Wali weebuuzizza engeri ebitundu by’obuveera gye bisigala nga binywezeddwa bulungi nga tewali sikulaapu oba ggaamu? Riveting ekuwa eky’okugonjoola ekyesigika. Mu ndagiriro eno, tujja kunoonyereza ku bintu ebikulu eby’okusiba obuveera, amakulu gaakyo mu makolero ag’enjawulo, n’engeri y’okulondamu enkola entuufu. Ojja kuyiga ins and outs of riveting plastic parts for strong, durable connections.

riveting ya pulasitiika kye ki?

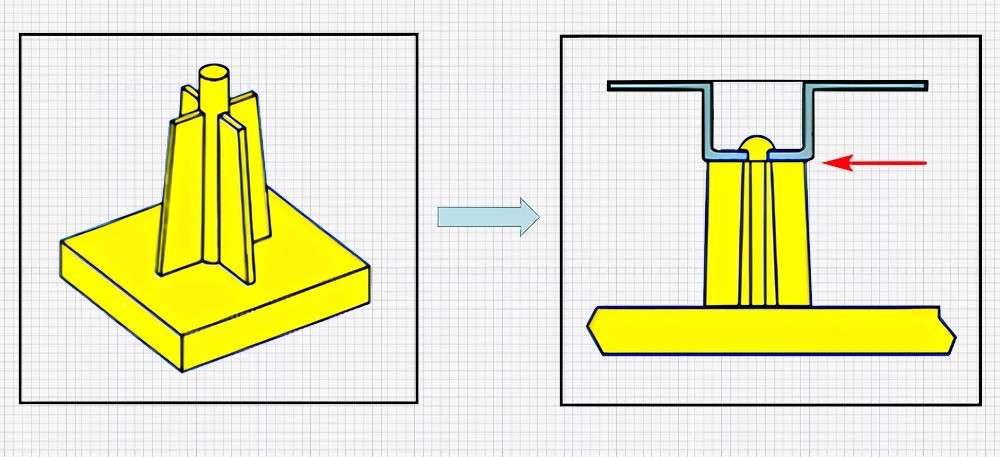

Obuveera obuyitibwa riveting nkola ya kusiba mu ngeri ya makanika. Kizingiramu okukozesa empalirizo ey’ekyekulungirivu okukyusa ekisambi kya rivet munda mu kinnya. Kino kikola omutwe, nga kigatta ebitundu ebingi.

Bw’ogeraageranya n’ebyuma ebikuba riveting, obuveera obuyitibwa riveting bulina enjawulo enkulu. Tekyetaagisa rivets oba posts endala. Wabula ekozesa ebizimbe eby’obuveera nga empagi oba embiriizi. Bali mu mubiri gwa pulasitiika.

Ebirungi n'ebibi ebiri mu buveera riveting .

Obuveera obuyitibwa riveting bulina ebirungi n’ebibi ebiwerako. Ka tulabe nnyo.

Ebirungi ebimanyiddwa ennyo:

Ensengeka y’ekitundu ennyangu, okukendeeza ku nsaasaanya y’ebikuta .

Easy assembly, tewali bikozesebwa oba ebisiba eby’enjawulo ebyetaagisa .

Okwesigamizibwa okw’amaanyi .

Asobola rivet ensonga eziwera omulundi gumu, okulongoosa obulungi .

yeegatta ku bitundu bya pulasitiika, ebyuma, n’ebitali bya kyuma, ne mu bifo ebifunda .

Agumira okukankana okw’ekiseera ekiwanvu n’embeera ezisukkiridde .

Enkola ennyangu, ekekereza amaanyi, ey’amangu .

Okukebera omutindo gw'okulaba okwangu .

Ebizibu ebimanyiddwa:

Yeetaaga ebyuma ebirala ebikuba riveting ne tooling .

Tekisaanira migugu gya maanyi nnyo oba egy’ekiseera ekiwanvu .

okuyungibwa okw’olubeerera, tekuyinza kwekutulwamu oba okuddaabirizibwa .

Kizibu okuddaabiriza singa kiremereddwa .

Ayinza okwetaaga redundancy mu design phase .

| Enkizo | Obuzibu . |

| Enzimba ennyangu, ssente entono ez’ekikuta . | yeetaaga ebyuma ebirala n'ebikozesebwa . |

| Okukuŋŋaanya okwangu, okwesigika okw’amaanyi . | Si lwa migugu egy’amaanyi ennyo oba egy’ekiseera ekiwanvu . |

| yeegatta ku bintu eby’enjawulo mu ngeri ennungi . | Enkalakkalira, tesobola kwekutula oba okuddaabirizibwa . |

| Agumira okukankana n’embeera ezisukkiridde . | Kizibu okuddaabiriza, kiyinza okwetaaga redundancy . |

| Enkola ennyangu, ey’amangu, ekekkereza amaanyi . | - |

| Easy Visual Quality Okukebera Omutindo . | - |

Ebika by'enkola z'obuveera ezikola riveting .

Waliwo ebika bisatu ebikulu eby’enkola z’obuveera ezikola riveting. Zino zibeera za bbugumu, zikuba empewo eyokya, era zikuba ultrasonic riveting.

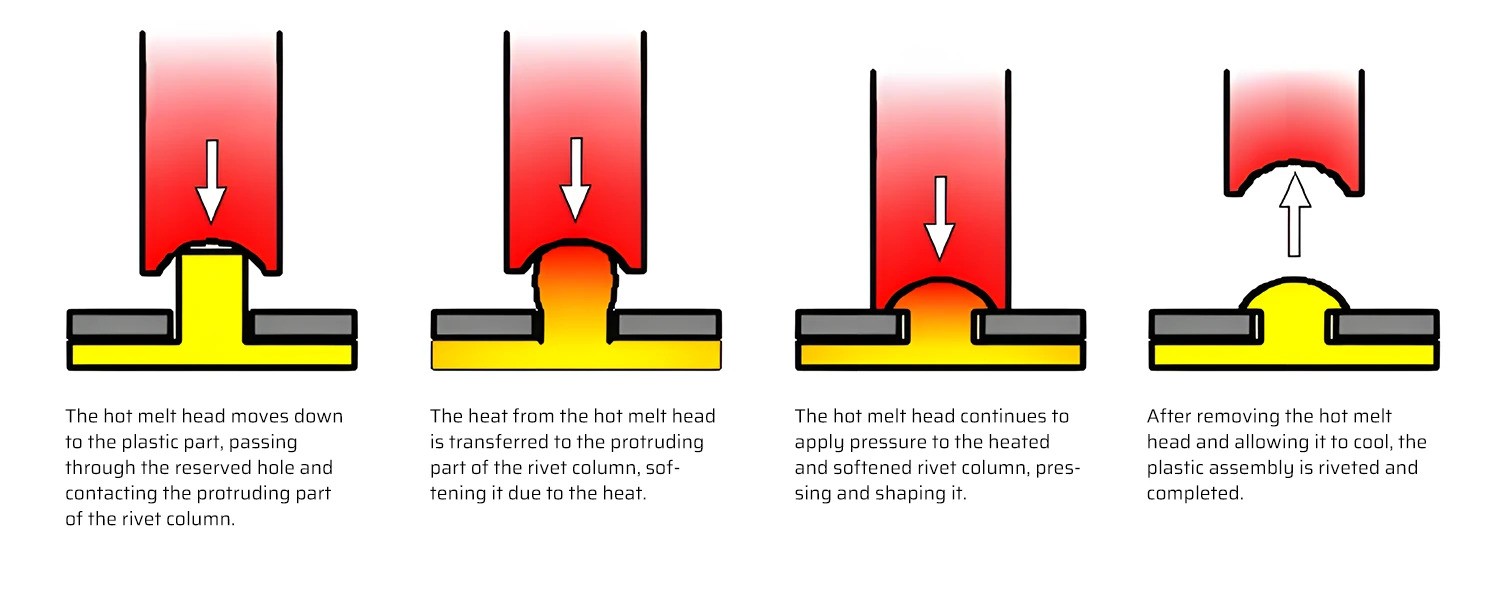

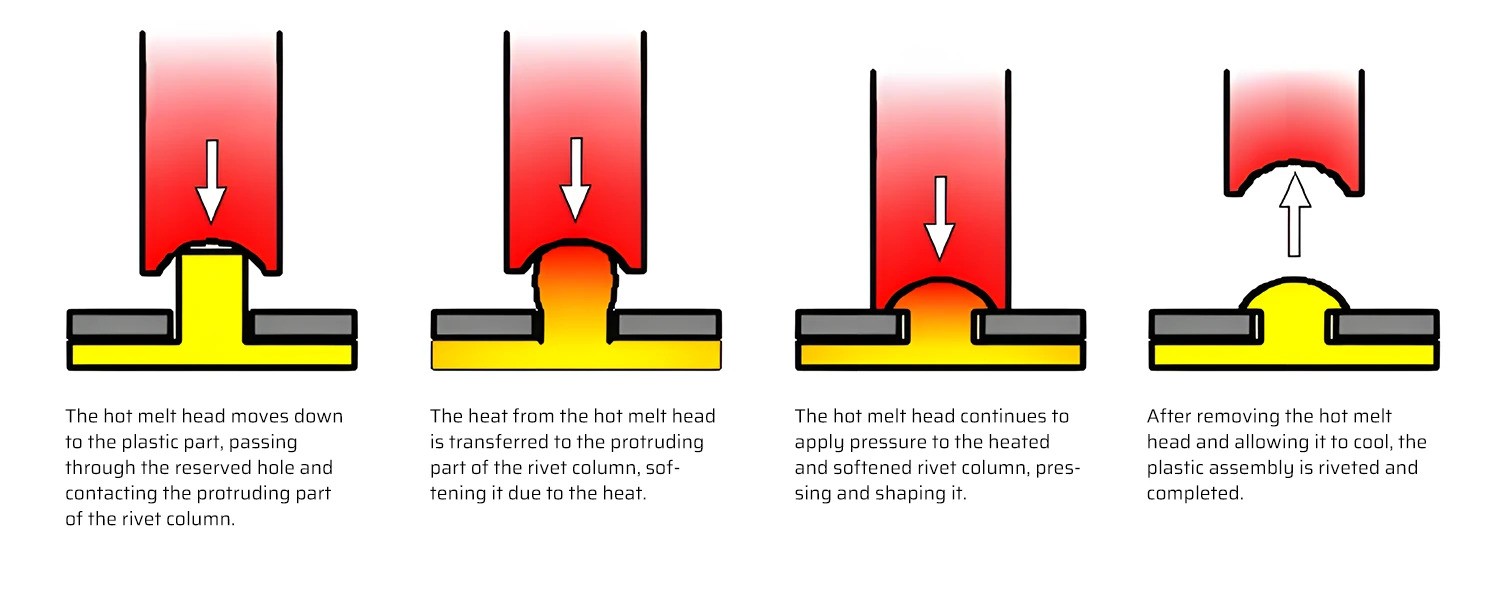

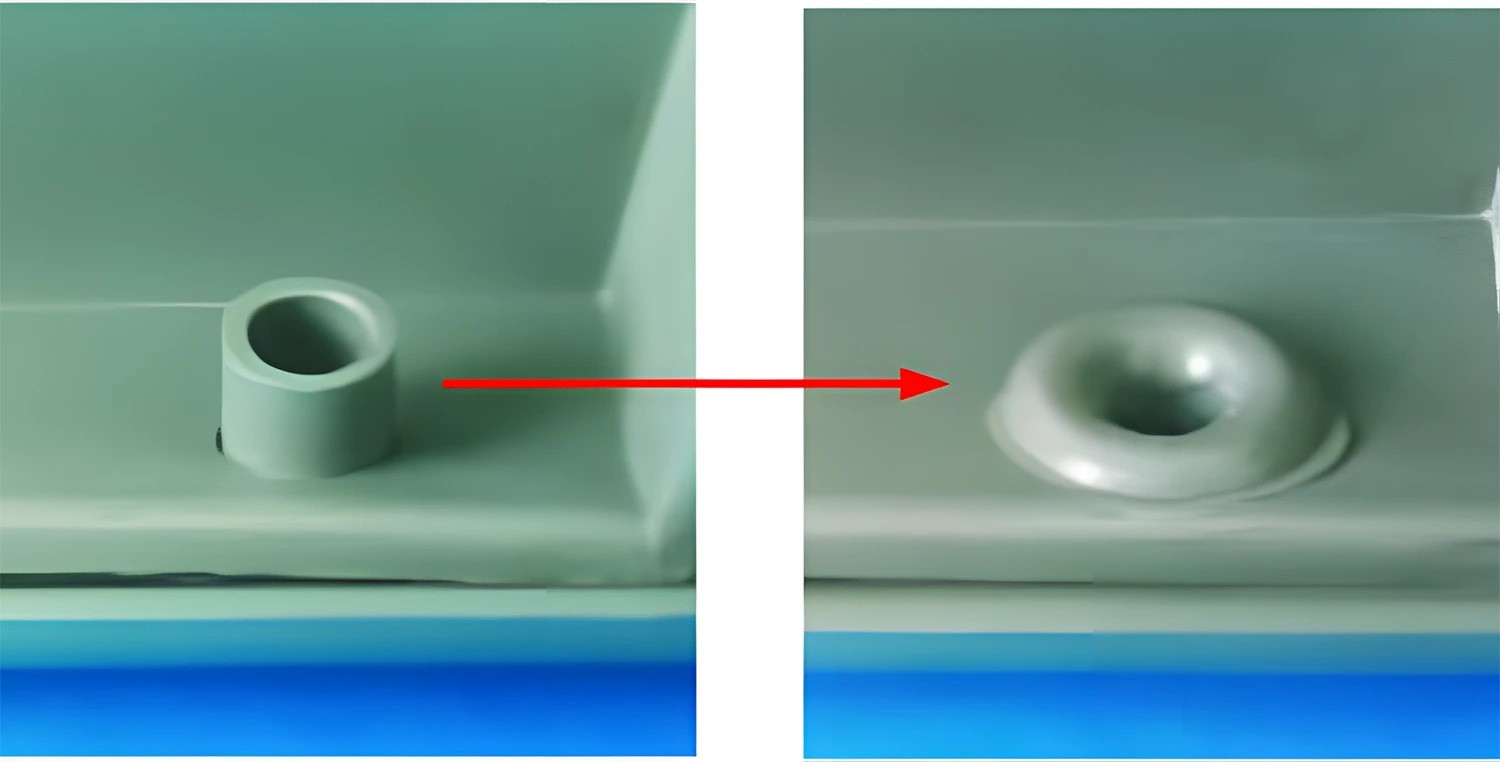

Hot Melt riveting .

