Plastiki dɔgɔyali ye pikiri kɛcogo ye min nafa ka bon kosɛbɛ, nka a ka ca a la, a ka teli ka faamuya. Ni plastiki wulilen bɛ nɛnɛ ani ka sabati, a bɛ kɛ ni jiginni ye, o bɛ na ni fɛn laban yeli ye min bɛ se ka fɛn laban dilan walima k’a tiɲɛ. Dɔgɔyali ɲɛnabɔli nafa ka bon walasa ka tiɲɛni mara, ka i yɛrɛ tanga fiɲɛw ma i n’a fɔ sɛgɛn, ani ka yɔrɔ mɔlenw dafalen sabati. I bɛ baara kɛ ni fɛn caman ye i n’a fɔ poliporopilini walima polimɛri minnu bɛ baara kɛ kosɛbɛ i n’a fɔ polikarbonati, dɔgɔyali faamuyali ani a kunbɛnni ye fɛnba ye min bɛ se ka kɛ sababu ye ka jateminɛ dafalen sɔrɔ, min bɛ se ka da a kan.

Nin bulɔgu in kɔnɔ, an bɛna plastiki dɔgɔyali suguya bɛɛ jira, k’aw ka faamuyali jugu sɔrɔ a ɲɛfɔli, a sababuw ani a furakɛcogo kan.

Mun ye plastiki dɔgɔyali ye pikiri kɛli la .

