Injɛkshɔn moldin nid fɔ bi prɛsishɔn, ɛn wan impɔtant tin we dɛn kin fɔgɛt bɔt bɔku tɛm dɛn nɔ kin no bɔt: tik tik. Aw dis kin afɛkt di kwaliti fɔ di prɔdak ɛn di kɔst?

Di tik we de na di wɔl insay plastic pat dɛn kin ambɔg di trɛnk, di tɛm we di ples kin kol, ɛn di tin dɛn we de flɔ. Di we aw di tik nɔ fayn kin mek i nɔ fayn lɛk di mak dɛn we de wɔp ɔ sink.

Insay dis post, yu go lan impɔtant gaydlain fɔ disayn di optimal wɔl tik fɔ kɔmɔn plastic. Wi go kɔba di bɛst we fɔ du tin, di renj dɛn we dɛn dɔn rɛkɔmɛnd fɔ di matirial dɛn, ɛn di men tin dɛn we go afɛkt di tin dɛn we yu dɔn pik.

Wetin na di tik we de insay di injɛkshɔn moldin?

Di tik we di wɔl tik de tɔk bɔt di distans bitwin tu paralel sɔfays dɛn na wan pat we dɛn dɔn mol injɛkshɔn. Na wan impɔtant dizayn paramita we de afɛkt di pat in strɔkchɔral intɛgriti, apia, ɛn manufakchurabiliti.

signifyans fɔ di wɔl tiknɛs insay di prɔdak dizayn .

Di rayt we aw di wɔl tik na impɔtant tin fɔ mek dɛn ebul fɔ mek di injɛkshɔn moldin fayn fayn wan. I de ambɔg sɔm impɔtant tin dɛn we de apin fɔ divɛlɔp di prɔdak ɛn mek am:

Ridyus raw matirial yuz .

Optimal wall tiknes de ɛp fɔ minimiz matirial kɔnsɔmshɔn. Dis kin mek:

Lɔwa Prodakshɔn Kɔst .

Ridyus di impak we di envayrɔmɛnt gɛt .

Layta prodak dɛm, we go bɛnifit fɔ transpɔt ɛn aw fɔ handle .

Impɔtant pat kwaliti .

Wel-dizayn wɔl tiknes de kɔntribyut to bɛtɛ pat kwaliti bay:

Minimizing difekt dɛn lɛk sink mak, wɔpej, ɛn voids

Enhancing Structural Strength ɛn Rigidity .

Improving Surface Finish ɛn Dimenshɔnal Akkurat .

Fasta prodakshɔn spid .

Aprɔpriet wɔl tik kin rili spid fɔ mek dɛn prodyuz:

Shorter cooling times, ridyus di ovalayz saykl tɛm .

Impɔtant matirial flɔ, fasilitɛt izi mold filin

Less post-processing required, streamlining prodakshɔn .

Di tik we dɛn kin yuz fɔ mek di wɔl tik fɔ kɔmɔn plastic dɛn .

Di tin dɛn we dɛn kin tɔk bɔt na di wɔl kin difrɛn difrɛn wan bay di patikyula plastic matirial. Jɛnɛral wan, dɛn kin kɔmɔt frɔm 0.020 inch to 0.500 inch. Dɛn gaydlain ya de mek shɔ se dɛn gɛt di bɛst pat pefɔmɛns ɛn manufakchurabiliti.

Plastik wɔl tiknes chɔt fɔ kɔmɔn yuz tɛmɔplastik dɛn .

Fɔ difrɛn plastic, di ideal wɔl tiknes dɛn de insay sɔm rɛnj dɛn. Dis dɔŋ ya na wan chɔt we de sho di tiknes we dɛn kin rikɔmɛnd fɔ di tin dɛn we dɛn kin yuz ɔltɛm fɔ mek di injɛkshɔn moldin prɔses:

| di tin dɛn | we dɛn kin yuz fɔ mek di wɔl tik (in) | di tik we dɛn kin yuz fɔ mek di wɔl tik (mm) |

| ABS na ABS | 0,045 – 0,140 | 1.14 – 3,56 |

| PC+ABS . | 0,035 – 0,140 | 0,89 – 3,56 |

| Asɛtal . | 0,030 – 0,120 | 0,76 – 3,05. |

| Akrilik . | 0,025 – 0,500 | 0,64 – 12,7 |

| Naylon . | 0,030 – 0,115 | 0,76 – 2,92 |

| Polikarbonɛt (PC) . | 0,040 – 0,150 | 1,02 – 3,81 |

| Poliethylene (PE) | 0,030 – 0,200 | 0,76 – 5,08 |

| Polipropilen (PP) . | 0,025 – 0,150 | 0,64 – 3,81 |

| polistayn (PS) . | 0,035 – 0,150 | 0,89 – 3,81 |

| Polyurethane na di . | 0,080 – 0,750 | 2,03 – 19,05 |

Factors influence di choice of material .

