PPS ko Polyphenylene an fara bunkasa a cikin shekarun 1960 a matsayin babban aikin polymer. Yana da gadar rata tsakanin hanyoyin robobi da kayan ci gaba, suna ba da kayan musamman waɗanda suke da mahimmanci a cikin masana'antu daban-daban.

A cikin wannan post, zamu bincika kayan kwalliyar PPS na musamman na PPS, aikace-aikace daban-daban, yadda aiki, kuma me yasa ya zama ba zai iya rayuwa ba a masana'antu daban-daban.

Tsarin sunadarai na PPS

Pokhadenlene (PPS) yana ba da juriya na zazzabi, tsayayye, da bayyanar opoque a matsayin thermoplasticalast na Semi-lu'ulu'u.

Tsarin kwayoyin halitta

Kobbin PPS ya kunshi raka'a-phenylene raka'a tana musayar ƙasa da haɗin sulfed. Wannan yana ba da pPS halayenta.

Sulfur atoms samar da hadari mai yawan lokuta tsakanin benzene zobba. Suna haɗa a cikin para (1,4) saiti, ƙirƙirar sarkar layin.

Tsarin Crystalline

PPS don samar da tsarin crystalline, wanda ke ba da gudummawa ga kwanciyar hankali na thereral da juriya na sinadarai.

Cellerirƙiri sel na erthoorhombic

Cellararriyar kwayar PPS shine Orthorhombic, tare da waɗannan girmankai:

a = 0.867 nm

b = 0.561 nm

C = 1.026 NM

Launar da aka ƙididdige daɗaɗɗar wuta don ingantaccen Crystal PPS shine 112 J / G. Wannan tsarin yana ba da babban matakin narkewarsa na 280 ° C.

Digiri na lu'ulu'u

Matsayin lu'ulu'u a cikin PPS ya fito daga 30% zuwa 45%. Ya dogara da:

Mafi girma lu'ulu'u yana ƙaruwa:

Ƙarfi

Tauri

Juriya na sinadarai

Zafi juriya

Lowerarancin lu'ulu'u na lu'ulu'u ya inganta:

Kuna iya shirya amorophous da kuma tsallake pps ta:

Zama sama da narkewar zafin jiki

Sanyaya zuwa 30 ° C a ƙasa yana narkewa

Rike awanni a cikin gaban iska

Wannan tsarin yana ba da PPP mai kyau kwarai kamar yadda-zazzabi juriya da rashin daidaituwa.

Nau'in pps filastik

PPS resin ya zo a cikin siffofi daban-daban, kowannensu tare da kaddarorin musamman wanda aka tsara don takamaiman aikace-aikace.

Linear Pps

Ya kusan ninki biyu na kwayar cutar pps na yau da kullun

Yana haifar da mafi girman iko, elongation, da kuma ƙarfin tasiri

Warke pps

An samar da PS na yau da kullun a gaban iska (O2)

Curing ya shimfida sarƙoƙi na kwayoyi kuma yana haifar da wasu rassan

Haɓaka nauyi na kwayoyin halitta kuma yana ba da halaye na therroset

Branched PPS

Yana da mafi girman nauyin kwayoyin fiye da pps na yau da kullun

Fasali da aka kara karfi polymer sarkar backbone

Inganta kaddarorin kayan aikin, iyawa, da kuma bututunsu

Tebur da ke ƙasa ya kwatanta kwatancin ƙwayoyin cuta daban-daban na PPS:

| PPS Type | Weekcular kwatanta |

| Pps na yau da kullun | Gindi |

| Linear Pps | Kusan pps biyu na yau da kullun |

| Warke pps | Ya karu daga pps na yau da kullun saboda fadada sarkar da farar fata |

| Branched PPS | Sama da pps na yau da kullun |

Nauyin kwayoyin na PPS yana taka muhimmiyar rawa wajen tantance kaddarorinta. Mafi girma kwayoyin nauyi gaba daya yana haifar da:

Koyaya, hakanan kuma zai iya haifar da ƙara danko, yin aiki mafi ƙalubale.

