fanga min bɛ mɔgɔ siri, o nafa ka bon kosɛbɛ walasa ka fɛn dilannenw dilan minnu ka ɲi kosɛbɛ. Nka, fanga joli bɛ bɔ? In Pikirili Molidali ., clamping force tigitigi b’a to nɔgɔ ka to ka datugu o baara senfɛ, ka fiɲɛw bali i n’a fɔ flash walima tiɲɛni. Nin sɛbɛn in kɔnɔ, i bɛna fanga jɔyɔrɔ dɔn, a bɛ nɔ bila a dilanni na cogo min na, ani fɛɛrɛ minnu bɛ se k’a jatebɔ ka ɲɛ walasa ka ɲɛtaa ɲuman sɔrɔ.

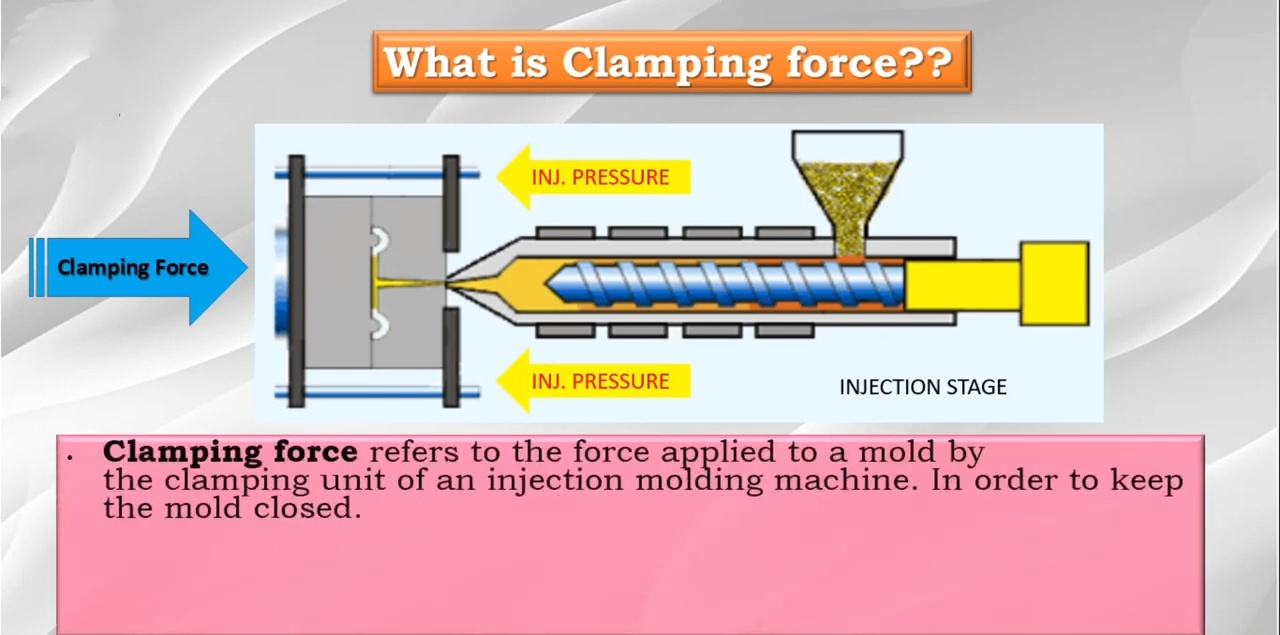

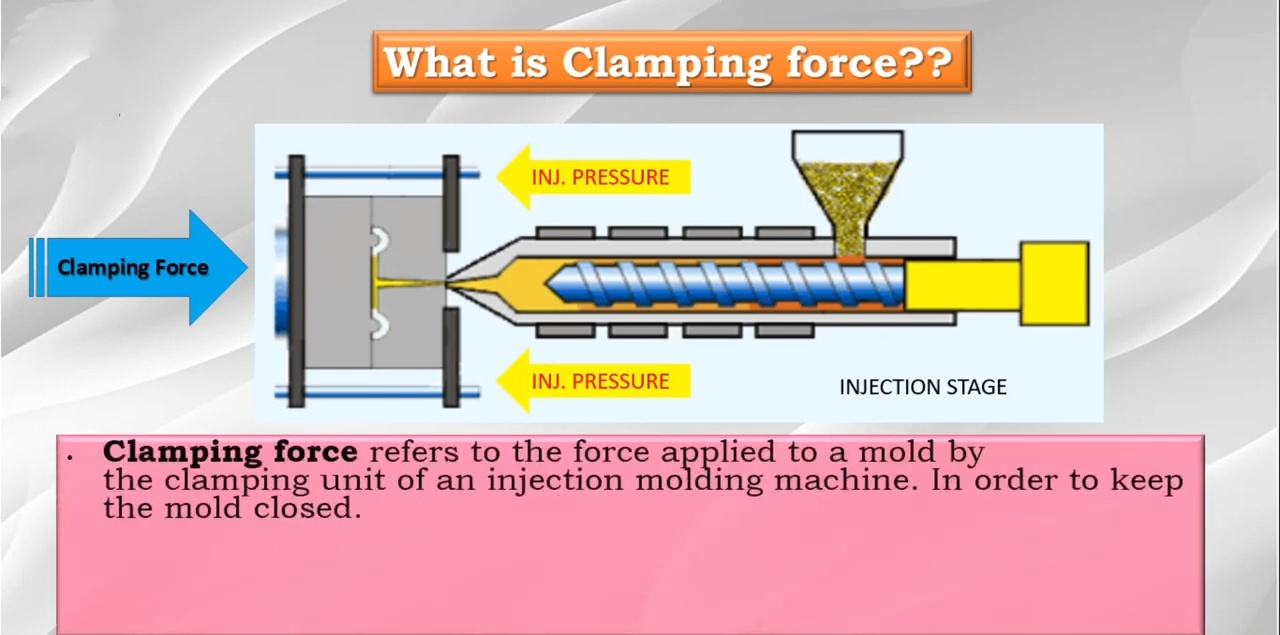

Mun ye fanga sirili ye pikiri kɛli la?

