Filastik shrinkage yana ɗaya daga cikin mafi mahimmanci har yanzu yawanci ba a fahimta da fannoni na allurar rigakafi. Kamar yadda molten filastik yayi sanyi kuma yana ƙarfafa, yana fuskantar matsala, yana haifar da canje-canje na girma wanda zai iya yin ko karya samfurin ƙarshe. Gudanar da tsinkaye yana da mahimmanci don kiyaye daidai, guje wa lahani kamar warping, da kuma tabbatar da amincin sassan. Ko kuna aiki tare da kayan yau da kullun kamar polypropylene ko manyan-aiwatar da polycarbonate, fahimta da sarrafa sakamako mara kyau, ingantacce.

A cikin wannan shafin, za mu gabatar da dukkan shrinage na filastik, yana ba da gudummawa ga zurfin fahimtar ku game da ma'anar sa, dalibai da mafita.

Mene ne shrinkage na filastik a cikin allurar

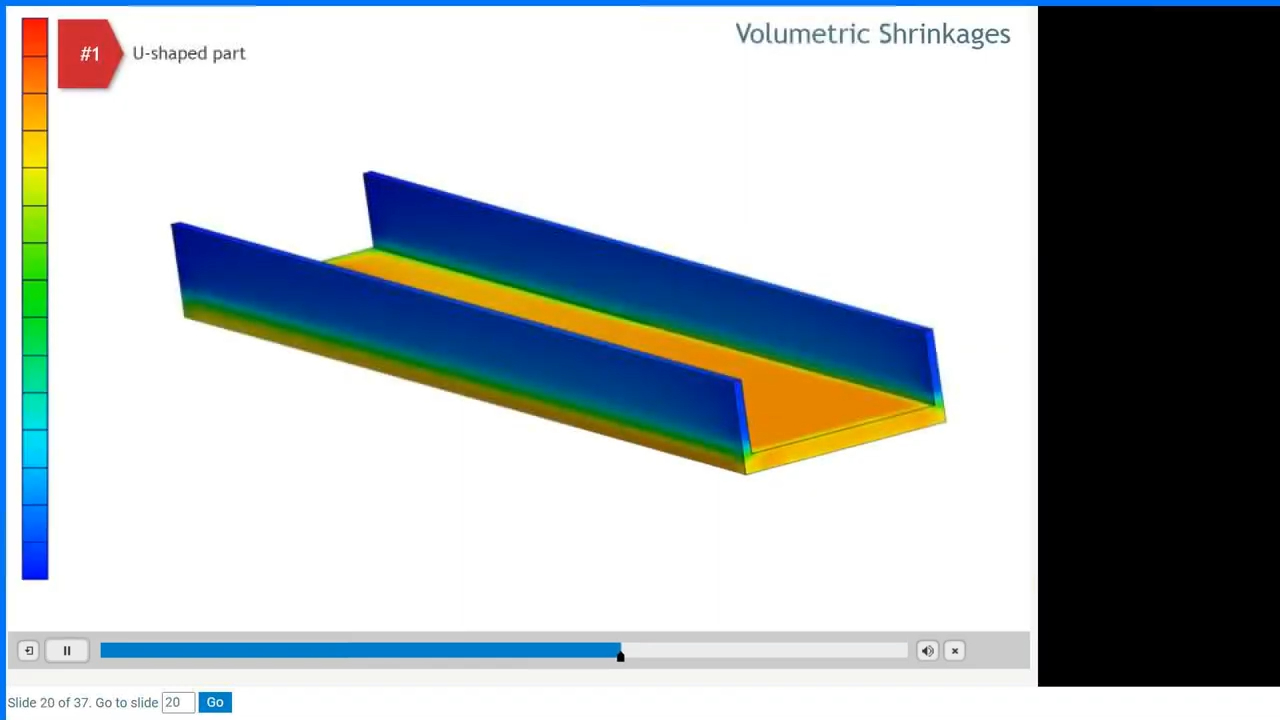

Filastik shrinkage shine ƙanƙantar da polymers na polymers lokacin sanyaya cikin allurar. Zai iya lissafin har zuwa har zuwa 20-25%% ragi, yana shafar girman samfurin ƙarshe da inganci.

