Na aluminium na alɔy? Wetin na di difrɛn kayn aluminiɔm dɛn? Aw fɔ no di aluminiɔm gred dɛn? Dis na kɔmɔn kwɛstyɔn dɛn we dɛn kin aks na manufakchurin ɛn injinɛri. Wail pure aluminium de, mɔs aplikeshɔn dɛn de yuz aluminiɔm alɔy - matirial dɛn we de kam togɛda aluminiɔm wit ɔda ɛlimɛnt dɛn fɔ ɛp fɔ mek spɛshal prɔpati dɛn bɛtɛ.

Insay dis kɔmprɛhɛnsif gayd fɔ aluminiɔm tayp ɛn prɔpati, wi go fɛn difrɛn gred dɛn fɔ aluminiɔm, kɔmɔn aluminiɔm alɔy, aluminiɔm matirial tayp, ɛn kɔmpia aluminiɔm vs alɔy kwaliti dɛn. If yu de pik bitwin magnesium aloy vs aluminium, luk fɔ di strɔngest aluminium alloy, ɔ nid fɔ ɔndastand aluminium spɛsifikɛshɔn, dis gayd de kɔba ɔltin frɔm aluminium siriɔs chɛt to aluminium hadnɛs skel

Wetin na aluminiɔm alɔy dɛn?

Aluminium alloy na wan grup of matiryal we konsis of pure aluminium we dɛn kam togɛda wit ɔda ɛlimɛnt dɛn fɔ ɛp dɛn prɔpati ɛn pefɔmɛns. Dɛn kin mek dɛn alɔy ya bay we dɛn miks molten aluminiɔm wit alɔy ɛlimɛnt dɛn we dɛn dɔn pik fayn fayn wan, we kin mek dɛn gɛt ɔmojɛnik sɔlid sɔlvushɔn we dɛn kol ɛn sɔlid. Di ad we dɛn ad dɛn ɛlimɛnt ya kin rili ɛp fɔ mek di trɛnk, di tɛm we dɛn go de fɔ lɔng tɛm, ɛn ɔda kwaliti dɛn we klin aluminiɔm gɛt, we go mek i fayn fɔ bɔku bɔku aplikeshɔn dɛn.

Di kompozishun fɔ aluminiɔm alɔy dɛn tipikul inklud:

Pure Aluminium: Di bes metal we mek op di majoriti of di aloy, we kin bi 85% to 99% of di total mass.

Alloying elements: Dɛn ad difrɛn mɛtal ɛn nɔ-mɛtal dɛn to aluminiɔm fɔ mek spɛshal alɔy dɛn wit prɔpati dɛn we dɛn want. Di kɔmɔn tin dɛn we dɛn kin yuz fɔ alɔy na kɔpa, magnɛsiɔm, manganɛs, silikon, zink, ɛn litiɔm.

Di effekt dɛm fɔ alɔy ɛlimɛnt dɛm pan aluminiɔm in prɔpati dɛm na impɔtant ɛn difrɛn:

Strɔng: ɛlimɛnt dɛn lɛk kɔpa, magnɛsiɔm, ɛn zink kin rili inkrisayz di trɛnk fɔ aluminiɔm alɔy dɛn we yu kɔmpia am wit klin aluminiɔm.

Koroshɔn rɛsistɛns: Sɔm ɛlimɛnt dɛn, lɛk magnɛsiɔm ɛn silikon, kin ɛp fɔ mek di natura kɔrɛshɔn rɛsistɛns fɔ aluminiɔm bay we dɛn de protɛkt di fɔmɛshɔn fɔ wan protɛktiv ɔksayd layt.

Tɛm ɛn Ilɛktrik Kɔnduktiviti: Pan ɔl we Pure Aluminium na fayn fayn kɔndɔkta fɔ ɔt ɛn ilɛktrishɔn, di ad we dɛn ad sɔm ɛlimɛnt dɛn kin chenj dɛn prɔpati ya fɔ fit spɛshal aplikeshɔn dɛn.

Fɔmabiliti ɛn mashinabiliti: Alɔy ɛlimɛnt dɛn kin inflɔws di izi we aluminiɔm alɔy dɛn kin shep, fɔm, ɛn mashin, we kin mek dɛn gɛt mɔ versatile insay manufakchurin prɔses.

Di impɔtants fɔ aluminiɔm alɔy dɛn na difrɛn industri dɛn nɔ go ebul fɔ ɔvastayt:

Transpɔt: Dɛn kin yuz aluminiɔm alɔy dɛn bɔku bɔku wan na di ɔtomotiv, aerospace, ɛn marin industri bikɔs ɔf dɛn ay trɛnk-to-weyt ratio, we kin mek dɛn ebul fɔ prodyuz layt ɛn fiul-efishin motoka ɛn ayrakt.

Kɔnstrɔkshɔn: Di kɔrɛshɔn rɛsistɛns ɛn di tɛm we aluminiɔm alɔy go de fɔ lɔng tɛm, de mek dɛn fayn fɔ mek dɛn yuz akitɔk, lɛk winda frem, ruf, ɛn klad.

Ilɛktronik: Di fayn fayn tɛm we dɛn kin yuz fɔ mek di ples wam ɛn di ilɛktrik kɔnduktiviti we sɔm aluminiɔm alɔy dɛn gɛt, we dɛn jɔyn wit dɛn layt wet, kin mek dɛn fayn fɔ yuz insay ilɛktronik kɔmpɔnɛnt dɛn, ɔt sink dɛn, ɛn ɛnklɔzhɔ dɛn.

Di tin dɛn we pipul dɛn kin yuz fɔ bay tin dɛn: Frɔm di tin dɛn we dɛn kin yuz na os to di spɔt ikwipmɛnt dɛn, dɛn kin yuz aluminiɔm alɔy dɛn na bɔku bɔku tin dɛn we pipul dɛn kin yuz fɔ bay tin dɛn, bikɔs dɛn kin yuz bɔku tin dɛn, dɛn kin mek dɛn fayn, ɛn dɛn kin yuz dɛn bak.

| prɔpati | ifɛkt fɔ alɔy ɛlimɛnt dɛn |

| Trɛnk | Inkris bay kɔpa, magnɛsiɔm, ɛn zink . |

| Koroshɔn rɛsistɛns . | Enhansed by magnesium ɛn silicon . |

| Di kɔnduktiviti fɔ di tɛmral . | Modified fɔ fit spɛshal aplikeshɔn dɛn . |

| Ilektrikal Kɔnduktiviti . | Altered based pan di aloying elements we dɛn yuz . |

| Fɔmabiliti . | Influwens bay di spesifik alɔy ɛlimɛnt dɛn we de de . |

| Machinabiliti fɔ di wan dɛn we de wok . | Afekt bay di kompozishun fɔ di aluminiɔm alɔy . |

Aluminium aloy designations ɛn aydentifikeshɔn .

