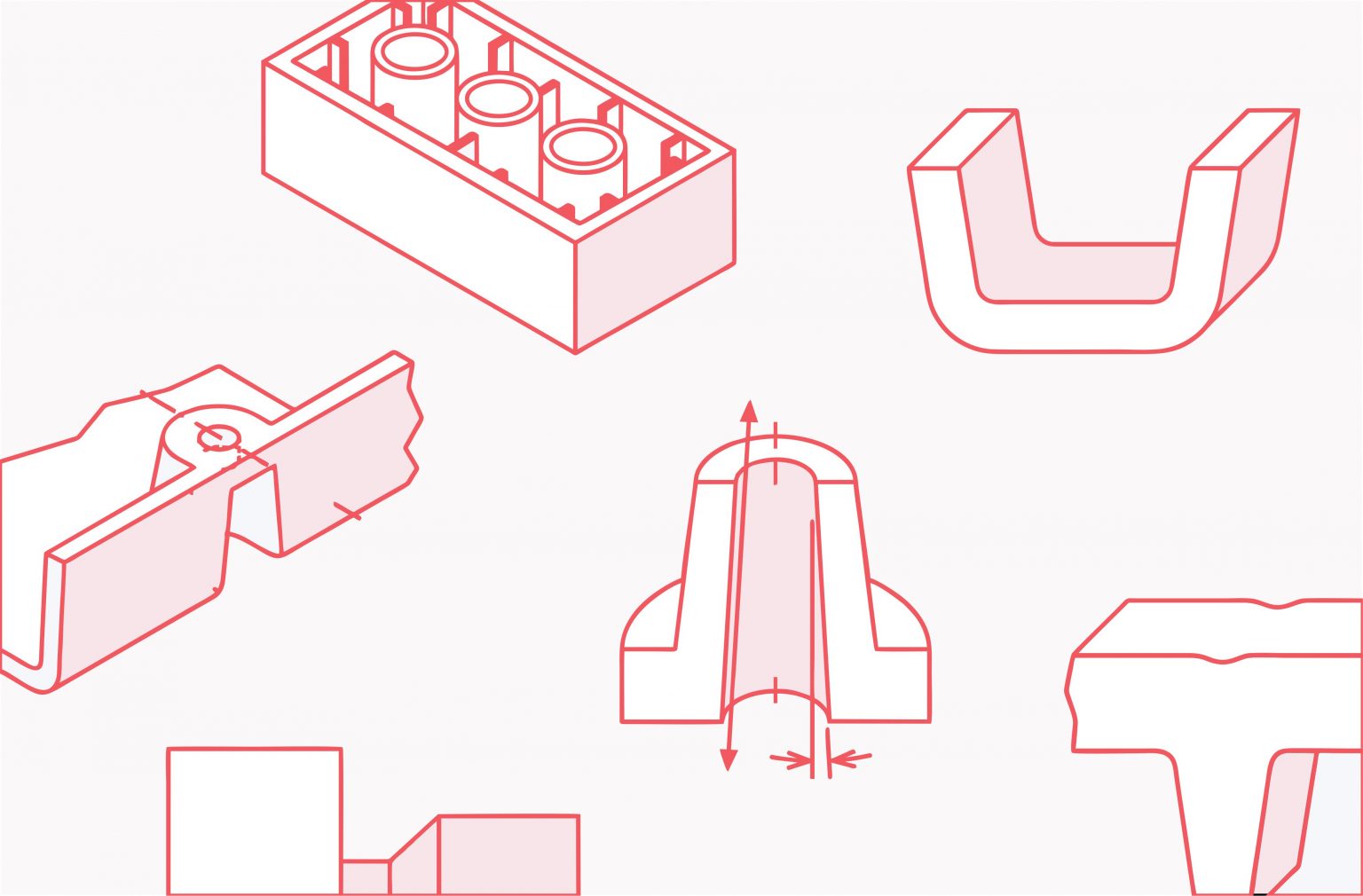

Abubuwa na asali a cikin tsarin tsarin filastik

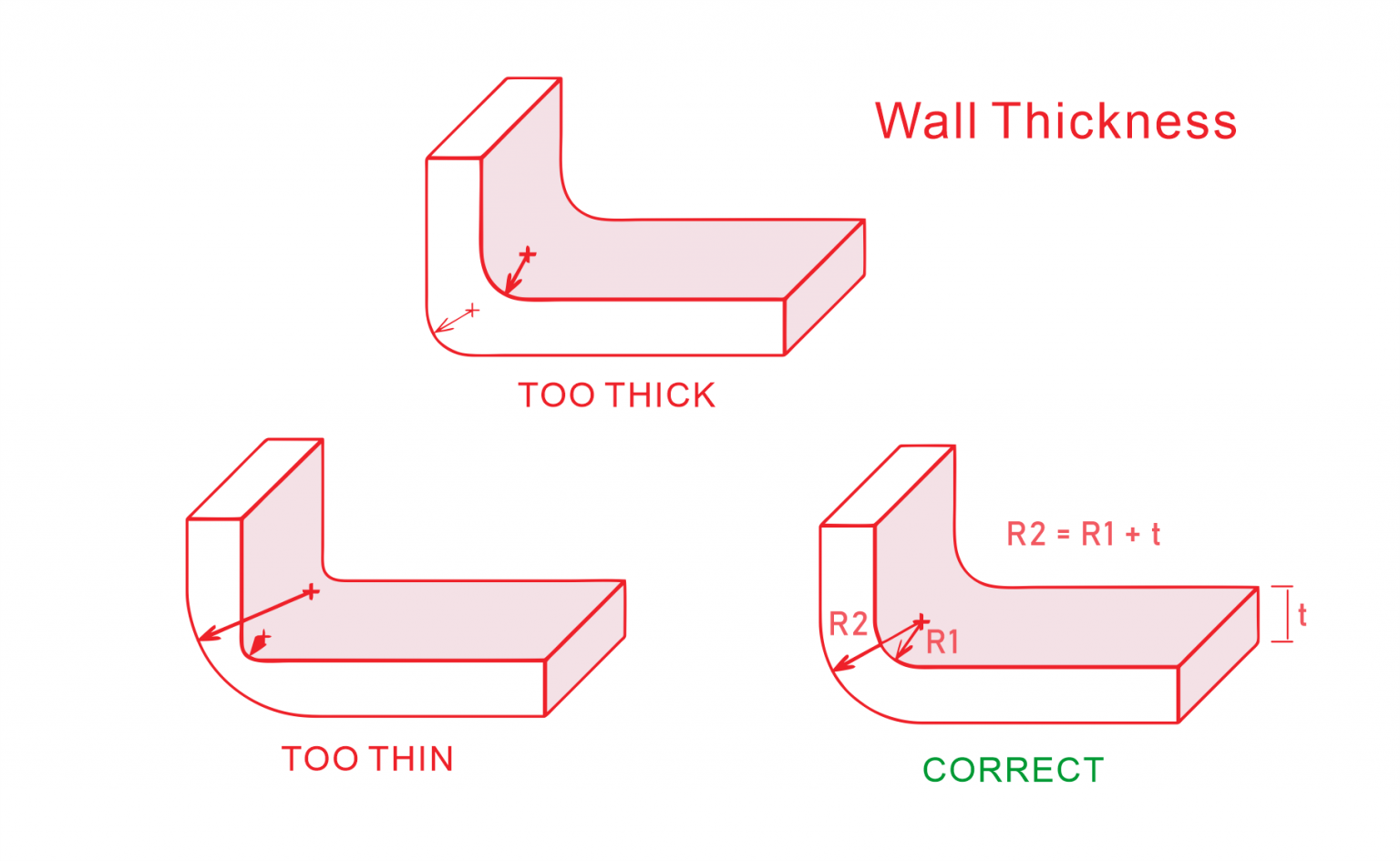

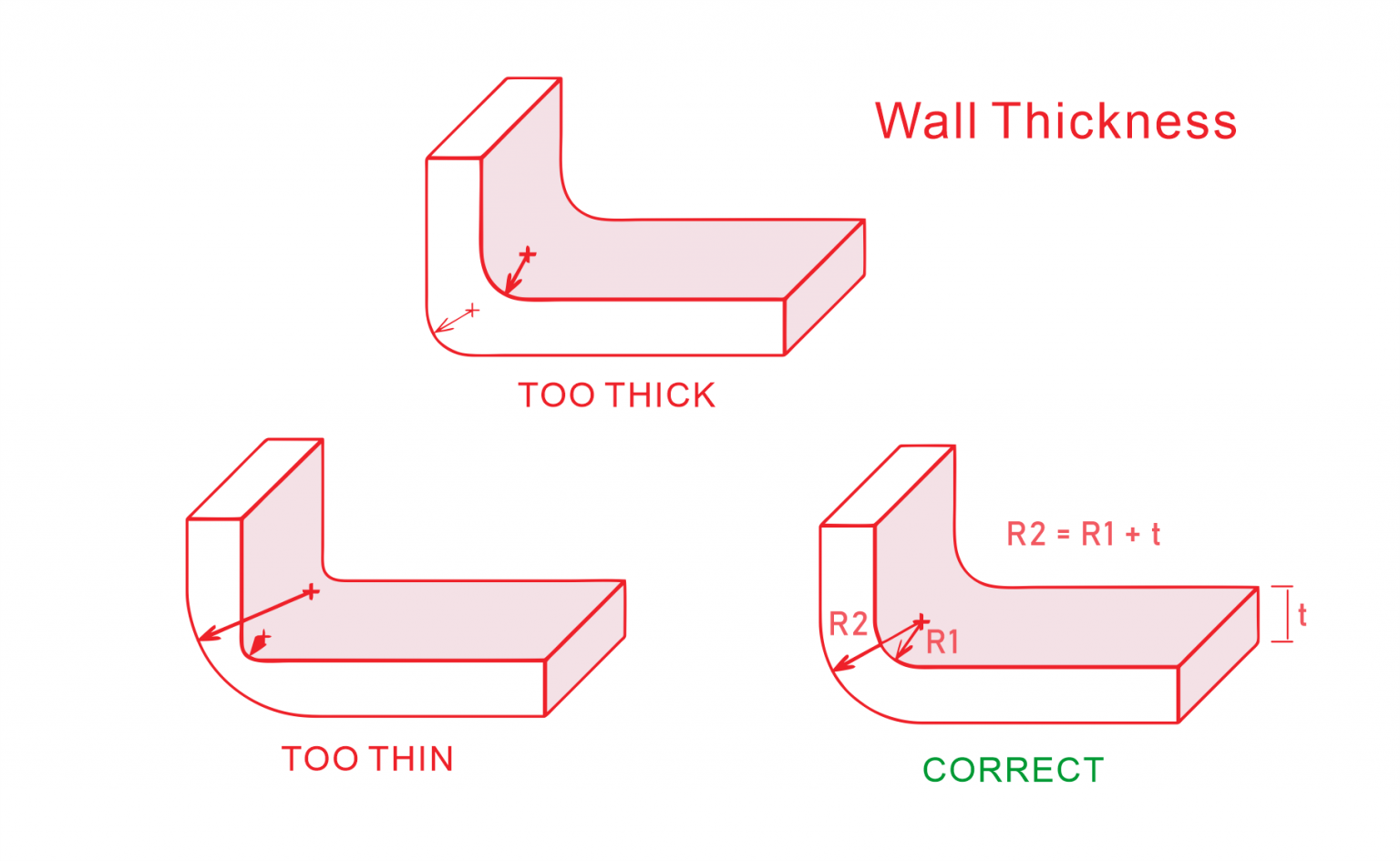

Kauri

Kauri kauri yana taka muhimmiyar rawa a cikin zanen samfurin filastik. Kauri da ya dace yana tabbatar da ingantaccen aiki, masana'antu da tsada.

