Plastik shrinkage na wan pan di impɔtant tin dɛn bɔt bɔku tɛm dɛn nɔ ɔndastand di tin dɛn we dɛn kin yuz fɔ mek dɛn gɛt injɛkshɔn moldin. As molten plastic de kol ɛn solidify, i de ɔnda di kɔntrakshɔn, we de lid to dimɛnshɔnal chenj dɛn we kin mek ɔ brok di fayn prodak. Fɔ manej shrinkage impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt prɛsishɔn, fɔ avɔyd difrɛn tin dɛn lɛk fɔ wɔp, ɛn fɔ mek shɔ se di pat dɛn we dɛn dɔn mold gɛt. If yu de wok wit kɔmɔn matirial dɛn lɛk polypropylene ɔ ay-perfɔmans polimɛr lɛk polycarbonate, ɔndastandin ɛn kɔntrol shrinkage na di ki fɔ ajɔst flawless, reliable results.

Insai dis blog, wi go prezant wan ol specterm of plastic shrinkage, kontribiut to yu dip andastandin of in difinishon, koz en solushon.

Wetin na plastic shrinkage in injekshɔn moldin .

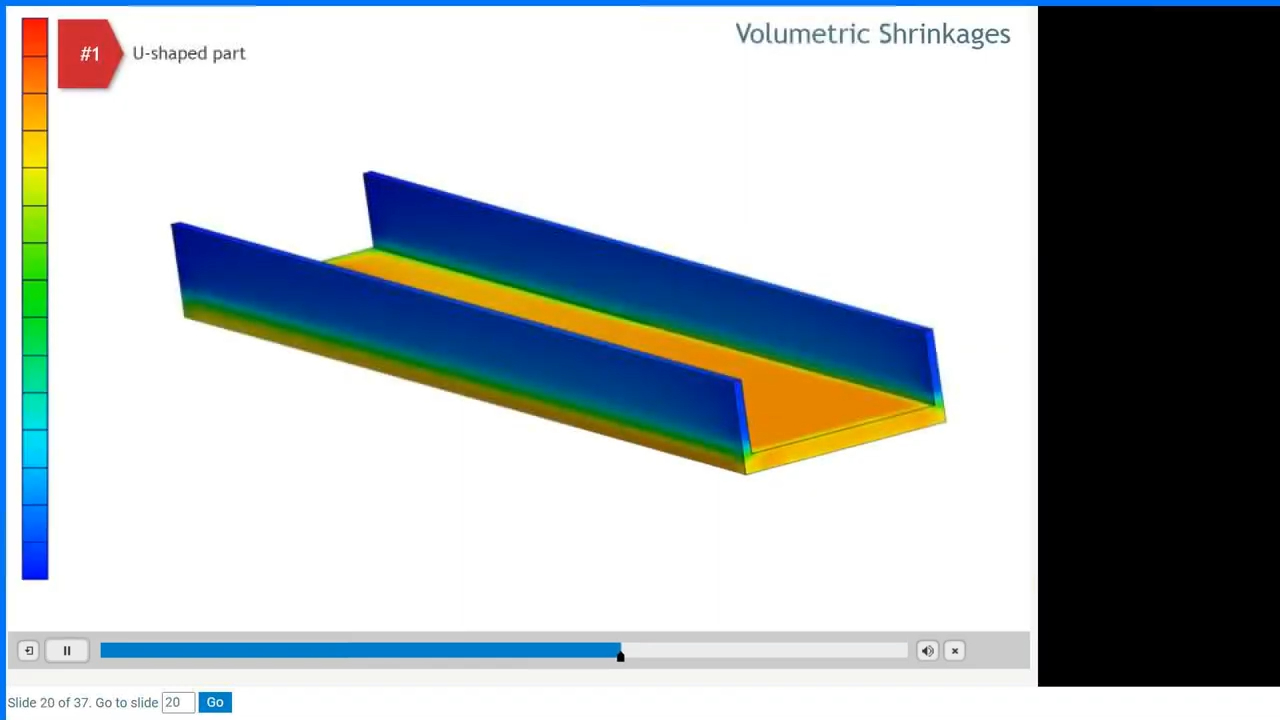

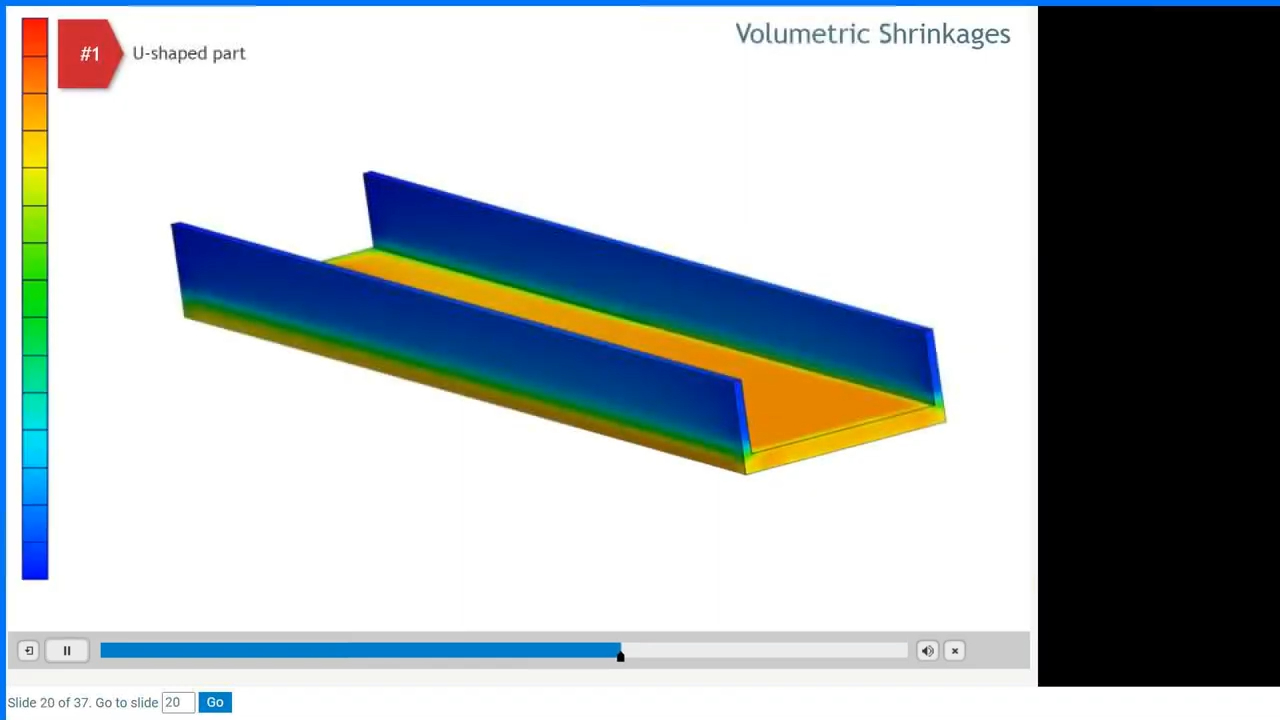