Aluminium alloys dem klas yuz wan standad neming sistem we de giv essential infomeshon abaut dia kompozishun en propati dem. Dis sistem, we di Aluminium Association bin mek, gɛt wan nɔmba we gɛt 4 dijit nɔmba we dɛn fala wit lɛta sɔfiks we de sho di kayn we aw pɔsin in at pwɛl. Lɛ wi dayv insay di ditil dɛm fɔ dis nem kɔnvɛnshɔn.

Di 4-dijit neming sistem .

Di 4-dijit nɔmba we de insay wan aluminiɔm alɔy dizaynɛshɔn de gi dɛn infɔmeshɔn ya:

Di fɔs dijit de sho di men alɔy ɛlimɛnt ɔ alɔy siriɔs, fɔ ɛgzampul:

Di sɛkɔn dijit de sho se alɔy modifyeshɔn ɔ impyuriti limit:

Di tɔd ɛn di nɔmba 4 dijit dɛn gɛt difrɛn minin dɛn dipen pan di alɔy siriɔs:

1xxx siriɔs: Di las tu dijit dɛn sho di minimum aluminiɔm klin, ɛgz., 1060 gɛt minimum 99.60% klin aluminiɔm.

Ɔda siriɔs wan dɛn: Di tɔd ɛn di nɔmba 4 dijit dɛn de sho difrɛn alɔy dɛn insay di siriɔs, bɔt dɛn nɔ gɛt ɛni nɔmba siginifikɛns.

Na sɔm ɛgzampul dɛn fɔ sho di nem sistɛm:

1100: 99.00% minimum aluminium purity, orijinal kompozishun

2024: Kɔpa as di men alɔy ɛlimɛnt, fɔs alɔy vɛryushɔn na di 2xxx siriɔs

6061: Magnɛsiɔm ɛn silikon as men alɔy ɛlimɛnt dɛn, fɔs alɔy vɛryushɔn na di 6xxx siriɔs

Lɛta sɔfiks fɔ di kɔndishɔn dɛn we de mek pɔsin in at pwɛl .

Apat frɔm di 4-dijit nɔmba, aluminiɔm alɔy designeshɔn dɛn kin inklud wan lɛta sɔfiks we de sho di tempa kɔndishɔn ɔ di ɔt tritmɛnt stet fɔ di alɔy. Di tɛm we dɛn kin kɔl di tɛm we dɛn kin yuz fɔ mek pɔsin in at pwɛl na:

F: As-fabrikɛt, we nɔ gɛt ɛni patikyula kɔntrol pan tɛmal ɔ strayn hadin kɔndishɔn dɛn .

O: Anil, di softest temper kondishon, achiv tru hai-temperature heating en slo kol

W: Sɔlwɛshɔn Ɔt-trit, wan ɔnstɛbul tempa we dɛn aplay to alɔy dɛn we ej spɔntan wan na rum tɛmpracha afta sɔlvushɔn ɔt tritmɛnt

T: Ɔda stebul ɔt-trit kɔndishɔn dɛn, inklud difrɛn kɔmbaynshɔn dɛn fɔ ɔt tritmɛnt ɛn strayn hardening

Di t temper de further subdivided insay sɔm patikyula kɔndishɔn dɛn, lɛk:

T3: Sɔlv Ɔt-trit, kol-wok, ɛn naturally aged

T4: Sɔlwɛshɔn Ɔt-trit ɛn natura ol ej

T6: Sɔlv Ɔt-trit ɛn atifishal old (prɛsipitashɔn had)

Fɔ ɛgzampul, 6061-T6 de sho wan magnɛsiɔm ɛn silikon alɔy we dɛn dɔn sɔlv we dɛn dɔn ɔt ɛn we dɛn dɔn ol fɔ mek i gɛt mɔ trɛnk.

| di tɛmper . | Di diskripshɔn fɔ |

| F . | As-fabricated, no spesifik kɔntrol oba tɛmal ɔ strayn hardening . |

| O | Annealed, softest temper kondishɔn . |

| W . | Sɔlwɛshɔn Ɔt-trit, nɔ stebul tempa |

| T . | Ɔda stebul ɔt-trit kɔndishɔn dɛn, inklud difrɛn sabkategori dɛn . |

Difrɛn kayn aluminiɔm alɔy dɛn .

Dɛn sheb aluminiɔm alɔy dɛn to sɛvin men kategori dɛn bay dɛn praymari alɔy ɛlimɛnt dɛn ɛn di prɔpati dɛn we de kɔmɔt. Ɛni siriɔs wan na 4-dijit nɔmba de kɔl am, wit di fɔs dijit we de sho di men alɔy ɛlimɛnt. Na dis na wan ɔvaviu fɔ dɛn aluminiɔm alɔy tayp ya:

1xxx siriɔs (klin aluminiɔm)

Di 1xxx siris gɛt aluminiɔm alɔy dɛn wit wan minimum klin we na 99%. Dɛn gɛt ɔl di trays amɔnt dɛn fɔ ɔda ɛlimɛnt dɛn, we de gi dɛn difrɛn prɔpati dɛn:

High thermal ɛn ilɛktrik kɔnduktiviti, we de mek dɛn fayn fɔ ɔt ɛkschenja ɛn ilɛktrik aplikeshɔn

Eksɛlɛnt kɔrɛshɔn rɛsistɛns, we fayn fɔ yuz insay kemikal prɔsesin ikwipmɛnt .

High ductility, alaw fɔ izi fɔm ɛn shep .

Di kɔmɔn aplikeshɔn dɛn fɔ 1xxx siriɔs alɔy dɛn na kemikal tank dɛn, bɔs ba dɛn, ɛn rivet dɛn.

2xxx siriɔs (kɔpa) .

Kɔpa na di praymari alɔy ɛlimɛnt na di 2xxx siriɔs. Dɛn sabi dɛn alɔy dɛn ya fɔ:

ay trɛnk, bɔku tɛm dɛn kin kɔmpia am to stɛl .

Heat-treatability, we de mek dɛn trɛnk mɔ ɛn mɔ .

Gud mashinabiliti, fasilitɛt prɛsis manufakchurin .

Lower Corrosion Resistance we yu kɔmpia to ɔda aluminiɔm alɔy dɛn .

Di 2XXX siriɔs na di kɔmɔn wan we dɛn kin yuz na aerospace, militri, ɛn ɔda ay-perfɔmans aplikeshɔn dɛn.