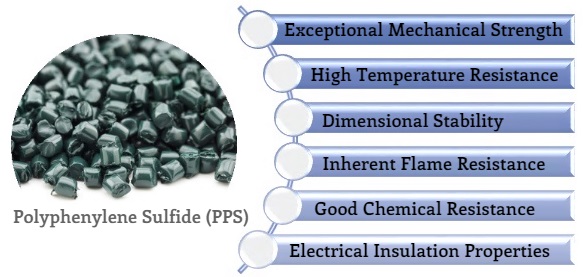

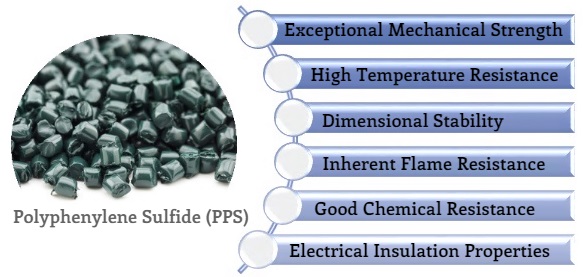

Kaddarorin PPS (polyphenalne sulfide) filastik

Pps filastik ya ba da haɗin haɗi na musamman na kaddarorin da suka sanya ta dace da aikace-aikace daban-daban.

Kayan aikin injin

PPS suna alfahari da fifikon kayan aikin yau da kullun, yana tabbatar da shi da kyau don aikace-aikacen neman.

Tenarfin da ke da ƙarfi: tare da ƙarfin tensile na 12,500 PSI (86 MPa), PPS na iya tsayayya da mahimman kaya ba tare da fashewa ba.

Tasirin juriya: duk da tsayayyensa, PPS yana da tasirin tasirin izod na 0.5 ft-lbs / a (27 J / M)

Modulal modulir na elasticity: A 600,000 PSI (4.1 GPA), PPS ta ci gaba da tsayayya da lanƙwasa tanadi, rike da amincin sa.

Dangantaka mai girma: PPS ta tabbatar da girmanta ko da a karkashin babban zazzabi da yanayin zafi, sanya shi dace da sassan da ke da matukar hakuri.

Properties na Thermal

PPS fice a cikin kwanciyar hankali da juriya, muhimmin abu ne ga aikace-gwaje-canje na zafi.

Heat Deflection Temperature: PPS can withstand temperatures up to 260°C (500°F) at 1.8 MPa (264 psi) and 110°C (230°F) at 8.0 MPa (1,160 psi).

Mafi kyawun layi na Finire Herarn Thermal: PPS yana nuna ƙananan canje-canje na zazzabi tare da bambancin zazzabi a 4.0 × 10⁻⁵ F (7.2 ° F (7.2 ° F (7.2 ° F (7.2 ° F (7.2 ° F (7.2 ° F (7.2 × 10⁻⁵ M / M / ° C).

Matsakaicin ci gaba da zazzabi: PPS za a iya amfani da PPS ci gaba cikin iska a yanayin zafi har zuwa 220 ° C (428 ° F).

Juriya na sinadarai

An san PPS saboda juriya na sinadarai, yin ya dace da matsanancin yanayin.

Juriya ga danshi: PPS din ya kasance ba illa da danshi, tabbatar da tsauraran yanayi a cikin yanayin zafi.

Juriya ga sunadarai daban-daban: PPS da tsayayya wa sinadarai masu ƙarfafawa, ciki har da karfi acid, bots, ƙwayoyin cuta, da hydrocarbons.

Kaddarorin lantarki

PPS na hasken wutar lantarki na PPS suna dacewa da aikace-aikacen lantarki.

Babban Resistrave na girma: PPP suna kiyaye juriya na tudun ko da a cikin mahalli mai girma, tare da tsararraki mai girma na 10⊃1; ω ω · cm.

Ikon Jiki: Tare da karfin kayan maye na 450 v / Mil (18 KV (mm), PPS suna tabbatar da ingantaccen rufi.

Ƙarin kaddarorin

PPS yana ba da wasu kayan abin da ake so:

Flame juriya: Yawancin maharan PPS suna wucewa da daidaitaccen Ul94V-0

Babban modulus lokacin da karfafa: karfafa pps maki nuna babban modulus, inganta karfi na inji.

Lowarancin sha na ruwa: tare da sha na ruwa kawai 0.02% na nutsewa, PPS ya dace don aikace-aikacen da ake buƙata rage ƙarancin danshi.