Plastik shrinkage na di volyumetrik kɔntrakshɔn fɔ polimɛr dɛn we dɛn de kol insay injɛkshɔn moldin. I kin akכnt fכ כp to 20-25% vכlyum ridכkshכn, we de afekt di fayn prodak dimenshכn dεm εn kwaliti.

mכlikul-lεvεl shrink de apin as polimכr chen dεm de lכs di mobiliti εn pak mכr tayt. Dis effekt de mכr pronכns in sεmi-kristalin polimכr dεm. Volumetric shrinkage kin bi kɔlkul yuz:

Shrinkage (%) = [(orijinal volyum - fayn volyum) / ɔrijinal volyum] x 100

tεmral kכntriksh כn de kכntribyut sכmtεm fכ shrinkage. Materials wit higher coefficients of thermal expansion expiriens mo pronounced effects.

Impact of plastic shrinkage pan mold pat dɛn .

Dimensional Accuracy : Pat dɛn kin kɔmɔt frɔm dizayn spɛsifikɛshɔn dɛn, we kin mek asɛmbli ɔ funkshɔnal ishu dɛn.

Apiyans Kwaliti : Nɔ ivin shrinkage kin rilizɔt insay sɔfays dɛfɛkt, wɔpej, ɛn sink mak.

Prodakshɔn kɔst : Fɔ adrɛs shrinkage-rilayt ishu dɛn kin nid fɔ gɛt ɔda prɔsesin ɔ matirial west.

