Yu dɔn ɛva wɔnda wetin rili de drɛb di kɔst fɔ injɛkshɔn moldin? Ilɛksɛf yu de prodyuz sɔm ɔndrɛd ɔ milyɔn pat dɛn, fɔ ɔndastand di tin dɛn we de biɛn di injɛkshɔn moldin ɛkspɛns na di men tin fɔ mek yu gɛt bɔku mɔni. Frɔm mold dizayn to matirial sɛlɛkshɔn ɛn prodakshɔn volyum, lɛ wi dayv insay aw yu kin kɔntrol kɔst dɛn we yu de mentɛn ay-kwaliti rizɔlt.

Wetin na injɛkshɔn moldin?

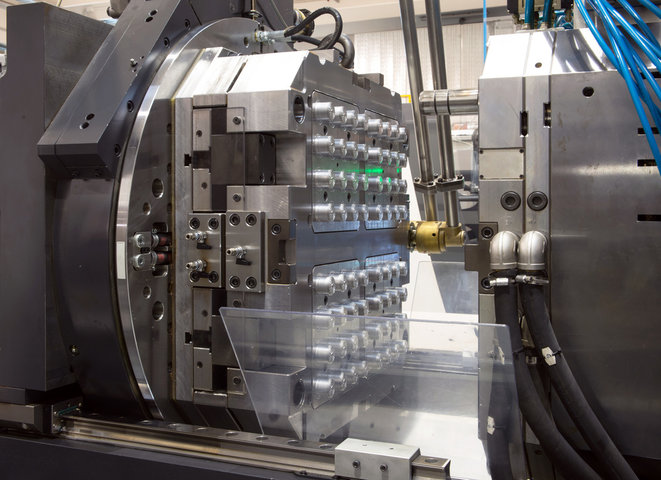

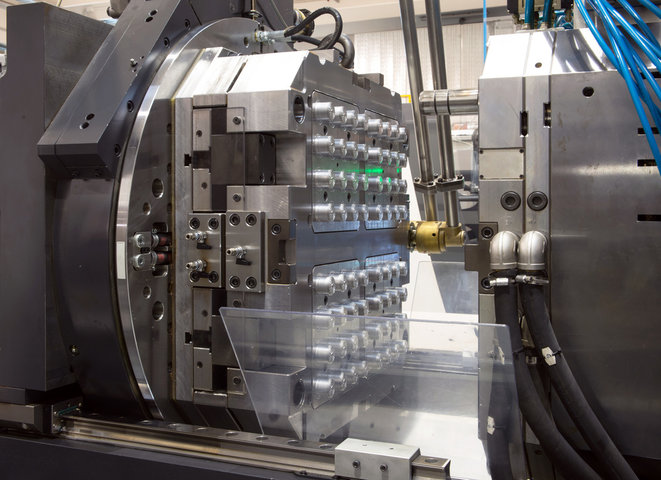

Injɛkshɔn moldin na wan manufakchurin prɔses we involv fɔ injɛkt molten matirial insay wan mol fɔ mek pat dɛn we gɛt prɛsis shep dɛn. Dis prɔses de wok bay we dɛn de mɛlt plastic ɔ ɔda tin, injɛkt am insay wan mol we dɛn dɔn mek bifo tɛm, ɛn alaw am fɔ kol ɛn sɔlid. Na wan pan di tɛknik dɛn we dɛn kin yuz mɔ fɔ mek ay kwaliti plastic kɔmpɔnɛnt dɛn insay bɔku bɔku wan.

Aw di injɛkshɔn moldin prɔses de wok?

Di injɛkshɔn moldin prɔses inklud sɔm ki stej dɛn:

Material Preparation : Dɛn kin wam di tɛmplastik pellet dɛn, lɛk ABS ɔ polypropylene te dɛn mɛlt.

Injekshɔn Faz : Dɛn kin injɛkt di tin we dɛn dɔn kɔt insay wan mol we dɛn gɛt ay prɛshɔn.

Cooling and solidifying : Di matirial de kol dɔŋ, i de at, ɛn tek di shep fɔ di mold.

Ejection : Dɛn kin pul di pat we dɔn strɔng frɔm di mold, ɛn i kin dɔn wan saykl.

Ki komponent dɛn fɔ di injɛkshɔn moldin sistem .

Mold : Di mold na di kɔr tul. I kin mek am wit mɛtal ɛn i kin gɛt tu af-af—sayd A ɛn sayd B. Sayd A kin mek di pat in ɔda say, we di sayd B kin shep di tin dɛn we de insay lɛk rib ɔ bɔs.

Mold Material : Bɔku pan di mol dɛn na aluminiɔm ɔ stɛl dɛn mek am, i dipen pan di prodakshɔn volyum ɛn di matirial we dɛn de mol.

Dizayn ficha dɛn : Mold dizayn dɛn inklud kɔling chanɛl dɛn, ejekta pin dɛn, ɛn rɔna sistem dɛn fɔ gayd matirial flɔ.

Injection Molding Machine : Di mashin gɛt wan hopper fɔ fid di raw matirial, wan barɛl we gɛt ɔt fɔ mɛlt am, ɛn wan haydrolik ɔ ilɛktrik mɛkanism fɔ injekt di molten plastic insay di mold.

