Nɛgɛ wulilen bɛ bɔn nɔgɔ la ka tɛmɛ aliminiyɔmu fɛnɲɛnamafagalan dilanni taabolo fɛ walasa ka yɔrɔw walima jagofɛnw dilan ni hakɛ tigitigiw ye. Aluminiyɔmu ingots walima scraps bɛ fɔlɔ ka wuli foro la funteni na min ka fisa ni 660 stages celsius ye. O ye aluminiyɔmu wuliyɔrɔ ye. O kɔfɛ, aluminiyɔmu sɔgɔlen bɛ bɔn ka ɲɛ, o bɛ se ka dilan ni cɛncɛn, nɛgɛ walima seramiki ye, ka kɛɲɛ ni fɛn laban ka kuran ye ani polisi fɛɛrɛ min ka di a ye.

Aluminiyɔmu . Die casting molds ye baarakɛminɛnw ye minnu dilannen don koɲuman, minnu bɛ cogoya laɲininen nuancɛ bɛɛ minɛ. Walasa ka kisi aluminiyɔmu wulilen funteni jugumanba ma, u fana bɛ furakɛ. A bɔlen kɔ, nɛgɛ bɛ nɛnɛ ani ka gɛlɛya nɔgɔ la, ka bɔgɔdaga kɛ tigitigi. Aluminiyɔmu fɛn min bɛ kɛ, o bɛ bɔ bɔgɔ la ni a nɛnɛna siɲɛ kelen. A tun bɛ se ka tɛmɛ finidoncogo caman fɛ, i n’a fɔ ja, sɔgɔli, walima sandingɛ, walasa k’a cogoya walima a kɛcogo ɲɛ.

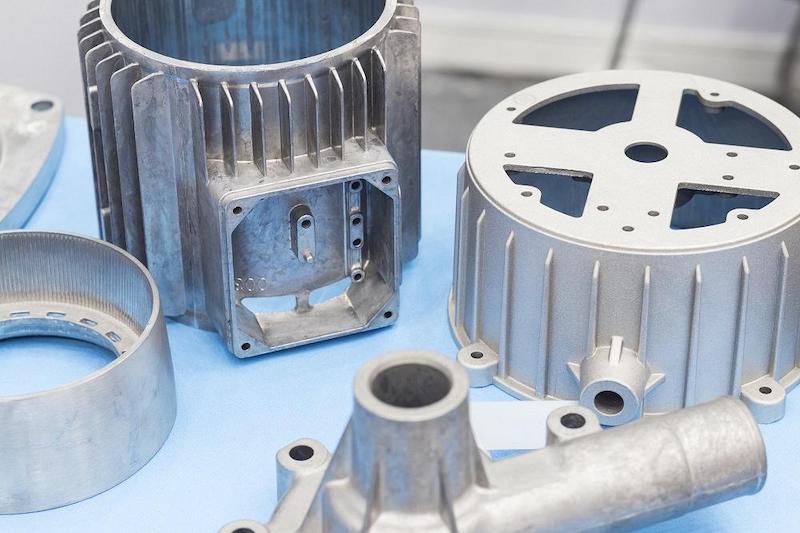

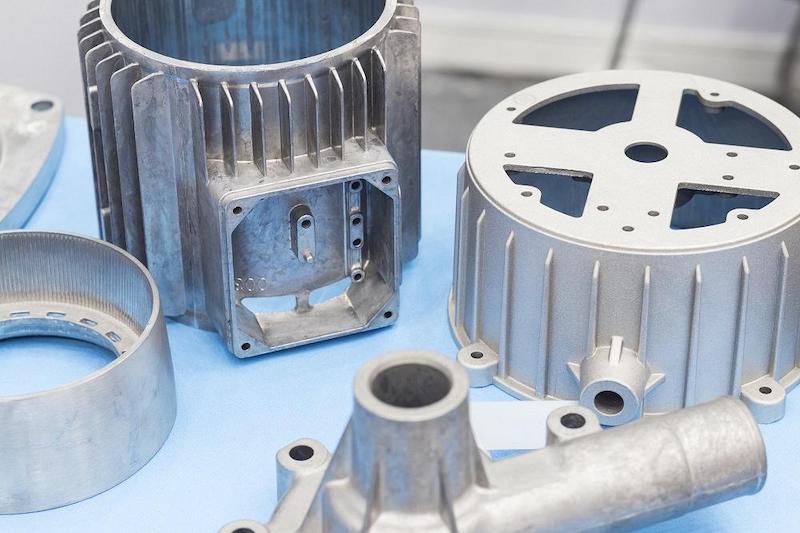

Aluminiyɔmu casting nafaw misali fitinin .

