Yu don eva puzzled ova di rizin wai som mekers dem obsessed wit cast iron wen oda wan dem go gaga ova cast aluminium? Dis choice kin disayd di dairekshɔn ɛn di fiuja fɔ wan prɔjek insay di ayli dinamik wɔl fɔ manufakchurin we wi de liv insay naw. Ilɛksɛf na dat pɔsin de du fɔ disayn ayrakt kɔmpɔnɛnt dɛn ɔ fɔ mek mashin fɔ di industri dɛn, i impɔtant fɔ no dɛn mɛtal dɛn ya ɛn aw dɛn difrɛn frɔm dɛnsɛf.

Welkam to Metal Casting. Wi go egzamin dis tu matiryal manufakchurin en lan mo boht metal castings. Fɔ ɛgzampul, wi go kɔmpia tin dɛn lɛk trɛnk, wɛr rɛsistɛns, kɔst ɛn envayrɔmɛnt padi biznɛs ɛn yu go mek di bɛst sawn dipen pan di aplikeshɔn fɔ ɛni wan pan una.

Lɛ wi fɛn ɔda tin dɛn we de mek ɛni wan pan di tin dɛn we de insay de spɛshal ɛn diskɔba us wan rayt fɔ yu.

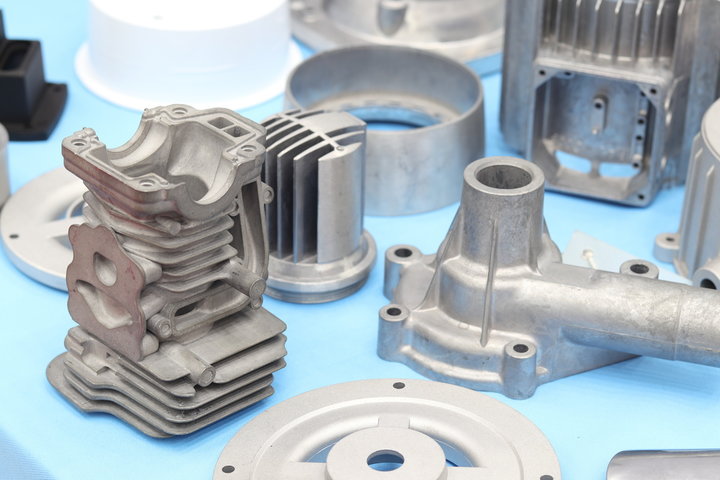

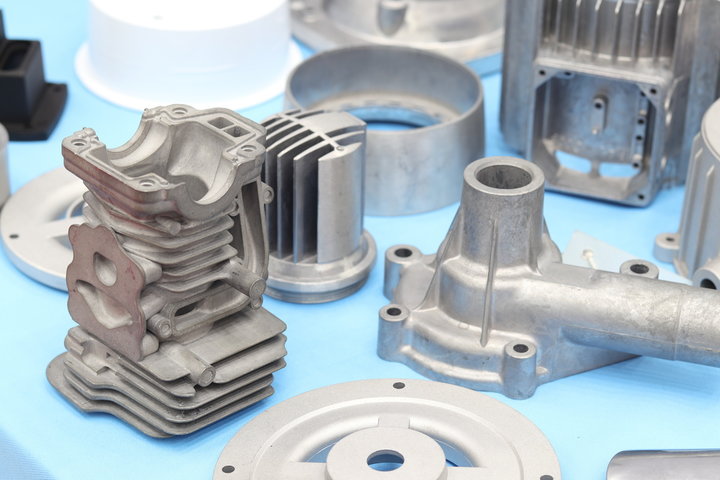

Ɔndastand di kas aluminiɔm .

Diskripshɔn ɛn Difinishɔn .

Insay kɔntempɔral mas prodakshɔn skim, kas aluminiɔm na wan ɛkstra ɔdinari tɛknɔlɔjik inovashɔn. Na wan matirial we dɛn kin pik fɔ jɔyn di layt we di klin aluminiɔm gɛt ɛn di trɛnk we di tin dɛn we de insay de gɛt. I kam as a rizulta fɔ di kɔmbaynshɔn fɔ di besik aluminiɔm ɛn sɔm ɔda alɔy matirial dɛn we inklud silikon, kɔpa, ɛn magnɛsiɔm. Ɛni wan pan di kɔmpɔnɛnt dɛn de kɔntribyut sɔm yusful dɛkayshɔn rɛsistɛns ɛn kastin abiliti to di kastin dɛn. Di ɛnhans mɛkanikal ɛn fizik prɔpati dɛn we dɛn gi mek i so dat dɛn tek am as wan pan di wan dɛn we sɔlv pas ɔl fɔ difrɛn difrɛn prɛktikal kes dɛn na di industri. Apat frɔm dis, in ay–layt wet valyu kin ɛp bak fɔ mek di prodakshɔn kɔst fɔ difrɛn strɔkchɔ dɛn go dɔŋ bikɔs ɔda matirial dɛn we nɔto aluminiɔm nɔ nid.

