Yala i delila k’i yɛrɛ ɲininka cogo min na plastiki yɔrɔw bɛ to ka siri ka ɲɛ ni juruw walima kola tɛ wa? Riveting bɛ fura dafalen di. Nin gafe in kɔnɔ, an bɛna plastiki riveting nafamaw sɛgɛsɛgɛ, a nafa ka bon izini suguya wɛrɛw la, ani fɛɛrɛ ɲuman sugandicogo. Aw bɛna plastiki yɔrɔw riveting ins ni outw dɔn ɲɔgɔndan barikamaw ni ɲɔgɔn cɛ minnu bɛ mɛn.

Plastiki riveting ye mun ye?

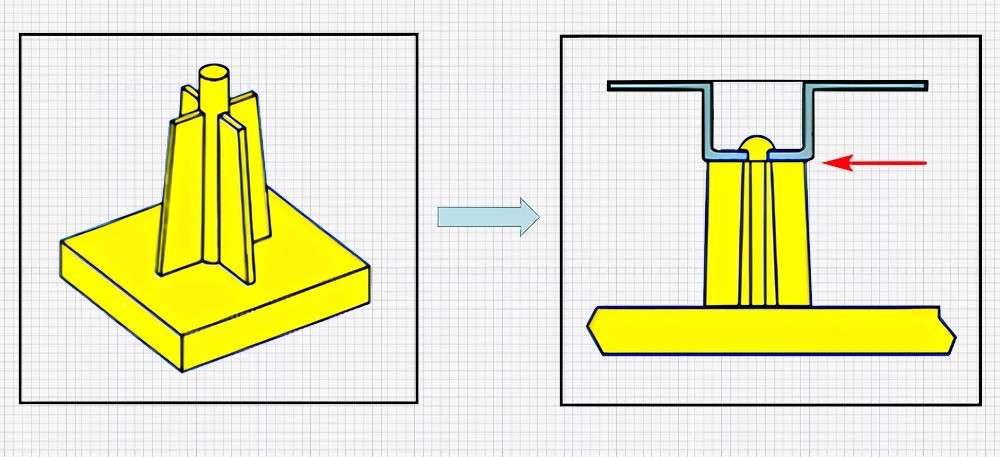

Plastiki riveting ye masinw siricogo ye. O ye ka baara kɛ ni fanga axiale ye walasa ka rivet dɔ ka shank (sɔgɔlan) sɔgɔ dingɛ kɔnɔ. O bɛ kɛ kunkolo ye, ka yɔrɔ caman siri ɲɔgɔn na.

Ni aw ye a suma ni nɛgɛ riveting ye, plastiki riveting bɛ danfara jɔnjɔn dɔw sɔrɔ. A tɛ rivets walima postes wɛrɛw wajibiya. O nɔ na, a bɛ baara kɛ ni plastiki fɛnw ye i n’a fɔ jɔw walima kɔkiliw. U ye plastiki farikolo yɔrɔ dɔ ye.

Nafa ni dɛsɛ bɛ plastiki riveting la .

Plastiki riveting nafa ni nafa caman bɛ a la. An ka a lajɛ kosɛbɛ.

Nafa minnu bɛ sɔrɔ ɲɔgɔn fɛ:

Yɔrɔ nɔgɔmanw sigicogo, ka dɔ bɔ nɔgɔ musakaw la .

A lajɛli ka nɔgɔn, a tɛ kɛ ni fɛn wɛrɛw ye walima a sirilanw mago tɛ .

dannayaba .

Ka rivet points multiple wherevately, ka baarakɛcogo ɲɛ ka ɲɛ .

A bɛ fara plastiki, nɛgɛ ani nɛgɛ tɛ yɔrɔ minnu na, hali yɔrɔ gɛlɛnw na .

A bɛ yɛrɛyɛrɛli kuntaalajan ni a cogoya juguw muɲu .

A ka nɔgɔn, a bɛ fanga tiɲɛ, a teliyalen don .

Sɛgɛsɛgɛli nɔgɔyalen ye yecogo ɲuman na .

Nafa minnu bɛ sɔrɔ tuma caman na:

A bɛ riveting minɛnw ni baarakɛminɛnw wɛrɛw de wajibiya .

A ma bɛn doni girinmanw ma walima doni kuntaalajanw ma .

Jɛɲɔgɔnya banbali, a tɛ se ka bɔ walima a bɛ se ka dilan .

A dilancogo ka gɛlɛn ni a ma ɲɛ .

A bɛ se ka kɛ ko a mago bɛ redundancy la design phase .

| Nafa | dɛsɛ . |

| sigicogo nɔgɔman, mɔli musaka dɔgɔyali . | A mago bɛ minɛn wɛrɛw ni baarakɛminɛnw na . |

| Lajɛ nɔgɔn, dannayaba . | A tɛ kɛ doni girinmanw walima doni kuntaalajanw ye . |

| A bɛ fɛn suguya caman fara ɲɔgɔn kan ka ɲɛ . | banbali, a tɛ se ka bɔ a la walima a bɛ se ka dilan . |

| A bɛ se ka yɛrɛyɛrɛ ni cogoya juguw muɲu . | A dilancogo ka gɛlɛn, a bɛ se ka kɛ ko a mago bɛ baara la . |

| Taabolo nɔgɔman, teliya, fanga-sɔrɔ-cogo . | - |

| Visual quality checks nɔgɔya . | - |

Plastiki riveting baarakɛcogo suguyaw .

Plastiki riveting kɛcogo suguya saba bɛ yen. U bɛ funteni riveting, fiɲɛ sumalen riveting, ani ultrasonic riveting.

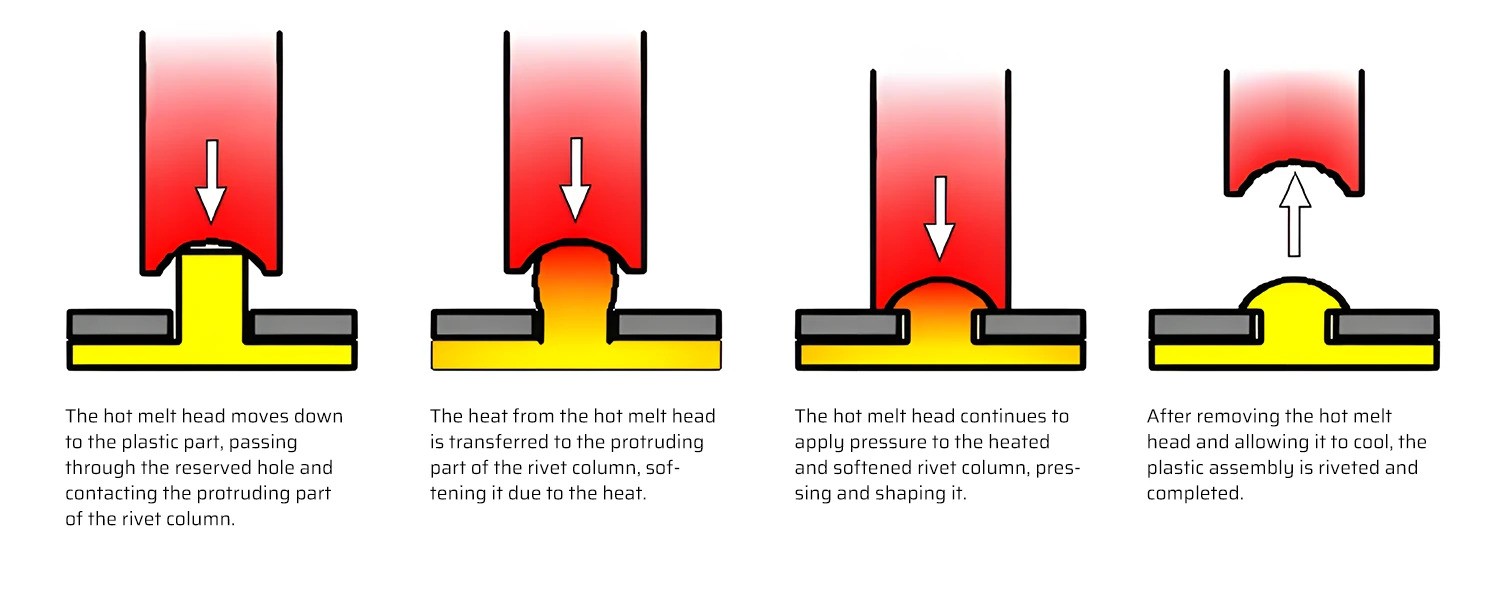

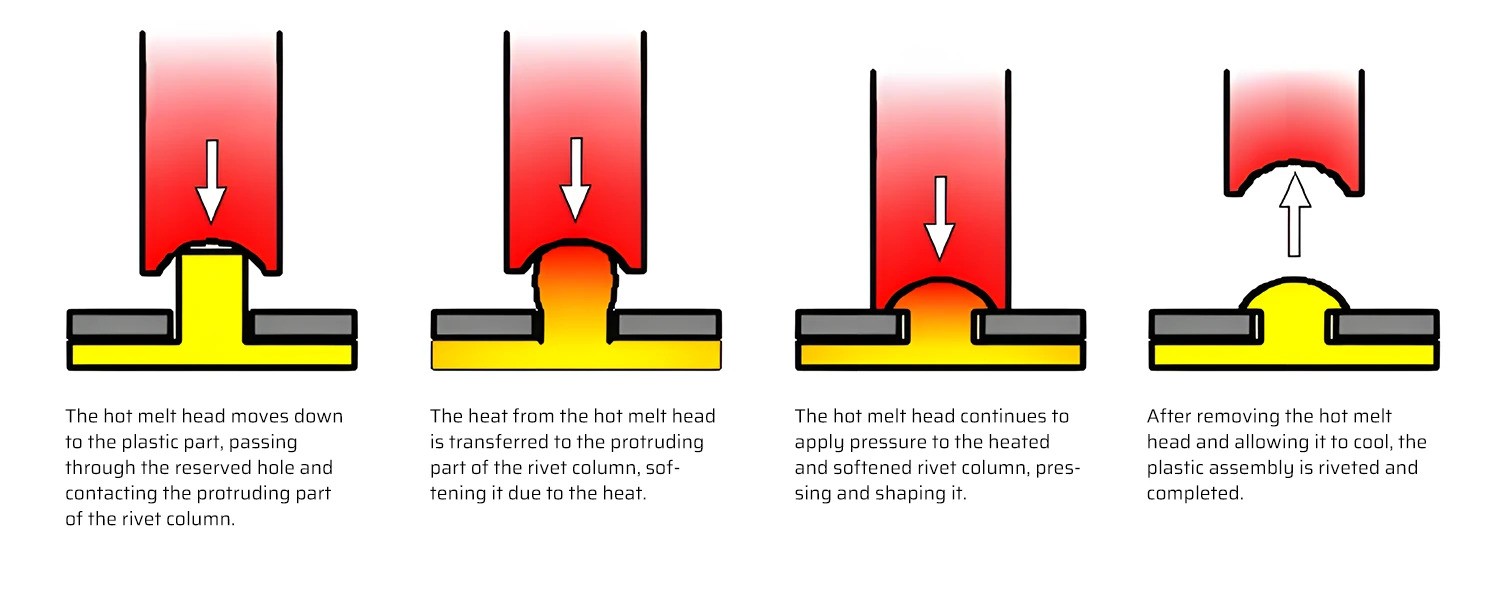

riveting rivé de la chaud .

Hot melt riveting ye contact-type process ye. A bɛ kɛ ni funteni-minɛn ye riveting head kɔnɔ. O bɛ nɛgɛ riveting kunkolo sumaya, o bɛ sɔrɔ ka plastiki rivet wuli k’a cogoya.

Nafaw:

Nafa minnu b’a la:

Nɛnɛko man ca, o bɛ se ka kɛ sababu ye ka plastiki nɔrɔ a kun na .

A ma bɛn rivet koloma belebelebaw ma .

Degun tolenba ani samali fanga dɔgɔyali .

A ma fɔ furaw ye minnu jɔyɔrɔ ka bon/labɛncogo la .