Hot Melt Riveting nkola ya kika kya kukwatagana. Kizingiramu ekyuma ekibugumya munda mu mutwe oguwunyiriza. Kino kibugumya omutwe gw’ekyuma ogukuba ennyimba, olwo ne gusaanuuka ne gubumba akaveera akayitibwa rivet.

Ebirungi:

Ebizibu:

Okunyogoza okutamala kiyinza okuvaako obuveera okunywerera ku mutwe .

Tekisaanira mpagi za rivet ennene .

High residual stress n’amaanyi agava mu kuggyamu wansi .

Tekirungi ku bintu ebirina ebisaanyizo by’okuteeka/okutereeza eby’okuteeka mu kifo eky’amaanyi .

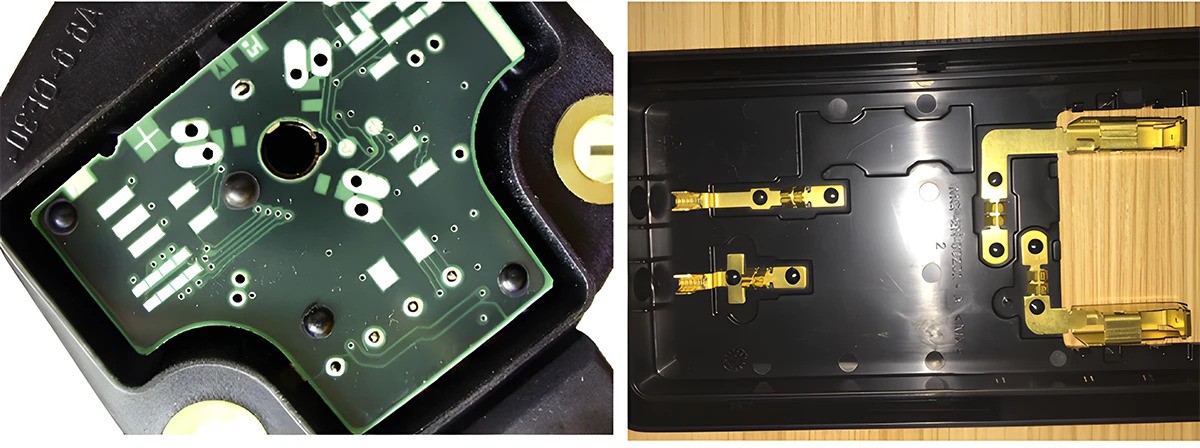

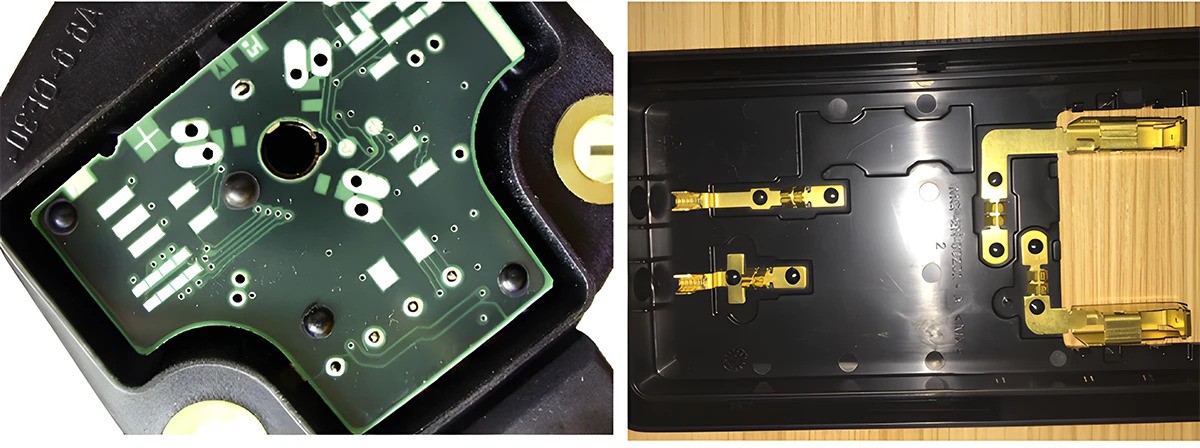

Hot melt riveting etera okukozesebwa ku PCB boards n’ebitundu ebiyooyoota obuveera.

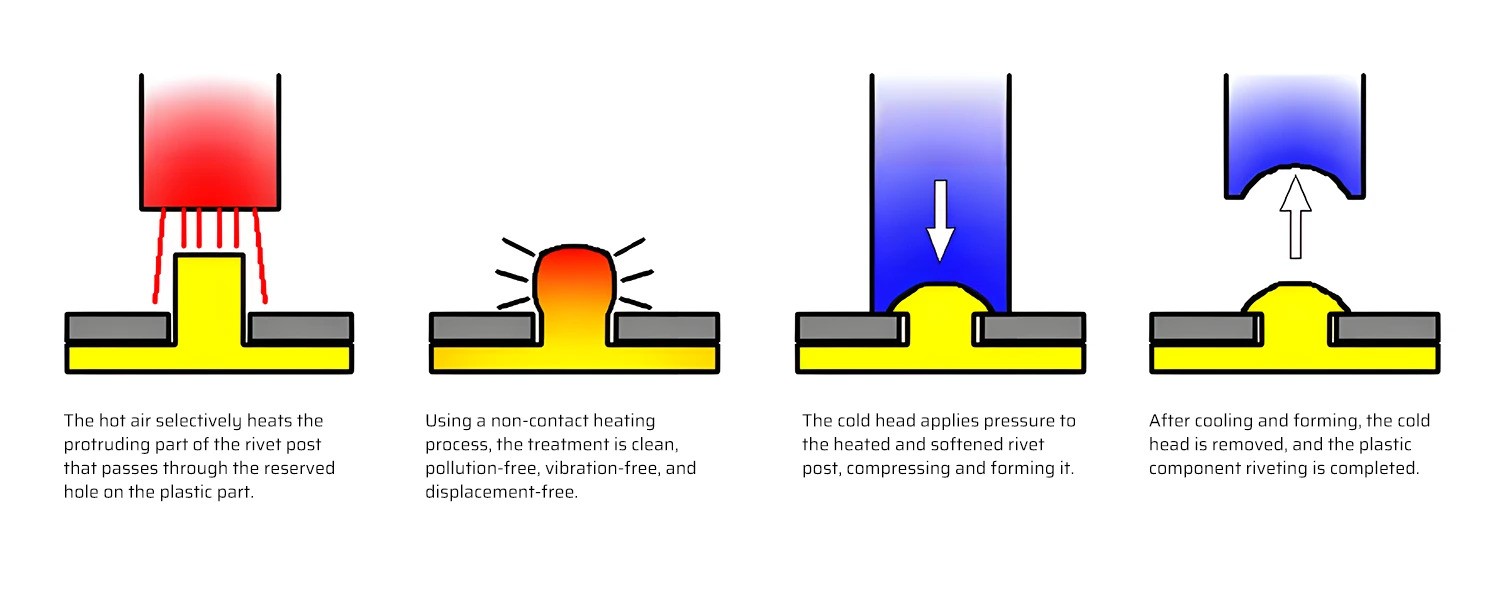

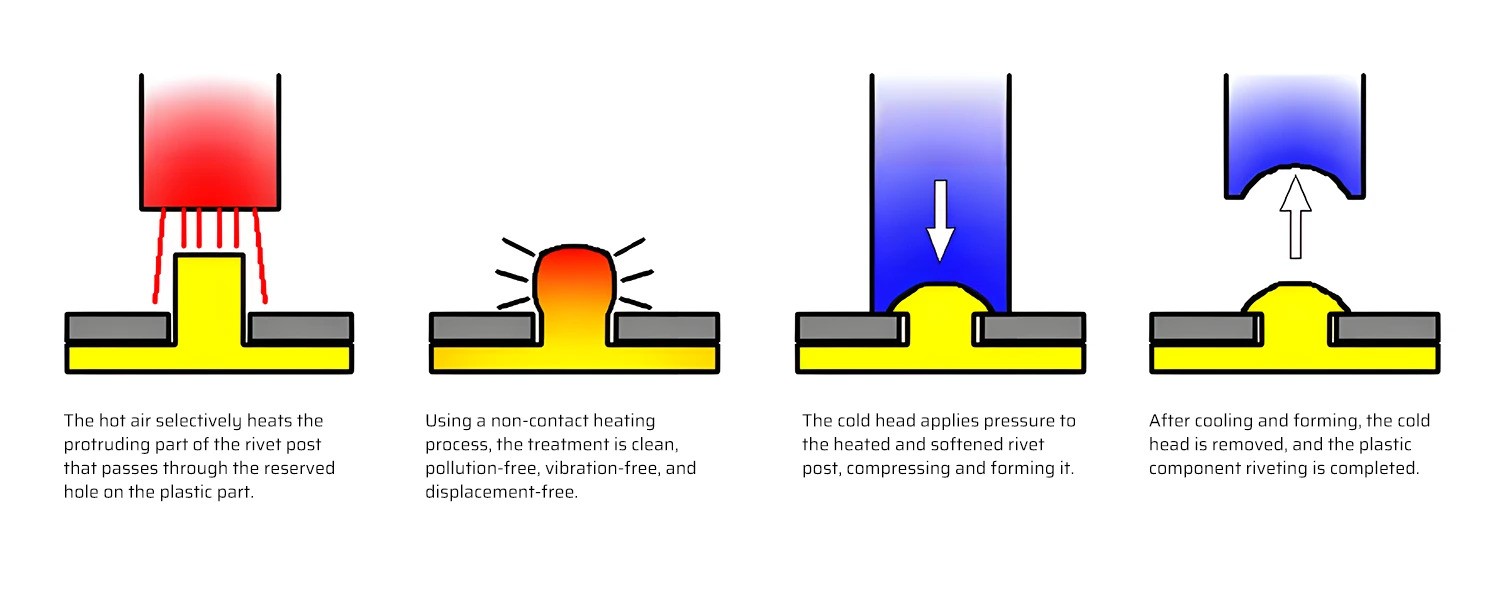

Okwokya empewo riveting (empewo eyokya ennyogovu riveting) .

Hot air riveting nkola ya non-contact. Ekozesa empewo eyokya okubugumya n’okugonza empagi ya rivet ey’akaveera. Oluvannyuma, omutwe ogukuba riveting gunyiga ne gubumba.

Enkola eno erina emitendera ebiri:

Ebbugumu: Empewo eyokya ebugumya mu ngeri y’emu empagi ya rivet okutuusa lw’eba efuuse malleable.

Okunyogoza: Omutwe ogw’ennyogoga ogunyirira gunyiga empagi egonvu, n’ekola omutwe omunywevu.

Ebirungi:

Okubuguma okwa yunifoomu kukendeeza ku situleesi ey’omunda .

Omutwe ogukuba riveting gujjuza mangu ebituli, okutuuka ku fixing effect ennungi .

Ebizibu:

Hot air riveting esaanira ebintu ebisinga obungi eby’obuveera obubuguma n’obuveera obunywezeddwa mu ndabirwamu.