Matsayi na kwayar cuta na kwayar cutar kwayoyin cuta a matsayin sarƙoƙi na polymer yana rasa motsi da fakitin sosai. Wannan tasirin shine mafi furta a cikin polymers na Semi-Crystalline. ƙwayar narkewa ta amfani da: Za'a iya lissafta

Shrinkage (%) = [(girma na ainihi - girma na ƙarshe) / Kara asali] x 100

Kwangilar Thermal ta ba da gudummawa sosai ga shrinkage. Kayan aiki tare da mafi yawan ƙwarewar haɓaka haɓakar haɓakawa na Therrardion ƙarin tasirin sakamako.

Tasirin Shirin Jirgin Sama akan sassan da aka gyara

Daidaitawa daidaito : Abubuwan na iya karkata daga ƙayyadaddun ƙirar ƙirar, haifar da ƙarin maganganu masu aiki.

Ingancin bayyanar bayyanuwa : Rashin kunya na iya haifar da lahani na farfajiya, WarPage, da alamun ruwa.

Kudin samarwa : magance matsalolin da suka shafi shrinkage sau da yawa yana buƙatar ƙarin aiki ko sharar gida.

Batutuwa na Aiwatar : Abubuwan da ke cikin girma na yau da kullun na iya haifar da gazawar aikin, musamman ma a cikin mahimman ayyuka.

GASKIYA Cuarin yin amfani da allurar rigakafi

Yin allurar rigakafi mai ƙima abu ne mai mahimmanci a samar da sassan filastik mai inganci. Abubuwa da yawa masu tasiri suna shafar ƙyallen, jere daga kayan abu don sarrafa yanayin, ƙirar sashi, da ƙirar ɓangaren. Fahimtar wadannan dalilai na taimakawa tabbatar da daidaito da daidaito da rage lahani yayin samarwa.

Abubuwan kayan abu

Crystalline vs Amorphous Rufe

Irin nau'in filastik - ko lu'ulu'u ne ko kuma amorphous-taka babban aiki a cikin shrinkage. Rikicin Crystalline, irin su PA6 da Pa66, nuna mafi girman raguwa saboda tsarin da aka tsara na kwayoyin halitta yayin da suke sanyi da kuka. Rikicin Amorphous kamar PC da Absasa lalata, kamar yadda tsarin kwayoyin su ba sa fama da manyan abubuwan da suka yi yayin sanyaya.

| Filastik na | nau'in shrinkage |

| Crystalline | Babban shrinkage |

| Amorphous | Low shrinkage |

Nauyi na kwayoyin

Nauyin kwayar filastik ma yana tasiri da shrinkage. Robosai tare da nauyin kwayoyin halittun kwayoyin halitta suna iya samun ragin ƙananan matsakaiciya saboda suna nuna yawan danko, suna rage yawan kwarara yayin sanyaya.

Flers da zaruruwa

FLERS, kamar ƙwayoyin gilashi, galibi ana ƙara su ne ga robobi don rage shrinkage. Wadannan 'yan wasan sun hana wuce gona da iri ta hanyar karfafa tsarin polymer, suna bayar da kwanciyar hankali. Misali, gilashin cike da gilashin (Pa) ya girgiza sosai da ƙasa da nailan.

Launi

Aljirar da aka kara wa filastik na iya yin tasiri harma, kodayake sakamakon su ba shi da furcin kwatankwacin. Wasu aladu na iya canza narkewar ruwa ko halaye masu sanyaya, cikin halaye da yawa.

