Koya ta yi mamakin yadda kayan filayen filastik suka zauna lafiya ba tare da dunƙule ba ko manne? Riveting yana ba da ingantaccen bayani. A cikin wannan jagorar, zamu bincika ainihin mahimmancin filastik, mahimmancin masana'antu a cikin masana'antu daban-daban, da kuma yadda za a zabi hanyar da ta dace. Za ku koya ins da kuma fitar da kayan kwalliyar filastik don karfi, haɗi masu jan hankali.

Mene ne Ruwan Filin Jirgin Sama?

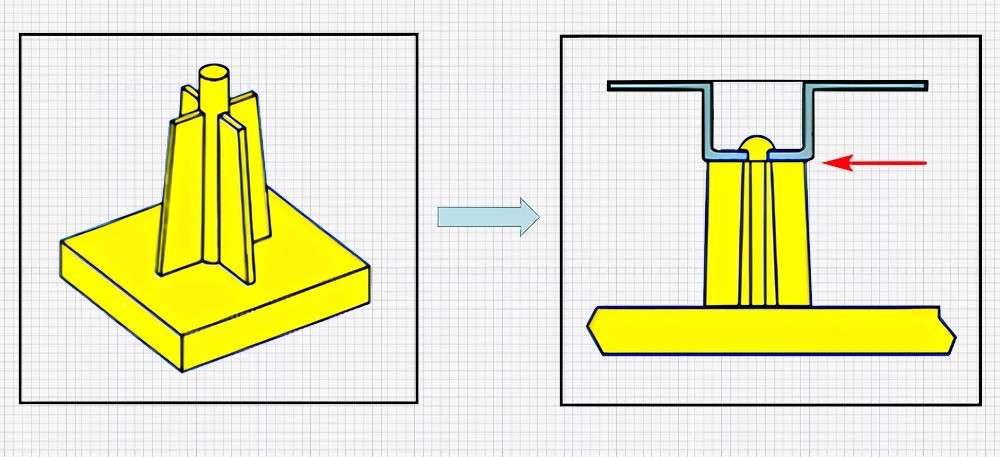

Filastik na filastik shine hanyar sauri na inji. Ya ƙunshi amfani da ƙarfi don lalata shankar da ke cikin rami. Wannan yana wakiltar kai, haɗa sassa da yawa.

Idan aka kwatanta da baƙin ƙarfe na ƙarfe, riveting filastik yana da wasu mahimman bambance-bambance. Ba ya buƙatar ƙarin rivets ko posts. Madadin haka, yana amfani da tsarin filastik kamar ginshiƙai ko hakarkarinsa. Suna cikin jikin filastik.

Fa'idodi da rashin amfanin filastik

Murmushin filastik yana da fa'idodi da yawa da rashin amfani. Bari mu duba kusa.

Amfanin gama gari:

Tsarin sashi mai sauƙi, rage farashin molds

Setoiledarancin taro, babu ƙarin kayayyaki ko masu ɗaukar hoto

Babban dogaro

Na iya rivet maki da yawa lokaci guda, inganta ingancin aiki

Ya shiga cikin filastik, ƙarfe, da sassan da ba karfe ba, ko da a cikin sarari m

Rike dogon lokaci da matsanancin yanayi

Mai sauki, mai cetonka, tsari mai sauri

Sauƙaƙan yanayin gani mai sauƙi

Rashin daidaituwa na yau da kullun:

Na bukatar ƙarin kayan aiki da kayan aiki

Bai dace da karfi-karfi ko lodi na dogon lokaci ba

Haɗin dindindin, ba a cire shi ba

Wahalar gyara idan ya gaza

Na iya buƙatar sake magana a cikin tsarin ƙira

| Kyau | Rashin Rashin |

| Tsarin sauki, ƙarancin farashi mai ƙarfi | Yana buƙatar ƙarin kayan aiki da kayan aiki |

| Maɓallin sauƙi mai sauƙi, babban abin dogaro | Ba don ƙarfi ko ƙarfi ba ko lodi na dogon lokaci |

| Ya shiga abubuwa daban-daban yadda yakamata | Na dindindin, ba a yarda da shi ba |

| Rage jijiyoyin jiki da matsanancin yanayi | Da wuya a gyara, na iya buƙatar farashi |

| Sauki, azumi, tsari mai ceton kuzari | - |

| Sauƙaƙan abubuwa masu sauƙi mai sauƙi | - |

Nau'in filastik riveting tafiyar matakai

Akwai manyan nau'ikan nau'ikan kayan kwalliya na filastik. Suna da zafi narke Riveting, iska mai zafi, da riving na ultrasonic.