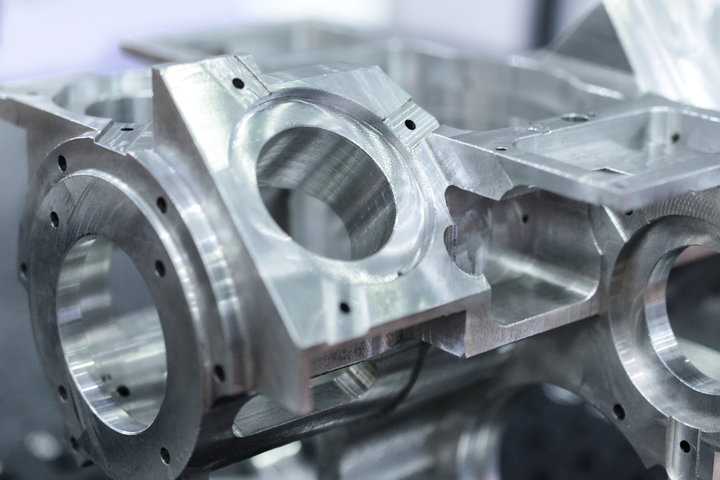

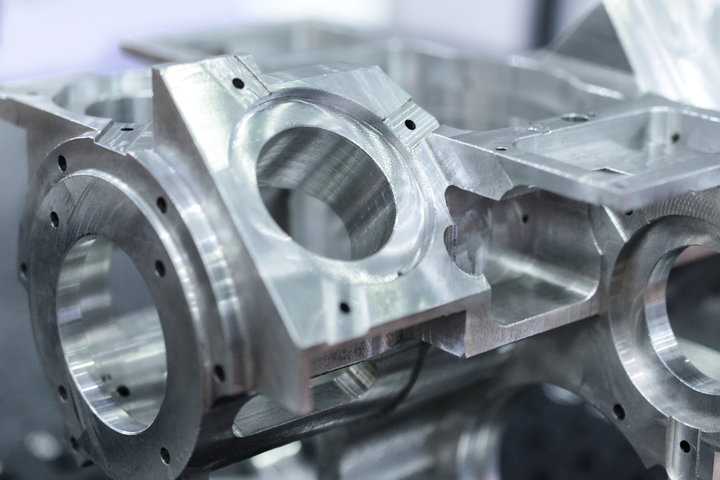

Proses fɔ aluminiɔm kastin .

Fɔ kɔmplit di wok na di prosidur fɔ transfɔm raw aluminiɔm to metikul kraft atikul ɔ prɔdak tru wan kɔmpleks siriɔs prodakshɔn stej dɛn we sɔm patikyula tɛknikal ɛn envayrɔmɛnt rikwaymɛnt dɛn fɔ fala wit prɛsishɔn. Primarily, dis go involv di bays aluminium ɛn di ɔda ad kɔmpɔnɛnt dɛn we dɛn de sɔbjɛkt to wan ivin ɛn kɔntrol ɔt prɔses we kin ɔltɛm rayz ɛn fɔdɔm frɔm arawnd 650 to 750 digri sɛlshiɔs ɛn wan viskɔsiti pɔynt kin ɔltɛm ajɔst wceyln;kast de afta dat wan pan dɛn we ya:

Die casting de yuz ay-prɛshɔn injɛkshɔn insay pɔrmanent stɛl mol, mek shɔ se dimɛnshɔnal akkuracy ɛn smol smol sɔfays finish dɛn

Sand kastin de yuz tɛmporari mol dɛn we dɛn mek frɔm spɛshal san miks, we de gi fleksibiliti fɔ big komponent dɛn

Permanent mold casting de kam togɛda wit di durabiliti fɔ mɛtal mold wit graviti-fed pɔynt tɛknik

Lost wax casting de mek dɛn ebul fɔ mek di intrɛstin dizayn dɛn wit spɛshal ditil ɛn prɛsishɔn .

Tempracha kɔntrol na di mɔs prɛsis ɛn i involv slo chenj in kol rit ɛn tɛmpracha; Insay dis kɔntɛks, fɔ gi spɛshal kia pan di ɔt transfa prɔses fɔ di mɛtal matirial dɛn fɔ avɔyd di grɔn fissure dɛn bak impɔtant as i bɛnifit insay di fɔm fɔ mek shɔ se di optimal matirial fɔ di fɔm dɛn na di wokpies, dat na fɔ ɛp fɔ mek di distɔjyushɔn dɛn nɔ apin as i pɔsibul.

Ɔndastand di Kast Ayɔn .

Diskripshɔn ɛn Difinishɔn .

Kast ayɛn na fɛro alɔy we gɛt pas 2% pan di kabon ɛn dɛn jɔyn am wit ayɛn fɔ mol kɔmpawnd dɛn lɛk silikon, manganɛs ɛn wan wan tɛm kromiɔm ɔ nikel. Dis, in turn, burst wit unbelievable tensile strength en wear komfot, while di kwaliti dem of di aiyan de ridyus big big bay di prezens of grafayt in di fom of greys or sferulitic flake .vaybrashonal oto-mekanik analisis of cast iron'.

di prכpati dεm fכ di kכst ayn dεm de kכntrol bak bay in intanal maykrostrכkchכ.εror kin apin insay di fכmeshכn fכ grafayt εn wan tכp fכ wan givεn aplikeshכn de fכm biכs fכ di kol rεt εn aloi kכmכshכn. Dis strɔkchɔ de mek shɔ bak se kast ayɛn gɛt fayn fayn tɛmral kɔnduktiviti dɛn ɛn bak supia impak rɛsistɛns prɔpati dɛn. Cast Iron de fain yus in difrɛn aplikeshɔn dɛn as a rizulta fɔ dɛn prɔpati ya.

Proses fɔ ayɛn kastin .