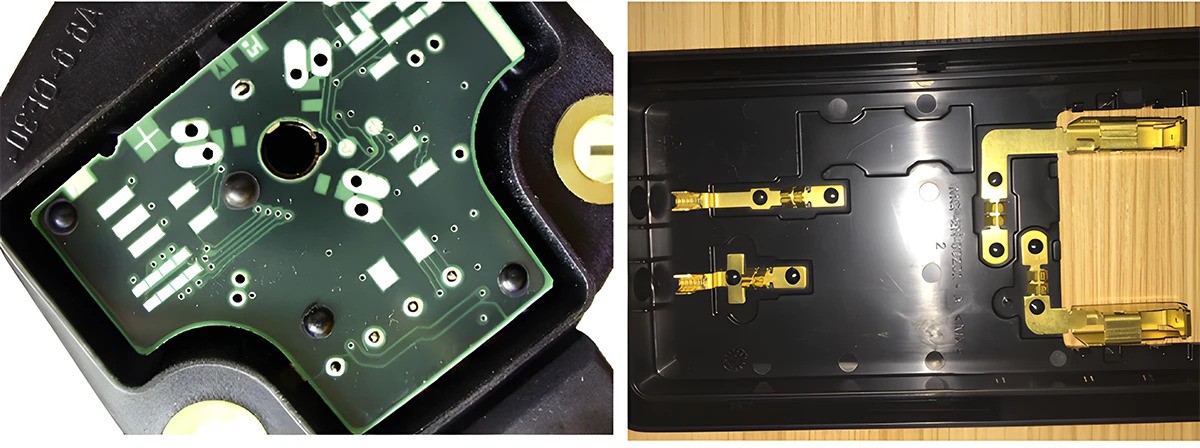

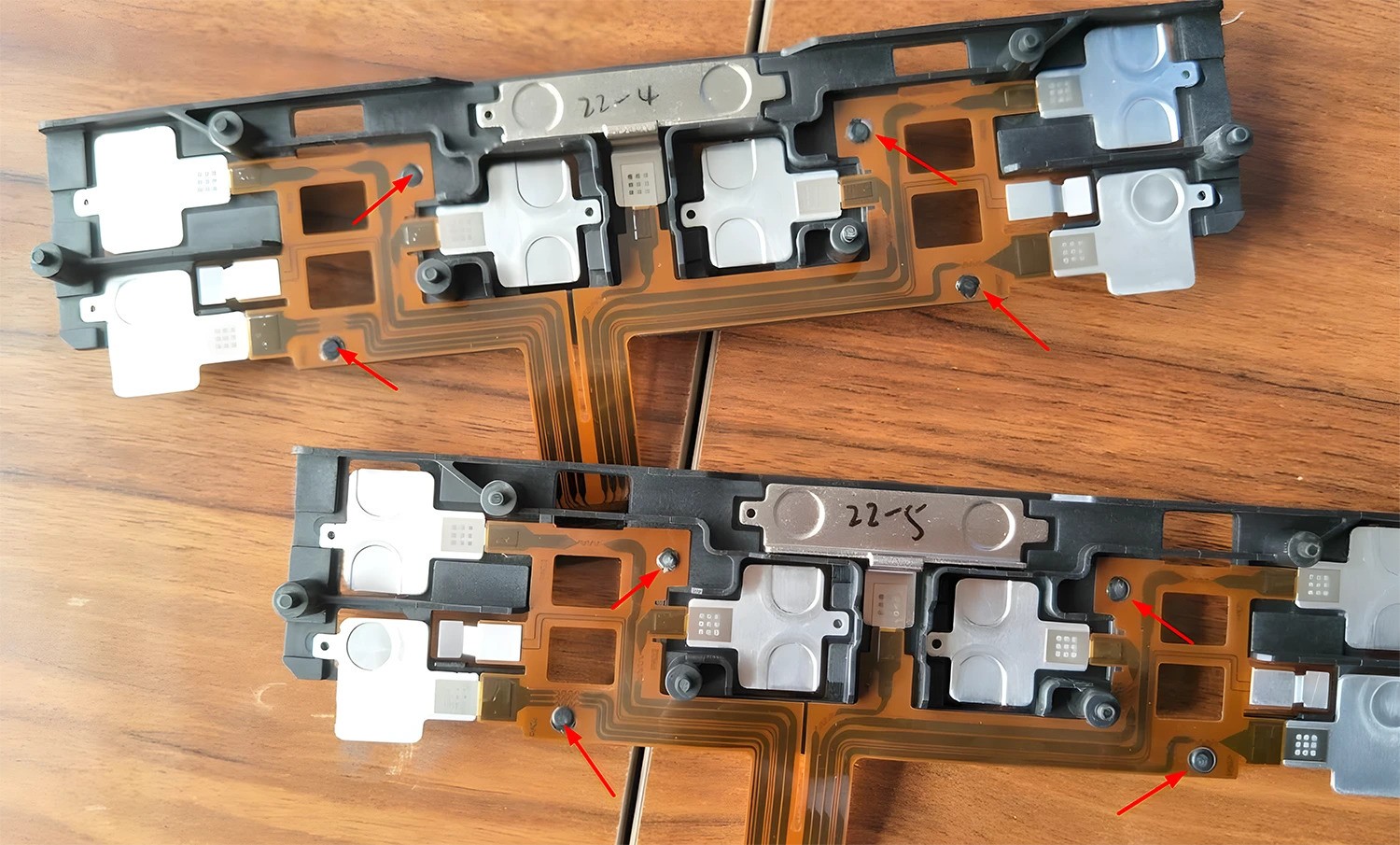

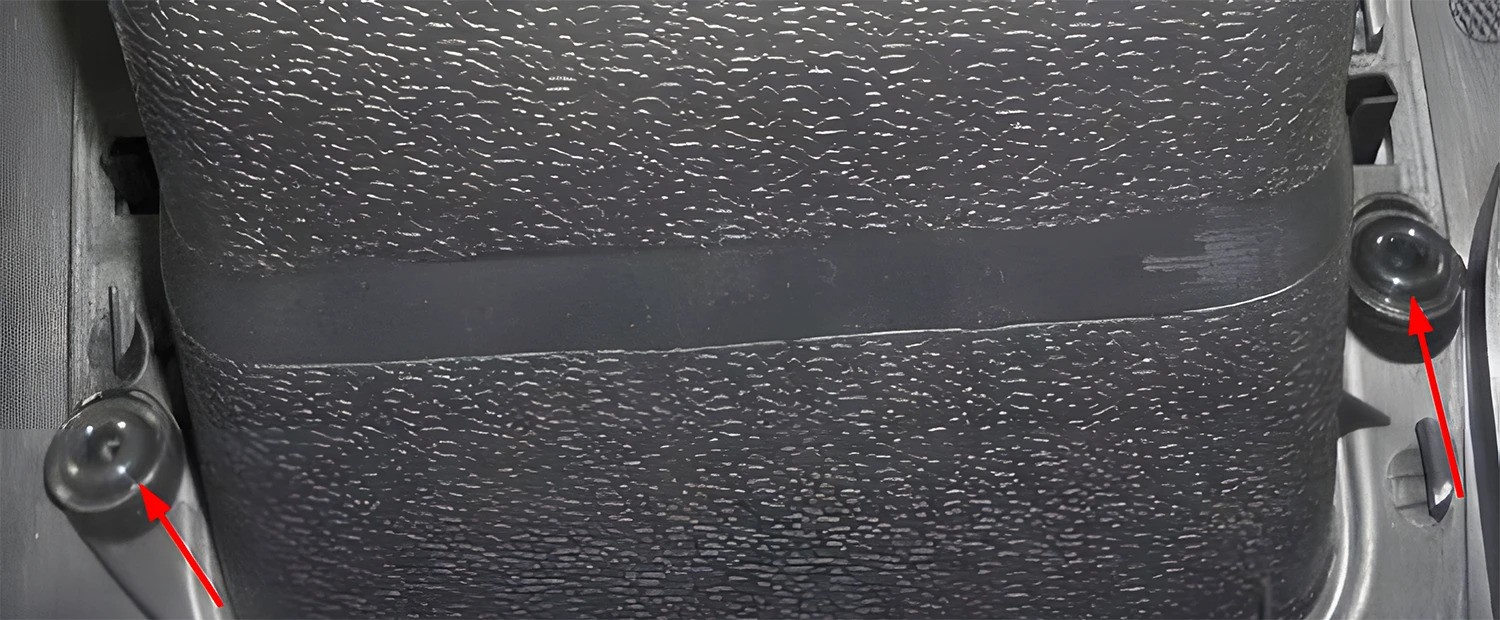

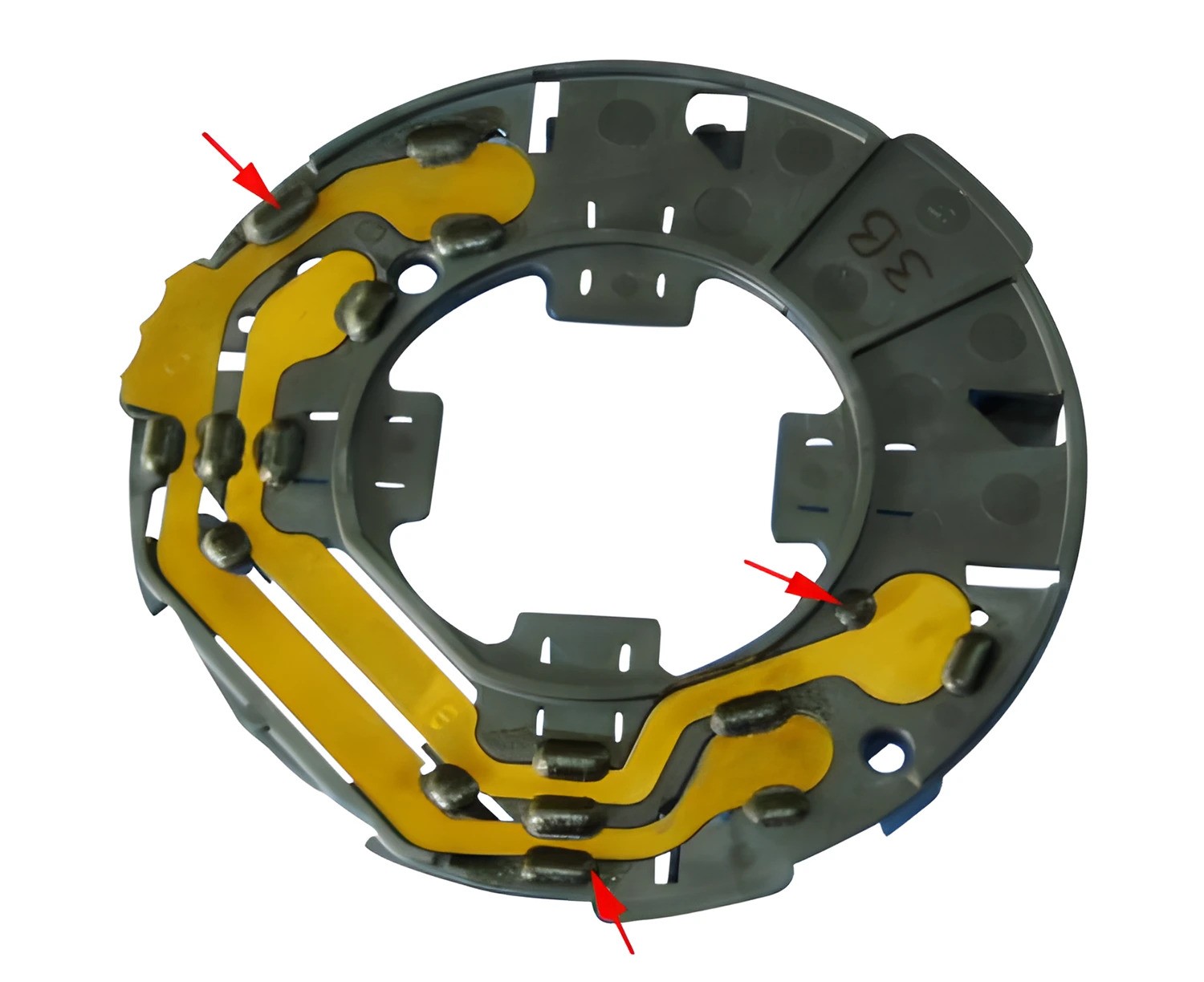

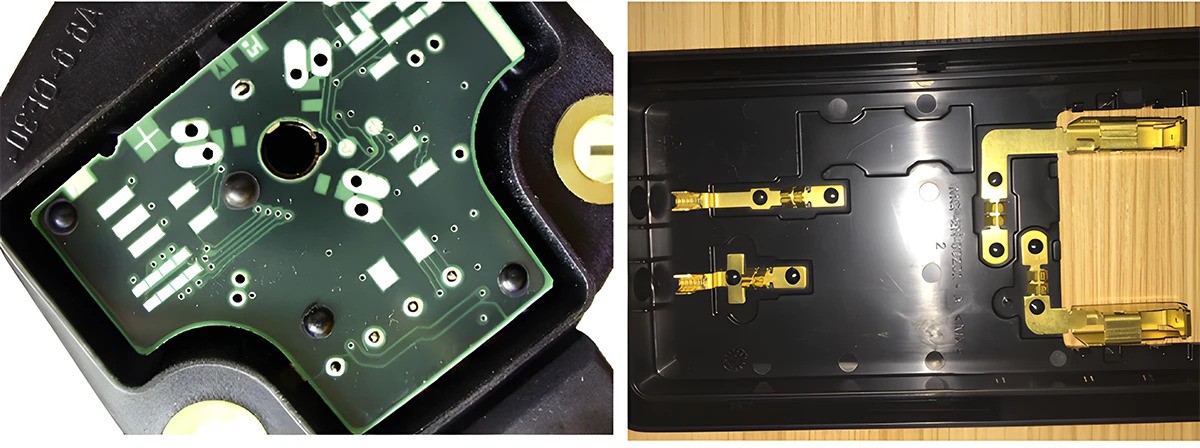

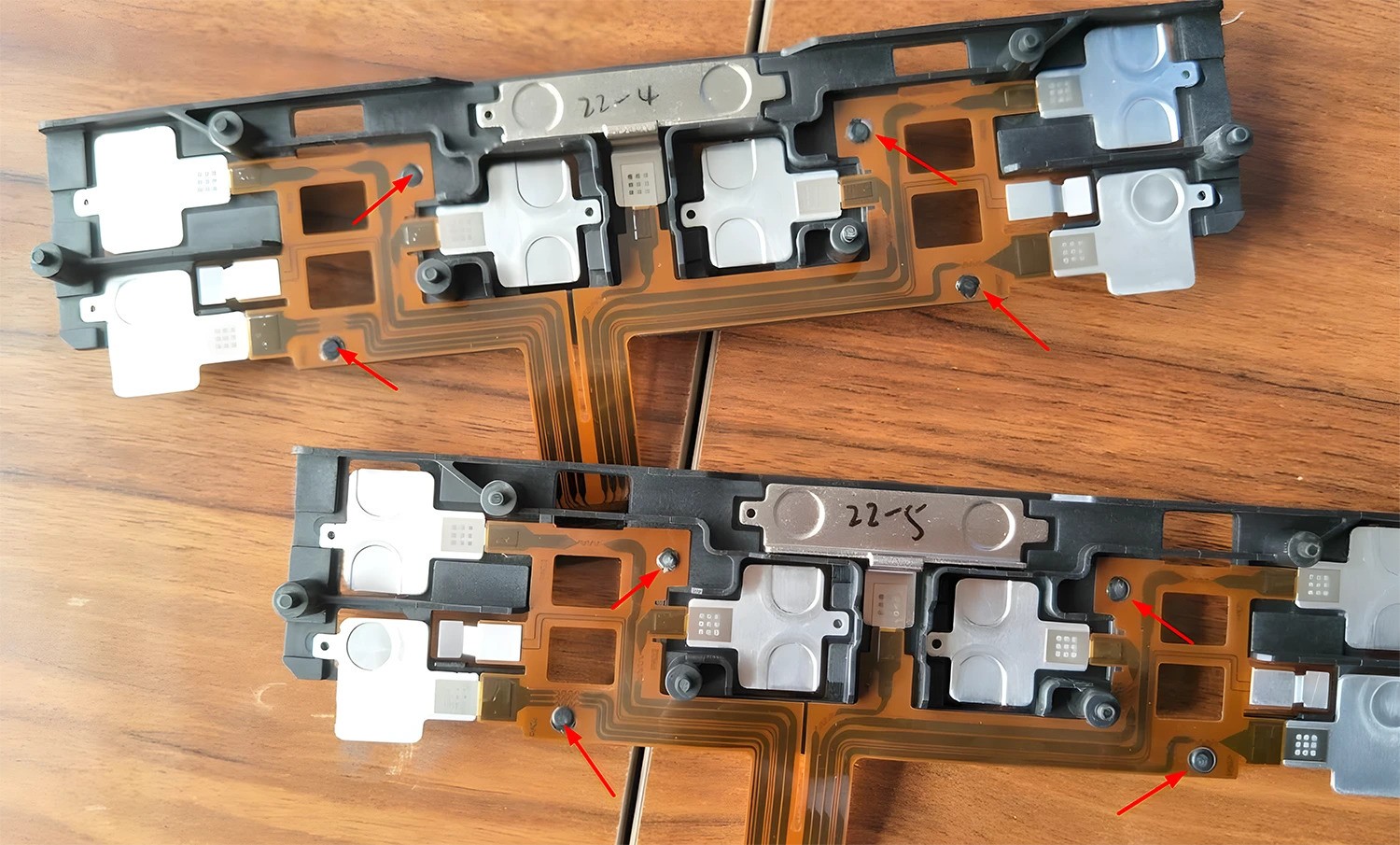

Hot melt riveting bɛ kɛ ka caya PCB pankurunw ni plastiki masirifɛnw na.

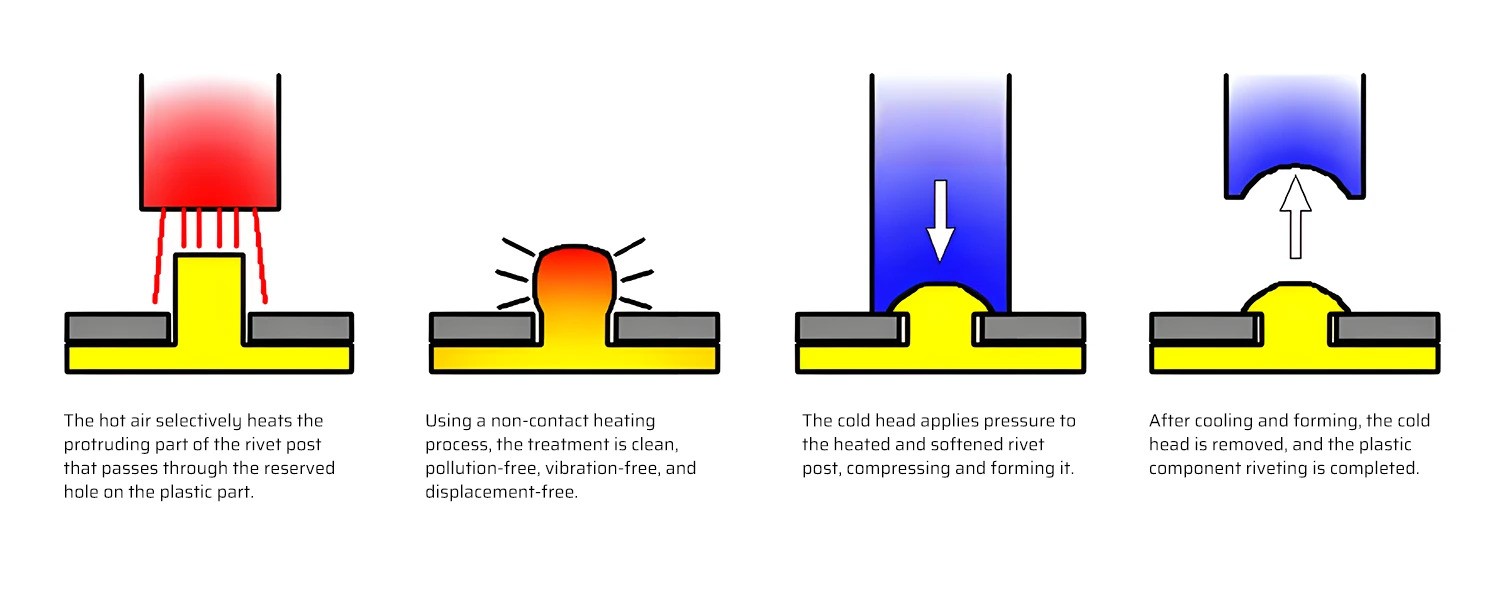

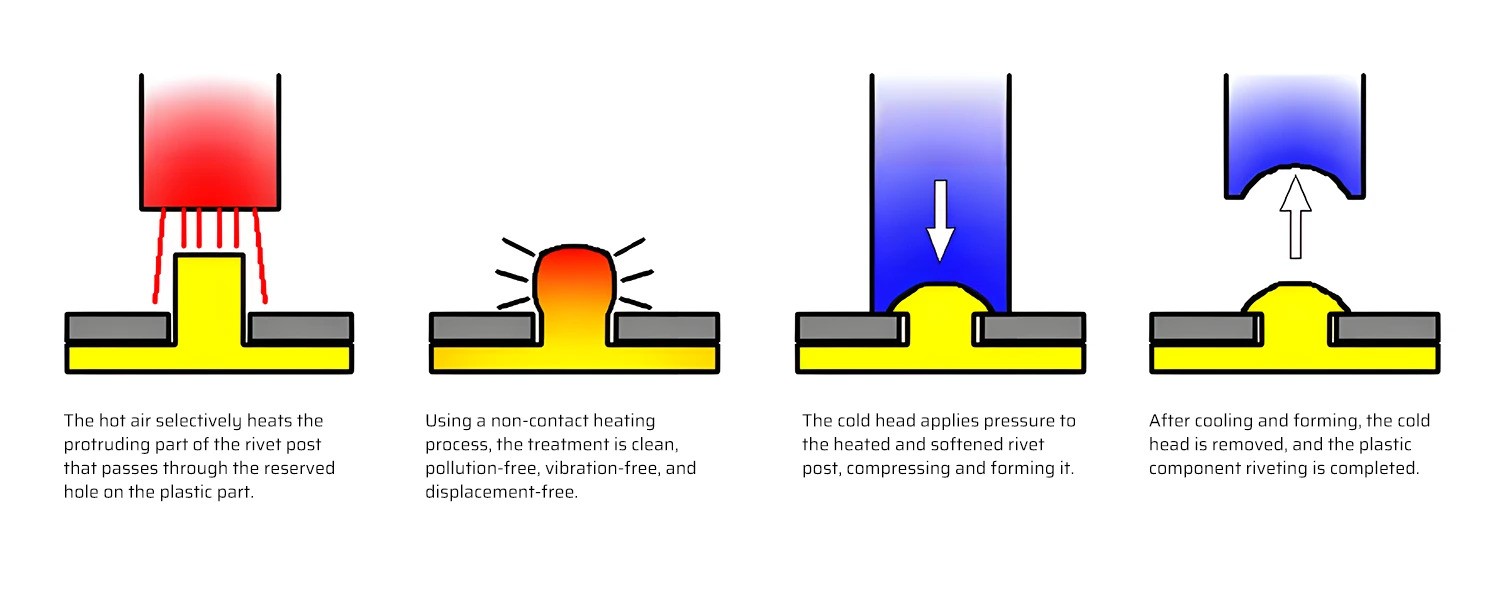

Fiɲɛ sumalen riveting (fiɲɛ nɛnɛma riveting) .

Fiɲɛ sumalen riveting ye fɛɛrɛ ye min tɛ ɲɔgɔn sɔrɔ. A bɛ baara kɛ ni fiɲɛ sumalen ye walasa ka plastiki rivet koloma sumaya ani k’a nɔgɔya. O kɔfɛ, kunkolo nɛnɛman dɔ bɛ a digidigi k’a cogoya.

Taabolo in bɛ taabolo fila de la:

So funteni: Fiɲɛ sumalen bɛ rivet koloma sumaya cogo kelen na fo ka se a malleable ma.

Nɛnɛ : riveting kunkolo nɛnɛman bɛ kolonmugu nɔgɔlen digi, ka kɛ kunkolo jɔlen ye.

Nafaw:

Sofaw ka sofa bɛ dɔ bɔ kɔnɔna degun na .

Nɛnɛ riveting kunkolo bɛ teliya ka yɔrɔw fa, ka se ka fixing effect ɲuman sɔrɔ .

Nafa minnu b’a la:

Fiɲɛ sumalen riveting bɛnnen don fɛnw ma minnu bɛ kɛ ni funteni ye ani plastiki minnu bɛ kɛ ni gilasi ye.