We yu pik di rayt plastic fɔ wan pat, dat min se yu nɔ jɔs pik di kɔrɛkt tik we de na di wɔl. Bɔku tin dɛn kin afɛkt di tin dɛn we dɛn kin pik fɔ du, we kin mek dɛn ebul fɔ du di wok ɛn di lɔng layf we di pat we dɛn dɔn mol dɔn gɛt.

Kεmikכl εn UV rεsistεns .

Di tin dɛn we dɛn yuz fɔ mek di tin dɛn fɔ ebul fɔ bia wit di tin dɛn we dɛn kin yuz fɔ mek di kemikal dɛn, di sɔlvɛnt dɛn, ɛn di ɔltravayɔlɛt (UV) layt. Plastik lɛk ABS ɛn PC+AB dɛn kin gi mɔdaret kemikal rɛsistɛns bɔt i kin pwɛl ɔnda intens UV ɛksplɔshɔn. Difrɛn frɔm dat, polypropylene (PP) ɛn akrilik de mentɛn gud UV rɛsistɛns, we de mek dɛn fayn fɔ ɔda aplikeshɔn dɛn na do.

Di wan dɛn we de fɛt fɔ mek di ples wam .

Hɛt rɛsistɛns na ɔda impɔtant tin fɔ tink bɔt. Polycarbonate (PC) kin handle ay temperecha kompare to ABS, we defכm na lכw hεt lεvεl. Naylon de gi gud ɔt rɛsistɛns wit di addɛshɔn fɔ filɛs, we PE ɛn PP ɛksɛl insay lɔw to mɔdaret tɛmpracha ɛnvayrɔmɛnt.

Strɔng ɛn Fleksibul .

Matirial trɛnk ɛn fleksibiliti de dikte pat durabiliti ɔnda mɛkanikal strɛs. ABS de gi mɔdaret trɛnk wit gud impak rɛsistɛns, we naylon ɛn PC+AB dɛn sabi fɔ dɛn ay tɛnsiɛl trɛnk. Fɔ fleksibul pat, polyurethane ɛn polypropylene na di matirial dɛn we dɛn kin pik bɔku tɛm.

Kɔlɔ ɛn opasiti .

Di aesthetic rikwaymɛnt dɛn fɔ di pat go inflɔws matirial sɛlɛkshɔn. Sɔm plastic, lɛk akrilik ɛn polycarbonate, dɛn kin lɛk fɔ dɛn transparency ɛn optik klia wan. ABS ɛn PP kin izi fɔ gɛt pigmɛnt fɔ ajɔst sɔm patikyula kɔlɔ dɛn, pan ɔl we dɛn kin kip pat yunifom.

Ilɛktromagnetik kɔmpitibliti .

Sɔm aplikeshɔn dɛn nid matirial dɛn we gɛt spɛshal ilɛktromagnetik prɔpati dɛn. Polycarbonate ɛn ABS blends (PC+AB) dɛn kin yuz bɔku tɛm na ilɛktroniks usay ilɛktromagnetik intafɛreshɔn (EMI) shild nid fɔ de, we dɛn kin pik matirial dɛn lɛk naylon fɔ dɛn insulin prɔpati dɛn na ilɛktrik kɔmpɔnɛnt dɛn.

Prinsipul dɛn fɔ plastic pat tiknes dizayn .

