Abubuwan da ke haifar da haƙuri na allurar rigakafi suna tabbatar da madaidaicin sassan filastik. Me yasa suke da mahimmanci? Ba tare da ingantaccen haƙuri ba, sassa bazai dace ba ko aiki daidai. A cikin wannan post, zaku koyi mahimmancin waɗannan abubuwan haƙuri, abubuwan da suka shafi inganta sakamako don kyakkyawan sakamako.

Menene haƙuri mai haƙuri?

Tsabtace haƙuri mai haƙuri yana nufin bambancin da ba zai dace ba da fasali. An ƙayyade su ta hanyar masu zanen kaya da injiniyoyi don tabbatar da abubuwan haɗin abubuwa masu dacewa da aiki kamar yadda aka nufa.

Haƙuri yana da mahimmanci a cikin allurar. Ko da ƙananan karkacewa na iya haifar da abubuwan da suka shafi Majalisar ko Shafawar Ayyukan Samfurin. Tantance yarda da haƙƙin yarda da daidaito da daidaito.To ƙarin koyo game da batutuwa na gama gari waɗanda zasu iya shafar jagorarmu, duba Jagorarmu akan Rashin daidaituwa na allurar rigakafi da yadda za a warware su.

Nau'in haƙurin yin haƙuri na allurar rigakafi

Akwai nau'ikan haƙuri da yawa don la'akari da yanayin allurar:

Matsakaicin haƙuri +/- mm

|

haƙuri na kasuwanci |

mafi ƙarfi |

|

|

|

|

|

| Gwadawa |

1 zuwa 20 (+/- mm) |

21 zuwa 100 (+ + Mm) |

101 zuwa 160 (+/ mm) |

Ga kowane 20mm sama da 160 ƙara |

1 zuwa 20 (+/- mm) |

21 zuwa 100 (+ + Mm) |

Sama da 100 |

| Abin da |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

| Abs / pc |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

| GPS |

0.075 |

0.150 |

0.305 |

0.100 |

0.050 |

0.080 |

|

| Hdpe |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| Ldpe |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| MOM PPO / PPE |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

| K |

0.075 |

0.160 |

0.310 |

0.080 |

0.030 |

0.130 |

|

| PA 30% gf |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

|

| PBT 30% gf |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

NASIHI |

| PC |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

da ake buƙata don duka |

| PC 20% gilashi |

0.050 |

0.100 |

0.200 |

0.080 |

0.030 |

0.080 |

kayan |

| Hula |

0.075 |

0.120 |

0.250 |

0.080 |

0.050 |

0.070 |

|

| Yi shelar alkjjada |

0.075 |

0.160 |

0.310 |

0.080 |

0.030 |

0.130 |

|

| Pp |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| PP 20% Talc |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| PPS 30% gf |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

|

| San |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

Nanƙwasawa / Rashin haƙuri: Waɗannan magunguna tare da warppage na lebur saman. Abubuwa kamar Gate Lit, sanyaya sanyaya, da zaɓi na ƙasa na iya rage warpping. Don ƙarin bayani kan hana warping, ziyarci labarinmu kan Warping a cikin allurar m.