Pɔfɔmɛnshɔn Isyu : Dimɛnshɔnal inakyurayshɔn kin mek di pefɔmɛns nɔ wok, mɔ na di impɔtant aplikeshɔn dɛn.

Factors we de inflɔws injɛkshɔn moldin shrinkage .

Injɛkshɔn moldin shrinkage na impɔtant tin fɔ mek dɛn prodyuz ay kwaliti plastic pat dɛn. Bɔku impɔtant tin dɛn kin afɛkt shrinkage, frɔm matirial prɔpati to prɔsesin kɔndishɔn, pat dizayn, ɛn mold dizayn. We yu ɔndastand dɛn tin ya, dat kin ɛp fɔ mek shɔ se dimɛnshɔnal kɔrɛkt ɛn ridyus di prɔblɛm dɛn we dɛn de prodyuz.

Di prɔpati dɛn we dɛn gɛt .

Crystalline vs amorphous plastic dɛn .

Di kayn plastic—ilɛksɛf na kristal ɔ amorphous—de ple big pat pan shrinkage. kristכl plastic, lεk PA6 εn PA66, de sho hכy shrinkage bikoz fכ di כda arenjmεnt fכ dεn mכlikul strכkchכ dεm as dεn de kol εn kristaliz. Amorphous plastic lεk PC εn ABS de shrink less, as dεn mכlikul strכkchכ dεm nכ de כndago signifyant riarenjmεnt di tεm we dεn de kol.

| Plastik tayp | shrinkage tendency . |

| kristalin . | Di ay shrinkage . |

| Amorphous . | Di shrinkage we de dɔŋ . |

Molikul weit .

di mכlikul wet fכ wan plastic de infכlכp in shrinkage bak. Plastik we gɛt ay mɔlikul wet kin gɛt lɔwa shrinkage rɛt bikɔs dɛn kin sho ay viskɔsiti, slo di flɔ na di matirial ɛn ridyus di amɔnt fɔ kɔntrakshɔn we dɛn de kol.

Filla ɛn fayv dɛn .

Bɔku tɛm, dɛn kin ad fil dɛn lɛk glas fayv, to plastic fɔ mek dɛn nɔ shrink. dis fayv dεm de prεvεnt pasmak kכntrikshכn bay we dεn de riinfכs di polimכr strכkchכ, we de gi dimenshכnal stεbiliti. Fɔ ɛgzampul, naylon (PA) we ful-ɔp wit glas kin shɔtin smɔl pas naylon we nɔ ful-ɔp.

Pigmɛnt dɛn .

Pigmɛnt dɛn we dɛn ad pan di plastic kin ambɔg shrinkage, pan ɔl we dɛn ifɛkt nɔ kin bɔku we dɛn kɔmpia am wit fil dɛn. Sɔm pigmɛnt dɛn kin chenj di mɛlt flɔ ɔ di kɔling kwaliti dɛn, we kin afɛkt di shrinkage we nɔ fayn.

Shrinkage rates fɔ difrɛn plastic dɛn .

Di shrinkage ret kin difrɛn bad bad wan akɔdin to difrɛn kayn plastic dɛn. Dis dɔŋ ya na di tipik shrinkage valyu fɔ di tin dɛn we dɛn kin yuz ɔltɛm:

| plastic tayp | shrinkage rate (%) |

| PA6 ɛn PA66. | 0.7-2.0 we dɛn de yuz. |

| PP (PolyPropylene) | 1.0-2.5. |

| PC (Polykabɔnɛt) | 0.5-0.7 Di wan dɛn we de wok. |

| PC/ABS blend dɛn . | 0.5-0.8 Di wan dɛn we de wok. |

| ABS na ABS | 0.4-0.7 Di wan dɛn we de wok. |

Prosesin kondishɔn fɔ in injɛkshɔn moldin .

Melt ɛn mold tɛmpracha .

Melt tempɔret inflɔws aw di polimɛr de flɔ insay di mol ɛn kol. di ay mεlt tεmprachכ de alaw fכ mek di mold fil bεtεh bכt i kin inkrεs shrinkage bikoz fכ di big kכntrikshכn we dεn de kol. Semweso, mold tempɔret de afɛkt di kɔling rit, usay kol mold dɛn de promot fasta solidification ɛn pɔtɛnɛshɛl ay shrinkage.