Ka yaba da kauri na kauri na

| kayan filastik kayan filastik |

mai ƙarancin ƙasa (mm) |

ƙananan sassa (mm) |

manyan sassan (mm) |

manyan sassan (mm) |

| Nail |

0.45 |

0.76 |

1.5 |

2.4-3.2 |

| PE |

0.6 |

1.25 |

1.6 |

2.4-3.2 |

| Zasa |

0.75 |

1.25 |

1.6 |

3.2-5.4 |

| Hula |

0.8 |

1.5 |

2.2 |

4-6.5 |

| PVC |

1.2 |

1.6 |

1.8 |

3.2-5.8 |

| Pp |

0.85 |

1.54 |

1.75 |

2.4-3.2 |

| PC |

0.95 |

1.8 |

2.3 |

3-4.5 |

| Yi shelar alkjjada |

0.8 |

1.4 |

1.6 |

3.2-5.4 |

| Abin da |

0.8 |

1 |

2.3 |

3.2-6 |

Abubuwan da suka shafi zaɓin riguna na bango

Filastik kayan aikin

Sojojin waje sun jimre

Dokokin tsaro

Abubuwan da ake jurewa

Ka'idojin wuta

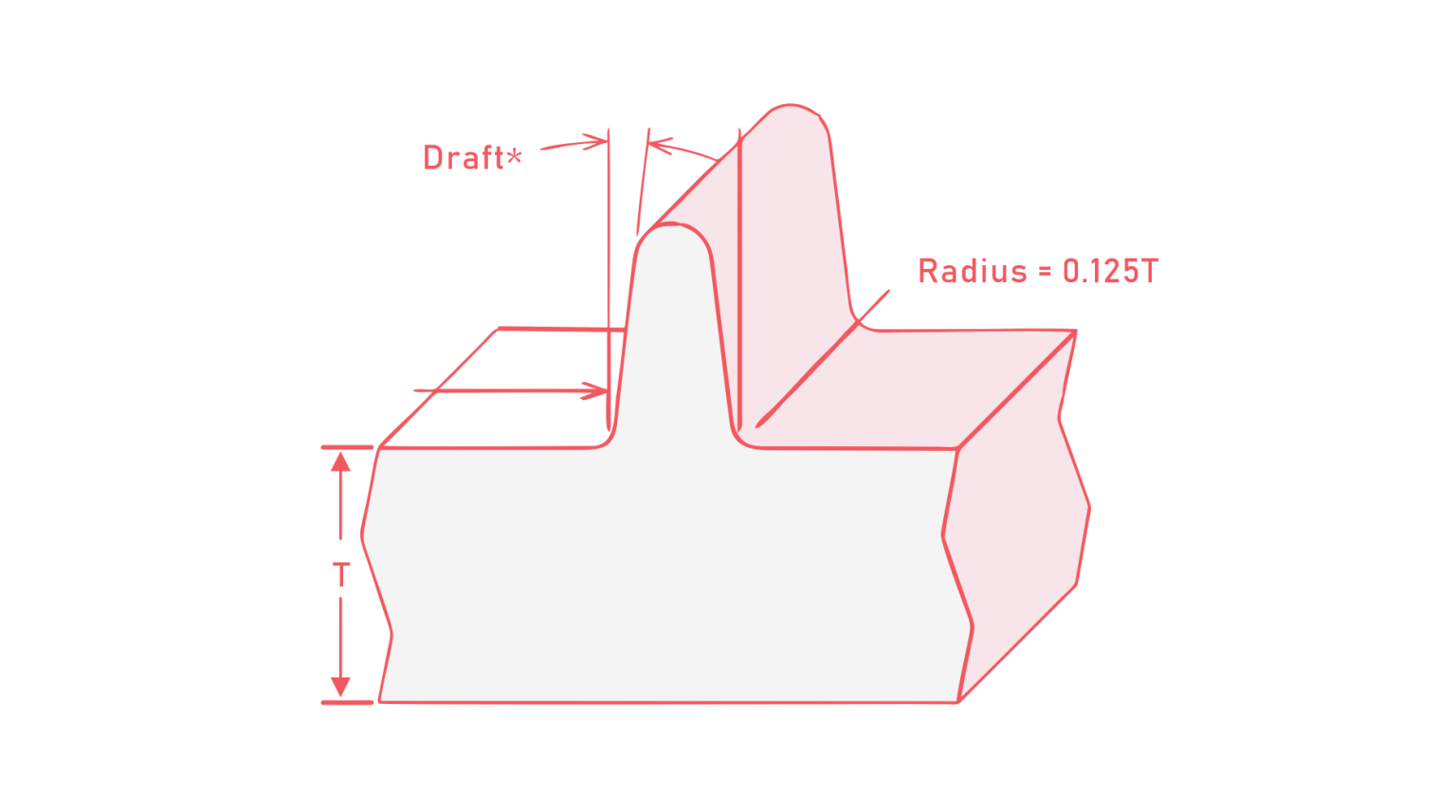

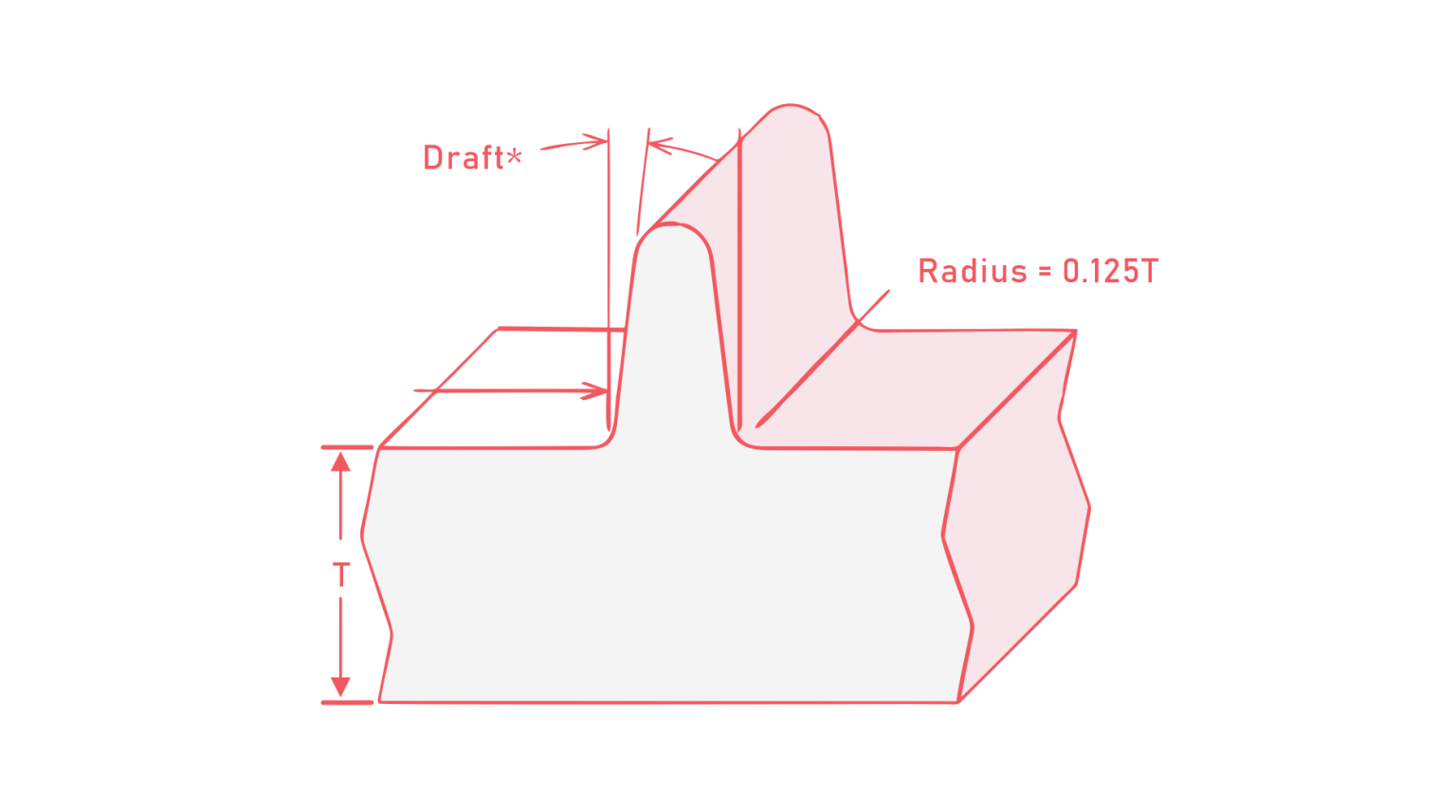

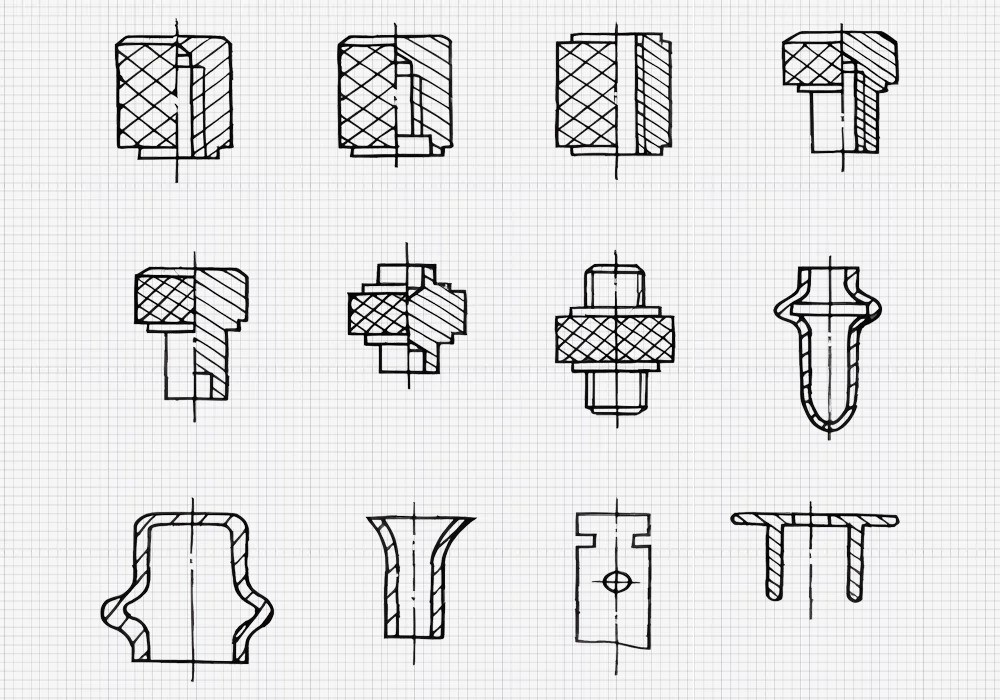

Karfafa hakarkarinsa

Mai karfafa hakarkarinsa yana inganta karfin gwiwa na gaba daya, hana nakasassu na kayan, da kuma inganta amincin tsari.