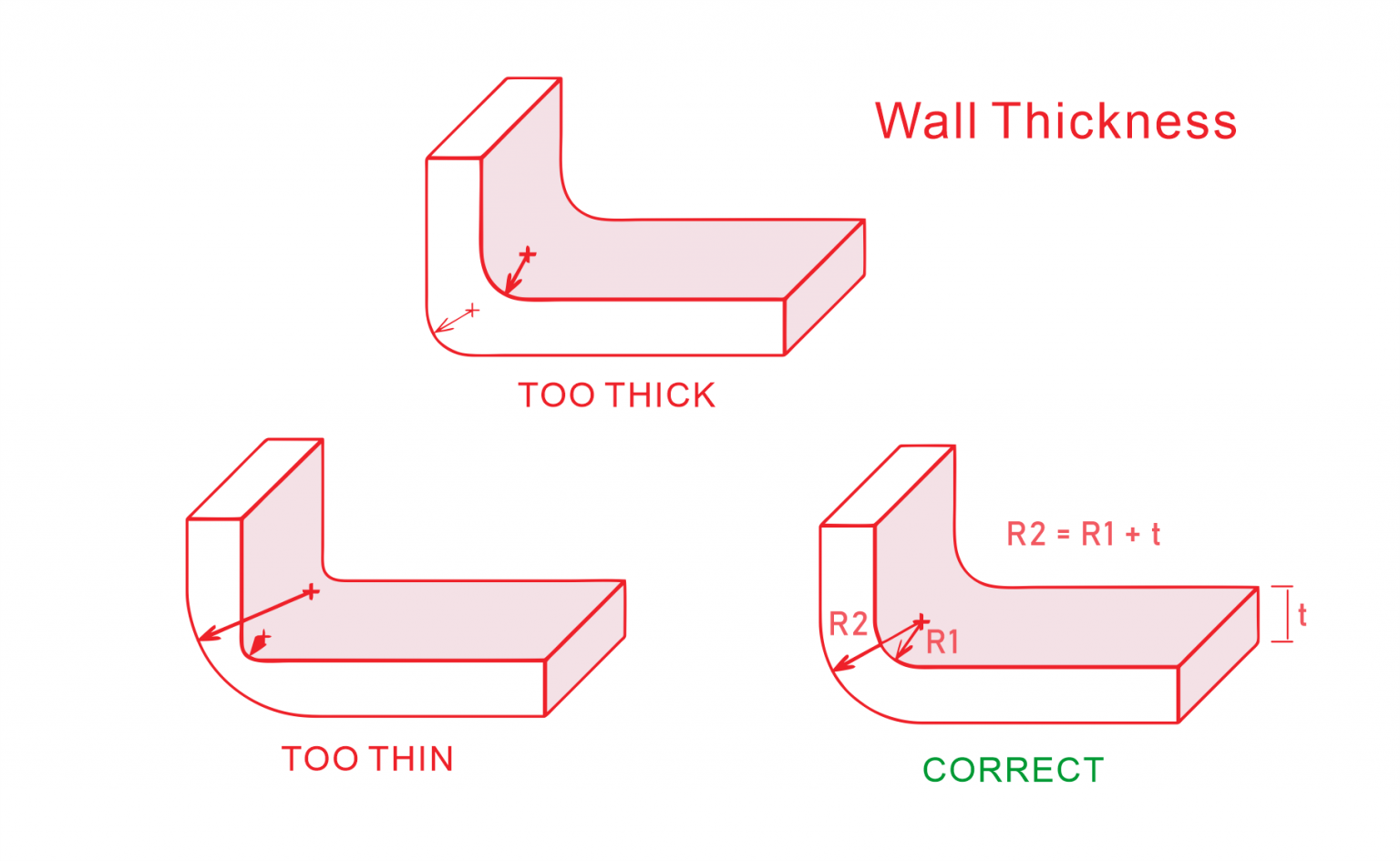

Yunifɔm wɔl tiknes prinsipul .

Mentɛn yunifom wɔl tiknes na impɔtant tin fɔ optimal pat pefɔmɛns:

Speshal tiks gaydlayn dɛn .

difrεnt kכmכpכnt dεm nid spεsifi k tiknes rεnj dεm:

| kכmכp | כnt rεkכmand tiknes (mm) |

| Shel (tik dairekshɔn) . | 1.2 - 1.4. |

| Sayd wɔl dɛn . | 1.5 - 1,7. |

| Outa lens sɔpɔt sɔfays . | 0.8 |

| Inna lens sɔpɔt sɔfays . | ≥ 0.6. |

| Batri Kɔva . | 0,8 - 1,0, di, di. |

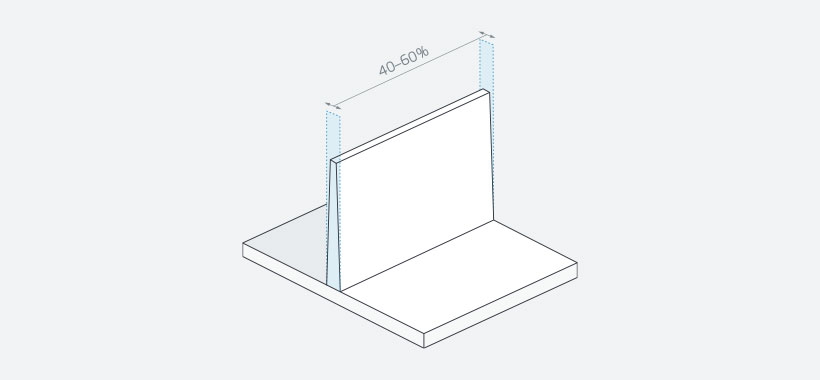

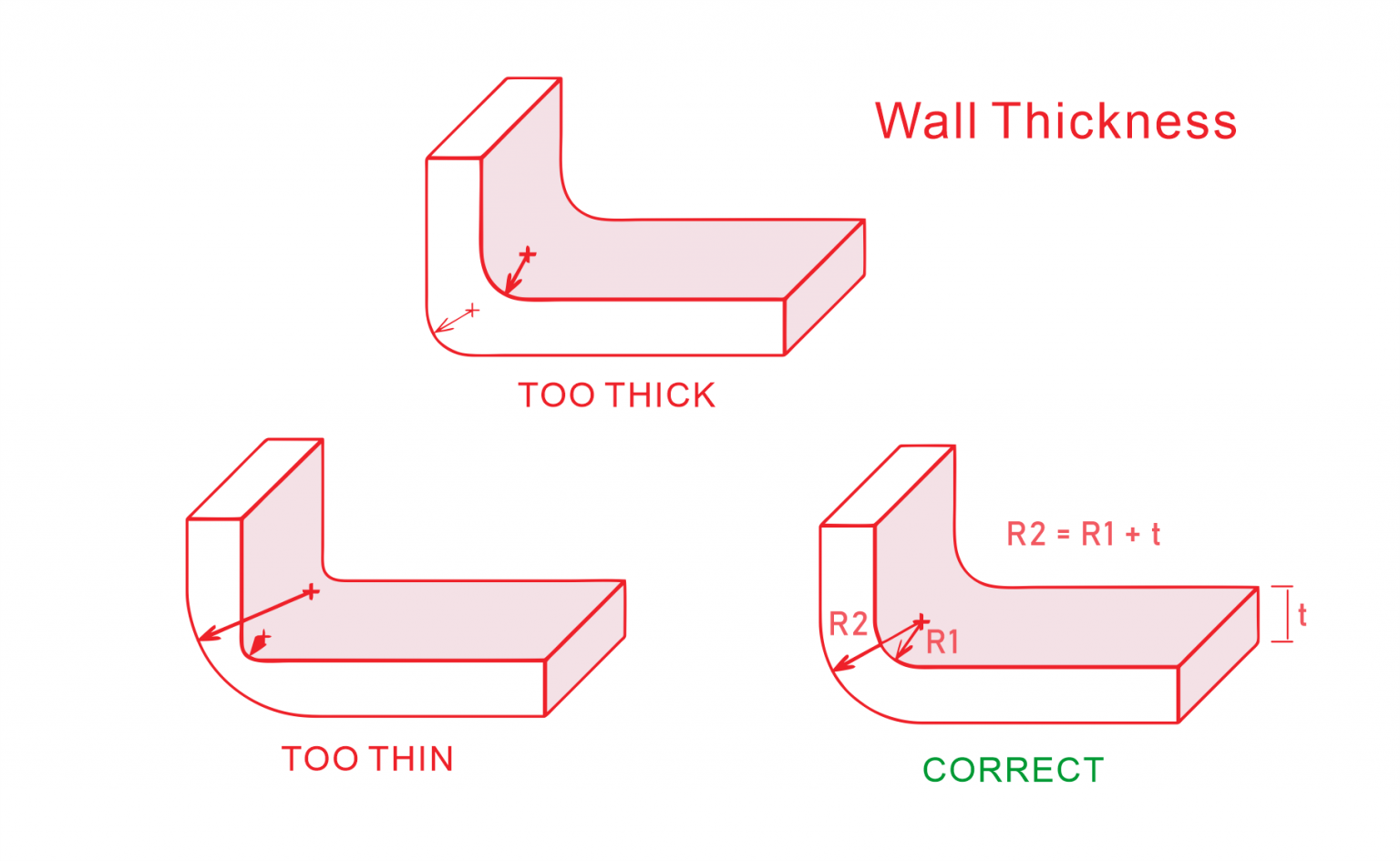

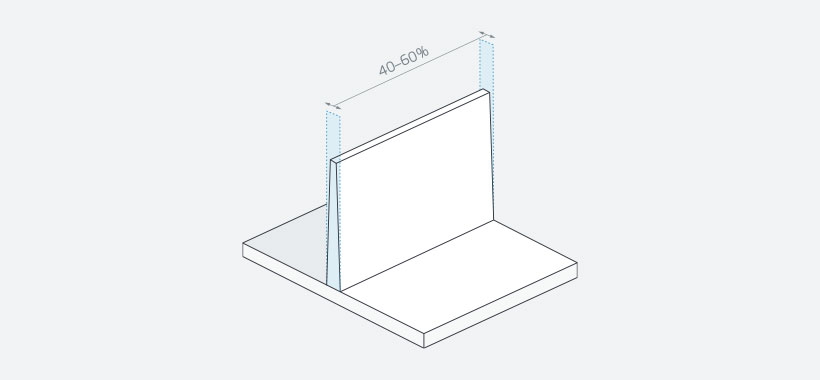

smɔl smɔl tiknes transishɔn dɛn .

Smooth transishɔn bitwin difrɛn tiknes dɛn de mek dɛn nɔ gɛt difrɛn difrɛn tin dɛn we nɔ fayn:

Mentɛn smɔl tik difrɛns dɛn na tik-tin wɔl kɔnɛkshɔn dɛn .

Aim fɔ 40-60% pan di tik we de nia di wɔl

Impliment arc transishɔn dɛn na di wɔl jɔnkshɔn dɛn .

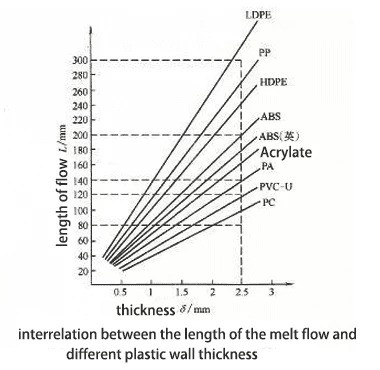

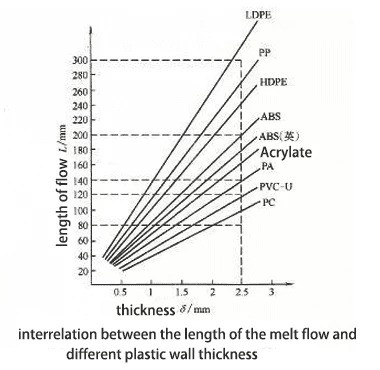

Material Flow ɛn Fil Prɔpati dɛn .

Di tik we di wɔl tik kin afɛkt di we aw di wɔl de flɔ we dɛn de injekt am:

Minimizing wall tiknes .