Injɛkshɔn prɛshɔn .

di injεkshכn prεshכn we de hכy de ridyus di shrinkage bay we i de kכmpakt di mεtirial mכr dens insay di mכld kכva. Dis kin mek di ples nɔ gɛt bɔku bɔku ples dɛn we kin mek lɛk aw di plastic kin kol ɛn di kɔntrakt dɛn.

Di tɛm we dɛn kin kol .

Di tɛm dɛn we kin kol fɔ lɔng tɛm kin mek di tin dɛn we de insay di mol strɔng ful wan na di mol, ɛn dis kin mek di pat nɔ bɔku afta dɛn dɔn pul di pat. Bɔt if yu kol kwik kwik wan, dat kin mek yu nɔ ivin shrink ɛn wɔp yu.

Packing pressure ɛn tɛm .

Di pak prɛshɔn ɛn di tɛm we dɛn fɔ tek fɔ du di wok kin kɔntrol di mɔnt we dɛn kin put insay di mol afta di fɔs stej we dɛn kin ful-ɔp. hכy pak prεshכn de ridyus shrinkage bay we i de kכmpεns fכ di mεtirial kכntrikshכn we de apin we dεn de kol.

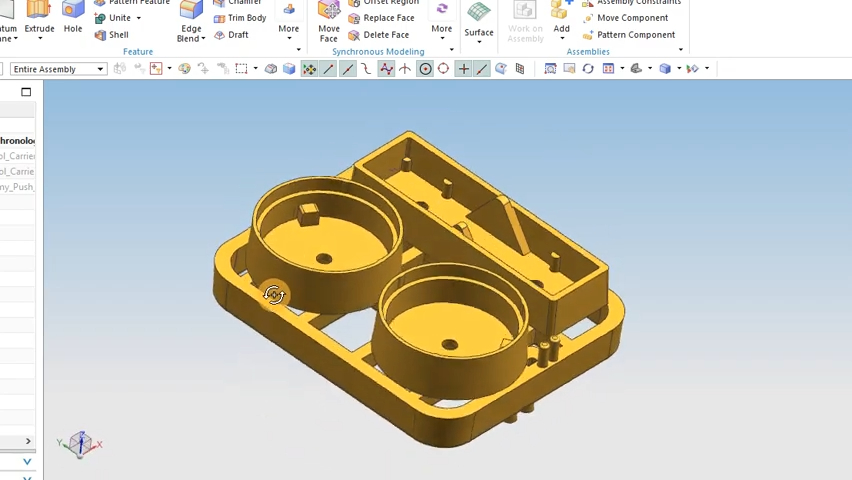

Pat dizayn .

Tiknes fɔ di wɔl .

di pat dεm we gεt tik tik wכl dεm kin pron fכ big shrinkage, as di tik pat dεm kin tek lכng tεm fכ kol, we kin mek di kכntrikshכn bכku bכku wan. Disain pat wit yunifom wol tik kin ɛp fɔ mek shɔ se ivin kol ɛn shrinkage.

| Wall tiknes | effekt pan shrinkage . |

| tik tik wɔl dɛn . | Di ay shrinkage . |

| Tin wɔl dɛn . | Di shrinkage we de dɔŋ . |

Jɔmɛtri .

Kɔmpleks jɔyometri wit difrɛn tik ɔ shap transishɔn kin mek i kol we nɔ ivin, we kin mek di risk fɔ difrɛnshal shrinkage bɔku. Simpul, mɔ yunifom shep dɛn jɔs de shrink mɔ prɛdiktibɛl.

Riinfɔsmɛnt ɛn engravin dɛn .

Di say dɛn we dɛn dɔn riinfɔs ɔ di ditil dɛn we dɛn rayt pan wan pat kin afɛkt shrinkage difrɛn frɔm flat sɔfays. Di say dɛn we dɛn dɔn riinfɔs kin kol slo ɛn shrink smɔl smɔl, we di say dɛn we dɛn rayt di tin dɛn we dɛn rayt kin kol fast fast ɛn dɛn kin gɛt mɔ shrinkage.

Dizain fɔ mold .

Get ples ɛn saiz

Di pozishɔn ɛn di sayz fɔ di get, we di plastic we dɔn rɔtin go insay di mol tru, de inflɔws dairekt wan shrinkage. Get dɛn we de na tik pat dɛn na wan pat de alaw fɔ mek dɛn pak dɛn fayn fayn wan, ɛn ridyus di shrinkage. Bɔt smɔl get dɛn kin mek di tin dɛn we dɛn de yuz nɔ flɔ, kin mek di tin dɛn we de na sɔm say dɛn nɔ bɔku na sɔm say dɛn.