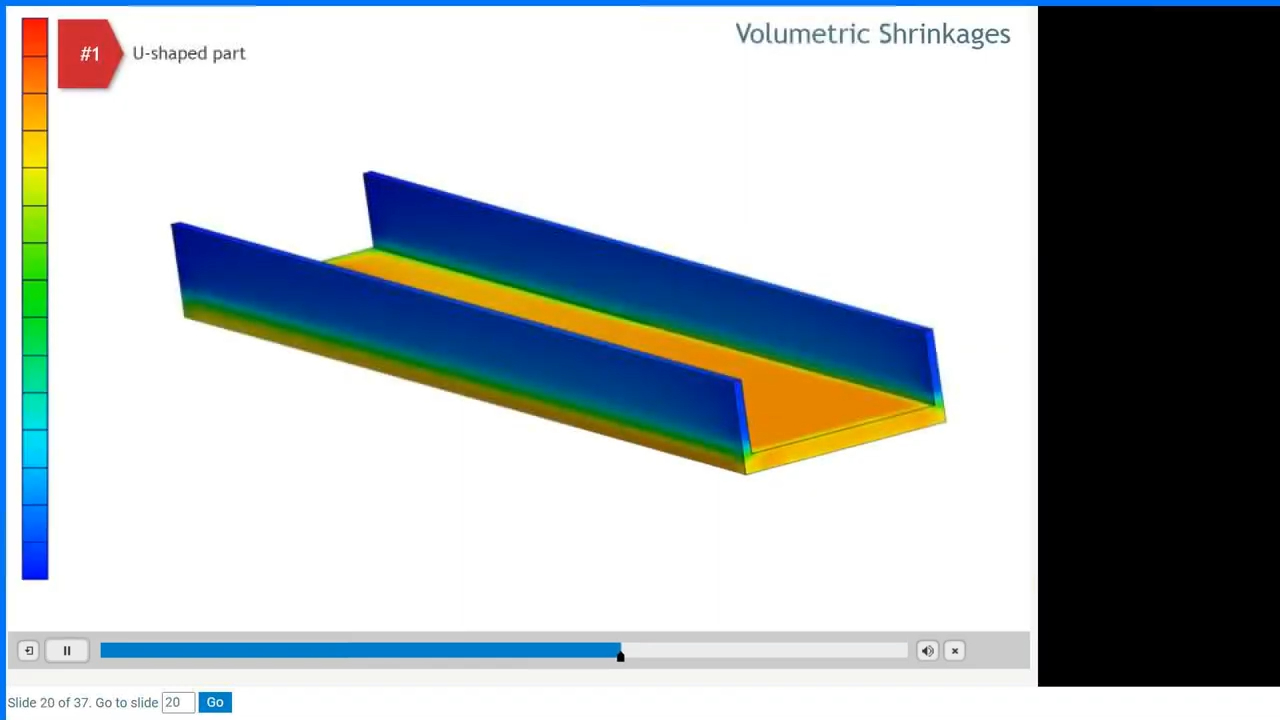

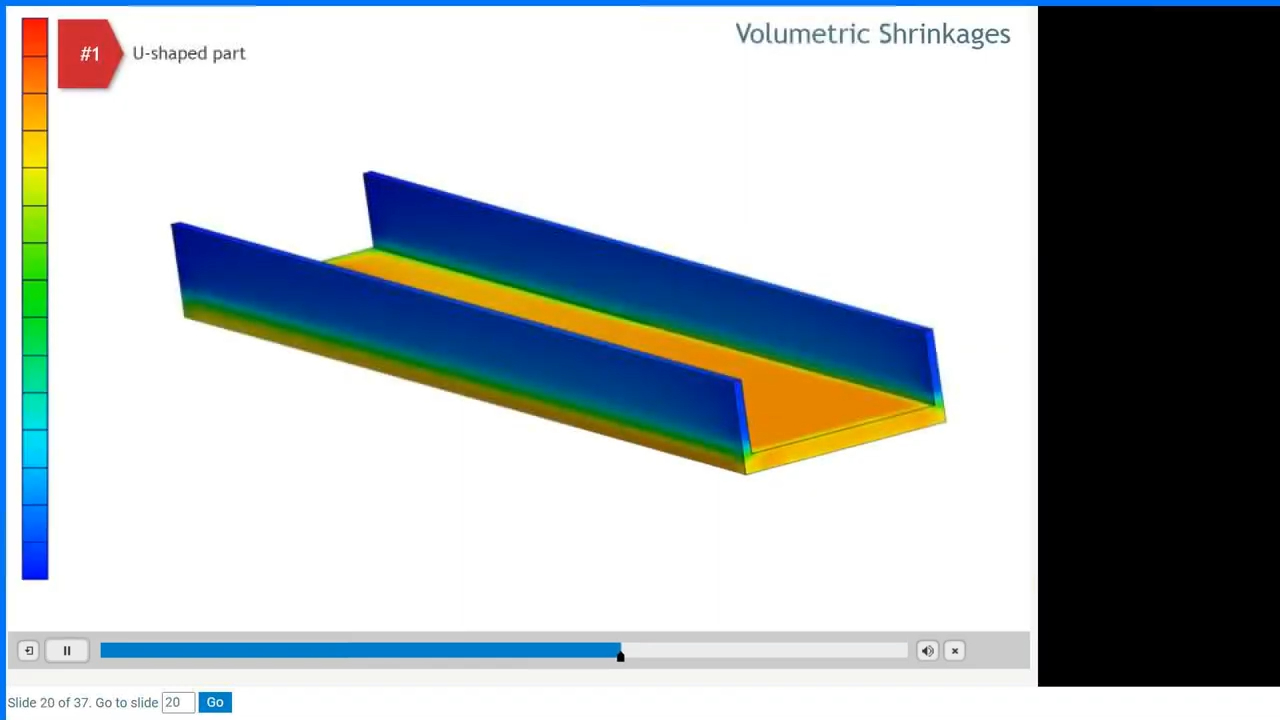

Plastiki dɔgɔyali ye polimɛriw ka volumɛtriki sɔgɔli ye nɛnɛ waati la pikiri kɛli la. A bɛ se ka kɛ fo ka se 20-25% hakɛ dɔgɔyali ma, o bɛ nɔ bila fɛn labanw hakɛ ni a jogo la.

Molecules-level shrinkage bɛ kɛ iko polimɛri cakɛdaw bɛ bɔnɛ u ka taama na ani ka u pake ka ɲɛ. O nɔ in bɛ ye ka ɲɛ polimɛriw la minnu bɛ wele ko semi-crystalline. Volumetrique shrinkage bɛ se ka jate ni:

dɔgɔyali (%) = [(sariyasen fɔlɔ - volume laban) / volume originale] x 100 .

Sumaya bɛ kɛ sababu ye ka dɔgɔya kosɛbɛ. Fɛn minnu ka funteni bonya hakɛ ka bon, olu bɛ nɔ caman sɔrɔ.

Plastiki dɔgɔyali nɔ min bɛ sɔrɔ yɔrɔw la minnu dilannen don .

Dimensional accuracy : Yɔrɔw bɛ se ka bɔ dilancogo ɲɛfɔliw la, ka kɛ sababu ye ka ɲɔgɔn lajɛ walima ka baara kɛ.

Yecogo ɲuman : Dɔgɔyali min tɛ kelen ye, o bɛ se ka kɛ sababu ye ka dugukolo sanfɛla tiɲɛniw, kɛlɛw, ani jisigiyɔrɔw taamasiɲɛw sɔrɔ.

Fɛn dilanni musakaw : Ka ɲɛsin fɛnw dɔgɔyali ma minnu bɛ tali kɛ fɛnw dɔgɔyali la, tuma caman na, o bɛ baara wɛrɛw walima fɛnw tiɲɛni de wajibiya.

Baarakɛcogo koɲɛw : Dimensionnel inaccuracies bɛ se ka kɛ sababu ye ka baara kɛcogo dɛsɛ, kɛrɛnkɛrɛnnenya la baara gɛlɛnw na.

Fɛn minnu bɛ se ka kɛ sababu ye ka pikiri kɛcogo dɔgɔya .