Ruwan Shrinkage na robobi daban-daban

Ruwan shrinkage yana bambanta sosai a cikin nau'ikan robobi. Da ke ƙasa akwai kyawawan dabi'u na yau da kullun don kayan da aka yi amfani da su na yau da kullun: Ma'amir

| mai | narkewa (%) |

| PA6 da PA66 | 0.7-2 |

| Pp (polypropylene) | 1.0-2.5 |

| PC (polycarbonate) | 0.5-0.7 |

| PC / Abs cakuda | 0.5-0.8 |

| Abin da | 0.4-0.7 |

Sarrafa yanayin sarrafawa a cikin allurar gyada

Narke da zafin jiki

Nest zazzabi yana rinjayar yadda polymer yana gudana cikin ƙirar da sanyi. A mafi kyawun yanayin zafi yana ba da izinin cika mold amma na iya ƙaruwa da shrinkage saboda mafi girman ƙwarewa yayin sanyaya. Hakazalika, zazzabi m.

Shirya

Matsin rigakafin allura mafi girma yana rage shrinkage ta hanyar aiwatar da kayan dosek. Wannan yana rage yawan void sarari wanda zai iya samar da filastik na filastik da kwangila.

Lokacin sanyi

Sau da yawa mai sanyaya mai sanyaya yana ba da damar abu don cikakken bayani a cikin ƙirar, yana rage shrinkage bayan an fitar da sashin. Koyaya, sanyi mai saurin sanyi na iya haifar da shrinkage da warping.

Shirya matsi da lokaci

Matsakaicin matsin lamba da kuma tsawan tsawan adadin adadin kayan allura cikin ƙirar bayan kammala matakin farko. Matsin matsin lamba mafi girma yana rage shrinkage ta hanyar diyya don ƙirar duniya da ke faruwa yayin sanyaya.