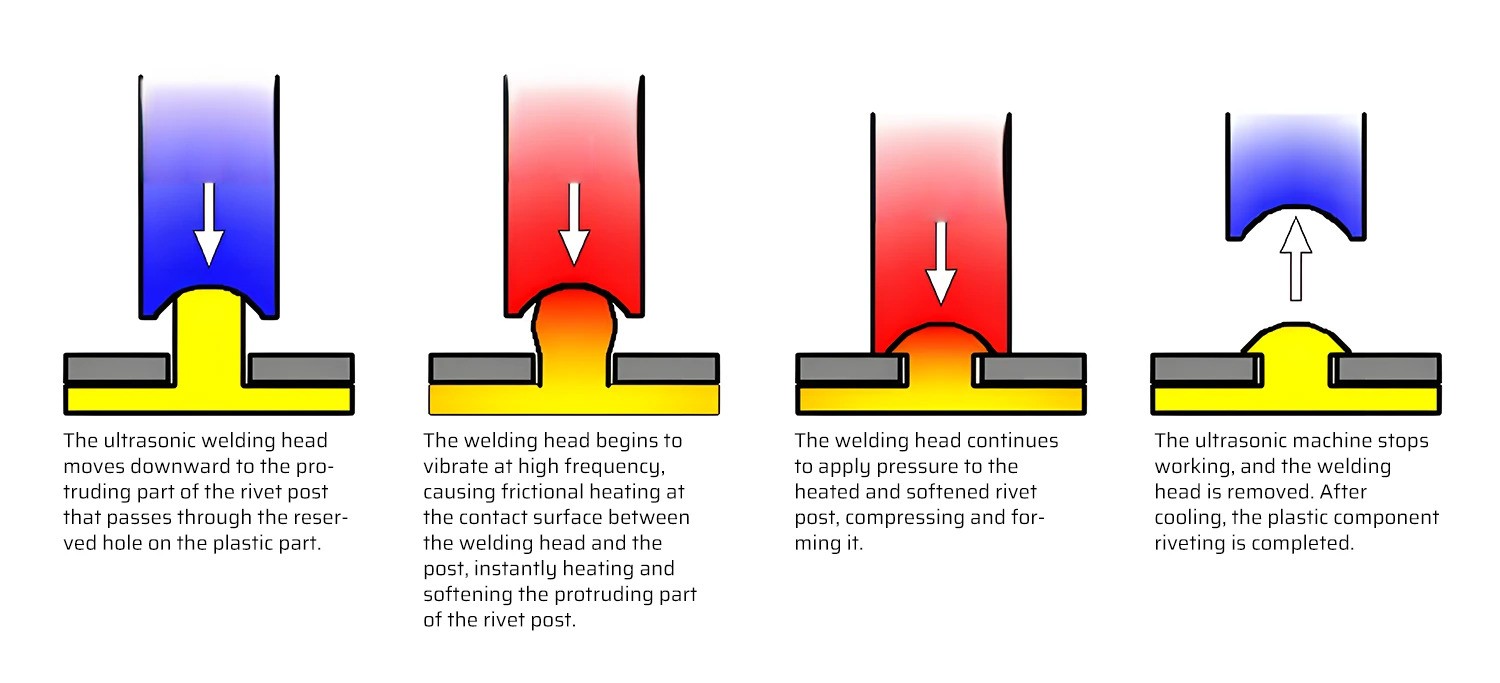

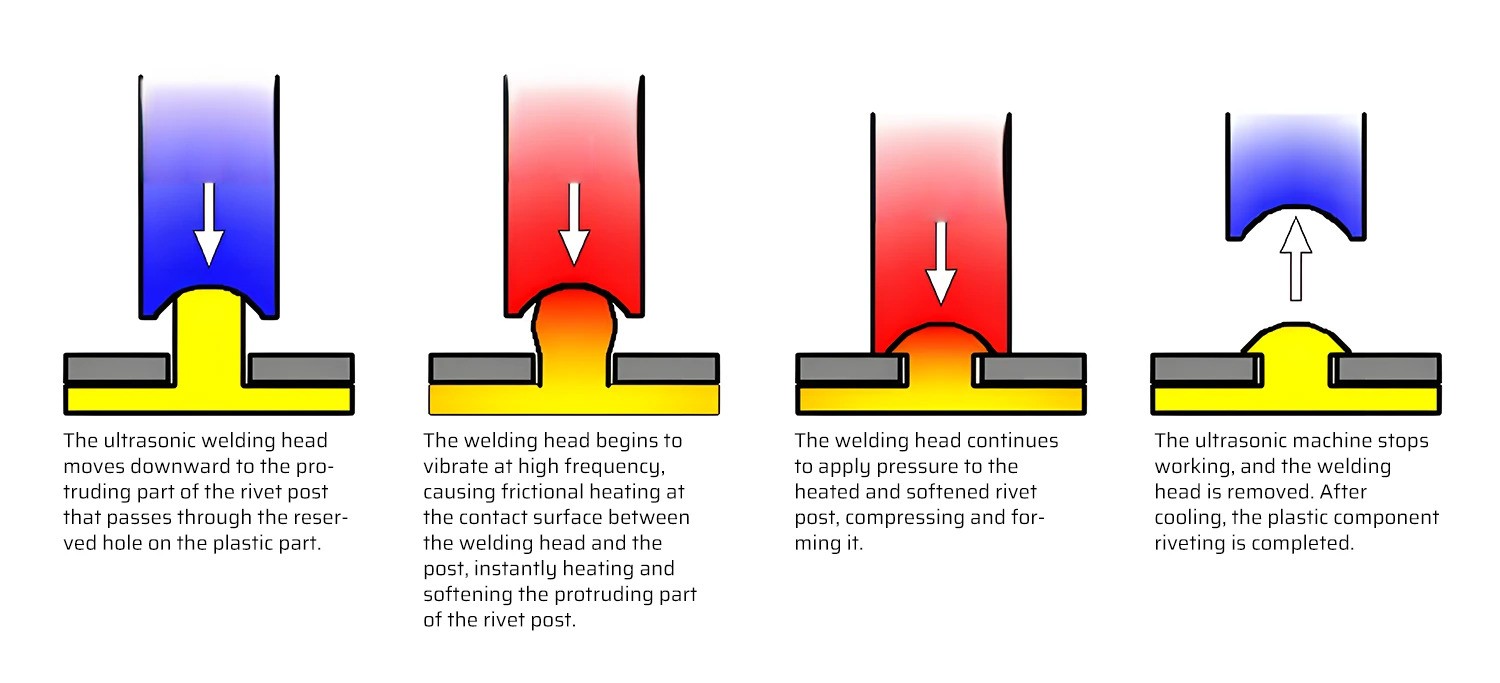

Riveting ultrasonic .

Ultrasonic riveting ye contact-type processus wɛrɛ ye. A bɛ baara Kɛ ni 'yɛrɛyɛrɛli ye min bɛ Kɛ ni frequency (yɛrɛyɛrɛli) ye walasa ka funteni Bɔ ani ka plastiki rivet (partiki) kulu in wuli.

Nafaw:

Nafa minnu b’a la:

Sumaya tɛ kelen ye, o bɛ se ka kɛ sababu ye ka kolonw lajɔ walima ka u tiɲɛ .

Jatebɔ janya danma ni a bɛ baara kɛ ni welding kunkolo kelen ye .

Yɛrɛyɛrɛli bɛ se ka yɔrɔw tiɲɛ fo ka se hakɛ dɔ ma .

Ultrasonic riveting tɛ bɛn gilasi fibre matériaux ma walima minnu bɛ ni wuliyɔrɔw ye minnu ka bon.

Nin ye taabolo saba ninnu sangaɲɔgɔnma ye:

| Taabolo | tasuma-fanga-minɛn | riveting fanga | labɛnni nɔ | teliya | minɛnw sɛgɛsɛgɛli . |

| A ka ca . | Contact (Nɛgɛ kunkolo) . | dannaya tɛ min na , a bɛ se ka yɛrɛyɛrɛ . | a nafa ka bon ka da a ka nɔgɔya dafabaliya kan . | 6-60S . | Yɛlɛma donna, min ka gɛlɛn kosɛbɛ . |

| fiɲɛ sumalen . | A tɛ se ka kɛ (fiɲɛ sumalen) . | Sanfɛ, a tɛ sɛgɛsɛgɛli kɛ yɛrɛyɛrɛ la . | A ka ɲi kosɛbɛ, a bɛ yɔrɔw fa pewu . | 8-12S . | A bɛ se ka ladilan ani ka a riveting . |

| Ultrasonic . | Contact (Vibration) . | dannaya tɛ min na . | a nafa ka bon ka da a ka nɔgɔya dafabaliya kan . | <5S . | Kunnafoni danma ni a kunkolo jɛlen . |

rivet kunkolo suguya minnu bɛ sɔrɔ plastiki yɔrɔw la .

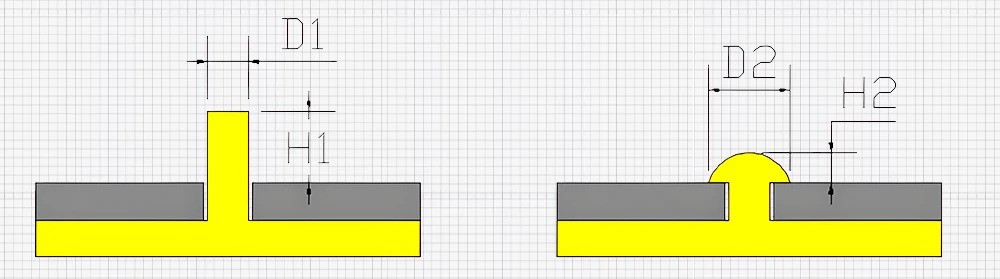

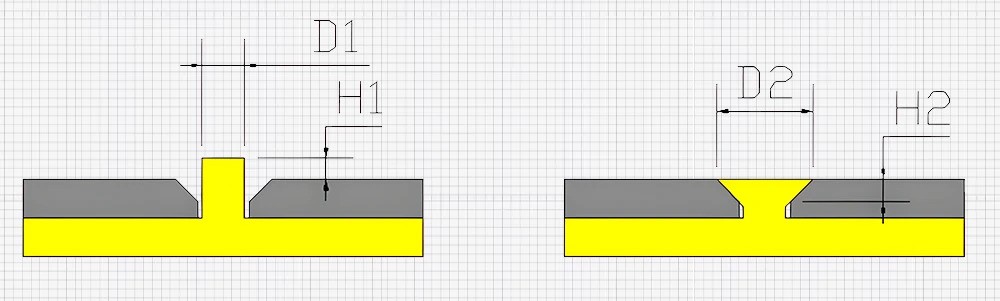

Ni a bɛ fɔ plastiki riveting ma, rivet kunkolow jateminɛcogo n’u hakɛw nafa ka bon kosɛbɛ. An ka suguya dɔw lajɛ minnu bɛ kɛ tuma caman na.