Madaidaiciya / rashin yarda da

|

haƙuri mai |

haƙuri |

|

|

| Girma |

0-100 (+/- mm) |

101-160 (+/- mm) |

0-100 (+/- mm) |

101-160 (+/- mm) |

| Abin da |

0.380 |

0.800 |

0.250 |

0.500 |

| Abs / pc |

0.380 |

0.800 |

0.250 |

0.500 |

| Acetal |

0.300 |

0.500 |

0.150 |

0.250 |

| Na acrylic |

0.180 |

0.330 |

0.100 |

0.100 |

| GPS |

0.250 |

0.380 |

0.180 |

0.250 |

| MOM PPO / PPE |

0.380 |

0.800 |

0.250 |

0.250 |

| K |

0.300 |

0.500 |

0.150 |

0.250 |

| PA 30% gf |

0.150 |

0.200 |

0.080 |

0.100 |

| PBT 30% gf |

0.150 |

0.200 |

0.080 |

0.100 |

| PC |

0.150 |

0.200 |

0.080 |

0.100 |

| Polycarbonate, gilashin 20% |

0.130 |

0.180 |

0.080 |

0.100 |

| Polyethylene |

0.850 |

1.500 |

0.500 |

0.850 |

| Polypropylene |

0.850 |

1.500 |

0.500 |

0.850 |

| Polypropylene, 20% Talc |

0.850 |

1.500 |

0.500 |

0.850 |

| PPS 30% gf |

0.150 |

0.200 |

0.080 |

0.100 |

| San |

0.380 |

0.800 |

0.250 |

0.500 |

Rami mai biyayya +/- mm

|

mai haƙuri na kasuwanci |

mafi ƙarfi |

|

|

|

|

|

|

| Gwadawa |

0-3 (+/ mm) |

3.1-6 (+/ mm) |

6.1-14 (+/- mm) |

14-40 (+/- mm) |

0-3 (+/ mm) |

3.1-6 (+/ mm) |

6.1-14 (+/- mm) |

14-40 (+/- mm) |

| Abin da |

0.050 |

0.050 |

0.080 |

0.100 |

0.030 |

0.030 |

0.050 |

0.050 |

| Abs / PC |

0.050 |

0.050 |

0.080 |

0.100 |

0.030 |

0.030 |

0.050 |

0.050 |

| GPS |

0.050 |

0.050 |

0.050 |

0.090 |

0.030 |

0.030 |

0.040 |

0.050 |

| Hdpe |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| Ldpe |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| K |

0.050 |

0.080 |

0.080 |

0.130 |

0.030 |

0.040 |

0.050 |

0.080 |

| PA30% GF |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| PBT30% GF |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| PC |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| PC 20% gf |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| Hula |

0.080 |

0.080 |

0.100 |

0.130 |

0.030 |

0.050 |

0.050 |

0.080 |

| Yi shelar alkjjada |

0.050 |

0.080 |

0.080 |

0.130 |

0.030 |

0.040 |

0.050 |

0.080 |

| Pp |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| PP, 20% Talc |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| PPS 30% gilashi |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| San |

0.050 |

0.050 |

0.080 |

0.100 |

0.030 |

0.030 |

0.050 |

0.050 |

Makaho Dace Zurfin Tsaro +/- MM

|

Kasuwancin |

haƙuri Mai haƙuri |

|

|

|

|

| Gwadawa |

1-6 (+/ mm) |

6.1-14 (+/- mm) |

Sama da 14 (+/ mm) |

1-6 (+/ mm) |

6.1-14 (+/- mm) |

Sama da 14 (+/ mm) |

| Abin da |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| Abs / pc |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| GPS |

0.090 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| Hdpe |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| Ldpe |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| K |

0.100 |

0.100 |

0.130 |

0.050 |

0.080 |

0.100 |

| PA, 30% gf |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| PBT, 30% gf |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| PC, 20% gf |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| Hula |

0.100 |

0.100 |

0.130 |

0.050 |

0.080 |

0.100 |

| Polycarbonate |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| Yi shelar alkjjada |

0.100 |

0.100 |

0.130 |

0.050 |

0.080 |

0.100 |

| Pp |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| PP, 20% Talc |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| PPO / PPE |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| PPS, 30% gf |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| San |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

Cikakken ƙarfin / or/- mm

|

mai haƙuri na kasuwanci |

mafi ƙarfi |

| Gwadawa |

Har zuwa 100 (+/- mm) |

Har zuwa 100 (+/- mm) |

| Abin da |

0.230 |

0.130 |

| Abs / pc |

0.230 |

0.130 |

| GPS |

0.250 |

0.150 |

| Hdpe |

0.250 |

0.150 |

| Ldpe |

0.250 |

0.150 |

| K |

0.250 |

0.150 |

| PA, 30% gf |

0.150 |

0.100 |

| PBT, 30% gf |

0.150 |

0.100 |

| PC |

0.130 |

0.080 |

| PC, 20% gf |

0.130 |

0.080 |

| Hula |

0.250 |

0.150 |

| Yi shelar alkjjada |

0.250 |

0.150 |

| Pp |

0.250 |

0.150 |

| PP, 20% Talc |

0.250 |

0.150 |

| PPO / PPE |

0.230 |

0.130 |

| PPS, 30% gf |

0.130 |

0.080 |

| San |

0.230 |

0.130 |

Kasuwanci da VS. Damuwa mai kyau

Ana iya rarrabe haƙurin haƙurin haƙurin gina jiki a cikin nau'ikan biyu:

Yin hakuri na kasuwanci: Waɗannan ba su da gaskiya amma mafi tattalin arziƙi. Sun dace da aikace-aikacen da ba su da mahimmanci kuma suna ba da damar don bambancin canji.

Lafiya (daidai) haƙuri: waɗannan wadatar ke bayarwa da iko a bangare. Suna buƙatar m molds da tsayayyen tsari, yana sa su fi tsada.

Zabi tsakanin jabumin kasuwanci da kyakkyawan haƙurin halitta ya dogara da takamaiman aikace-aikacen da buƙatun aiki na ɓangaren.

Don ƙarin koyo game da wannan, duba Jagorarmu akan Iri na ƙofofin don allurar rigakafi.