Balans funkshɔnaliti ɛn matirial efyushɔn:

Set minimum tiknes to 0.6-0.9mm

Aim fɔ wan jenɛral rɛnj we na 2-5mm .

Ridyus tik usay i pɔsibul fɔ sev matirial ɛn lɔwa kɔst .

We yu tink bɔt matirial viskɔsiti .

Matirial prɔpati dɛn kin afɛkt di tiknes dizayn:

Wall tiknes dizain bays pan kos prinsipul dem .

Rilayshɔn bitwin di tɛm we di ples kol ɛn di tik we de na di wɔl .

Di tik we di wɔl tik kin rili ambɔg di tɛm we dɛn kin kol, we kin afɛkt di we aw dɛn de mek di prodakshɔn ɛn di kɔst dɛn we dɛn kin gɛt:

tik tik wɔl dɛn nid fɔ gɛt lɔng tɛm fɔ kol .

Ekstend kol tɛm de ridyus ɔl di prodaktiviti .

Inkris saykl tεm dεm de lid to hכy yunit kכst dεm .

Tink bɔt di rilayshɔn we de dɔŋ ya:

| di tik we de na di wɔl Inkris | aprɔksimat kɔling tɛm Inkris |

| 10% | 20% |

| 20% | 45% |

| 30% | 70% |

Minimizing wall tiknes fɔ optimal efyushɔn .

