Injɛkshɔn moldin na wan pan di we dɛn we go wok fayn ɛn we dɛn kin skel fɔ mek plastic pat dɛn, mɔ we dɛn de yuz ay volyum. Dis we ya, bɔt, nɔto witout chalenj. Wan pan di bad bad tin dɛn we di wan dɛn we de mek tin dɛn fɔ du fɔ kɔntinyu fɔ fɛt na di fɔmɛshɔn fɔ blak spat ɛn blak spɛk dɛn na di prɔdak dɛn we dɛn dɔn mol. Dɛn smɔl smɔl dɛfekt ya kin tan lɛk se dɛn nɔ impɔtant, bɔt dɛn kin rili stɔp di aesthetic ɛn functional qualities of a part, we kin mek dɛn de dilɛy di prodakshɔn dilɛys, riwɔk, ɔ ivin di prɔdak rijɛkt. Fɔ industri dɛn we nid ay prɛsishɔn, lɛk ɔtomotiv ɔ mɛdikal manufakchurin, dɛn imprɛfɛkshɔn ya kin mek di prɔdak nɔ wok fayn.

Insay dis atikul, wi go ɛgzamin di rut kɔz dɛm fɔ blak spat ɛn spɛk, we fɔ no dɛn, ɛn di bɛst we fɔ protɛkt ɛn mitigate dɛn ɔkɔrɛshɔn.

Wetin na blak ples ɛn blak spɛk?