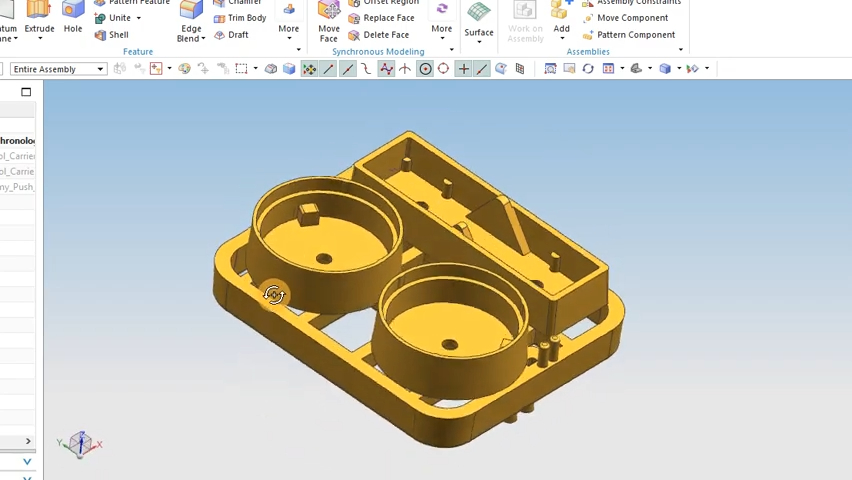

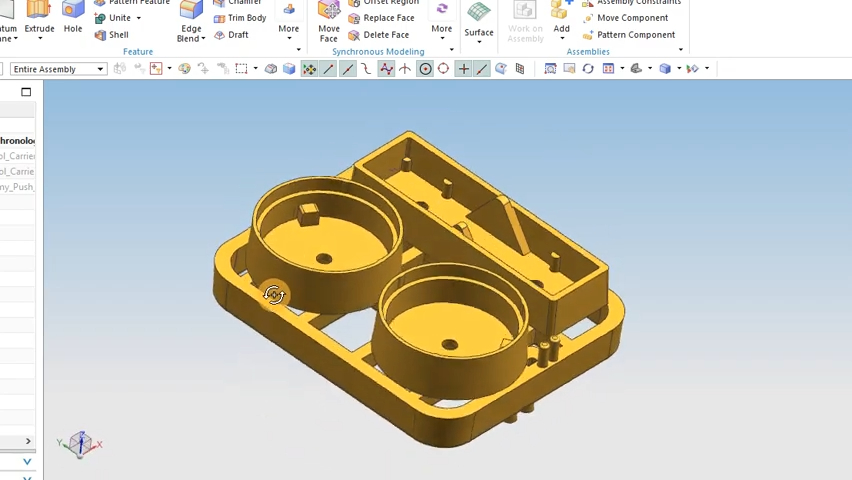

Pikiriw dilanni dɔgɔyali ye fɛnba ye min bɛ kɛ ka plastiki yɔrɔw dilan minnu ka ɲi kosɛbɛ. Fɛn jɔnjɔn caman bɛ nɔ bila dɔgɔyali la, k’a ta fɛnw cogoyaw la ka taa a bila baarakɛcogo la, a yɔrɔ dɔw dilanni na, ani a dilanni na. Nin ko ninnu faamuyali bɛ dɛmɛ ka dimension (hakilila) tiɲɛni sabati ani ka fiɲɛw dɔgɔya u dilanni senfɛ.

Material Propriétés .

Kristali Vs Plastics amorphes .

Plastiki suguya — a kɛra kristalɛ ye wo, a kɛra a tɛ kɛ cogo min na wo, a jɔyɔrɔ ka bon kosɛbɛ a dɔgɔyali la. Plastiki kristalɛw, i n’a fɔ PA6 ani PA66, olu bɛ dɔgɔyaliba jira k’a sababu kɛ u ka molekiyɔmuw jɔcogo labɛnni ye cogo labɛnnen na n’u bɛ nɛnɛ ani n’u bɛ kristalize. Plastiki amorphes i n’a fɔ PC ani ABS bɛ dɔgɔya dɔɔnin, bawo u ka molekiyɔmuw jɔcogo tɛ labɛn kokura kosɛbɛ nɛnɛ waati.

| Plastiki suguya | dɔgɔyali ŋaniya . |

| Kristalline . | shrinkage haute . |

| Amorphe . | shrinkage low . |

Molecules girinya .

Plastiki molekiyɔmu girinya fana bɛ nɔ bila a dɔgɔyali la. Plastiki minnu girinya ka bon, olu ka teli ka dɔgɔya hakɛ la bawo u bɛ sɔgɔli caman jira, u bɛ fɛn in bolicogo sumaya ani ka a jiginni hakɛ dɔgɔya nɛnɛ waati.

Fillers ani fibres .

Filɛlikɛlanw, i n’a fɔ gilasi fiyɛw, olu ka teli ka fara plastiki kan walasa ka dɔ bɔ u dɔgɔyali la. O fiɲɛw bɛ sɔgɔsɔgɔninjɛ kojugu bali ni polimɛri jɔcogo barika bonya ye, ka dimension stabilité di. Misali la, nilon (PA) min falen bɛ gilasi la, o bɛ dɔgɔya kosɛbɛ ka tɛmɛ nylon fabali kan.

Pigments .