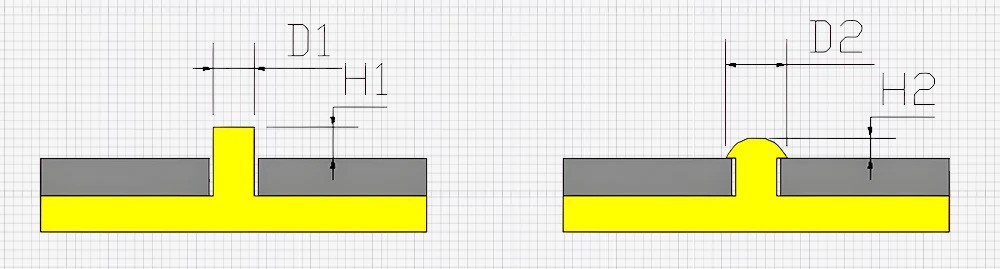

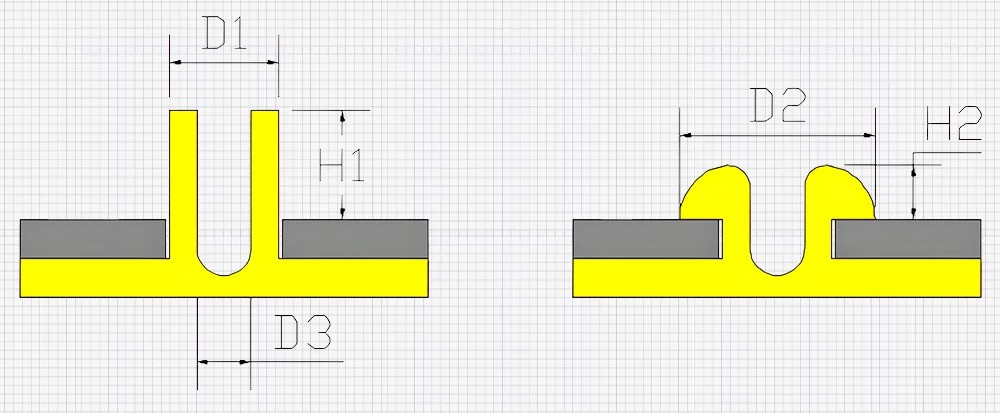

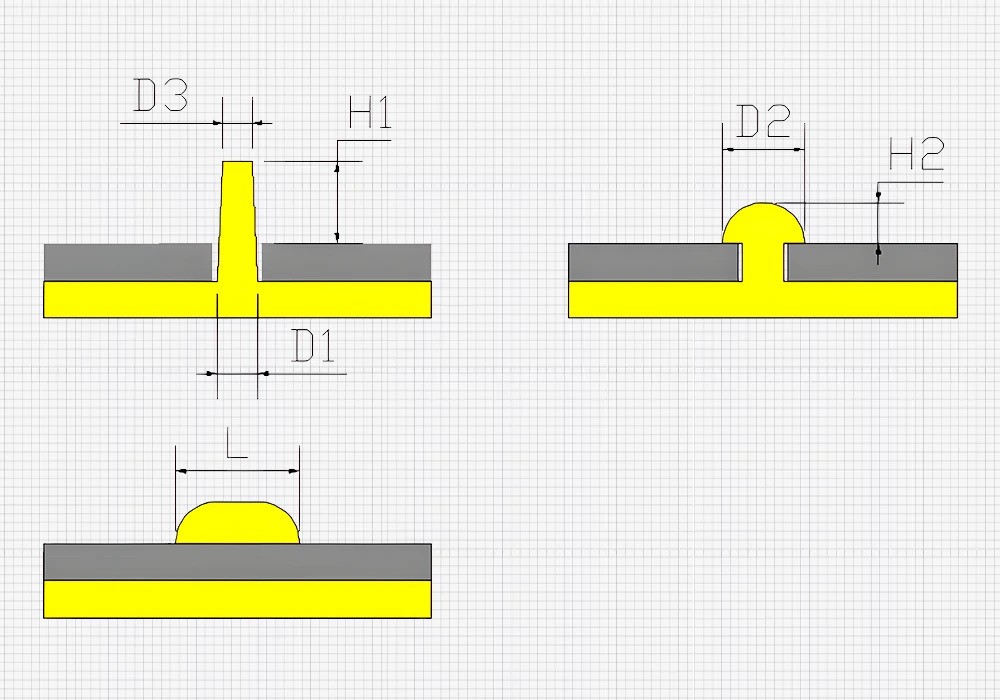

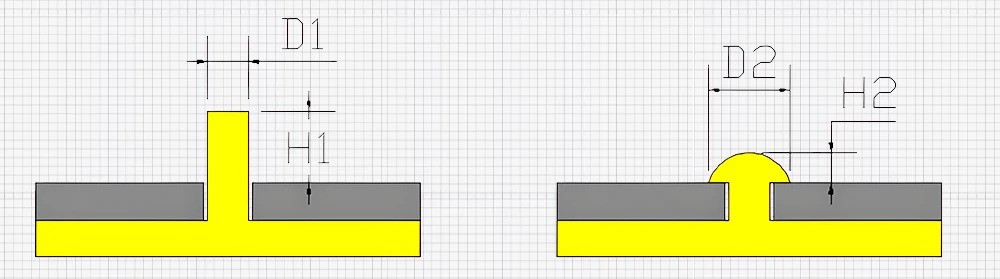

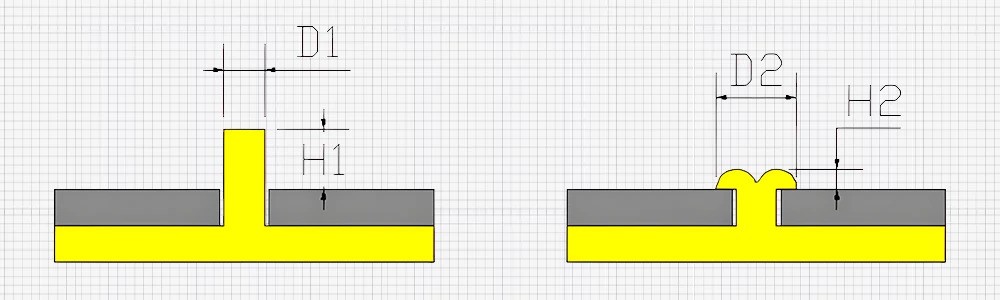

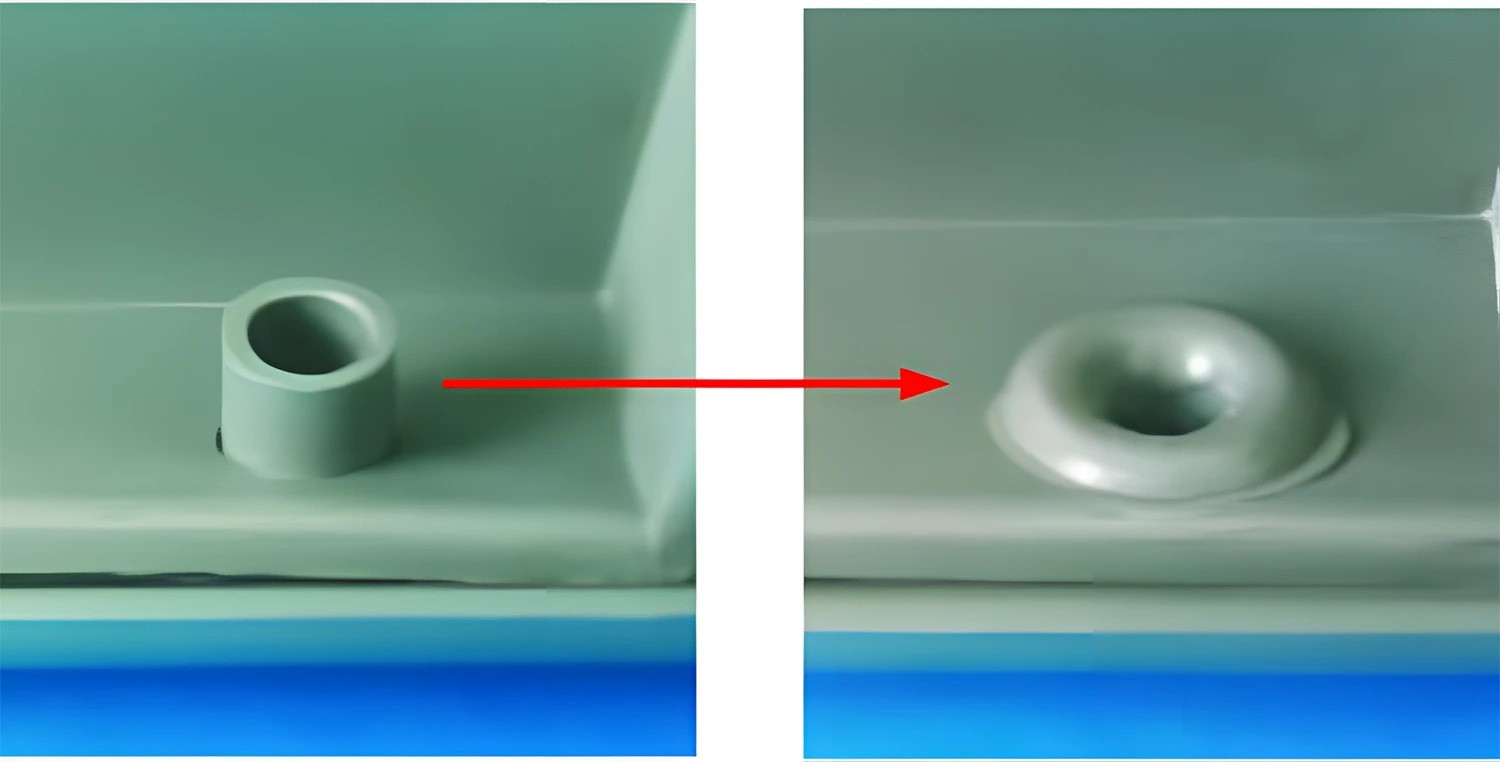

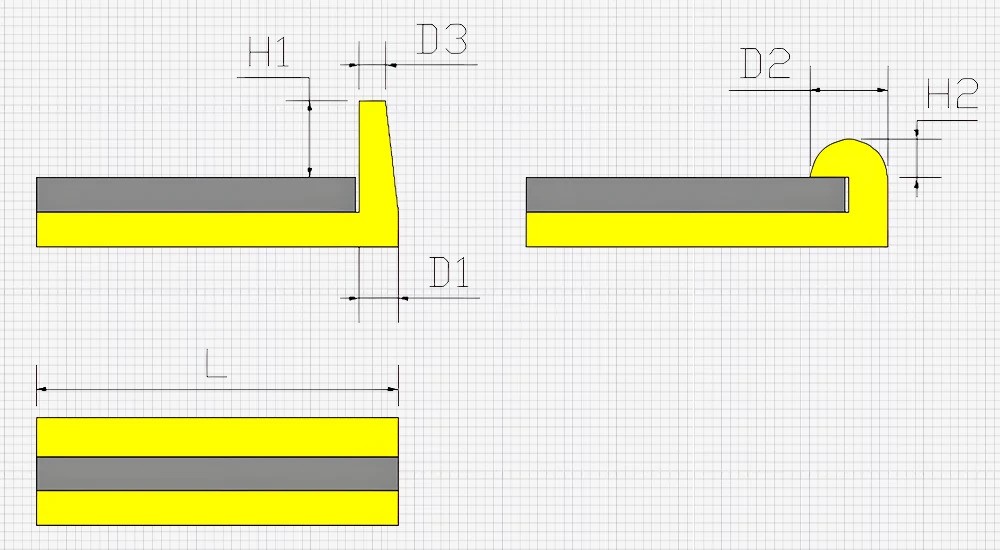

1. Semi-cilcular rivet kunkolo (profil belebele) .

Nin ye suguya ye min ka ca ni suguya tɔw bɛɛ ye. A bɛ kɛ ni fanga caman tɛ mago ɲɛ, i n’a fɔ PCBw walima dekoratif yɔrɔw la.

Fɛn minnu ye nin ye:

A bɛnnen don rivet kolomaw ma ni D1 < 3mm ye (a ka fisa > 1mm walasa ka kari bali)

H1 ye caman na (1,5-1,75) * D1.

D2 bɛ 2 d1 lamini, H2 bɛ 0,75 d1 ɲɔgɔn bɔ.

Jateden kɛrɛnkɛrɛnnenw sinsinnen bɛ hakɛ jiginni kan: S_HEAD = (85%-95%) * S_Column .

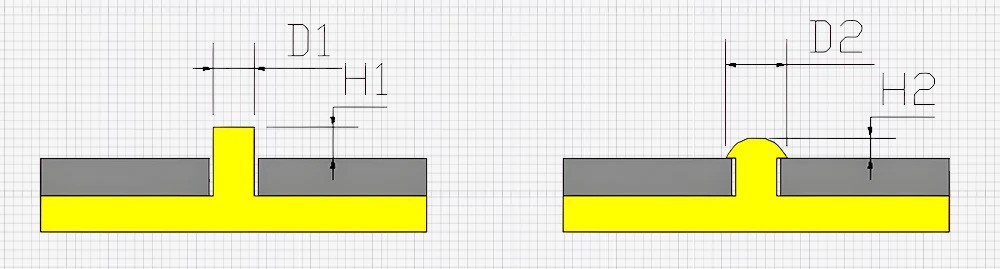

2. Semi-circulaire rivet kunkolo (profil fitinin) .

Nin suguya in ka riveting waati ka surun ka tɛmɛ profile belebele kan. A bɛ kɛ fana baara barikamaw kama, i n’a fɔ FPC kabɔliw walima nɛgɛmafɛnw.

Dilancogo jateminɛw:

D1 < 3mm, a ka fisa > 1mm .

H1 ye normalement 1.0 * D1 ye.

D2 ye 1,5 d1 ɲɔgɔn ye, H2 bɛ 0,5 d1 lamini.

Volume Conversion: S_HEAD = (85%-95%) * S_Column .