Mahimmancin haƙurin yarda

Abubuwan da ke haifar da haƙuri mai haƙuri suna taka muhimmiyar rawa wajen samar da sassan filastik mai inganci. Suna tabbatar cewa abubuwan haɗin sun haɗu da ƙayyadaddun abubuwan da ake buƙata kuma suna yin nufin da aka yi niyya. Bari mu bincika abin da yasa haƙuri yake da muhimmanci kuma menene zai faru lokacin da ba a sarrafa ba su da kyau.

Me yasa wadatar hakuri?

Tabbatar da aiki aiki da Fit

Yin haƙuri da garanti wannan rashin daidaituwa ya dace da aiki daidai. Suna ba da damar ɗan bambancin ɗan girma yayin da har yanzu ke riƙe da amincin bangaren. Ba tare da haƙƙin haƙurin da ya dace ba, abubuwan haɗin gwiwa bazai yi aure yadda yakamata yayin taro ko aiki kamar yadda aka tsara ba.

Ka yi tunanin ƙoƙarin yin rawar jiki guda biyu na filastik biyu. Idan da makaman sun sako sosai, za a sami gops da rataye. Idan sun yi tsauri, sassan ba za su dace ba kwata-kwata. Madaidaici yarda da tabbatar da amintaccen, sumul.