Mobili seko ni dɔnko ye yɔrɔ dɔ ye, aluminiyɔmu sɔgɔli bɛ kɛ yɔrɔ min na waleyali la. Motɛri kɔnɔfɛnw i n’a fɔ silinda kunkolow ni pisiniw bɛ .

A dilannen don ni aliminiyɔmu fɛn nɔgɔmanw ye, nka a bɛ mɛn. O bɛ mobili girinya bɛɛ lajɛlen dɔgɔya, ka dɔ fara sɛnɛfɛnw nafa kan, ka motɛri baarakɛcogo ɲɛ bawo aluminiyɔmu ka funteni bɛ tɛmɛ kosɛbɛ.

Ɲininkaliw ni jaabiw aluminiyɔmu casting kan:

J: Aluminiyɔmu casting suguya jumɛnw bɛ yen?

Aluminiyɔmu sɛnɛcogo suguya wɛrɛw bɛ se ka tila ka kɛ suguya caman ye.

Die casting: Nin wale in bɛ kɛ ni aluminiyɔmu wulilenw wajibiyali ye degunba la ka kɛ nɛgɛmugu ye min bɛ wele ko die. A bɛ baara kɛ kosɛbɛ walasa ka fɛn caman dilan, ka yɔrɔw dilan minnu bɛ tiɲɛ kosɛbɛ ani minnu bɛ kɛ cogo nɔgɔman na. Die casting ka ɲi kosɛbɛ casting ma min ka bon ani a ɲɛ ka fin.

Cɛɲi : bɔgɔdaga dilanni fɛɛrɛ kɔrɔlen dɔ, cɛncɛn bɛ kɛ ka cɛncɛn ɲagaminen kɛ ka bɔgɔdaga dilan. A bɛnnen don ka baarabaw kɛ ani ka dilancogo caman sɛmɛntiya. Nka, a laban ni a cogoya tiɲɛni tɛ bonya i n’a fɔ die casting.

Mɔbili kɛcogo basigilen : Nin fɛɛrɛ in bɛ baara kɛ ni mɔbili ye min bɛ se ka baara kɛ kokura, a ka c’a la, a bɛ kɛ ni nɛgɛ ye, o bɛ fini ni cogoya ɲuman di ka tɛmɛ cɛncɛn kan nka a tɛ fɛn caman kɛ a dilanni gɛlɛya siratigɛ la, wa a bɛnnen don kosɛbɛ fɛn dilanni na min bɛ kɛ ni fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

Coin casting: Nin fɛɛrɛ in bɛ dɔn ka dakunw dilan minnu kurulen don kosɛbɛ ani minnu ka ɲi kosɛbɛ, ka sizo cogoya dɔ dilan, o kɔfɛ, u bɛ da ni tasuma kunbɛnlan ye walasa ka mɔli kɛ. Ni sizo bɛ wuli, aliminiyɔmu wulilen bɛ bɔn foroko kɔnɔ.

J: Aluminiyɔmu karamɔgɔya: U ye mun ye?

A: Jɛkulu caman bɛ se ka kɛ ka aluminiyɔmuw dilan, u kelen-kelen bɛɛ bɛ ni jogo danfaralenw ye:

Aluminiyɔmu molten bɛ wajibiya ka kɛ nɛgɛmugu ye, min bɛ wele ko die, degunba la die-casting kɛtuma na. A bɛ nɔ bɔ kosɛbɛ baara caman na wa a bɛ dilancogo tigitigiw ni nɔgɔmanw di. Degun die casting ka ɲi kosɛbɛ yɔrɔ finmanw ni yɔrɔ finmanw bɛɛ la.

Cɛɲi : bɔgɔdaga dilanni fɛɛrɛ kɔrɔlenw dɔ la kelen, cɛncɛn filili ye ka cɛncɛn ɲagaminen kɛ ka bɔgɔdaga dilan. A bɛnnen don ka baarabaw kɛ ani ka dilancogo caman sɛmɛntiya. Nka, a laban ni a tiɲɛni tɛ bonya i n’a fɔ die casting.