Jagororin ƙira don ƙarfafa haƙarƙarin

Fannoni na kirkirar ƙirar da ke buƙatar kulawa

Guji tarin kayan abu a haƙoran haƙoran

Kula da perpendicularity zuwa bangon waje

Rage girman haƙarƙarin a kan gangara

Yi la'akari da bayyanar alamun alamun haskoki

Daftarin kusurwa

Anglassungiyoyi masu sauƙin cirewa a cikin cirewa a cikin molds, tabbatar da ingantaccen kayan sarrafawa da sassa masu inganci.

Shawarar da aka ba da shawarar kusurwoyi na kayan masarufi

| - |

daban |

daban |

| Abin da |

35'-1 ° |

40'-1 ° 20 ' |

| Zasa |

30'-1 ° |

35'-1 ° 30 ' |

| PC |

30'-50 ' |

35'-1 ° |

| Pp |

25-50 ' |

30'-1 ° |

| PE |

20'-45 ' |

25'-45 ' |

| Hula |

30'-1 ° |

35'-1 ° 30 ' |

| Yi shelar alkjjada |

30'-1 ° |

35'-1 ° 30 ' |

| K |

20'-40 ' |

25'-40 ' |

| Hpvc |

50'-1 ° 45 ' |

50'-2 ° |

| SPV |

25-50 ' |

30'-1 ° |

| CP |

20'-45 ' |

25'-45 ' |

Fannoni na zabin zaɓi na kusurwa na buƙatar kulawa

Zabi karami kusurwa don manyan abubuwa masu tsayi da manyan abubuwa

Yi amfani da kusurwoyi mafi girma don sassan da ke da ƙimar shrinkage

Daftarin daftarin don abubuwan da aka tsara don hana karce

Daidaita kusurwa dangane da zurfin tsinkaye don saman juzu'i

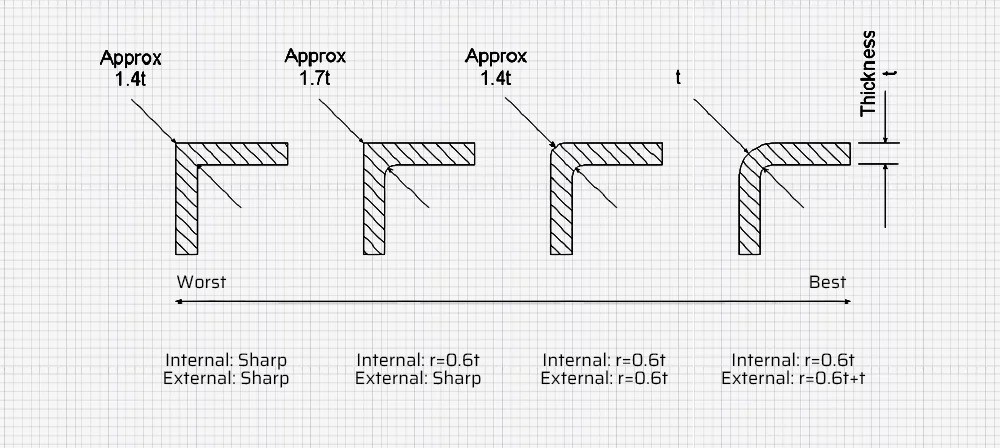

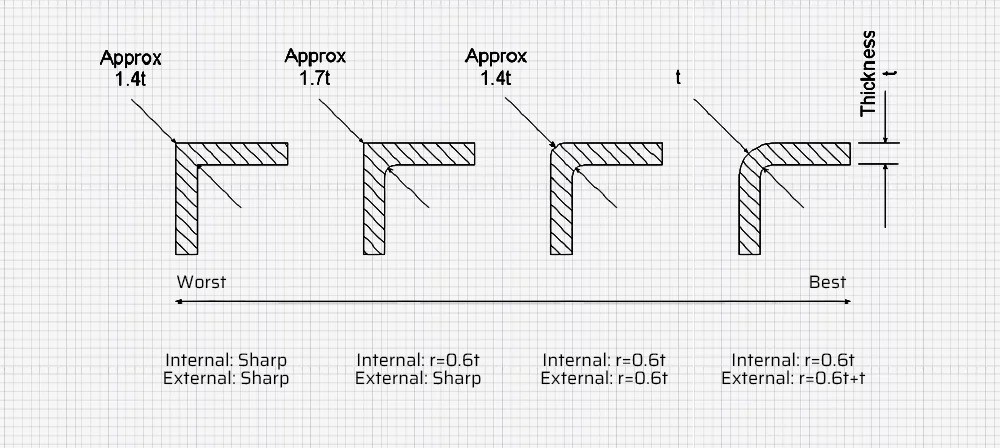

R kusurwar (sasannin zagaye)

Yawon shakatawa na rage maida hankali, sauƙaƙe filastikar filastik, da sauƙaƙewa.