Tebur mai zuwa yana taƙaita mahimman kaddarorin pps filastik:

| dukiya | darajar |

| Tenerile ƙarfi (Astm d638) | 12,500 PSI (86 MPa) |

| IZOD tasirin IZOD (ASM D256) | 0.5 ft-lbs / a (27 J / M) |

| Modulal modulir (Astm d790) | 600,000 PSI (4.1 GPa) |

| Zazzabi na zazzabi (Astm D648) | 500 ° F (260 ° C) @ 264 PSI |

| Ingantacciyar hanyar layin da aka gabatar | 4.0 × 10⁻⁵ in / in / ° f |

| Matsakaicin cigaban zazzabi | 428 ° F (220 ° C) |

| Jerarancin tsayayya (ASM D257) | 10⊃1; ⁶ ω · cm |

| Ikon Murmuyricci (Astm D149) | 450 v / Mil (18 KV / MM) |

| Ruwa kai (Astm D570, 24h) | 0.02% |

Wadannan kaddarorin suna yin sahihan zaɓi don aikace-aikacen da ke neman babban aiki, karkara, da dogaro a cikin mahalli kalubale.

Masana'antar masana'antar pps filastik

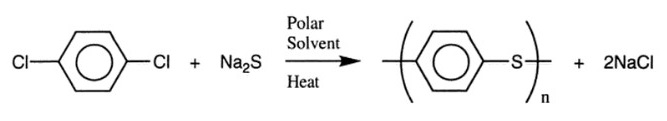

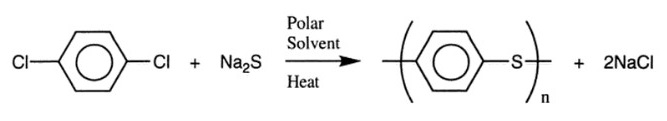

A dauki na sodium sulfide da dichllenzenzene a cikin polar sauran ƙarfi don samar da polyphenylene (PPS)

Farkon sababbin abubuwa a cikin samar da PPS

Labarin PPS ya fara ne a shekara ta 1967 tare da edmonds da dutse a Philis Pedroume. Sun kirkiro aiwatar da aikin kasuwanci na farko a karkashin alamar sunan Ryton.

Abubuwan fasali na asali tsari:

Samar da ƙananan ƙwayoyin cuta mai nauyi

Mafi dacewa ga aikace-aikace aikace-aikace

Da ake buƙata na da ake buƙata don grading maki

Dabarun masana'antu na zamani

Abincin PPS na yau ya samo asali sosai. Hanyoyin zamani suna nufin:

Chinadan sunadarai da gyara

Fadar PPS ta ƙunshi mai hankali na sunadarai. Ga kayan girke-girke na asali:

Haɗa sodium sulfide da dichlorobarzene

Ara da polar da aka tsara (misali, n-methylyrololololololorida)

Zafi zuwa kusan 250 ° C (480 ° F)

Kalli sihiri ya faru!

Tsarin aikin da tasirinsa

Ciniki yana da mahimmanci ga pps na aji. Yana faruwa a kusa da melting matsayi tare da dash na iska.

Tasirin Cining:

Aikin polar da polar a cikin samar da PPS

Kwallan Polar sune jarumen da ba a sansu ba na samar da PPS. Su:

Abubuwan da aka yi amfani da su na musamman da aka yi amfani da su:

Kowane sauran ƙarfi yana kawo dandano kansa zuwa jam'iyyar PPS, ta shafi halayen samfurin karshe.

Aikace-aikace na polyphenylen (PPS) filastik a saman masana'antu

PPS filastik ya sami amfani dashi a cikin masana'antu daban-daban saboda haɓakar kayan haɗinsa na musamman.

Autometotive da Aerospace

A cikin bangarori da Aerospace, ana amfani da PPS don abubuwan haɗin da ke buƙatar karko, juriya da zafi, da kwanciyar hankali.

An yi amfani da abubuwan haɗin injin: PPS a cikin haɗin haɗi, kyawawan, da kuma ƙarfin zafin jiki da ƙarfin sa na inji suna da mahimmanci.

Ana amfani da kayan aikin mai: Abubuwan PSP a cikin tsarin man fetur saboda juriya na sinadarai da ƙarfin tsayayya da yanayin zafi.

Ana samun PPSims na jirgin sama a cikin jirgin sama na jirgin sama da kuma bangarorin ciki na ciki, inda haskensa ya amfane shi.

Kayan lantarki da abubuwan lantarki

PPS na hasken wutar lantarki na PS suna dacewa da aikace-aikacen lantarki da na lantarki.

Masu haɗin kai da kuma insulators: Ana amfani da PPS a cikin masu haɗin kai da kuma insulator saboda babban ƙarfinsu da kwanciyar hankali.