fanga min bɛ kɛ ka mɔgɔw siri, o ye fanga ye min bɛ nɔgɔ tilayɔrɔw to ɲɔgɔn na pikiri kɛtuma na. A bɛ iko vise grip belebeleba dɔ, ka fɛn bɛɛ minɛ a nɔ na.

O fanga in bɛ Bɔ masin ka ji-yɔrɔ-ko la walima kuran-motow la. U bɛ nɔgɔ tilayɔrɔw gɛrɛ ɲɔgɔn na ni fanga ye min tɛ se ka da a la.

N’an y’a fɔ cogo nɔgɔman na, fanga min bɛ mɔgɔ siri, o ye degun ye min bɛ kɛ walasa ka nɔgɔw datugu. A bɛ suman ton walima mɛtɛrɛ tɔniko la.

Miiri k’a filɛ i n’a fɔ masin ka farikolo fanga. Ni a sirilan barika ka bon, a bɛ se ka degun caman sɔrɔ.

jɔyɔrɔ min bɛ sirili fanga la pikiri kɛcogo la .

O sirilan ye pikirijikɛlan dɔ yɔrɔ koloma ye. A bɛ kɛ ni platen jɔlen ye ani platen lamagannen ye, minnu bɛ nɔgɔ tilayɔrɔ fila minɛ. O sirilan, a ka c’a la, ji walima kuran, o bɛ fanga sɔrɔ min ka kan ka kɛ walasa ka nɔgɔ datugu pikiri kɛtuma na.

Nin ye fanga sirili ye cogo min na, o bɛ kɛ ka kɛɲɛ ni fɛn ye min bɛ kɛ ka fɛnw labɛn, o bɛ kɛ cogo min na, o bɛ kɛ cogo min na.

Nɔgɔ bɛ datugu, wa a sirilan bɛ a sirili fanga fɔlɔ kɛ walasa nɔgɔ tilayɔrɔw ka to ɲɔgɔn na.

Pikiri yɔrɔ bɛ plastiki wuli ka a pikiri kɛ nɔgɔbɔlan kɔnɔ degunba la.

Ni plastiki wulilen bɛ ka kɔnɔna fa, a bɛ degun kunbɛn min b’a ɲini ka nɔgɔ tilayɔrɔw gɛrɛ ɲɔgɔn na.

sirili yɔrɔ bɛ siri fanga mara walasa ka o degun kunbɛn ani ka nɔgɔ datugu.

Ni plastiki nɛnɛna ani ka a sabati, a sirilan bɛ mɔli da wuli, a yɔrɔ bɛ bɔ.

Ni fanga ɲuman ma sɔrɔ, yɔrɔw tun bɛ se ka fiɲɛw sɔrɔ i n’a fɔ:

Flash (fɛn min bɛ tɛmɛn a kan ni a bɛ se ka kɛ a la)

Shorts shots (filling incomplete) .

Warping walima Dimension koɲɛw .

Nafa min b’a la ka fanga sɔrɔ min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye .

Ka fanga sɔrɔ ka ɲɛ, o nafa ka bon kosɛbɛ jogoɲumanya ni baarakɛcogo ɲuman na,

Clamping force ɲuman bɛ a jira ko:

Yɔrɔ minnu ka ɲi kosɛbɛ .

Mold Life min ka jan .

Fanga baaracogo ɲuman .

Sikili waati teliya .

Fɛnw tiɲɛni dɔgɔyali .

Fɛn minnu bɛ nɔ bila sirili fanga la pikiri kɛli la .

Fɛn jɔnjɔn caman bɛ sirili fanga jira min ka kan ka kɛ pikirijikɛlanw dilanni na, ka a lajɛ ko mɔli bɛ to ka datugu o kɛcogo la ani ka fiɲɛw bali. O kow ye yɔrɔ ye min bolodara, a kɔnɔna degun, a ka fɛnw cogoya, a dilanni, ani a baaracogo.

yɔrɔ min bolodara ani a nɔfɛkow ka ɲɛsin fanga sirili ma .