Jagororin ƙira don Rassers R

Radius na ciki Radius: 0.50 zuwa 1.50 sau 1

Mafi karancin Radius: 0.30mm

Kula da kauri tufafi lokacin da suke tsara kusurwa

Guji kusurwar da ake zagayawa akan saman mold

Yi amfani da mafi ƙarancin 0.30m Radius don gefuna don hana karyewa

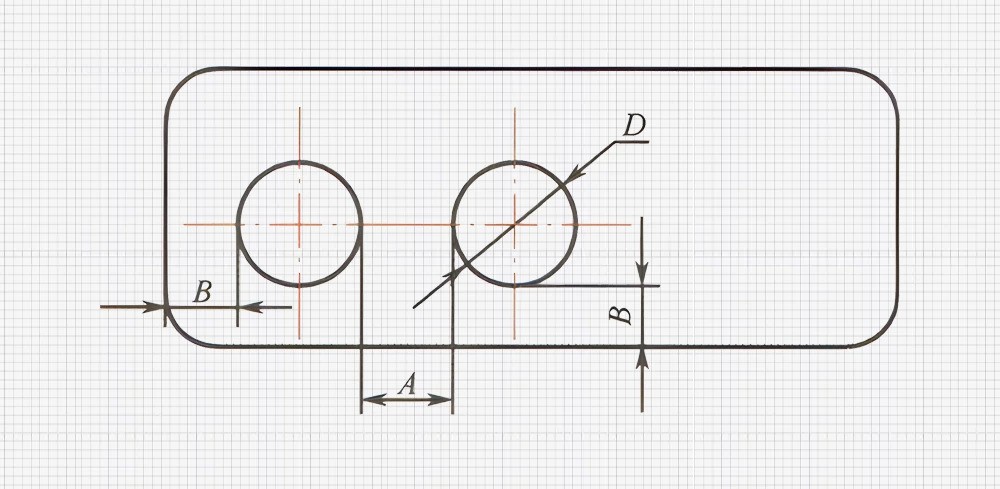

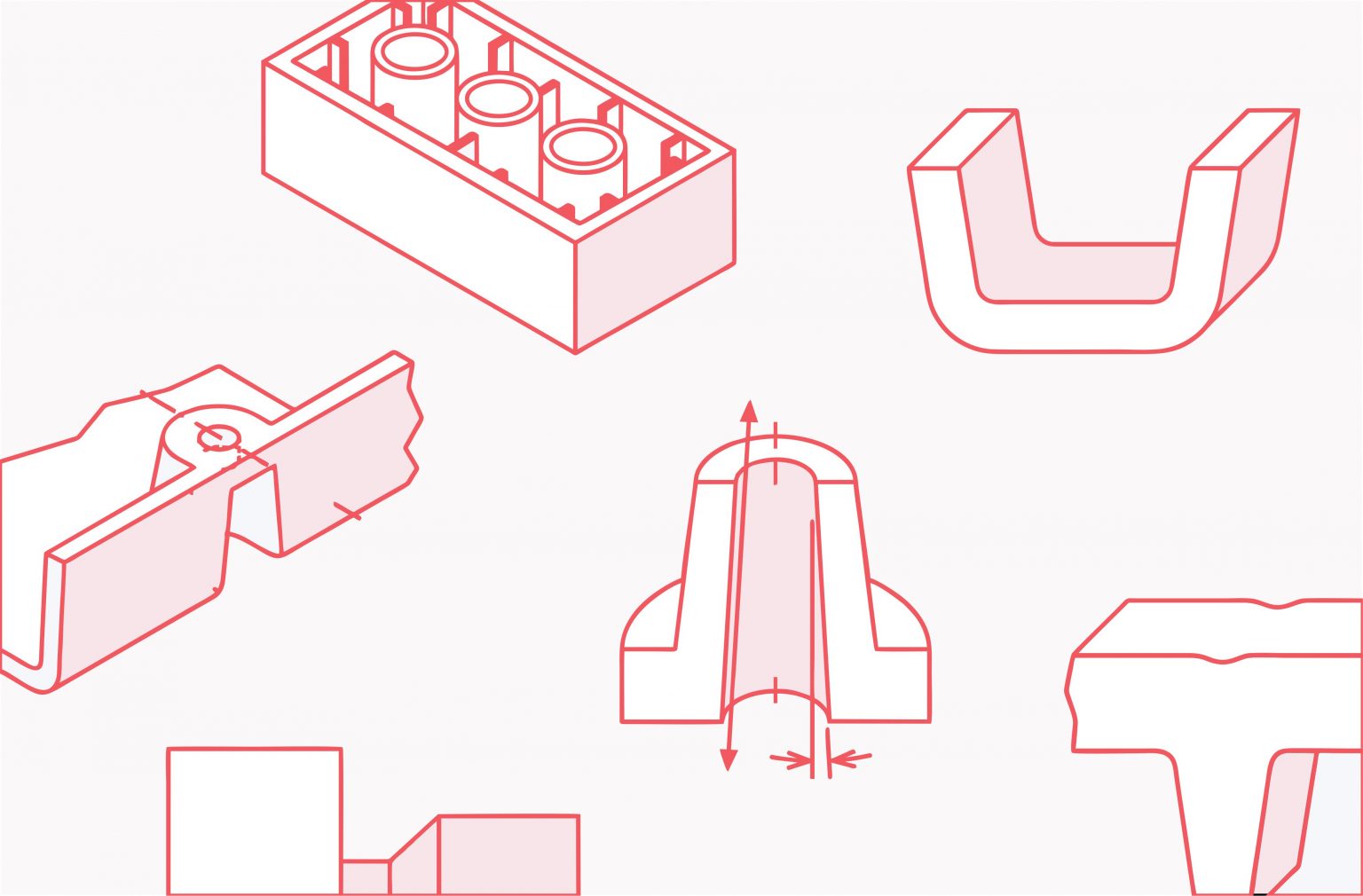

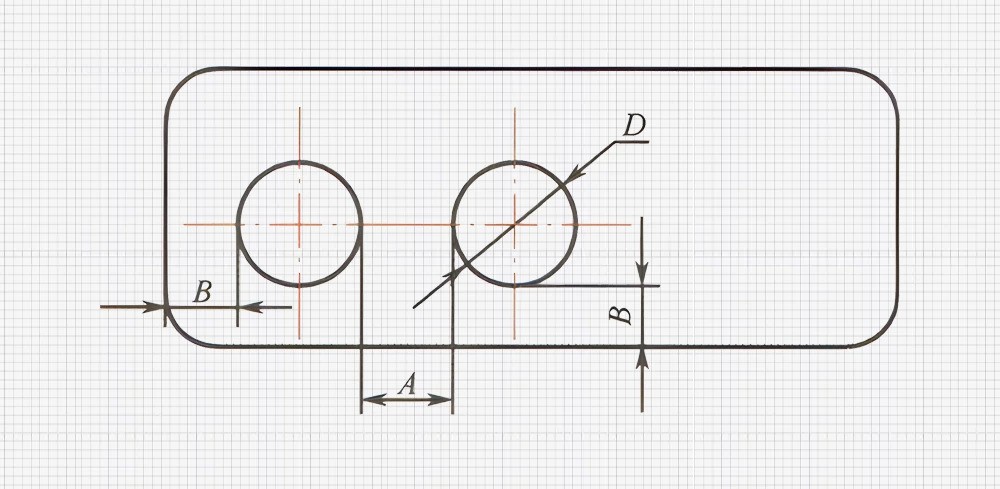

Ramuka

Ramuka suna ba da ayyuka daban-daban a cikin samfuran filastik kuma suna buƙatar la'akari da ƙira da hankali.

Bukatar Kifi don Rames

Dangantaka tsakanin diamita rami da zurfi

Tsarin ƙira don nau'ikan rami na musamman

Mataki

Ramuka na Angled: Daidaita AXIS tare da alamar buɗewar hanya lokacin da zai yiwu

Ramuka na gefe da abubuwan shigowa: la'akari da Core Core Tsarin Tsarin ko Ingantaccen Tsarin Zane