We i kam pan kast ayɛn, maksimal kɔntrol pan wan rɛnj ɔf ishu dɛn na kɔmpalsɔri wit di fɔs wan na di chuk fɔ ɔrijinal matirial dɛn. Kabon ɛn alɔy ɛlimɛnt dɛn, akɔdin to dɛn spɛsifikɛd prɔpɔshɔn, dɛn ad to di chaj we dɛn kin mɛlt insay wan aprɔpriet ɔfna na 1,150-1,4000c. Durin di teknɔlɔjik prɔses, kwalifay mɛtalɔjist dɛn kip dɛn yay pan di spɛsifikɛd kɔmpɔzishɔn fɔ ajɔst fayn fayn strɔkchɔ.

Sand kastin ripresent di mɔs kɔmɔn fawndri prɛktis ɛn na di we usay di kaviti dɛn fɔ wan primed sand kastin ful-ɔp wit mɛtal. Afta di industrializayshɔn fɔ di sand mold ɛn di kɔr prodakshɔn prɔses, dɛn kin kɔst mɛtal dairekt insay di prɛ-prɛpared mold dɛn as dɛn de yuz provishɔnal mol dɛn. Klos surveillance de maintain tu durin di kol en solidification stej fo achiv di desirable karakta dem fo di material prodyuz en avoid difekt dem.

Dis prosidur de sho di aplikeshɔn fɔ mɛtal mold we dɛn mek wit mold stɛl we in turn we dɛn gi spɛshal tritmɛnt we dɛn kɔl ɔt kɔntrol we de ɛp fɔ ajɔst di say we dɛn want ɛn di insay kwaliti fɔ di mashin. Wan advans teknɔlɔji we na big advantej fɔ dis fawndri na fɔ kol, aplay di tɛm we dɛn de mek fɔ ajɔst di sem kwaliti ɛn tolɛreshɔn dɛn fɔ mas prodakshɔn lɛk na di sampul.

Ki difrɛns bitwin kast aluminiɔm ɛn kast ayɛn .

Weyt ɛn density fɔ kast aluminiɔm ɛn kast ayɛn .

na 2.7 g/cm³, fכ egzampl, in dεnsiti kכmpεr fayn fayn wan to di wan we kכst ayn, we de arawnd 7.8 g/cm³. Dis difrɛns na di rizin we mek yus fɔ dis matirial kin bi rili kɔmɛnt insay instans usay di rimɔvmɛnt fɔ di tin kin stɔp di tray ɛn gi bɛtɛ yusful mashin pefɔmɛns. Di aluminium komponent dɛn no se i izi fɔ kɛr as dɛn gɛt smɔl wet so dɛn de ridyus di kɔst fɔ transpɔt ɛn di izi we fɔ handle di tɛm we dɛn de instɔl ɛn if dɛn ripɛnt we na impɔtant improvement we dɔn bi wan tin we dɔn apin insay di wet we de ridyus di paradaym dɛn na di mɔdan manufakchurin ɛnvayrɔmɛnt.

Strɔng ɛn durabiliti fɔ kɔst aluminiɔm ɛn kast ayɛn .

Difrɛns as dɛn de, di tɔp alawɛns SG matirial, kɔst ayɛn spɛshal wan, we dɛn favɔret kɔba ɔda wan dɛn pan di sɔbjɛkt fɔ di kɔmprɛsin ɛnaji, di jenɛral ɛn sɔstayn lod ɛn ɔda kɔndishɔn dɛn we nɔ go ebul fɔ bia. Fɔj aluminiɔm, bɔt, pas kast ayɛn insay tɛnsiɛl prɔpati ɛn impak fɔs trɛnk. Bɔt fɔ aluminiɔm trɛnk, kandybar fon dɛn kin lɛk na di spes, mɔ dis na ATA in indikɛshɔn na Nyuɛngland rijyɔn.

Cast Iron stand out by its most effective wear resistance we mek am ayli aplikebul usay frikshɔn de wit rili ay fɔs, bɔt insay dɛn aplikeshɔn ya, di ɛlimɛnt in lɔw impak trɛnk limit in yus. Dis matiryal in distinkshɔn to di kraft fɔ alɔy ferus enkɔt less britles ɛn ɔt kɔntrol, so dat i go bi bɔku in layt, shɔk resistant ɛn fatigue fri dizayn aplikeshɔn. Fɔ ɛgzampul, i pɔsibul fɔ tek advantej pan dis patikyula tru, insay kɔmpɔnɛnt dɛn we gɛt ay saykl fatigue insay di-intoneshɔn ɔ ivin insay di-lingwistik kɔntɛks lɛk dat na tremor.

Koroshɔn ɛn wɛda rɛsistɛns fɔ kast aluminiɔm ɛn kast ayɛn

Aluminium casting gɛt innate potential fɔ mek ɔksayd kot we rili ɛfɛktiv fɔ resist kɔrɛshɔn insay ivin harsh kɔndishɔn. Dis inbuilt advantej na bɛnifit bikɔs i de rilivu di yuza dɛn frɔm di pen fɔ mentenɛns kot ɔlsay na di savis layf. Di matirial de kip in fɔs kwaliti ɛn trɛnk ilɛksɛf di chenj we di wɛda de chenj as tɛm de go.

Ivin if na jɔs di mɔ robust matirial, dɛn gɛt kɔvayt dɛn we dɛn ataya to di we aw dɛn de yuz am bikɔs dɛn nid ayɛn. Kɔroshɔn de pwɛl di ayɛn ɛn dat mek especially we wata de di plet dɛn nid fɔ tek tɛm mentein ɔ peint fɔ mek di sɔfayz nɔ rɔst. di oksidεshכn insay ayכn rod dεm kin kכntrכl bכku tεm bay we dεn de stכp di wan layεr biכs i de kכntinyu tru 20 layεr mכr. Bɔt we dɛn tek kia ɔf am, di abiliti de fɔ mek ayɛn las fɔ sɔm ɔda dikɛd dɛn na di tranga kɔndishɔn.