Materials : Tɛmɔplastik, lɛk polypropylene (PP) ɛn akrilonitril Butadiene Styrene (ABS), dɛn kin yuz am fɔ injɛkshɔn moldin bikɔs dɛn kin yuz dɛn bɔku bɔku tin dɛn ɛn dɛn kin yuz dɛn bak.

Wetin mek injɛkshɔn moldin na fayn tin fɔ mek dɛn prodyuz bɔku bɔku wan .

Fast prodakshɔn saykl dɛm : Wan singl injɛkshɔn saykl kin tek less dan wan minit, we kin mek i fayn fɔ big rɔn.

Kost Efisiensi : Pan ɔl we di fɔs mold kɔst dɛn ay, di prays fɔ ɛni pat de drɔp dramatik wan wit ay kwantiti.

High Precision : Injection molding de mek pat dɛn we gɛt tayt tolɛreshɔn ɛn kɔnsistɛns kwaliti, we de ridyus west.

Factors we de ditarmin injekshɔn moldin kɔst .

1. Kɔst fɔ di tul .

Initial Tuling Invɛstmɛnt .

Bɔku tɛm, di mol na di big wan we dɛn kin yuz fɔ mek dɛn gɛt injɛkshɔn moldin. Dɛn kin print am 3D, dɛn mek am wit aluminiɔm, ɔ dɛn mek am wit stɛl. Mold prayz kin difrɛn bay di kɔmplisiti, saiz, ɛn di tin dɛn we dɛn kin pik:

3D Printed Molds : Di bɛst fɔ prototyping ɔ low-volume rɔn, prays frɔm $100 to $1,000.

Aluminium Molds : I fayn fɔ mek dɛn mek di mid-volyum, we go kɔst $2,000 to $5,000.

Stilin Molds : I fayn fɔ mek dɛn mek ay-volyum, frɔm $5,000 to pas $100,000.

Aw mold kɔmplisiti impak dɛn kɔst .

Kɔmpleks mold dizayn dɛn kin mek di kɔst dɛn go ɔp. Ficha dɛn lɛk ɔnda-kɔt, pat saiz, ɛn draft angul dɛn de mek di tul dɛn kɔmplisiti bɔku:

Undercuts and Draft Angles : Mɔ ditayla dizayn dɛn nid advans mold fabrikeshɔn, we de ad to di kɔst.

Pat saiz : Big pat dɛn nid big big mold dɛn, we dia pasmak.

Kastom molds vs. universal molds : Kastom mold dɛn de mach di rayt spɛsifikɛshɔn dɛn, bɔt yunivasal mold dɛn kin kɔt kɔst if dɛn kin aksept fɔ yuz versatility.

Mold layfspan ɛn durabiliti .

Mold layfspan dipen pan di prodakshɔn volyum ɛn matirial. High-volume molds tipikli nid stɛl fɔ mek i go te, we di low-volume molds kin yuz aluminium ɔ 3D-printed materials:

Low-volume molds : Short layfspan, afordabul fɔ smɔl prodakshɔn rɔn.

ay-volyum molds : i kin te ɛn i kin de fɔ lɔng tɛm; Dɛn kin lɛk fɔ yuz stɛl mol fɔ yuz fɔ lɔng tɛm.

| mold type |

best use |

ɛstimat kɔst |

| Mold we dɛn print 3D . |

Low-volume runs . |

$100 - $1,000 |

| Aluminium mold . |

Mid-Volume de rɔn . |

$2,000 - $5,000 |

| Stilin mold . |

Di rɔn dɛn we gɛt ay vɔlyum . |

$5,000 - $100,000+ |

2. Di kɔst fɔ di ikwipmɛnt dɛn .

Di kayn mashin dɛn we dɛn kin yuz fɔ mek injɛkshɔn .

Difrɛn mashin dɛn de gi difrɛn lɛvul dɛn fɔ prɛsishɔn, spid, ɛn kɔst:

Ilɛktrik mashin dɛn : ay prɛsishɔn, ɛnaji-efishin, bɔt ay initial kɔst.

Hydraulic Machines : Durable ɛn kɔst-ɛfɛktiv, bɔt nɔ prɛsis.

Hybrid Machines : Na miks fɔ ɔl tu, we de gi prɛsishɔn ɛn durabiliti bɔt na ay prays.

Di kɔst fɔ mashin kin difrɛn:

Smɔl-smɔl prodakshɔn : Dɛsktɔp mashin dɛn kin kɔst less dan $10,000.

Big-big prodakshɔn : Indastrial mashin dɛn kin pas $100,000.

In-haus prodakshɔn vs. ɔtsɔsing .

Biznɛs pipul dɛn fɔ disayd if dɛn fɔ bay mashin ɔ fɔ mek ɔda tin dɛn fɔ mek dɛn wok. Ɛni opshɔn gɛt in prɔs ɛn kɔns:

In-haus Prodakshɔn : Mɔ kɔntrol pan kwaliti ɛn lida tɛm, bɔt nid fɔ gɛt signifyant apfrɔnt invɛstmɛnt.