Mɔbili basigilen: Nin wale in bɛnnen don kosɛbɛ ni hakɛ cɛmancɛw ni caman ye bawo a bɛ baara kɛ ni mɔbiliw ye minnu bɛ se ka baara kɛ kokura, minnu bɛ kɛ ni nɛgɛ ye tuma caman na, minnu bɛ cogoya ni jogo ɲuman di ka tɛmɛ cɛncɛn sɔgɔli kan nka u bɛ hɔrɔnya dɔgɔya dilancogo hɔrɔnya la.

Coin Moulding: Nin wale in bɛ danfara don a ka fɛn misɛnninw na, minnu ka dɔgɔ kosɛbɛ, minnu bɛ sizo dɔ dilan. Ni sizo bɛ wuli, o mɔli bɛ datugu ni finimugu ye min dilannen don ni fɛn ye min bɛ kɛ ka a kɛ fɛn ye min bɛ kɛ ka a kɛ fɛn ye min bɛ kɛ ka a kɛ fɛn ye min bɛ kɛ ka a kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

Tansiyɔn ni girinya dɔgɔyali : Nin fɛɛrɛ ninnu bɛ aluminiyɔmu fili moliw kɔnɔ ni tansiyɔn dɔgɔyali ye walima ni tansiyɔn dɔgɔman ye. A bɛ baara kɛ kosɛbɛ aerospace seko ni dɔnko siratigɛ la walasa ka fɛn ɲumanw sɔrɔ minnu bɛ ni masin jogo ɲumanw ye.

J: Yala a bɛ se ka kɛ ka aluminiyɔmu castingw kɛ ka caya wa?

A: Fɛn caman bɛ aluminiyɔmuw kɛ fɛn ye min bɛnnen don dɔrɔn nka a ka teli ka kɛ fɛn ye min bɛ kɛ ka caya:

Scalability: Fɛn minnu ka ɲi kosɛbɛ, olu bɛ se ka dilan tuma bɛɛ fɛn kɛmɛ caman na ka se miliyɔn caman ma ni die casting ani fɛɛrɛ wɛrɛw ye minnu bɛ baara kɛ kosɛbɛ.

Musow ka musaka: musaka min bɛ kɛ u ka jate la, o bɛ dɔgɔya kosɛbɛ jamana kɔnɔ, o b’a to a bɛ se ka kɛ wariko ta fan fɛ.

Baara caman: Aluminiyɔmu yɔrɔ mɔlenw ka jogo nɔgɔmanw ni barikamaw nafa ka bon mobili, aerospace, jɔli ani seko ni dɔnko siratigɛ la.

Fɛnɲɛnɛmako doncogo : Teknoloji kɔrɔlenw ɔtomatizi ni jogoɲumanya kɔlɔsili la, o bɛ nɔgɔya ka taa a fɛ ka baarabaw kɛ ni aluminiyɔmu casting ye.

J: Yala dan bɛ aluminiyɔmu casting la wa?

A: Hali ni nafa caman bɛ aluminiyɔmu na, dan bɛ u la:

Minɛn jɔnjɔnw musaka cayara: Nɛgɛko musaka, kɛrɛnkɛrɛnnenya la die casting la, o bɛ se ka kɛ sababu ye ka musaka dɔgɔya fɛn dilannikɛla misɛnninw bolo .

Porozɛw koɲɛw: Gazi walima porosity dɔgɔyali bɛ se ka nɔ bila masinw fanga n’u dafalen na.

Material Assembly (Matériel Assembly): Fɛn dɔw bɛ se ka kɛ fɛn kɛrɛnkɛrɛnnenw dilanni na minnu bɛ se ka funteni caman muɲu ani ka aluminiyɔmu wulilen ka se ka baara kɛ .

Bonya dantigɛliw: A bɛ se ka kɛ ko a filicogo dɔw tɛ bɛn yɔrɔ misɛnniw walima yɔrɔ fitininw ma.

J: Aluminiyɔmu yɔrɔ dɔ ka cogoya bɛ lajɛ cogo di?

A: Jogoɲini min bɛ kɛ ka aluminiyɔmu caman dilan, o ye fɛn caman ye, wa a bɛ baara kɛ ni fɛɛrɛ caman ye, i n’a fɔ:

Sɛgɛsɛgɛli yelen: Aw ye yɔrɔw dafabaliya ɲini ka fara faraw kan, ka porosite, ani ka kondisiyɔn kɛ cogo bɛnbali la.