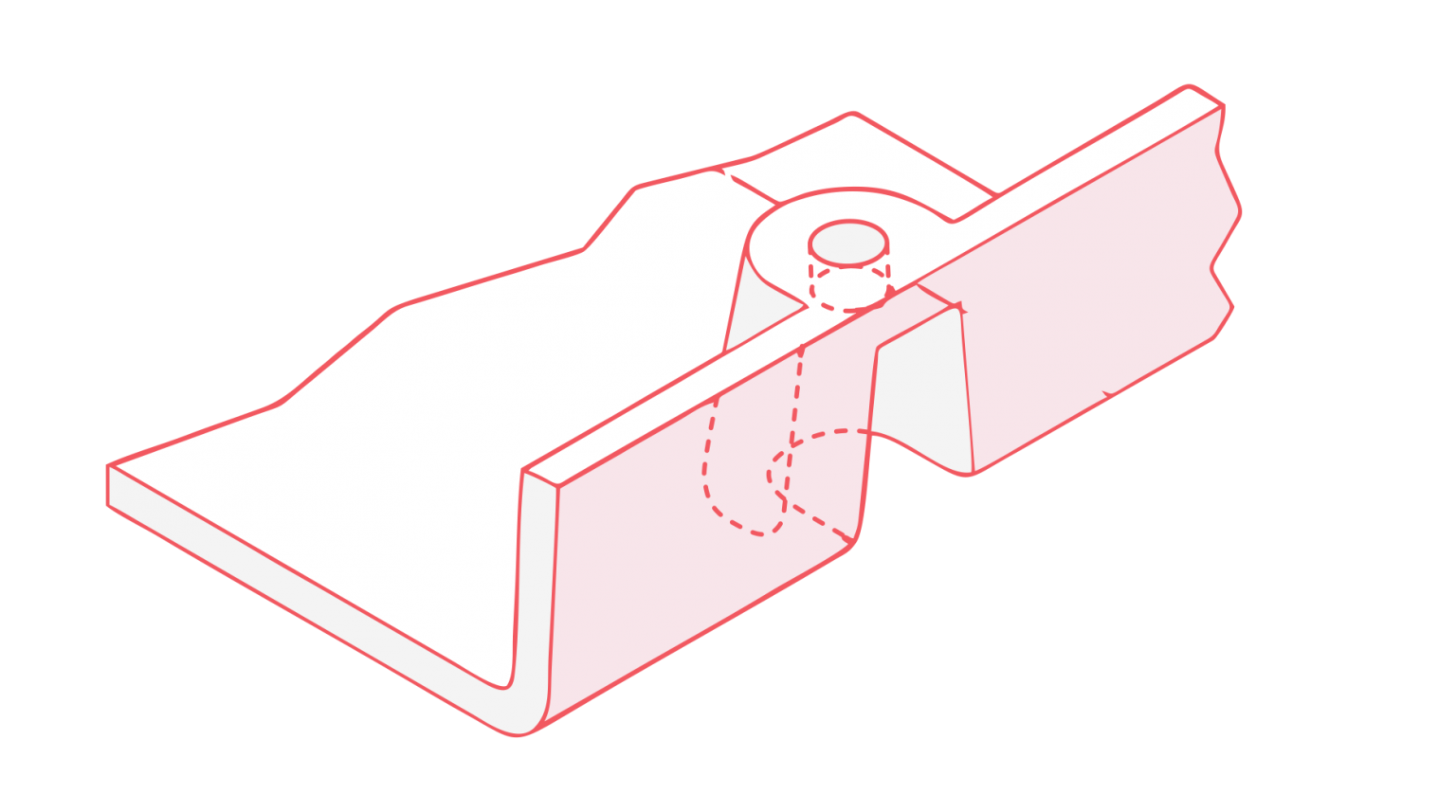

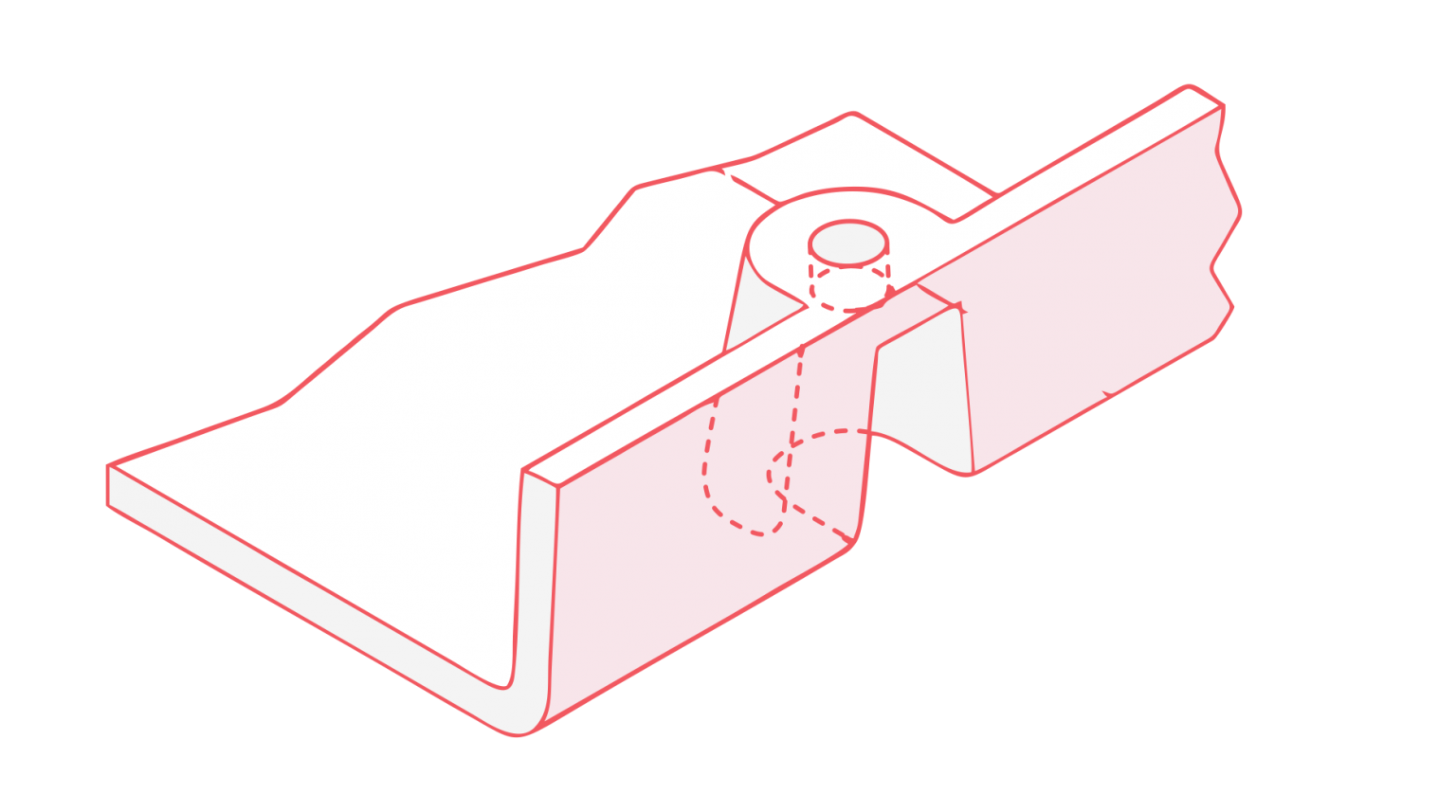

Bosses

Shugabanni suna ba da tarin taro, tallafawa sauran sassan, da kuma inganta tsarin tsari.