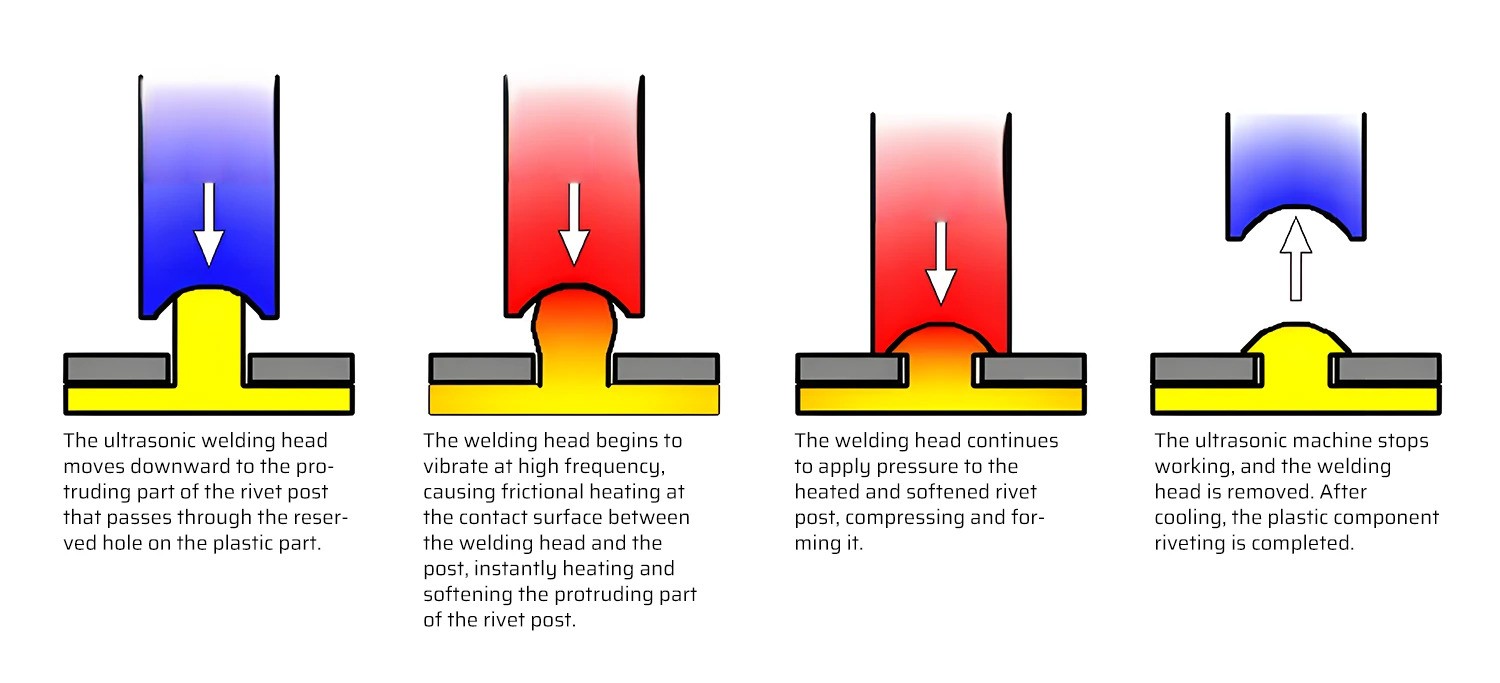

Ultrasonic riveting .

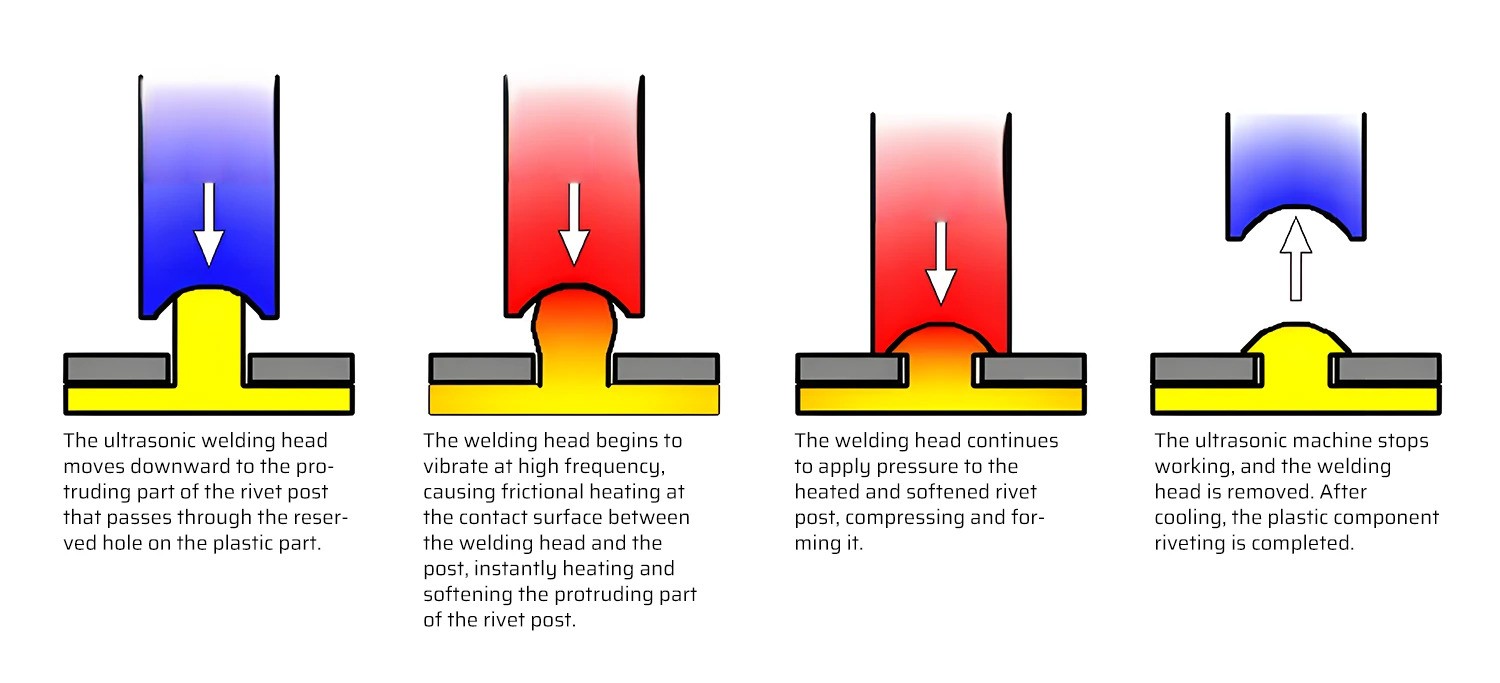

Ultrasonic riveting y’enkola endala ey’ekika ky’okukwatagana. Ekozesa okukankana kwa frequency enkulu okukola ebbugumu n’okusaanuusa empagi ya rivet ey’akaveera.

Ebirungi:

Ebizibu:

Okubuguma okutali kwa bwenkanya kuyinza okuleeta empagi ezitambula oba ezifuuse empologoma .

Ebanga ly’okusaasaanya limit singa okozesa omutwe gumu ogw’okuweta .

Okukankana kuyinza okwonoona ebitundu okutuuka ku ddaala eritali limu .

Ultrasonic riveting tekisaanira bikozesebwa bya ndabirwamu oba ebyo ebirina ebifo ebisaanuuka ebingi.

Wano waliwo emmeeza y’okugeraageranya enkola essatu:

| enkola | y’okufumbisa enkola | riveting amaanyi | okutereeza effect | speed | ebyuma flexibility . |

| Okusaanuuka okw'ebbugumu . | Tuukirira (omutwe gw'ekyuma) . | Obuteesigika, obuwulize ku kukankana . | Obulemu olw’okugonza okutali kujjuvu . | 6-60s . | Enkyukakyuka mu ngeri ekwatagana, enzibu . |

| Empewo eyokya . | Non-Contact (empewo eyokya) . | Waggulu, si sensitive ku vibration . | Excellent, ejjuza ddala ebituli . | 8-12s . | Ebbugumu eritereezebwa n’okuwunyiriza . |

| Ultrasonic . | Tuukirira (Okukankana) . | Tekyesigika . | Obulemu olw’okugonza okutali kujjuvu . | <5s . | Okufuga okutono nga kuliko omutwe ogugatta . |

Ebika by'omutwe ebya rivet ebya bulijjo ku bitundu by'obuveera .