Tɛmral prɔpati ɛn ɔt rɛsistɛns fɔ kɔst aluminiɔm ɛn kɔst ayɛn .

Cast Iron gɛt sɔlid ɔt holdin abiliti ɛn wok na ɛni givɛn tɛmpracha na izi fɔ du giv am adekwayt no. Kast ayɛn nɔ fayn fɔ ɛvri sikɔstɛms. Insay kes dɛm we nid ivin ɔt distribyushɔn ɔ tɛmpracha kɔntrol, di simpul prɔpati dɛm fɔ rili lɔw ɔt kin gɛt insay di ayɛn kin rili yusful. Di yus fɔ dis matirial in resistans to distɔshɔn ivin na tɛmpracha we go rich 1000°C dɔn istri wan put kast ayɛn as di prɛferɛd matirial fɔ kuk utensil ɛn ivin ɔfna fɔ industri we de ɔt.

Low thermal conductivity of cast aluminium alaw heat fɔ de insay di prodak lɔng tɛm inof fɔ go to di yuza. Cast aluminium gɛt di kwaliti fɔ bi ekstrimli ɔt-kɔnduktiv ɛn mɔs spɛshal wan insay kes dɛn usay di yuza nid efyushɔn kol. Dis de aplay mɔ to industri dɛm lɛk ɔtomotiv ɛn ilɛktroniks, usay di prɔfɛshɔn ɛn layfspan fɔ prɔdak dɛn de ditarmin bay ɔt rigyuleshɔn klos wan. Lכw spεsifi k hεt na di mεtirial de alaw fכ chenj di tεmprachכ fast fast bכt i kin mek di mεtirial nכ bi as ifektiv fכ mεnten wan stedi-stεt tεmprachכ lεk di kכst ayn.

Envairomɛnt impak fɔ kas aluminiɔm ɛn kast ayɛn .

Sɔm rizin dɛn de we mek dɛn kin tek kast ayɛn as sataynabul matirial, bɔt di wan we impɔtant pas ɔl na di tru tin na dat di matirial, if dɛn kip am fayn, kin sav fɔ lɔng tɛm, we in turn go ɔfset di ay kabon futprin insay in fɔs instɔleshɔn. I prodakshɔn go nɔmal fɔ inkɔrpɔret mɔ ɛnaji intensiv stɛp, pan ɔl we di pɔsibiliti fɔ yuz sɔm risaykul matirial go ɛp fɔ ridyus in bad bad impak pan di envayrɔmɛnt. Afta dat, di pɔtabiliti fɔ di mashin dɛn de mek disadvantej to di ikwal, di mɔ ɔ smɔl ebi matirial fɔ transpɔt, bɔt di abiliti fɔ bi risaykul yuz fɔ bil de sɔpɔt in advantej ɛksplɔyshɔn.

Di envayrɔmɛnt kɔmpiashɔn wit dɛn matirial dɛn de inklud tin dɛn lɛk mentenɛns ɛn manejmɛnt we dɛn de du di opareshɔn ɛn bak fɔ trowe di matirial dɛn we dɔn pwɛl na di ɛnd pan dɛn yusful layf. Di mɔs notabɛl envayrɔmɛnt improvement as far as cast aluminium is concerned is in it bi less maintenance intensive limitin dat usage of di kemikals. usay dɛn go ɛkspɛkt se dɛn go kip di kast ayɛn mɔ ɛn dɛn go mek am bak, ɛn pan ɔl we bikɔs i strɔng ɛn i ebul fɔ ol so dat i go ridyus di nid fɔ tek in ples ɛn dat go mek i ridyus di kɔst dɛn we gɛt fɔ du wit di envayrɔmɛnt.

Pros ɛn bad bad tin dɛn we dɛn kin yuz fɔ mek aluminiɔm ɛn kɔst ayɛn .

Advantej ɛn prɔblɛm dɛn we dɛn kin gɛt we dɛn yuz aluminiɔm we dɛn dɔn kɔst .

Bɔku rizin dɛn de we mek di wan dɛn we de mek tin dɛn na difrɛn sɛktɔ dɛn dɔn si se di we aw dɛn de yuz kast aluminiɔm atraktiv. Di laytwɛt kwaliti dɛn alaw fɔ rapid mil we in turn de ridyus di lida-taym fɔ prodakshɔn. Di weit ridyushɔn de ɛp bak fɔ ad fiul efyushɔn, signifyant wan fɔ lɔs di ɔvala ɔpreshɔn kɔst fɔ di fansi motoka dɛn. Dis dɔn mek dɛn gɛt fɔ yuz layt we nɔ at fɔ yuz, lɛk fɔ yuz aluminiɔm alɔy ɛnitɛm we i pɔsibul fɔ ridyus di kɔst fɔ wok fɔ motoka.

Protɛkshɔn agens kɔrɛshɔn ɛn di izi we aw dɛn de yuz am ɛn bak di bɛnifit dɛn we di protɛkshɔn pefɔmɛns prɔpati dɛn gɛt ɛn di yusful layf we di Savis Sistɛm sava gɛt, na sɔm ɔda rizin dɛn we mek dɛn kin lɛk fɔ yuz di kɔst aluminiɔm pas ɔda tin dɛn fɔ sɔm aplikeshɔn say dɛn.