Outsourcing : Lower capital costs, ideal for smɔl biznɛs, bɔt kin mek dɛn nɔ gɛt bɔku kɔntrol pan prodakshɔn kwaliti ɛn tɛm.

| mashin tayp |

bɛst yus |

ɛstimat kɔst |

| Desktɔp mashin . |

Low-volume runs . |

<$10,000 pipul dɛn. |

| Indastrial Mashin . |

Di rɔn dɛn we gɛt ay vɔlyum . |

$50,000 - $200,000+ |

3. Matirial kɔst fɔ injɛkshɔn moldin .

Kɔmɔn injɛkshɔn moldin matirial ɛn dɛn kɔst .

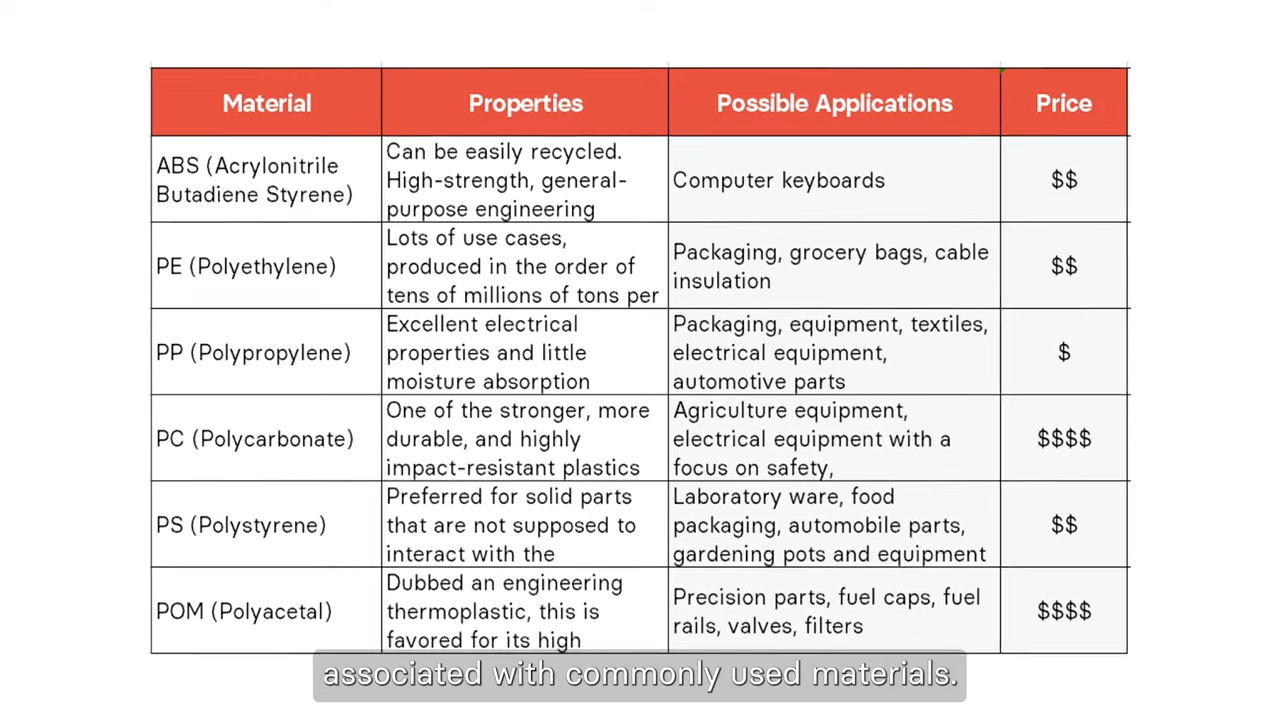

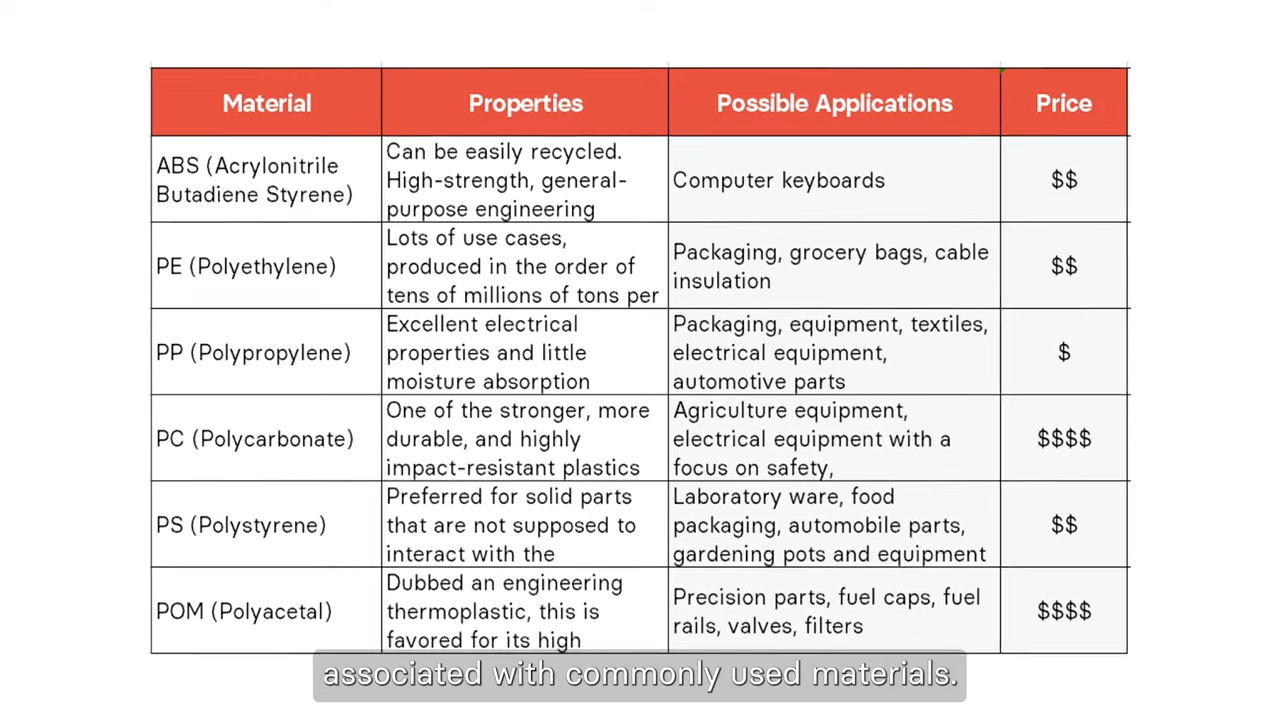

Di choice of matiryal signifyantli afekt di kost. Dɛn kin yuz tɛmplastik dɛn mɔ fɔ injɛkshɔn moldin, ɛn ɛni wan pan dɛn gɛt spɛshal prɔpati ɛn prayz:

ABS : I kin te, i kin yuz bɔku bɔku tin dɛn; Arawnd $1.30 fɔ wan kg.

Polypropylene (PP) : Layt, i nɔ de rɔtin to kemikal dɛn; Na lɛk $0.90 fɔ wan kg.

Polyethylene (PE) : Fleksibul, impak-rɛsistɛns; Arawnd $1.20 fɔ wan kg.

polycarbonate (PC) : Strɔng, ay klia wan; Kost $2.30 fɔ wan kg.

Fɔ pik di rayt tin fɔ yu prɔjek .

Fɔ pik di rayt tin de dipen pan di aplikeshɔn. Di kɔst-ɛfɛktiv fɔ balans trɛnk, fleksibiliti, ɛn rɛsistɛns to tɛmpracha ɔ kemikal:

Material Properties vs. Cost : Lower-cost materials lɛk PP kin fayn fɔ simpul pat dɛn, we dia dia wan dɛn lɛk PC nid fɔ gɛt ay-pafɔmɛnshɔn prodak.