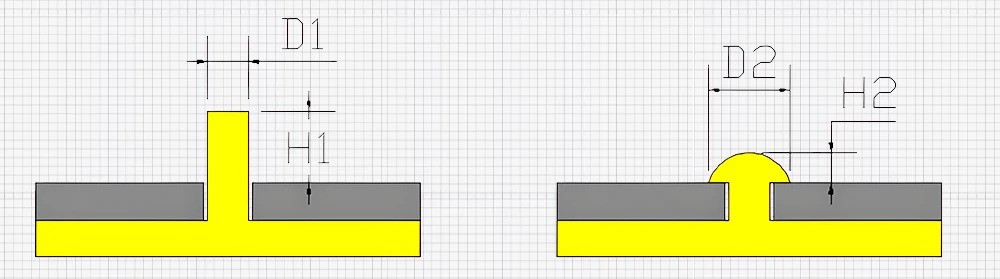

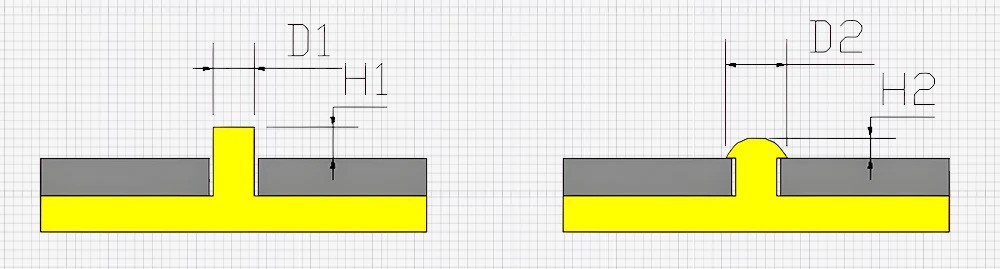

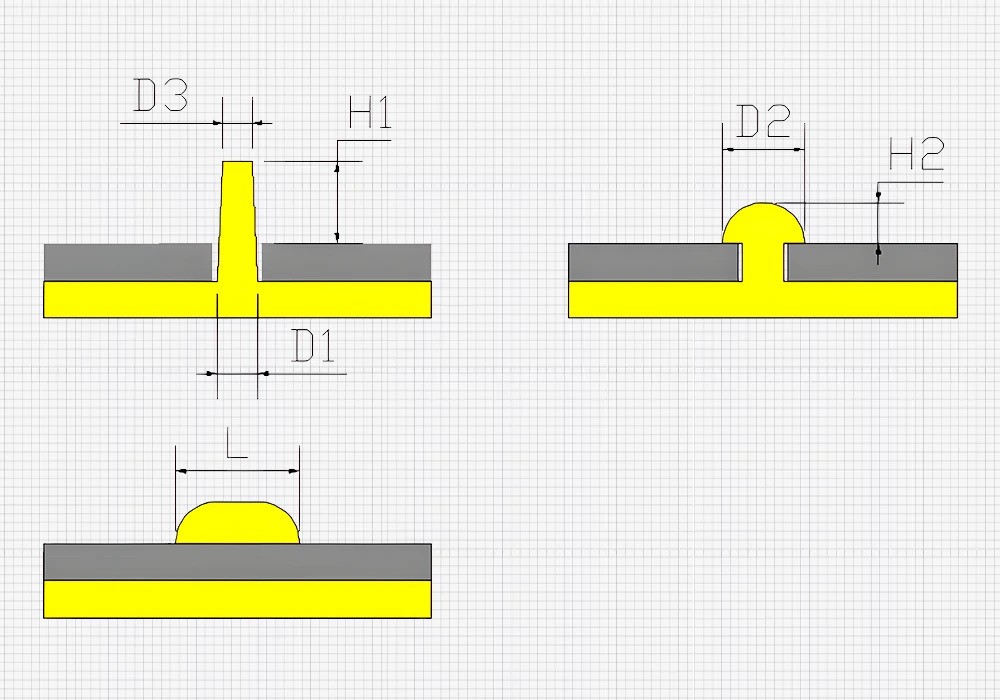

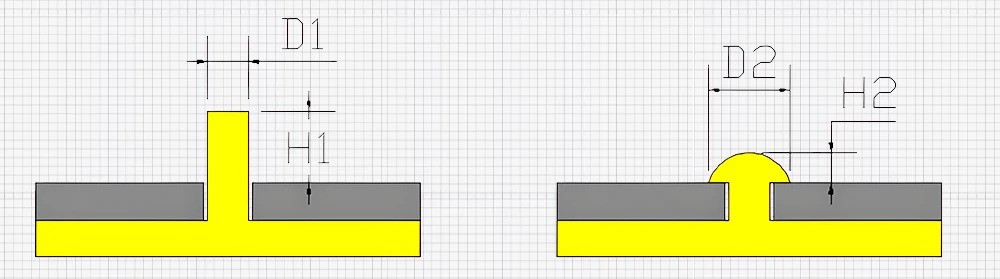

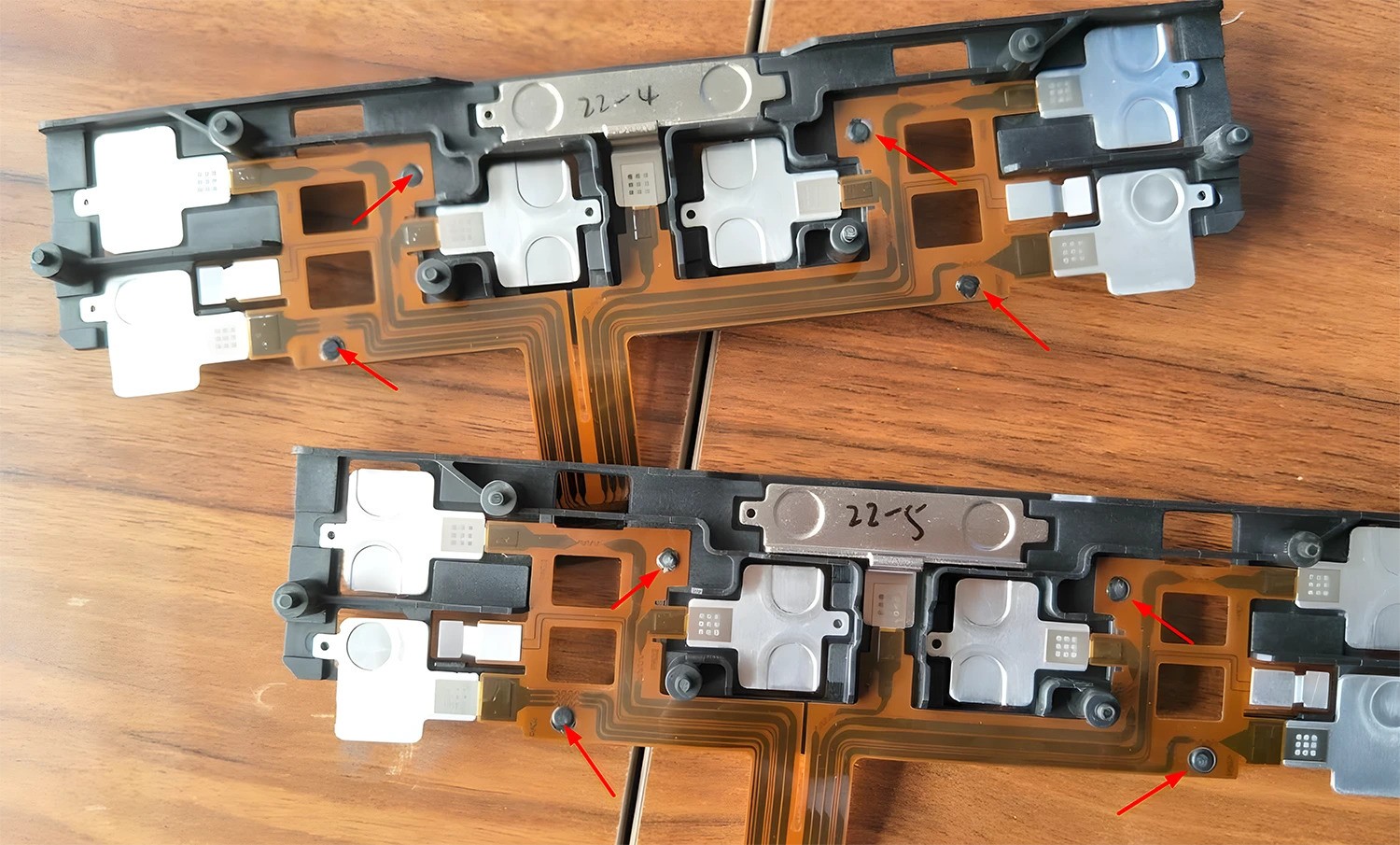

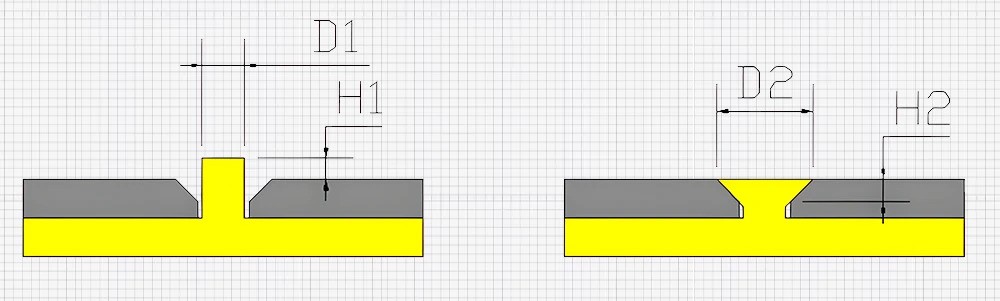

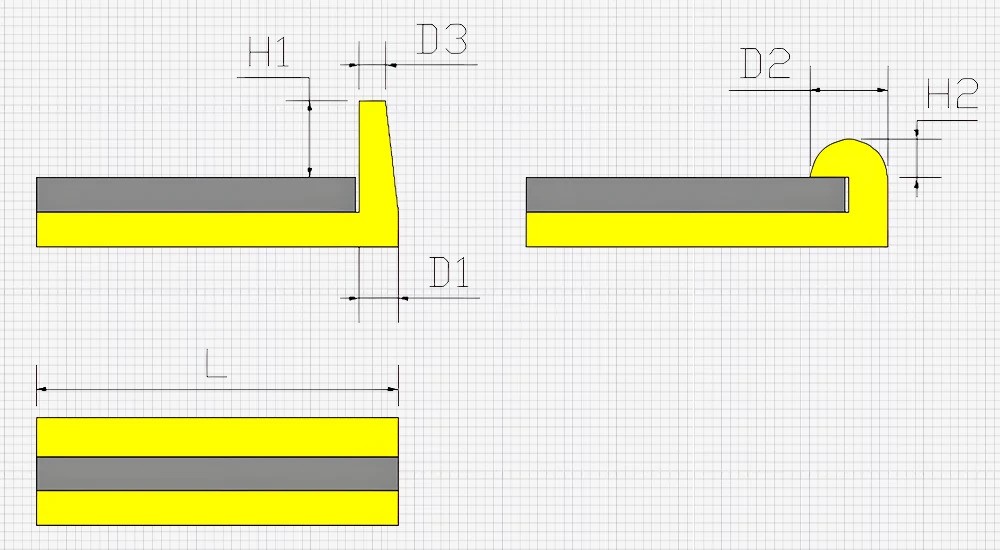

Bwe kituuka ku buveera obuyitibwa riveting, geometry n’ebipimo by’emitwe gya rivet bikulu nnyo. Ka tulabe ebika ebimu ebya bulijjo.

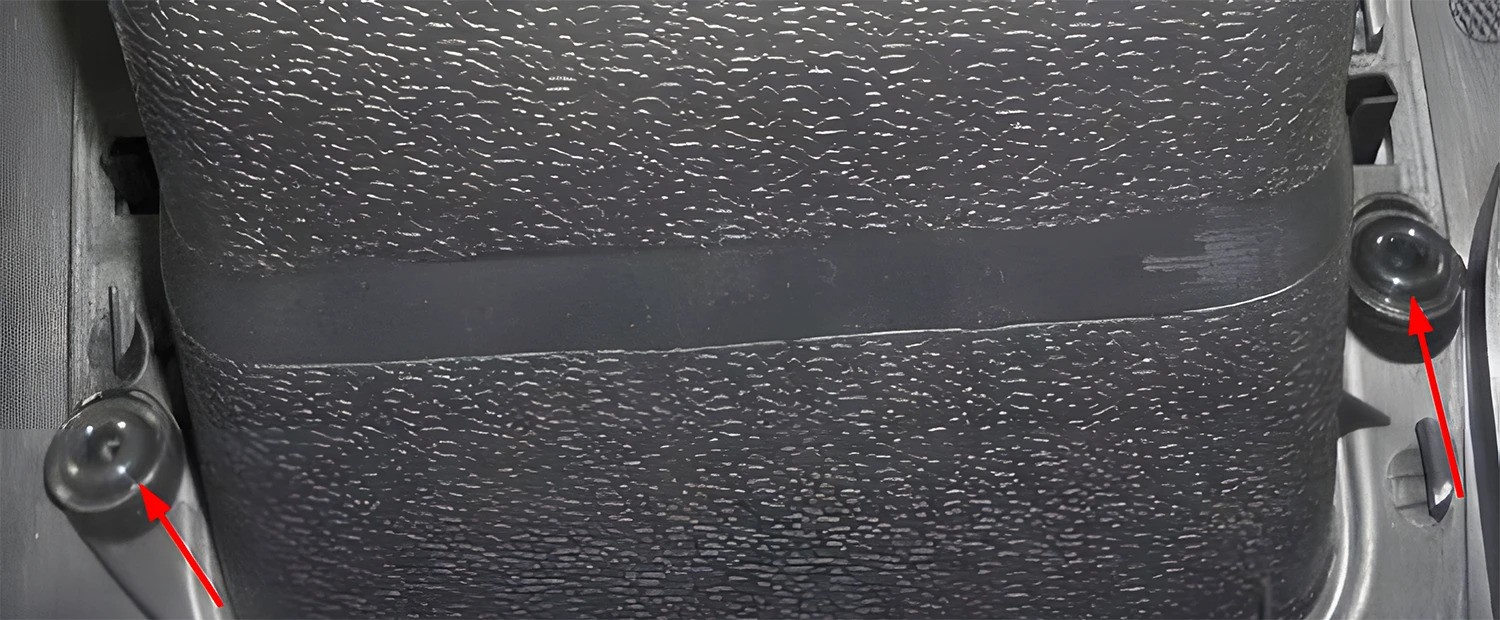

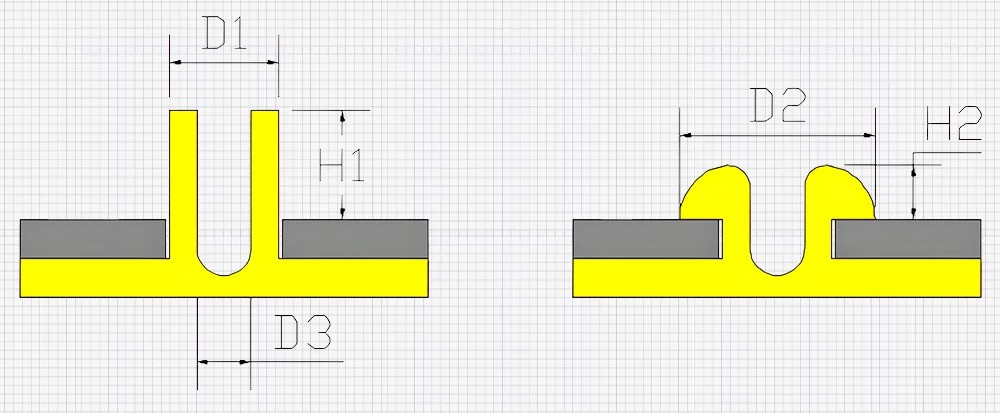

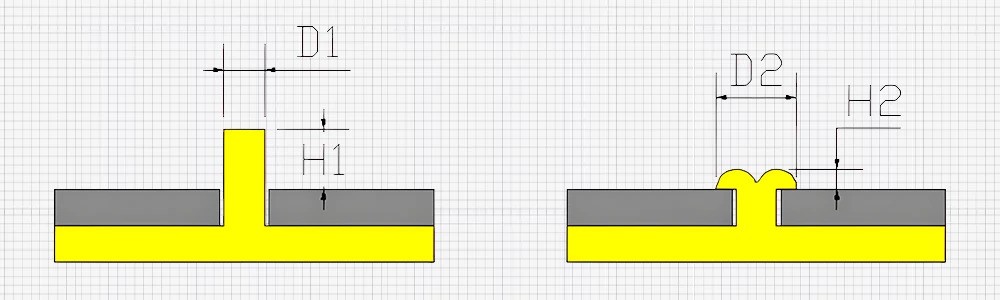

1. Omutwe gwa rivet ogw’enkulungo (omutwe omunene) .

Kino kye kika ekisinga okumanyibwa. Ekozesebwa ng’amaanyi amangi tegwetaagisa, nga mu PCBs oba ebitundu eby’okwewunda.