Hakɛ hakɛ: Aw ye aw jija fɛnw ka to ka muɲu muɲuli fɛnw na ni minɛnw ye i n’a fɔ kalifa, mikromɛtiriw, ani koordinatɛri sumanikɛlanw (CMMS).

Kɔrɔbɔli min tɛ tiɲɛni ye (NDT): k’a sɔrɔ a yɔrɔ bɛ farati la, fɛɛrɛw ni ultrasonic walima X-ray bɛ kɛ walasa ka kɔnɔna dafalanw sɔrɔ.

Mekaniki sɛgɛsɛgɛliw : sɛgɛsɛgɛli minnu bɛ kɛ fɛnw kan i n’a fɔ tension fanga, janya, ani gɛlɛya walasa yɔrɔ in ka se k’a baaracogo muɲu.

Kisi jateminɛ: Ka a lajɛ ko aluminiyɔmu sɔgɔli kɛcogo bɛ bɛn fɛnw sariyaw ma minnu ka di.

Tiɲɛw minnu bɛ mɔgɔ ɲɛnajɛ:

Aluminiyɔmu ye nɛgɛ camanba ye dugukolo kan, nka a tɛ ye nɔgɔya la a cogoya la; A ka c’a la, a bɛ tali kɛ fɛnw na minnu tɛ kelen ye.

Aluminiyɔmu lasegincogo bɛ fanga kɛmɛsarada la duuru ɲɔgɔn de wajibiya min bɛ kɛ ka aluminiyɔmu kura bɔ ka bɔ kabakurun na.

Aluminiyɔmu casting daminɛna san 1800 waatiw la, wa kabini o waati, a ye fɛn caman sɛmɛntiya izini caman na.

Aluminiyɔmu ka funteni jiginni kojugu b’a to a ka ɲi kosɛbɛ fɛnw ma minnu bɛ funteni jɛnsɛnni wajibiya, i n’a fɔ radiyatɛriw ni funtenibɔlanw.

Aluminiyɔmu sɔgɔlenw bɛ kɛ tuma bɛɛ aerospace porogaramuw la k’a sababu kɛ u fanga ni u girinya hakɛ ka bon.

Aluminiyɔmu Forged bɛ se ka fura suguya caman kɛ, i n’a fɔ anodizing, walasa ka sɔgɔli ni dugukolo sanfɛla gɛlɛya sabati.

Tolerance level in aluminium casting bɛ se ka kɛ fɛn kɛrɛnkɛrɛnnen ye i n’a fɔ milimɛtɛrɛ 0,2, ka kɛɲɛ ni casting kɛcogo ye.

Aluminiyɔmu ka nafolo minnu tɛ baga ye, olu b’a to a bɛnnen don porogaramuw ma dumuni ni furakɛli baarakɛyɔrɔw la.

Yɔrɔ taamasiyɛn damadɔw, i n’a fɔ Washinton Monument yɔrɔba, olu dilannen don ni aliminiyɔmu casting ye.

Aluminiyɔmu wulilen ka ji bɛ a to a ka se ka mildew dilancogo gɛlɛnw fa, o b’a to a ka ɲi kosɛbɛ seko ni dɔnko baaraw ni fɛn masirilenw na.

Kuncɛli:

Fɛɛrɛ nafama dɔ don bi . Rapid Manufacturing , aluminiyɔmu sɛnɛni bɛ fɛɛrɛw ni daɲɛw fara ɲɔgɔn kan walasa ka yɔrɔw dilan minnu mago bɛ seko ni dɔnko siratigɛ caman na. Nafa caman bɛ aluminiyɔmu na, k’a ta mobili baarakɛcogo ɲɛnabɔli la ka se fɛn dilanni baarakɛminɛnw dilanni ma. Aluminiyɔmu sɛnɛni bɛna kɛ fɛnba ye jɔli baara la san caman kɔnɔ, k’a sababu kɛ yiriwali sabatili ye, fɛɛrɛko ɲɛtaa ani cɛsiri sabatili la, fɛnw sababu fɛ, k’a sababu kɛ fɛnw lasegincogo gɛlɛya ye.

Ka fara aluminiyɔmu casting kan, Team MFG fana bɛ dilan . teliya prototyping services ., CNC Machining Services , ani . Pikiriw dilanni baara minnu bɛ kɛ walasa ka aw magow ɲɛ. Aw ye anw sɔrɔ bi!