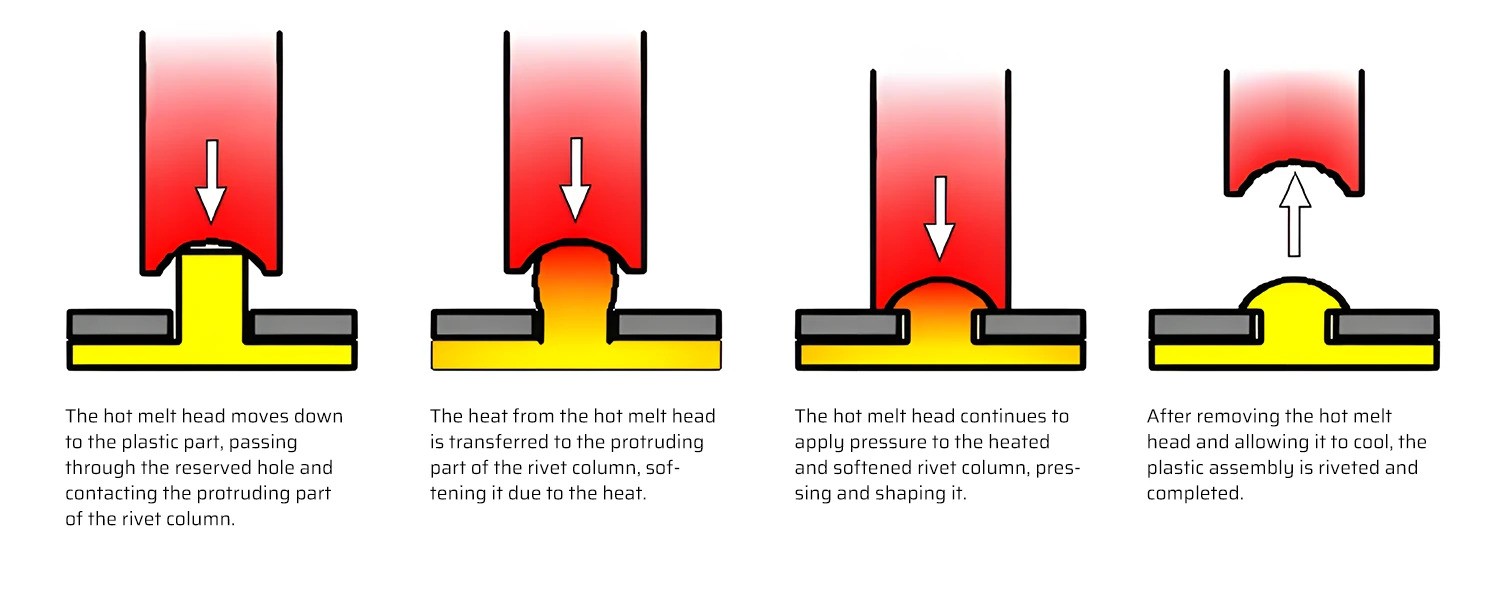

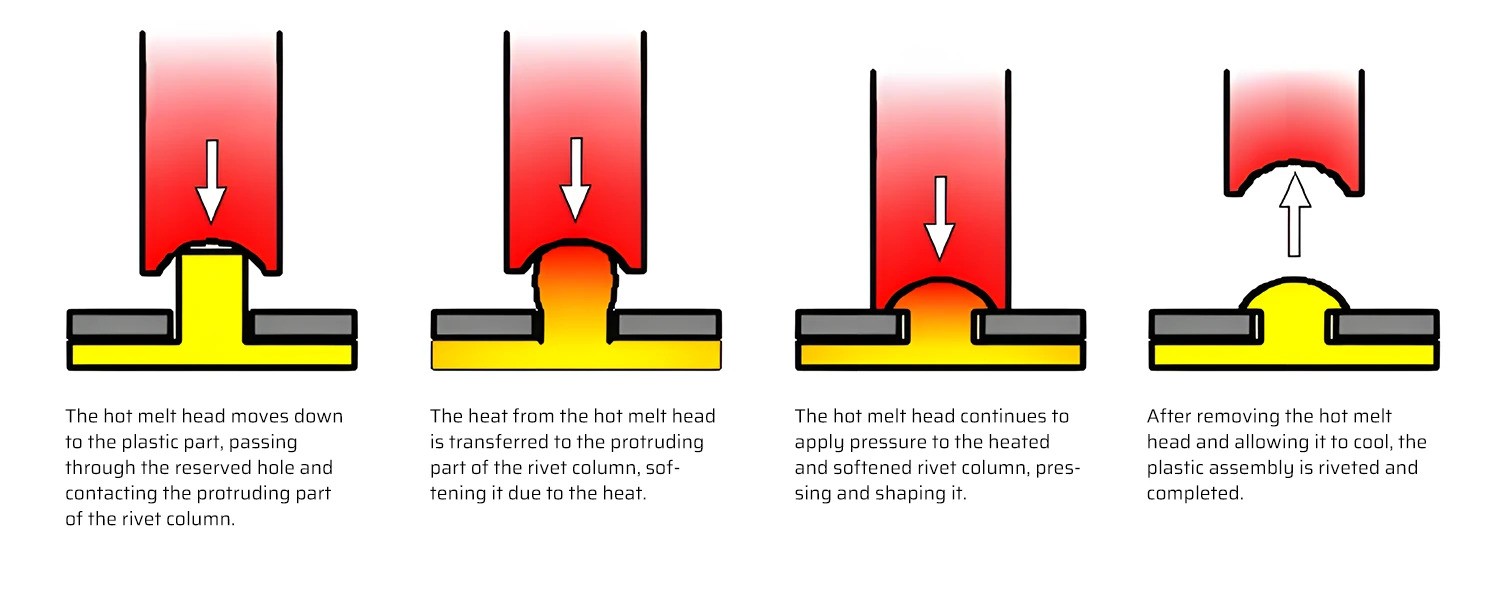

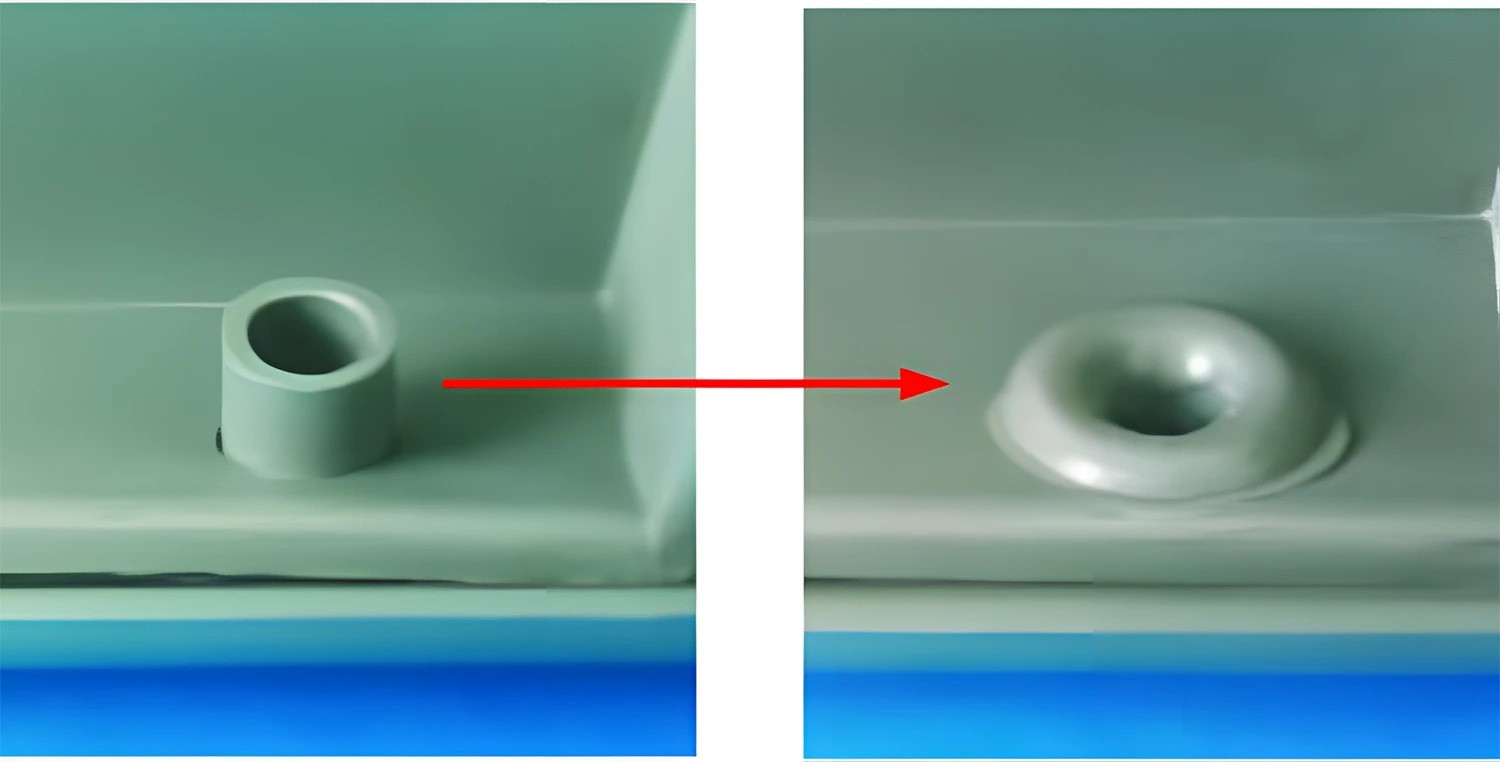

Narkewar ruwa

Narkeancin shakatawa mai zafi shine tsari mai lamba. Ya ƙunshi bututu mai dumama a cikin bakin kai. Wannan heats da ƙarfe riving na ƙarfe, wanda ya narke da kuma siffofin filastik rivet.

Abvantbuwan amfãni:

Rashin daidaituwa:

Rashin isasshen sanyaya na iya haifar da filastik don tsaya a kai

Bai dace da manyan kayayyaki ba

Babban tashin hankali da ƙananan ƙarfi

Ba a ba da shawarar samfuran ba tare da manyan buƙatun / gyara

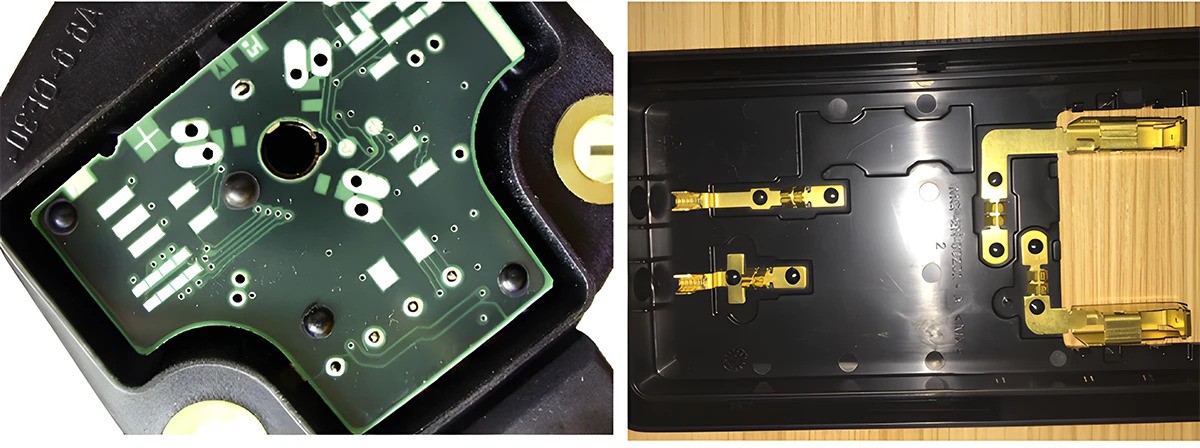

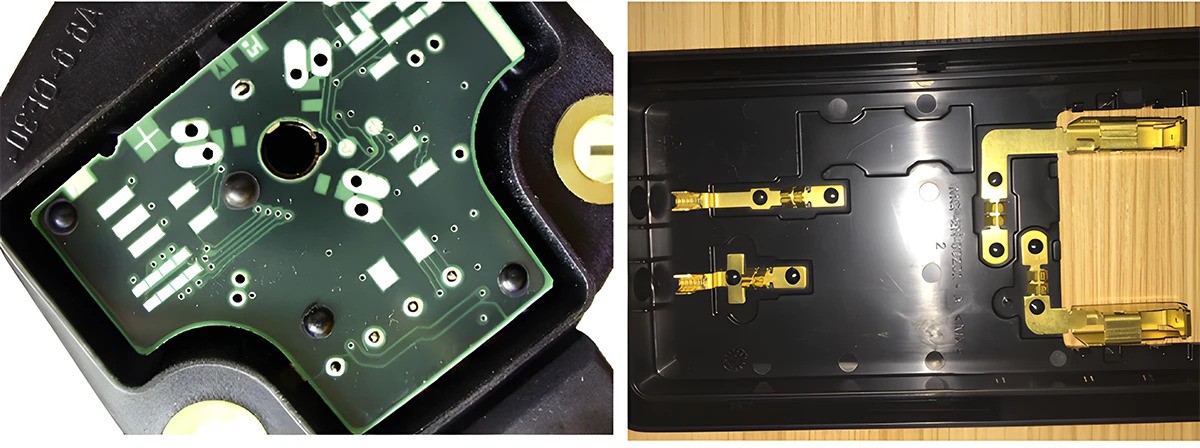

Ana amfani da kayan kwalliyar ruwa mai zafi don allon PCB da sassan filastik.

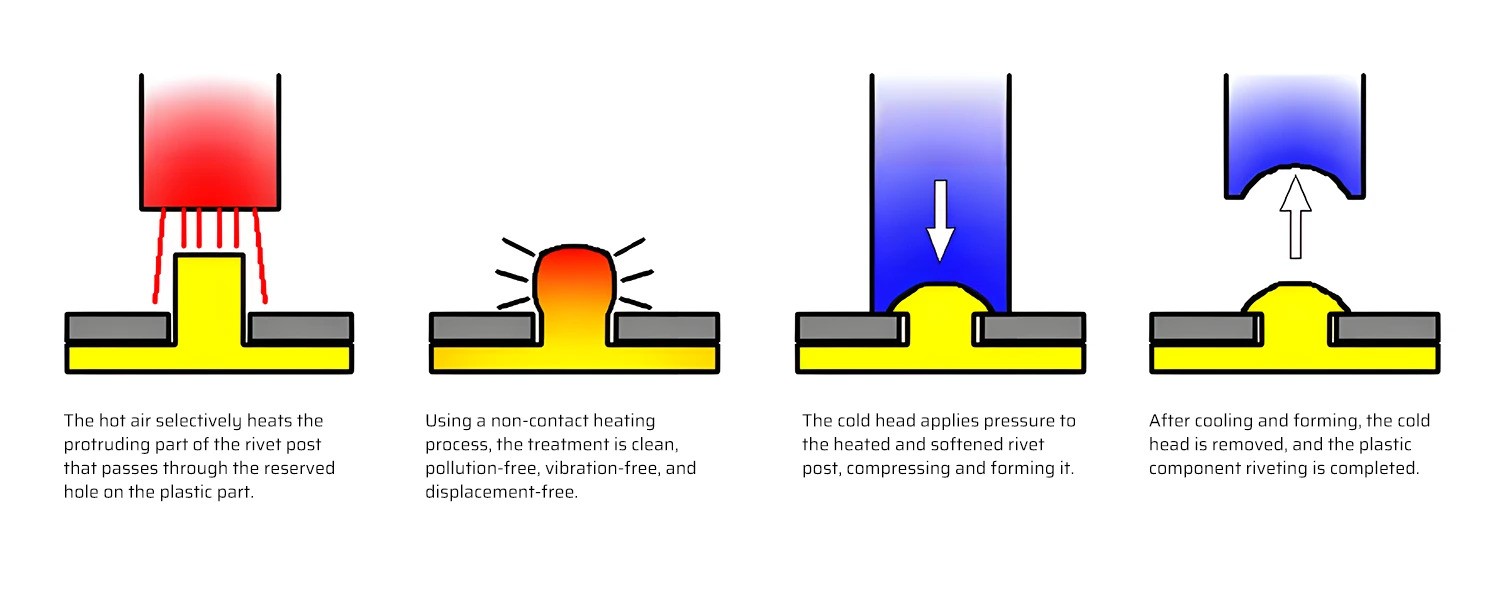

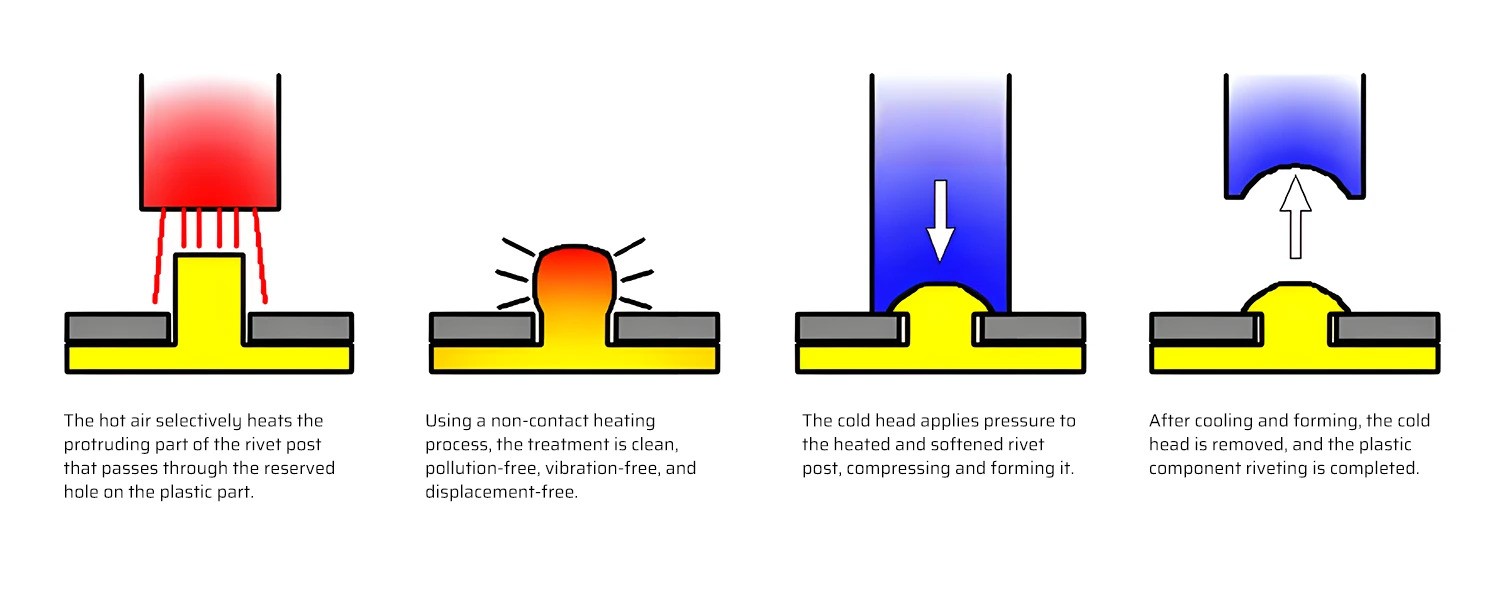

Zafi iska riveting (iska mai zafi mai sanyi)

Iska mai zafi riveting tsari ne na lamba. Yana amfani da iska mai zafi zuwa zafi da kuma taushi shafi rivumn call. Sannan, wani sanyi mai sanyi da aka samu yana farawa kuma yana siffata shi.

Tsarin yana da matakai biyu:

Hajewa: iska mai zafi tana ɗaukar nauyin rivet na rivet har sai da shi ne masarautar.

Sanyaya: Kaya mai sanyi da aka yiwa alama ta firamare shafi mai laushi, tana haifar da shugaban.