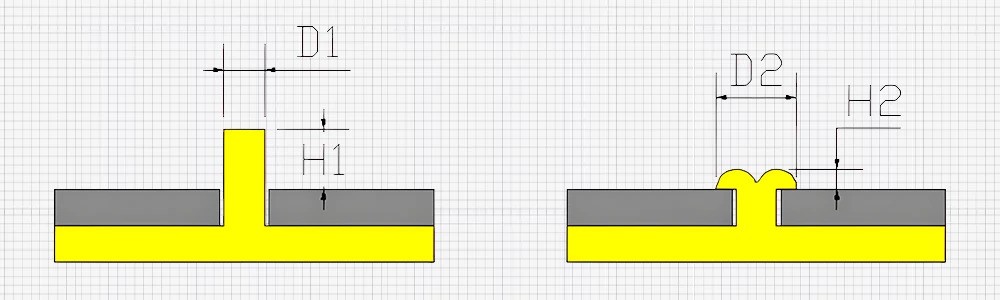

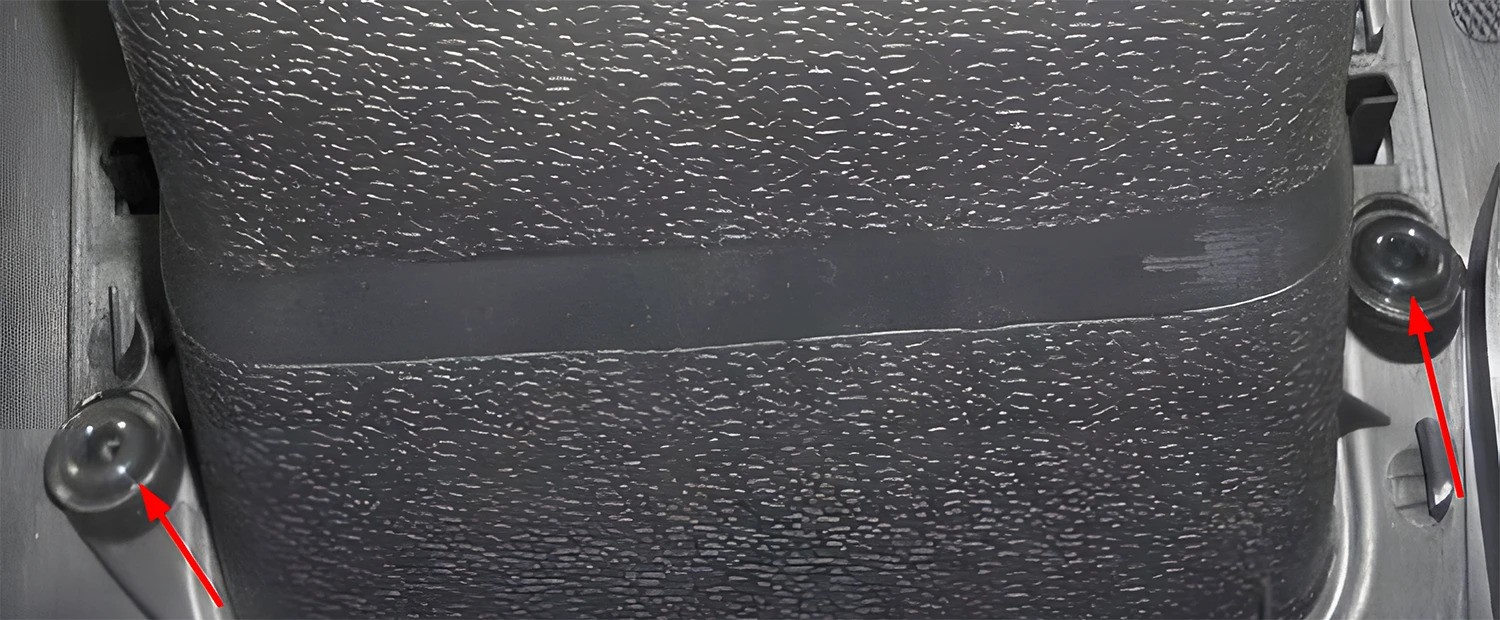

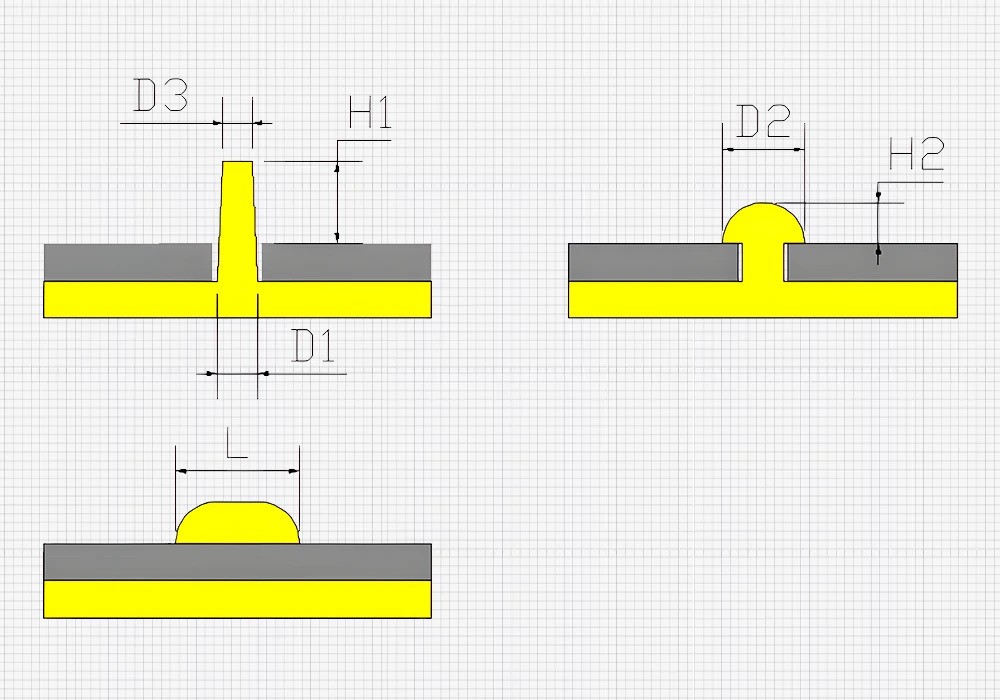

3. Double semi-circulaire rivet kunkolo .

rivet koloma minnu bɛ yan olu ka bon dɔɔnin ka tɛmɛ semi-circular types kan. O dilancogo bɛ riveting waati surunya ani ka a sɔrɔcogo ɲɛ. A bɛ kɛ ni fiɲɛ fanga ka bon kosɛbɛ.

Fɛn minnu ye nin ye:

A bɛnnen don rivet kolomaw ma ni D1 ye 2-5mm cɛ .

H1 ye 1,5 * D1 ye a ka c’a la.

D2 ye d1 2 ɲɔgɔn ye, H2 bɛ 0,5 d1 lamini.

Volume Conversion bɛ kɛ .

rivet column ani moule hot riveting head centers ka kan ka bɛn ka kɛɲɛ ni u dilanni ye ka ɲɛ .

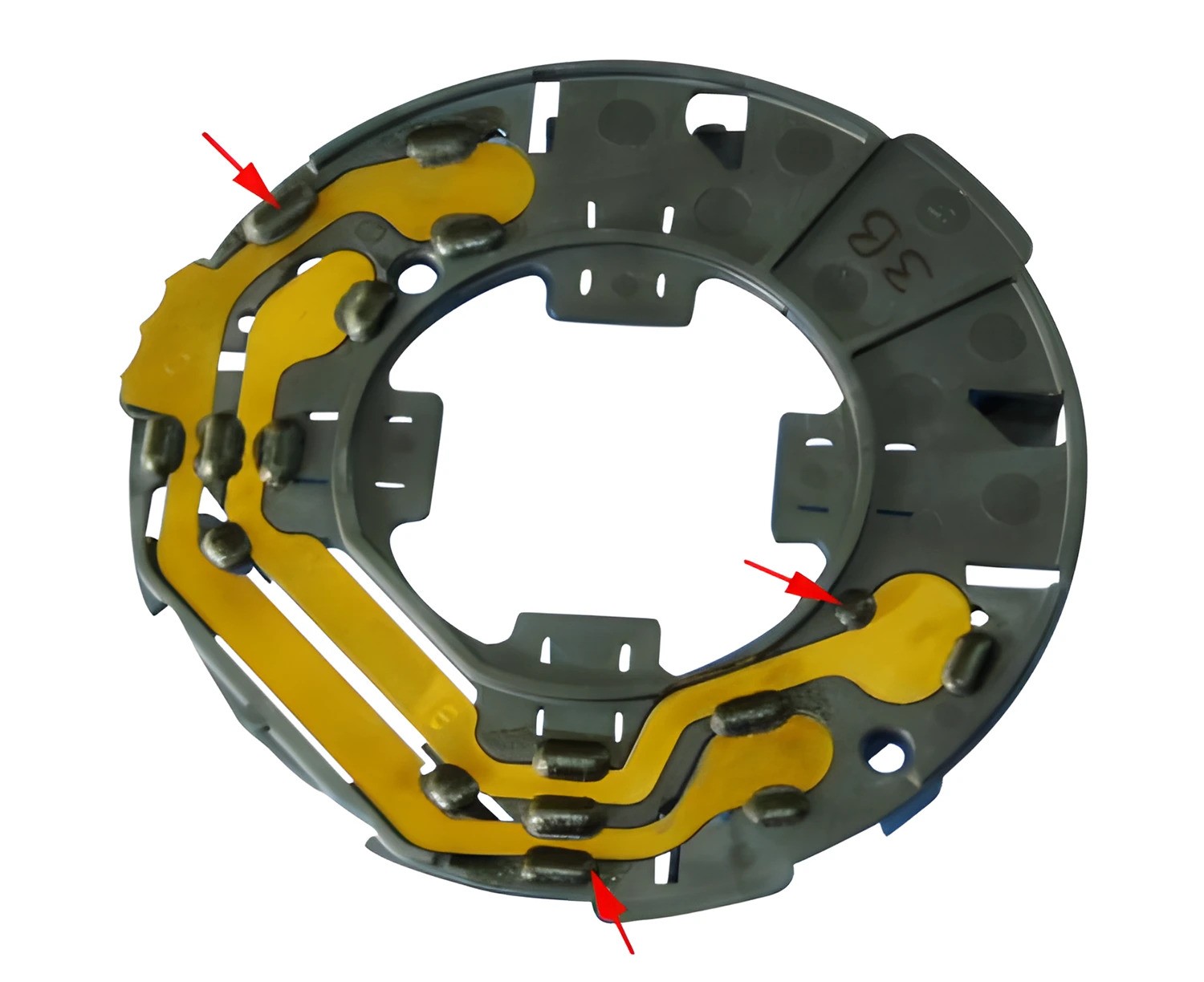

4. Annular rivet kunkolo .

Ni rivet koloma janya bɛ ka bonya, kolonw bɛ kɛ ni kɔnɔnatumuw ye. U bɛ riveting waati surunya, ka sɔrɔw ɲɛ ka ɲɛ, ani ka dɔgɔyali balili bali. Nin suguya in ye baarakɛcogo ye min mago bɛ fixing strength sanfɛ.

Kɛcogow:

D1 > 5mm .

H1 ye (0,5-1,5) * D1, a nafa ka dɔgɔn a cɛmancɛw la .

Kɔnɔna D ye 0,5 * D1 ye walasa kɔ ka dɔgɔya .

D2 bɛ 1,5 d1 lamini, H2 bɛ 0,5 d1 ɲɔgɔn bɔ.

Volume Conversion bɛ kɛ .

Hali kolonw kɔnɔna funteni bɛ dɛmɛ ka kunkolow dilan minnu bɛ se .

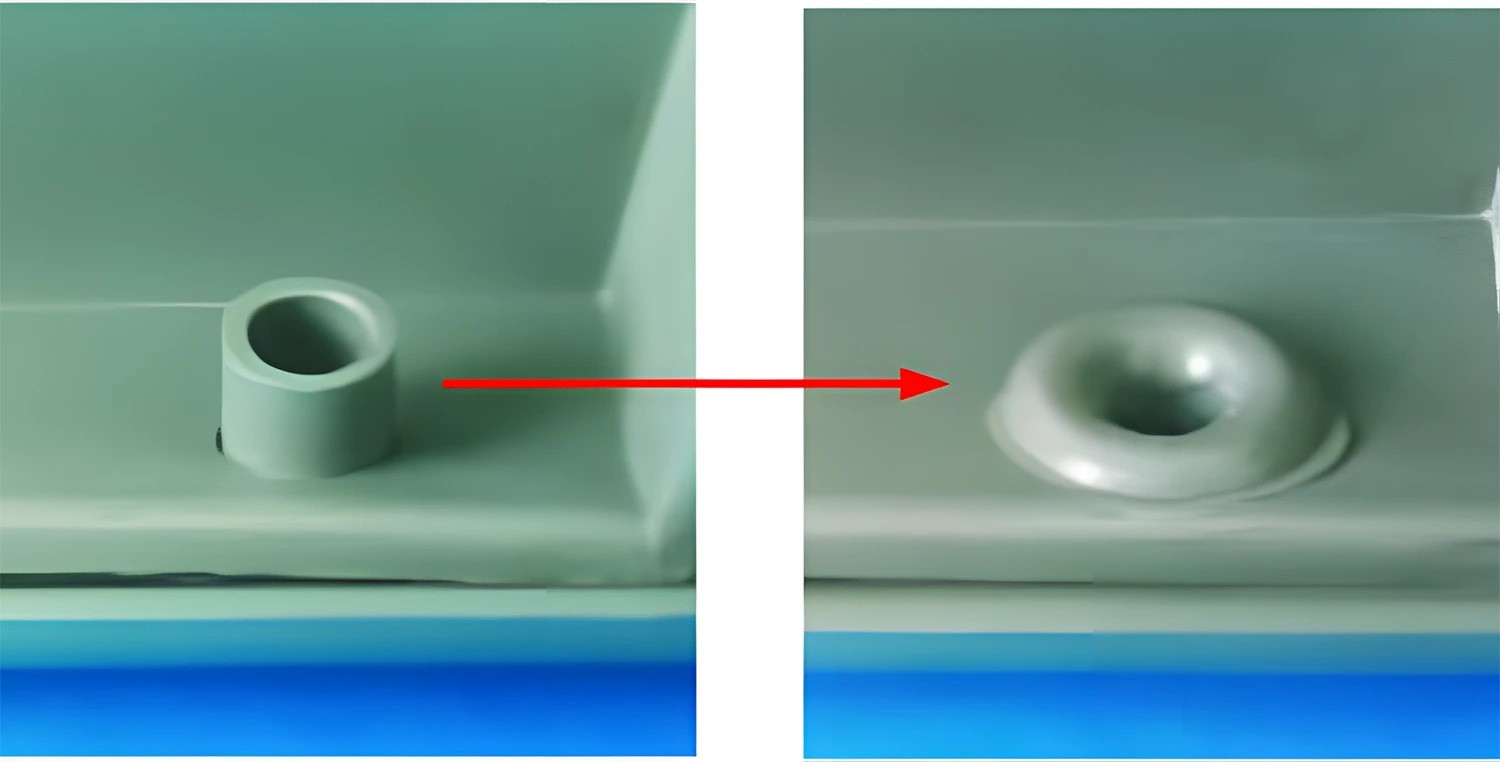

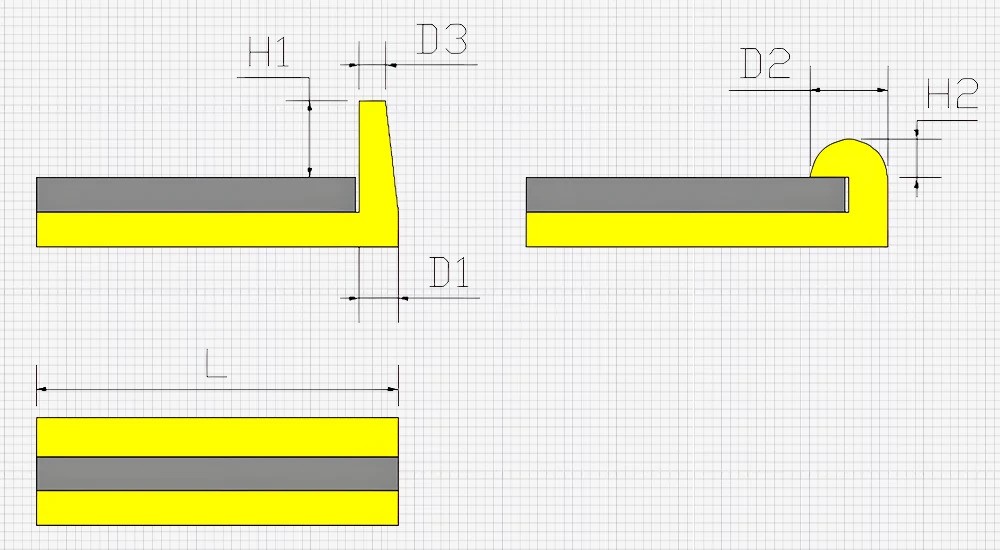

5. Flat rivet kunkolo .

Kungolo fla bɛ Bɛn ni kunkolo dabɔlen man kan ka Bɔ a sanfɛla la.