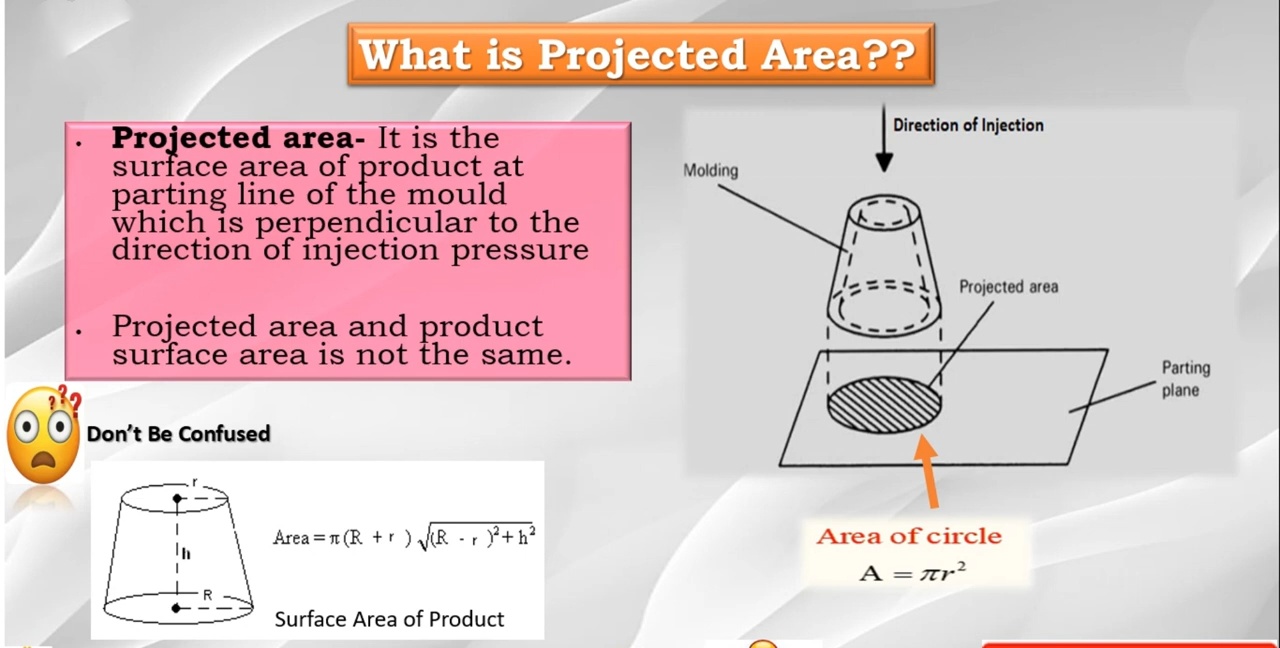

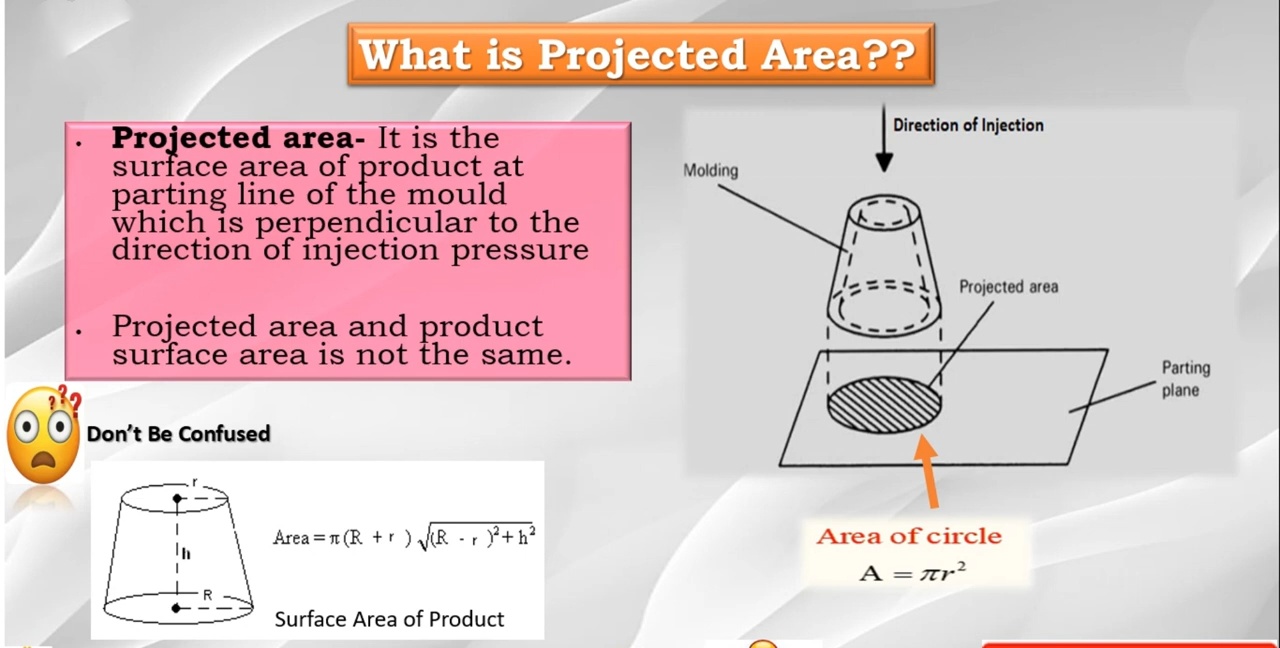

Yɔrɔ min bolodara, o ɲɛfɔli :

Yɔrɔ min bolodara, o bɛ tali kɛ yɔrɔ dilannen yɔrɔba la, i n’a fɔ a bɛ ye cogo min na ka bɔ sirili sira fɛ. A bɛ yɔrɔ in jira kɔnɔna fanga la min bɛ sɔrɔ plastiki wulilen fɛ pikiri kɛtuma na.