Part Design

Kauri

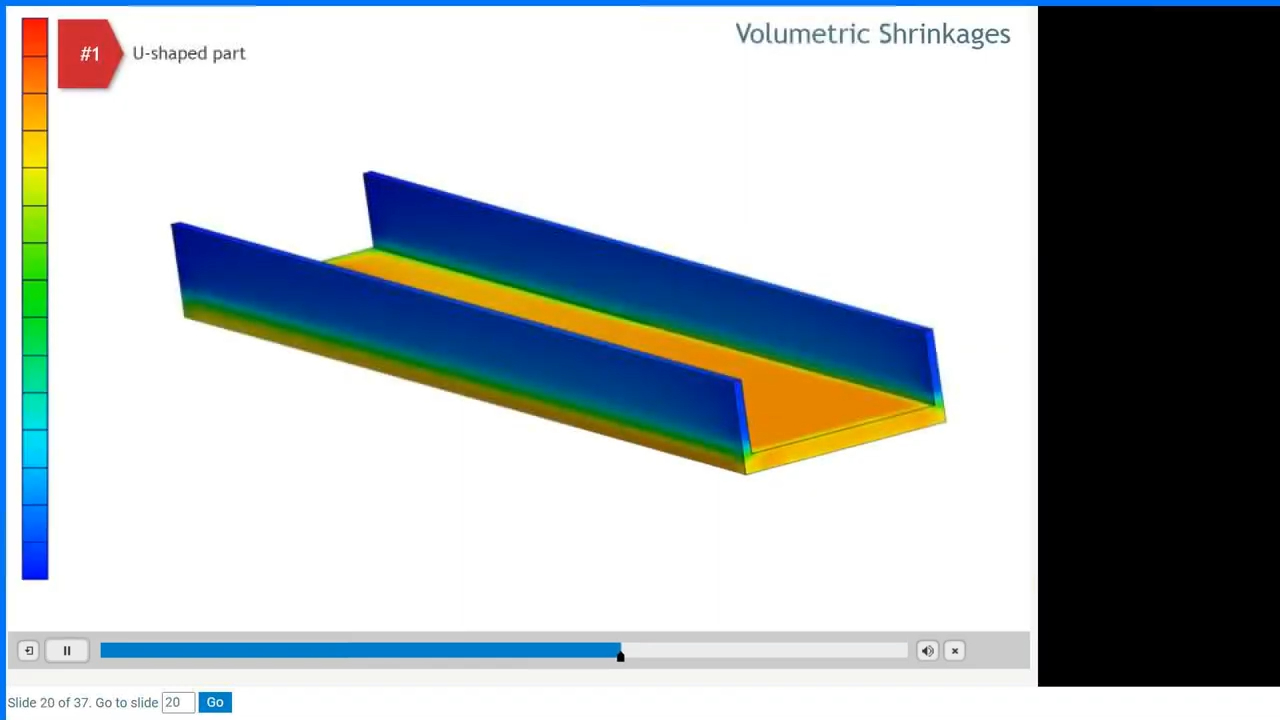

Abubuwan da ke tare da bangon kauri suna iya yiwuwa ga mafi girman shrinkage, kamar yadda sassan kauri suka dauki lokaci mai tsawo don kwantar da hankali, jagoranta zuwa mafi mahimmancin tasiri. Tsararren sassa tare da kauri bango na iya taimaka ma sanyaya da shrinkage.

| Tasirin | kauri akan Shari |

| Lokacin farin ciki bango | Mafi girma shrinkage |

| Ganyen bakin ciki | Ƙananan shrinkage |

Lissafi

Tsabtace geometries tare da launuka daban-daban ko sauye-sauye sau da yawa suna haifar da m sanyaya, wanda ke ƙara haɗarin ƙyamar shrinkage. Mafi sauki, ƙarin siffofin uniform gaba ɗaya suna raguwa da yawa.

Ƙarfafa abubuwa da kuma inganta

Yankunan da aka karfafa ko sanya bayanai game da wani sashi na iya shafar shrinkage daban da lebur saman. Sashin da aka karfafa na iya sanyi da sannu a hankali, yana raguwa kaɗan, yayin da wuraren da aka zira kwallaye zasu iya sanyaya da sauri da kuma fuskantar ƙarin shrinkage.