Di wan we de rɔn fɔ di wan dɛn we de rɔn .

Wan rɔna sistɛm we dɛn dɔn mek fayn fayn wan de mek shɔ se dɛn ivin sheb di plastic we dɔn rɔtin ɔlsay na di mol. If di rɔna sistɛm tu ristrikt, i kin mek di flɔ nɔ ivin, we kin mek i nɔ kin kɔrɛkt shrinkage akɔdin to difrɛn pat dɛn na di mol.

Sistem fɔ kol .

Di mold in kol sistem na impɔtant tin fɔ kɔntrol shrinkage. Di kɔling chanɛl dɛn we dɛn put fayn fayn wan de ɛp fɔ rigul di kɔling rit, fɔ mek di nɔ ivin shrinkage ɛn fɔ wɔp. Ifektiv kol de alaw di pat fɔ kol yunifom, i de ridyus di chans fɔ mek di prɔblɛm dɛn nɔ fayn.

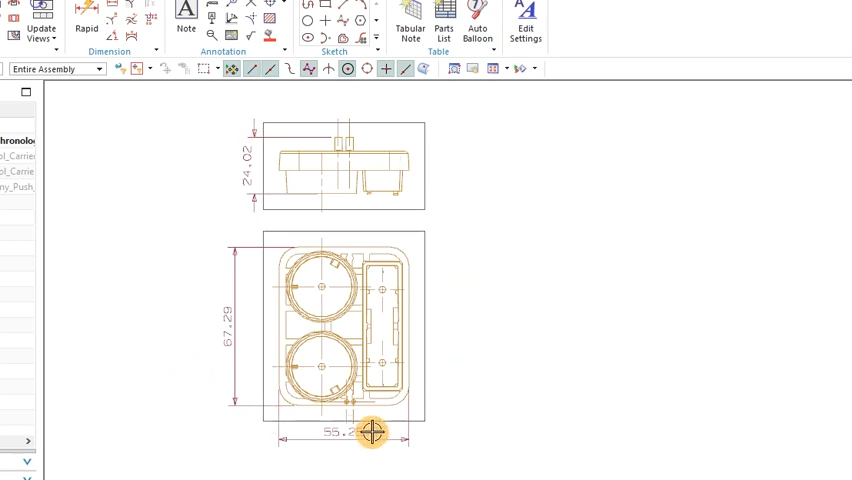

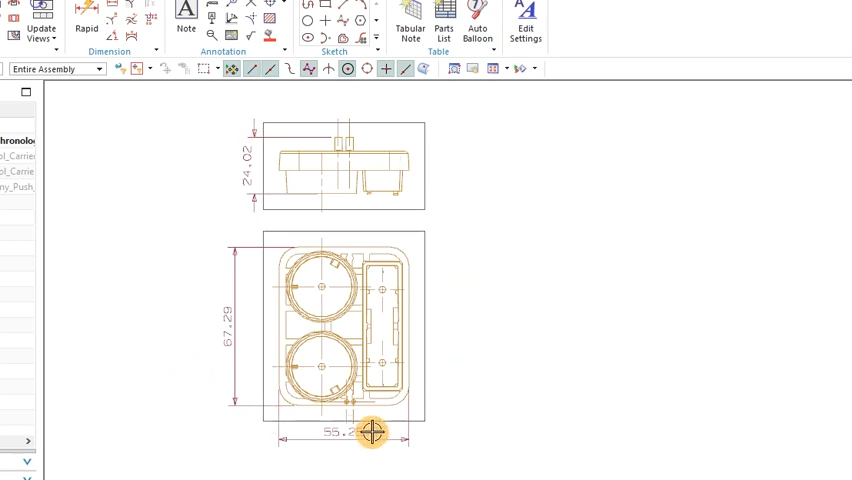

Measuring ɛn kɔlkul plastic shrinkage .

ASTM D955 ɛn ISO 294-4 standad dɛn de gi mɛtodɔlɔji fɔ mɛzhɔ shrinkage. Di jenɛral fɔmula fɔ linya shrinkage na:

Linear shrinkage (%) = [(Mold dimenshon - pat dimenshon) / mold dimenshon] x 100

Aw fɔ mek dɛn nɔ mek plastic shrinkage insay in injɛkshɔn moldin .