Abvantbuwan amfãni:

Aure-dumake yana rage damuwa na ciki

Cold Riveting kai da sauri ya cika gibba, cimma kyakkyawan sakamako mai gyara

Rashin daidaituwa:

A iska mai zafi Riving da ya dace da mafi yawan kayan aikin thermoplastic da robobi masu karfafa gilashi.

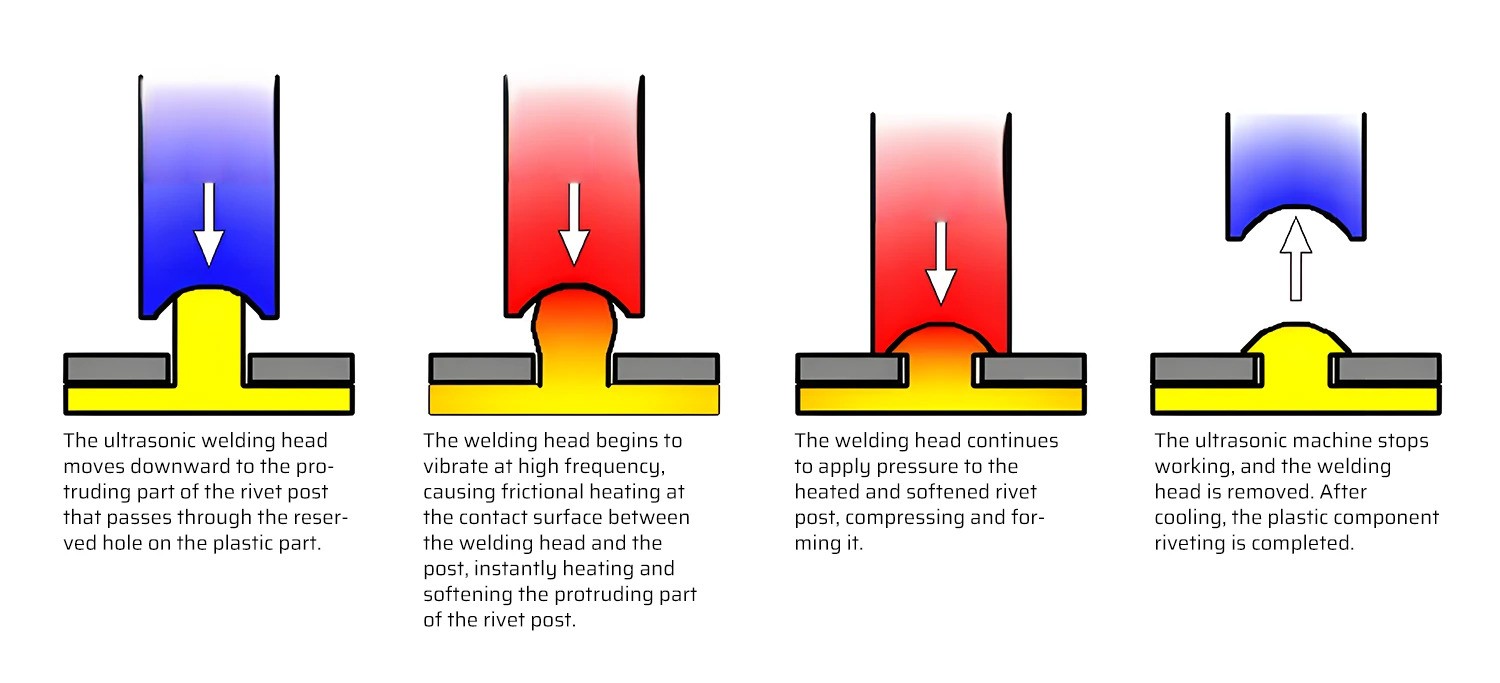

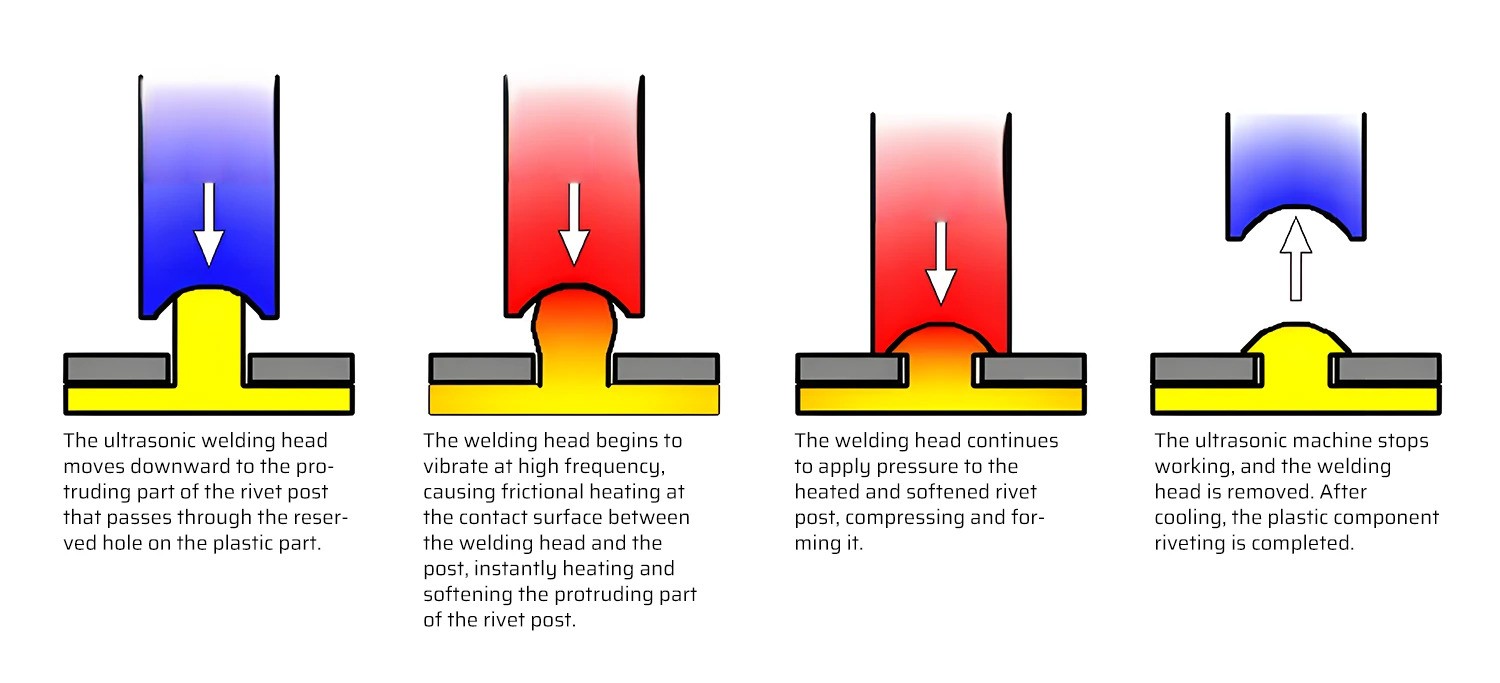

Ultrasonic Riveting

Ultrasonic Riveting wani nau'in tsari ne mai lamba. Yana amfani da matsanancin ƙarfi don samar da zafi da narke cikin shafi rivum na ruwa.

Abvantbuwan amfãni:

Rashin daidaituwa:

Rashin dumama na iya haifar da sako-sako ko lalata

Iyakar abin da ya ɓata idan kuma ta amfani da shugaban welding guda

Girgizawa na iya lalata abubuwan da aka lalata zuwa wani gwargwado

Ultrasonic Riveting bai dace da kayan Fiber na Fiber ko waɗanda ke da maki Melting ba.

Ga kwatancen tebur na tafiyar hawa uku:

| aiwatar | da dumama hanyar | riveting mai ƙarfi mai ƙarfi | yana gyara gyara yanayin aiki | mai saurin | gyara kayan aiki |

| Narke zafi | Tuntuɓi (M Karfe) | Ba abin dogaro ba, kula da girgizawa | Rashin nasara saboda cikakkiyar sifta | 6-60s | Hade, hadaddun canji |

| Iska mai zafi | Ba a kira lamba ba (iska mai zafi) | High, ba kula da girgizawa | Madalla da cikakkiyar gibba | 8-12s | Daidaitacce dumama da riveting |

| Na Ultrasonic | Tuntuɓi (rawar jiki) | Wanda ba a iya dogara ba | Rashin nasara saboda cikakkiyar sifta | <5s | Iyakance iko tare da hade kai |

Nau'in rivet na yau da kullun don sassan filastik

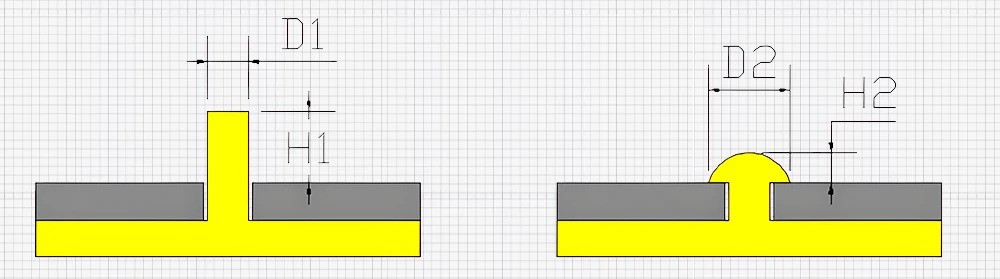

Idan ya zo ga riveting filastik, lissafi da kuma girman shugabannin rivet suna da mahimmanci. Bari mu kalli wasu nau'ikan yau da kullun.