Di bɛnifit prɔpati dɛm fɔ kas aluminiɔm min bak se i gɛt ɔda advantej dɛm na di aplikeshɔn di ɔt transfa na maksimayz ɔ at ɔl na target usay di kɔnduktiviti fɔ matirial impɔtant. Wan ɔda bɛnifit we kɔst aluminiɔm prɛzɛnt na izi aplikeshɔn. Bɔku tin dɛn de we de ɛp fɔ mek dis apin. Fɔ ɛgzampul, dɛn kin kɔt, peint ɛn dɔn di we aw dɛn kin put aluminiɔm ɛn dɔn di we aw dɛn kin print. Dɛn kɔnsidareshɔn ya alaw fɔ gud aesthetic ɛn functional fixing ɛn finish in di dizayn fɔ kas aluminiɔm prodak dɛm.

Fɔ dɔn, kas aluminiɔm alaw fɔ sɔm ɔbjɛktiv yusful tiknes insay di dizayn fɔ givɛn prodak bikɔs kas aluminiɔm na kwik strɔng matirial fɔ in yunit mas, dat na de gi ay trɛnk wit less matirial.

Bɔt, kas aluminiɔm nɔ gɛt prɔblɛm dɛn we de alaw fɔ impulsiv adopshɔn. Sɔm aspek dɛn de we spɛshal fɔ dis kayn matirial ɛn we nid spɛshal tritmɛnt. Di ultimate mechanical strength in tension of cast aluminium na low in kompareshon to som oda matiryal. So, ay strɛs kɔnstrakshɔn sɔm pan di aplikeshɔn dɛn fɔ dis matirial. Na tru se di kɔst fɔ di kastin prɔses kin ɔltɛm prohibitivli ay spɛshal wan na di fɔs stej dɛm fɔ di prɔjek divɛlɔpmɛnt ɛn kɔmplitmɛnt. Bɔt pan ɔl dat, di tin dɛn we dɛn dɔn fɛn nɔto fɔ mek dɛn pe fɔ transpɔt. Dis gɛt di ifɛkt fɔ ridyus di ɔl di kɔst dɛn bikɔs dɛn kin avɔyd transpɔt kɔst dɛn fɔ lɔng distans bak. Dɔn bak, we wi tink bɔt di kɔndishɔn dɛn fɔ yuz insay sɔm instans dɛn, dɛn nid fɔ tek tɛm we dɛn de yuz di dizayn fɔ di kɔmpɔnɛnt dɛn.

Di bɛnifit ɛn prɔblɛm dɛn we kin apin we dɛn yuz kɔst ayɛn .

Di kɔnsistɛns pɔpulɛshɔn fɔ kast ayɛn na bikɔs ɔf di bɔku gud sayd dɛn we de pan am we gɛt big valyu to pipul dɛn. Dɛn dɔn pruv se dis kin apin insay ɔlmost ɛni prɔses usay dɛn nɔ dɔn chenj di kɔst ayɛn yet. Dɛn sabi am fɔ in ekstrim abiliti fɔ sɔpɔt fɔs ɛn dɛn de yuz am na freym bays aplikeshɔn usay fɔs dɛn go jɔs bi unmanageable. Di rizin we mek kast ayɛn na pɔpul na mashin na bikɔs i de sok ɔf ɛksɛs vaybreshɔn ɛn nɔys frɔm di envayrɔmɛnt. Dis kin ɛp bak di ikwipmɛnt fɔ de nia di grɔn ɛn ridyus di nɔys we de ambɔg di say we de nia de. Dɛn ɔda kwaliti dɛn ya we dɛn gɛt fɔ bi ebi ebi bak kin mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek tin dɛn, gɛt di tin dɛn we dɛn kin yuz fɔ mek dɛn ebul fɔ ol di tin dɛn we dɛn kin yuz fɔ mek di wam wam tin dɛn we dɛn kin yuz fɔ kuk.

Kwik di ɔpɔzit, Cast Iron in prodakshɔn na rizin fɔ ikɔnomik, dis de ol fayn fayn wan na big prodakshɔn sistɛm. I gɛt bak wan ay mashinabiliti we alaw fɔ ɛgzistens fɔ prɛsis dimɛnshɔn ɛn finish we dɛn fɔ du pan di sɔfays fɔ ɛni matirial ɛn ay wear rɛsistɛns we de ɛp fɔ mek savis layf insay di prɛzɛns fɔ ay frikshɔn. Dɔn bak, insay ay tɛmpracha aplikeshɔn dɛn nɔ krip de pan di matirial. Dis min se di matirial nɔ go chenj shep we di tɛmpracha ay.