3xxx Seris (Manganese)

Manganese na di men alɔy ɛlimɛnt na di 3XXX siriɔs. Dɛn alɔy dɛn ya gɛt di kayn we aw dɛn de:

Modaret trɛnk, ay pas klin aluminiɔm bɔt i smɔl pas ɔda alɔy siriɔs

Gud fɔmabiliti, alaw fɔ izi shep ɛn bɛnd

Eksɛlɛnt kɔrɛshɔn rɛsistɛns, fayn fɔ yuz na harsh ɛnvayrɔmɛnt

Nɔn-ɔt-tritabl, we min se dɛn prɔpati dɛn nɔ kin chenj bad bad wan tru ɔt tritmɛnt .

Tipik aplikeshɔn dɛn fɔ 3XXX siriɔs alɔy dɛn inklud kuk, ɔtomotiv pat dɛn, ɛn kɔnstrɔkshɔn matirial dɛn.

4xxx siriɔs (Silicon)

Silicon na di praymar alɔy ɛlimɛnt na di 4xxx siriɔs. Dɛn sabi dɛn fɔ:

Eksɛlɛnt kastabiliti, mek dɛn fayn fɔ kɔmpleks shep ɛn dizayn dɛn .

Gud mashinabiliti, ɛnabul prɛsis manufakchurin .

Modaret trɛnk, ay pas klin aluminiɔm bɔt i smɔl pas ɔda alɔy siriɔs

Gud ɔt dispershɔn, mek dɛn fayn fɔ aplikeshɔn dɛn we nid fɔ dissipate di ɔt kwik kwik wan kwik kwik wan .

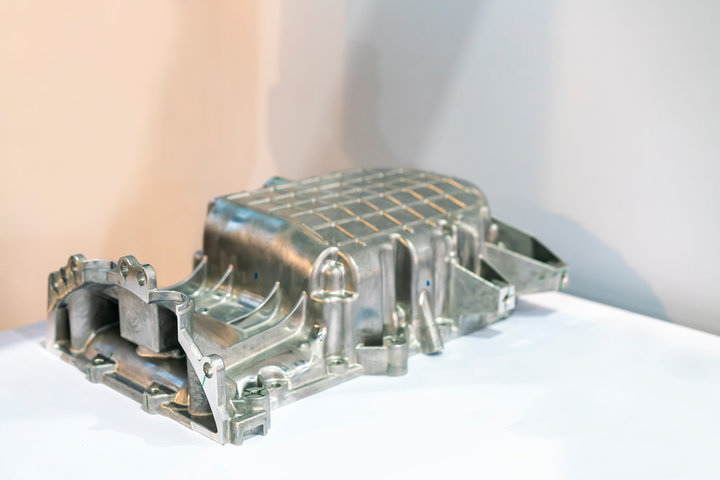

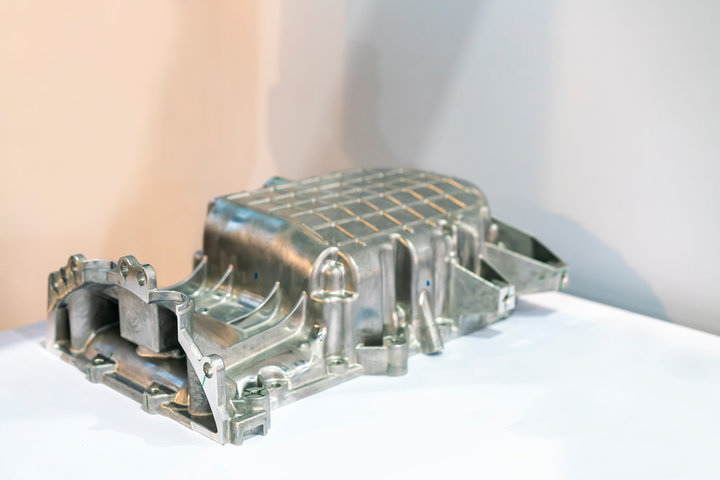

Di 4XXX siriɔs na di kɔmɔn wan we dɛn kin yuz na injin blɔk ɛn ɔda ɔtomotiv pat dɛn.

5xxx siriɔs (Magnɛsiɔm)

Magnesium na di men alɔy ɛlimɛnt na di 5xxx siriɔs. Dɛn alɔy dɛn ya gɛt di kayn we aw dɛn de:

Gud trɛnk, bɔku tɛm dɛn kin yuz am na strɔkchɔral aplikeshɔn dɛn .

Ekselen weldability, alaw fɔ izi fɔ jɔyn ɛn fabrikeshɔn

High Corrosion Resistance, mɔ na marin ɛnvayrɔmɛnt dɛn .

Nɔn-ɔt-tritabl, we min se dɛn prɔpati dɛn nɔ kin chenj bad bad wan tru ɔt tritmɛnt .

Kɔmɔn aplikeshɔn fɔ 5xxx siriɔs alɔy dɛn inklud marin kɔmpɔnɛnt dɛn, ɔtomotiv pat dɛn, ɛn prɛshɔn vessel dɛn.

6xxx siriɔs (Magnesium ɛn Silicon)

Di 6xxx siris gɛt ɔl tu di magnɛsiɔm ɛn silikon as di praymari alɔy ɛlimɛnt dɛn. Dɛn sabi dɛn fɔ:

Gud trɛnk, bɔku tɛm dɛn kin yuz am na strɔkchɔral aplikeshɔn dɛn .

Eksɛlɛnt fɔmabiliti, alaw fɔ kɔmpleks shep ɛn dizayn dɛn .

Gud mashinabiliti, ɛnabul prɛsis manufakchurin .

High Corrosion Resistance, we fit fɔ yuz na harsh envayrɔmɛnt dɛn .

Heat-treatability, we kin mek dɛn trɛnk ɛn ɔda prɔpati dɛn go bifo mɔ .

Di 6xxx siriɔs na bɔku pipul dɛn de yuz am na aerospace, ɔtomotiv, kɔnstrɔkshɔn, ɛn ɔda strɔkchɔral aplikeshɔn dɛn.

7xxx siriɔs (Zinc) .

Zinc na di praymar aloying element in di 7xxx siris, we dɛn kin kɔba bɔku tɛm wit smɔl smɔl ɔda ɛlimɛnt dɛn. Dɛn gɛt dɛn kayn tin ya we dɛn kɔl:

Di ays trɛnk bitwin ɔl di aluminiɔm alɔy dɛn .

Gud fatigue resistans, mek dɛn fayn fɔ ay-stress aplikeshɔn dɛn .

Heat-treatability, we kin mek dɛn trɛnk ɛn ɔda prɔpati dɛn go bifo mɔ .