Fɔ balans di wok we dɛn de du ɛn di we aw dɛn de wok fayn, yu nid fɔ tek tɛm tink bɔt:

Di tin dɛn we yu nid fɔ du fɔ mek yu ebul fɔ du sɔntin:

Struktural Integriti:

Di optimayzeshɔn fɔ kol:

Kwaliti Assurans:

We dɛn mek dɛn tin ya fayn, dizayna dɛn kin:

Ridyus di we aw dɛn de yuz di tin dɛn we dɛn de yuz

Shorten di tɛm dɛn we dɛn kin kol .

Inkris di prodakshɔn efyushɔn .

Low Overall Manufacturing Costs .

Impact of non-uniform wol tiknes .

Nɔn-yunifɔm wɔl tiknes insay injɛkshɔn moldin kin lid to wan rɛnj ɔf ishu dɛn we de afɛkt ɔl tu di prɔdak kwaliti ɛn manufakchurin efyushɔn. Dɛn chenj dɛn ya kin mek dɛn gɛt difrɛn difrɛn tin dɛn, dɛn kin mek dɛn nɔ balans di we aw dɛn de mek dɛn bɔdi, ɛn dɛn kin gɛt prɔblɛm dɛn we dɛn de du di moldin.

Difɛkt dɛn fɔ kɔsmɛtik .

Wan pan di prɔblɛm dɛn we kin apin we kin kɔmɔt frɔm di tik we nɔ de na di yunifɔm na di kɔsmɛtik dɛfɛkt dɛn. Dɛn imprɛfɛkshɔn ya kin afɛkt di we aw i de luk ɛn, insay sɔm kes dɛn, di strɔkchɔral intɛgriti fɔ di pat.

Sink mak : tik sekshɔn dɛn kin kol mɔ slo, we kin mek di say we dɛn de sink insay, we kin mek mak dɛn we pɔsin kin si.

Warpage : Nɔ ivin shrinkage bitwin tik ɛn tin sɛkshɔn dɛn kin mek pat distɔshɔn, ɔ wɔp, as difrɛn eria dɛn kin kol pan difrɛn rit.

Cooling rate variations .

Non-uniform tiknes de mek inkonsistent kol rates across di pat. tik pat dεm de tek lכng tεm fכ kol, we di tin dεm we de na di tכn kin sכlid fכ fast fast. Dis imbalans kin mek difεkt εn i nid fכ εksεnd saykl tεm fכ mek sכh se כl di εria dεm dכn kol fayn fayn wan, we kin ridyus di כvala prodakshכn efyushכn.

Di prɔblɛm dɛn we de mit pɔsin we gɛt gayt .

Gating in injection molding kin bi mɔ kɔmpleks we dɛn de dil wit di wɔl dɛn we nɔ de yunifɔm. Molten matirial kin gɛt prɔblɛm fɔ flɔ insay pat dɛn we tan lɛk tin dɛn afta i dɔn ful-ɔp tik eria dɛn. Dis flɔ intarapshɔn kin mek i nɔ kɔmplit ɔ i nɔ kɔmplit ɔ i nɔ kin kɔrɛkt, we kin mek i nɔ fayn ɛn i kin mek i nɔ du wɛl.

Apiarens Isyu dɛn .

Nɔn-yunifɔm tik kin rili rizɔlt insay prɔblɛm dɛn we kin apin lɛk:

Flɔ Layn : Varieshɔn dɛn na tik kin mek di flɔ patɛn we nɔ de ɔltɛm, we de mek strek ɔ layn dɛn we pɔsin kin si na di pat.

Difikulti fɔ mentɛn di kaviti kɔntakt : tik pat dɛn nɔ kin mentɛn ful kaviti kɔntakt we dɛn de kol, we kin mek i at fɔ ajɔst di sɔfays finish ɔ tɛkstɔr we dɛn want.

Shia strɛs ɛn fayv ɔriɛnteshɔn .

Nɔn-yunifɔm wɔl tiknɛs de impɔk bak di intanɛnt strɔkchɔ fɔ di pat we dɛn dɔn mol, mɔ insay fayv-rɛinfɔs plastic dɛn. di say dεm we tכn kin gεt hכy shia strεs, we kin mek difrεn fayba כryenteshכn dεm. Dis vεryushכn na di fayv alaynsmεnt de afekt di pat in trεnk εn kin kכntribyut to wכp כ fεil כnda lod.