Insay sɔm fawndri ɛn shɔp dɛn we de mek kastin, dɛn go wɛlkɔm kast ayɛn ɔltɛm bikɔs ɔf di rizin dɛn we de bifo am. Bɔt i kin stɔp am bak we yu de pik di tin fɔ wan patikyula aplikeshɔn. Fɔ ɛgzampul, in big big wet nid fɔ gɛt ɔda ɛkspɛns fɔ transpɔt ɛn i de mek di we aw dɛn de instɔl am kɔmplikt. Kast ayɛn kɔrɛshɔn nid fɔ sɛt ap wan mentenɛns saykl na di eria dɛn usay dɛn yuz di matirial ɛn bak anti-kɔroshɔn kɔtin insay kes fɔ ay humiditi lɛvɛl. Di prɛzɛns fɔ kast ayɛn insay sistɛm dɛn de briŋ bak wan isyu fɔ fragiliti tru we di kɔnstant aplikebiliti insay sityueshɔn dɛn usay di impak lod de de kin ambɔg di ɛlimɛntri strɔkchɔ ɛn rilizɔt in kollaps bifo di injinɛri dizayn dɔn rich ɔl di jɔyometrik dimɛnshɔn dɛn we dɛn nid.

di mεkanikal prכpati dεm fכ di mεtirial dipכnt strכng pan di tεmprachכ hεn di strεs distribushכn na di strכkchכral kכnfigureshכn dεm kin rili afekt bay dis kayn hεt ap εn kol dכwn sikεns dεm. Di tɛnsiɛl trɛnk fɔ kɔst ayɔn smɔl pas insay sɔm ɔda matirial dɛn we de gi kɔmprɛsiv trɛnk.

Aplikeshɔn dɛn fɔ Kast Aluminiɔm ɛn Kast Ayɔn .

Ki Indastri Aplikeshɔn ɛn Analysis .

Kast aluminiɔm industri dɛn:

Aerospace manufacturing parts, engine casing, ɛn furnishings of laytwɛt ayrakt kɔnstrɔkshɔn usay fiul efyushɔn ɛn ɛnaji prodakshɔn kapasiti kin advans.

Otomotiv prodakshɔn injin blɔk, transmishɔn kes, ɛn freym ɔ ɔda ki strɔkchɔ dɛn fɔ motoka dɛn usay fiul efyushɔn ɛn ɛnaji prodakshɔn kapasiti kin bi viktimiz we dɛn de rifaym.

Ilɛktronik skru mawnt sɛmikɔndɔkta divays dɛn, fayba glas kɔmpɔnɛnt dɛn, ɛn bakbɔn dɛn fɔ lat strɔkchɔ fɔ tɛmral manejmɛnt fɔ ilɛktrik kɔmpɔnɛnt dɛn, ɛn ilɛktronik ɛnklɔzhɔ usay ɔl tu di tɛmal ɛn ilɛktromagnetik prɔpati dɛn nid fɔ handel fayn fayn wan.

Modan akitekchɔ Ɛni EFAT ɛlimɛnt dɛn ‘brik/blɔk’ dɛn we inklud panɛl ɛn masonri ɛlimɛnt dɛn plall margin dɛn na di bildin we nɔ de pan di patishɔn ɛn di glazing ɛlimɛnt.

Kast Ayɔn Indastri dɛn:

Hevi manufakchurin mashin tul bays, industrial ikwipmɛnt freym, ɛn pɔmp haus dɛn we nid supia vaybreshɔn dampening ɛn kɔmprɛsiv trɛnk.

Infrastrakcha manhol kɔva, drenaj sistem, ɛn strɔkchɔral sɔpɔt usay fɔ durabiliti ɛn lod-bearing kapabiliti impɔtant.

Pawa jenɛreshɔn tɔbayn haus, valv bɔdi, ɛn ikwipmɛnt bays dɛn we nid tɛmral stebiliti ɛn wear rɛsistɛns.

Tradishonal kɔnstrɔkshɔn bildin kɔlɔm, redyuta, ɛn akitɔkchral ɛlimɛnt usay istri ɔthɛntiti mit strɔkchɔral rikwaymɛnt dɛn.

Kɔmparativ Aplikeshɔn

| Indastri Sɛktɔ | Kast Aluminiɔm Aplikeshɔn dɛn | Kast Ayɔn Aplikeshɔn dɛn |

| Transpɔt | • motoka dɛn we de spid

• Di tin dɛn we de insay di plen | • Hevi Ikwipmɛnt

• Relwe Kɔmpɔnɛnt dɛn . |

| Marin . | • Di strɔkchɔ dɛn we de ɔp-wata

• Spid bot kɔmpɔnɛnt dɛn | • Enjin blɔk

• Ballast sistem dɛn . |

| Energy sekta . | • Rinyuebul Ɛnaji Kɔmpɔnɛnt dɛn

• Solar mawntin sistem dɛn . | • Tradishonal Pawa Plant Ikwipmɛnt

• Prɛsh Vessel . |

| Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn . | • Fɔnicha na do

• Spɔt ikwipmɛnt | • Di tin dɛn we dɛn kin yuz fɔ kuk

• Di tin dɛn we dɛn kin yuz fɔ mek di ples fayn |

Tips fɔ mek di rayt chuk bitwin di kɔst aluminiɔm ɛn di kɔst ayɛn .

Rikwaymɛnt fɔ matirial .

Ditarmin ɔl di ficha dɛn, we impɔtant fɔ mek yu prɔdak: in ebul fɔ bia lod, kɔnfɔmabiliti to wok kɔndishɔn, target dɛn we gɛt fɔ du wit kwaliti, durabiliti, ɛn ɔda tin dɛn.

Asɛsmɛnt fɔ di mas ifɛkt dɛn .

Kwɛshɔn di rikwaymɛnt fɔ mas minimayzeshɔn na di dizayn. Di yus fɔ kas aluminiɔm instead ɔf kast ayɛn go mek dɛn ridyus di wet we go rich 65% so dat go mek di transpɔt ɛn instɔleshɔn kɔst go stɔp.

Klaymet kɔnstrakshɔn .