Design Notes:

D1 < 3mm .

H1 ye 0,5 * D1 ye a ka c’a la.

D2 ani H2 ka da a hakɛ jiginni kan .

A yɔrɔ jɛlen mago bɛ janya bɛrɛ la walasa ka countersinking kɛ .

A janya tɛ se ka kɛ sababu ye ka jɛɲɔgɔnya kɛ min tɛ se ka da a kan ani ka fanga dɔgɔya .

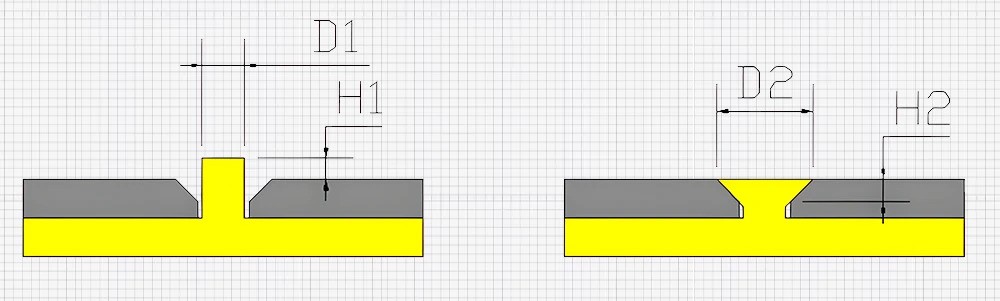

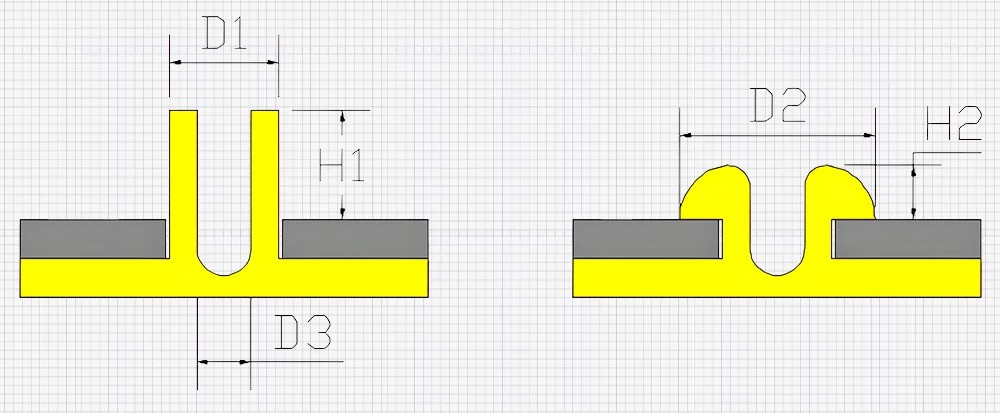

6. Ribé rivet kunkolo .

Aw bɛ baara kɛ ni kunkolow ye minnu bɛ ni jiribolo ye ni aw mago bɛ yɔrɔba la min ka bon nka yɔrɔ tɛ aw bolo kolonw kɔnɔ.

Fɛn minnu ye nin ye:

Base diamètre D1 < 3mm, sanfɛ cɛmancɛ D3 = (0,4-0,7) * D1.

H1 ye (1,5-2) * D1 ye, a ka dɔgɔ ni kulu janya L ye .

D2 ye d1 2 ɲɔgɔn ye, H2 bɛ 1,0 d1 lamini.

Volume Conversion bɛ kɛ .

7. Flanged rivet kunkolo .

Kungolo flakɛlenw ka ɲi kosɛbɛ ɲɔgɔndanw ma minnu bɛ crimping walima wrapping wajibiya.

Dilancogo jateminɛw:

Base diamètre D1 < 3mm, sanfɛ cɛmancɛ D3 = (0,3-0,5) * D1.

H1 ye (1,5-2) * D1, min ka dɔgɔ ni koloma janya ye L .

D2 ye normalement 2 d1 ye, H2 bɛ 1,0 d1 ɲɔgɔn bɔ.

Volume Conversion bɛ kɛ .

Dilan jateminɛw rivet kuluw ni rivet kunkolow kan .

Ni aw bɛ rivet kuluw ni kunkolow dilan, fɛn jɔnjɔn caman bɛ yen aw ka kan ka minnu to aw hakili la. An k’u sɛgɛsɛgɛ k’a jɛya.

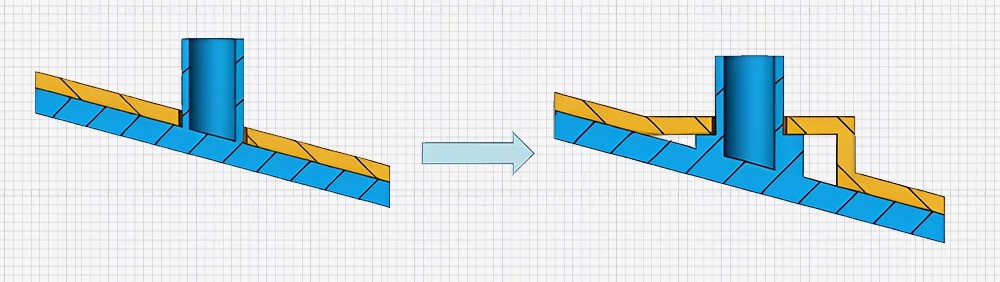

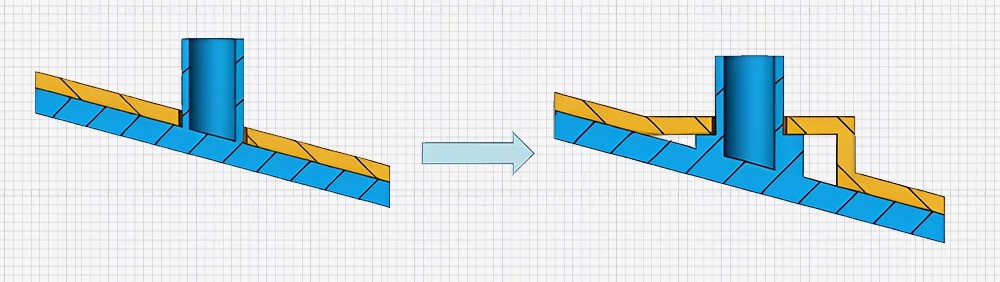

rivet jɔw dilanni yɔrɔw la minnu bɛ wuli walima minnu ka jan basi la .

Ni rivet koloma bɛ plan inclined kan walima a yɔrɔ ka jan a basigilen na, a ka kan ka kɛ ni dilan kɛrɛnkɛrɛnnen ye. Fɛɛrɛ fila filɛ nin ye:

Dilancogo rivet kuluw kan yɔrɔw la minnu bɛ wuli .

Ni yɔrɔw bɛ wuli, rivet koloma ka kan ka jɔ yɔrɔ la. O bɛ a to a bɛ bɛn ɲɔgɔn ma ka ɲɛ ani ka sirili lakana.

Dilancogo min bɛ kɛ rivet kolon na min bɛ sigi sanfɛ basigi sanfɛ .

Ni kolon bɛ sanfɛ basigi sanfɛ, dɛmɛnanw farali nafa ka bon. U bɛ kurukuruni walima kari bali riveting waati la.

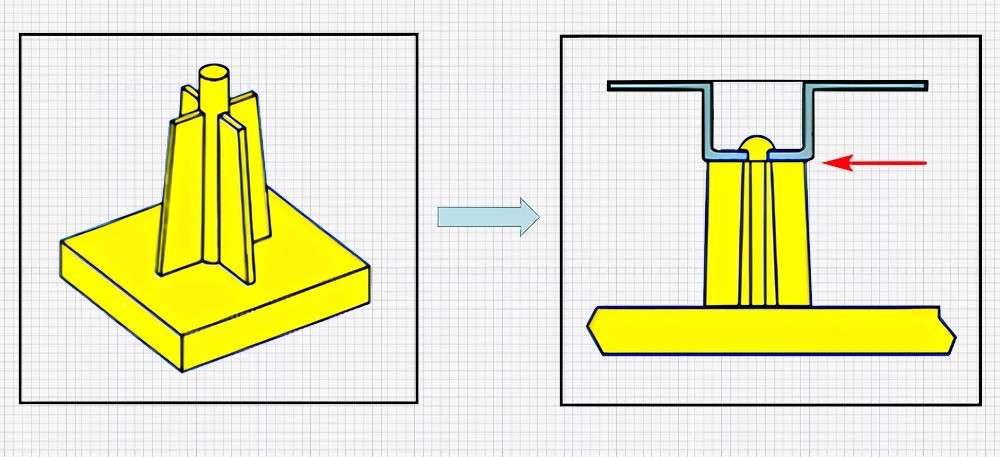

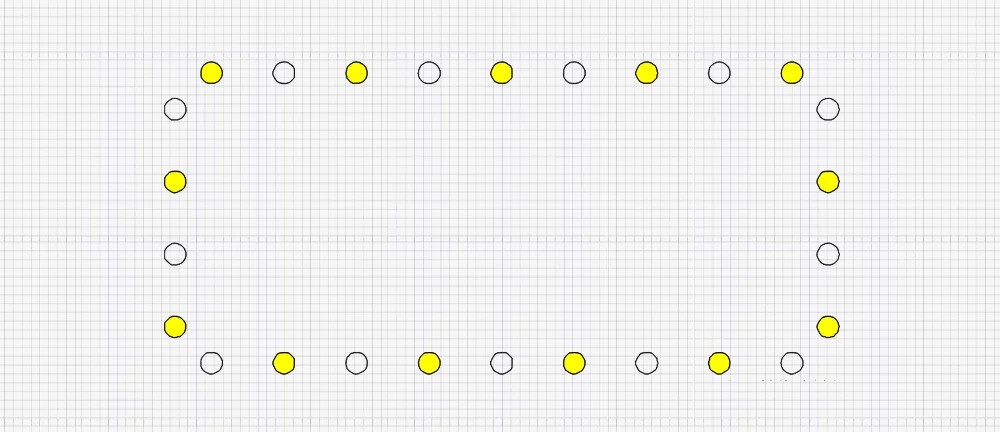

redundancy design nafa ka bon .

Plastiki riveting bɛ ɲɔgɔndan banbaliw dilan minnu dilanni ka gɛlɛn ni u ma se. Ka baarakɛbaliya don dilancogo la, o nafa ka bon kosɛbɛ.

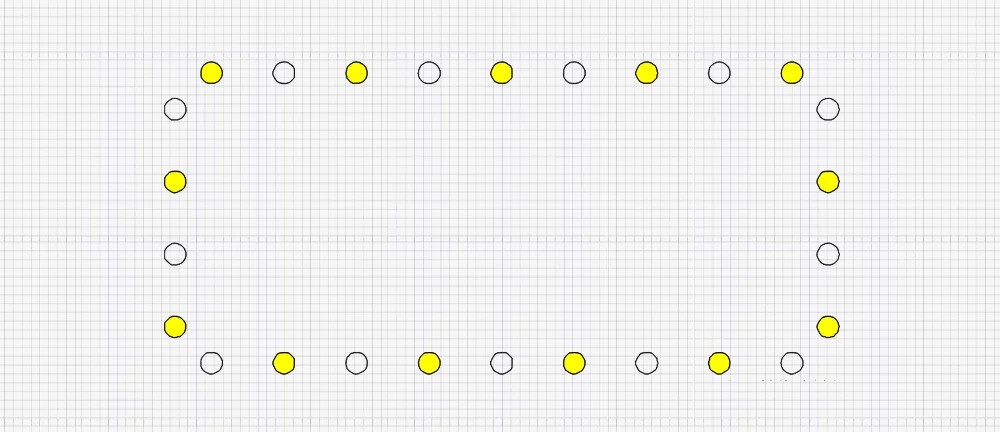

Fɛɛrɛ dɔ ye ka rivet jɔw ni dingɛw hakɛ caya siɲɛ fila. A daminɛ na, seti fɔlɔ dɔrɔn de bɛ Kɛ (misali la, jɛman). Ni dilan ka kan, seti filanan (misali la, finman) bɛ kɔpi di.

O redundancy bɛ cogo filanan di i ma ka dilan, ka dɔ fara riveted assembly bɛɛ ka dannaya kan.

Jɛɲɔgɔnya min bɛ rivet kunkolo ni koloma hakɛw cɛ .