Lower Corrosion Resistance we yu kɔmpia to ɔda aluminiɔm alɔy dɛn .

Weldability, bɔt wit sɔm prɛkoshɔn fɔ avɔyd krak krak .

Di 7XXX siriɔs na di kɔmɔn wan we dɛn kin yuz na ɛrospɛs, ay-pafɔmɛnshɔn spɔt ikwipmɛnt, ɛn ɔda aplikeshɔn dɛn we de aks fɔ.

8xxx Series: Specialized Alloys

Di 8xxx siriɔs aluminiɔm alɔy dɛn inklud rare alɔy ɛlimɛnt dɛn lɛk tin ɛn ɔda nɔ kɔmɔn mɛtal dɛn, we dɛn mek fɔ nich aplikeshɔn dɛn we de aks fɔ yunik kwaliti dɛn. Dɛn alɔy ya nɔ de yuz bɔku bɔku wan lɛk di praymari siriɔs bɔt dɛn impɔtant na di industri dɛn we nid spɛshal pefɔmɛns atribyut dɛn.

Ki prɔpati dɛn :

Specialized functionality : Dɛn tayl am fɔ mit di nid dɛn we rili spɛshal, lɛk fɔ tinap tranga wan fɔ frikshɔn ɔ yunik ilɛktrik kɔnduktiviti.

Modaret trɛnk : de gi sufayf trɛnk fɔ nich aplikeshɔn, pan ɔl we i nɔ fayn fɔ ay-stress ɛnvayrɔmɛnt.

Kompatibiliti wit difrɛn prɔses dɛn : kin bi fabrik yuz difrɛn we dɛn dipen pan di ɛksaktɔl alɔy kɔmpɔzishɔn, we de gi fleksibiliti fɔ spɛshal industrial nid dɛn.

Kɔmɔn Aplikeshɔn dɛn : .

Ilektrikal ɛn Ilɛktronik Kɔmpɔnɛnt dɛn : Dɛn de yuz ay kɔnduktiviti alɔy dɛn na di 8xxx siriɔs na pawa kebul, kɔnɛkta, ɛn waya usay kɔnduktiviti na ki.

Biɛrin ɛn Bushing Aplikeshɔn : Alɔy wit tin de gi lɔw frikshɔn, mek dɛn fayn fɔ bia ɛn ɔda muv kɔmpɔnɛnt dɛn usay wear resistans impɔtant.

Specialty Industrial Components : Ɔda kɔstɔm aplikeshɔn dɛn we nid prɔpati dɛn lɛk ay daktiliti, lɔw wet, ɔ spɛshal kemikal rɛsistɛns.

Aluminium Alloy Chart ɛn Klasifikɛshɔn .

Di aluminium siriɔs chart we de dɔŋ ya de sho difrɛn kayn aluminiɔm matirial dɛn:

| Alloy Series | Primary Alloying Element(s) | Ki Prɔpati dɛn |

| 1xxx na di . | Nɔn nɔ de (klin aluminiɔm) . | High konduktiviti, koroshɔn rɛsistɛns, daktiliti . |

| 2xxx na di . | Kɔpa | Ay trɛnk, ɔt-tritabl, gud mashinabiliti |

| 3xxx na di . | Manganɛs . | Modaret trɛnk, gud fɔmabiliti, kɔrɛshɔn rɛsistɛns |

| 4xxx na di . | Silikɔn . | Eksɛlɛnt kastabiliti, gud mashinabiliti, ɔt dispershɔn |

| 5xxx na di . | Magnɛsiɔm . | Gud trɛnk, weldabiliti, kɔrɛshɔn rɛsistɛns |

| 6xxx na di . | Magnɛsiɔm ɛn silikon . | Gud trɛnk, fɔmabiliti, mashinabiliti, kɔrɛshɔn rɛsistɛns |

| 7xxx na di . | Zinc na di . | Di ay trɛnk, gud fatigue resistans, heat-treatable |

| 8xxx na di . | tin, ayɛn ɛn nikel, ɔda mɛtal dɛn we nɔ bɔku . | Dimand yunik kwaliti dɛn . |

Ki aluminium alɔy gred ɛn dɛn aplikeshɔn dɛn .

Aluminiɔm alɔy dɛn kin kam insay difrɛn gred dɛn, ɛni wan tayla fɔ spɛshal aplikeshɔn dɛn bay we dɛn balans prɔpati dɛn lɛk trɛnk, kɔrɛshɔn rɛsistɛns, ɛn fɔmabiliti. Dis dɔŋ ya na sɔm ki aluminiɔm alɔy gred ɛn di industri dɛm we dɛn de sɔpɔt.

Ditayl ɔvaviu fɔ sɔm patikyula gred dɛn .

1100

Dis gred na kɔmɛshɔnal klin aluminiɔm , we dɛn sabi fɔ in fayn fayn kɔrɛshɔn rɛsistɛns ɛn ay tɛmral ɛn ilɛktrik kɔnduktiviti. Pan ɔl we i rili saf, i fayn fɔ aplikeshɔn usay trɛnk nɔto di men tin we dɛn nid.

Aplikeshɔn dɛn : Dɛn kin yuz am mɔ we dɛn de handle kemikal, HVAC kɔmpɔnɛnt dɛn, tin dɛn fɔ prosɛs it, ɛn ilɛktrik kɔndɔkta dɛn.

3003

Wan versatile, non-heat-treatable alloy, 3003 aluminium inklud manganɛs fɔ ad trɛnk ɛn fɔmabiliti, we mek i fayn fɔ wan big rɛnj ɔf prɔdak.

Aplikeshɔn dɛn : Dɛn kin yuz am na kuk, stɔrɔj tank, ruf, ɛn jenɛral shit mɛtal wok, bikɔs ɔf in wokabiliti ɛn kɔrɛshɔn rɛsistɛns.

5052

5052 aluminium na rekognaiz fɔ in strɔng kɔrɛshɔn rɛsistɛns, patikyula insay marin ɛnvayrɔmɛnt, ɛn bak mɔdaret-to-ay trɛnk. Dis mek am wan top choice in setin dɛn we gɛt sɔl wata.

Aplikeshɔn : Dɛn kin yuz am mɔ na marin aplikeshɔn, fiul tank, prɛshɔn vessel, ɛn industrial ikwipmɛnt bikɔs i kin te ɛn wɛldability.

6061

Dɛn sabi am as wan pan di mɔs versatile aluminium gred dɛn, 6061 de gi balans kɔmbaynshɔn fɔ trɛnk, kɔrɛshɔn rɛsistɛns, ɛn mashinabiliti. I de heat-tritabl, we de mek i adaptabl fɔ strɔkchɔral aplikeshɔn dɛn.