Allo Circuit: Pps ya samo amfani da allon allo na da'ira, tallafawa miniamin da babban aiki.

Aikace-aikacen Microectronics: PPS sun dace da aikace-aikacen microectronics, suna ba da kyakkyawan kwanciyar hankali da kuma allurar rigakafi.

Masana'antar aiki ta sinadarai

Jin juriya na PPS ta sanya ta dace da abubuwan da aka fallasa su ga sinadarai masu lalata.

Bawuloli da famfo: ana amfani da PPS a cikin bawul, yana motsa jiki a cikin aikace-aikacen sarrafa sunadarai saboda yana tsinke sinadarai masu tsauri a cikin yanayin zafi.

Filin tace: Ana amfani da PPS a cikin gidajen tace, tabbatar da tsarewa da juriya na sinadarai a cikin tsarin tacewa.

Seals da Greets: PPS yana da kyau ga Seals da Gastani a cikin yanayin sunadarai, suna ba da dadewa da dadewa ga lalata.

Kayan aiki

PPS yana aiki a cikin kayan aiki na kayan aiki don sandar juriya da ƙarfin injina.

Gears da bears: Ana amfani da pps a cikin gears, befingings, da sauran abubuwan da suka sami kayan masarufi da ke buƙatar babban ƙarfin lantarki da girma.

Ana amfani da abubuwan damfara: PPS a cikin vanes damfara saboda yana ba da ƙarfi da ƙarfi cikin karkara wajen neman masana'antu masana'antu.

Aikace-aikacen Wear-mai tsauri: Ana amfani da kayan haɗin PPS a cikin sutura da busasshiyar, samar da ƙananan tashin hankali da kuma babban sanadin juriya a cikin masana'antar masana'antu.

Masana'antar semiconduct

PPS yana samun aikace-aikacen a cikin masana'antar semiconductor don tsarkake ta da kuma rufaffiyar ta.

Ana amfani da abubuwan sarrafawa na semiconductor: An yi amfani da PPS a cikin masu haɗin, Lissafin sadarwa, garken zafi, da kuma matsa lamba a cikin kayan aiki na Semiconductor a kayan aiki

Aikace-aikacen na musamman don aikace-aikacen Semicontortor: Fasali na PPS kamar Tecatron se da SX an tsara su don aikace-aikacen sxicontorics, suna miƙa tsarkakakkun aikace-aikacen semicondant.

Ininiyan inji

Ana amfani da PPS a aikace-aikacen injiniyoyi daban-daban.

Ana amfani da sassan damfara da yankuna: Pps ana amfani dashi a cikin damfara da abubuwan famfo saboda juriya na sinadarai da ƙarfin injiniya.

Jagororin sarkar da faranti na tushe: Pps ya samo amfani da shi a cikin jagororin sarkar da faranti na tushe, suna ba da juriya da kwanciyar hankali.

Sauran masana'antu

Ana amfani da filastik PPS a wasu masana'antu da yawa:

Ana amfani da kayan masarufi: An yi amfani da abubuwan pPS a cikin dyeing, bugu, da kayan aiki, suna bayar da tsauri da juriya da sinadarai.

Ana amfani da na'urorin likita: PPS ana amfani da PPS a cikin ɓangaren kayan aiki saboda juriya na sunadarai da ƙarfin tsayayya da tafiyar sinadarai.

Kayan aikin mai da kayan gas: Ana amfani da PPS a cikin kayan ƙasa na ƙasa, suttura, da masu haɗin, inda kwanciyar hankali da kwanciyar hankali suna da mahimmanci.

Tebur mai zuwa yana taƙaita mahimman aikace-aikacen filastik pps filastik a kan masana'antu daban-daban masana'antu:

| masana'antu | aikace-aikace |

| Autometotive da Aerospace | Abubuwan injiniyoyi, sassan tsarin mai, masu lura da jirgin sama |

| Kayan lantarki | Masu haɗin, insulators, allon da'ira, microectronics |

| Chememer aiki | Bawuloli, famfo, gidaje na tace, hatimin, Gaskunan |

| Kayan aiki | Gears, bearings, abubuwan haɗin abubuwa, sassan da ke jurewa |

| Semiconductor | Abubuwan sarrafawa na kayan masarufi, maki na musamman don samar da kayan aiki na Semiconduction |

| Ininiyan inji | Kamfanin damfara da kabadwa, Jagoran sarkar, faranti |

| M | Dyeing da kwamfutar buga littattafai, injina sarrafa |

| Na likita | Kayan kayan aikin |

| Man da Gas | Kayan aiki na ƙasa, seals, masu haɗin kai |

Pokalphenylene (PPS) ingantawa

Za'a iya amfani da ƙari da yawa da kuma ƙarfafa abubuwa don haɓaka kaddarorin pik filastik.