Yɔrɔ jateminɛlen dɔncogo :

Yɔrɔ kɛnɛw kama, yɔrɔ jateminɛ ni janya caya ye ni bonya ye. Ni aw bɛ yɔrɔw lajɛ minnu bɛ kɛ ni circular ye, aw bɛ baara kɛ ni formula ye:

Yɔrɔ bɛɛ lajɛlen bɛ bonya ni kɔnɔnatumuw hakɛ ye nɔgɔ la.

Jɛɲɔgɔnya min bɛ yɔrɔ kofɔlen ni fanga sirili cɛ :

yɔrɔ min ka bon kosɛbɛ, o bɛ fanga caman de wajibiya walasa ka nɔgɔ bali ka da wuli pikiri kɛtuma na. O bɛ Kɛ k’a sababu Kɛ ko yɔrɔ min ka bòn, o bɛ Nà ni kɔnɔna degunba ye.

Misaliw : .

Yɔrɔ kogo janya : Kogo finmanw bɛ dɔ fara kɔnɔna degun kan, o bɛ kɛ sababu ye ka fanga caman siri walasa ka nɔgɔ minɛ ka datugu.

Flow length-to-thickness ratio : Ni o hakɛ bɛ caya, degun bɛ caya ka taa a fɛ ka bɔ a kɔnɔ, ka dɔ fara a mago kan ka fanga siri.

cavity pressure ani a ka fanga min bɛ sɔrɔ fanga la .

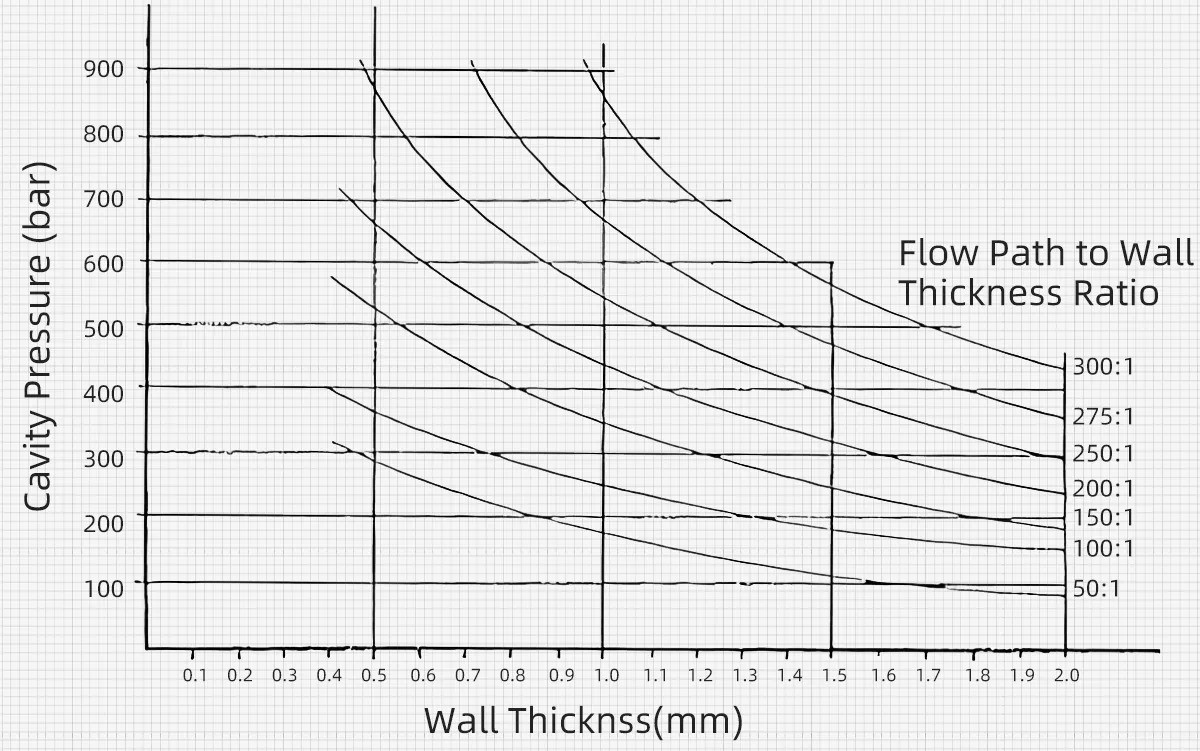

Kɔnɔbara tansiyɔn ɲɛfɔli :

kɔnɔna tansiyɔn ye kɔnɔna tansiyɔn ye min bɛ kɛ ni plastiki wulilen ye ni a bɛ mɔni fa. A bɛ bɔ fɛnw cogoyaw la, pikiri teliya la, ani jateminɛ kɛcogo la.