Pigments minnu bɛ fara plastiki kan, olu bɛ se ka nɔ bila dɔgɔyali la, hali ni u nɔ bɛ ye ka caya ni a bɛ tali kɛ fasaw la. Pigment dɔw bɛ se ka wuli walima ka nɛnɛ cogoya Changer, ka nɔ bila a dɔgɔyali la cogo nɔgɔman na.

dɔgɔyali hakɛw ka ɲɛsin plastiki suguya caman ma .

Dɔgɔyali hakɛw bɛ danfara ka caya plastiki suguya wɛrɛw kɔnɔ. Nin ye fɛnw ye minnu bɛ kɛ ka fɛnw dɔgɔya, olu bɛ sɔrɔ fɛnw na minnu bɛ kɛ ka caya:

| plastiki suguya | dɔgɔyali hakɛ (%) . |

| PA6 ani PA66 . | 0,7-2,0. |

| PP (polypropilene) . | 1,0-2,5 ye. |

| PC (polycarbonate) . | 0,5-0,7 ye. |

| PC/ABS ɲagaminenw . | 0,5-0,8 ye. |

| ABS . | 0,4-0,7 ye. |

IN INGININCE MOLDING BAARAW ƝƐNABƆLI SENFƆLI .

Aw bɛ a wuli ani ka a mɔ .

Funteni min bɛ wuli, o bɛ nɔ bila polimɛri bɛ woyo cogo min na ka don nɔgɔ la ani ka nɛnɛ. Funteni minnu bɛ wuli ka caya, olu bɛ kɛ sababu ye ka mɔni fa ka ɲɛ nka u bɛ se ka dɔ fara u dɔgɔyali kan ka da a kan u bɛ se ka wuli ka caya nɛnɛ waati. O cogo kelen na, nɔgɔ funteni bɛ nɔ bila nɛnɛ hakɛ la, yɔrɔ min na, nɔgɔ nɛnɛmanw bɛ a to solidifikatɛri teliya la ani a bɛ se ka dɔgɔya.

Pikiri tansiyɔn .

Pikiri tansiyɔn ka bon, o bɛ dɔ bɔ a dɔgɔyali la ni a bɛ kɛ ka fɛn in sɔgɔ ka caya nɔgɔbɔlan kɔnɔ. O bɛ yɔrɔ lakolon hakɛ dɔgɔya min bɛ se ka kɛ ni plastiki bɛ nɛnɛ ani ka kontra kɛ.

nɛnɛ waati .

Nɛnɛ waati janw bɛ a to fɛn in ka se ka gɛlɛya ka a dafa nɔgɔ la, ka dɔ bɔ a dɔgɔyali la a yɔrɔ bɔlen kɔfɛ. Nka, nɛnɛ teliya kojugu bɛ se ka kɛ sababu ye ka dɔgɔya ani ka kirin.

Paki degun ni waati .

Paki tansiyɔn ni a kuntaala bɛ fɛn hakɛ min pikiri kɛ foroko kɔnɔ, o bɛ a fa waati fɔlɔ kɔfɛ. Paki tansiyɔn jiginni bɛ dɔ bɔ a dɔgɔyali la ni a bɛ kɛ ni fɛnw jiginni ye nɛnɛ waati.

Yɔrɔ min bɛ kɛ ka fɛnw dilan .

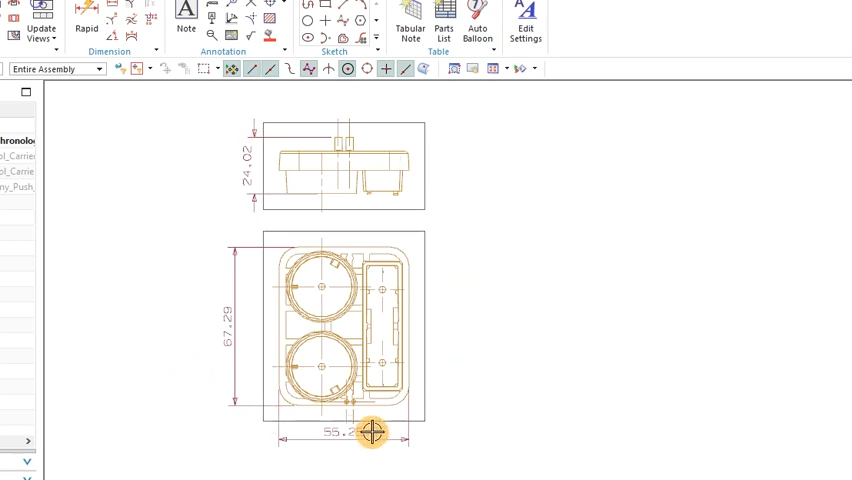

Kogo ka bon .

Yɔrɔ minnu kogow ka bon, olu ka teli ka dɔgɔya, bawo yɔrɔ minnu ka bon, olu bɛ waati jan ta ka nɛnɛ, o bɛ na ni u jiginni ye kosɛbɛ. Ni aw ye yɔrɔw dilan ni kogo janya ye kelen ye, o bɛ se ka dɛmɛ don hali ni a bɛ nɛnɛ ani ka dɔgɔya.

| Kogo janya | nɔ min bɛ sɔrɔ dɔgɔyali la . |

| Kogow ka bon . | shrinkage ka bon . |

| Kogo finmanw . | dɔgɔyali dɔgɔyali . |

Geometri .