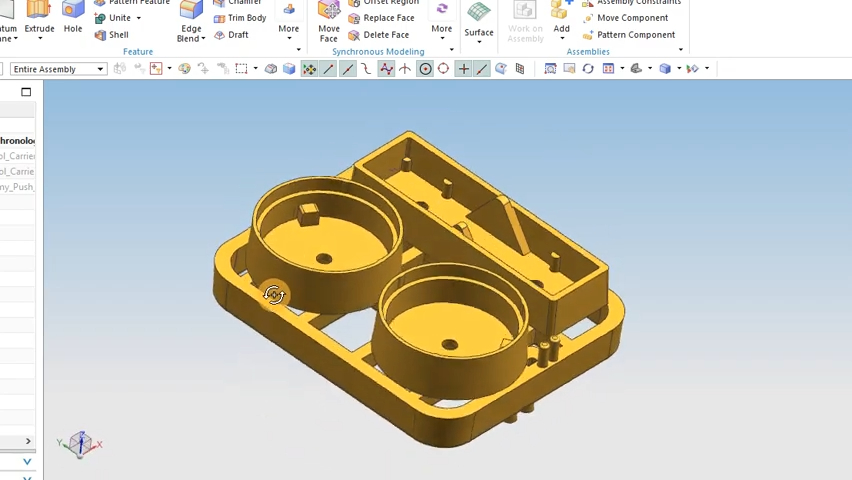

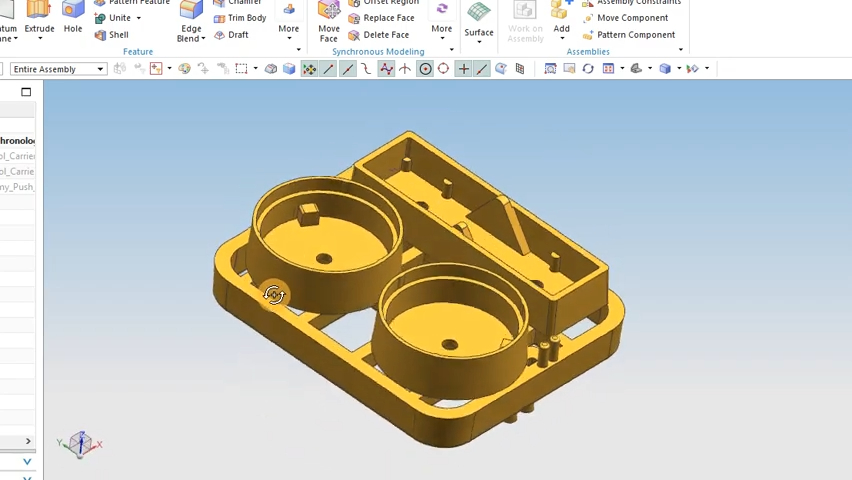

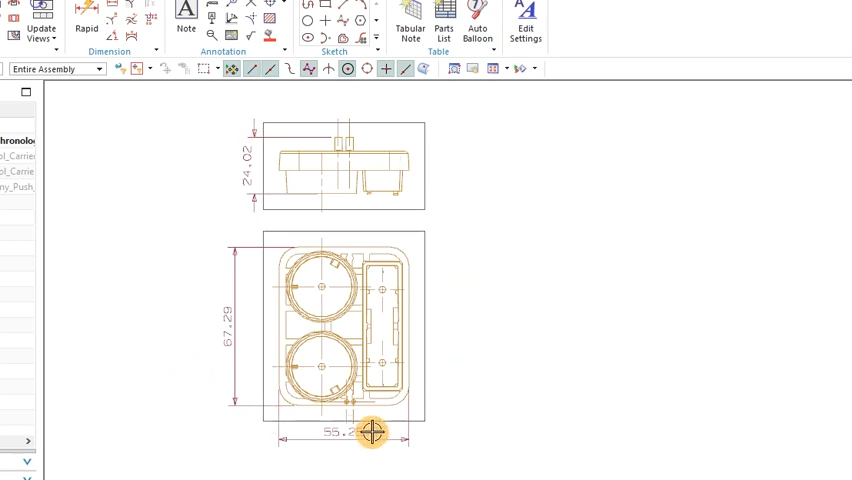

Mallaka ƙira

Matsakaicin Gateo

Matsayi da girman ƙofar, wanda ta hanyar matsar da filastik ya shiga cikin ƙirar, yana tasiri kai tsaye. Gates din da ke cikin sassan kauri na wani sashi yana ba da damar kyakkyawan shiryawa, rage shrinkage. Kananan ƙofofin, a gefe guda, na iya iyakance kwararar kayan, suna haifar da mafi girma shrinkage a wasu yankuna.

Tsarin tsere

Tsarin mai tsere da aka tsara yana tabbatar da ko da rarraba filastik na filastik a cikin mold. Idan tsarin mai tsere ya zama ma ya hana, yana iya haifar da gudummawa mara kyau, wanda ya haifar da raguwa a fadin sassa daban daban na m.

Tsarin sanyaya

Tsarin sanyaya na mold yana da mahimmanci ga sarrafa shrinkage. Sun sanya tashoshin sanyaya yadda yakamata suna taimakawa wajen tsara darajar sanyaya, hana hana rashin kunya da warping. Ingantaccen sanyaya yana ba da damar ɓangaren don kwantar da hankali, rage yiwuwar lahani.