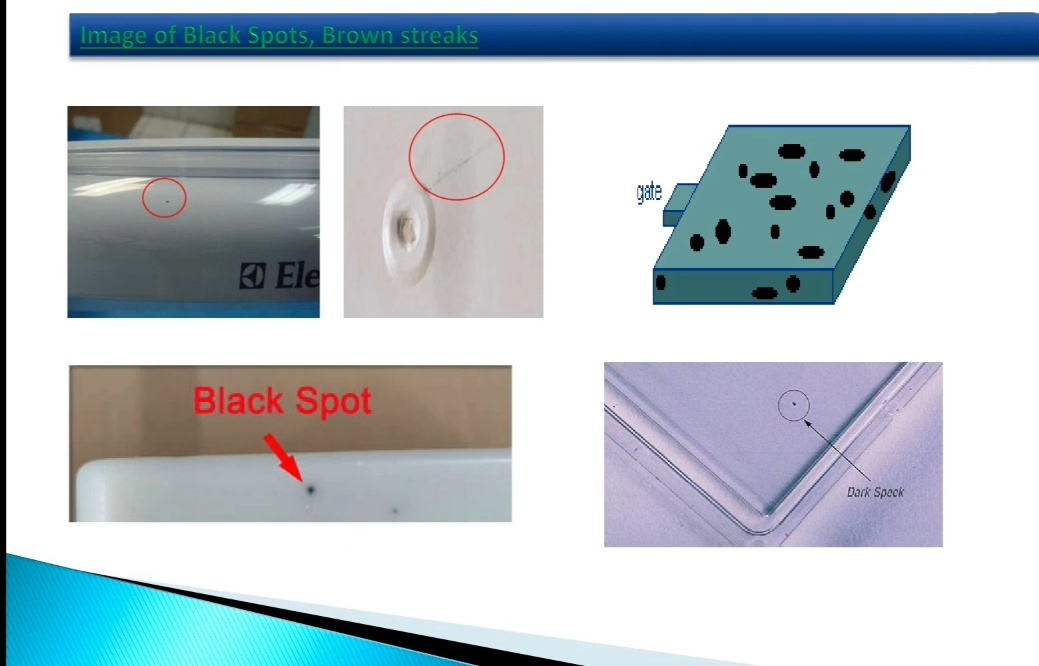

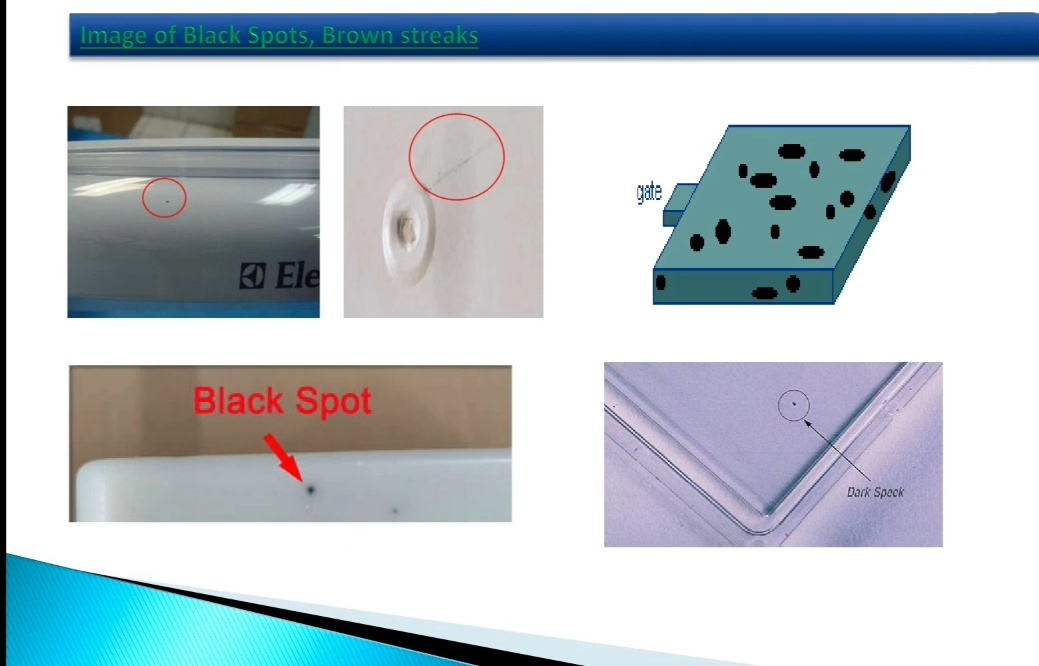

Blak spat ɛn spɛk na smɔl, lokaliz Difɛkt dɛn we kin apin na di say we dɛn de ɔ insay di pat dɛn we dɛn dɔn mol. Dɛn kin gɛt dak brawn ɔ blak kɔlɔ ɛn bɔku tɛm dɛn kin fɛn dɛn na say dɛn usay di plastic we dɔn rɔtin dɔn gɛt strɛs pasmak. Dɛn difrɛns ya kin apin na say dɛn we nɔ de nia dɛnsɛf, strek, ɔ as klasta, we kin mek dɛn si dɛn ɔl tu to di nekɛd yay ɛn ɔnda maykroskɔpik inspekshɔn.

Dɛn difrɛn difrɛn tin ya kin apin na wɛl layn dɛn, nia rib, kɔna, ɔ ɔda say dɛn usay di tin we de flɔ kin ambɔg. Dɛn kin apia na random, afɛkt di aesthetic apil ɛn, insay sɔm kes dɛm, di strɔkchɔral intɛgriti fɔ di mold pat.

Karakta dɛn fɔ Blak Spɔt dɛn:

| Prɔpati | Diskripshɔn |

| Kɔlɔ | Blak ɔ brawn, nɔ-riflektiv |

| Shep | sɛkɔral, flaky, klasta, streaked |

| Tekstur na di . | bɔku tɛm i kin brok, i kin izi fɔ brok . |

| Sheb | i nɔ de ɔltɛm; I kin apia na di say we dɛn de ɔ insay . |

Blak spat nɔto jɔs wan kɔsmɛtik prɔblɛm; Sɔntɛnde, dɛn kin sho dip tin dɛn we de insay di injɛkshɔn moldin prɔses, lɛk fɔ pwɛl di matirial ɔ kɔntaminɛshɔn, dɛn ɔl tu kin wik di pat ɛn kɔmprɔmis di we aw i de wok. Dis na spɛshal kɔnsyusɔn insay ay-pɔfɔmɛnshɔn aplikeshɔn usay prɛsishɔn ɛn durabiliti na ki.