Ƙari da ƙarfafa

Tebur mai yana kwatanta kaddarorin da ba

| zuwa | ya | ba | cika |

| Density (kg / l) | 1.35 | 1.66 | 1.90 - 2.05 |

| Tenerile ƙarfi (MPa) | 65-85 | 190 | 110-130 |

| Elongation a karya (%) | 6-8 | 1.9 | 1.0-1.3 |

| Modulal modulir (MPA) | 3800 | 14000 | 16000-19000 |

| Karfin karfi (MPA) | 100-130 | 290 | 180-2020 |

| Izod ya ba da tasiri mai tasiri (KJ / M⊃2;) | - | 11 | 5-6 |

| HDT / A @8 MPA (° C) | 110 | 270 | 270 |

* Ya danganta da gilashi / mai filler rabo

Takamaiman ƙari ga kayan haɗin dukiya

Za'a iya amfani da takamaiman ƙari ga manufa da haɓaka ƙwararrun kaddarorin PPS:

Alkali karfe silatics don kulawa ta danko

Alkalli Karfe Silating, Alkali Karfe sulfiyawa, da amino acid, za a iya amfani da Oligomers na silly ether da danko na PPS.

Alli chloride don karuwar nauyi

Toshe copolymers don magance cigaba

Sadfonic acid

Tebur mai zuwa ya taƙaita adadin abubuwan da aka yi amfani da su don takamaiman kayan haɓaka mallaki:

| buƙatun mallakar | dukiya |

| Low narke kwarara, babban danko | Alkalli Karfe Silatics, Alkali Karfe sulfiyawa, amino acid, iligomers na silyl ether |

| Quara yawan kwararar kwayar halitta | Alli chloride kara a lokacin polymerization |

| Inganta tasirin juriya | Hada da toshe codlymers a farkon amsa |

| Quara yawan crystallization | Sulfonic acid ssers tare da wakili na nucleating |

| Ƙara yawan kwanciyar hankali, yawan zafin jiki | Alkali karfe ko alkali duniya m karfe dithionate |

Sarrafa dabarun sarrafa pps filastik

Za'a iya sarrafa PPP ta amfani da dabarun dabaru daban-daban, gami da jiga-gyare, cirewa, busa molding, da maching.

Allurar gyara

Yin allurar rigakafi shine hanyar aiki gama gari don PPS, yana ba da babban aiki da daidaito.

Abubuwan bushewa

Zazzabi da saiti

Da shawarar silima zafin jiki na PPS shine 30033 c.

Ya kamata a kula da yanayin yanayin mold tsakanin 120-160 ° C don tabbatar da kyakkyawan lu'ulu'u da rage warping.

Rushewar cututtukan cuta na 40-70 MPa ya dace da ingantaccen sakamako.

An ba da shawarar dunƙule na 40-100 RPM don PPS.

Mold la'akari

Saboda ƙarancin danko na PPS, ƙwararrun mold dole ne a bincika don hana yadari.

Don cika maki pPP, ya kamata a yi amfani da zafin jiki mafi girma don kauce wa sa a kan ganga, dunƙule, da kuma tarko.

Hawa

Za'a iya fitar da PPS cikin siffofi daban-daban, kamar zaruruwa, fina-finai, sanduna, da slags.

Bude molding

Za a iya aiwatar da PPS ta amfani da dabarun motsa jiki.

Machining PPS

PPS yana da mashin da ke da mashin, yana ba da tabbataccen madaidaici da rikice-rikice.

Mahimmanci na pre-bushewa cikin aiki

PPS-bushewa pps yana da mahimmanci don cimma kyakkyawan sakamako mai kyau.

Tebur mai zuwa yana taƙaita dabarun aiki da kuma abubuwan da suke ɗauka:

| kayan aikin su | sarrafa |

| Allurar gyara | Pre-bushewa, zazzabi da saitunan matsin lamba, kwanciyar hankali |

| Hawa | Yanayin bushewa, sarrafa zazzabi, fiber da samar da fim |

| Bude molding | Range -ayeri ya kasance, la'akari da cikakken maki |

| Maching | Zabin sanyaya, tsari na fushi, aiwatar da daidaito |

Ta hanyar fahimta da Inganta waɗannan dabarun sarrafawa, masana'antun za su iya samar da sassan PPS masu inganci da kayan aiki don aikace-aikace daban-daban.