Impact of additives : Filla ɛn aditiv (lɛk kɔlɔrant ɔ UV stebyulayza) de inkrisayz matirial kɔst bɔt dɛn kin nid am bays pan di prɔdak spɛsifikɛshɔn dɛn.

| Material |

ki ficha dɛn |

prays fɔ wan kg |

| ABS na ABS |

Durable, laytwɛt . |

$1.30 fɔ di mɔni. |

| Polipropilen (PP) . |

Fleksibul, kemikal resistant . |

$0.90 fɔ di wan dɛn we de. |

| Poliethylene (PE) |

Impact Resistant, Risaykulabl |

$1.20 fɔ di mɔni. |

| Polikarbonɛt (PC) . |

ay klia wan, strɔng . |

$2.30 fɔ di mɔni. |

4. Leba ɛn Savis Kɔst .

Labor in injekshɔn moldin .

Ivin if bɔku pan di injɛkshɔn moldin prɔses na ɔtomatik, leba stil de ple wan rol. Di men say dɛn usay di kɔst fɔ wok kin apin na:

Sɛtup Kɔst : Initial mashin kɔnfigyushɔn fɔ wan patikyula pat.

Ripa Kɔst : Mentɛnans ɛn pat Riplesmɛnt fɔ di mashin ɛn mold.

Monitoring Costs : Di ɔpreshɔn dɛn we de ɔvasayz di ɔtomɛshɔn prɔses, mek shɔ se dɛn prodyuz pat dɛn kɔrɛkt wan.

Outsɔsing savis kɔst dɛn .

We dɛn de ɔtsɔs, di wokman ɛn di savis provayda fi dɛn de ad to di ɔl di kɔst. Dɛn kɔst ya na:

Transpɔt ɛn Lɔjistik : Shipin dɔn dɔn pat frɔm di ɔtsɔs prɔvayda.

Kwaliti Kɔntrol : Mek shɔ se di pat dɛn mit di standad dɛn, bɔku tɛm dɛn kin nid fɔ gɛt mɔ fi.

Mak : Savis provayda dɛn de chaj fɔ manej di injɛkshɔn moldin prɔses.

Injekshɔn moldin kɔst bay prodakshɔn volyum .

1. Low-volyum injekshɔn moldin .

Wetin na lɔw-volyum prodakshɔn?