Koz fɔ blak spat ɛn spɛk na injɛkshɔn moldin .

Fɔ adrɛs blak ples ɛn spɛk fayn fayn wan fayn fayn wan, i rili impɔtant fɔ ɔndastand di tin dɛn we de mek dɛn tin ya fɔs. Bɔku bɔku wan, dɛn kayn bad bad tin ya kin bi bikɔs ɔf tu men tin dɛn: matirial kabonayzeshɔn ɛn kɔntaminɛshɔn ..

1. Material kabonizayshɔn .

Kabonayzeshɔn kin apin we di plastic matirial ɔva ɔt ɛn bigin fɔ pwɛl, bɔku tɛm bikɔs ɔf di tɛm we dɛn de liv fɔ lɔng tɛm na di injɛkshɔn moldin mashin. As di matirial de pan ɔt fɔ tu lɔng, i bigin fɔ brok dɔŋ, we de mek di patikyula tin dɛn we dɔn char we de apia lɛk blak spat ɔ spɛk na di las prɔdak.

Bɔku tin dɛn kin ɛp fɔ mek dɛn gɛt kabonayzeshɔn, we inklud:

Skru Surface Wear .

As tɛm de go, we yu wɛr di skru, dat kin mek plastic mɛlt de te, ɛn dis kin mek yu gɛt kabonayzeshɔn.

Plastik we dɛn dɔn mek we dɔn lɛf we dɛn dɔn pwɛl .

Gap dɛn na mashin kɔnɛkshɔn pɔynt dɛn (ɛgz., skru rɔket ed, noz, flɛnch) alaw molten plastic fɔ stagnate, fɔm kaboniz blak spat dɛn.

Lɔng prodakshɔn saykl dɛn .

Ekstend saykl ɔ yuz big mashin fɔ smɔl prɔdak dɛn de mek di matirial rezidenshɛl tɛm na di barɛl bɔku, we de mek di risk fɔ kabonayzeshɔn go ɔp.

Adheshɔn .

Sɔm ɛnjɛnɛri plastic dɛn lɛk PC kin lɛk fɔ fala di mɛtal sɔfays we dɛn dɔn rimɛl, we de mek layers we gɛt kabon we dɛn gɛt ay tɛmpracha. Insulation durin shɔt stɔp ɛn pul di matirial bifo shutdown ɛp fɔ mek dis nɔ apin.

Skru Kapasiti .

Mismatch bitwin di prɔdak saiz ɛn di skru saiz kin mek dɛn de fɔ lɔng tɛm. Ideal dwelling taim de anda 5 minit, wit maksimum 15 minit. Fɔ ridyus di barɛl in tɛmpracha de ɛp fɔ mek di ples nɔ pwɛl fɔ lɔng tɛm.

Dead angles in konekshon .

Ded angles na di skru ed, flɛnch, ɛn noz kin trap matirial, we kin mek degradation ɛn diskoloreshɔn. Fɔ mek shɔ se dɛn asɛmbli di rayt we kin mek dɛn nɔ gɛt dɛn prɔblɛm ya.

Surface Wear .

Uneven skru surfaces de promot lingering of material, we de kontribiut to blak spot fomeshon. Difrɛn matirial dɛn, lɛk PC ɔ PMMA, nid spɛshal skru kɔtin, we alɔy skru dɛn nid fɔ fulɔp di matirial dɛn we ful-ɔp.

Kεmikכl kכroshכn .