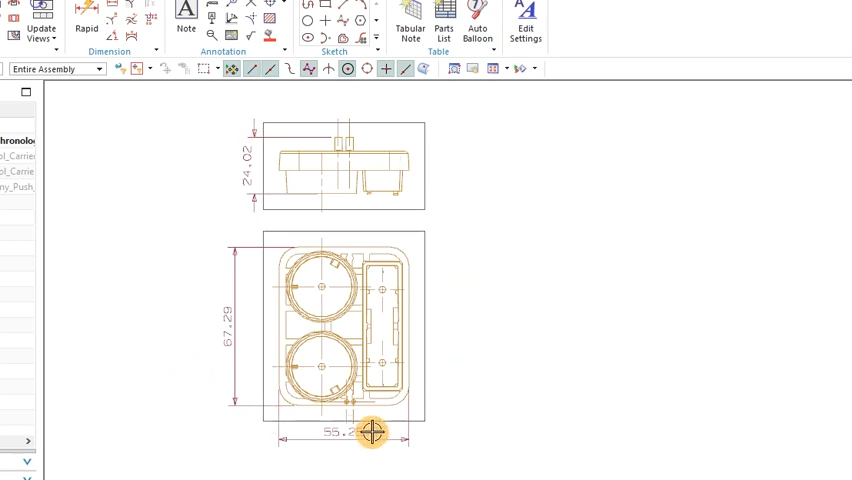

Aunawa da lissafin daskararre filastik

Astm D955 da ISO 2944 Matsayi suna ba da hanyoyin don auna shrinkage. Janar for tsari na Linear Shrinkage shine:

Linear Shrinkage (%) = [((m girma - bangare na bangare) / mold girma] x 100

Yadda za a hana shrinkage

Tsarin ƙira

Inganta Tsarin Kudi

Daya daga cikin ingantattun hanyoyi don rage shrinkage ne ta hanyar inganta ƙirar ɓangaren da kanta. Partangarorin tare da sutura tufafi na kwantar da hankali sosai a hankali, yana haifar da daidaito a dukkanin samfuran. Gujewa sauyawa da kuma kula da canje-canje na hankali a cikin kauri zai iya taimakawa rage damuwa da warping. Fasali kamar hakkin da aka ƙara don ƙarfafa wuraren da ke iya yiwuwa ga shrinkage yayin riƙe kayan da ke gudana.

| Tsarin tsari | akan Shanƙasa |

| Kayan aiki | Yana rage sanyaya sanyaya da shrinkage |

| Sharp transition | Kara hadarin warping |

| Inganta (hakarkarin / Gussets) | Inganta tsarin tsari |

Zabin Abinci

Nau'in kayan filastik da aka yi amfani da shi yana da tasiri sosai akan shrinkage. Abubuwan da suka dace da kayan kwalliya (PC) da Abs suna da ƙananan ƙuruciyar Sharnkage idan aka kwatanta su da kayan crystalline kamar na polypropylene (PP) da nailan (PP6). Dara da flurers kamar zaruruwa na gilashin kuma zasu iya rage shrinkage, yayin da suke taimakawa tsaftace kayan yayin sanyaya. Ma'aikatan kwayoyin halitta da kaddarorin Thermal yakamata su daidaita tare da ƙirar samfurin da aikin da aka yi niyya.

| Kayan | Sharimai |

| Amorphous (PC, Abs) | M |

| Crystalline (PP, PA6) | M |

| Cika (gilashin cike) | M |

Hanyoyi dabarun sarrafawa

Daidaita sigogi

Gudanar da sigogi masu aiki shine mabuɗin don sarrafa shrinkage. Theara yawan zafin jiki na ƙwararrun yana inganta kayan abu, amma kuma yana ƙara yawan shrinkage azaman kwangilar kayan aiki a lokacin sanyaya. Za a iya saita yanayin zazzabi yana buƙatar saita yadda ya dace don tabbatar da cikawar da ya cika ba tare da haifar da wuce kima ba. Ta hanyar daidaita waɗannan masu canji, masana'antun za su iya samun mafi kyawun sarrafa sanyaya da ƙanƙantar da kayan.