Ensonga enkulu:

Esaanira empagi za rivet ezirina d1 < 3mm (ekisinga obulungi > 1mm okuziyiza okumenya)

H1 okutwalira awamu ye (1.5-1.75) * D1.

D2 eri ku 2 d1, H2 eri nga 0.75 d1.

Ennamba ezenjawulo nga zisinziira ku kukyusa obuzito: S_HEAD = (85%-95%) * S_COLUMN .

2. Omutwe gwa rivet ogwa semi-circular (obutono) .

Ekika kino kirina ekiseera ekimpi eky’okusanyuka okusinga ku profile ennene. Era ya kukozesebwa mu maanyi amatono, gamba nga waya za FPC oba enzizi z’ebyuma.

Ebirina okulowoozebwako mu kukola dizayini:

D1 < 3mm, okusinga > 1mm .

H1 mu budde obutuufu eba 1.0 * d1.

D2 eri nga 1.5 d1, H2 eri ku 0.5 d1.

Okukyusa Volume: S_Head = (85%-95%) * S_COLUMN .

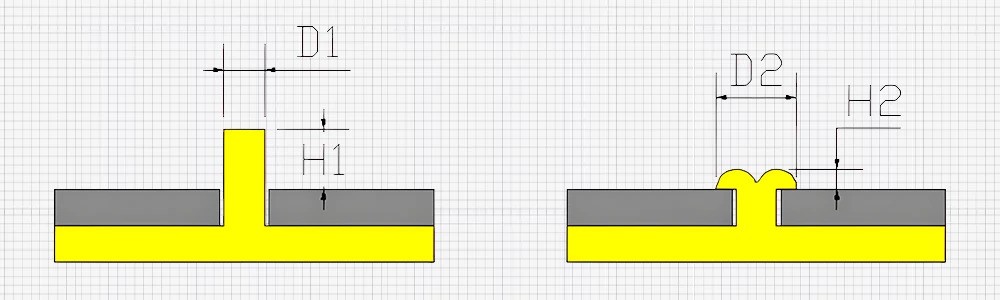

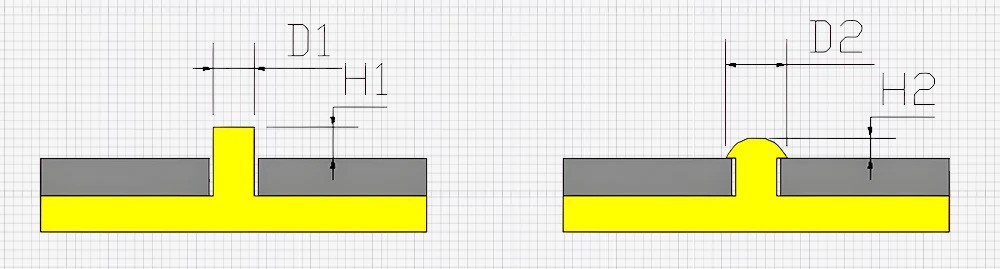

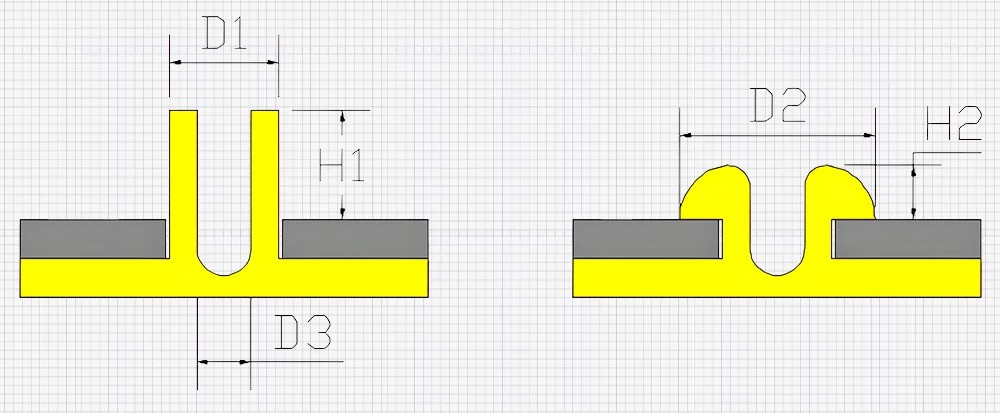

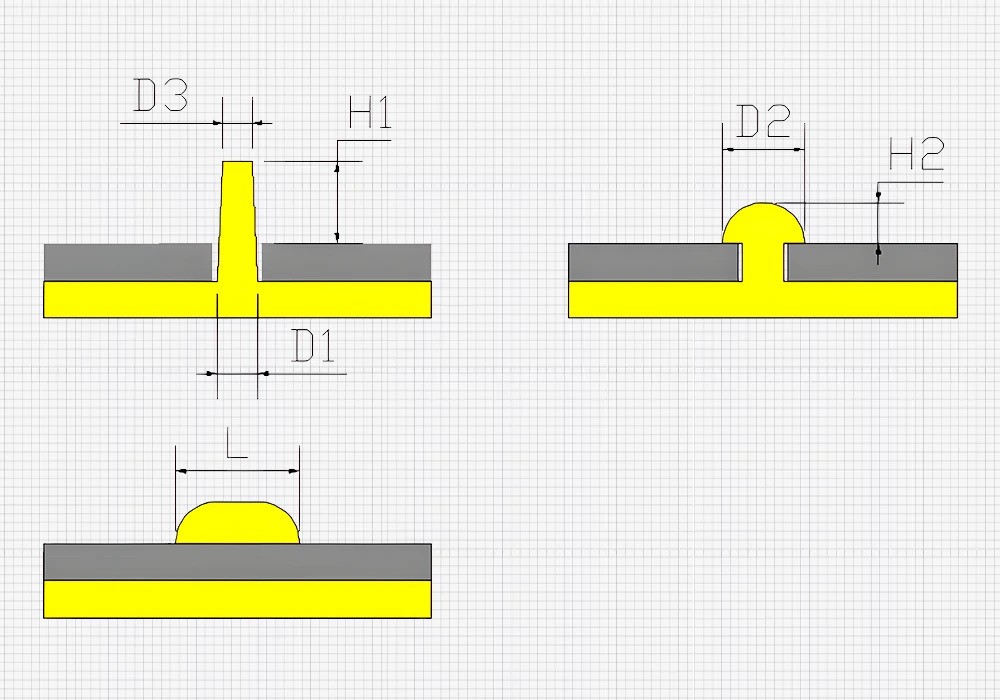

3. Omutwe gwa rivet ogw’emirundi ebiri ogw’ekitundu ekiyitibwa rivet .

Empagi za rivet wano zisingako katono ku bika bya semi-circular. Dizayini eno ekendeeza ku budde bw’okusanyuka n’okulongoosa ebivaamu. Ekozesebwa nga amaanyi g’okutereeza aga waggulu geetaagibwa.

Ensonga enkulu:

Esaanira empagi za rivet nga zirina D1 wakati wa 2-5mm .

H1 mu ngeri entuufu 1.5 * d1.

D2 eri nga 2 d1, H2 eri ku 0.5 d1.

Okukyusa Volume kikola .

rivet column ne mold hot riveting head centers zirina okukwatagana ku nnongoos .

4. Omutwe gwa Rivet ogw’omu Annular .

Nga rivet column diameter yeeyongera, empagi ezirimu ebituli zikozesebwa. Zikendeeza ku budde, zitereeza ebivaamu, n’okuziyiza obuzibu bw’okukendeera. Ekika kino kya kusaba okwetaaga amaanyi g’okutereeza aga waggulu.

Obubonero:

D1 > 5mm .

H1 ye (0.5-1.5) * D1, omuwendo omutono ku dayamita ennene .

Inner D eri 0.5 * d1 okwewala okukendeera kw'omugongo .

D2 eri ku 1.5 d1, H2 eri nga 0.5 d1.

Okukyusa Volume kikola .

N’okufumbisa empagi ezirimu ebituli kiyamba okukola emitwe egy’ebisaanyizo .

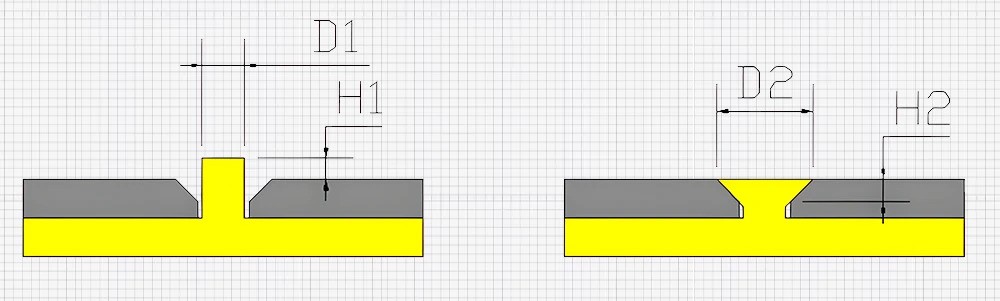

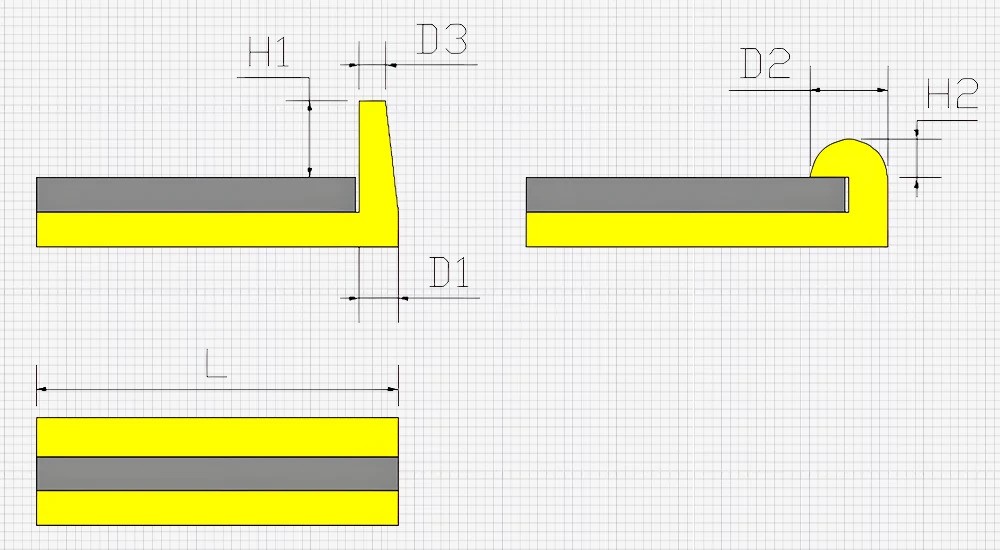

5. Omutwe gwa rivet ogupapajjo .

Emitwe egya fulaati gisaanira ng’omutwe ogukoleddwa tegulina kufuluma ku ngulu.

Ebiwandiiko ebikwata ku dizayini:

D1 < 3mm .

H1 mu ngeri entuufu 0.5 * d1.

D2 ne H2 okusinziira ku kukyusa obuzito .

Ekitundu ekiyungiddwa kyetaaga obuwanvu obumala okusobola countersinking .

Obugumu obutamala buleeta okuyungibwa okuteesigika n’amaanyi agatali gamala .

6. Omutwe gwa Rivet oguliko emiguwa .

Kozesa emitwe egy’embavu ng’olina ekifo ekinene eky’okukwatagana naye nga tolina kifo kya mpagi ezirimu ebituli.

Ensonga enkulu:

Obuwanvu bw’omusingi D1 < 3mm, obuwanvu bwa waggulu D3 = (0.4-0.7) * D1.

H1 ye (1.5-2) * D1, ntono okusinga obuwanvu bw’empagi L .

D2 eri nga 2 d1, H2 eri ku 1.0 d1.

Okukyusa Volume kikola .

7. Omutwe gwa Rivet ogwa flanged .

Emitwe egya flanged ginyuma nnyo eri ebiyungo ebyetaagisa okunyiga oba okuzinga.

Ebirina okulowoozebwako mu kukola dizayini:

Obuwanvu bw’omusingi D1 < 3mm, obuwanvu bwa waggulu D3 = (0.3-0.5) * D1.

H1 ye (1.5-2) * D1, wansi w’obuwanvu bw’empagi l .

D2 mu budde obutuufu eba 2 d1, H2 eri nga 1.0 d1.

Okukyusa Volume kikola .

Design considerations ku kolums za rivet n'emitwe gya rivet .

Bw’oba okola dizayini y’empagi n’emitwe gya rivet, waliwo ebintu ebikulu ebiwerako by’olina okukuuma mu birowoozo. Ka tuzitunule mu bujjuvu.