Korosiv tin dɛn (ɛgz., CO2, O2, asid) kin mek kɔrɛshɔn pan skru sɔfays, we kin mek dɛn gɛt tin dɛn we de te ɛn blak spat dɛn. If yu yuz nitrided ɔ plet skru dɛn, dat kin ɛp fɔ stɔp dis.

| factor | kɔz fɔ mek dɛn | nɔ gɛt kabonayzeshɔn/best prɛktis . |

| Skru Surface Wear . | Plastik mɛlt de ling pan say dɛn we dɔn pwɛl, we de mek dɛn gɛt kabonayzeshɔn as tɛm de go. | Inspekshɔn ɛn riplesmɛnt fɔ skru dɛn we dɔn pwɛl ɔltɛm; Yuz di rayt kɔtin fɔ di matirial. |

| Plastik we dɛn dɔn mek we dɔn lɛf we dɛn dɔn pwɛl . | Plastik de gɛda insay gap dɛn na mashin kɔnɛkshɔn pɔynt dɛn. | mek shɔ se tayt kɔnɛkshɔn dɛn de na di mashin; Klin di noz ɔltɛm, rɔket ed, ɛn flɛnch. |

| Lɔng prodakshɔn saykl dɛn . | Fɔ lɔng tɛm, di tin dɛn we de na di barɛl kin mek i pwɛl. | Ridyus di prodakshɔn saykl tɛm dɛn; Klin mashin dɛn bitwin saykl dɛn fɔ pul di tin dɛn we dɔn lɛf. |

| Adheshɔn fɔ di tin dɛn we dɛn yuz fɔ mek di tin dɛn . | Matirial dɛm lɛk PC adhere to mɛtal ɛn kaboniz we dɛn rihit. | Yuz insuleshɔn we yu de stɔp fɔ shɔt tɛm; Epel matirial ɛn rɔn wan purging saykl bifo shutdown. |

| Skru Kapasiti . | Mismatch bitwin prodak saiz ɛn skru saiz de prolɔng di tɛm fɔ de. | Optimize skru saiz fɔ prodakt volyum; Limit di de tɛm fɔ lɛs 15 minit. |

| Dead angles in konekshon . | Melt stagnates at skru ed, flange, noz, fכm kabכnayz spot. | mek shɔ se dɛn asɛmbli di rayt wan; Minimize dead angles durin mashin setup. |

| Surface Wear . | Di say dɛn we nɔ ivin de mek di tin dɛn we de de fɔ lɔng tɛm ɛn we de pwɛl. | Yuz hardened ɔ aloy skru dɛn bays pan di matirial we dɛn de mol; Riples skru dɛn as nid de. |

| Kεmikכl kכroshכn . | Korosiv sɔbstans dɛn de degrade skru ɛn barɛl sɔfays. | Yuz nitrided ɔ plet skru fɔ faya-pruf ɔ kemikal riaktiv matirial. |

2. Kɔntaminɛshɔn .

Bɔt di kɔntaminɛshɔn de tɔk bɔt fɔrina matirial ɔ patikyula tin dɛn we dɛn nɔ bin want fɔ put insay di plastic we dɛn de mol. Dɛn kɔntaminɛnt ya kin kɔmɔt frɔm difrɛn say dɛn, insay ɛn na do:

Dust and Debris : Insay di say dɛn we dɛn de mek tin dɛn, mɔ di wokshɔp dɛn we opin, di dɔst ɛn di tin dɛn we de na di ays kin izi fɔ sɛtul pan di tin dɛn ɔ di mashin dɛn, we kin mek di plastic dɔti di tɛm we dɛn de mek di mol. Dis na patikyula prɔblɛm fɔ layt-kɔlɔ ɔ transparent plastic.

Impyurities in di raw matirial : Dɛn kin introdyus kɔntaminɛnt dɛn bak bifo tɛm insay di sapɔt chen, we dɛn de pak, transpɔt, ɔ we dɛn de prosɛs. Dɛn bad bad tin dɛn ya nɔ kin de na di nekɛd yay, bɔt we dɛn dɔn mol dɛn, dɛn kin sho as blak spɛk ɔ strek.