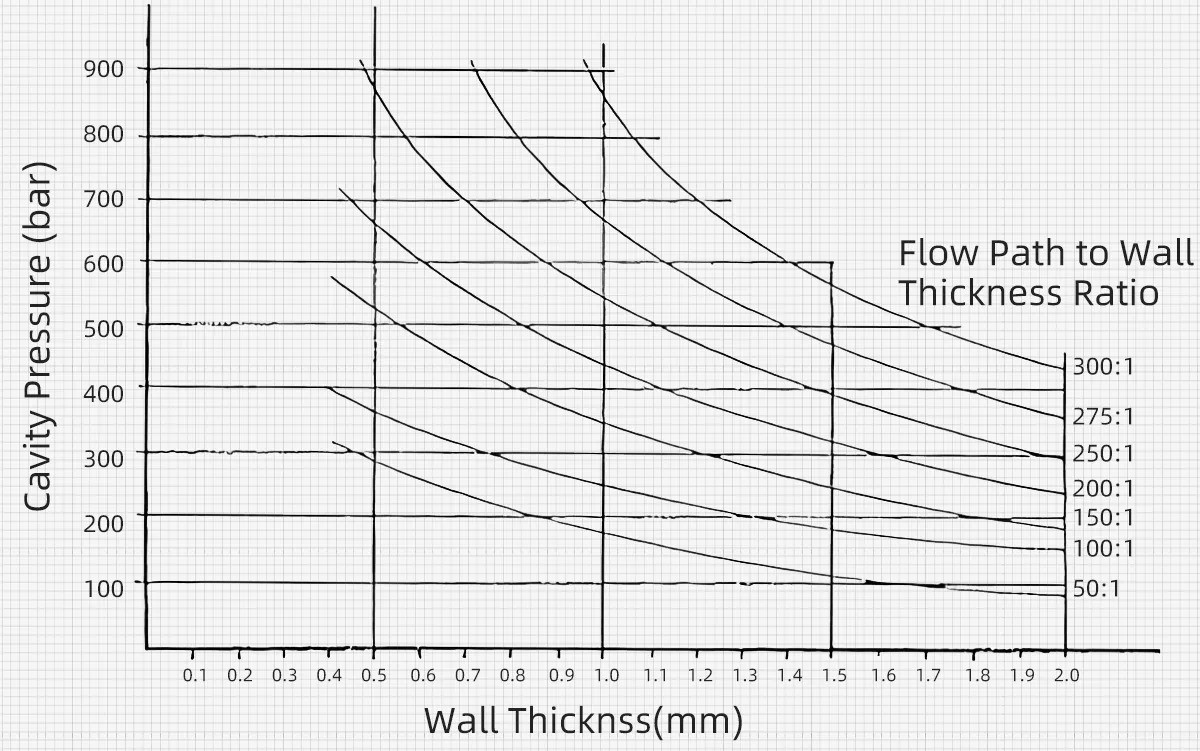

Jɛɲɔgɔnya min bɛ cavity pressure kogo janya ni sira ni thickness ratio cɛ .

Fɛn minnu bɛ nɔ bila kɔnɔbara tansiyɔn na : .

Kogo janya : Yɔrɔ minnu kogow ka fin, olu bɛ na ni kɔnɔna tansiyɔnba ye, ka sɔrɔ kogow ka bon, olu bɛ degun dɔgɔya.

Pikiri teliya : Pikiri teliya teliya bɛ na ni kɔnɔna degunba ye nɔgɔ kɔnɔ.

Material Viscosity : Plastiki minnu ka bon kosɛbɛ, olu bɛ se ka u tanga ka caya, ka dɔ fara degun kan.

Kɔnɔna tansiyɔn bɛ nɔ bila fanga la cogo min na :

ni kɔnɔna tansiyɔn bɛ ka bonya, fanga caman ka kan ka sɔrɔ walasa ka nɔgɔ bali ka da. Ni sirili fanga ka dɔgɔn kojugu, nɔgɔ bɔli bɛ se ka kɛ, o bɛ na ni fiɲɛw ye i n’a fɔ flash. Ni aw bɛ kɔnɔna tansiyɔn jateminɛ ka ɲɛ, o bɛ dɛmɛ ka sirili fanga bɛnnen dɔn.

Matériel propriétés et de conception .

Materiel properties : .

Viscosité : Plastiki minnu bɛ ye kosɛbɛ, olu bɛ woyo nɔgɔya la, o bɛ fanga caman wajibiya.

density : denser matériaux mago bɛ tansiyɔn caman na walasa ka nɔgɔ fa ka ɲɛ.

Mold design factors : .

Runner System : Bololabaarakɛla minnu ka jan walima minnu ka gɛlɛn, olu bɛ se ka dɔ fara degun wajibiyalenw kan.

Da hakɛ ni a sigiyɔrɔ : Da minnu ka dɔgɔn walima minnu jɔyɔrɔ man ɲi, olu bɛ dɔ fara u mago kan ka siri fanga caman na.

Pikiri teliya ni a funteni .

Pikiri teliya ni nɔgɔ hakɛ fila bɛɛ bɛ nɔ bila plastiki bɛ woyo cogo min na ani ka a jɔ cogo min na. Pikiri teliya teliya la ani nɔgɔw funteni dɔgɔyali la, a ka c’a la, o bɛ dɔ fara kɔnɔna kɔnɔna tansiyɔn kan, o la, a bɛ fanga caman wajibiya walasa ka nɔgɔ datugu o baara senfɛ.

Cogo min na ka jatebɔ fanga jate pikiri kɛli la .

Jatebɔ fanga tɛ rocket science ye, nka a nafa ka bon kosɛbɛ ka ɲɛsin molding ma. An ka fɛɛrɛ suguya caman sɛgɛsɛgɛ, k’a ta basigilen na ka se ɲɛtaa ma.