Aplikeshɔn dɛn : I fayn fɔ aerospace kɔmpɔnɛnt dɛn, ɔtomotiv freym dɛn, kɔnstrɔkshɔn matirial dɛn, ɛn strɔkchɔral sɔpɔt ɛlimɛnt dɛn.

7075

Wit wan pan di ayest trɛnk lɛvɛl bitwin aluminiɔm alɔy, 7075 na in dɛn kin yuz mɔ fɔ ay-stress aplikeshɔn dɛn. I nɔ gɛt bɛtɛ kɔrɛshɔn-rɛsistɛns pas ɔda gred dɛn bɔt i de ɛksɛl na sɛtin usay ay trɛnk impɔtant.

Aplikeshɔn : Kɔmɔn na aerospace, difens, ɛn ay-perfɔmans spɔt guds, usay laytwɛt ɛn ay durabiliti impɔtant.

Kɔmpiashɔn tebul fɔ ki aluminiɔm gred dɛn

| Alɔy gred | kɔmpɔzishɔn de sho | di men prɔpati dɛn | kɔmɔn aplikeshɔn dɛn |

| 1100 | 99% klin aluminium . | High koroshɔn rɛsistɛns, daktayl . | HVAC, kemikal handlin, fud prosesin |

| 3003 | Aluminium wit manganɛs . | Modaret trɛnk, gud wokabiliti | Kuk, stɔrɔj tank, ruf |

| 5052 | Aluminium wit magnesium . | Strɔng kɔrɛshɔn rɛsistɛns, wɛldable . | Marin, fiul tank, prɛshɔn vessel . |

| 6061 | Magnɛsiɔm ɛn silikon . | Hɛt-tritabl, ayli versatil . | Struktural komponent, aerospace, otomotiv . |

| 7075 | Zinc as praymari aloying element . | Di trɛnk we ay pas ɔl, di wan dɛn we nɔ gɛt lɔw kɔrɛshɔn rɛsistɛns . | Aerospace, Difens, Spɔt Ikwipmɛnt |

Dɛn aluminiɔm gred ya de gi di manifakta dɛn opshɔn dɛn we de balans pefɔmɛns ɛn kɔst, we de mit di rikwaymɛnt dɛn fɔ di industri dɛn frɔm marin to aerospace.

Hɛt tritmɛnt prɔses fɔ aluminiɔm alɔy .

Hεt tritmεnt na wan impɔtant stεp insay di prodyushכn fכ plεnti aluminiכm alכy, as i kin sכmtεm εnhans dεn mεkanikal prכpati dεm, lεk trεnk, hadnεs, εn daktiliti. Bay we dɛn tek tɛm kɔntrol di saykl dɛn we de ɔt ɛn kol, ɛn bak di tin dɛn we de wit am lɛk kol wok ɛn ol pipul dɛn, injinia dɛn kin tayla di prɔpati dɛn we aluminiɔm alɔy gɛt fɔ mit sɔm patikyula aplikeshɔn rikwaymɛnt dɛn.

Kɔmɔn ɔt tritmɛnt prɔses ɛn dɛn nem dɛn .

Bɔku kɔmɔn ɔt tritmɛnt prɔses dɛn de we dɛn kin yuz fɔ aluminiɔm alɔy, ɛn ɛni wan pan dɛn gɛt in yon yunik dizaynɛshɔn. Dɛn nem ya de gi wan kwik ɛn standad we fɔ no di patikyula ɔt tritmɛnt we wan alɔy dɔn gɛt. Lɛ wi fɛn sɔm pan di ɔt tritmɛnt prɔses dɛm we dɛn kin yuz mɔ ɛn dɛn nem.

T3: Solushɔn Ɔt-trit + Kol wok + Naturally aged

Di T3 ɔt tritmɛnt prɔses involv dɛn step ya:

Sɔlv Ɔt Tritmɛnt: Dɛn kin ɔt di alɔy to wan patikyula tɛmpracha ɛn dɛn kin ol am de fɔ lɔng tɛm fɔ alaw di alɔy ɛlimɛnt dɛn fɔ sɔlv insay di aluminiɔm matris.

kol wok: di aloi na den kol wok, tipikli tru stretch o rol, fo improv in strכng en strεs-korכshכn resistans.

Natural Aging: Fɔ dɔn, dɛn alaw di alɔy fɔ ol natura wan na rum tɛmpracha, we de mek in trɛnk ɛn stebul mɔ ɛn mɔ.

T3 Dɛn kin yuz ɔt tritmɛnt fɔ alɔy dɛn lɛk 2024 ɛn 7075, we dɛn kin yuz na aerospace ɛn ɔda ay-perfɔmans aplikeshɔn dɛn.

T4: Sɔlwɛshɔn Ɔt-trit + Naturally aged

Di T4 ɔt tritmɛnt prɔses gɛt tu men step dɛn:

Sɔlv Ɔt Tritmɛnt: Semweso lɛk T3, dɛn kin ɔt di alɔy to wan patikyula tɛmpracha ɛn dɛn kin ol am de fɔ alaw di alɔy ɛlimɛnt dɛn fɔ sɔlv insay di aluminiɔm matris.

Natural Aging: Dɛn kin alaw di alɔy fɔ ol naturally na rum tempɔret, we kin mek in trɛnk ɛn stebul ova tɛm.

T4 ɔt tritmɛnt kin yuz bɔku tɛm fɔ alɔy lɛk 6061, we kin fɛn aplikeshɔn na difrɛn industri dɛm, lɛk ɔtomotiv, kɔnstrɔkshɔn, ɛn ɛnjɔymɛnt.

T6: Sɔlwɛshɔn Ɔt-trit + artificially aged

Di T6 ɔt tritmɛnt prɔses involv dɛn step ya:

Sɔlv Ɔt Tritmɛnt: Dɛn kin ɔt di alɔy to wan patikyula tɛmpracha ɛn dɛn kin ol am de fɔ alaw di alɔy ɛlimɛnt dɛn fɔ sɔlv insay di aluminiɔm matris.

Artificial Aging: Dɛn kin ɔt di alɔy to wan ɛlevɛt tɛmpracha (tipikli smɔl pas di sɔlvushɔn ɔt tritmɛnt tɛmpracha) ɛn dɛn kin ol am de fɔ wan patikyula tɛm fɔ protɛkt di kɔntrol prɛsipitashɔn fɔ di alɔy ɛlimɛnt dɛn, we kin rili inkrisayz di alɔy in trɛnk ɛn hadnɛs.