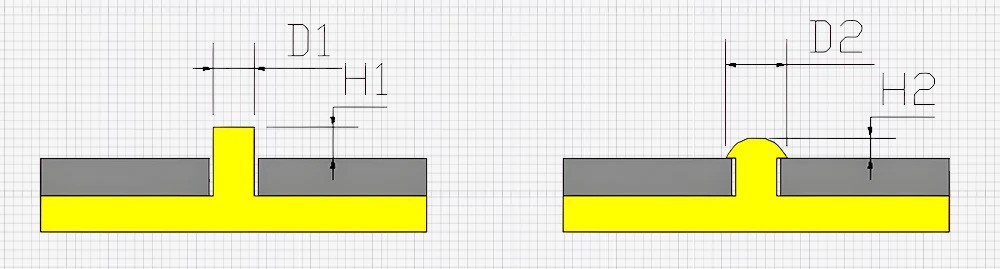

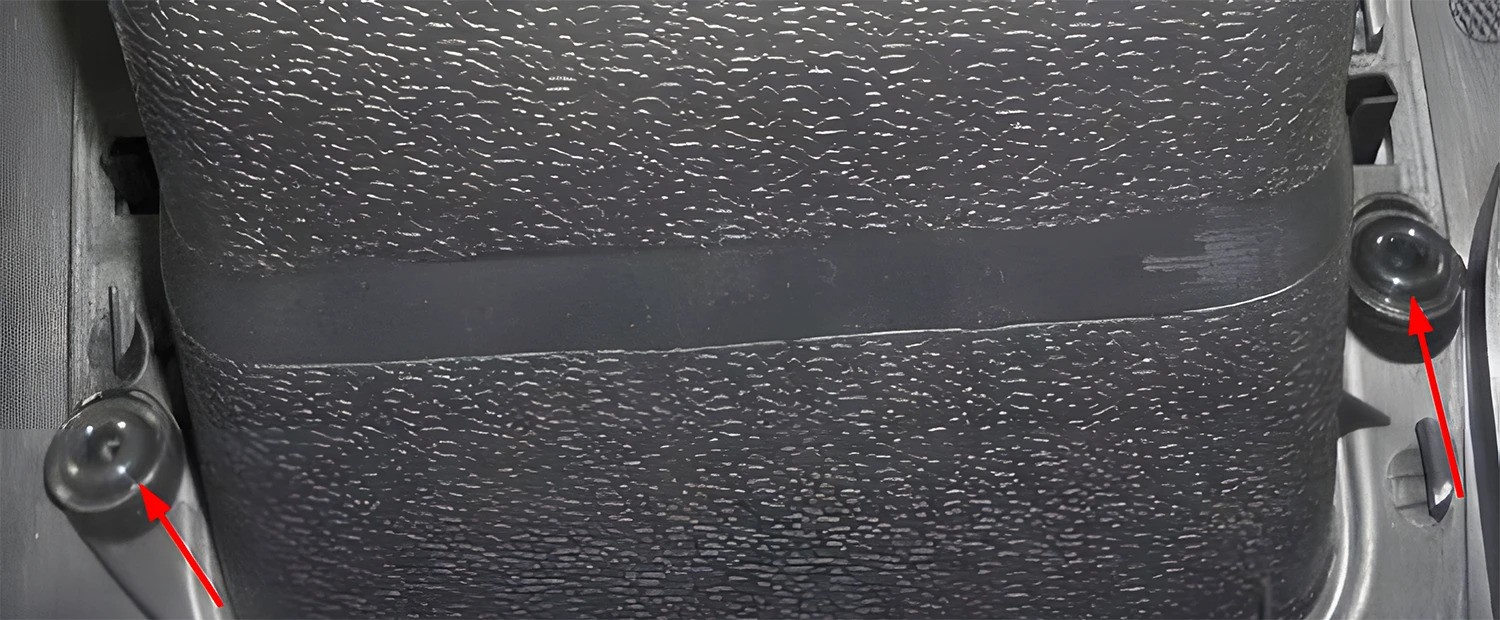

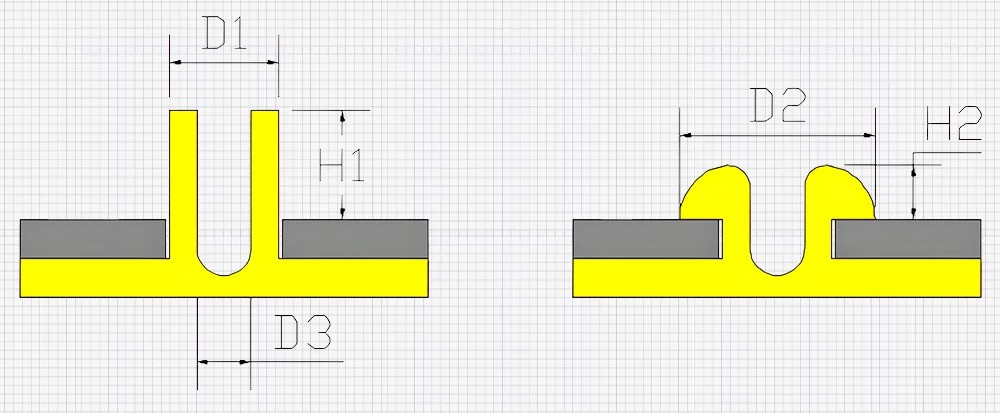

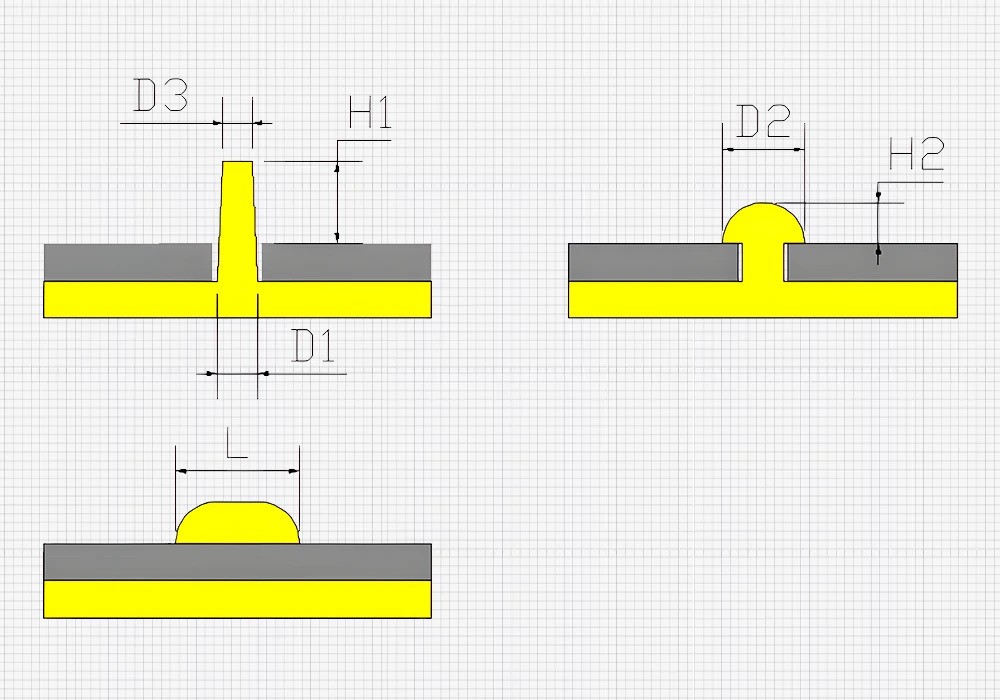

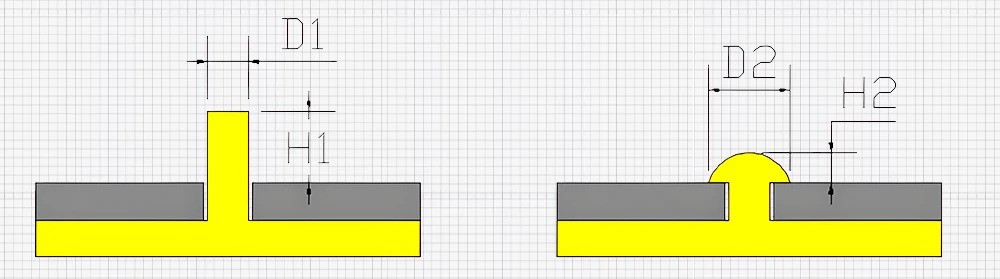

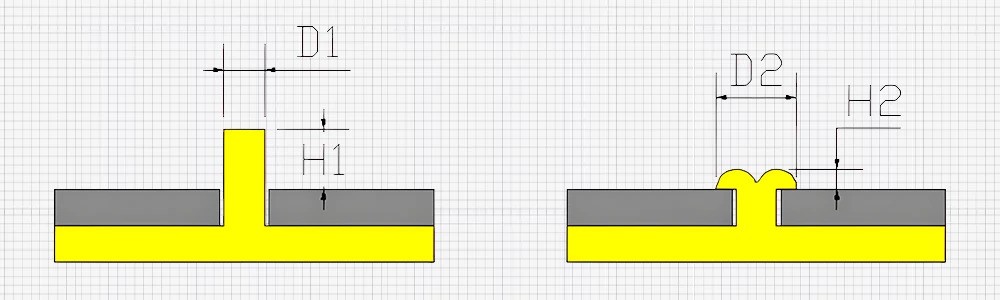

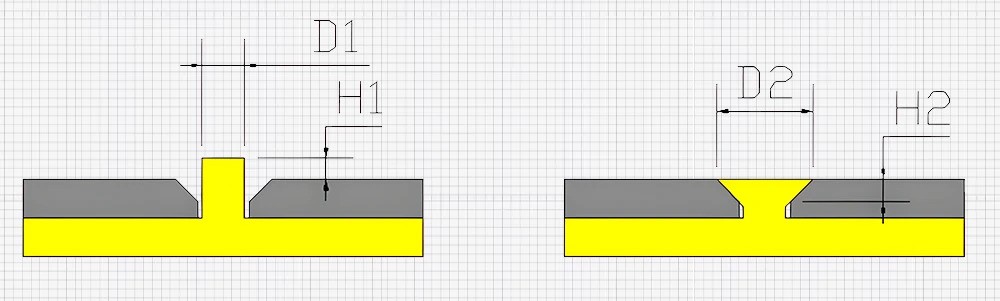

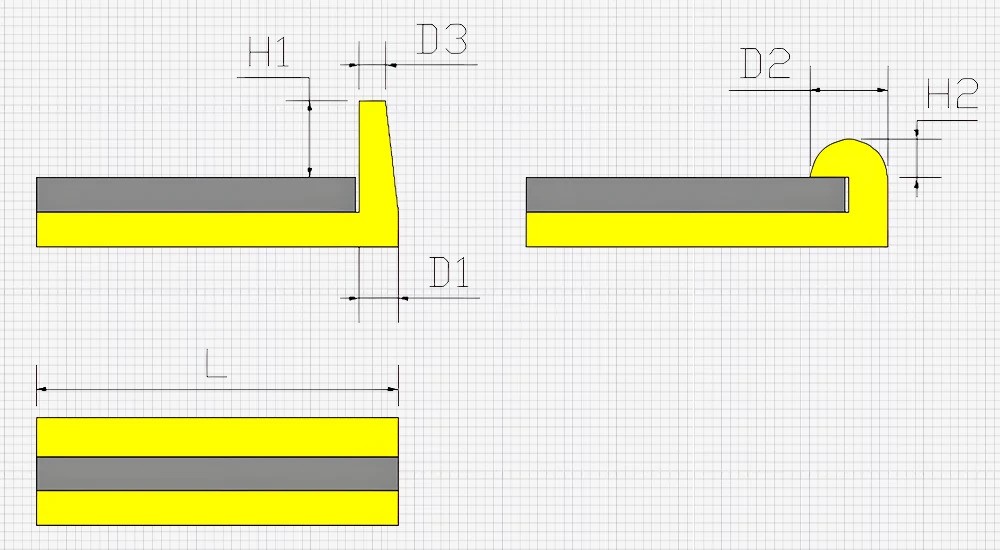

1. Semi-madauwari rivet kai (babban bayanin martaba)

Wannan shine nau'in yau da kullun. Ana amfani da shi lokacin da ba a buƙatar ƙarfin ƙarfi ba, kamar a cikin kwararru ko sassan ado.

Mabuɗin Key:

Ya dace da ginshiƙan rivet tare da D1 <3mm (formally> 1mmm don hana fashewa)

H1 gabaɗaya (1.5-1.75) * D1

D2 yana kusa da 2 D1, H2 kusan 0.75 D1

Takamaiman lambobi dangane da juzu'i na girma: S_HEUHEHED = (85% -95%) * S_Column