Di tin dɛn we de apin na di envayrɔmɛnt : Ivin na say dɛn we dɛn dɔn mɛn fayn fayn wan, tin dɛn lɛk we pɔsin de it di briz ɔ we i nɔ de yuz bɔku bɔku ilɛktrishɔn kin mek di patikyula tin dɛn we de na di pat dɛn na di pat dɛn, de mek di tin dɛn we nɔ pafɛkt.

| sɔs | diskripshɔn . |

| Dust we de na do . | Dust ɔ dɔti frɔm di wokshɔp ɛnvayrɔmɛnt . |

| Impyuriti dɛn na di Matirial dɛn . | Kontaminant dɛn we dɛn miks we dɛn de du di prɔses . |

| Di tin dɛn we de apin na di envayrɔmɛnt . | Di tin dɛn we de na di ays ɔ di statik we de mek dɔst we de mek dɛn atrak . |

Bɔku tɛm, dɛn kin ebul fɔ avɔyd kɔntaminɛshɔn tru strɛng os kipin ɛn envayrɔmɛnt kɔntrol, bɔt we i apin, i kin at fɔ tray ɛn pul. dis fכrin patikyula dεm nכ de כnli kכmprכmis di apinεns fכ di pat bכt kin wik in strכkchכ כ chenj di fכnshכn we i want.

Fɔ no di Blak Spɔt dɛn .

Fɔ no di blak spat dɛn kin tan lɛk se i stret, bɔt fɔ du dat wit prɛsishɔn nid fɔ mek dɛn du am di rayt we. Pan ɔl we i izi fɔ si big big blak spat dɛn, bɔku difrɛn difrɛn tin dɛn we nɔ fayn na maykroskɔpik ɛn yu kin jɔs si am ɔnda magnifyeshɔn. Standart praktis kin involv fɔ inspɛkt pat dɛn ɔnda maykroskɔp na 200x magnifyeshɔn. Dis de alaw fɔ wan ditayla analisis fɔ di difɛkt in saiz, shep, ɛn ples.

Di krayteria fɔ jɔj:

Sayz : Blak spat kin de frɔm maykroskɔpik to sɔm milimita in dayamita.

Di say we dɛn de : Difɛkt dɛn we de na di say we dɛn de, kin smɔl pas di wan dɛn we de insay di pat, we kin afɛkt di matirial in strɔkchɔral intɛgriti.

Shep : Spɔt kin tan lɛk sɛkɔral, flaky, ɔ ivin as streak ɔ layn.

Severity : Sɔm bad bad tin dɛn na jɔs kɔsmɛtik, ɔda wan dɛn kin sho dip tin dɛn we kin mek pat nɔ wok.

Standards fɔ jɔj Blak Spɔt dɛn .

Fɔ mek shɔ se dɛn kɔnsistɛns, ɔl tu di saplay ɛn di kɔstɔma dɛn de abop pan di standad dɛn we dɛn dɔn mek fɔ ebul fɔ evaluate blak ples dɛn. Dɛn standad ya kin ɛp fɔ no if wan pat kin akseptabl fɔ yuz ɔ nid fɔ wok bak.

Di Supplier’s Control Standards : Di wan dɛn we de gi dɛn raw matirial kin gi gaydlayn dɛn bɔt di akseptabl lɛvɛl dɛn fɔ di dɔti ɛn blak spat dɛn. Dɛn standad ya de ɛp di wan dɛn we de mek di tin dɛn fɔ disayd if di raw matirial dɛn fayn fɔ gɛt ay kwaliti moldin.

Di Standart dɛn fɔ Apiɛns di Kastamɔ : Di kɔstɔma dɛn kin gɛt dɛn yon rikwaymɛnt fɔ di vijual kwaliti fɔ di fayn prodak. Dis na tru mɔ na industri dɛn lɛk ilɛktroniks, ɔtomotiv, ɛn kɔshɔma guds, usay di apinɛns kin afɛkt di prɔdak in makɛtabiliti.