1. Formula basigilen .

Equation basigilen min bɛ kɛ ka ɲɛsin fanga sirili ma o ye :

fanga sirili fanga = yɔrɔ × pressure projeté .

ɲɛfɔli minnu bɛ kɛ a yɔrɔw kan:

Aw bɛ ninnu caya, ani aw ye aw ka clamping force jateminɛlen sɔrɔ.

2. Formula émpiriques .

Tuma dɔw la, jateminɛ teliyalenw de ka kan. O yɔrɔ de la, fɛɛrɛw bɛ na ni nafa ye.

KP fɛɛrɛ

sirili fanga (T) = kp × yɔrɔ jateminɛlen (cm²) .

KP hakɛw bɛ danfara ka kɛɲɛ ni fɛnw ye:

PE/PP: 0,32 ye.

ABS: 0,30-0,48 ye.

PA/POM: 0,64-0,72.

350 BAR Fɛɛrɛ

sirili fanga (T) = (350 × yɔrɔ jateminɛlen (cm²)) / 1000 .

Nin fɛɛrɛ in bɛ a jira ko tansiyɔn basigilen bɛ 350 bar la.

Fɛɛrɛw sɔrɔcogo ɲumanw ni u gɛlɛyaw .

Nafa minnu bɛ yen:

Cons:

3. Jatebεcogo kɔrɔlenw .

Walasa ka jateminɛ kɛ ka ɲɛ, aw bɛ fɛnw cogoya ni u baarakɛcogo jateminɛ.

Termoplastique flow characteristics Grouping

| grade | thermoplastique matériaux | flow coefficients . |

| 1 | GPP, Hips, LDPE, LLDPE, MDPE, HDPE, PP, PP-EPDM . | ×1.0. |

| 2 | PA6, PA66, PA11/12, PBT, PETP | ×1,30~1,35. |

| 3 | CA, Cab, Cap, Cp, Eva, Pur/TPU, PPVC . | ×1,35~1,45. |

| 4 | ABS, ASA, SAN, MBS, Pom, BDS, PPS, PPO-M . | ×1,45~1,55. |

| 5 | PMMA, PC/ABS, PC/PBT | ×1,55~1,70. |

| 6 | PC, PEI, UPVC, Peek, PSU | ×1,70~1,90. |

Tablo de flow coefficients de commun thermoplastique matériaux .

Jatebɔ taabolo senfɛ-senfɛ .

A’ ye yɔrɔ jateminɛ .

Aw bɛ kɔnɔna tansiyɔn jateminɛ ni jibɔ janya ni a janya hakɛ ye .

Aw bɛ fɛnw kulu multiplication constant kɛ .

Yɔrɔ caya ni tansiyɔn ladilanen ye .

Misali: ka ɲɛsin PC yɔrɔ ma ni 380cm⊃2 ye; yɔrɔ ani 160 bar basigilen tansiyɔn :

siri fanga = 380cm² × (160 bar × 1,9) = tɔni 115,5 .

4. CAE porogaramuw jatebɔ .

Ka ɲɛsin yɔrɔw ma minnu ka gɛlɛn walima minnu mago bɛ fɛn caman na, CAE porogaramuw nafa ka bon kosɛbɛ.

MoldFlow ni o ɲɔgɔnna porogaramuw daminɛ .

O porogaramuw bɛ pikiri kɛcogo simulatigɛ. U bɛ kɔnɔna degunw ni fanga sirili kofɔ ni tiɲɛniba ye.

Nafa minnu bɛ sɔrɔ CAE la .

Jatew bɛ sɔrɔ jateminɛ gɛlɛnw kan .

A bɛ fɛnw cogoya ni u baarakɛcogo jateminɛ .

A bɛ kartiw dilan minnu bɛ se ka kɛ ni degun ye .

A bɛ dɛmɛ ka mɔli dilanni ni a baaracogo paramɛtɛrɛw ɲɛnabɔ ka ɲɛ .

Misali: fanga jatebɔ min bɛ kɛ ka polikarbonati lanpan minɛ .

An ka an yɛrɛ su ji la ka kɛ misali lakika ye. An bɛna clamping force jate polikarbonati lanpan minɛyɔrɔ la.

Misali faamuyali .

An ka lanpantigi bɛ ni nin fɛn ɲɛfɔlen ninnu ye:

Kɛmɛsarada la: 220mm

Kogo ka bon: 1,9-2.1mm .

Fɛn min bɛ sɔrɔ a la: polikarbonati (PC) .

Design: pin-shaped center gate .

Flow sira min ka jan: 200mm .

Polikarbonati bɛ dɔn a ka sɔgɔli ka bon. O kɔrɔ ye ko a mago bɛna kɛ degun caman na walasa ka mɔni fa.

Jatebɔ senfɛ-senfɛ .

An ka taabolo tiɲɛ:

Jatebɔ janya ni kogo janya hakɛ:

hakɛ = jibɔ sira janya / kogo min ka fin= 200mm / 1.9mm= 105:1.

A’ ye basibɔn basigilen tansiyɔn jateminɛ:

Aw bɛ a ladilan ka kɛɲɛ ni fɛnw cogoyaw ye:

Jatebla yɔrɔ jateminɛlen:

Yɔrɔ = π * (Dimi/2)⊃2;= 3.14 * (22/2)⊃2; = 380 cm²

Jatebɔ fanga:

Fanga = tansiyɔn * yɔrɔ= 304 bar * 380 cm²= 115.520 kg= 115,5 ton

Yɛlɛma donna lakana ni baarakɛcogo ɲuman na .