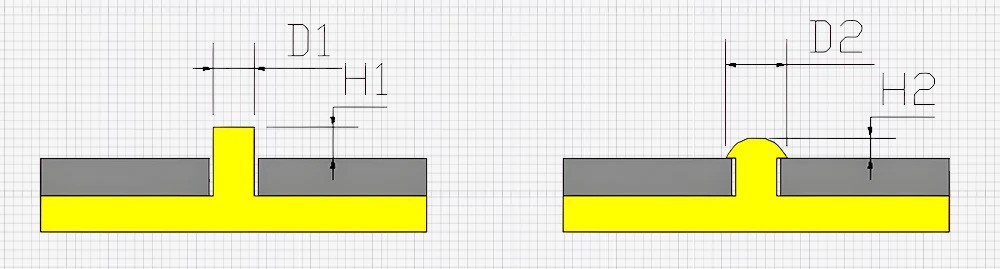

2. Semi-madauwari rivet kai (karamin bayanin martaba)

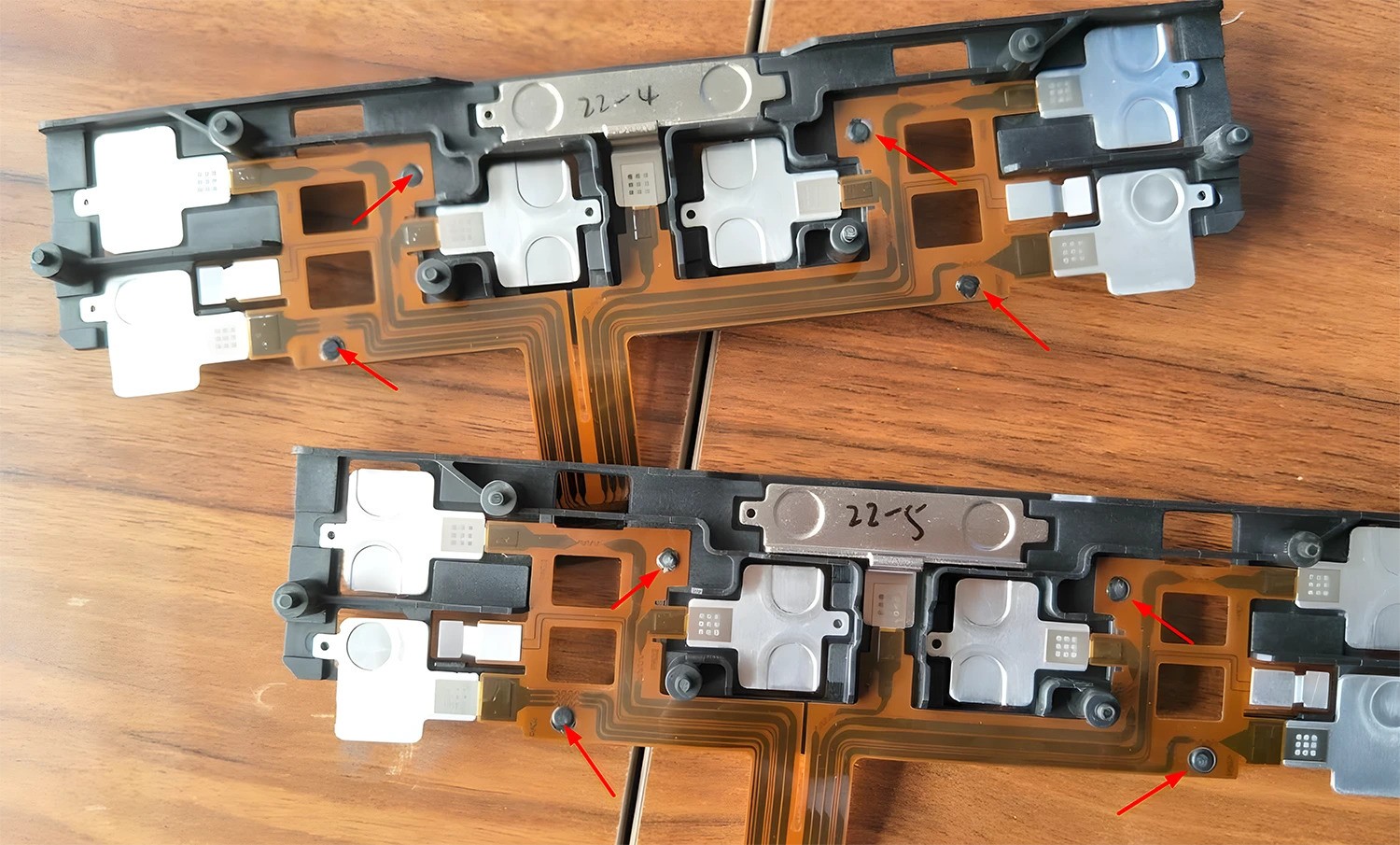

Wannan nau'in yana da ɗan gajeren lokaci fiye da babban bayanin martaba. Hakanan don aikace-aikacen ƙaranci, kamar igiyoyin FPC ko maɓuɓɓugan ƙarfe.

Matsayi na Tsara:

D1 <3mm, zai fi dacewa> 1mm

H1 kullum 1.0 * D1

D2 kusan 1.5 D1, H2 yana kusa da 0.5 D1

Canje-canje: S_Head = (85% -95%) * S_Column

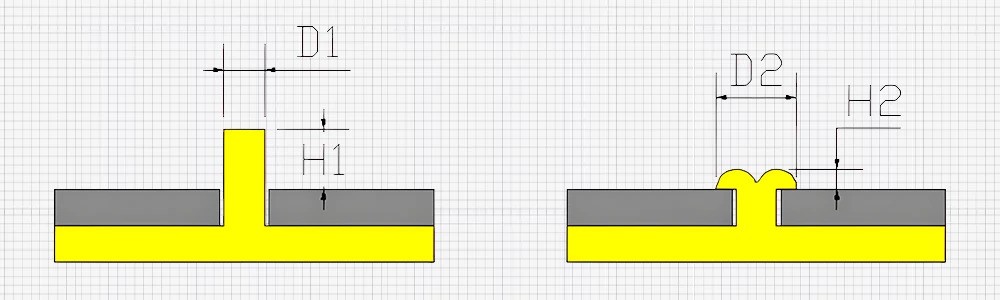

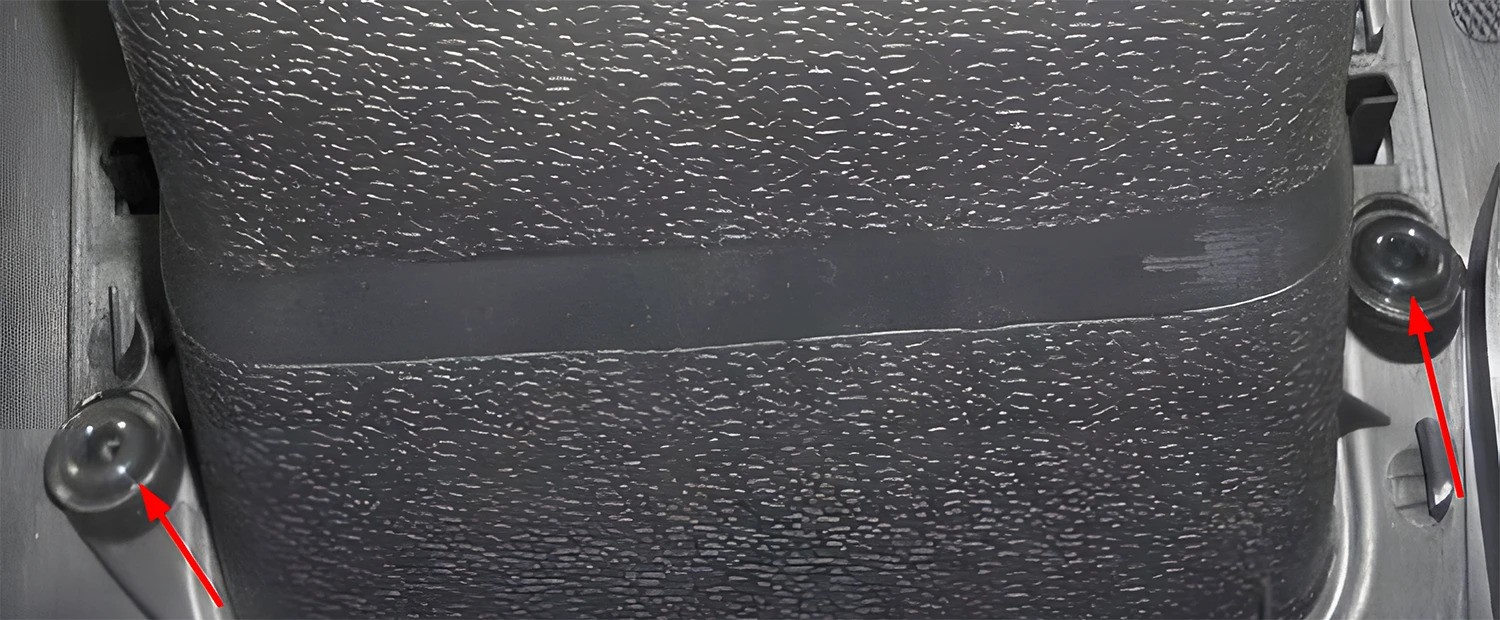

3. Biyu semi-madauwari rivet kai

Gashin rivet anan sun fi girma girma fiye da nau'in madaukaki. Wannan ƙirar ta takaice lokacin Ruwa da Inganta sakamako. Ana amfani da shi lokacin da ake buƙatar ƙarfi mafi girma.

Mabuɗin Key:

Ya dace da ginshiƙan rivet tare da D1 tsakanin 2-5mm

H1 yawanci 1.5 * D1

D2 kusan 2 D1, H2 yana kusa da 0.5 D1

Canje-canje na girma ya shafi

Rajiyayyen shafi na Rivet da Mold Raving Head

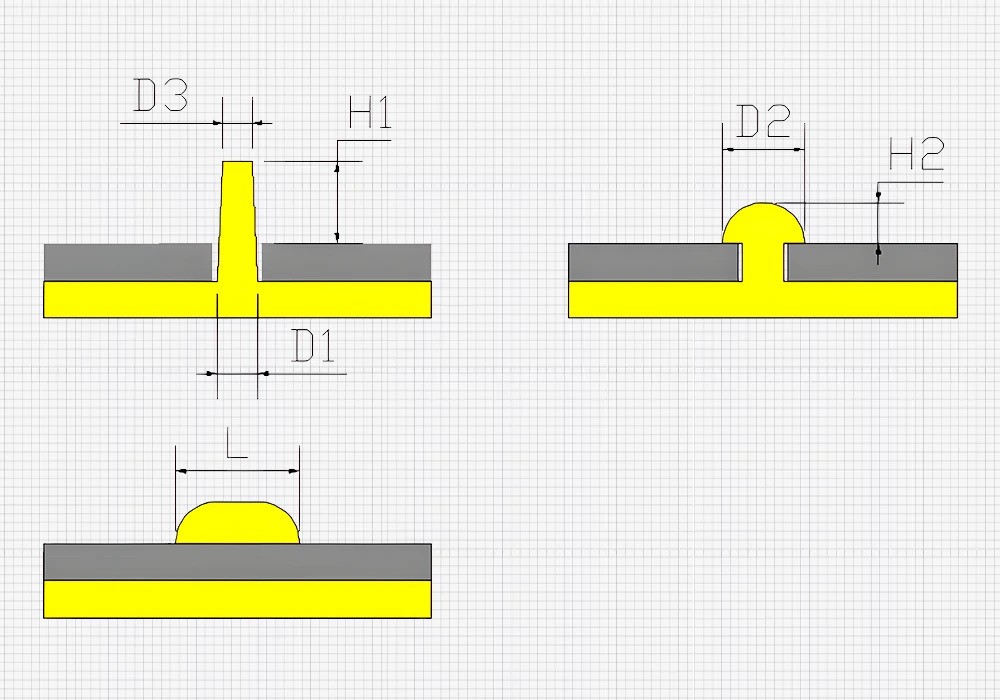

4. Shawar Rabuwa

Kamar yadda rivet shafi diamita yana ƙaruwa, ana amfani da m ginshiƙan. Sun gajartar lokacin riveting, inganta sakamako, kuma hana lahani lahani. Wannan nau'in shine don aikace-aikacen da ke buƙatar mafi girman ƙarfi.

Halaye:

D1> 5mm

H1 shine (0.5-1.5) * D1, karancin darajar diamita mafi girma

Inner d shine 0.5 * D1 don guje wa baya

D2 yana kusa da 1.5 D1, H2 shine kusan 0.5 D1

Canje-canje na girma ya shafi

Ko da dumama na m ginshiƙan yana taimakawa kan hanyoyin da suka cancanta

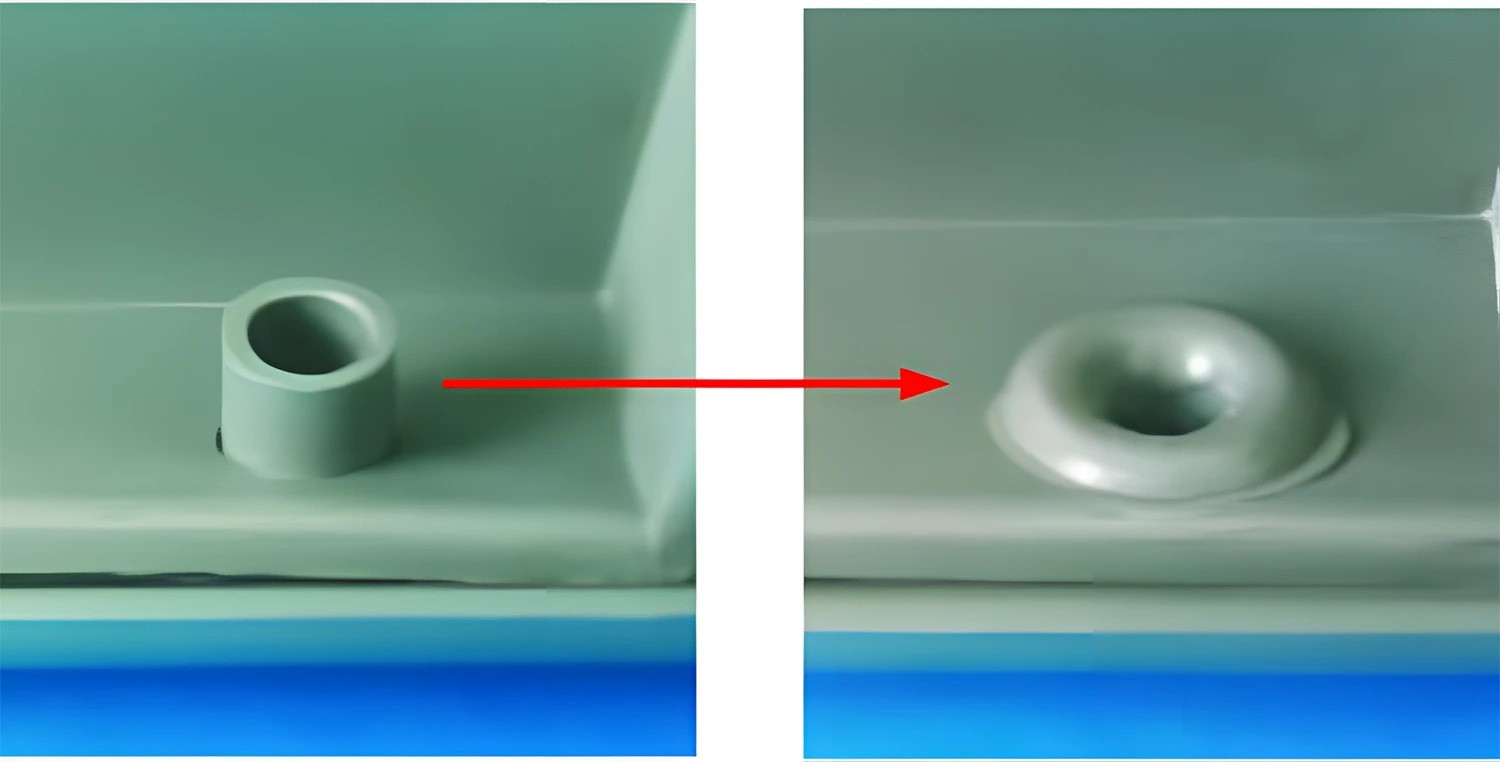

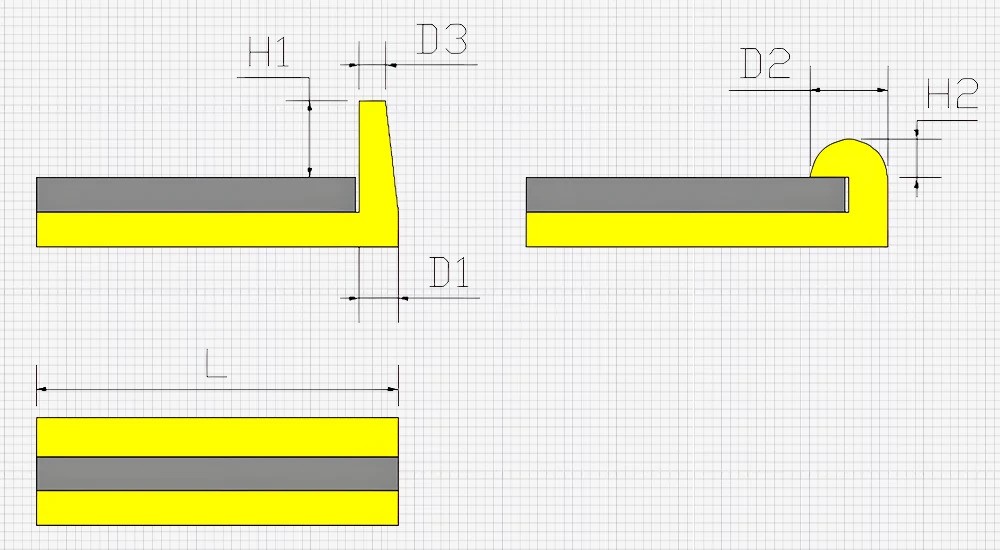

5. Lebur rivet kai

Litattafan lebur sun dace lokacin da kafa ya kamata bai kamata ya fito daga farfajiya ba.

Na'urar zane:

D1 <3mm

H1 yawanci 0.5 * D1

D2 da H2 dangane da juyawa girma

Bangare da aka haɗa yana buƙatar isasshen kauri don countering

Rashin isasshen kauri yana haifar da haɗin da ba za'a iya dogara da shi ba

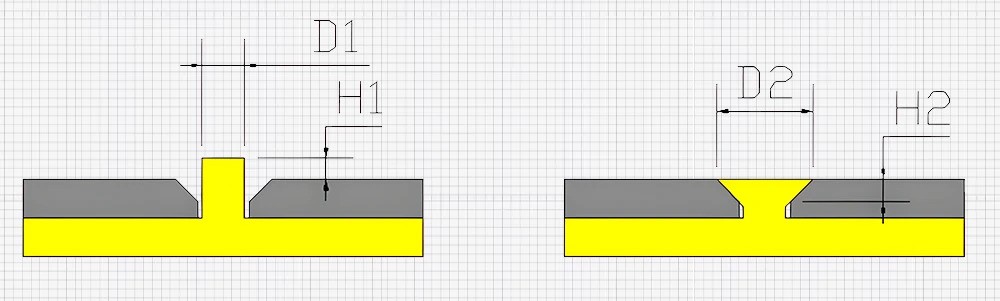

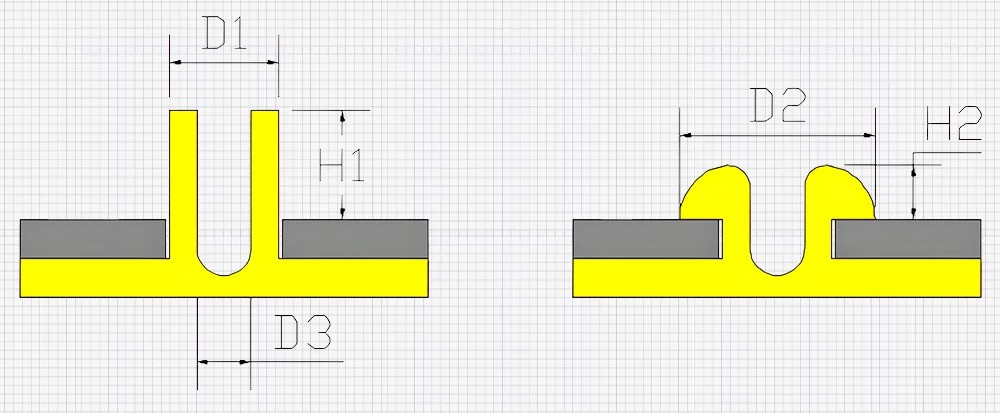

6. Ribbed Rivet kai

Yi amfani da shugabannin ribbed lokacin da kuke buƙatar mafi girma lamba yankin amma ba ku da sarari don m ginshifi.

Mabuɗin Key:

Tasirin tushe D1 <3mm, saman diamita D3 = (0.4-0.7) * D1

H1 shine (1.5-2) * D1, kasa da tsayin column l

D2 kusan 2 D1, H2 yana kusa da 1.0 D1

Canje-canje na girma ya shafi

7. Flanged Rivet Shugaban

Flanged shugabannin suna da kyau don masu haɗin da suna buƙatar aikata laifi ko rufewa.

Matsayi na Tsara:

Tasirin tushe D1 <3mm, saman diamita D3 = (0.3-0.5) * D1

H1 shine (1.5-2) * D1, kasa da tsayin shafi l

D2 yawanci 2 D1, H2 kusan 1.0 d1

Canje-canje na girma ya shafi

Tsarin ƙira don ginshiƙan rivet da kuma shugabannin rivt

A lokacin da ke zayyana kayan rivet da kawuna, akwai dalilai da yawa da yawa don kiyayewa. Bari mu bincika su daki-daki.

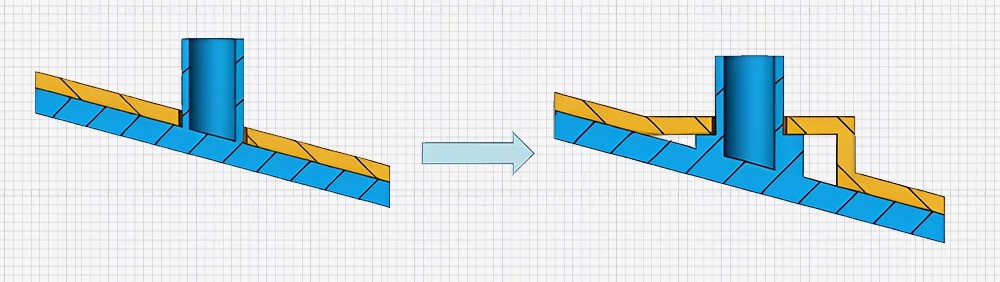

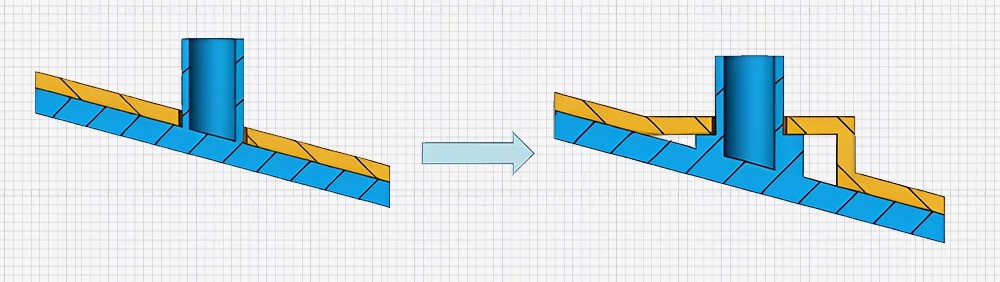

Tsara kayan kwalliyar rivet a saman saman ko nesa daga tushe

Idan shafi rivet yana kan jirgin sama mai karkata ko nesa daga gindin tushe, ana buƙatar ƙirar musamman ta musamman. Ga hanyoyi guda biyu:

Hanyar Tsara don ginshiƙan rivet a saman saman

Don karkatar da abubuwa, shafi rivet ya kamata ya zama perpendicular zuwa farfajiya. Wannan yana tabbatar da daidaituwa sosai kuma amintaccen sauri.

Hanyar Design Design Shafukan Rivet a sama da tushe

Lokacin da shafi ya fi girma sama da tushe, ƙara tsarin tallafi yana da mahimmanci. Suna hana awo ko kuma hutu yayin riveting.