Jateminɛ gɛlɛnw ni u janya tɛ kelen ye walima ni u jiginni ka nɔgɔn, olu ka teli ka kɛ nɛnɛ ye min tɛ kelen ye, o bɛ dɔ fara danfara dɔgɔyali farati kan. Siginiden nɔgɔmanw, minnu bɛ kɛ kelen ye, a ka c’a la, olu bɛ dɔgɔya ka ɲɛ.

Barokunw ni jaw .

Yɔrɔ minnu barika ka bon walima kunnafoni jalenw yɔrɔ dɔ kan, olu bɛ se ka nɔ bila dɔgɔyali la cogo wɛrɛ la ka tɛmɛ yɔrɔ fla kan. Yɔrɔ minnu barika ka bon, olu bɛ se ka nɛnɛ dɔɔni dɔɔni ani ka dɔgɔya, ka sɔrɔ yɔrɔ minnu jalen don, olu bɛ se ka nɛnɛ joona ani ka dɔgɔya ka taa a fɛ.

Mold design .

Gate yɔrɔ ani a bonya .

Da in jɔyɔrɔ n’a bonya, plastiki sɔgɔlen bɛ don foroko kɔnɔ min fɛ, o bɛ nɔ bila a yɛrɛ la ka dɔgɔya. Da minnu bɛ yɔrɔ dɔ la, yɔrɔ minnu ka bon, olu bɛ kɛ sababu ye ka fɛnw falen ka ɲɛ, ka dɔ bɔ u dɔgɔyali la. Faan wɛrɛ fɛ, da misɛnniw bɛ se ka dan sigi fɛnw bolicogo la, o bɛ na ni dɔgɔya ye yɔrɔ dɔw la.

Bololabaarakɛlaw ka sigida .

Bololabaarakɛla ka fɛɛrɛ min dilannen don koɲuman, o bɛ a to a ka kɛ ni plastiki wulilen ye ka a tilatila ka a tila. Ni bolibagaw ka sigida bɛ dankari kojugu, o bɛ se ka kɛ sababu ye ka jibɔ kɛ cogo la min tɛ kelen ye, o bɛ kɛ sababu ye ka dɔ bɔ ɲɔgɔn na nɔgɔ yɔrɔw la minnu tɛ kelen ye.

Cooling System .

Moli ka nɛnɛbɔlan nafa ka bon kosɛbɛ walasa ka a dɔgɔya. Nɛnɛ siraw minnu bilalen don ka ɲɛ, olu bɛ dɛmɛ ka nɛnɛ hakɛ labɛn, ka dɔgɔyali ni sɛgɛnbaliya bali. Nɛnɛ nafama bɛ a to a yɔrɔ bɛ nɛnɛ cogo kelen na, o bɛ dɔ bɔ fiɲɛ hakɛ la.

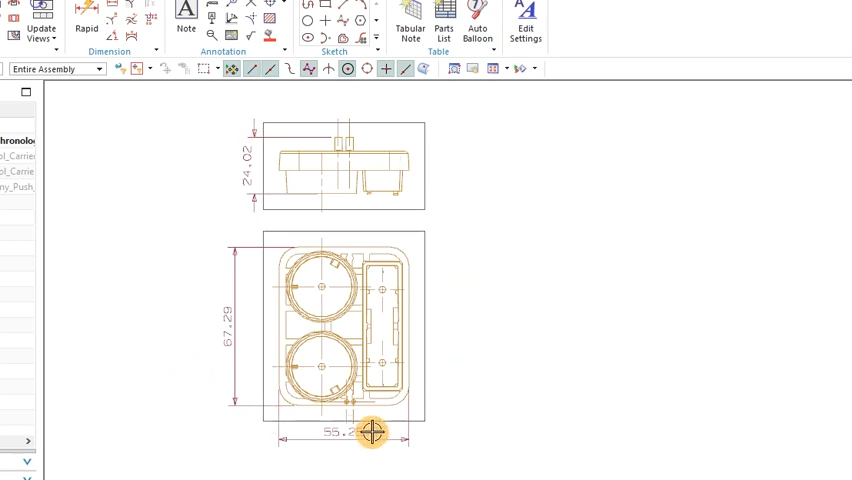

Plastiki dɔgɔyali sumani ni jatebɔ .

ASTM D955 ani ISO 294-4 sariyaw bɛ fɛɛrɛw di walasa ka dɔgɔyali suman. Formula général de shrinkage lineaire ye:

Linear shrinkage (%) = [(mold dimension - part dimension) / moule dimension] x 100 .

Cogo min na ka plastiki dɔgɔya in in injection molding .

Dilanko jateminɛw .

Optimizing part design .