Walasa ka lakana, an bɛ lamini ka se masin hakɛ nata ma min bɛ sɔrɔ. Masina min bɛ ton 120 bɔ, o tun bɛna bɛn.

Aw ye nin ko ninnu jateminɛ ka ɲɛsin baarakɛcogo ɲuman ma:

A daminɛ ni tɔni 115,5 ye ani ka ladilan ka kɛɲɛ ni a yɔrɔ cogoya ye .

Monitor for flash walima short shots .

Aw bɛ fanga dɔgɔya dɔɔni dɔɔni ni aw bɛ se ka jogo tiɲɛ .

Pikirili mɔli masin sugandili ani a sirili fanga matching .

Pikiri kɛcogo ɲuman sugandili nafa ka bon kosɛbɛ walasa ka ɲɛtaa sɔrɔ. A tɛ fanga dɔrɔn de kan - fɛn caman bɛ na baara la.

Jɛɲɔgɔnya min bɛ fanga ni masin paramɛtɛrɛw cɛ .

Clamping force tɛ yɔrɔ kelen na. A sirilen bɛ kosɛbɛ masinw ka fɛnsɛbɛnni wɛrɛw la:

Pikiri seko: .

Vis hakɛ:

Mold Opening Stroke:

Tie Bar Spacing:

A ka kan ka i ka mɔli hakɛ jate .

A ka ca a la, mɔni belebelebaw mago bɛ masinw na minnu fanga ka bon ni u sirili fanga ye .

Reference ranges for common plastic products .

Fanga sirili magow tɛ kelen ye. Nin ye gafe ye min bɛ se ka kɛ

| fɛn | ye min bɛ se ka kɛ fɛn | ye min bɛ se ka kɛ fɛn ye min bɛ se | ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ wele |

| Minɛnw kogo finmanw . | Poliporopilini (pp) . | 500 cm² | tɔni 150-200 . |

| Mobili yɔrɔw . | ABS . | 1000 cm² | tɔni 300-350 . |

| Elektronikiw ka so . | Polikarbonati (PC) . | 700 cm² | tɔni 200-250 . |

| Bouteli kapisi . | HDPE . | 300 cm² | tɔni 90-120 . |

Tablo min bɛ sanfɛ, o bɛ ɲɛfɔli gɛlɛn di fɛn suguyaw ma minnu bɛ bɛn ɲɔgɔn ma ni fanga wajibiyalen ye. O ja ninnu bɛ se ka ɲɔgɔn ta ka kɛɲɛ ni yɔrɔ dɔw ka gɛlɛya ye, u ka fɛnw cogoya ani u dilanni.

Fanga min tɛ tiɲɛ ye, o kɔlɔlɔw .

Ka fanga sɔrɔ ka ɲɛ, o nafa ka bon kosɛbɛ pikiri kɛli la. A ka dɔgɔn kojugu walima a ka ca kojugu, o bɛ se ka kɛ sababu ye ka ko juguw kɛ. An ka gɛlɛyaw sɛgɛsɛgɛ minnu bɛ se ka kɛ.

Fanga min bɛ se ka kɛ fɛn ye min tɛ se ka kɛ .

Ni aw ma fanga caman kɛ, gɛlɛya damadɔw bɛ se ka sɔrɔ:

Flash Formation .

Fɛn tɛmɛnenw bɛ bɔ nɔgɔ tilayɔrɔw ni ɲɔgɔn cɛ .

A bɛ bɔli finmanw dilan, minnu man ɲi yɔrɔw kan .

A bɛ tigɛ wɛrɛw de wajibiya, ka dɔ fara sɛnɛfɛnw musaka kan .

A yɔrɔ ka ɲi kosɛbɛ .

Dimensionnel inaccuracies ka sababu kɛ moule separation ye .

Fali dafabali, kɛrɛnkɛrɛnnenya la, yɔrɔ minnu kogow ka fin .

A yɔrɔ girinyaw tɛ bɛn ɲɔgɔn ma sɛnɛfɛnw bɛɛ lajɛlen na .

Mold tiɲɛni .

fanga tɛmɛnen fanga .

Fanga caman kɛli fana tɛ jaabi ye. A bɛ se ka kɛ sababu ye:

Masina don .

Degun kunntanw bɛ sɔrɔ jibolisiraw kan .

Accelerated wear of tie bars ani plates .

Masina surunyalen ɲɛnamaya .

fanga tiɲɛni .

Fanga sanfɛla bɛ fanga caman de wajibiya .

A bɛ dɔ fara sɛnɛfɛnw bɔli musakaw kan .

A bɛ dɔ bɔ baarakɛcogo bɛɛ lajɛlen na .

Mold tiɲɛni .

Gɛlɛya bɛ sɔrɔ ka ɲɛsin kɔnɔna degun ma .

Nafa min bɛ a la ka fanga ɲuman mara.

Balannako fanga-dafalen ye fɛnba ye min bɛ se ka kɛ sababu ye ka fɛnw labɛn ka ɲɛ. Nin ye mun ye a nafa ka bon:

Yɔrɔ min bɛ to ka kɛ fɛn ye min bɛ to ka kɛ .