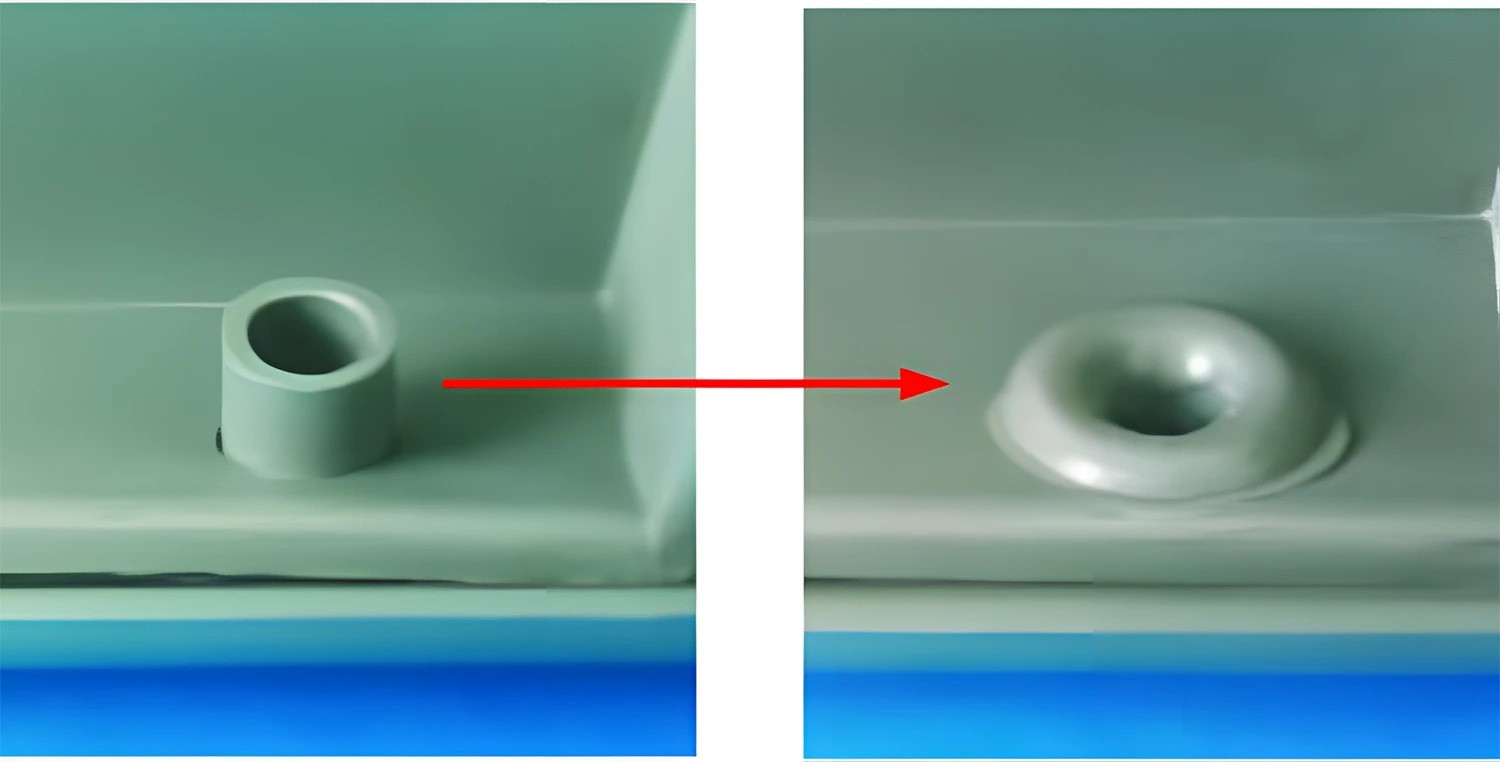

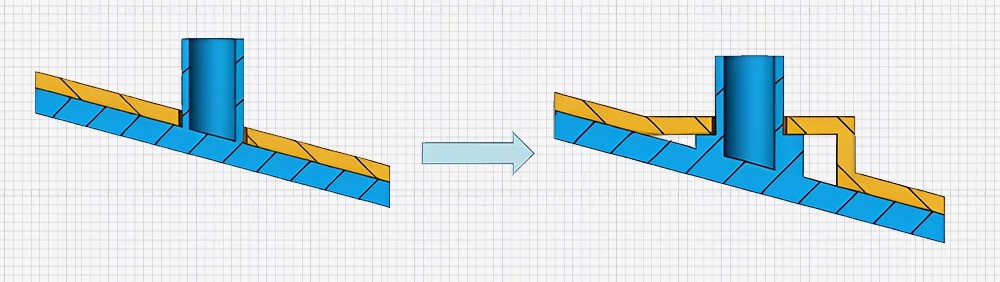

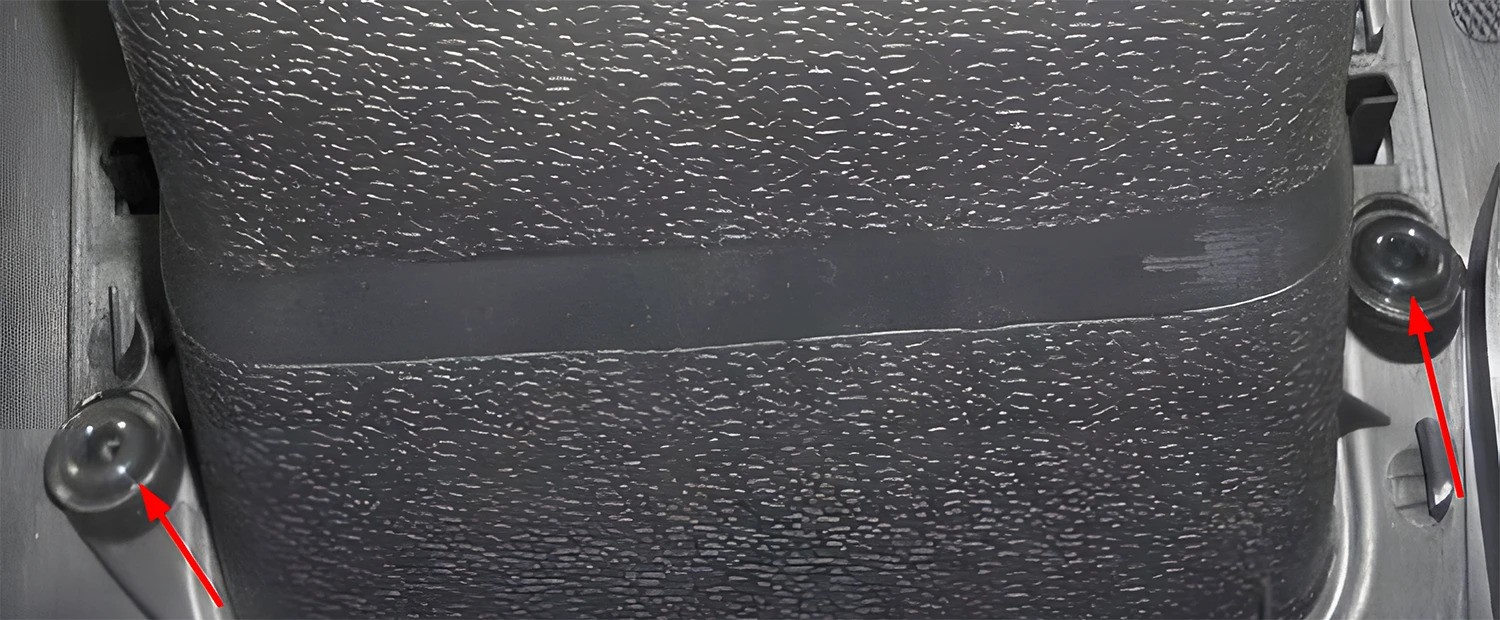

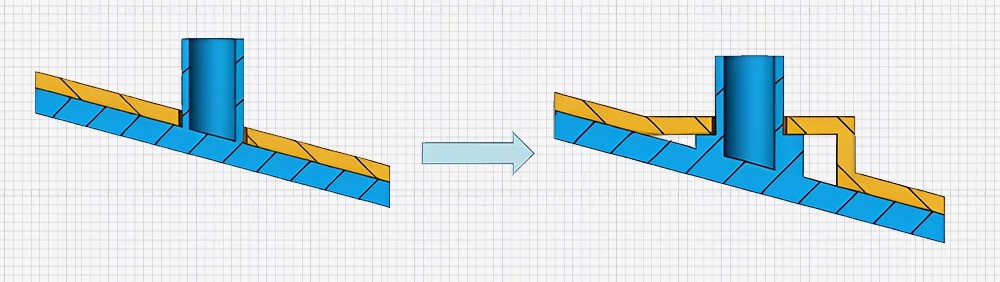

Okukola dizayini ya rivet empagi ku bifo ebiserengese oba ewala okuva ku musingi .

Singa empagi ya rivet ebeera ku nnyonyi eserengese oba wala okuva ku ngulu w’omusingi, dizayini ey’enjawulo yeetaagibwa. Wano waliwo enkola bbiri:

Enkola y’okukola dizayini y’empagi za rivet ku bitundu ebiserengese .

Ku bitundu ebiserengese, empagi ya rivet erina okuba nga yeesimbye ku ngulu. Kino kikakasa okukwatagana okutuufu n’okunyweza okusiba.

Enkola y’okukola dizayini y’empagi ya rivet eteekeddwa waggulu waggulu ku ngulu w’omusingi .

Empagi bw’eba waggulu waggulu w’omusingi, okugattako ensengekera z’obuyambi kikulu nnyo. Ziziyiza okufukamira oba okumenya nga zikuba rive.