Fɛɛrɛ ɲuman minnu bɛ se ka kɛ walasa ka dɔ bɔ dɔgɔyali la, olu dɔ ye ka a yɔrɔ yɛrɛ dilanni ɲɛ ka ɲɛ. Yɔrɔ minnu kogow janya bɛ kɛ kelen ye, olu bɛ nɛnɛ cogo kelen na, o bɛ kɛ sababu ye ka fɛn bɛɛ lajɛlen dɔgɔya tuma bɛɛ. Ni aw bɛ aw yɛrɛ tanga jiginni nɔgɔlenw ma ani ka fɛn dɔw mara dɔɔni dɔɔni, o bɛ se ka dɔ bɔ kɔnɔna degunw ni kirinni na. Fɛn minnu bɛ kɛ i n’a fɔ kɔkiliw walima kɔkiliw, olu bɛ se ka fara u kan walasa ka yɔrɔw barika bonya minnu ka teli ka dɔgɔya ka sɔrɔ ka fɛnw to u ka taa ɲɛ.

| Design factor | effect on shrinkage . |

| Uniform mur thickness . | A bɛ dɔ bɔ nɛnɛ ni dɔgɔyali cogo la min tɛ kelen ye . |

| Tɛmɛsira nɔgɔlenw . | A bɛ dɔ fara a farati kan . |

| Barikamasiyɔn (ribs/gussets) . | A bɛ sigicogo sabatili ɲɛ . |

Material Selection .

Plastiki suguya min bɛ kɛ, o bɛ nɔba bila a dɔgɔyali la. Fɛn minnu tɛ fɛn ye i n’a fɔ polikarbonati (PC) ani ABS, olu ka dɔgɔya hakɛ ka dɔgɔn ni u bɛ tali kɛ fɛnw na minnu bɛ kɛ ni kristalɛ ye i n’a fɔ poliporopilini (PP) ani nilon (PA6). Ni aw ye fasaw fara a kan i n’a fɔ gilasi fiyɛw, o fana bɛ se ka dɔ bɔ a dɔgɔyali la, barisa u bɛ dɛmɛ ka fɛn sabati nɛnɛ waati. O fɛn in girinya ni a funteni cogoya ka kan ka bɛn ni fura in dilanni n’a laɲini ye.

| Matériel | shrinkage . |

| Amorphe (PC, ABS) . | Fɛ́gɛn |

| Kristali (pp, PA6) . | Jamanjan |

| Falen (Pa min falen bɛ ni gilasi ye) . | Fɛ́gɛn |

Baarakɛcogo fɛɛrɛw .

Molding paramètres ladilanni .

Baara kɛcogo paramɛtɛrɛw kɔlɔsili ye fɛnba ye min bɛ se ka kɛ sababu ye ka fɛnw dɔgɔyali ɲɛnabɔ. Ni dɔ farala mɔni funteni kan, o bɛ fɛnw bɔli ɲɛ, nka a bɛ dɔ fara fana ka dɔgɔya ni fɛn bɛ sɛgɛn ka caya nɛnɛ waati. Funteni hakɛ ka kan ka sigi ka ɲɛ walasa ka a lajɛ ka ɲɛ ka sɔrɔ a ma dɔgɔya kojugu. Ni u ye o fɛn caman sɛmɛntiya, fɛn dilannikɛlaw bɛ se ka fɛn in nɛnɛni ni a sɔgɔli ɲɛnabɔ ka ɲɛ.

tansiyɔn kunbɛnni .

Pikiri ni pakew tali tansiyɔn bɛ nɔ bila a la ka ɲɛ. Pikiri tansiyɔn ka bon, o b’a to nɔgɔ bɛ fa pewu, ka yɔrɔ lakolonw dɔgɔya ani ka fɛnw sɔgɔli musaka bɔ. Paki degun bɛ kɛ ka to ka fɛn pikiri kɛ nɔgɔ la fali fɔlɔ kɔfɛ, o bɛ dɛmɛ ka dɔ bɔ a dɔgɔyali la ni plastiki bɛ nɛnɛ.

| Paramɛtiriw | nɔfɛko bɛ dɔgɔya . |

| Pikiri tansiyɔn ka bon . | A bɛ dɔ bɔ dɔgɔyali la . |

| Aw bɛ dɔ fara a ka pakew kan . | A bɛ cooling shrinkage sara . |

Fɔɔnɔ fɛɛrɛw .

Nɛnɛ waati ni a hakɛ fana jɔyɔrɔ ka bon kosɛbɛ dɔgɔyali ɲɛnabɔli la. Nɛnɛ waati janw bɛ sira Di dɔɔnin dɔɔnin, hali nɛnɛ ma, o min bɛ dɔ Bɔ danfara ni dɔgɔyali danfara la a yɔrɔ bɛɛ la. Nɛnɛ kɛcogo i n’a fɔ nɛnɛbɔlanw minnu dilannen don koɲuman, olu bɛ a to a yɔrɔ bɛ nɛnɛ cogo kelen na, ka yɔrɔ funtenimaw bali minnu bɛ se ka kɛ sababu ye ka sigida laminiko dɔgɔya.

| nɛnɛ fɛɛrɛ | nafa . |

| Fɔɔnɔ waati jan . | A bɛ dɔ bɔ warping ni shrinkage (dɔgɔyali) kɛcogo la min tɛ kelen ye . |

| A ka kan ka kɛ ni kanw ye . | Aw bɛ a lajɛ hali ni a bɛ nɛnɛ ani ka dɔgɔya . |

Mold design optimisation .