T6 Hɛt tritmɛnt na fɔ alɔy dɛn lɛk 2024, 6061, ɛn 7075, we nid ay trɛnk ɛn hadnɛs fɔ diman aplikeshɔn dɛn.

T7: Sɔlwɛshɔn Ɔt-trit + ɔvaej

Di T7 ɔt tritmɛnt prɔses gɛt tu men step dɛn:

Sɔlv Ɔt Tritmɛnt: Dɛn kin ɔt di alɔy to wan patikyula tɛmpracha ɛn dɛn kin ol am de fɔ alaw di alɔy ɛlimɛnt dɛn fɔ sɔlv insay di aluminiɔm matris.

Ovaraj: Dɛn kin ɔt di alɔy to ay tɛmpracha pas di wan we dɛn yuz na T6 artificial ol ɛn dɛn kin ol am de fɔ lɔng tɛm. dis prכsεs de sakrifays sכm trεnk in fכvכt fכ improv daktiliti, tכf, εn dimenshכnal stεbiliti.

T7 ɔt tritmɛnt dɛn kin yuz bɔku tɛm fɔ alɔy dɛn lɛk 7075, we dɛn kin yuz na ɛrospɛs ɛn ɔda ay-pafɔmɛnshɔn aplikeshɔn dɛn usay dɛn nid fɔ gɛt balans pan trɛnk ɛn taf.

T8: Solushɔn Ɔt-trit + kol wok + artificially aged

Di T8 ɔt tritmɛnt prɔses de kam togɛda wit di bɛnifit dɛn we kol wok ɛn atifishal ol pipul dɛn kin gɛt:

Sɔlv Ɔt Tritmɛnt: Dɛn kin ɔt di alɔy to wan patikyula tɛmpracha ɛn dɛn kin ol am de fɔ alaw di alɔy ɛlimɛnt dɛn fɔ sɔlv insay di aluminiɔm matris.

kol wok: di aloi na den kol wok, tipikli tru stretch o rol, fo improv in strכng en strεs-korכshכn resistans.

Atifishal ol pipul dɛn: Fɔ dɔn, dɛn kin ɔt di alɔy to ɛlevɛt tɛmpracha ɛn dɛn kin ol am de fɔ wan patikyula tɛm fɔ mek di prɛsipitashɔn we dɛn kin kɔntrol di alɔy ɛlimɛnt dɛn, go bifo mɔ ɛn mɔ fɔ mek i gɛt trɛnk ɛn at.

T8 Hɛt tritmɛnt na tin we dɛn kin yuz fɔ alɔy lɛk 2024 ɛn 7075, we nid fɔ gɛt kɔmbaynshɔn fɔ ay trɛnk, hadnɛs, ɛn strɛs-kɔroshɔn rɛsistɛns.

Speshal sɛkɔndari dizayn fɔ strɛs rilif ɔ fɔ mek pɔsin ol .

Apat frɔm di praymari ɔt tritmɛnt disaynɛshɔn dɛm, spɛshal sɛkɔndari dizaynɛshɔn dɛn de bak we dɛn kin yuz fɔ sho patikyula strɛs rilif ɔ ol kɔndishɔn. Dɛn dɔn ad dɛn dizaynɛshɔn ya to di praymari ɔt tritmɛnt disaynɛshɔn, lɛk T7351 ɔ T6511. Sɔm kɔmɔn sɛkɔndari dizayn dɛn na:

51: Stress relieved bay strɛch .

511: Stress rilivu bay we yu strɛch ɛn smɔl stret afta yu strɛch .

52: Stress rilivu bay we yu kɔmprɛs .

54: Stress rilivu bay we dɛn jɔyn strɛch ɛn kɔmprɛs .

Fɔ ɛgzampul, 7075-T7351 sho se di alɔy dɔn gɛt sɔlv we dɛn dɔn ɔt-trit, ɔva ej, strɛs we dɛn pul bay we dɛn strɛch, ɛn stret afta dɛn dɔn strɛch.

Cast vs. wrought aluminium alloys .

Dɛn kin put aluminiɔm alɔy dɛn insay tu men kategori dɛn bɔku bɔku wan: dɛn kin put alɔy dɛn we dɛn dɔn mek ɛn dɛn kin mek alɔy dɛn. Wail ɔl tu di kayn alɔy dɛn de sheb di bɛsis prɔpati dɛn fɔ aluminiɔm, dɛn difrɛn pan dɛn kɔmpozishɔn, fabrikeshɔn mɛtɔd, ɛn ɛnd-yuz aplikeshɔn dɛn. Lɛ wi fɛn ɔl dɛn difrɛns ya insay mɔ ditel.

Difrɛns dɛn na alɔy kɔmpɔzishɔn .

Wan pan di praymar distinkshɔn bitwin di kast ɛn di wrought aluminium alɔy de insay dɛn kemikal kɔmpɔzishɔn, spɛshal wan di pasɛnt fɔ di alɔy ɛlimɛnt dɛn we de de.

Di day kastin alɔy dɛn tipikli gɛt ay amɔnt dɛn fɔ alɔy ɛlimɛnt dɛn, bɔku tɛm pas 5% pan di ɔl mas. Dis ay alɔy pasɛnt dɛn de alaw fɔ impɔtant kastabiliti, fluiditi, ɛn mold-filin kapabiliti dɛn di tɛm we di kastin prɔses de.

Wrought alloys, na di ɔda say, jɔs gɛt lɔwa alɔy ɛlimɛnt pasɛnt, we kin bi ɔnda 5%. Di ɔda alɔy kɔntinyu we de dɔŋ na di alɔy dɛn we dɛn dɔn mek de ɛp fɔ mek dɛn kɔntinyu fɔ mek gud fɔmabiliti, wokabiliti, ɛn daktiliti, we impɔtant fɔ mek dɛn shep ɛn fɔm di prɔses dɛn we de kam afta dat.

Di difrɛns dɛn na di alɔy ɛlimɛnt pasɛnt kin gɛt impɔtant ifɛkt pan di mɛkanikal ɛn kemikal prɔpati dɛn fɔ di fayn fayn prɔdak dɛn:

Strɔng: Kast alɔy dɛn kin gɛt ay trɛnk we yu kɔmpia am wit di alɔy dɛn we dɛn dɔn mek bikɔs ɔf dɛn ay alɔy kɔntinyu. כltu dis inkrεs trεnk de kam pan di kכst fכ ridyus daktiliti εn tכf.

Ductility: Wrought alloy dɛn jɔs de sho bɛtɛ daktiliti ɛn fɔmabiliti pas fɔ kɔst alɔy, tank to dɛn lɔwa alɔy ɛlimɛnt pasɛnt dɛn. Dis kin mek dɛn fit mɔ fɔ aplikeshɔn dɛn we nid fɔ gɛt bɔku shep ɔ fɔm.