Rivet kunkolo ni kolomayɔrɔw hakɛw bɛ ɲɔgɔn na kosɛbɛ. Jɛɲɔgɔnya jɔnjɔn dɔw filɛ nin ye minnu ka kan ka jateminɛ:

rivet kunkolo cɛmancɛ (D2) bɛ kɛ a ka ca a la siɲɛ 2 ɲɔgɔn na kolon cɛmancɛ (D1) .

rivet kunkolo janya (H2) bɛ kɛ a ka ca a la D1 siɲɛ 0,75 ɲɔgɔn na kunkolo belebelew la minnu bɛ sɛrɛkili tilancɛ la, ani D1 siɲɛ 0,5 kunkolo semi-circular kunkolo misɛnninw na .

Dimensions kɛrɛnkɛrɛnnenw ka kan ka da hakɛ jiginni kan: s_head = (85%-95%) * S_Column .

Nin hakɛ jiginni in b’a to rivet kunkolo bɛ se ka kɛ fɛn ye min bɛ se ka jɛɲɔgɔnya barikama sɔrɔ, min lakananen don, k’a sɔrɔ a ma tiɲɛ kojugu.

Matériel adaptabilité pour plastique riveting .

Plastikiw bɛɛ man ɲi riveting ma. An ka fɛn kolomaw sɛgɛsɛgɛ minnu bɛ fɛn dɔ ka ladamuni dantigɛ.

Thermoplastiques vs.

Thermoplastiques bɛ se ka wuli ka u cogoya caman sɛgɛsɛgɛ funteni hakɛ kɛrɛnkɛrɛnnen dɔ kɔnɔ. U ka ɲi kosɛbɛ riveting kama.

O ni thermosets bɛ gɛlɛya kudayi ni a sumana. U ka gɛlɛn ka rivet kɛ ni fɛɛrɛw ye minnu bɛ kɛ ka kɛɲɛ ni sariya ye.

O la, a ka c’a la, fɛn dilannenw jɔcogo bɛ tali kɛ funteni hakɛ la ni riveting (riveting) ka kan ka kɛ.

Plastiki amorphes vs semi-crystalline .

Thermoplastiques bɛ tila ka taa a fɛ ka kɛ amorphe ani semi-crystalline suguyaw ye. U kelen-kelen bɛɛ bɛ ni jogo kɛrɛnkɛrɛnnenw ye minnu bɛ nɔ bila riveting na.

Plastiki amorf (min tɛ krisiti ye) .

Labɛnni min bɛ kɛ ni molekiyɔmu ye min tɛ labɛn .

nɔgɔya dɔɔnin dɔɔnin ani ka wuli ni gilasi jiginni funteni ye (TG) .

A bɛnnen don riveting kɛcogo saba bɛɛ ma (sumaya funteni, fiɲɛ sumalen, ultrasonic) .

Plastiki semi-crystalline .

Labɛnni min bɛ kɛ ka kɛɲɛ ni molekiyɔmu ye .

A bɛ se ka wuli ka bɔ a nɔ na (TM) ani a ka kirisitaliya yɔrɔ .

Aw bɛ to solide la fo ka se a sɔgɔli yɔrɔ la, o kɔ aw bɛ teliya ka a gɛlɛya ni a nɛnɛna .

A bɛnnen don kosɛbɛ ka funteni riveting kɛ ka da a kan a bɛ se ka suma ni a ye .

Regular-like structure bɛ fanga minɛ ultrasonic la, ka ultrasonic riveting kɛ gɛlɛya ye .

A ka teli ka wuli yɔrɔ minnu na, olu bɛ fanga ultrasonic caman de wajibiya walasa ka wuli .

Hakilina ɲuman minnu ka kan ka kɛ walasa ka ultrasonic riveting (amplitude sanfɛ, design joint, welding head contact, distance, fixtures)

Aw bɛ daminɛ ka ɲɔgɔn sɔrɔ rivet kulu sanfɛla ni welding kunkolo ni ɲɔgɔn cɛ ka ɲɛsin concentration energy ma .

Fillers (misali la, fibres gilasi) nɔ .

Fillers bɛ se ka nɔba bila plastiki dɔ ka riveting baara la. An ka gilasi fiyɛw lajɛ i n’a fɔ misali.

Fɛn minnu ye nin ye:

Danfaraba min bɛ u ni ɲɔgɔn cɛ plastiki ni galasi fiyɛw cɛ .

riveting riveting hot: funteni hakɛ tigitigi (±10°) Crucial .

Funteni caman bɛ kɛ sababu ye ka gilasi fiyɛri sanji, nɔrɔli, ani yɔrɔ gɛlɛnw sɔrɔ .

Funteni dɔgɔyali bɛ na ni kariw ni nɛnɛ ye .

Ultrasonic riveting: Vibration Energy caman ka kan ka kɛ walasa ka plastiki wuli .

Filler kɔnɔkow ɲɛfɔli:

<10% : a nɔ min ka dɔgɔn fɛnw nafa kan, nafa bɛ minnu na fɛn nɔgɔlenw na (pp, PE, PPS) .

10-30%: A bɛ dɔ bɔ riveting fanga la .

-

30%: A bɛ nɔba bila riveting baarakɛcogo la .

Fɛn wɛrɛw nafa minnu bɛ ultrasonic riveting nɔ na:

Gɛlɛya: Gɛlɛya min ka bon kosɛbɛ, o bɛ riveting (riveting) ɲɛ ka taa a fɛ .

Fɛn min bɛ wuli ka bɔ a nɔ na: wuliyɔrɔ minnu ka bon, olu bɛ fanga ultrasonic caman de wajibiya .

Saniya: Saniya ka bon, o bɛ dɔ fara riveting kan, ka sɔrɔ nɔgɔ minnu bɛ sɔrɔ fɛnw na minnu bɛ segin ka kɛ, olu bɛ dɔ bɔ baarakɛcogo la .

Plastiki fɛn minnu bɛ kɛ ka riveting kɛ .

Plastiki ɲuman sugandili nafa ka bon kosɛbɛ walasa ka riveting kɛ ka ɲɛ. An ka fɛɛrɛ dɔw lajɛ kosɛbɛ minnu bɛ kɛ tuma caman na.

Poliyetilɛni density (LDPE) .

LDPE ka density (dansi) ka dɔgɔn k’a sababu kɛ a ka molecular (molecules) jɔcogo ye min falen don lafiya la. A bɛ se ka wuli ka bɔ a nɔ na nka a ka gɛlɛn.

Fɛn minnu bɛ se ka kɛ:

Poliporopilini (pp) .

PP bɛ baara kɛ kosɛbɛ iziniw kɔnɔ, k’a ta mobili la ka taa a bila a foroko la. A bɛ kemikaliya ni kuran sɔgɔli ɲuman di.

Aplikasi:

Nylon .

Nilon, kɛrɛnkɛrɛnnenya la nilon 6/6, o ka di fɛn dilanni na. A ka friction dɔgɔman b’a to a ka ɲi girinw ni birikiw ma.

Kɛcogow:

A bɛ kemikɛli fanba kɛlɛ, nka a bɛ se ka bin a kan ni asidi barikamaw, alikɔliw ani alkali ye .

Asidi dilu ka se ka tulu ni tulumafɛnw kɛlɛ cogo ɲuman na .

A bɛ kɛ ka snap rivets kɛ, ka rivets bɔ a la, ani ka push-in knob head rivets .

Asetal (polyoxyméthylène, POM) .

Acetal, walima pom, barika ka bon, a ka gɛlɛn, a bɛ se ka ji, funteni, kemikaliw ani furajiw kɛlɛ. Kuranko insulasi jogo ɲumanw b’a la.

A bɛ baara kɛ ni minnu ye:

gears, bushings, mobili da minɛw .

Panneau de turn de turn de trouver .

Panɛliw ka baarakɛlaw .

Snap-in flush top rivets .

Polisulfone (PSU) .

PSU bɛ baara kɛ kɛrɛnkɛrɛnnenya la k’a sababu kɛ a ka funteni ni a ka masina seko ka bon.

Fɛn minnu ye fɛnba ye:

resistance chimique ɲuman .

A bɛ kɛ furakɛli fɛɛrɛw la, furaw la, dumuni dilanni na, ani ɛntɛrinɛti la .

A bɛnnen don snap rivets .

Fɛnw nafaw sumalen .

Nin ye tabali ye min bɛ nin fɛn ninnu nafaw suma ɲɔgɔn na:

| Properties | LDPE | PP | Nylon 6/6 | Acetal | PSU . |

| Tensile fanga (PSI) . | 1 400 ye . | 3 800-5 400 . | 12 400 ye . | 9 800-10 000 . | 10 200 ye . |

| Impact Toughness (J/M⊃2;) | No break . | 12,5-1,2. | 1.2 | 1,0-1,5 ye. | 1.3 |

| Dielektriki fanga (kv/mm) . | 16-28 . | 20-28 . | 20-30 . | 13,8-20 . | 15-10 . |

| densité (g/cm³) | 0,917-0,940 . | 0,900-0,910 ye . | 1,130-1,150 ye . | 1,410-1,420 ye . | 1,240-1,250 ye . |

| Max. Baara min bɛ kɛ ka taa a fɛ temp. | 212°F (100°C) | 266°F (130°C) | 284°F (140°C) | 221°F (105°C) | 356°F (180°C) |

| Insulation thermal (w/m·k) . | 0,320-0,350 . | 0,150-0,210 . | 0,250-0,250 . | 0,310-0,370 . | 0,120-0,260 . |

Aw ye aw hakili to a la ko farankanw ni sabatili bɛ se ka nafa dɔw bonya. Misali la, UV sabatililanw bɛ se ka Nylon ka kɛnɛyako ɲɛ.

Cogo min na ka rivet hakɛ bɛnnen sugandi .

Sariyabaju min bɛ kɛ .

Fɛɛrɛ nɔgɔman dɔ ye ka rivet diamètre (rivet cɛmancɛ) basigi plates (plates) minnu bɛ fara ɲɔgɔn kan, olu girinya kan. Nin ye sariya ye min bɛ wele ko

rivet diamètre = 1/4 × plate thickness .

O hakɛ in b'a Jira ko rivet bɛ Bɛn ni fɛn ye a bɛ min Minɛ ɲɔgɔn na. A bɛ fɔ fana ko grip range.

Fɛn minnu ka kan ka jateminɛ .

Hali ni sariyaba ye daminɛ ɲuman ye, fɛn wɛrɛw bɛ yen minnu ka kan ka to an hakili la:

Material Propriétés .

Joint design .

Joli suguya (lap, butt, etc.) .

Loading conditions (Shear, tension, etc.) .

Aesthetics .

Lajɛ kɛcogo .

O kow bɛ se ka nɔ bila rivet hakɛ ɲuman na. Tuma dɔw la, a bɛ se ka kɛ ko i ka kan ka bɔ sariyaba la walasa ka ɲɛtaa ɲumanw sɔrɔ.

Misaliw ni jatebɔw .

An ka misali damadɔw lajɛ walasa ka hakɛ jateminɛcogo jira.

Misali 1: .

Misali 2nan : .

Plate janya: 10 mm .

Rivet diamètre = 1/4 × 10 mm = 2,5 mm .

lamini fo ka se hakɛ dantigɛlen ma, misali la, milimɛtɛrɛ 3 .

Misali 3nan : .

Fali ka bonya: 2 mm (Flananw bɛ kɛ ka ɲɛ) .

Rivet diamètre = 1/4 × 2 mm = 0,5 mm .

Aw bɛ dɔ fara a hakɛ fitinin kan, misali la, milimɛtɛrɛ 1, walasa a sigili nɔgɔya ani a fanga .

Aw ye aw hakili to a la ko nin jatebɔ ninnu bɛ daminɛyɔrɔ di. Aw ye aw ka ɲinini kɛcogo kɛrɛnkɛrɛnnenw jateminɛ tuma bɛɛ ani ka ladilanni kɛ i n’a fɔ a mago bɛ cogo min na.

| Plate thickness (mm) | rivet diamètre (mm) . |

| 1-2. | 1 |

| 3-4 ye. | 1-2. |

| 5-8 ye. | 2-3 ye. |

| 9-12 ye. | 3-4 ye. |

| 13-16 . | 4-5 . |

Kuncɛli

Nin gafe in kɔnɔ, an ye riveting kɛcogo suguya caman sɛgɛsɛgɛ plastiki yɔrɔw la, i n’a fɔ funteni funteni, fiɲɛ sumalen, ani ultrasonic fɛɛrɛw. An ye kuma fana rivet kunkolo suguya wɛrɛw kan ani u baarakɛcogo kɛrɛnkɛrɛnnenw kan.

Ka riveting kɛcogo ɲuman ni fɛnw sugandi, o nafa ka bon kosɛbɛ walasa ka jɛɲɔgɔnya barikamaw ni sabatilenw sabati plastiki lajɛw kɔnɔ. Sugandili ɲuman bɛ se ka nɔba bila i ka fɛn dilannenw ka ɲɛnamaya jan na ani u ka baara kɛcogo la.

Sisan, nin dɔnniya in bɛ i la, an b’i jija i ka nin hakilinaw waleya i ka porozɛw kan. O kɛli fɛ, i bɛna sɔrɔw sɔrɔ minnu ka fisa ani i ka fɛn dilannenw ka fɛn dilanni cɛsiriw la. Aw ye anw sɔrɔ bi !