Da ni Runner System Design .

Da ni bolibagaw ka baarakɛcogo bɛ nɔ bila fɛn in bɛ woyo cogo min na ka don bɔgɔ la, o min bɛ nɔ bila a yɛrɛ la ka dɔgɔya. Dabaw walima da caman yɔrɔ minnu bɛ kɛ, olu b’a to nɔgɔ bɛ fa joona ani cogo kelen na, o bɛ dɔ bɔ a dɔgɔyali hakɛ la ka da a falenbaliya kan. Bololabaarakɛlaw ka dilancogo ɲuman nafa ka bon walasa ka jibɔ dantigɛliw dɔgɔya, o bɛ kɛ sababu ye ka degun basigilen sɔrɔ kɔnɔna bɛɛ la.

Cooling System Design .

Nɛnɛmafɛnw nafa ka bon kosɛbɛ walasa u ka se ka dɔgɔya. Fɔɲɔ siraw ka kan ka bila nɔgɔbɔlan kɛrɛfɛ walasa ka funteni bɔli yɛrɛ la. Ka fara o kan, ka baara kɛ ni cooling channels conformal ye, minnu bɛ tugu o kɔ .

Gɛlɛyaw ɲɛnabɔli dɔgɔyali koɲɛw .

Gɛlɛyaw ni furaw minnu bɛ sɔrɔ tuma caman .

Pikiriw dilanni dɔgɔyali bɛ se ka kɛ sababu ye ka ko suguya caman kɛ. Gɛlɛya dɔw filɛ nin ye minnu bɛ kɛ tuma caman na ani u furakɛcogo minnu bɛ se ka kɛ:

kɛlɛ ɲɛ .

Optimiser cooling system design .

Aw bɛ baarakɛcogo funteni ladilan .

modify part design for uniform mur thickness .

Sink marks .

Aw bɛ dɔ fara pakew degunni ni u waati kan .

A yɔrɔ dɔw labɛn kokura walasa ka tilayɔrɔmuguw bɔ yen .

Aw bɛ gazi dɛmɛ ni pikirijikɛlan ye yɔrɔbaw la .

Voids .

Aw bɛ dɔ fara pikiri teliya ni tansiyɔn kan .

Aw bɛ vacuum dɛmɛ ka molding kɛ .

Optimiser gate yɔrɔ ni a bonya .

Dimensions inaccuracies .

Paramɛtɛrɛw minnu bɛ kɛ ka ɲɛ, olu bɛ kɛ ka ɲɛ .

Aw bɛ baara kɛ ni ɔridinatɛri simulation ye walasa ka dɔgɔya kiraya jira .

Jateminɛ kɛcogo ɲɛnabɔli (SPC) waleyali .

Ko minnu kɛra .

Kalansen 1nan: Mobili Dashboard .

Gɛlɛya : Mobili dilanko tɔnba dɔ ye WarPage koɲɛw ɲɛnabɔ u ka dashboard pannew kɔnɔ.

Fɛnɲɛnɛma : U ye nin fɛn ninnu waleya :

Cooling channels minnu dilannen don kokura walasa ka nɛnɛ kɛ cogo kelen na .

Baarakɛcogo funteni ladilanen .

rib design modifié ka dɔgɔya diferential shrinkage .

Result : WarPage dɔgɔyara ni 60% ye, ka jogoɲumanya sariyaw dafa.

Kalansen 2nan : Electronic Enclosure .

Gɛlɛya : Kunnafoni-falen-falen-tɔn dɔ ye jisigiyɔrɔw sɔrɔ u ka minɛnw da la.

Fɛn min ye fura ye : Ekipu ye nin fɛɛrɛ ninnu ta:

Aw bɛ dɔ fara pakew dilanni tansiyɔn kan ni 15% ye .

Packing waati janya ni segin 2 ye .

Dakun belebelebaw minnu dilannen don kokura ni coring ye .

Result : Sink marks eliminated, ka fɛn dilannenw ɲɛnajɛcogo ɲɛ.

Kalansen 3nan : furakɛli minɛnw yɔrɔ .

Gɛlɛya : Dɔgɔtɔrɔso minɛn dilannikɛla dɔ ye dimension accuracy koɲɛw ɲɛnabɔ a yɔrɔ gɛlɛn dɔ la.

Fɛnɲɛnɛma : u ye waleyali Kɛ : .

Simulasiyɔn porogaramu kɔrɔlenw ka ɲɛsin dɔgɔyali ma kirayakuma .

Nɔgɔ ni funteni hakɛ kɔlɔsili tigitigi .

Custom Material Blend ni dɔgɔyali jogo dɔgɔyali .

Result : A ye dimension tolerances sɔrɔ ±0.05mm kɔnɔ, ka minɛnw baarakɛcogo sabati.