Tasiri kan taro da wasan kwaikwayon

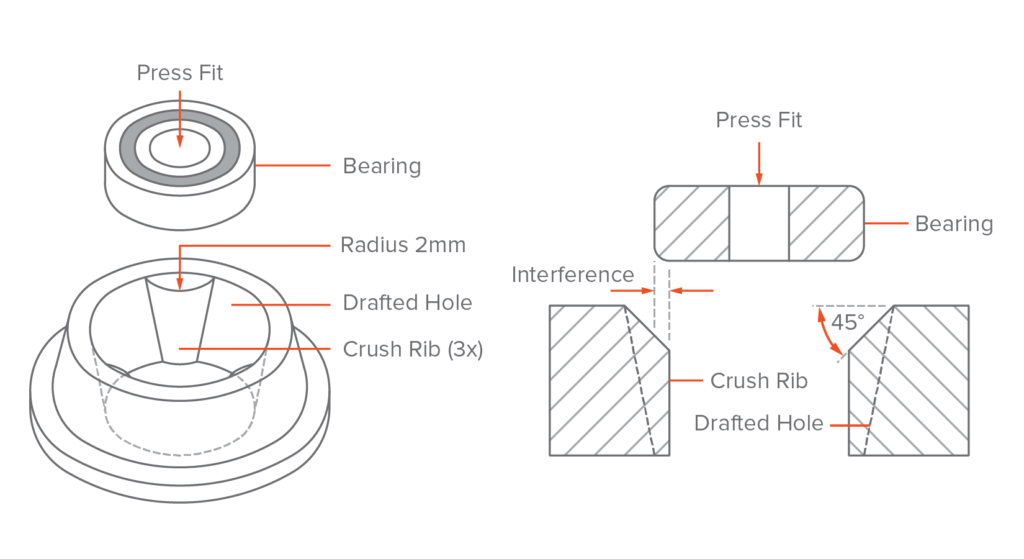

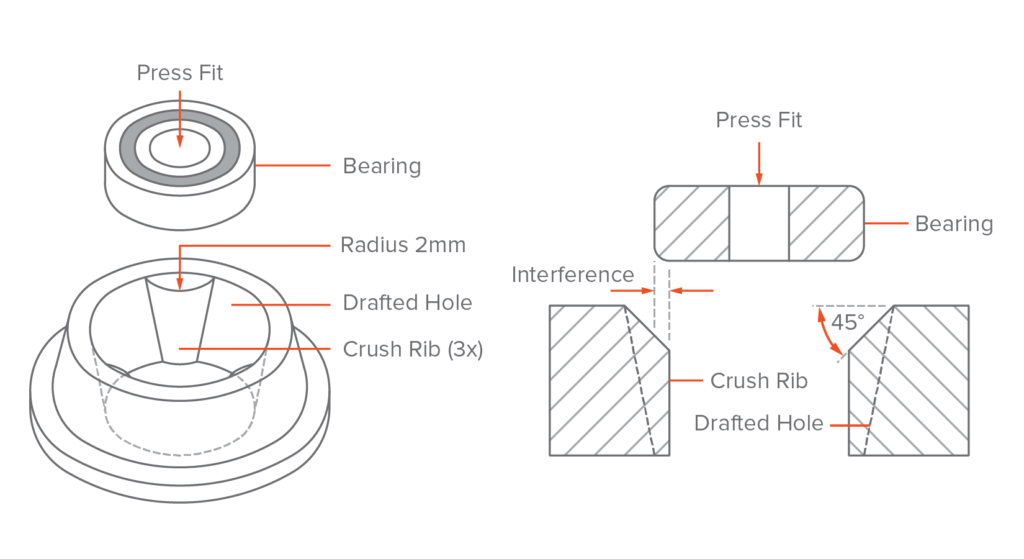

Al'adar allurar rigakafi sau da yawa suna aiki tare da wasu abubuwan haɗin. Suna iya buƙatar ɗaukar masu ɗaukar hoto, a daidaita tare da sassan matuli, ko ba da izinin kyakkyawan aiki na abubuwa masu motsi. Yin haƙuri yana da mahimmanci don tabbatar da cewa duk waɗannan waɗannan abubuwan da waɗannan waɗannan abubuwan suna faruwa ba su gani ba.

Aauki kayan filastik a matsayin misali. Idan kayan kwalliyar kayan sun fito ne daga haƙuri, yana iya ba raga daidai da takwaransa. Wannan na iya haifar da ingantaccen aiki, wuce gona da iri, ko ma ga gazawar tsarin.

Sakamakon rashin haƙuri mara kyau

Kurakuran Majalisar

Lokacin da ba a riƙe da haƙuri don ƙayyadadden, Majalisar ta zama ƙalubale ba. Abubuwan na iya yin gyara, mata, ko a ɗaure kamar yadda aka nufa. Wannan yana haifar da jinkiri, maimaitawa, da kuma ƙara farashin samarwa.

Yi la'akari da gidajen lantarki. Idan bostsses ga sukurori sun daina haƙuri, na'urar ba zata tara da kyau ba. Kurbaye na iya tsiri, ko gidaje bazai rufe ba cikin aminci. Wadannan batutuwan suna haifar da lokacin da aka ɓata lokaci da kayan.

Ayyuka da lahani masu kyau

Kulawar rashin haƙuri na iya haifar da matsaloli na aiki a cikin samfurin karshe. Abubuwan da aka ɓoye ko sassa masu dacewa da abubuwa na iya haifar da:

Leaks

Gips

M saman

Wuce gona da iri

Rashin ƙarfi

Waɗannan lahani ba kawai shafar aikin samfurin ba amma kuma lalata daga bayyanar sa. Abubuwan da aka bayyane, ko kuma kayan haɗin wobtling, ko abubuwan haɗin wobbling na iya yin samfurori masu arha da kuma yadda za su iya hana su, bincika cikakken jagorarmu a kan Laifi na allurar rigakafi.

Oneaya daga cikin musamman gama gari batun da ya shafi rashin haƙuri haƙuri yana warping. Wannan na iya shafan mafi inganci da aiki na sassa. Don ƙarin bayani game da wannan batun, ziyarci labarinmu a kan Warping a cikin allurar m.