Minɛnw ka ɲɛnamaya janya .

Kuwame ka baarakɛcogo ɲuman .

Sikili waati teliya .

Dɔgɔyali hakɛ dɔgɔyali .

Aw ye aw hakili to a la ko fanga ɲuman tɛ yɔrɔ kelen na. A bɛ se ka kɛ a mago bɛ ladilanni na ka da:

Kɔlɔn fanga kɔlɔsili ni a labɛncogo ɲuman nafa ka bon walasa ka sɛnɛfɛnw mara minnu ka ɲi kosɛbɛ, minnu bɛ ɲɛ.

Fɛɛrɛ ɲumanw walasa ka fanga sɔrɔcogo ɲuman sabati .

Ka se ka fanga dafalen sɔrɔ, o tɛ baara ye min bɛ kɛ siɲɛ kelen. A bɛ ɲini ka jateminɛ kɛ ka taa a fɛ ani ka ladilanni kɛ. An ka fɛɛrɛ ɲuman dɔw sɛgɛsɛgɛ walasa aw ka pikiri kɛcogo ka ɲɛ.

Moule de conceptions de mold de mold .

Mold design ɲuman nafa ka bon kosɛbɛ walasa ka fanga ɲuman sɔrɔ:

Aw bɛ baara kɛ ni balannako ye walasa ka tansiyɔn tila ɲɔgɔn na cogo kelen na .

Aw bɛ fiɲɛbɔlan ɲuman kɛ walasa ka fiɲɛ minɛta ni degunw dɔgɔya .

Aw ye jateminɛ kɛ yɔrɔ jateminɛ na walasa ka yɔrɔ jateminɛlen dɔgɔya ni a bɛ se ka kɛ .

Design ni kogo janya kelen ye walasa ka hali degun tilali sabati .

Material Selection ani a nɔfɛkow .

Fɛn minnu tɛ kelen ye, olu bɛ siri fanga suguya wɛrɛw la:

| Fɛn minnu | bɛ tali kɛ ɲɔgɔn na, olu ka kan ka kɛ . |

| PE, PP . | Fɛ́gɛn |

| ABS, PS . | Hakɛ |

| PC, POM | Jamanjan |

Aw bɛ fɛnw sugandi ni hakilitigiya ye. Aw ye a yɔrɔ wajibiyalenw ni a baarakɛcogo nɔgɔya fila bɛɛ jateminɛ.

Masina ladonni ni a jateminɛ .

Ladonni tuma bɛɛ bɛ a to a bɛ se ka kɛ ni fanga tigitigi ye:

Aw bɛ jibolisiraw lajɛ ni u bɛ bɔ walima ni u bɛ don .

kalibreli tansiyɔn jateminɛnanw san o san .

Aw bɛ sɛgɛsɛgɛli kɛ ni degun taamasiɲɛw ye walima ni u ma bɛn ɲɔgɔn ma .

Aw bɛ platiw saniya ani ka u tobi ka ɲɛ .

Kɔlɔsili ni ladilanni kɛli a dilanni senfɛ .

Clamping force tɛ set-and-forget ye. Aw bɛ nin taamasiɲɛ ninnu kɔlɔsi:

Aw bɛ fanga ladilan ni aw ye koɲɛw kɔlɔsi. Yɛlɛma misɛnninw bɛ se ka danfarabaw don.

Hakɛ jiralanw ni kɔrɔsili fɛɛrɛw .

Baara kɛ ni kunnafoniw ye walasa ka i ka baara kɛcogo ɲɛ:

Aw bɛ basigi sirili fanga dɔ sigi sen kan .

Aw bɛ a ladilan 5-10% farali la ka da a yɔrɔ cogoya kan .

Aw bɛ jaabiw sɛbɛn ladilan kelen-kelen bɛɛ la .

Database correlating force dɔ dabɔ walasa ka a yɔrɔ jogo .

Baara kɛ ni nin kunnafoniw ye walasa ka setup nataw ni gɛlɛyaw ɲɛnabɔli kɛ .

Misali la, a bɛ se

| kɛ ko a bɛ se ka | ka | : | kɛ ko a bɛ se ka kɛ ko |

| 90 | Foɲisi | Damadɔ | ±0,5% . |

| 95 | Foɲisi | Foɲisi | ±0,2% . |

| 100 | A ka dɔgɔ . | Foɲisi | ±0,1% . |

Aw bɛ dumuni duman yɔrɔ ɲini yɔrɔ min na jogo jiralanw bɛɛ ka ɲi.

Kuncɛli

Faamuyali ni jatebɔ fanga la, o nafa ka bon walasa ka pikiri kɛ ka ɲɛ. A bɛ yɔrɔ dɔw cogoya sabati, ka fiɲɛw bali, ani ka mɔni ɲɛnamaya janya. Take-aways kunbabaw ye yɔrɔ projɛlen jɔyɔrɔ, fɛnw cogoyaw, ani baarakɛcogo paramɛtiriw jɔyɔrɔ ye ka ɲɛsin clamping force ɲuman ma. Aw ye nin dɔnniya in waleya aw ka porozɛw kɔnɔ walasa ka ɲɛtaa ɲumanw sɔrɔ ani ka sɛnɛfɛnw dilanni nafama kɛ.