Fɔ ɛgzampul, di ɔtomotiv industri kin nid pat dɛn we nɔ gɛt wan bɔt, wit strikt tolɛreshɔn fɔ blak ples ɔ impɛrɛfɛkshɔn. Difrɛn frɔm dat, prɔdak dɛn we dɛn kin yuz fɔ mek industri kin telɛ smɔl smɔl, nɔ-strɔkchɔral dɛfɛkt dɛn as lɔng as dɛn nɔ de ambɔg di wok we di pat de du.

Di we dɛn fɔ protɛkt ɛn handel blak ples dɛn .

Pan ɔl we Blak Spɔt na kɔmɔn tin fɔ mek dɛn mol injɛkshɔn, dɛn kin ebul fɔ stɔp dɛn tru di rayt we ɛn di we aw dɛn de du tin. Di strateji dɛn fɔ protɛkt pipul dɛn kin pe atɛnshɔn fɔ mek di ikwipmɛnt klin, fɔ mek dɛn kɔntinyu fɔ mek am fayn fayn wan, ɛn fɔ mek dɛn nɔ gɛt dɔti.

1. Strateji fɔ Prɛvenshɔn .

Fɔ klin ɔltɛm : Fɔ mek dɛn nɔ bil di tin dɛn we gɛt kabon ɔ di tin dɛn we dɛn dɔn yuz fɔ mek tin dɛn, fɔ klin di skru, barɛl, ɛn di mol dɛn bɔku tɛm na impɔtant tin. If yu yuz ay-viskɔsiti klin kɔmpawnd dɛn, dat kin ɛp fɔ pul di tin dɛn we lɛf we go mek yu gɛt kaboniz.

Purging Systems : We yu de klin di mashin ɔltɛm we yu de yuz spɛshal purging kɔmpawnd dɛn we yu de yuz fɔ pul di mashin, dat de ɛp fɔ pul ɛni plastic we dɔn pwɛl we go mek blak pipul dɛn gɛt blak spat.

Short-tem en long-tem maintenance : Dɛn fɔ inspɛkt ɛn mentenɛt di ikwipmɛnt dɛn lɛk skru, noz, ɛn mold ɔltɛm. Dɛn fɔ chenj di pat dɛn we dɔn pwɛl kwik kwik wan fɔ mek dɛn nɔ gɛt prɔblɛm dɛn we gɛt fɔ du wit di we aw dɛn de wɛr, ɛn bɔku tɛm dɛn kin mek dɛn gɛt dɔti.

2. Fɔ handle blak-spɔt pat dɛn .

We blak spat dɛn apia, di wan dɛn we de mek di tin dɛn fɔ disayd if dɛn go ebul fɔ wok bak di pat ɔ dɛn fɔ skrap dɛn. Sɔm pat dɛn we gɛt smɔl blak ples kin stil mit di kɔstɔma dɛn standad if di dɛfɛkt na nɔ-strɔkchɔral ɛn kɔsmɛtik. Bɔt insay kes dɛn we di dɛfɛkt kɔmprɔmis di pat in wok ɔ di we aw i luk, dɛn kin nid fɔ trowe di pat.

Riwok pat : Sɔm dɛfɛkt dɛn kin klin ɔ polish ɔf if dɛn smɔl ɛn sɔfa-lɛvel.

Skrap pat dɛn we nɔ fayn : Insay impɔtant aplikeshɔn dɛn, mɔ na industri dɛn lɛk wɛlbɔdi biznɛs ɔ aerospace, ɛni prɔblɛm we pɔsin kin si na grɔn fɔ rijɛkt.

Specialized Cleaning Methods : Teknik lɛk fɔ yuz baking soda paste ɔ kɔmɛshɔnal purging kɔmpawnd kin ɛp fɔ pul stubborn blak spat dɛn we dɛn de prodyuz.

Aw fɔ Impɔtant Blak Spɔt Isyu dɛn .

Pan ɔl we prɛvɛnshɔn na di bɛst we fɔ du tin, di wan dɛn we de mek di tin dɛn kin ɛp bak fɔ mek blak ples dɛn apin tru difrɛn prɔses ɔptimayzeshɔn dɛn. Dɛn tin ya na ɔl tu di shɔt tɛm ajɔstmɛnt ɛn di lɔng tɛm ikwipmɛnt kia strateji.