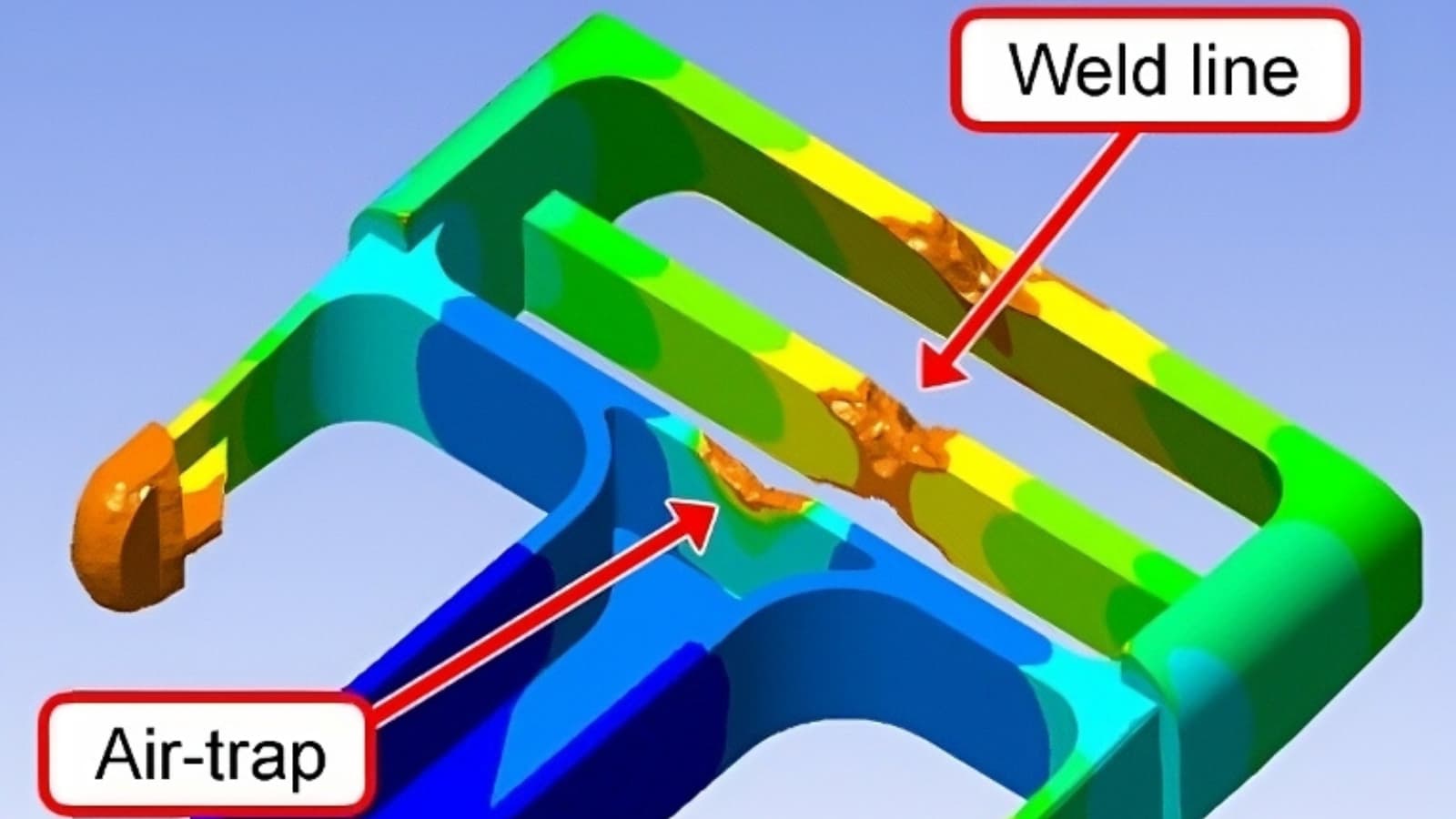

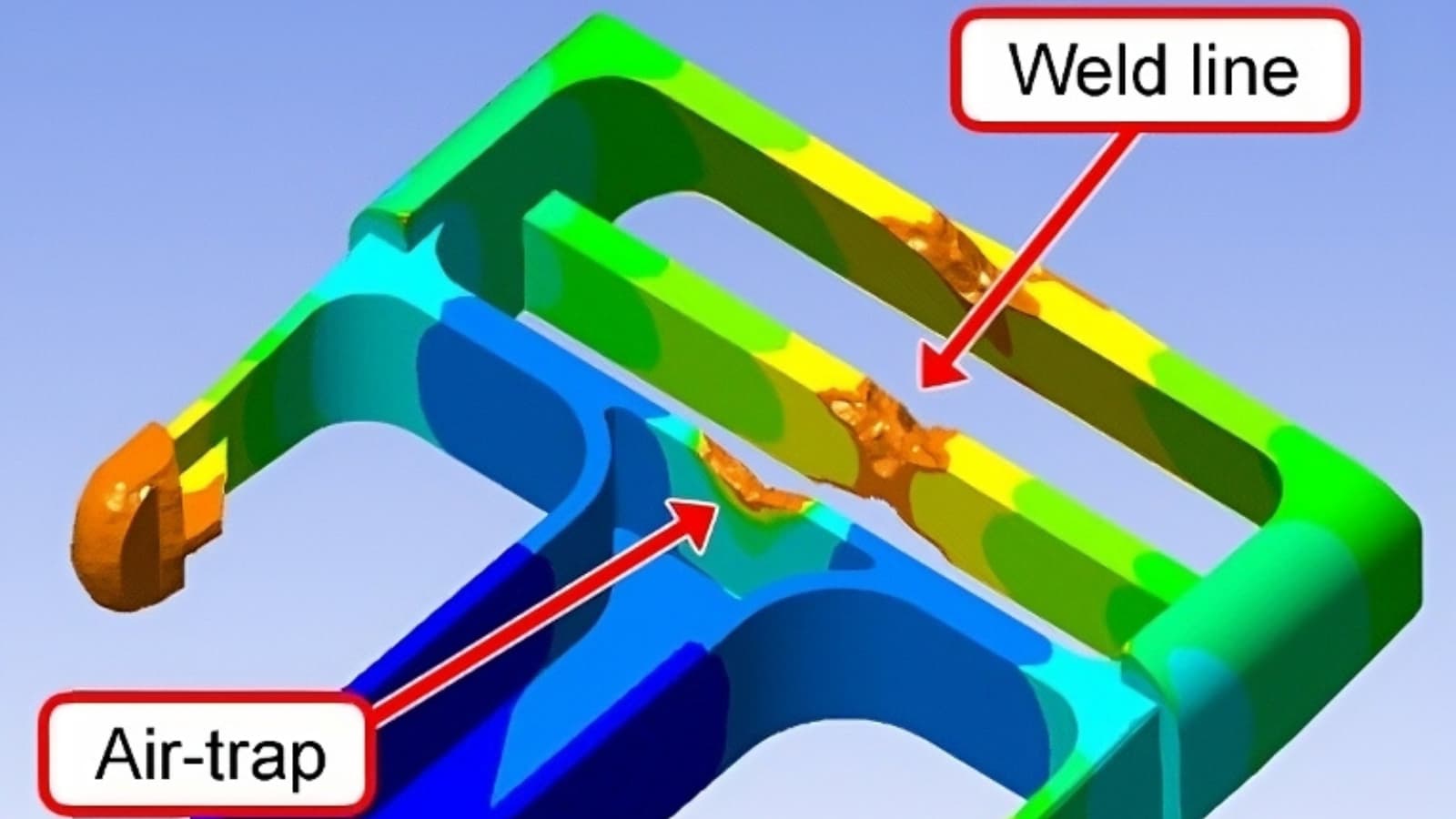

Wani batun mai ban sha'awa wanda zai iya fitowa daga ikon haƙuri mara kyau shine bayyanar alamun ruwa. Wadannan na iya zama matsala musamman a wuraren da ake iya sassanta. Don ƙarin koyo game da alamun alamun ruwa da kuma yadda za a hana su, ga Jagorarmu a Alamar sanya alama a cikin allurar.

Abubuwa suna shafar haƙurin yarda

Samun m jaddada a cikin allurar da ake buƙata yana buƙatar la'akari da abubuwa da yawa. Daga ɓangaren zane zuwa zaɓi na kayan, kayan aikin gona, da sarrafa sarrafawa, kowane bangare yana taka muhimmiyar rawa. Bari mu nutse cikin mahimman abubuwan da ke tasiri ga haƙurin hakoran gyara na gyara.

Part Design

Gaba daya girman

Duk girman bangaren yana da tasiri mai tasiri ga hakora. Mafi girma sassa don fuskantar ƙarin shrinkage lokacin sanyaya, yana sa ya da wahala don kula da m juriya. Masu zanen kaya suna buƙatar asusun don wannan lokacin da bayanin girman tasirin abubuwa da haƙuri.

Kauri

Kauri bangon kauri yana da mahimmanci don sarrafa haƙuri. Bambancin cikin kauri a cikin kauri na bango na iya haifar da sanyaya sanyaya da shrinkage, wanda ya haifar da warpage da girma rashin jituwa. Yana da mahimmanci don kula da tufafi na gari a duk ɓangaren.