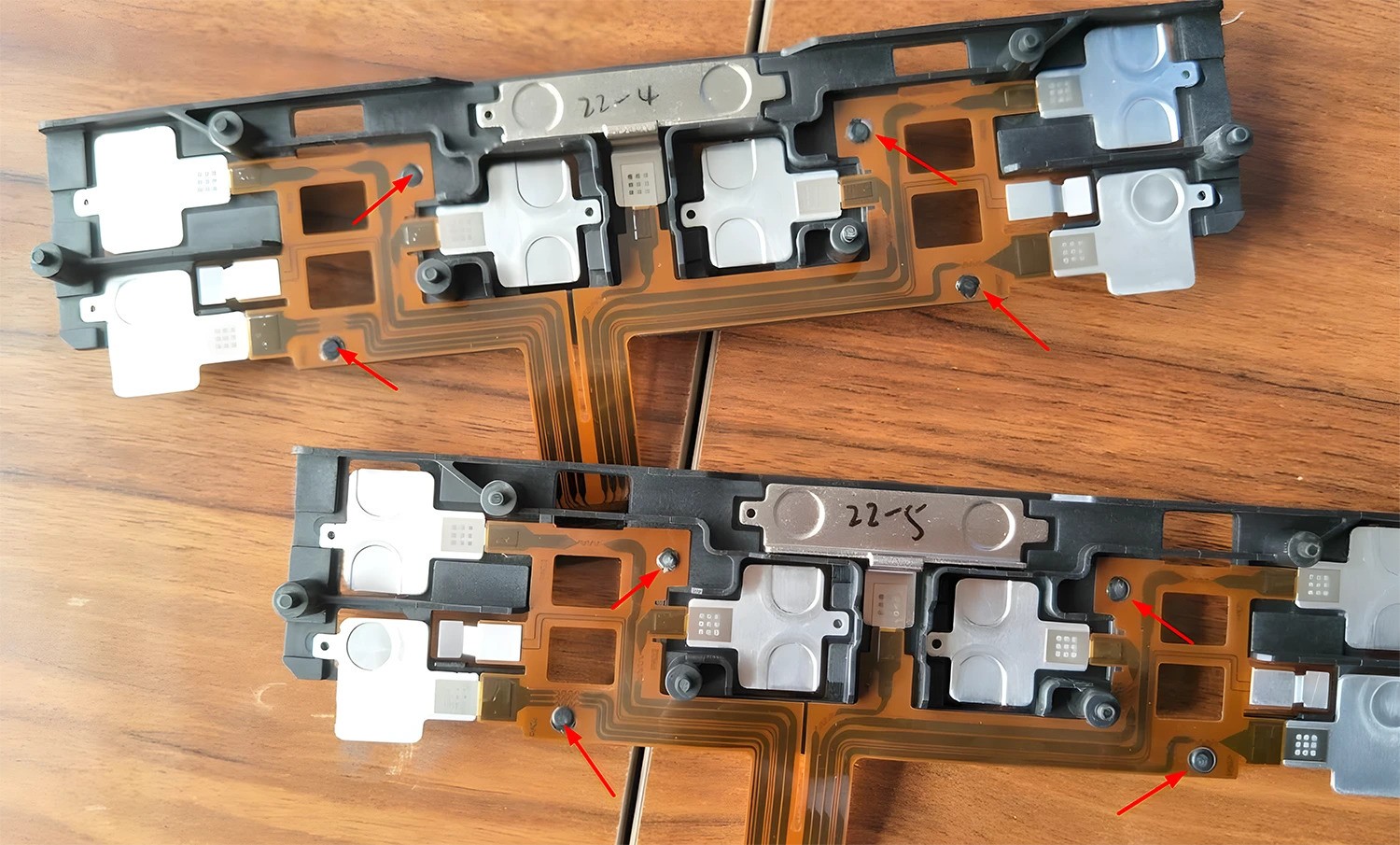

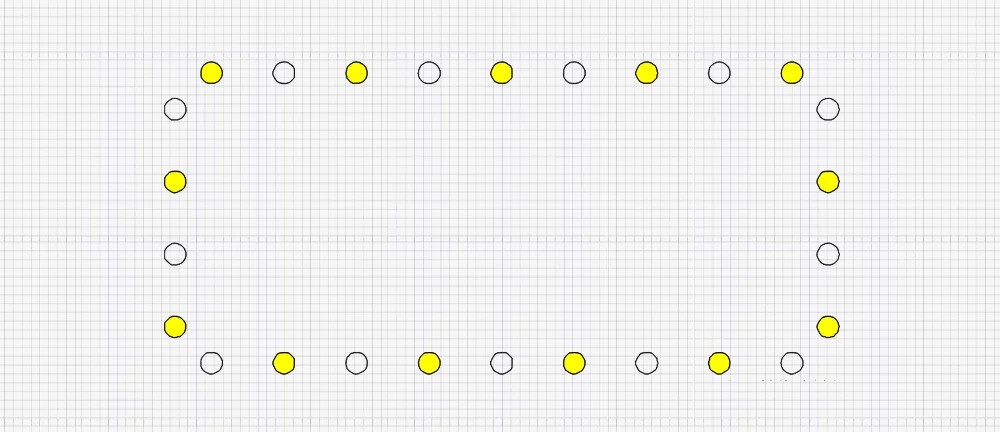

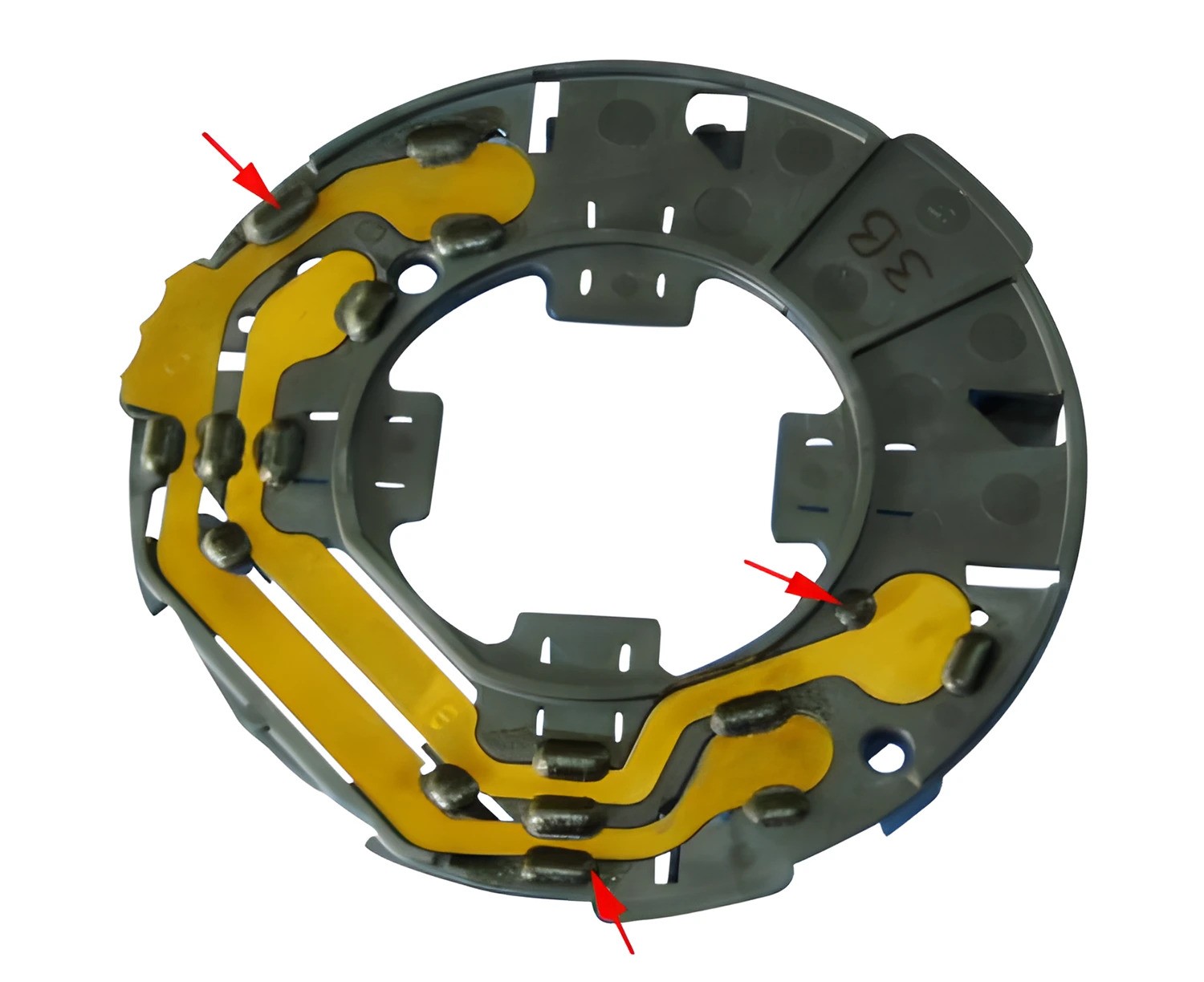

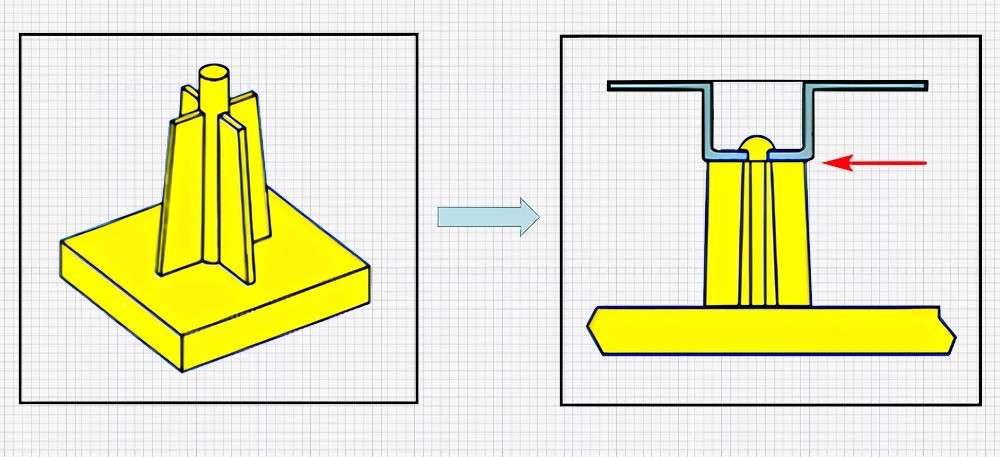

Muhimmancin ƙirar ƙira

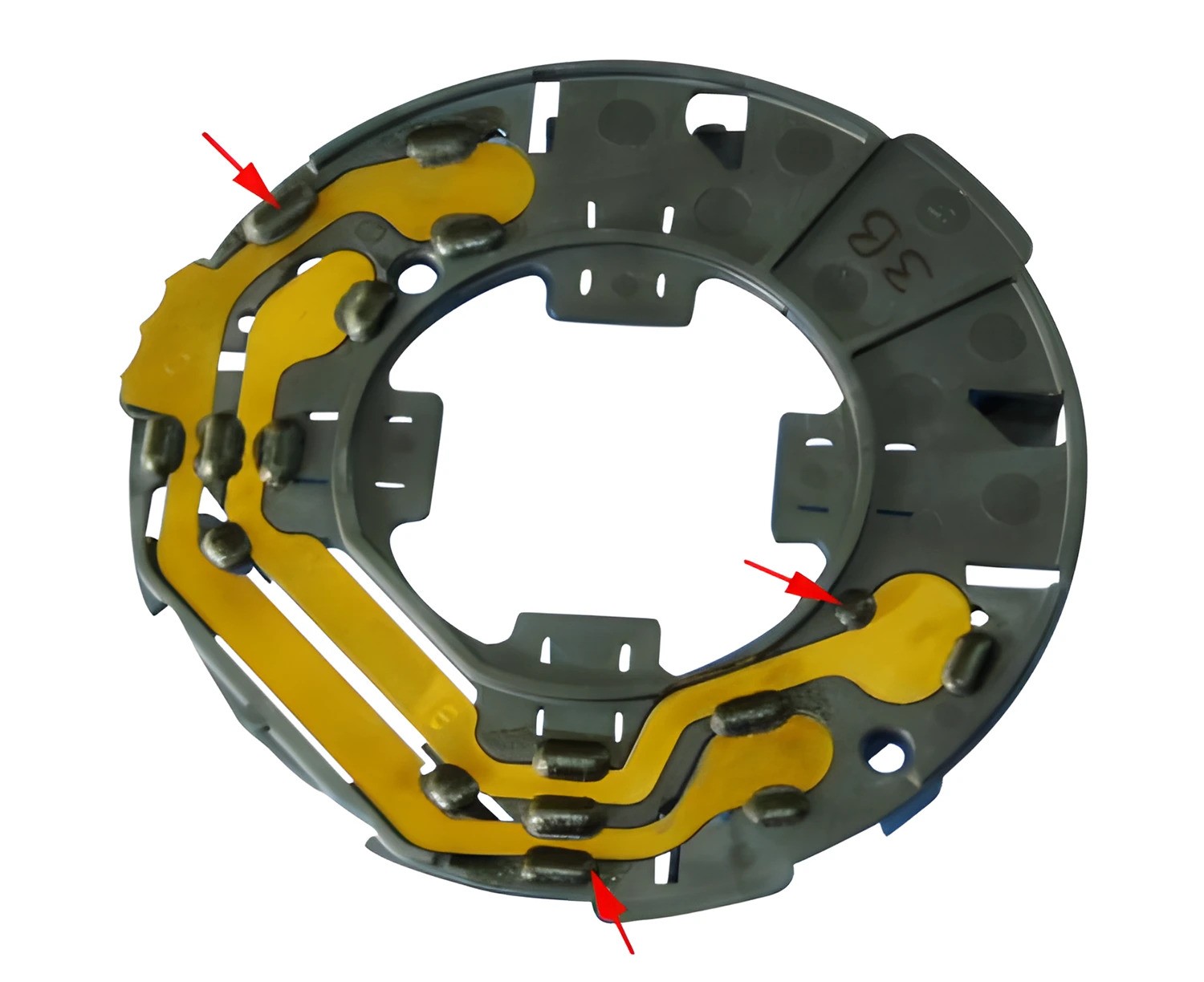

Murmushi na filastik yana haifar da haɗi na dindindin waɗanda ke da wuyar gyara idan sun kasa. Hada Rednarcy a cikin zane yana da mahimmanci.