Jagororin ƙa'idar ƙira na asali don shugabanni

Height: ≤ sau 2.5 sau biyu diamita

Yi amfani da haƙarƙarin ƙarfafa ko haɗi zuwa bangon waje lokacin da zai yiwu

Tsara don filastik filastik mai laushi da kuma sauƙaƙewa

Tsarin ƙirar don kayan daban-daban

Abs: M diamita ≈ 2x na ciki diamita; Yi amfani da hakarkarinsa don karfafa

Pbt: ƙirar tushe akan haƙar tsallake. Haɗa zuwa gefen gefe lokacin da zai yiwu

PC: Cikin Rarraba Bases tare da haƙarƙari; Yi amfani da taro da tallafi

PS: Yanke hakarkarin don karfafa; Haɗa zuwa gefen gefe lokacin da ke kusa

PSU: M diamita na waje na diamita na ciki; tsawo ≤ 2x na diamita

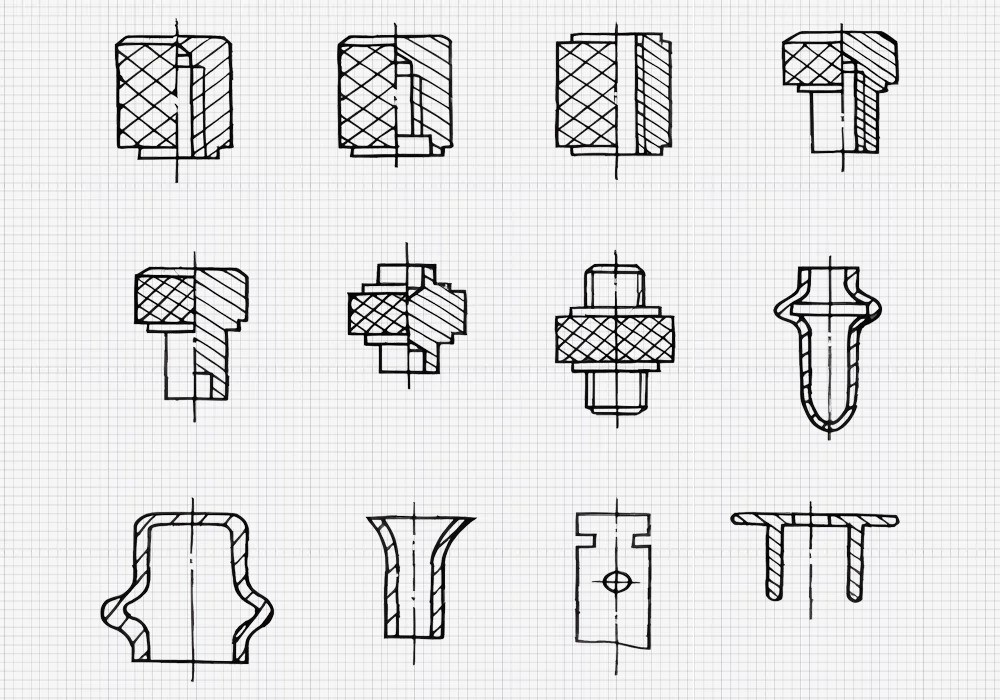

Abun ciki

Insanet yana taimakawa aikin aiki, samar da abubuwan kayan ado, kuma inganta zaptioni zaɓuwar taro a sassan filastik.

Siffar da tsarin tsari na kafawa

Abubuwan kirkirori: jituwa tare da yankan ko stamping tafiyar matakai

Ingantaccen injin: isasshen abu da girma

Hadadden karfin: isasshen fasalin kayan gini don amintaccen abin da aka makala

Matsayi: Canjin Silinda Mayakan don Matsayi Mai Sauki

Yin rigakafin Flash: sun hada da rufe tsarin maigidan

Post-sarrafawa: Tsarin don gudanar da sakandare (threading, yankan, flaket)

Tsarin ƙira lokacin amfani da abubuwan haɗin

Tabbatar da daidaitaccen wuri a tsakanin molds

Createirƙiri haɗi masu ƙarfi tare da sassan molds

Hana lalacewar filastik

Yi la'akari da bambance-bambancen fadada tsakanin Saka da kayan filastik

Samfurin kayan aiki da rubutu / tsarin tsari

Tsarin rubutu na kayan filastik

Za'a iya tsara hanyoyin kayan filastik tare da ɗaɗɗun rubutu na haɓaka kayan ado, ayyuka, da ƙwarewar mai amfani. Kayan sararin samaniya na gama gari sun hada da:

M

Spark-etched

Metched attched

Zanen zane

Santsi saman

Mummunan saman sakamako sakamakon saman molds. Suna bayarwa:

Spark-etched saman

Wanda aka kirkiro ta hanyar sarrafa ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta, spark-etched saman samar da:

Passed etched saman

Wadannan saman saman suna nuna alamu da yawa a cikin murfin murfin, yana bayar da:

Zanen saman

Hanyoyin zane-zanen an ƙirƙira ta hanyar tsarin sarrafawa kai tsaye zuwa cikin mold, bada izinin:

Ayyukan kusurwa kwana don saman juzu'i

A lokacin da ke zayyana saman texted saman, la'akari da ƙara daftarin kusurwa don sauƙaƙe wani ɓangare:

| zurfin zane |

da aka ba da shawarar ƙarin ƙarin daftarin kwana |

| 0.025 mm |

1 ° |

| 0.050 mm |

2 ° |

| 0.075 mm |

3 ° |

| > 0.100 mm |

4-5 ° |

Rubutu da tsarin tsari

Products samfuri sau da yawa haɗa rubutu da alamu don yin bashin, umarni, ko dalilai na ado. Wadannan abubuwan za a iya tashe ko an sake shi.

Ya tashe vs.

Shawarwari: Yi amfani da saman saman don rubutu da tsari lokacin da zai yiwu.

Fa'idodi na saman:

Sauƙaƙe sarrafa mold

Mai sauƙin kulawa

Ingantaccen aiki

Don zane yana buƙatar fasali mai lalacewa

Airƙiri yankin da aka karba

Ta tayar rubutu ko tsari a cikin lokacin hutu

Kula da bayyanar fure gaba ɗaya yayin da sauƙaƙe ƙirar mold

Rubutu da tsarin girma

| fasalin |

da aka ba da shawarar girma |

| Height / Zurfin |

0.15 - 0.30 mm (da aka tashe) |

|

0.15 - 0.25 mm (repled) |

Bayanin girman rubutu

Bi waɗannan jagororin don kyakkyawan zane:

Tadaya na bugun jini (a): ≥ 0.25 mm

Jerawa tsakanin haruffa (b): ≥ 0.40 mm

Distance daga haruffa zuwa baki (c, d): ≥ 0.60 mm

Questionarin rubutu / tsarin kirkirar kirkirar kirkira

Guji kaifi kusurwa a rubutu ko tsarin

Tabbatar da girman yana haifar da tsari mai sarrafa

Yi la'akari da tasirin rubutu / tsari akan karfin gaba

Kimanta tasirin rubutu / tsari akan kwararar kayan yayin gyada

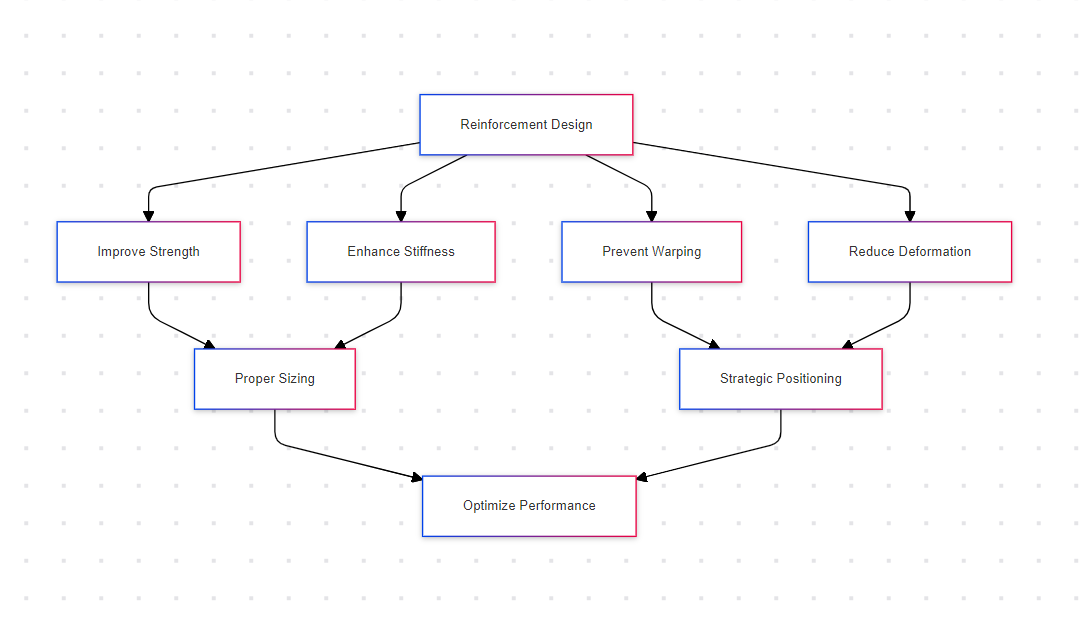

Treearfafa tunanin ƙira

Ingantaccen tsarin tsarin

Tsarin na ƙarfafa yana taka muhimmiyar rawa wajen inganta aikin ci gaban kayayyakin filastik. Suna inganta ƙarfi da ƙarfi, taurin kai, da kwanciyar hankali.