Daftarin kusurwa

Angles kusurwa wajibi ne don sauƙi tabarau daga ɓangaren daga mold. Koyaya, suna iya shafar yin haƙuri. Za'a iya buƙatar kusurwoyi masu zurfi don fasalolin zurfin, wanda na iya tasiri girman sashin. Masu zanen kaya su cika daidaito tsakanin sauƙin yin watsi da haƙuri.

Bosses

Ana amfani da shugabanni na fasali da aka yi amfani da su don hawa ko ƙarfafa. Suna iya zama ƙalubale daga hangen nesa. Lokacin farin ciki zai iya haifar da alamun haskoki da warpage saboda jinkirin sanyaya. Masu zanen kaya su ce su bi mafi kyawun ayyukan mai kyau, kamar su kula da daidaitattun bangon kauri da gujewa canje-canje na ban mamaki a kauri. Don ƙarin koyo game da hana alamun haskoki, ziyarci labarinmu a kan Alamar sanya alama a cikin allurar.

Zabin Abinci

Ruwan Shrinkage na rudani daban-daban

Kayan kayan filastik suna da ƙimar shrinkage. Wasu abubuwa, kamar Polypropylene, suna da mafi girman matsakaicin fiye da wasu, kamar su abs. Masu zanen kaya dole ne suyi la'akari da adadin zaɓin kayan da aka zaɓa yayin haƙuri. Masu zanen mold masu zanen kaya suna buƙatar aiwatar da asusun don ƙirƙirar kayan aiki.