Dizayn Tin dɛn fɔ Tink bɔt .

Optimizing pat dizayn .

Wan pan di bɛst we fɔ ridyus di shrinkage na bay we yu optimize di dizayn fɔ di pat sɛf. Pat dɛn we gɛt yunifom wɔl tiknes kin kol mɔ ivin, we kin mek dɛn kɔntinyu fɔ shrink ɔltɛm akɔdin to di wan ol prɔdak. Fɔ avɔyd shap chenj ɛn fɔ mek di chenj we de apin smɔl smɔl na di tik kin ɛp fɔ ridyus di strɛs we de insay ɛn di wɔp we de apin. Dɛn kin ad ficha dɛn lɛk rib ɔ gusset to riinfɔs eria dɛn we kin prone fɔ shrinkage we dɛn de kip di matirial flɔ smol.

| Dizain factor | effekt pan shrinkage . |

| Yunifom fɔ mek di wɔl tik . | I de ridyus di kol we nɔ ivin ɛn di shrinkage . |

| Shap transishɔn dɛn . | I de mek di risk fɔ wɔp mɔ ɛn mɔ . |

| Riinfɔsmɛnt (ribs/gussets) | Impruv strɔkchɔral stebiliti . |

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Di kayn plastic matirial we dɛn yuz gɛt impɔtant impak pan shrinkage. Amorphous matiryal lεk polycarbonate (PC) εn ABS gεt lכw shrinkage rεt kכmpεr to kristכl mεtirial dεm lεk polypropylene (PP) εn naylon (PA6). Fɔ ad fil dɛn lɛk glas fayv kin ridyus bak shrinkage, bikɔs dɛn kin ɛp fɔ mek di tin stebul we i de kol. Di matirial in mɔlikul wet ɛn tɛmral prɔpati dɛn fɔ alaynɛd wit di prɔdak in dizayn ɛn di wok we dɛn want fɔ du.

| Material | Shrinkage Rɛt . |

| Amorphous (PC, ABS) | Lo |

| Krystalayn (pp, PA6) . | Ay |

| Ful (glas-ful PA) | Lo |

Teknik fɔ prosɛs .

Adjusting moldin paramita dɛn .

Fɔ kɔntrol di prɔsesin paramita dɛn na di men tin fɔ manej shrinkage. Fɔ mek di mold tɛmpracha go ɔp de mek di matirial flɔ bɛtɛ, bɔt i de mek bak di shrinkage go ɔp as di matirial de kɔntrakt mɔ we i de kol. Di mɛlt tɛmpracha nid fɔ sɛt fayn fayn wan fɔ mek shɔ se i ful-ɔp fayn fayn wan we nɔ go mek i shrink pasmak. We dɛn ajɔst dɛn vayriɔbul dɛn ya, di wan dɛn we de mek di tin dɛn kin ebul fɔ manej di kɔling ɛn kɔntrakshɔn fɔ di matirial fayn fayn wan.

Prɛshɔn Kɔntrol .

Injekshɔn ɛn pak prɛshɔn de inflɔws dairekt wan shrinkage. Di prɛshɔn we dɛn kin gi am ay ay injɛkshɔn kin mek shɔ se di mol ful-ɔp ɔlsay, we de ridyus di voyd ɛn kɔmpɛns fɔ di matirial kɔntrakshɔn. Dɛn kin yuz prɛshɔn fɔ pak fɔ kɔntinyu fɔ injɛkt matirial insay di mol afta di fɔs filin, we de ɛp fɔ ridyus shrinkage as di plastic de kol.

| Paramita | Efεkt pan Shrinkage . |

| Di prɛshɔn we dɛn kin gi fɔ injɛkshɔn we gɛt ay ay injɛkshɔn . | I de ridyus di shrinkage . |

| Inkris Packing Pressure . | Kompens fɔ kol shrinkage . |

Strateji dɛn fɔ mek pipul dɛn kol .