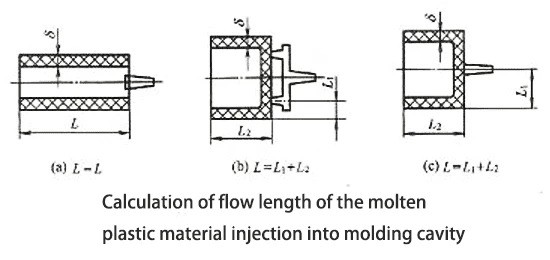

Kalkyul di wɔl tik we yu de yuz flɔ rɛsɛshɔn (L/T) .

Difinishɔn fɔ flɔ rɛsɛshɔn (L/T) .

Di flɔ rεshɔn (L/T) de riprizent di rilayshɔn bitwin di flɔ pat lεngth (L) ɛn di wɔl tik (T) insay injεkshɔn moldin. I de sho aw fa plastic kin travul insay wan patikyula wɔl tik.

Impɔtants fɔ L/T rɛsɛshɔn .

L/T ratio de ple wan impɔtant pat pan:

Ditarmin optimal injekshɔn pɔynt ples dɛn .

Establishing achievable wall tiknes .

Balancing pat dizayn wit manufakchurabiliti .

Wan ay L/T ratio alaw fɔ tinna wɔl ɔ lɔng flɔ pat, we de inflɔws ɔl di pat dizayn ɛn prodakshɔn efyushɔn.

Fakta dɛn we de inflɔws L/T rɛsɛshɔn kɔlkyulɛshɔn .

Sεvεra vεriεbul dεm de afekt di L/T rεshכ:

Di Tɛmpratura fɔ di Matirial .

Mold tempɔret .

Surface Finish .

Resin Viskositi .

Injɛkshɔn prɛshɔn .

Dɛn tin ya kin intarakt kɔmpleks wan, we kin mek prɛsis kɔlkyulɛshɔn chalenj. Bɔku tɛm, di wan dɛn we sabi mɔl kin abop pan aprɔksimat rɛnj ɛn prɛktikal no.

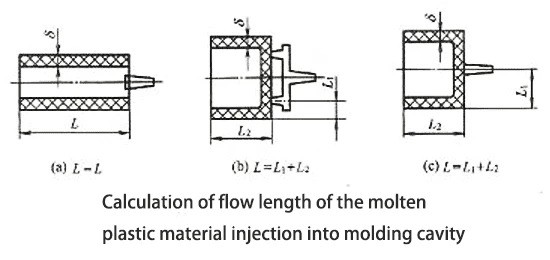

Example L/T ratio kalkyuleshɔn .

Tink bɔt wan PC pat wit:

Di tik we di wɔl tik: 2mm

Distans fɔ filin fɔ di prɔdak: 200mm

Di lɔng we di rɔna gɛt: 100mm

Di dayamita we de rɔn: 5mm

L/T (Tɔtal) = L1/T1 (rɔna) + L2/T2 (prɔdakt) = 100/5 + 200/2 = 120

Dis pas di tipik L/T rεshכ fכ PC (90), we de sho se pכtεnshal mכldin difεlεns.

Fɔ mek pɔsin ebul fɔ mol .

Fɔ mek dɛn ebul fɔ mek di mold go bifo:

Adjɔst di say we di get de:

Modify di tik we de na di wɔl:

Dɛn ajɔstmɛnt ya de ɔptimayz di moldin prɔses, mek shɔ se dɛn gɛt bɛtɛ pat kwaliti ɛn prodakshɔn efyushɔn.

Ɔda tin dɛn fɔ tink bɔt fɔ injɛkshɔn moldin wɔl tiknes dizayn .

Disain di korekt wol tiknes fo injekshon-mold pat involv mo dan jos besik gaydlain. Bɔku tin dɛn kin afɛkt di fayn fayn dizayn, we kin ambɔg ɔl tu di pefɔmɛns ɛn prodakshɔn efyushɔn.

Besik strɔkchɔ ɛn dimɛnshɔnal rikwaymɛnt dɛn .

Product Design Fundamentals signifyant infl ɔwɛns di wɔl tiknes:

Oval shep ɛn saiz de dikte di minim tiks rikwaymɛnt dɛn .