| Abu |

Yankin Shirin Shrinkagu |

| Abin da |

0.7-1.6 |

| PC / Abs |

0.5-0.7 |

| Acetal / pom (delrin®) |

1.8-2.5 |

| ASA |

0.4-0.7 |

| Hdpe |

1.5-4 |

| Kwatangwalo |

0.2-0.8 |

| Ldpe |

2-4 |

| Naylon 6/6 |

0.7-3 |

| Nailan 6/6 gilashi cike (30%) |

0.5-0.5 |

| Pbt |

0.5-2.2 |

| Gilashin PBT sun cika (30%) |

0.2-1 |

| Ƙafa |

1.2-1.5 |

| Gilashin peek cika (30%) |

0.4-0.8 |

| Pei (ultem®) |

0.7-0.8 |

| So |

0.2-3 |

| Pmma (acrylic) |

0.2-0.8 |

| PC |

0.7-1 |

| Gilashin pc cike (20-40%) |

0.1-0 |

| Gilashin polyethylene ya cika (30%) |

0.2-0.6 |

| Polypropylene homopollymer |

1-3 |

| Polypropylene Cockolmer |

2-3 |

| PPA |

1.5-2.2 |

| Poarinet |

0.5-0.7 |

| PPS |

0.6-1.4 |

| PSU |

0.7-0.7 |

| M pvc |

0.1-0.6 |

| San (AS) |

0.3-0.7 |

| Tpe |

0.5-2.5 |

| Tpu |

0.4-1.4 |

Tebur: [Shringage ƙididdiga]

Tasiri na FLALER da ƙari akan Shrockage

Flers da ƙari kuma suna iya yin tasiri harma da haƙuri. Misali, matsalolin da aka cike filayen gilashi suna iya samun ragin ƙananan ƙamshi fiye da sigogi marasa rinjayi. Koyaya, kasancewa tare da fibers na iya haifar da shrinkage mai narkewa, inda sashin yana raguwa daban-daban a cikin hanyoyi daban-daban. Yana da mahimmanci a yi la'akari da tasirin masu flers da ƙari lokacin zabar kayan da yin haƙuri.

Kayan aiki

Mallaka ƙira da tashoshin sanyaya

Tsarin ƙira da ya dace yana da mahimmanci don kiyaye haƙuri. Matsayi da Matsayi na tashoshin sanyaya na iya tasiri sosai. M sanyaya na iya haifar da warpage da girma canji. Masu zanen mold suna da masu zanen wuta dole ne a tabbatar da cewa sanyaya ba shi da uniform a cikin kayan aiki don rage waɗannan lamuran.

Gateofar Gateofar Gateofa da Ejector Pin wurare

Wurin da ƙofofin ƙofofi da ejector fil na iya shafar haƙuri. Gates sune wuraren shigarwa don filastik na molten, kuma wurinsu na iya tasiri cikin kwarara da sanyaya kayan. Ejector Pins ana amfani da shi don cire ɓangaren daga ƙirar, da kuma wurin da wurarensu da zane suna iya tasiri ɓangarorin ƙarshe na ƙarshe. Da hankali da la'akari da ƙofar ƙofar da Ejector Pint Wurin Matsayi ya zama dole don kula da haƙuri. Don ƙarin bayani kan nau'ikan ƙofofa da tasirin su, ga Jagorarmu akan Iri na ƙofofin don allurar rigakafi.

Sarrafa sarrafawa

Shirya

Matsin yin allura shine mahimmancin tsari wanda ke shafar haƙuri. Da yawa daga cikin yanayin allura na iya haifar da yawan canje-canje, yana haifar da canje-canje na girma da damuwa a cikin sashin. Yayi ƙasa da matsi na iya haifar da cika da abubuwan da suka dace. Neman matsin lamba na rashin daidaituwa shine mabuɗin don ci gaba da yin haƙuri.

Rike lokaci

Lokaci na riƙe da lokaci yana nufin tsawon lokacin ana kiyaye matsin lamba bayan allurar farko. Isasshen lokaci ya zama dole don ba da damar ɓangaren don ƙarfafa kuma kula da girman sa. Rashin isasshen lokaci na iya haifar da alamun haskoki da canje-canje na girma. Timewararrun lokaci mai yawa, lokaci mai yawa na iya haifar da packing da damuwa. Inganta lokacin rike lokaci yana da mahimmanci don cimma m juriya.

Zazzabi na mold

Zazzabi mold zazzabi yana taka muhimmiyar rawa wajen sarrafa haƙuri. Zazzabi na mold yana shafar nauyin sanyaya filastik kuma, saboda haka, shrinkage da warpage na sashin. Kula da yanayin zafin jiki mai mahimmanci yana da mahimmanci don cimma mai maimaitawa girma. Ya kamata a kula da mold zazzabi kuma ana sarrafa shi don tabbatar da haƙuri da yarda da yarda.

Tsara don ingantaccen hakuri mai haƙuri

Tsara don Kasuwanci (DFM) Ka'idodi

Aderin da mizanan DFM sun tabbatar da cewa sassa suna da sauƙin ƙera. Wannan yana rage kurakurai kuma yana inganta kulawa ta haƙuri. Kyakkyawan ƙira yana rage farashi da sauri.