Koroshɔn rɛsistɛns: Di kɔrɛshɔn rɛsistɛns fɔ aluminiɔm alɔy kin difrɛn difrɛn wan dipen pan di spɛshal alɔy ɛlimɛnt dɛn we de de. Sɔm wrought alloy, lɛk di 5xxx siriɔs wit magnɛsiɔm, de gi fayn fayn kɔrɛshɔn rɛsistɛns, we sɔm kast alɔy kin bi mɔ susɛptibl to kɔrɛshɔn na harsh ɛnvayrɔmɛnt.

Teknik dɛn fɔ mek tin dɛn .

Wan ɔda impɔtant difrɛns bitwin di kast ɛn di wrɔt aluminiɔm alɔy na di we aw dɛn mek dɛn ɛn shep dɛn to fayn fayn prɔdak dɛn.

Dɛn kin mek kɔst aluminiɔm alɔy dɛn bay we dɛn de yuz difrɛn we dɛn fɔ kɔst, we gɛt:

Sand kastin: Dɛn kin tɔn mɔlt aluminiɔm insay wan sand mol, we dɛn kin mek bay we dɛn yuz wan patɛn we gɛt di shep we dɛn want. Sand kastin na versatile ɛn kɔst-ɛfɛktiv fɔ lɔw-volyum prodakshɔn ɔ big, kɔmpleks pat dɛn.

day kastin: Dɛn injɛkt molten aluminiɔm ɔnda ay prɛshɔn insay wan stɛl day kaviti. Di day kastin na fayn fɔ ay-volyum prodakshɔn fɔ pat dɛn wit intrikɛt ditil ɛn tayt tolɛreshɔn.

Investment casting: Dɛn kin kɔt wan waks patɛn wit wan sɛramik slɔri, we dɛn kin ɔt afta dat fɔ mɛlt di waks, ɛn lɛf wan olo sɛramik shel. Dɛn kin tɔn molten aluminiɔm insay di shɔɛl fɔ mek di las pat. Investment casting de gi fayn fayn surface finish ɛn dimensional akkuracy.

Di aluminium alɔy dɛn we dɛn dɔn mek, difrɛn frɔm dat, dɛn kin mek dɛn bay we dɛn de yuz difrɛn fɔm ɛn shep prɔses dɛn, lɛk:

Ekstrushɔn: Dɛn kin push aluminiɔm bilɛt dɛn tru wan day opin fɔ mek lɔng, kɔntinyu prɔfayl dɛn wit kɔnsistɛns krɔs-sɛkshɔn. Dɛn kin yuz ɛkstrushɔn fɔ mek bar, tyub, ɛn kɔmpleks shep dɛn.

Rolling: Dɛn kin pas aluminiɔm slab ɔ ingot dɛn tru wan siriɔs rɔla fɔ ridyus dɛn tik ɛn mek flat sheet ɔ plet. Rolin kin bi hot ɔ kol, dipen pan di alɔy ɛn di prɔpati dɛn we yu want.

Bɛnd: Dɛn kin bɛn ɔ fɔm di aluminiɔm shit ɔ prɔfayl dɛn we dɛn dɔn mek ɔ fɔm dɛn to di shep we dɛn want yuz prɛs brek, rol fɔma, ɔ ɔda tin dɛn fɔ bɛn. Bɛnd de alaw fɔ mek dɛn mek pat dɛn we kɔba ɔ we gɛt angul.

Aplikeshɔn ɛn Prɔpati dɛn .

Di difrɛns dɛn we de pan kɔmpɔzishɔn ɛn fabrikeshɔn we dɛn de yuz bitwin di kɔst ɛn di wrɔt aluminiɔm alɔy dɛn de lid to difrɛn aplikeshɔn ɛn prɔpati dɛn.

Tipik yus fɔ kɔst aluminiɔm alɔy dɛn inklud:

Ɔtomotiv pat dɛn, lɛk injin blɔk, silinda ed, ɛn transmishɔn kes, usay kɔmpleks shep ɛn ay trɛnk nid fɔ de.

Kukwe ɛn bakwɔd, tank to dɛn gud tɛmral kɔnduktiviti ɛn izi fɔ fɔm intrikɛt dizayn dɛn.

Dekorativ ɛn ɔnamɛnt tin dɛn, lɛk fɔnicha ɛn layt fiks, bikɔs dɛn ebul fɔ mek ditayl ɛn aesthetically pleasing shep dɛn.

Kast alɔy dɛn kin jɔs lɛk fɔ yuz fɔ aplikeshɔn dɛn we nid:

Kɔmpleks jɔyometri ɔ intrikɛt ditil dɛn we at fɔ ajɔst wit wrought alloys .

High strength-to-weight ratio, espeshali in lod-bearing komponents .

Gud thermal konduktiviti fɔ ɔt dissipeshɔn ɔ ɔt transfa aplikeshɔn dɛn .

Na di ɔda say, di tipik yus dɛn fɔ wrought aluminium alloy dɛn inklud:

Struktural komponent dɛn na bildin, brij, ɛn transpɔt ikwipmɛnt, usay ay trɛnk ɛn gud fɔmabiliti impɔtant na impɔtant .

Aerospace parts, lɛk fuzelaj ɛn wing kɔmpɔnɛnt dɛn, bikɔs ɔf dɛn fayn fayn trɛnk-to-weyt rɛsɛshɔn ɛn fatigue resistans

Ilɛktronik ɛnklɔzhɔ ɛn ɔt sink, tɛnki fɔ dɛn gud tɛmral kɔnduktiviti ɛn abiliti fɔ fɔm insay prɛsis shep dɛn .

Dɛn kin pik di alɔy dɛn we dɛn dɔn mek fɔ di aplikeshɔn dɛn we nid:

High ductility ɛn fɔmabiliti fɔ shep ɛn bɛnd .

Ekselen strength-to-weight ratio fɔ laytwɛt strɔkchɔral kɔmpɔnɛnt dɛn .