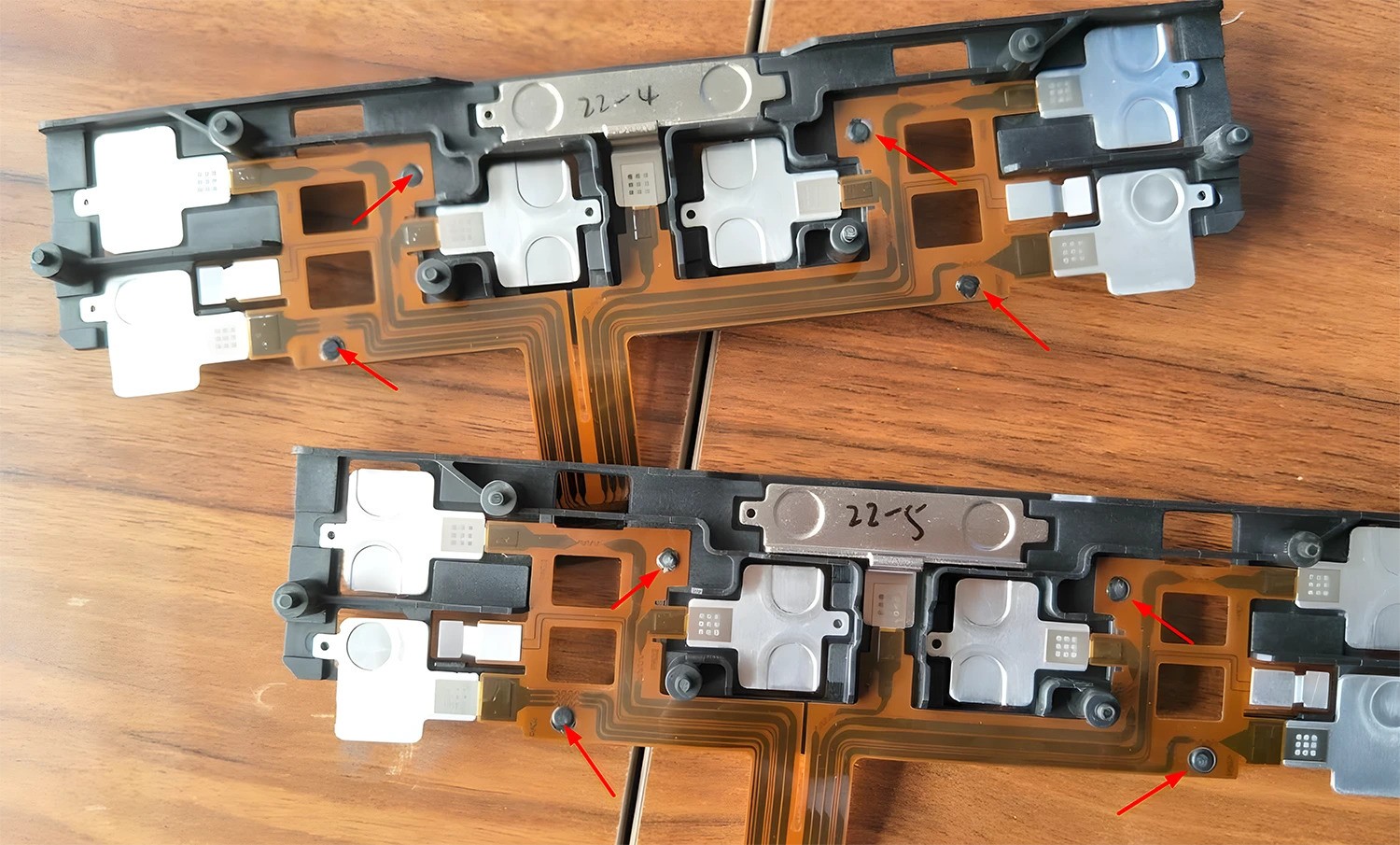

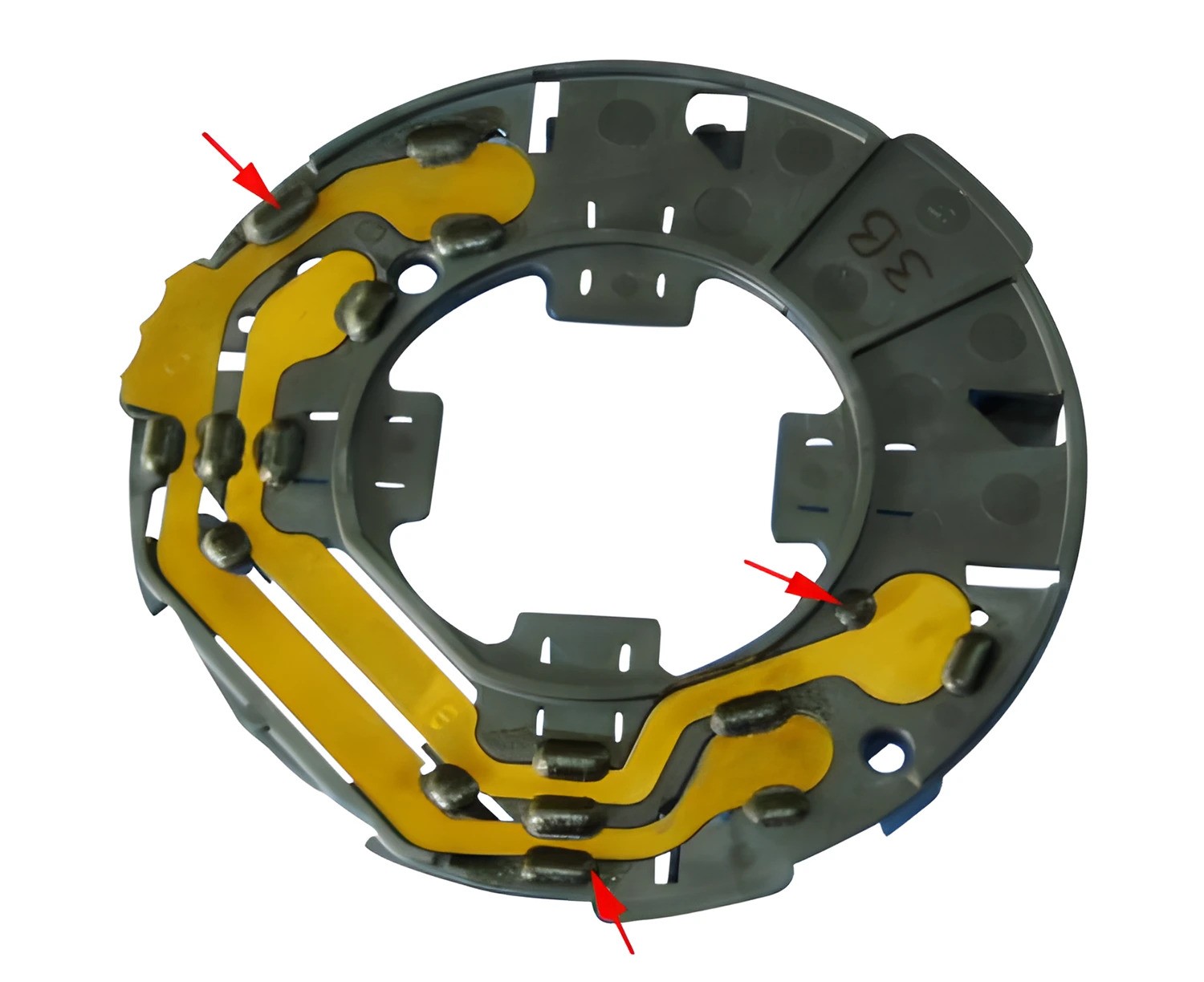

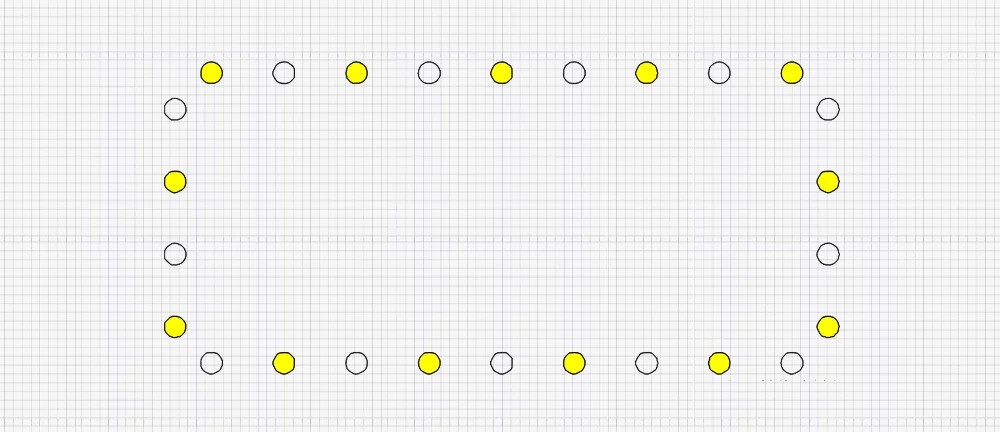

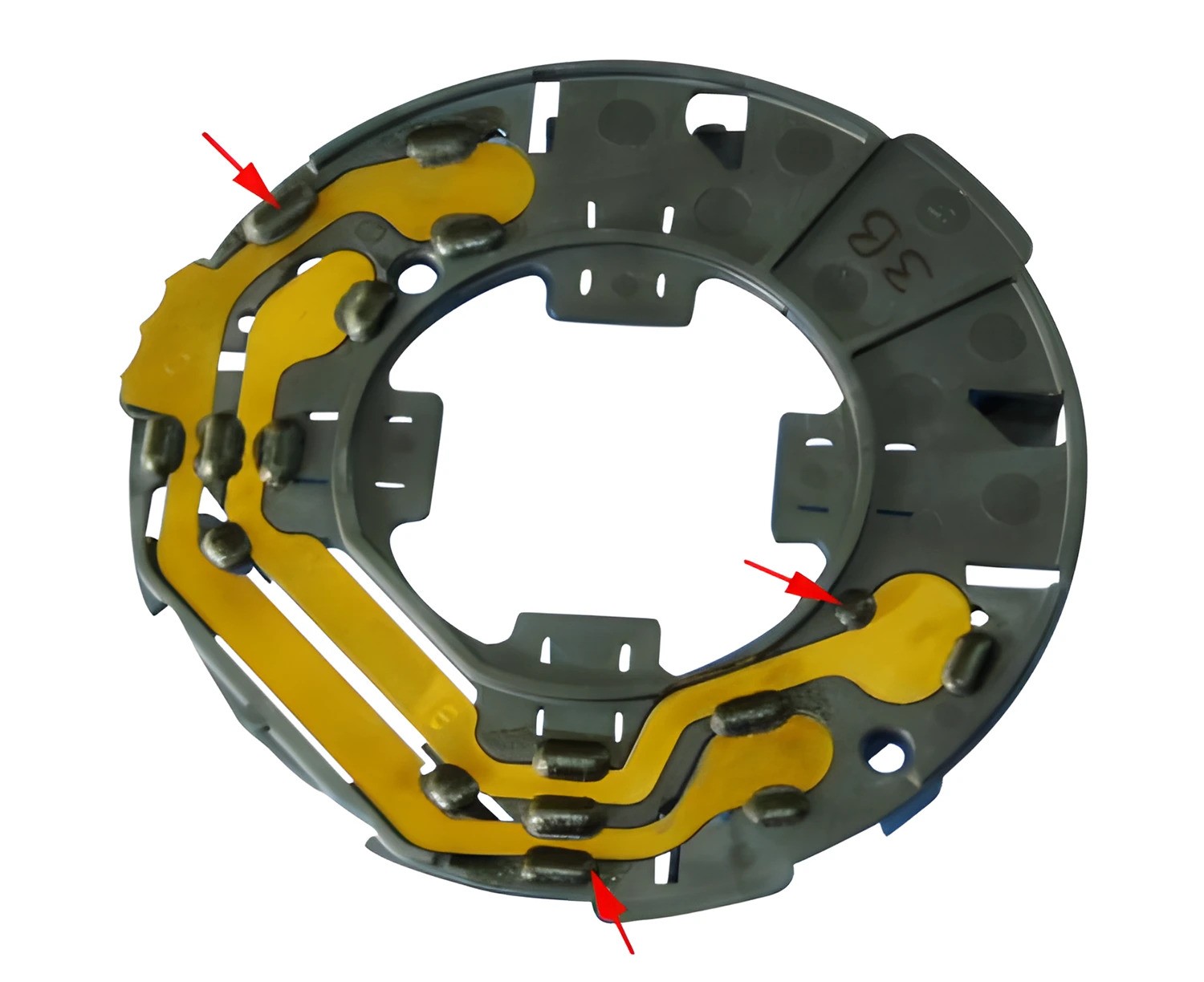

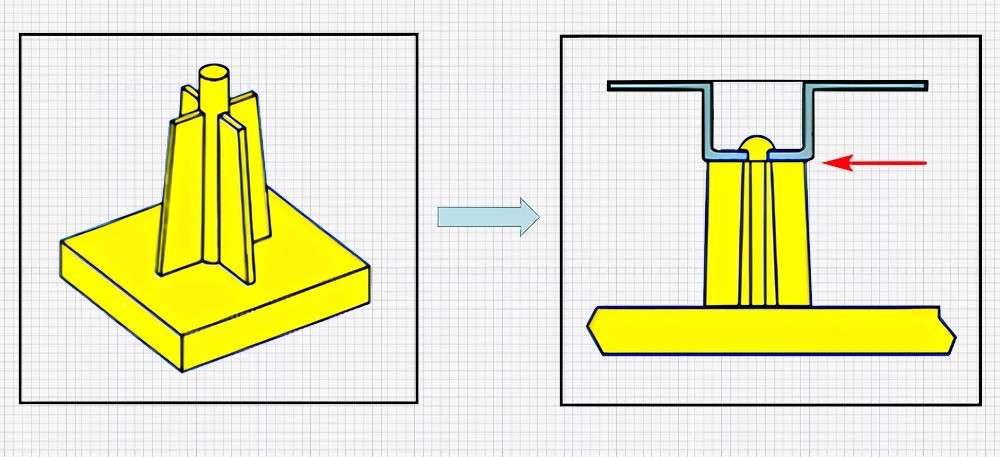

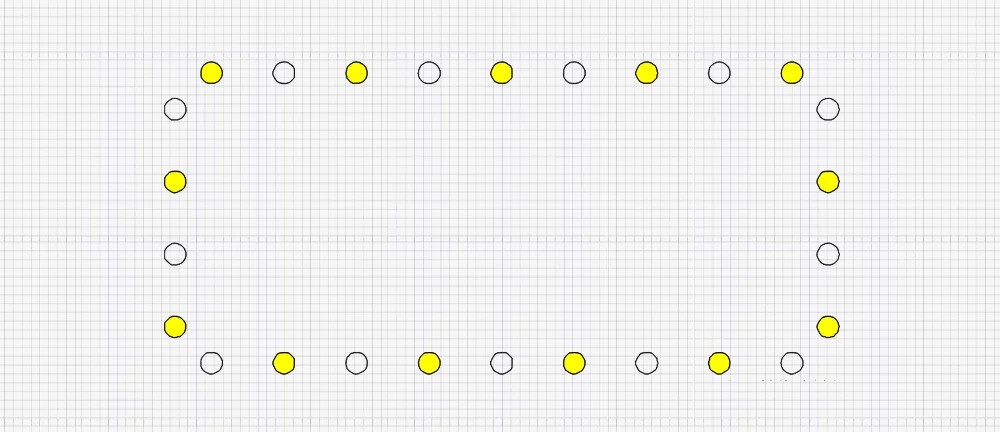

Obukulu bw'okukola Redundancy Design .

Obuveera obuyitibwa riveting bukola ebiyungo eby’olubeerera ebikaluba okuddaabiriza singa biremererwa. Okuyingiza redundancy mu dizayini kyetaagisa nnyo.