Lɔw-volyum prodakshɔn de tɔk bɔt manufakchurin smɔl kwantiti, tipikli bitwin 100 to 1,000 pat. Na kɔmɔn fɔ yuz fɔ protɔtayp ɔ kɔstɔm ɔda usay big kwantiti nɔ nid. Smɔl-batch prodakshɔn na fayn tin fɔ tɛst nyu prɔdak bifo yu skel ɔp.

Mold Costs : Fɔ mek dɛn nɔ rɔn smɔl, bɔku tɛm biznɛs dɛn kin yuz 3D print mold dɛn . Dis na di wan dɛn we nɔ de tek bɔku mɔni, we kin kɔmɔt frɔm $100 to $1,000 ..

Per-part cost : Di kɔst fɔ ɛni pat de ay pasmak na lɔw-volyum prodakshɔn bikɔs di fiks mold kɔst dɛn de sheb akɔdin to smɔl yunit dɛn. Fɔ ɛgzampul, if dɛn mek wan mol fɔ pe 1,000 dɔla ɛn 100 pat dɛn, dɛn kin pe ɔl di pat dɛn we gɛt 10 dɔla fɔ mek dɛn pe di mold nɔmɔ.

| prodakshɔn volyum |

mold tayp |

mold kɔst |

kɔst fɔ wan pat |

| 100 - 1,000 pat dɛn |

Mold we dɛn print 3D . |

$100 - $1,000 |

Di wan we ay pas ɔl ($4.5+) |

Ustɛm na lɔw-volyum prodakshɔn ideal?

Low-volume prodakshɔn na pafɛkt fɔ protɔtayp nyu dizayn ɔ manufakchurin limited prodak rɔn fɔ makɛt tɛst. I yusful bak fɔ kɔmni dɛn we want fɔ fleksibul pan prɔdak ajɔstmɛnt dɛn we dɛn nɔ kɔmit to ay volyum.

2. Mid-volyum injekshɔn moldin .

Wetin na mid-volyum prodakshɔn?

Mid-volyum prodakshɔn tipikli de bitwin 5,000 to 10,000 yunit . I de strik wan balans bitwin prototyping ɛn ful-skel manufakchurin. Dis levul of prodakshɔn na fayn fɔ smɔl-to-midul biznɛs we de luk fɔ prodyuz wan prɔdak insay mɔdaret kwantiti.

Kost brekdaun fɔ mid-volyum prodakshɔn

Mold Costs : Dɛn kin yuz mashin aluminium mold dɛn fɔ yuz fɔ mek midul-volyum bikɔs dɛn de gi gud kɔmprɔmis bitwin di kɔst ɛn di we aw dɛn go de fɔ lɔng tɛm. Dɛn mol dɛn ya kin kɔst bitwin $2,000 to $5,000 ..

Mold Wear and Tear : Aluminium mold kin handle op to som tausin pat bifo wear en tear bigin afekt kwaliti. Dis durabiliti de ɛp fɔ kɔntrol di kɔst fɔ lɔng tɛm.

| prodakshɔn volyum |

mold tayp |

mold kɔst |

kɔst fɔ wan pat |

| 5,000 - 10,000 pipul dɛn |

aluminiɔm we dɛn mek wit mashin . |

$2,000 - $5,000 |

Modaret ($3) . |

3. Di injɛkshɔn we gɛt bɔku bɔku injɛkshɔn dɛn .

Wetin na ay-volyum prodakshɔn?

Di ay-volyum prodakshɔn de tɔk bɔt di we aw dɛn de mek tɛn tawzin to ɔndrɛd tawzin pat dɛn . Dis na di mɔs kɔst-ɛfɛktiv we fɔ big-big prodakshɔn rɔn, we fayn fɔ industri dɛn lɛk ɔtomotiv ɛn kɔshɔma guds.

Kost efisiensi fɔ ay-volyum prodakshɔn

Stilin mold : ay-volyum projɛkt dɛn nid stɛl mold , we dɛn sabi fɔ dɛn durability ɛn abiliti fɔ handle ripit prodakshɔn saykl dɛn. Dɛn mol dɛn ya kin kɔst mɔ fɔs, frɔm $5,000 to pas $100,000 , bɔt dɛn kin las fɔ lɔng tɛm.

Lower per-part cost : As di prodakshɔn volyum de go ɔp, di kɔst fɔ ɛni pat de go dɔŋ bad bad wan bikɔs di fiks mold kɔst de spred akɔdin to tawzin ɔ ivin milyɔn yunit dɛn.

| prodakshɔn volyum |

mold tayp |

mold kɔst |

kɔst fɔ wan pat |

| 10,000+ pat dɛn |

Stilin mold . |

$5,000 - $100,000+ |

Lɔw ($1.75) |

Ki factors fɔ tink bɔt fɔ ay-volyum projɛkt dɛn .

Mashin Choice : Fɔ ay-volyum rɔn, di chus fɔ mashin (ilɛktrik, haydrolik, ɔ haybrid) kin impɔk efyushɔn ɛn kɔst.

Material Selection : We yu pik di rayt matirial, i de ɛp fɔ mek yu kɔntinyu fɔ de ɛn fɔ mek yu nɔ spɛn bɔku mɔni pas big big prodakshɔn saykl dɛn.