Short-Tɛm Sɔlwɛshɔn dɛn .

Di tin dɛn we dɛn dɔn ful-ɔp wit tin dɛn we dɛn dɔn ful : Di tin dɛn lɛk PC + GF (glas fayba) kin wok fayn fɔ klin di skru barɛl bay we dɛn de skrap di matirial dɛn we gɛt kabon.

Tempracha Sayklin : We yu chenj di tɛmpracha di tɛm we dɛn de mek di prodakshɔn saykl dɛn, dat kin ɛp fɔ pul di stubborn residue ɛn ridyus di kabonayzeshɔn we de bɔku.

Fɔ lɔng tɛm mentenɛns .

Mashine Maintenance : Kɔnsistent mentenɛns fɔ skru, barɛl, ɛn ɔda mashin kɔmpɔnɛnt dɛn kin ridyus di ɔkɔrɛshɔn fɔ blak spat dɛn bad bad wan bikɔs ɔf matirial dɛgradishɔn ɔ wear.

Klin Prodakshɔn Envayrɔmɛnt : Insay say dɛn we ivin smɔl smɔl tin dɛn we nɔ fayn nɔ fayn, lɛk we dɛn de mek ilɛktronik ɔ mɛrɛsin divays, klin rum prodakshɔn kin ɛp fɔ mek di tin dɛn we de na di ays nɔ bɔku.

Material Selection : Fɔ pik matirial dɛn we nɔ kin gɛt bɔku bɔku kabonayzeshɔn ɔ kɔntaminɛshɔn kin ɛp bak fɔ ridyus blak spat dɛn, mɔ fɔ lɔng prodakshɔn rɔn dɛn.

Troubleshooting blak spot in injekshɔn moldin .

We blak spat dɛn apia, fɔ sɔlv prɔblɛm impɔtant fɔ no di rut kɔz ɛn impruv kɔrɛkt akshɔn dɛn. Bɔku tɛm dis kin min fɔ luk sɔm impɔtant tin dɛn, lɛk di kɔndishɔn we di ikwipmɛnt de, di kwaliti we di tin dɛn gɛt, ɛn di sɛtin dɛn fɔ di moldin prɔses.

Trobulshut Gayd:

| Kɔz | Sɔlwɛshɔn . |

| Di tɛm we dɛn de liv de . | ridyus di tɛm we dɛn de liv; Mek shɔ se dɛn klin di ples fayn fayn wan . |

| Dust frɔm mold wear . | Klin Mold Surfaces ɔltɛm . |

| Inkɔrɛkt barɛl tɛmpracha . | Adjɔst ɛn wach di barɛl tɛmpracha . |

Bay we dɛn de adrɛs dɛn tin ya sistamatically, di wan dɛn we de mek dɛn kin ridyus di apin we blak spat dɛn kin apin ɛn impruv di ɔl prodakshɔn kwaliti.

Dɔn

Blak spat ɛn spɛk na injɛkshɔn moldin na mɔ pas jɔs wan aesthetic ishu—dɛn kin sho dip prɔblɛm wit matirial dɛgradishɔn ɔ kɔntaminashɔn. We dɛn ɔndastand di tin dɛn we kin mek dɛn nɔ fayn, dɛn kin impruv di we aw dɛn de du tin fayn fayn wan, ɛn dɛn kin du mentenɛns ɔltɛm, di wan dɛn we de mek dɛn kin ridyus di blak ples dɛn ɛn mek di ɔl kwaliti fɔ dɛn prɔdak dɛn bɛtɛ. Dis nɔ jɔs de ridyus di west ɛn riwɔk bɔt i de mek shɔ bak se di prɔdak dɛn mit di kɔstɔma dɛn ɛkspɛkteshɔn ɛn di rigyuletɔri standad.