Enkola emu ekubisaamu emirundi ebiri omuwendo gw’empagi n’ebituli bya rivet. Mu kusooka, seti enkulu yokka (okugeza, eya kyenvu) ekozesebwa. Singa okuddaabiriza kwetaagibwa, seti eyokubiri (okugeza, enjeru) egaba backup.

Okukendeeza kuno kukuwa omukisa ogw’okubiri ogw’okuddaabiriza, okwongera ku bwesigwa okutwalira awamu obw’ekibiina ekirina riveted.

Enkolagana wakati w’omutwe gwa rivet n’ebipimo by’empagi .

Ebipimo by’omutwe gwa riveti n’empagi bikwatagana nnyo. Wano waliwo enkolagana enkulu gy’olina okulowoozaako:

rivet head diameter (D2) okutwalira awamu ekubisaamu emirundi 2 ku dayamita y’empagi (D1) .

Rivet head height (H2) kitera okuba nga emirundi nga 0.75 D1 ku mitwe eminene egy’enkulungo semi, ate emirundi 0.5 ku mitwe emitono egy’enkulungo egy’ekitundu .

Ebipimo ebitongole birina okusinziira ku kukyusa obuzito: s_head = (85%-95%) * S_Column .

Okukyusa obuzito buno kukakasa nti omutwe gwa rivet gulina ekintu ekimala okukola okuyungibwa okw’amaanyi, okunywevu awatali kasasiro ayitiridde.

Material Adaptability okusobola okusiiga obuveera .

Si buli buveera nti busaanira okusiba rive. Ka twekenneenye ensonga enkulu ezisalawo engeri ekintu gye kiyinza okukyusaamu.

Thermoplastics vs. ebisengejja .

Thermoplastics zisobola okusaanuuka ne ziddamu okutondebwa mu bbugumu erigere. Zino zisinga kukwata ku riveting.

Okwawukana ku ekyo, thermosets zikaluba enkalakkalira nga zibuguma. Bazibu okusiba rivet nga bakozesa enkola za standard.

N’olwekyo, ensengekera z’ebintu zitera okuzingiramu obuveera obuyitibwa thermoplastics nga kyetaagisa riveting.

Amorphous vs. semi-crystalline ebiveera .

Thermoplastics zongera okugabanyizibwamu ebika bya amorphous ne semi-crystalline. Buli emu erina engeri ez’enjawulo ezikwata ku riveting.

Obuveera obutaliimu bifaananyi (obutali bwa kirisitaalo) .

Enteekateeka ya molekyu etali nnungi .

Okugonza mpolampola n’okusaanuuka ku bbugumu ly’okukyusa endabirwamu (TG) .

Esaanira enkola zonsatule ezikola riveting (hot melt, hot air, ultrasonic)

Semi-crystalline obuveera .

Enteekateeka ya molekyu eragiddwa .

Ekifo eky’enjawulo eky’okusaanuuka (TM) n’ekifo eky’okuddamu okubeera ku mutindo .

Sigala nga mugumu okutuusa ng’otuuka ku kifo ekisaanuuka, olwo onyweze mangu ng’onyogozeddwa .

Ekisinga okusaanira okusaanuuka okw’ebbugumu olw’okubuguma okugatta n’okukola .

Ensengekera ya bulijjo eringa eya sseppulingi enywa amaanyi ga ultrasonic, ekifuula ultrasonic riveting okusoomoozebwa .

Ebifo eby’okusaanuuka ebisingako byetaaga amaanyi mangi aga ultrasonic okusaanuuka .

Okulowooza ku dizayini eyegendereza okwetaagisa okusobola okusiiga eddoboozi ery’amaanyi (amplitude ey’oku ntikko, dizayini y’ekiyungo, okukwatagana kw’omutwe gw’okuweta, ebanga, ebinyweza)

Okukendeeza ku kukwatagana okusooka wakati wa rivet column waggulu n’omutwe gwa welding okusobola okusengejja amaanyi .

Impact of fillers (okugeza, ebiwuzi by’endabirwamu) .

Ebijjuza bisobola okukosa ennyo omutindo gw’akaveera aka riveting. Ka tulabe ebiwuzi by’endabirwamu ng’ekyokulabirako.

Ensonga enkulu:

Enjawulo ennene mu bifo ebisaanuuka wakati w’obuveera n’obuwuzi bw’endabirwamu .

Hot Melt Riveting: Okufuga ebbugumu mu ngeri entuufu (±10°) Ekikulu .

Ebbugumu erya waggulu lireeta enkuba y’obuwuzi bw’endabirwamu, okunywerera, n’ebifo ebikaluba .

Ebbugumu eri wansi livaako enjatika n’okutondebwa mu bunnyogovu .

Ultrasonic riveting: Amasoboza amalala ag’okukankana ageetaagisa okusaanuusa obuveera .

Endagiriro y’ebirimu ebijjuza:

<10%: Ekitono ku nkola y’ebintu, eby’omugaso eri ebintu ebigonvu (PP, PE, PPS) .

10-30%: Ekendeeza ku maanyi aga riveting .

-

30%: kikwata nnyo ku kukola riveting .

Ebintu ebirala ebikwata ku bintu ebikosa ultrasonic riveting:

Obukakanyavu: Obukakanyavu obw’oku ntikko okutwalira awamu bulongoosa riveting .

Ekifo eky’okusaanuuka: ebifo eby’okusaanuuka ebisingako byetaaga amaanyi amangi aga ultrasonic .

Obulongoofu: Obulongoofu obw’amaanyi bwongera ku riveting, ate obucaafu mu bintu ebikozesebwa okuddamu okukola bukendeeza ku mutindo .

Ebikozesebwa mu buveera ebikozesebwa mu kukola riveting .

Okulonda ekintu ekituufu eky’obuveera kikulu nnyo okusobola okukola obulungi. Ka tulabe nnyo ku bimu ku bikozesebwa ebitera okukolebwa.

Polyethylene (LDPE) .

LDPE erina density entono olw’ensengekera yaayo eya molekyu epakiddwa mu ngeri etali nnywevu. Kikyukakyuka naye nga kikaluba.

Ebintu ebikulu:

Polypropylene (PP) .

PP ekozesebwa nnyo mu makolero gonna, okuva ku mmotoka okutuuka ku kupakira. Ewa obuziyiza obulungi eddagala n’okuziyiza amasannyalaze.

Okusaba:

Okupakinga amazzi n'eby'okunaaba mu maka .

rivets za ratchet ezisajja/omukazi .

Snap-in flush top rivets .

Fir omuti rivets .

Nylon .

Nylon naddala Nylon 6/6, yettanirwa nnyo mu by’amakolero. Okusikagana kwayo okutono kigifuula ennungi ku ggiya ne bbeeri.

Obubonero:

Eziyiza eddagala erisinga obungi, naye esobola okulumbibwa asidi ow’amaanyi, omwenge, ne alkali .

Okuziyiza obubi asidi omutono, okuziyiza okulungi ennyo eri amafuta ne giriisi .

Ekozesebwa ku snap rivets, unscrewing rivets, ne push-in knob head rivets .

acetal (polyoxymethylene, pom) .

Acetal oba Pom, mugumu, nkakanyavu, era agumira obunnyogovu, ebbugumu, eddagala, n’ebiziyiza. Kirina eby’obugagga ebirungi eby’okuziyiza amasannyalaze.

Enkozesa:

gears, bushings, emikono gy'omulyango gw'emmotoka

Ebisiba ebisiba ku kipande kya kwata y’okukyuka .

Abadigize ba panel .

Snap-in flush top rivets .

Polysulfone (PSU) .

PSU ekozesebwa mu nkola ez’enjawulo olw’obusobozi bwayo obw’ebbugumu n’ebyuma ebingi.

Ebikulu Ebirimu:

Okuziyiza eddagala okulungi .

Ekozesebwa mu tekinologiya w’ebyobujjanjabi, eddagala, okukola emmere, n’ebyuma ebikozesebwa mu byuma bikalimagezi

Esaanira okusiba rivets .

Okugerageranya eby’obugagga by’ebintu .

Wano waliwo emmeeza egeraageranya eby'obugagga by'ebintu bino:

| eby'obugagga | LDPE | PP | Nylon 6/6 | Acetal | PSU . |

| Amaanyi g’okusika (PSI) . | 1,400 . | 3,800-5,400 . | 12,400 . | 9,800-10,000 | 10,200 . |

| Obugumu bw’okukuba (J/M⊃2;) . | Tewali kuwummulamu . | 12.5-1.2. | 1.2 | 1.0-1.5. | 1.3 |

| Amaanyi ga dielectric (KV/mm) . | 16-28 . | 20-28 . | 20-30 . | 13.8-20 . | 15-10 . |

| Densite (g/cm³) . | 0.917-0.940 . | 0.900-0.910 . | 1.130-1.150 . | 1.410-1.420 . | 1.240-1.250 . |

| max. Obuweereza obutasalako Temp. | 212°F (100°C) . | 266°F (130°C) . | 284°F (140°C) . | 221°F (105°C) . | 356°F (180°C) . |

| Okuziyiza ebbugumu (w/m·k) . | 0.320-0.350 . | 0.150-0.210 . | 0.250-0.250 . | 0.310-0.370 . | 0.120-0.260 . |

Kijjukire nti ebirungo ebigattibwamu n’ebinyweza bisobola okutumbula eby’obugagga ebimu. Okugeza, UV stabilizers zisobola okulongoosa omutindo gwa Nylon ogw’ebweru.

Engeri y'okulondamu rivet ya sayizi entuufu .

Etteeka erya bulijjo .

Enkola ennyangu kwe kusinziira ku dayamita ya riveti ku buwanvu bw’ebipande ebigattibwa. Wano waliwo etteeka ly'engalo:

rivet diameter = 1/4 × Obugumu ku pulati .

Omugerageranyo guno gukakasa nti rivet egeraageranye n’ekintu ky’ekwata wamu. Era kimanyiddwa nga Grip Range.

Ensonga z’olina okulowoozaako .

Wadde ng’etteeka erya bulijjo ly’entandikwa ennungi, waliwo ensonga endala z’olina okukuuma mu birowoozo:

Ebintu ebikozesebwa .

Dizayini y'awamu .

Ekika ky'ekiwanga (lap, butt, n'ebirala)

Embeera y’okutikka (shear, tension, n’ebirala)

Aesthetics .

Enkola y’okukuŋŋaanya .

Ensonga zino zisobola okukwata ku sayizi ya rivet esinga obulungi. Mu mbeera ezimu, oyinza okwetaaga okuva ku tteeka erya bulijjo okusobola okufuna ebisinga obulungi.

Ebyokulabirako n’okubalirira .

Ka tulabe ebyokulabirako ebitonotono okulaga enkola y’okugerageranya.

Eky’okulabirako 1:

Eky’okulabirako 2:

Obugumu bw’epulati: mm 10 .

rivet diameter = 1/4 × 10 mm = mm 2.5 .

round okutuuka ku standard size esinga okumpi, okugeza, 3 mm .

Eky’okulabirako 3:

Obugumu bw’epulaati: mm 2 (epulati ennyimpi) .

rivet diameter = 1/4 × 2 mm = mm 0.5 .

Yongera okutuuka ku sayizi entono ey’omugaso, okugeza, mm 1, okusobola okwanguyirwa okuteekebwawo n’amaanyi .

Jjukira nti okubalirira kuno kuwa entandikwa. Bulijjo lowooza ku byetaago ebitongole eby’okusaba kwo era okole ennongoosereza nga bwe kyetaagisa.

| Obugumu bw’epulati (mm) | obuwanvu bwa riveti (mm) . |

| 1-2. | 1 |

| 3-4. | 1-2. |

| 5-8 . | 2-3 . |

| 9-12 . | 3-4. |

| 13-16 . | 4-5 . |

Mu bufunzi

Mu ndagiriro eno, twanoonyereza ku nkola ez’enjawulo ez’okusiba ebitundu by’obuveera, omuli okusaanuuka okw’ebbugumu, empewo eyokya, n’enkola za ultrasonic. Twogeddeko ne ku bika by’emitwe gya rivet eby’enjawulo n’okukozesebwa kwabyo okwetongodde.

Okulonda enkola entuufu ey’okusiba n’ebikozesebwa kikulu nnyo okulaba ng’okuyungibwa okw’amaanyi era okuwangaala mu nkuŋŋaana z’obuveera. Okulonda okutuufu kuyinza okukwata ennyo ku bulamu obuwanvu n’enkola y’ebintu byo.

Kati nga bw’olina okumanya kuno, tukukubiriza okukozesa amagezi gano ku pulojekiti zo. Bw’okola bw’otyo, ojja kulaba ebivaamu ebirungi n’enkuŋŋaana ezeesigika ennyo mu mirimu gyo egy’okukola. Tukwasaganye leero !