Aw fɔ Ridyus Injɛkshɔn Moldin Kɔst .

1. Optimayz mold dizayn .

Dizayn fɔ Manufakchurin (DFM) Prinsipul dɛn .

We yu yuz DFM prinsipul dɛn, i kin ridyus di kɔst fɔ injɛkshɔn mɔ ɛn mɔ bay we yu mek di mold ɛn di pat dizayn simpul:

Fɔ pul di tin dɛn we nɔ nid : Fɔ pul kɔmpleks jɔyometri, ɔnda-kɔt, ɔ tɛkstɔr we nɔ nid de ridyus di kɔmplisiti we di mol gɛt, we de mek ɔl tu di manufakchurin tɛm ɛn di matirial kɔst dɛn go dɔŋ.

Simplifying mold design : Fit dɛn lɛk stip draft angul ɔ intrikɛt intanɛnt kaviti dɛn de inkrisayz kɔst. Di dizayn dɛn we dɛn dɔn mek simpul kin ridyus di nid fɔ mek dɛn yuz mɔ mold fɔ mek tin dɛn, we kin mek di mol dɛn nɔ dia ɛn kwik fɔ mek dɛn prodyuz.

Yuz Yunivasal Mɔld dɛn .

Bɔku tɛm, yunivasal mold dɛn na ɔda we we nɔ go tek bɔku mɔni pas di kɔstɔm mold dɛn:

We fɔ yuz Yunivasal Mɔld : Yunivasal mold dɛn fayn we pat dɛn gɛt di sem kayn dizayn we dɛn nid, we de alaw fɔ yuz di sem mol bak akɔdin to difrɛn prɔjek dɛn.

Kost sevings : Self-mating parts en simplified dizain kin drastikli ridyus di nid fo multiple molds. Wan yunivasal mold kin mek di kɔst fɔ di tul dɛn go dɔŋ bay we dɛn nɔ nid fɔ mek difrɛn mol fɔ ɛni wan pan di patikyula pat dɛn.

| Mold Design Strategy |

Benefits |

| Fɔ pul di tin dɛn we nɔ nid fɔ apin . |

Ridyus di kɔmplisiti ɛn di kɔst . |

| Yunivasal mold dɛn . |

Fɔs mol, lɔwa tul kɔst . |

2. Material Sɛlɛkshɔn ɛn Optimayzeshɔn .

Fɔ pik tin dɛn we nɔ gɛt bɔku mɔni .

Fɔ pik di rayt tin na di men tin fɔ ridyus di kɔst dɛn we yu nɔ go kɔmprɔmis di pefɔmɛns:

Balancing Cost and Performance : Dɛn kin yuz matirial dɛn lɛk ABS ɛn polypropylene bɔku bɔku wan bikɔs ɔf dɛn lɔw kɔst ɛn gud pefɔmɛns kwaliti dɛn. ABS de kɔst lɛk $1.30 fɔ wan kilo, ɛn polypropylene ivin smɔl na $0.90 fɔ wan kg.

We fɔ yuz prɛmiɔm matirial : Fɔ pat dɛn we nid ay ɔt ɔ impak rɛsistɛns, ay-kɔst matirial lɛk polycarbonate kin nid pan ɔl we dɛn ay prays.

Di we aw dɛn de ridyus di west .

Minimizing Material Waste kin rili stɔp di kɔst:

Optimizing wall thickness : Tinner walls Ridyus matirial yus we nɔ afɛkt pat trɛnk, provid di dizayn sɔpɔt am.

Yuz risaykul plastic : inkorporet risaykul plastic insay di manufakchurin proses de lo di matiryal kos en improves sastaynabiliti. Risaykul tɛmplastik dɛn de gi di sem kayn prɔpati dɛn na wan lɔwa prayz pɔynt.

| Material Selection Strategy |

Benefits |

| Fɔ pik tin dɛn we nɔ gɛt bɔku mɔni . |

Ridyus di kɔst fɔ ɛni pat pan di kɔst . |

| Plastik dɛn we dɛn dɔn risaykul . |

Lɔwa matirial kɔst, sastaynabiliti . |

3. Inkris di prodakshɔn volyum .

Economies of skel in injekshɔn moldin .

Fɔ prodyuz ay volyum de ɛp fɔ sheb fiks kɔst akɔdin to mɔ pat dɛn, we de ridyus di kɔst fɔ wan yunit:

Big batch dɛn we de dɔŋ di kɔst : As di prodakshɔn volyum de go ɔp, di fɔs mold ɛn sɛtup kɔst dɛn de spred akɔdin to wan big nɔmba pan di pat dɛn, we de drɛb dɔŋ di pe-pat kɔst.

Balancing prodakshɔn nid : Pan ɔl we ay-volyum prodakshɔn de gi lɔwa kɔst fɔ ɛni pat, i impɔtant fɔ balans prodakshɔn volyum wit aktual dimand fɔ avɔyd invɛntari kɔst we nɔ nid.

Batching di sem kayn prɔjek dɛn togɛda .