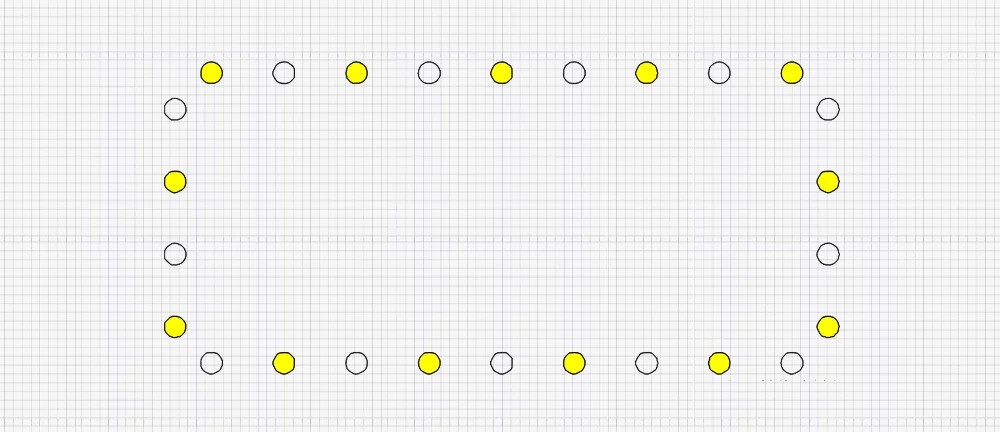

Hanya ɗaya tana sauƙaƙe adadin ginshiƙan rivet da ramuka. Da farko, kawai farkon saiti (misali, rawaya). Idan ana buƙatar gyara, sakandare na sakandare (misali, fari) yana ba da madadin.

Wannan sabuntawar tana baka dama ta biyu a gyara, kara yawan dogaro da yankin da aka yi.

Dangantaka tsakanin rivet shugaban da shafi na shafi

Girman girman kai da shafi suna da alaƙa da juna. Anan akwai wasu mahimman alaƙa don la'akari:

REVET kai diamita (D2) gabaɗaya yana kusan sau 2 da keɓaɓɓu na diamita (D1)

REVET Shugaban Heigh (H2) yawanci yana kusan 0.75 sau D1 don manyan semi-madauwari shugabannin, da sau 0.5 d1 don karamin semi-madauwaci

Adadin girman ya kamata ya dogara da juyawa na girma: S_Head = (85% -95%) * S_Column

Canjin ƙara yana tabbatar da cewa shugaban rivet yana da isasshen kayan da zai samar da ƙarfi, haɗi mai tsaro ba tare da sharar gida ba.

Abubuwan da suka dace na kayan aikin filastik

Ba dukkanin farhohi sun dace da riveting ba. Bari mu bincika abubuwan mabuɗin da ke tantance daidaiton abu.

Thermoplastics vs. thermosets

Thermoplastics iya narke kuma a sake yin tsayayya da takamaiman kewayon zafin jiki. Suna da kyau don riveting.

Sabanin haka, thermosets harden dindindin lokacin da mai zafi. Suna da wuyar rivet ta amfani da daidaitattun hanyoyin.

Saboda haka, tsarin samfuran sau da yawa ya ƙunshi thermoplastics lokacin da ake buƙatar Riveting.

Amorutan vs. Semi-Crystalline

An kara rarrabe thermoplastics zuwa amorphous da kuma nau'ikan crystalline. Kowannensu yana da halaye na musamman waɗanda ke shafar riveting.

Amorphous (ba crystalline) robobi

Rashin Tsarin kwayoyin halitta

Sannu a hankali da kyau da narke a zazzage canjin zafin jiki (tg)

Ya dace da duk shirye-shiryen riving guda uku (narke mai zafi, iska mai zafi, ultrasonic)

Jawabin Semi-Cryalline

Da umarnin kwayoyin halitta

Bambanta melting maki (TM) da kuma recrystallization aya

Kasance mai kai tsaye har sai an rage maki melting, sannan ka inganta lokacin da aka sanyaya

Mafi dacewa ga narkewar narke saboda haduwa da dumama da kuma forming

Tsarin bazara na yau da kullun-kamar yana ɗaukar ƙarfin ultrasonic, yin ultrasonic riving maƙullin

Manyan maki Melting suna buƙatar ƙarin makamashi na ultrasonic don narke

Darajar da ake buƙata na ƙira da ake buƙata don riveting na ultrasonic (amplitude mafi girma, ƙirar haɗin gwiwa, walda adireshin kai, nesa, gyarawa)

Rage lamba na farko tsakanin shafi rivet sama da walda don mai da hankali da ƙarfi

Tasiri na FLMER (misali, Fibers Gilashin)

FLERS na iya shafar aikin kayan kwalliyar filastik. Bari mu kalli finafinan gilashi a matsayin misali.

Mabuɗin Key:

Babban bambanci a cikin Melting maki tsakanin filastik da gilashi

Daidaita Yankara: Daidai Ingancin Zazzabi (± 10 °)

Babban yanayin zafi yana haifar da hazo na gilashi, m, da m saman

Low yanayin zafi yana haifar da fasa da sanyi tsari

Ultrasonic Riveting: Maɗa ƙarfin ƙarfin rawar jiki da ake buƙata don narke filastik

Jagorori Mai Sauti:

Sauran kaddarorin kayan da suka shafi riving na ultrasonic:

Hardness: Hardness mafi girma gabaɗaya yana inganta riveting

Maɗaukaki Batun: Matsayin Melting yana buƙatar ƙarin makamashi ultrasonic

Tsarkakewa: Girma mai girma yana inganta riveting, yayin da immurities a cikin kayan da aka sake amfani dashi rage aiki

Kayan filastik da aka yi amfani da su a cikin riveting

Zabi kayan filastik na dama yana da mahimmanci ga riveting riveting. Bari mu kusanci wasu zaɓuɓɓukan gama gari.

Lowerarancin polyethylene (LDPE)

LDPE yana da ƙarancin yawa saboda tsarin kwayoyin halitta. Yana da sassauƙa duk da haka mai tauri.

Mabuɗin Key:

Polypropylene (PP)

Anyi amfani da PP sosai a kan masana'antu, daga kayan aiki don ɗaukar hoto. Yana ba da kyawawan juriya da sunadarai da kuma rufin wutar lantarki.

Aikace-aikace:

Jirgin ruwa da kayan wanka

Namiji / Mace Ratchet Rivets

Snap-a cikin saman rivets

FIR Tree Rivets

Nail

Nailan, musamman nailon 6/6, shahararren ne a masana'antu. Jaradancinsa yana sa ya dace da goron garshe da abubuwan ɗauka.

Halaye:

Ya sake fitar da manyan sunadarai, amma ana iya kawo shi da ƙarfi acid, giya, da alkalis

Rashin jure rashin tsirar acid, kyakkyawan juriya ga mai da cokali

An yi amfani da shi don Snap Rivets, rivets rivets, da kuma turawa-a Knob kai rivets

Acetal (polyoxymethylene, pom)

Acetal, ko pom, mai ƙarfi, m, da tsayayya wa danshi, zafi, sinadarai, da kuma somals, da magunguna. Yana da kaddarorin rufin lantarki na lantarki.

Amfani:

Ganuwa, bushings, kofar kofar mota

Kwata-kwata juye da sauri

Kwatanni 'yan wasan

Snap-a cikin saman rivets

Polysulfone (PSU)

Ana amfani da PSU a aikace-aikace na musamman saboda babban ƙarfinsa da injin din.

Abubuwan da ke cikin Key:

Kyakkyawan juriya

Amfani da shi a Fasaha Fasaha, Magana, sarrafa abinci, da wutan lantarki

Ya dace da raruwar rivets

Kwatanta kaddarorin kayan

Ga tebur kwatanta kaddarorin waɗannan kayan:

| kaddarorin | LDPE | PP | Na'anar 6/6 | Acetal | PSU |

| Tenarfin tensile (PSI) | 1,400 | 3,800-5,400 | 12,400 | 9,800-10,000 | 10,200 |

| Tasiri taama (J / M⊃2;) | Babu hutu | 12.5-1.2 | 1.2 | 1.0-1.5 | 1.3 |

| Illecric Interricar (KV / MM) | 16-28 | 20-28 | 20-30 | 13.8-20 | 15-10 |

| Density (g / cm³) | 0.917-0.940 | 0.900-0.910 | 1.130-1.150 | 1.410-1.420 | 1.240-1.250 |

| Max. Ci gaba da sabis na Temple. | 212 ° F (100 ° C) | 266 ° F (130 ° C) | 284 ° F (140 ° C) | 221 ° F (105 ° C) | 356 ° F (180 ° C) |

| Rufin thermal (w / m un) | 0.320-0.350 | 0.150-0.210 | 0.250-0.2.2550 | 0.310-0.370 | 0.120-0.22660 |

Ka tuna da cewa ƙari da kayan kwalliya na iya haɓaka wasu kaddarorin. Misali, mai karu na ruwa na iya inganta aikin Nylon.

Yadda za a zabi madaidaicin madaidaicin rivet

Janar na babban yatsa

Hanya mai sauƙi ita ce ta kafa tushen rivet a kan kauri daga cikin faranti. Ga hukuncin babban yatsa:

Rivet diamita = 1/4 × plate kauri

Wannan rabo yana tabbatar da cewa rivet daidai gwargwado ga kayan yana riƙe tare. Hakanan an san shi da kewayon riko.

Abubuwa don la'akari

Duk da yake babban mulkin abu ne mai kyau na farawa, akwai wasu dalilai don kiyayewa:

Abubuwan kayan abu

Tsarin haɗin gwiwa

Nau'in haɗin gwiwa (lap, butt, da sauransu)

Loading yanayin (Shear, tashin hankali, da sauransu)

Maganin ado

Tsarin taro

Waɗannan dalilai na iya tasiri mafi kyawun rivet. A wasu halaye, kuna iya buƙatar karkace daga jiyya ta gaba ɗaya don cimma sakamako mafi kyau.

Misalai da lissafi

Bari mu kalli wasu 'yan misalai don ba da misalin tsarin sizing.

Misali 1:

Misali na 2:

Plate kauri: 10 mm

Rivet diamita = 1/4 × 10 mm = 2.5 mm

Zagaye har zuwa daidaitaccen ma'auni, misali, 3 mm

Misali 3:

Plate kauri: 2 mm (faranti na bakin ciki)

Rivet diamita = 1/4 × 2 mm = 0.5 mm

Theara zuwa mafi ƙarancin girman m, misali, 1 mm, don sauƙi na shigarwa da ƙarfi

Ka tuna, waɗannan lissafin suna ba da farawa. Koyaushe yi la'akari da takamaiman buƙatun aikace-aikacen ku kuma yi gyare-gyare kamar yadda ake buƙata.

| Plate kauri (mm) | rivet diamita (mm) |

| 1-2 | 1 |

| 3-4 | 1-2 |

| 5-8 | 2-3 |

| 9-12 | 3-4 |

| 13-16 | 4-5 |

Ƙarshe

A cikin wannan jagorar, mun bincika hanyoyin riving daban-daban don sassan filastik, gami da narkewar zafi, iska mai zafi, da hanyoyin ultrasonic. Mun kuma tattauna nau'ikan jivet daban-daban da takamaiman aikace-aikacen su.

Zabi tsarin riveting na dama da kayan yana da mahimmanci don tabbatar da haɗi masu ƙarfi a cikin majalisun filastik. Zaɓin da ya dace na iya yin tasiri sosai da tsawon rai da aikin samfuran ku.

Yanzu da muke da wannan ilimin, muna ƙarfafa ku da ku yi amfani da waɗannan fahimta ga ayyukanku. Ta yin hakan, zaku tabbatar da mafi kyawun babban taro a cikin ayyukan masana'antar ku. Tuntube mu a yau !