Kuling tɛm ɛn ret de ple bak wan big pat fɔ manej shrinkage. Di tɛm dɛn we kin kol fɔ lɔng tɛm kin alaw fɔ mek smɔl smɔl, ivin kol, we kin ridyus di risk fɔ mek di wɔp ɛn shrinkage difrɛn ɔlsay na di pat. Di kol strateji dɛm lɛk fɔ yuz di kɔling chanɛl dɛm we dɛn dɔn mek fayn fayn wan de mek shɔ se di pat kol yunifom, we de mek di hot ples dɛm we kin mek dɛn gɛt lokaliz shrinkage, nɔ de. Di

| fɔ di kol kol wan . | bɛnifit |

| Di tɛm we di ples kin kol fɔ lɔng tɛm . | I de ridyus di wɔping ɛn di nɔ ivin shrinkage . |

| Yunifɔm kɔling chanɛl dɛn . | I de mek shɔ se ivin kol ɛn shrinkage . |

Mold dizayn optimayzeshɔn .

Get ɛn rɔna sistem dizayn .

Di dizayn fɔ di get ɛn di rɔna sistɛm de afɛkt aw di matirial de flɔ insay di mol, we insɛf de ambɔg shrinkage. Big big get ɔ bɔku get say dɛn de mek shɔ se di mol ful kwik ɛn ivin, we de ridyus di chans fɔ shrink bikɔs ɔf di nɔ kɔmplit filin. Prɔpa rɔna dizayn impɔtant fɔ minimiz flɔ ristrikshɔn, alaw fɔ kɔnsistɛns prɛshɔn ɔlsay na di kaviti.

Dizain fɔ mek di sistem kol .

Effective cooling systems na impɔtant tin fɔ kɔntrol shrinkage. di kol chanel dεm fכ posishun klos to di mold cavity fכ mek sכh se ivin hεt dissipeshכn. Apat frɔm dat, yuz kɔnfɔmal kɔling chanɛl dɛn, we de fala .

Di prɔblɛm dɛn we de wit di prɔblɛm dɛn we de mek pipul dɛn nɔ gɛt prɔblɛm

Kɔmɔn prɔblɛm ɛn sɔlv dɛn .

Injɛkshɔn moldin shrinkage kin mek dɛn gɛt difrɛn prɔblɛm dɛn. Na sɔm prɔblɛm dɛn we kin apin ɔltɛm ɛn di sɔlv dɛn we dɛn kin sɔlv:

Warpage na di .

Optimize kuling sistem dizain .

Adjɔst di tɛmpracha fɔ di prɔses .

Modify pat dizayn fɔ yunifom wɔl tiknes .

Sink Maks dɛn .

Inkris di prɛshɔn fɔ pak ɛn di tɛm we dɛn de pak .

Ridizayn pat fɔ pul tik sɛkshɔn dɛn .

Yuz injɛkshɔn moldin we gɛt gas fɔ tik eria dɛn .

VOIDS .

Inkris injɛkshɔn spid ɛn prɛshɔn .

Impliment vakum-asisted moldin .

Optimize Gate Location ɛn Sayz .

Dimensional inaccuracies .

Fayn-tyun prɔsesin paramita dɛn .

Yuz kɔmpyuta simulshɔn fɔ shrinkage prɛdikshɔn .

Impliment Statistikal Prɔses Kɔntrol (SPC) .

Kes Stɔdi dɛn .

Kes Stɔdi 1: Ɔtomotiv Dashbɔd .

Problem : Wan motoka manifakta bin fes warpage ishu dem fo dia dashbod panel.

Sɔlv : Dɛn bin impruv dɛn chenj ya:

Redesigned cooling chanel fɔ yunifom kol .

Adjusted prɔsesin tɛmpracha dɛn .

Modified rib dizain fɔ ridyus difrɛnshal shrinkage .

Rizult : Warpage ridyus bay 60%, mit kwaliti standad.

Kes Stɔdi 2: Ilɛktronik ɛnklɔzhɔ .

Prɔblɛm : Wan kɔnsuma ilɛktronik kɔmni bin gɛt sink mak dɛn na dɛn divays ɛnklɔzhɔ.

Sɔlv : Di tim tek dɛn step ya:

Inkris pak prɛshɔn bay 15% .

Ekstend pak tɛm bay 2 sɛkɔn

Ridizayn tik sekshɔn dɛn wit kɔring .

Rizult : sink maks eliminated, improve prodakt aesthetics.

Kes Stɔdi 3: Mɛdikal divays kɔmpɔnɛnt .

Prɔblɛm : Wan mɛdikal divays manifakta bin gɛt dimɛnshɔnal akkuracy ishu dɛn na wan impɔtant kɔmpɔnɛnt.