We yu jɔyn di sem kayn prɔjek dɛn, dat kin mek yu ebul fɔ wok fayn fayn wan:

| Strateji |

Kɔst Sevins |

| Di prodakshɔn volyum we de go ɔp . |

Ridyus kɔst fɔ ɛni pat tru ikɔnomi dɛn fɔ skel . |

| Batching di sem kayn prɔjek dɛn . |

Sprɛdin fiks kɔst akɔs mɔ yunit dɛn . |

4. Embras 3D print mold fɔ prototyping .

We yu de yuz 3D print mold dɛn .

3D print mold na wan kɔst-ɛfɛktiv sɔlvishɔn fɔ smɔl prodakshɔn rɔn ɔ protɔtayp:

Short runs and prototyping : 3D printin kin prodyuz mold kwik ɛn afɔdabul fɔ shɔt prodakshɔn saykl, we de pul di nid fɔ kɔst mɛtal mold dɛn di tɛm we di prototyping faz.

Cost Advantages : Di apfrɔnt kɔst fɔ 3D print mold dɛn de fa fawe pas tradishɔnal aluminiɔm ɔ stɛl mold dɛn, bɔku tɛm dɛn kin de frɔm $100 to $1,000 , we kin mek i fayn fɔ mek dɛn it kwik kwik wan ɛn fɔ mek smɔl-batch.

Limiteshɔn fɔ 3D printin insay injɛkshɔn moldin .

Wail 3D print molds ofa kos sevings, dem tu kam wit limit:

Durability : 3D print mold nɔ kin te lɛk mɛtal mold, we kin mek dɛn nɔ fit fɔ mek dɛn prodyuz ay-volyum.

Limited to Simple Designs : Mɔ kɔmpleks dizayn dɛn kin stil nid tradishɔnal CNC-machin mold fɔ mek dɛn kɔrɛkt ɛn fɔ mek dɛn go de fɔ lɔng tɛm.

| 3D print molds |

benefits and limitations |

| Bɛnifit dɛn |

Low cost, fast prodakshɔn fɔ shɔt rɔn . |

| Limiteshɔn dɛn . |

Limited durability, simpul dizayn dɛn nɔmɔ . |

Injekshɔn moldin kɔst kalkyulatɔ tul dɛn .

Aw fɔ Ɛstimat Yu Injɛkshɔn Mɔldin Kɔst .

Fɔ ɛstimat injɛkshɔn moldin kɔst kin bi kɔmpleks, bɔt sɔm ɔnlayn tul dɛn kin mek di prɔses simpul. Dɛn tul ya de yuz input dɛn lɛk pat saiz, matirial, mold kɔmplisiti, ɛn prodakshɔn volyum fɔ gi kɔst ɛstimat.

Ovaviu fɔ di pɔpul ɔnlayn kɔst ɛstimɛta dɛn .

Bɔku kɔst ɛstimat tul dɛn kin ɛp yu fɔ kɔl yu injɛkshɔn moldin ɛkspɛns:

CustomPart : Dis tul de alaw yuzman fɔ input difrɛn pat ditel fɔ gɛt kwik kɔst ɛstimat. I yuz-frenli ɛn i de gi brekdɔwn fɔ matirial, mold, ɛn prodakshɔn kɔst.

Protolabs : Dɛn sabi am fɔ rapid prototyping, ProtoLabs de gi wan kɔlkyulɛta we de gi prɛsis kot dɛn we dɛn bays pan prodakshɔn volyum ɛn matirial sɛlɛkshɔn. I kin ɛp mɔ fɔ di wan dɛn we de luk fɔ gɛt pat kwik kwik wan.

Icomold : Dis ɛstimat de gi ditayl kot dɛn we dɛn bays pan CAD mɔdel dɛn, we de alaw di wan dɛn we de yuz am fɔ ɔplod dizayn ɛn gɛt fidbak wantɛm wantɛm. I fayn fɔ mɔ kɔmpleks prɔjek dɛm we nid kɔrɛkt kɔst analisis.

| tul |

ficha dɛn |

| CustomPart . |

Fast ɛstimat fɔ matirial, mold, leba |

| ProtoLab dɛn . |

Instant quotes, rapid prototyping opshɔn dɛn . |

| Icomold na di . |

CAD-based quotes fɔ kɔmpleks pat dizayn dɛn . |

Fɔ gɛt kot frɔm di wan dɛn we de gi savis .

We yu dɔn yuz kɔst kɔlkyulɛta fɔ gɛt ɛstimat, fɔ rich to savis provayda dɛn fɔ kot kin gi yu klia pikchɔ fɔ di aktual kɔst.

Wetin fɔ luk fɔ insay kot ɛn savis agrimɛnt dɛn .

We yu de rivyu kot frɔm injɛkshɔn moldin prɔvayda dɛn, i impɔtant fɔ pe atɛnshɔn to sɔm tin dɛn:

Setup Fees : Sɔm prɔvayda dɛn kin chaj ɔda fi fɔ mashin sɛtup ɔ mold pripiamɛnt.

Lid Tayms : Luk fɔ rial lida tɛm dɛn we fit yu prɔjek tɛmlayn. Fasta savis dɛn kin kam bɔku tɛm pan prɛmiɔm.