Nin ko kɛlenw b’a jira ko fɛɛrɛ caman bɛ yen minnu ɲɛsinnen bɛ gɛlɛyaw ɲɛnabɔcogo ma, olu nafa ka bon kosɛbɛ. U b’a jira cogo min na dilancogo caman caman cili, baarakɛcogo ɲuman, ani fɛnw sugandili bɛ se ka gɛlɛya gɛlɛnw ɲɛnabɔ ka ɲɛ, gɛlɛya gɛlɛnw bɛ minnu na pikiri kɛli la.

Kuncɛli

dɔgɔyali ɲɛnabɔli ɲuman bɛ ɲini ka jateminɛ kɛ fɛnw cogoyaw la, a yɔrɔ ni a dilanni kɛcogo ɲuman na, ani a baarakɛcogo kɔlɔsili koɲuman. Sɛgɛsɛgɛli minnu bɛ senna ani fɛɛrɛko ɲɛtaa minnu bɛ senna, olu bɛ ka taa a fɛ ka dɔgɔyali kunbɛncogo fɛɛrɛw ɲɛ ka taa a fɛ pikiri kɛcogo la.

Aw b’a fɛ ka aw ka plastiki dilanni kɛcogo ɲuman sɔrɔ wa? Team MFG ye i ka taa-ka-segin jɛɲɔgɔn ye. An kɛrɛnkɛrɛnnen don gɛlɛya caman kunbɛnni na i n’a fɔ plastiki dɔgɔyali, ka fɛɛrɛ kuraw di minnu bɛ ɲɛnajɛko ni baarakɛcogo bɛɛ sabati. An ka dɔnnikɛlaw ka jɛkulu ye fɛn ye min bɛ se ka di fɛnw ma minnu bɛ tɛmɛ i ka jigiya kan. Aw ye anw sɔrɔ rightnow.

Ɲininkaliw jaabiw ka ɲɛsin plastiki dɔgɔyali ma .

1. Mun de bɛ kɛ sababu ye ka dɔ bɔ plastiki pikiri kɛli la?

Dɔgɔyali bɛ kɛ ni plastiki bɛ nɛnɛ ani ka a gɛlɛya foroko kɔnɔ. Nɛnɛ waati, polimɛri cakɛdaw bɛ ɲɔgɔn sɔrɔ, o bɛ kɛ sababu ye ka fɛn in dɔgɔya a hakɛ la. Fɛn minnu bɛ kɛ i n’a fɔ fɛn suguya, mɔli funteni, ani nɛnɛ hakɛw, olu bɛ nɔ bila a dɔgɔyali hakɛ la.

2. Plastiki suguya bɛ nɔ jumɛn bila dɔgɔyali la?

Plastiki suguya wɛrɛw bɛ dɔgɔya ni hakɛ wɛrɛw ye. Plastiki kristalɛw i n’a fɔ poliporopilini (PP) ani nylon (PA) caman bɛ dɔgɔya kosɛbɛ k’a sababu kɛ kristalɛ jɔcogo ye nɛnɛ waati la, ka sɔrɔ plastiki amorfs i n’a fɔ ABS ani polikarbonati (PC) bɛ dɔgɔya ka dɔgɔn bawo u jɔcogo tɛ fɛn caman Changer.

3. A bɛ se ka dɔgɔya cogo di pikiri kɛli la?

Dɔgɔyali bɛ se ka dɔgɔya ni baarakɛcogo ɲuman ye i n’a fɔ pakew tali tansiyɔn caya, nɔgɔ ladilanni ani funteni hakɛ, ani ka nɛnɛ kɛcogo kelen sabati nɛnɛbɔlanw fɛ minnu dilannen don koɲuman. Ni aw bɛ fasaw kɛ i n’a fɔ gilasi fiyɛw, o fana bɛ dɔ bɔ a dɔgɔyali la ni polimɛri barika bonya ye.

4. Mɔbili dilanni ni a yɔrɔ jateminɛ bɛ nɔ bila cogo di ka dɔgɔya?

Mold design ani part geometry bɛ nɔba bila dɔgɔyali la. Kogo janya tɛ kelen ye, nɛnɛ sira bilali man ɲi, walima da minnu tɛ yen cogo bɛnbali la, olu bɛ se ka kɛ sababu ye ka danfara dɔgɔya, ka kɛ sababu ye ka kirinni walima ka fɛnw tiɲɛ. Yɔrɔw dilanni ni kogo janya kelen ye ani ka a lajɛ ko nɛnɛ dafalen bɛ dɛmɛ ka dɔgɔyali kunbɛn.

5. Plastiki suguya caman dɔgɔyali hakɛ bɛ kɛ cogo di?

dɔgɔyali hakɛw bɛ danfara ka kɛɲɛ ni plastiki ye. Nafa minnu bɛ sɔrɔ ɲɔgɔn fɛ olu ye:

Poliporopilini (pp): 1,0% - 2,5% .

Nilon (PA6): 0,7% - 2,0% .

ABS: 0,4% - 0,7% .

Polikarbonati (PC): 0,5% - 0,7% .