Sarrafa matsin lamba

Allura da tattara matsin lamba kai tsaye shrinkage. Horarfin allura mafi girma yana tabbatar da cewa mold ya cika gaba daya, rage voids kuma yana rama don ƙanƙantar kayan duniya. Ana amfani da matsi na tattarawa don ci gaba da yin amfani da kayan cikin ƙirar bayan cika da farko, wanda ke taimaka wa rage shrinkage kamar yadda filastik yayi sanyi.

| Tasirin | siga akan shrinkage |

| Mafi girman tsari | Rage shrinkage |

| Ƙara matsin lamba | Rama don sanyaya shrinkage |

Dabarun sanyaya

Lokaci mai sanyaya da ƙididdiga kuma suna taka rawa wajen sarrafa shrinkage. Sau da yawa mai sanyaya mai sanyaya yana ba da damar a hankali, har ma sanyaya, wanda ke rage haɗarin warping da bambancin shrinkage a duk faɗin sashin. Daballin sanyaya kamar suna amfani da tashoshin sanyaya sanyaya da aka tsara don tabbatar da cewa sashi yana sanyaya daidai, yana hana wuraren zafi wanda zai iya haifar da shrinkage.

| Cooling dabarun | amfana |

| Tsawon sanyaya lokaci | Rage warping da rashin kunya |

| Uniform mai santsi | Yana tabbatar da koda sanyi da shrinkage |

Ingantaccen Tsarin Tsarin Mallaka

Gateofar Gateofar da Tsarin Runner

Tsarin ƙofar da mai gudu yana shafar yadda kayan ke gudana cikin ƙirar, wanda ke hasala tasirin shamaki. Manyan ƙofofin ƙofa ko ɗakunan ƙofa suna tabbatar da cewa mold ya cika da sauri kuma a ko'ina, yana rage damar da cika saboda cika cika. Tsarin mai gudu yana da mahimmanci don rage girman ƙuntatawa, yana ba da izinin matsin lamba a cikin rami.

Tsarin tsarin sanyaya

Ingantaccen tsarin sanyaya suna da mahimmanci don ikon shrinkage. Tashoshin sanyaya ya kamata a sanya su kusa da kogon igiyar ciki don tabbatar da cutar da zafi. Bugu da ƙari, ta amfani da tashoshin sanyaya mai sanyaya, wanda ke biysuwa

Shirya matsala

Matsaloli gama gari da mafita

Allurar rigakafi mai narkewa na iya haifar da batutuwa daban-daban. Anan akwai wasu matsaloli masu yawan gaske da kuma hanyoyin su na iya.

Warppage

Alamar ruwa

Kara matsa lamba da lokaci

Redesign sashe don kawar da sassan farin ciki

Yi amfani da ƙwararrun allurar gas

Voids

Girmama saurin allura da matsin lamba

Aiwatar da iska-da aka taimaka

Inganta Matsakaicin Cofar da Girma

ANABATARWA

Dalili: Rashin Tsara

Magani:

Nazari na Case

Karatun Karatun 1: Dandalin Kayan Aiki

Matsala : Kamfanin Kamfanin Kamfanin ya fuskanci batutuwan Walopage a bangarorin dashboard.

Magani : Suna aiwatar da canje-canje masu zuwa:

Canja mai sanyaya sanyaya hoto don sandar sutura

Daidaitattun yanayin aiki

Canza haƙarƙƙarfan haƙarƙarin rage bambancin shrinkage

Sakamakon : Warmu ya rage da kashi 60%, hade da ka'idojin ingancin.

Karatun nazarin 2: Mawaka lantarki

Matsala : Kamfanin Kamfanin Kamfanin Kamfanin Kamfanin Kamfanin Spaukar Alamar Wating a cikin hanyoyin haɗin na'urar.

Magani : Teamungiyar ta dauki wadannan matakan:

Sakamako : Alamomin da aka share sun cire, inganta inganta kayan aiki.