Kwaliti garanti : Mek shɔ se di savis provayda gɛt garanti fɔ pat kwaliti, we inklud fɔ tolɛreshɔn, fɔ dɔn, ɛn fɔ gɛt di kɔrɛkt tin dɛn.

Tips fɔ tɔk wit di wan dɛn we de gi dɛn tin dɛn fɔ it .

Fɔ tɔk bɔt bɛtɛ ret kin mek yu ɔl yu ɔl injɛkshɔn moldin kɔst go dɔŋ:

Bundle Orders : We yu jɔyn bɔku prɔjek dɛn insay wan big ɔda kin ɛp fɔ mek yu spre fiks kɔst, we go mek yu gɛt bɛtɛ prayz fɔ ɛni pat.

Rikwest bɔku kot : Fɔ gɛt kot frɔm difrɛn saplay dɛn de alaw yu fɔ kɔmpia prayz ɛn tɔk bɔt tɛm.

Fleksibul Lid Tayms : If yu gɛt fleksibul dedlayn, yu kin ebul fɔ tɔk bɔt lɔwa kɔst bay we yu alaw di pɔsin we de gi yu ɔda tin fɔ fit yu ɔda na dɛn schedule.

| di men tin dɛn fɔ tink bɔt |

wetin mek dɛn impɔtant |

| Sɛtup Fi dɛn . |

Afects upfront kos dɛn . |

| Lid tɛm dɛn . |

Impacts Projekt Taymlayn dɛn . |

| Kwaliti garanti dɛn . |

Mek shɔ se kɔnsistɛns pat kwaliti . |

| Tips fɔ tɔk bɔt di tin dɛn we dɛn fɔ du . |

Ɛp fɔ lɛ di kɔst dɛn go dɔŋ tru bɔnd ɔ fleksibul dedlayn . |

Kɔnkliushɔn: Injɛkshɔn Mɔldin Kɔst .

Injɛkshɔn moldin kɔst na inflɔwɛns bay sɔm ki factor dɛm, inklud mold dizayn ɛn matirial sɛlɛkshɔn , ikwipmɛnt kɔst , prodakshɔn volyum , ɛn leba ɛkspɛns . Fɔ mek dɛn nɔ spɛn bɔku tɛm fɔ mek dɛn gɛt mɔ injɛkshɔn fɔ mek dɛn nɔ sakrifays di kwaliti, i impɔtant fɔ yuz dizayn fɔ mek (DFM) prinsipul dɛn , pik di tin dɛn we nɔ go tek bɔku mɔni , ɛn mek dɛn ebul fɔ mek di prodakshɔn volyum fayn fayn wan. Yuz yunivasal mold ɔ 3D print mold fɔ shɔt rɔn, ɛn fɔ jɔyn prɔjek fɔ mek dɛn ebul fɔ du mɔ, na fayn fayn we bak fɔ kip di kɔst dɔŋ.

If yu de plan fɔ wan injɛkshɔn moldin projɛkt, tink bɔt fɔ wok wit Tim MFG. Fɔ gɛt mɔ advays ɔ kɔmpleks dizayn dɛn we dɛn mek fɔ yu, kɔntak Prɔfɛshɔnal Savis fɔ gɛt ɛkspɛkt gayd ɛn optimize yu prodakshɔn prɔses.

FAQs: Injekshɔn moldin kɔst dɛn .

Wetin na di tipik kɔst rɛnj fɔ injɛkshɔn moldin tul?

Mold dɛn we nɔ bɔku: $2,000 - $25,000

Midul Komplexiti: $25,000 - $100,000

Ay kɔmplisiti: $100,000 - $1,000,000+

Aw di prodakshɔn volyum de afɛkt fɔ ɛni yunit kɔst?

Di ay volyum dɛn jɔs de lɔwa fɔ ɛni yunit kɔst .

Example: 1,000 units kin kost $10/unit, while 100,000 units kin drop to $1/unit

Wetin na di mɔs kɔst-ɛfɛktiv matirial fɔ injɛkshɔn moldin?

Polypropylene (PP) kin shɔt pas ɔl

ABS de gi yu gud balans fɔ di kɔst ɛn di pefɔmɛns .

Material choice dipen pan spesifik pat we dɛn nid .

Aw bɔku 3D print mold dɛn kin sev pan prototyping kɔst?

Wetin na di brek-ivin pɔynt fɔ in-haus vs. ɔtsɔs prodakshɔn?

Varies widely bays pan pat kɔmplisiti ɛn volyum .

Jɛnɛral Rul: In-haus kin bi kɔst-ɛfɛktiv na 10,000+ pat ɛvri ia

Aw bɔku matirial west ɛn rɔna dɛn de ad pan ɔl di kɔst dɛn?

Wetin na di kɔst impak fɔ pat dizayn kɔmplisiti?

Simpul pat kin kɔst 25-50% smɔl fɔ prodyuz pas kɔmpleks wan dɛn .

Ɛni ɔda tin (we dɛn dɔn kɔt, tɛkstɔr, ɛn ɔda tin dɛn) de mek di mɔl ɛn prodakshɔn kɔst dɛn bɔku