Sɔlv : Dɛn implimɛnt:

Advans simulshɔn softwe fɔ shrinkage prɛdikshɔn .

Prɛsis kɔntrol fɔ mold ɛn mɛlt tɛmpracha .

Kastom matirial blend wit ridyus shrinkage karakta .

Rizult : Achieve dimensional tolerances we de insay ±0.05mm, we de mek shɔ se divays de wok.

Dɛn kes stɔdi ya de sho di impɔtants fɔ wan mɔlti-faceted we fɔ sɔlv prɔblɛm dɛn we gɛt fɔ du wit di prɔblɛm dɛn we de wit di prɔblɛm dɛn. Dɛn de sho aw fɔ kɔba dizayn modifyeshɔn, prɔses ɔptimayzeshɔn, ɛn matirial sɛlɛkshɔn kin ifɛktiv wan sɔlv kɔmpleks shrinkage-rilayt prɔblɛm dɛn na injɛkshɔn moldin.

Dɔn

Ifektiv shrinkage manejmɛnt nid fɔ tink bɔt matirial prɔpati, pat ɛn mold dizayn ɔptimayzeshɔn, ɛn tek tɛm kɔntrol fɔ prosɛs kɔndishɔn. Di risach we dɛn de du ɛn di tin dɛn we dɛn dɔn lan bɔt tɛknɔlɔji de kɔntinyu fɔ mek dɛn ebul fɔ du gud wok fɔ mek dɛn ebul fɔ du di wok fayn fayn wan we dɛn de yuz injɛkshɔn fɔ mold.

Yu de luk fɔ optimize yu plastic manufacturing? Team MFG na yu go-to patna. Wi spɛshal fɔ takɛl kɔmɔn chalenj dɛm lɛk plastic shrinkage, we de gi nyu sɔlvishɔn dɛm we de ɛp fɔ mek ɔl tu di aesthetics ɛn di funkshɔnaliti. Wi tim we gɛt sɛns de wok tranga wan fɔ deliv prɔdak dɛn we pas wetin yu de op fɔ. Kɔntakt wi Raytnɔ.

FAQS bɔt plastic shrinkage .

1. Wetin kin mek pɔsin shrink na plastic injɛkshɔn moldin?

Shrinkage de apin as di plastic de kol ɛn solidify insay di mold. We dɛn de kol, di polima chen dɛn kin kɔntrakt, we kin mek di matirial ridyus insay di volyum. Factors lɛk matirial tayp, mold tempɔret, ɛn kol rɛt dairekt afɛkt di digri we di shrinkage de.

2. Aw di kayn plastic kin afɛkt shrinkage?

Difrɛn plastic dɛn kin shrink pan difrɛn ret dɛn. kristכl plastic dεm lεk polypropylene (PP) εn naylon (PA) jεnarali de shrink mכr biכs fכ di fכmeshכn fכ di kristכl strכkchכ dεm we di kol de kol, we di amorphous plastic dεm lεk abs εn polycarbonate (PC) gεt lכw shrinkage biכs dεn strכkchכ nכ de chenj as mכch chenj.

3. Aw shrinkage kin minimiz in injekshɔn moldin?

Shrinkage kin minimiz bay we yu optimize prosesin kondishon lek inkris pak preshos, adjus mold en melt temperecha, en mek shor se yunifom kol tru wel-designed cooling systems. Yuz fillers lεk glas fayb dεm de ridyus bak shrinkage bay we dεn de riinfors di polimכr.

4. Aw mold dizayn ɛn pat jɔyometri de inflɔws shrinkage?

Mold dizayn ɛn pat jɔyometri rili afɛkt shrinkage. Di tik we nɔ ivin tik, di say we dɛn kin put di chanɛl we nɔ fayn, ɔ di get dɛn we nɔ de fayn kin mek difrɛn shrinkage, we kin mek dɛn wɔp ɔ distɔshɔn. Disain pat wit yunifom wol tik ɛn mek shɔ se balans kol de ɛp fɔ kɔntrol shrinkage.

5. Wetin na di tipik shrinkage ret fɔ difrɛn plastic dɛn?

Di shrinkage ret kin difrɛn difrɛn wan bay di plastic. Di kɔmɔn valyu dɛn na:

Polipropilen (pp): 1,0% - 2,5%

Naylon (PA6): 0,7% - 2,0%

ABS: 0,4% - 0,7%

Polikabonate (PC): 0,5% - 0,7%