Karatun Karatun 3: Abubuwan Na'urar Na'urar Likita

Matsala : Ma'aikatar na'urar na'urar likita ta fuskance matsalolin daidaito cikin mahimman kayan aiki.

Magani : sun aiwatar dasu:

Ingantaccen software na zamani don hangen nesa

Madaidaicin iko na mold da narke yanayin zafi

Kayan yau da kullun suna haɗuwa tare da rage halayen shrinkage

Sakamako : An sami haƙuri mai haƙuri a tsakanin ± 0.05mm, tabbatar da ayyukan na'urar.

Karatun wadannan kararraki suna ba da mahimmancin tsarin da yawa don magance matsalolin shrinkage. Suna nuna yadda ke yin gyare-gyare, tsarin aiwatar da tsari, da zaɓin kayan aiki na iya warware matsalolin da ke da alaƙa da rikice-rikice a cikin allurar.

Ƙarshe

Inganci Sharia mai tasiri yana buƙatar la'akari da kaddarorin kayan, sashi da ingantaccen ingantawa, da kuma kula da yanayin sarrafa. Ci gaba da ci gaba da ci gaba da ci gaba da fasaha na ci gaba da inganta dabarun gudanarwa na shrinkage a cikin allurar.

Neman inganta masana'antar filastik? Teamungiyar Mfg ita ce abokiyar zama. Mun kware a cikin magance matsalolin gama gari kamar shrinkage, yana ba da sabbin hanyoyin ingantattun abubuwan da ke haɓaka duka kayan ado da ayyukan. Teamungiyar mu na masana an sadaukar da ita don isar da samfuran da suka wuce tsammaninku. Tuntube mu?

Faqs game da matattarar filastik

1. Me ke haifar da shrinkage a cikin yanayin allurar filastik?

Shirin shrinkage yana faruwa kamar yadda filastik yayi sanyi da kuma ƙarfafa a cikin mold. A lokacin sanyaya, da polymer Chain Cinadar, haifar da kayan don rage girman. Abubuwan kamar nau'in kayan aiki, zazzabi mold, da ƙimar sanyaya kai tsaye shafan matsayin shrinkage.

2. Yaya nau'in filastik ke shafar shrinkage?

Abubuwan da aka shimfiɗa daban-daban daban-daban. Rikicin Crystalline kamar polypropylene (PP) da nailan (PA) Gaba ɗaya ya mamaye tsarin kwalliya yayin sananniyar shrinkage tunda tsarinsu ba ya yin canji da yawa.

3. Ta yaya za a rage girman shrinkage a cikin allurar da aka yi?

Shrinkage zai iya rage girman yanayin aiki kamar su kara yawan kayan tattarawa, yana daidaita yanayin zafi da narke yanayin sanyi ta hanyar tsarin sanannun sanyaya ta hanyar tsarin sanyaya. Amfani da masu flers kamar 'yan bindiga na gilashin kuma suna rage shrinkage ta hanyar ƙarfafa polymer.

4. Ta yaya zane mai zane da kuma sashen geometry tasirin shrinkage?

Designerarancin ƙira da ɓangare na Geometry sosai yana shafar ƙyallen. Kauri a bangon bango mara kyau, matattara mai sanyaya hoto, ko kuma ƙofofin da ke tafe na iya haifar da bambanci daban-daban, yana haifar da warping ko murdiya. Kirkirar sassan tare da kauri bango ka kauri mai daidaitawa yana taimakawa sarrafa shrinkage.

5. Menene yawan shrinkage na riguna daban-daban?

Ruwan shrinkage ya bambanta dangane da filastik. Halittar gama gari sun hada da:

Polypropylene (PP): 1.0% - 2.5%

Nailan (PA6): 0.7% - 2.0%

ABS: 0.4% - 0.7%

Polycarbonate (PC): 0.5% - 0.7%