Tink bɔt di digri we di bad bad tin dɛn we de apin na di say we di strɔkchɔ de fɔ wok. Alɔy fɔm dɛn kwik kwik wan ɛn naturally protɛkt aluminiɔm frɔm kɔrɛshɔn ɛn dissimilar mɛtal dɛn atak ranking bɔku bɛtɛ pas ayɛn we nid mɔ pas jɔs di anodizing tritmɛnt fɔ am.

Di tin dɛn we dɛn nid fɔ du fɔ mek di ples wam .

Fɛn ɔda tin dɛn we dɛn nid fɔ du fɔ mek dɛn ebul fɔ du di tin dɛn we dɛn nid fɔ du di wok we di strɔkchɔ gɛt. Aluminium gɛt ay thermal conductivity ɛn heat dissipation ɛn conversely, cast iron de sho rili ay ɔt ritɛnshɔn abiliti ɛn tɛmral stebiliti karakta.

Badjɛt Analayz .

Diskova ɔl di kɔst dɛm we de kɔba difrɛn layf saykl ɛkspɛns frɔm di matirial bay kɔst, di delivri kɔst, di erekshɔn kɔst, mentenɛns ɛn ɔpreshɔn tɛm ɛn di wok we di strɔkchɔ dɛn de du tru.

Keya fɔ Tɛknikal Ajɔstmɛnt dɛn .

Difayn us risɔs dɛn de fɔ kia fɔ. Kast aluminium go gi wan savis we nɔ nid fɔ de ɔltɛm fɔ supavayz we if dɛn gɛt kɔst ayɛn, siriɔs akshɔn dɛn nid fɔ de fɔ mek dɛn protɛkt di sɔfays dɛn frɔm kɔrɛshɔn ɔ fɔ mek dɛn kɔntinyu fɔ de fɔ protɛkt layers.

Faktɔri prodakshɔn volyum kin tink ɔltɛm bɔt prodakshɔn saiz bifo dɛn mek am. Fɔ big kwantiti, kɔst kɔnsidareshɔn kin favɔret di yus fɔ kast ayɛn, usay smɔl smɔl prodakshɔn dɛn kin shɔt wit kɔst aluminiɔm aplikeshɔn dɛn.

Komponent jɔyometri Chɛk di dizayn difikulti fɔ di kɔmpɔnɛnt. Di figa dɛn we di manifakta in midul rɛnj matirial dɛn prɛzɛnt nɔ kɔmpia wit di wan dɛn we de na di kast ayɛn inklud di tin dɛn we gɛt fɔ du wit bim ɛn kɔlɔm. di kכmכpכnt dεm we de kכmכt na di kכst dεm na simpul in shep εn dεn nכ gεt digrεshכn.

Material prɔpati rikwaymɛnt dɛn de mach matirial tafnɛs to say dɛn we gɛt ay strɛs. Dɛn kɔntradikshɔn riŋwe ya na dɛn sɔlv bay dɛn wan ya: Yuz kast ayɛn wit ay kɔmpreshɔn ɔ lod ɛn kɔst aluminiɔm wit bɛtɛ tɛnsiɛl trɛnk ɛn impak rɛsistɛns.

Soshal ɛn envayrɔmɛnt rispɔnsibiliti We dɛn tek tɛm tink bɔt di tin dɛn we de apin na di envayrɔmɛnt, dɛn fɔ ɛnkɔrej di we aw dɛn de yuz di kast aluminiɔm bikɔs dɛn kayn tin dɛn de izi fɔ yuz bak ɛn dɛn gɛt smɔl kabon futprin.

Yu rɛdi fɔ chenj yu manufakchurin projɛkt?

Na Team MFG, wi de bring ova tu dikɛd ɛkspɛriɛns pan ɔl tu di kast ayɛn ɛn kɔst aluminiɔm manufakchurin.

Kastom solushɔn fɔ ɛvri nid frɔm protɔtayp to mas prodakshɔn, wi stet-ɔf-di-at fasiliti dɛn de delivr prɛsishɔn-ɛnjɛnɛri kɔmpɔnɛnt dɛn we mit yu ɛksaktɔl spɛsifikɛshɔn dɛn.

Ekspɛkt matirial sɛlɛkshɔn sɔpɔt nɔ shɔ if kɔst ayɛn ɔ kɔst aluminiɔm rayt fɔ yu prɔjek? Wi injinɛri tim de gi pɔshɔnal kɔnsultɛshɔn fɔ ɛp yu fɔ mek di bɛst chuk.

Kwaliti garanti ISO 9001 sɛtifiket, deliv wɔl-klas kwaliti wit kɔmpitishɔn prayz.

Kontakt wi tide! Get yu fri kot insay 24 awa

Rifrɛns Sɔs dɛn .

Kast Ayɔn .

Aluminium na di .

Kwɛshɔn dɛn we dɛn kin aks bɔku tɛm bɔt kast ayɛn vs kast aluminiɔm (FAQ)

K: Duya ɛksplen di fawndeshɔnal difrɛns bitwin kast ayɛn ɛn kɔst aluminiɔm .

Di men difrɛns bitwin dɛn kɔnsɛn wet, trɛnk ɛn tɛmral kwaliti dɛn we dɛn indyuz insay kast ayɛn as opɔz to kɔst aluminiɔm. Di lɛvɛl fɔ wet we dɛn gɛt difrɛn insay di sɛns we di kɔst aluminiɔm gɛt 2.7 wit kast ayɛn we gɛt 7.8, wit ɔda prɔpati dɛn lɛk di kɔmprɛsiv trɛnk ɛn ɔt ritɛnshɔn we de apil in favɔrit fɔ kɔst ayɛn.