Fɔ ɛkspɛkt gayd fɔ yu manufakchurin projɛkt, kɔntakt wi. Wi injinia dɛn we gɛt ɛkspiriɛns go ɛp yu fɔ fɛn di dizayn, di tin dɛn we dɛn go pik, ɛn di we aw dɛn de mek tin dɛn fɔ mek shɔ se dɛn gɛt di bɛst rizɔlt. Patna wit Tim FMG fɔ sakrifays. Wi go tek yu prodakshɔn go na di nɛks lɛvul ..

FAQ dɛn .

1. Wetin kin mek blak spat ɛn blak spɛk na injɛkshɔn moldin?

Blak spat ɛn spɛk dɛn kin bi bikɔs ɔf matirial kabonayzeshɔn (we plastic kin ɔva ɔt ɛn we kin pwɛl) ɔ kɔntaminɛshɔn (fɔrin patikyula dɛn lɛk dɔst ɔ dɔti tin dɛn we kin kam insay di moldin prɔses).

2. Aw a go mek Blak Spɔt dɛn nɔ fɔm na mi pat dɛn we a dɔn mol?

Fɔ mek dɛn nɔ gɛt blak ples, mek shɔ se dɛn de klin di mashin ɔltɛm, yuz di kɔmpawnd dɛn we dɛn kin pul fɔ pul di tin dɛn we lɛf, ɛn mek dɛn kɔntinyu fɔ yuz di tin dɛn we dɛn de yuz fɔ ol di tin dɛn we dɛn nid fɔ mek dɛn nɔ gɛt kɔntaminɛshɔn.

3. Aw blak spat dɛn kin afɛkt di kwaliti fɔ mi prɔdak dɛn?

Blak spat kin negatif impak ɔl tu di apinɛns ɛn strɔkchɔral intɛgriti fɔ mold pat dɛn, we kin mek dɛn nɔ ebul fɔ mek prɔdak dɛn, mɔ na impɔtant aplikeshɔn dɛn lɛk ɔtomotiv ɔ mɛdikal divays dɛn.

4. Blak ples dɛn kin bi sayn ɔltɛm fɔ sho se dɛn dɔn pwɛl di tin dɛn we dɛn gɛt?

Nɔto ɔltɛm. Blak spat kin kɔmɔt frɔm matirial kabonizayshɔn (digrɛdyushɔn) bɔt i kin apin bak bikɔs ɔf kɔntaminɛshɔn frɔm ɛksternal patikyula dɛn lɛk dɔst ɔ dɔti we dɛn introduks di tɛm we dɛn de mol di prɔses.

5. Aw a go ebul fɔ no blak ples dɛn na di tin dɛn we dɛn dɔn mol?

Dɛn kin no blak spat dɛn wit dɛn yay, bɔt fɔ smɔl smɔl tin dɛn we nɔ fayn, dɛn kin yuz maykroskɔp we gɛt at le 200x magnifyeshɔn fɔ inspɛkt di sayz, shep, ɛn di say we di dɛfekt dɛn de.

6. Us mentenɛns prɔsis dɛn de ɛp fɔ ridyus blak spat dɛn na injɛkshɔn moldin?

Klin ɛn chɛk di skru, barɛl, ɛn mold kɔmpɔnɛnt dɛn ɔltɛm fɔ wɛr ɔ fɔ pwɛl. Dɔn bak, yuz purging kɔmpawnd ɛn mek shɔ se di ventilashɔn fayn ɛn klin na di prodakshɔn ɛnvayrɔmɛnt fɔ mek di kɔntaminɛshɔn nɔ bɔku.

7. Yu tink se dɛn kin pul blak spat dɛn na pat dɛn we dɔn ɔlrɛdi mol?

Sɔntɛnde, dɛn kin pul blak ples dɛn bay we dɛn de wok bak, lɛk fɔ polish ɔ fɔ klin di say we dɛn de. Bɔt if di difɛkt na insay ɔ kɔmprɔmis di strɔkchɔral intɛgriti, di pat kin nid fɔ trowe.