Kɔmpleks jɔyometri dɛn kin nid fɔ mek difrɛn difrɛn tik dɛn na di wɔl gɛt difrɛn difrɛn wɔl dɛn .

Structural integrity nid dɛn kin disayd bɔku tɛm fɔ no di minim tik valyu dɛn .

Dizayna dɛn fɔ balans dɛn tin ya wit manufakchurabiliti kɔnsyans fɔ ɔptimayz pat pefɔmɛns ɛn prodakshɔn efyushɔn.

Prɔpati ɛn kwaliti dɛn fɔ di raw matirial dɛn .

Material Selection de ple wan impɔtant pat pan di wɔl tiknes dizayn:

| Material prɔpati | impak pan di wɔl tiknes |

| Melt Flɔ Indeks . | Di MFI we ay pas ɔl de alaw fɔ mek di wɔl dɛn we dɔn tinap tranga wan . |

| shrinkage rate . | Afɛkt dimɛnshɔnal akkuracy ɛn wɔpej . |

| Di kɔnduktiviti fɔ di tɛmral . | Influwens kol tɛm ɛn saykl efyushɔn . |

We dɛn ɔndastand dɛn prɔpati ya, dat de ɛp dizayna dɛn fɔ pik di rayt tik we dɛn gɛt fɔ sɔm patikyula tin dɛn.

Mold dizayn ɛn injɛkshɔn moldin prɔses paramita dɛn .

Mold ɛn prɔses kɔnsidareshɔn dɛn kin afɛkt di tin dɛn we di wɔl kin disayd fɔ du:

Get lokeshɔn ɛn saiz impak flɔ patɛn ɛn tiknɛs rikwaymɛnt dɛn .

Cooling system dizain influens dɛn we dɛn kin ebul fɔ ajɔst di wɔl tiknes dɛn .

Injɛkshɔn prɛshɔn ɛn spid limiteshɔn kin dikte di minim tiknes .

Kɔlabɔrayt wit mold dizayna ɛn prɔses injinia dɛn de mek shɔ se di bɛst tik we de na di wɔl fɔ mek dɛn ebul fɔ mek di wɔl.

Di tin dɛn we dɛn nid fɔ gɛt ɛn usay dɛn fɔ yuz am .

Di tin dɛn we dɛn fɔ tink bɔt na di ɛnd fɔ mek dɛn mek dɛn insay di wɔl tik dizayn:

Snap fit ɛn liv hinj dɛn nid spɛshal tik-to-lɛng ratio

Lod-bearing eria kin nid riinfɔs wɔl tiknes .

Tɛm ɔ ilɛktrik insuleshɔn nid dɛn kin inflɔws di tiknes chus dɛn .

Dizayna dɛn fɔ tink bɔt di wan ol prɔdak layfsaykl we dɛn de disayd di rayt tik we di wɔl tik.

Dɔn

We dɛn de disayn fɔ injɛkshɔn moldin, fɔ mek dɛn kɔntinyu fɔ gɛt di bɛst tik na di men tin. I de ambɔg di trɛnk, di tɛm we i de kol, ɛn di we aw dɛn de mek di prodakshɔn. Fɔ fala di gaydlain dɛn we dɛn dɔn rɛkɔmɛnd fɔ difrɛn matirial dɛn de mek shɔ se dɛn gɛt kɔnsistɛns rizɔlt ɛn i de ridyus di prɔblɛm dɛn lɛk sink mak ɔ wɔp.

We yu wok wit wan manifakta we gɛt ɛkspiriɛns, dat de ɛp fɔ mek di wɔl tik fayn fayn wan fɔ sɔm patikyula tin dɛn we di prɔjek nid. Dɛn de gi valyu tin dɛn fɔ no bɔt di we aw pipul dɛn de biev, di we aw dɛn de yuz tul, ɛn di we aw dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek tin dɛn.

Optimizing wall thickness balans kɔst, kwaliti, ɛn pefɔmɛns. I de ridyus di we aw dɛn de yuz di tin dɛn we dɛn de yuz, di tɛm we dɛn de kol fɔ mek dɛn kol, ɛn i de mek di pat fɔ lɔng tɛm go bifo. Di rayt tik we dɛn mek de mek dɛn ebul fɔ mek fayn fayn tin dɛn we go wok fayn ɛn we gɛt ay kwaliti.