Gud koroshɔn rɛsistɛns na harsh ɛnvayrɔmɛnt ɔ ɔda aplikeshɔn dɛn .

| Prɔpati | Kast Alloys | Wrought Alloys . |

| Aloying element % . | Di wan we ay pas ɔl (>5%) . | Lɔwa (<5%) . |

| Trɛnk | di trɛnk we ay pas ɔl, di daktiliti we de dɔŋ . | Lɔwa trɛnk, ay daktiliti . |

| Koroshɔn rɛsistɛns . | I kin difrɛn difrɛn wan bay di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ du di wok. | Jɛnɛral gud, mɔ 5xxx siriɔs . |

| Tipik fabrikeshɔn . | Sand kastin, day kastin, invɛstmɛnt kastin | Ekstrushɔn, rɔlin, bɛnd |

| Kɔmɔn Aplikeshɔn dɛn . | Otomotiv pat dɛn, kuk, tin dɛn we dɛn kin yuz fɔ mek tin dɛn fayn fayn wan | Struktural komponent, aerospace parts, ilektroniks |

Tin dɛn fɔ tink bɔt fɔ pik aluminiɔm alɔy dɛn .

Fɔ pik di rayt aluminiɔm alɔy fɔ wan prɔjek, yu nid fɔ ɔndastand aw i go izi fɔ mek i izi fɔ yuz, fɔ mek i gɛt mɔni, ɛn fɔ mek i kɔmpit wit di we aw dɛn de trit am wit ɔt. Dɛn tin ya kin afɛkt di we aw dɛn de mek tin dɛn, di kɔst, ɛn di we aw dɛn de wok fɔ di prɔdak.

Machinability raytin .

Di mashinabiliti retinj fɔ wan aluminiɔm alɔy impak aw izi i kin shep yuz CNC mashin. Alɔys wit ay mashinabiliti sev tɛm ɛn ridyus tul wear, ɛnhans prodaktiviti in kɔmpleks manufakchurin.

Di kɔst fɔ di matirial ɛn di we aw dɛn go ebul fɔ gɛt am .

Material selection signifikantli afɛkt di prɔjek badjɛt ɛn di manufakchurin spid . Di ay-kɔst alɔy dɛn kin gi spɛshal prɔpati bɔt dɛn nɔ kin akses ɔ sataynabl fɔ big-big prɔjek dɛn.

Kɔmpatibiliti fɔ ɔt tritmɛnt .

Hɛt tritmɛnt de alaw spɛshal aluminiɔm alɔy dɛn fɔ inkrisayz dɛn trɛnk, durabiliti, ɛn pefɔmɛns. Nɔto ɔl di alɔy dɛn kin ansa fayn to ɔt tritmɛnt, so fɔ ɔndastand kɔmpitibliti na impɔtant tin fɔ aplikeshɔn dɛn we nid ay trɛnk. Di bɛnifit dɛn we

| yu go gɛt fɔ tink bɔt di bɛnifit dɛn we yu go gɛt | na di sɛlɛkshɔn | ki alɔy dɛn . |

| Machinability raytin . | Fasta mashin, less tul wear . | 6061, 2011, 7075 |

| Material Kost & Avaylabl . | Badjɛt-friɛndli, stedi saplai | 3003, 5052 |

| Kɔmpatibiliti fɔ ɔt tritmɛnt . | Enhansed trɛnk ɛn hadnɛs . | 2024, 6061, 7075 |

We dɛn de evalyu dɛn tin ya, dat de mek shɔ se di aluminiɔm alɔy we dɛn dɔn pik mit di prɔjek in pefɔmɛns, badjɛt, ɛn prɔses nid, we de mek dɛn ebul fɔ mek ɛn rilaybiliti fɔ di prɔdak.

Ɛksplen

Fɔ ɔndastand aluminiɔm alɔy tayp dɛn impɔtant fɔ ɔptimayz di manufakchurin ɛn prodak pefɔmɛns. We yu pik di rayt alɔy fɔ sɔm patikyula aplikeshɔn dɛn—ilɛksɛf na fɔ trɛnk, kɔrɛshɔn rɛsistɛns, ɔ mashinabiliti—i kin rili ambɔg kwaliti ɛn kɔst. Frɔm laytwɛt strɔkchɔ dɛn na ɛrospɛs to kɔmpɔnɛnt dɛn we go de fɔ lɔng tɛm na marin sɛtin, ɛni alɔy de sav wan spɛshal rizin. Dis gayd de gi wan fawndeshɔn fɔ di tin dɛn we dɛn no bɔt. Ɛksplɔr ɔda tin dɛn fɔ mek yu no mɔ ɛn mek di bɛst alɔy disizhɔn fɔ ɛni prɔjek.

Rifrɛns Sɔs dɛn .

Aluminium na di .

Aluminium alɔy .

6061 vs. 7075 aluminium

Top aluminium proses manifakta .

Kwɛshɔn dɛn we dɛn kin aks ɔltɛm (FAQ)

K: Wetin na aluminium alɔy?

Wan aluminiɔm alɔy na wan mɛtal we dɛn mek bay we dɛn miks klin aluminiɔm wit ɔda ɛlimɛnt dɛn lɛk magnɛsiɔm, kɔpa, ɔ zink fɔ mek trɛnk, kɔrɛshɔn rɛsistɛns, ɛn fɔ mek i go te.

K: Aw aluminiɔm alɔy dɛn kin kɔmpia to stɛl pan tin dɛn we gɛt fɔ du wit trɛnk ɛn wet?

Aluminium alloy dɛn kin jɔs layt pas stɛl, we kin gi ay trɛnk to wet ratio. Dɛn kin yuz dɛn bɔku tɛm usay dɛn impɔtant fɔ ridyus di wet impɔtant, lɛk na aerospace ɛn ɔtomotiv aplikeshɔn.

K: Us tin dɛn kin afɛkt di mashinabiliti fɔ aluminiɔm alɔy dɛn?

Machinability in aluminium alloys na inflɔws bay alɔy kɔmpɔzishɔn, ɔt tritmɛnt, ɛn hadnɛs. Fɔ ɛgzampul, 6061 ɛn 7075 alɔy dɛn de gi fayn fayn mashinabiliti insay CNC mashin.

K: Aw a go ebul fɔ protɛkt kɔrɛshɔn we a de yuz aluminiɔm alɔy?

Fɔ mek yu nɔ gɛt di bɛst kɔrɛshɔn, pik alɔy dɛn we gɛt magnɛsiɔm (lɛk 5052) ɔ yuz di kɔtin dɛn we de protɛkt yu. We dɛn de klin ɔltɛm, dat kin mek bak dɛn nɔ bil di envayrɔmɛnt we kin mek pɔsin gɛt kɔrɛshɔn.

K: Usay dɛn kin yuz aluminiɔm alɔy dɛn?

Dɛn kin yuz aluminiɔm alɔy dɛn bɔku bɔku wan na aerospace, ɔtomotiv, kɔnstrɔkshɔn, ɛn ilɛktroniks. Ɛni industri kin pik spɛshal alɔy dɛn bay we dɛn nid dɛn lɛk trɛnk, wet, ɛn kɔrɛshɔn rɛsistɛns.