Designarin ƙira don aikace-aikacen PPS

A lokacin da ƙira da PPS filastik, dole ne a ɗauka da yawa dalilai don tabbatar da ingantaccen aiki da tasiri-tasiri.

Zabi PPS don takamaiman aikace-aikace

Zabi PPS don takamaiman aikace-aikacen yana buƙatar kimantawa da hankali na musamman kaddarorin.

Juriya na sinadarai

PPS ta juriya game da sunadarai na PPS ya sa ya dace da aikace-aikace a cikin sarrafa sunadarai da kayan masana'antu.

Yana haifar da bayyanar acid mai ƙarfi, sansan, ƙwayoyin cuta na halitta, wakilan oxidic, da hydrocarbons.

Babban zafi --4

Ado mai kyau

Inji da kuma gamsarwa la'akari

Za'a iya yin makama zuwa kusa da haƙuri, sanya ya dace da hadaddun, da sassan da ke da juna.

Mactining na iya haifar da fatattaka da damuwa na ciki a cikin PPS.

Za'a iya magance waɗannan batutuwan ta hanyar ɓoye da kuma amfani da coolants da suka dace.

Wadanda ba su da ruwa mai narkewa, kamar iska mai narkewa da kuma fesa manzo da kuma fesa mists, ana ba da shawarar don cimma nasarar samar da ingancin ci gaba.

Yanayin kwanciyar hankali a duk yanayin zafi

PPS ta kiyaye kyakkyawan kwanciyar hankali mai kyau a cikin yanayin zafi.

Sakamakon farashi idan aka kwatanta da madadin kayan

Duk da yake PPS yana ba da kyakkyawan aiki, ya fi tsada fiye da manyan hanyoyin motsa jiki da yawa.

Masu zanen kaya su kimanta rabo mai tsada na amfani da PPS.

Madadin kayan, kamar peek, ana iya la'akari da aikace-aikacen karancin albashi.

Koyaya, haɗakar PPS na musamman na kadarorin galibi na har sau da yawa na tabbatar da mafi girman farashin sa a takamaiman aikace-aikace.

Muhalli da aminci la'akari

PPS an yi la'akari da shi lafiya kuma ba mai guba ba ne, amma dole ne a bi ka'idodin aminci da aminci.

PPS na iya haifar da haɗari ga lafiyar ɗan adam da mahalli idan ba a kula da shi da kyau ko kuma ba a dace ba.

Yakamata a bi ka'idoji da ingantaccen tsaro da kuma jagororin rage haɗari.

PPS yana da rashin juriya na UV UV, yana sa ya dace don aikace-aikacen waje ba tare da mayafin kariya ba.

Tebur mai zuwa yana taƙaita matsayin maɓallin ƙirar ƙirar don aikace-aikacen PPS:

| Kulawar Tsara | Abubuwan |

| Zabi PPS don takamaiman aikace-aikace | Chrismes Chememe, kwanciyar hankali na zafi, kwanciyar hankali |

| Mactining da ƙarewa | Annealing, coolants da suka dace, cracking na ciki da raguwar damuwa na ciki |

| Yanayin kwanciyar hankali a duk yanayin zafi | Ƙananan canje-canje na canje-canje, abin dogaro a cikin yanayi daban-daban |

| Cikakken la'akari | Mafi girma tsada fiye da daidaitattun robobi, kimantawa mai tsada, kayan madadin |

| Muhalli da aminci | Gabaɗaya lafiya, ladabi da ladabi na aminci, rashin juriya na UV UV |

Ƙarshe

PPS filastik yana ba da ingantattun abubuwa da babban aiki, yana tabbatar da dacewa don aikace-aikacen neman. Juriya ta sinadaran sunadarai, kwanciyar hankali na therr Isrh, da ƙarfin injin ya tabbatar da aminci a kan masana'antu.

Fahimtar pps ta gyara PPS, hanyoyin sarrafawa, da jagororin ƙira yana da mahimmanci don haɓaka yiwuwar sa. Tare da aikace-aikacen da ya dace, PPS ƙirƙirar samfurori masu dorewa a cikin mota, Aerospace, Wutar lantarki, da ƙari.

Tukwici: Kai mai son sha'awar dukkanin robobi