Makasudin Mabuɗin Tsarin Ingantawa:

Ingancin ƙarfi

Ingancin Inganta

Rike rigakafin

Raguwa na lalata

Matsayi mai kyau da sizing na ƙarfafa:

Yawan kauri: 0.4-0.6 Lokaci na Babban Jiki

Spacing:> 4 sau guda kauri na jiki

Height: <sau 3 babban kauri

Dunƙulewar dunƙulen skumar

Janar Ingantaccen: Mafi qarancin 1.0mm a kasa bangare ko rabawa

Hanyoyi masu tsauri:

Bayyanawa na ƙarfafawa don hana ginin kayan

Abubuwan da ke ciki a cikin hanyoyin da aka ƙarfafa

Tsarin halittun da aka samu na asali don siririn karfi

Guji maida hankali da damuwa

Murfurrationda damuwa na iya tasiri mai mahimmanci da tsarin kayan aikin filastik. Hanyoyin zane da suka dace na iya lalata waɗannan batutuwan.

Mahimmancin guje wa sasanninta:

Rage karfin aiki

Karuwar hadarin karya

Yuwuwar rashin nasara

Matakan don yawan hankali:

Kamba

Zagaye sasanninta

M subopes don sauyawa

A cikin hanji a sasanninta kaifi

| fasaha |

Bayanin |

rage |

| Kamba |

Beveled gefuna |

Rarrabawar damuwa ta hankali |

| Zagaye sasanninta |

Mai canzawa |

Yana kawar da kaifin damuwa |

| M gangara |

Canje-canje na kauri |

Hatta rarraba damuwa |

| A ciki hollowing |

Cire kayan a sasanninta |

Rage yanayin damuwa |

Tsararren Draft Dragles

Angles kusurran suna da mahimmanci don cin gashin kansu daga molds. Suna tasiri sosai da ingancin samarwa da ingancin samarwa.

Ka'idodi don tantance dabaru:

Yi amfani da kusurwoyin lamba duka (misali, 0.5 °, 1 °)

Kusurrai na waje> kusurwoyi na ciki

Kara kusurwa ba tare da yin sulhu ba

GWAMNATI SU SAMU DANCIN KUDI:

Sashi na zurfafa

Farfajiya

Kayan Sharimai

Zurfin zina

Tsarin zane na kusurwa na maki daban-daban na kayan daban-daban:

| kayan da |

aka ba da shawarar daftarin kusurwa |

| Abin da |

0.5 ° - 1 ° |

| PC |

1 ° - 1.5 ° |

| Pp |

0.5 ° - 1 ° |

| Zasa |

0.5 ° - 1 ° |

| So |

1 ° - 1.5 ° |

Tsarin tsari daga yanayin tsarin mold

Ingantacciyar zane mai laushi yana da mahimmanci don samar da filastik filastik. Yi la'akari da waɗannan bangarorin don inganta ɓangare da ƙirar ƙira.

Guji hadadden hadaddun tsari:

Sauki Kashi na Gashi

Rage fitilar

Rage ayyukan gefen

Guji tsarin yanke na ciki na ciki:

La'akari da bukatun sakin baya:

Bada isasshen sarari don motsi

Tsallake ya rufe hanyoyin

Inganta tsare-rikice a cikin mold

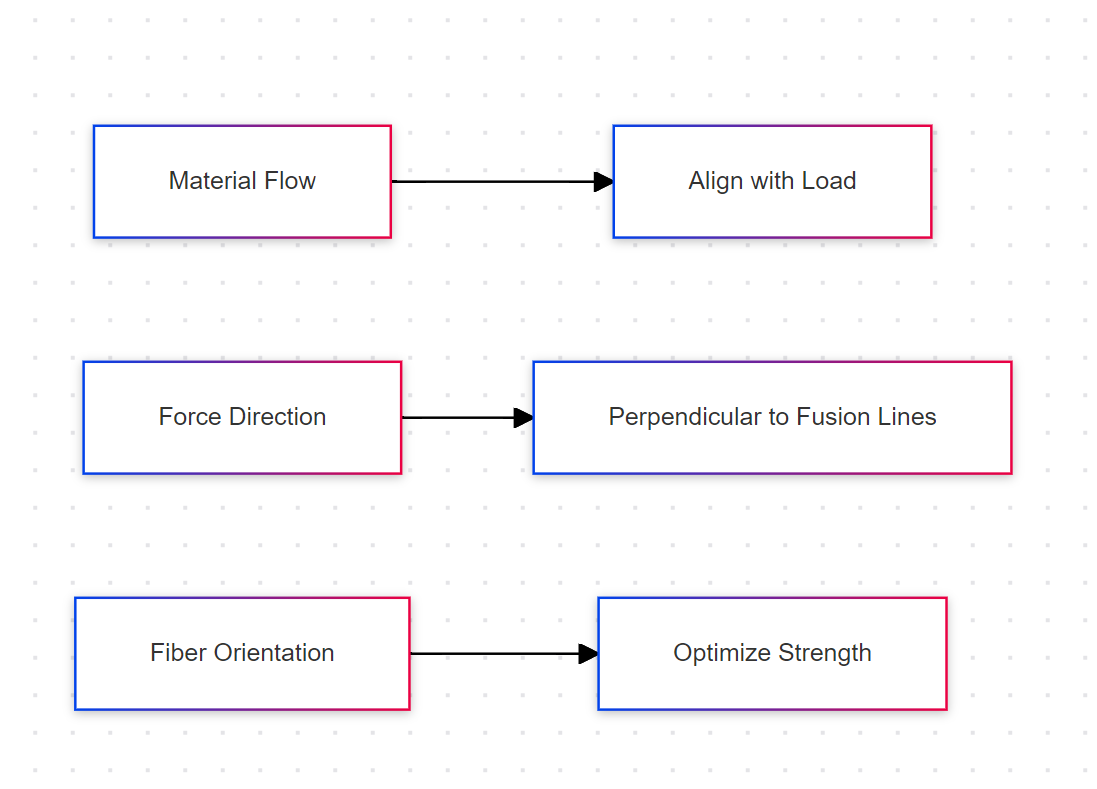

Tsara wa halaye marasa aiki na robobi

Yawancin filastik sun nuna kaddarorin da basu dace ba, suna buƙatar la'akari ta musamman don ƙara yawan aiki.

A layi a jera shugabanci na kayan tare da shugabanci mai ɗaukar nauyi:

Wajibi ne shugabanci ya danganta ga layin mursuna:

Tsarin tsari daga Haske

Tsarin Majalisar Haɗin yana tabbatar da ayyukan samfuri, tsawon rai, da kwanciyar hankali.

Guji yawan masu girma dabam da ƙananan haƙuri:

Designing Desigface Design:

BOT haɗi yana ɗauka don sassan filastik:

Taƙaitawa

A cikin zanen samfurin filastik, key tsarin tsari kamar kauri na bango, yana ƙarfafa haƙarƙarin haƙarƙari, da kuma kusurwar kusurwa suna da mahimmanci ga karko da aiki. Yana da matukar muhimmanci a yi la'akari da kaddarorin kayan, tsarin mold, da kuma taro yana buƙatar lokacin aiwatarwa. Designirƙirar tsarin tsari da kyau ba kawai inganta aikin samfuri ba ne amma kuma yana rage lahani da farashin masana'antu. Ta hanyar mai da hankali kan waɗannan abubuwan ƙira, masana'antun zasu iya tabbatar da ingancin filastik, farashin filastik masu inganci waɗanda ke haɗuwa da bukatun kayan aiki da kuma bukatun ado.