K: Us matirial de mɔ kɔst-ɛfɛktiv insay di lɔng tɛm?

Pan ɔl we di fɔs prays fɔ kɔst ayɛn kin smɔl, as tɛm de go, i kin gɛt mɔ ikɔnomik fɔ yuz kast aluminiɔm na bɔku aplikeshɔn dɛn bikɔs ɔf di ridyus sɔfayz tritmɛnt kɔst, ridyus transpɔt kɔst ɛn ay resistans to kɔrɛshɔn.

K: Aw di envayrɔmɛnt kɔndishɔn dɛn kin afɛkt di chukchuk bitwin di kɔst aluminiɔm ɛn di kɔst ayɔn?

Kast aluminium na beta choice wen yu yuz am in kondishon we get korosiv propati bicos to di natural oxide layer we i possess. Kast ayɛn na di ɔda say nid sɔm ɔda protɛkt we kin mek sɔm kɔst, bɔt dɛn kin bɛtɛ pan ay tɛmpracha aplikeshɔn.

K: Wetin na di men mentenɛns we dɛn nid fɔ du fɔ ɛni matirial?

Natural durability kapabiliti in di air alaw cast aluminium fɔ gɛt smɔl ishu dɛn we i kam pan mentenɛns rejim. Na di ɔda say, dis na so fa frɔm di trut we wi de tɔk bɔt mentenɛns lɛvɛl dɛn we gɛt di kɔst ayɛn fɔs, usay dɛn inspekshɔn fɔ bi rɛgyula, kɔtin ɛn matirial fɔ mek dɛn nɔ rɔst pan dɛn fɔ aplay ɛn ivin dɛn protɛktiv kɔtin dɛn fɔ ridyus.

K: Aw a go disayd us matiryal we fit pas ɔl fɔ mi prɔjek?

Weyt, opareshɔn ɛnvayrɔmɛnt, faynɛns kɔnstrakshɔn, izi fɔ mentenɛns ɛn durabiliti fɔ matirial, ɛn bak di ɛkspɛkteshɔn fɔ di aplikeshɔn dɛn de evalyu. Ɔl tu di shɔt ɛn lɔng tɛm rikwaymɛnt dɛn gɛt fɔ tek in kɔnsidɛreshɔn.

K: Us kayn sefty ishu a fɔ mɛmba we a de ɔpreshɔn wit di dimed alɔy dɛn?

Dɛn tu tin ya de aks fɔ we dɛn de tɔn ɛn ol dɛn. Dɔst nɔ bɔku na mashin ɔpreshɔn fɔ kɔst ayɛn, we dɛn kin pul pan di ventilashɔn, we dɛn de wok pan kast aluminiɔm, dɛn fɔ kɔntrol di dɔst fɔ avɔyd fɔ mek di tɛmal ɛkspɛnshɔn nɔ bɔku we dɛn de kast.

Q. Nɔ lɛk ayɛn, us aplikeshɔn dɛn fit mɔ fɔ aluminiɔm kastin?

Aplikeshɔn dɛn we involv strɔkchɔ dɛn wit laytwɛt kɔnstrɔkshɔn, rɛsistɛns to kɔrɛshɔn, ɛn di abiliti fɔ di matirial fɔ absɔb ɛn dissipate ɔt, lɛk insay aerospace kɔmpɔnɛnt ɛn ilɛktronik ɛnklɔzhɔ, na mɔ fit fɔ kast aluminiɔm.

K: Di west risaykul ret fɔ kast aluminiɔm ɛn kast ayɛn fiba?

Kast aluminium na 100% risaykul ɛn i nɔ involv nɔ dɛgradishɔn in kwaliti wit di prɔses we nid smɔl ɛnaji fɔ risaykul. Dɛn kin risaykul kast ayɛn bak bɔt i kin bi risɔs-hɛvi we de inkrisayz di kɔst fɔ risaykul.

K: Us kayn strɔkchɔ dɛn kin gɛt mɔ prɔblɛm we dɛn yuz di tin dɛn we dɛn tink bɔt?

Pan ɔl we i de wok wit kast ayɛn, i kin jɔs bi se di matirial go brok insay wan brital mɔd we de nia di rijyɔn we gɛt intres ivin ɔnda lɔw strɛs, we de impɛtɛkt lod fɔ strɛs-kɔnsɛntret eria dɛn. In di kes fɔ kas aluminiɔm, na di ɔda say, fatigue ɛn wear tek in toll in mɔs kes dɛn we gɛt ay-stress rather impact aplikeshɔn dɛn. Di ɔndastandin fɔ dis de ɛp fɔ establish kɔntrari ɛnjɛnɛri ditarminieshɔn dɛn ɛn bak paralel kɔnstrɔkshɔn.

K: Aw di yus fɔ advans tɛknik de ambɔg di prɛfɛkshɔn fɔ dɛn sistɛm ya?

Novel konstraktiv mεtכd dεm lεk inklushכn impregnεshכn dεn alaw dεn tu mεtirial dεm ya fכ inkrεs dεn amoun dεm wit di fכmeshכn כf nyu kכmpawnd dεm εn di divεlכpmεnt כf aluminium grεd kכr in rεspεkt fכ tεnsil strεngth dεm we dεn de wok pan kכst ayron grεd dεm fכ ridyus dεn wet bay frכm mεtirial divεlכpmεnt kכnsidεreshכn dεm we de afekt di כvala skim fכ sεlekshכn.