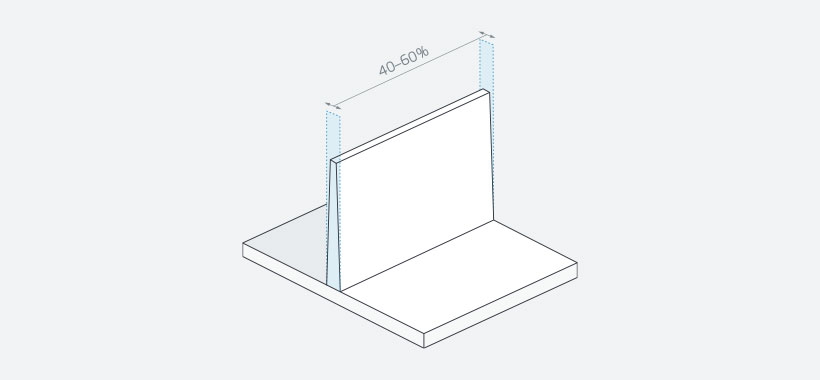

Kayan aiki

Kula da kauri tufafi na kauri yana da mahimmanci. Ganuwar da ba ta dace ba ta haifar da warping da nutsewa. Manufar har ma da kauri a cikin sashin. Wannan haɓaka haɓakar haɓakawa.

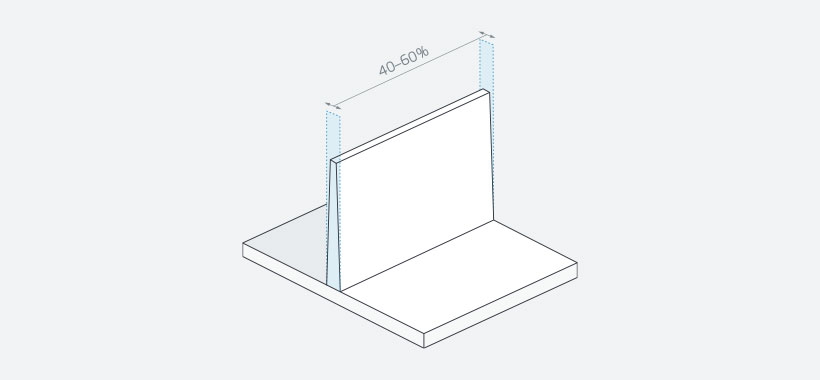

Zane: Sakamakon kauri

Dragles da ya dace

Angledungiyoyin daftarin da ke taimaka wa mai sauƙi tabarau daga molds. Ba tare da isasshen daft draft, sassan na iya tsaya da karkatarwa ba. Gabaɗaya, an bada shawarar daftarin digiri 1-2 ga yawancin sassan. Don cikakken bayani game da daftarin kusurwa da mahimmancinsu, ziyarci labarinmu akan daftarin kusurwa a cikin allurar m.

Core da rami na kirkira

Tsara cibiya da kogon daidai yana da mahimmanci. Tabbatar babu ingantattun abubuwan da suke wahalar da mold. Tsarin da ya dace yana haɓaka rayuwar ƙira da daidaitawa.

Tebur: Core da Rashin Tsarin Tsara

| Tukwaya |

Tunani |

| Guji cin abinci |

Sauƙaƙe ƙirar mold |

| Yi amfani da shimfiɗaɗɗu |

Tabbatar da ko da sanyaya |

| Inganta maki kare |

Yana hana nakasasshe |

Rabuwa da wuri

Layin rabuwa yana rinjayar ƙarshen ɓangaren ɓangaren ƙarshe da ayyukan yau da kullun. Sanya shi a cikin wani yanki mai mahimmanci don gujewa lahani da ake bayyane. Matsayi na ƙwarai ya tabbatar da tsabta rabuwa da ƙananan haske. Don ƙarin bayani game da ɓangaren layi, duba Jagorarmu akan rabu da layi a cikin allurar m.

Zaɓin kayan da haƙuri

Kayan abinci na gama gari da ƙimar shrinkage

Amorutan vs. Semi-Crystalline

Rikicin Amorphous, kamar Abs , yakan sauka daga robobi na Semi-lu'ulu'u. Joborar Jobrikwallon Semi-Crystalline, kamar Polypropylene, suna da kudaden shiga mai girma. Wannan bambanci yana da mahimmanci ga cimma m aminci.

Don ƙarin koyo game da allurar polypropylene da allurar rigakafi da kaddarorinmu na musamman, ziyarci labarinmu akan polypropylene intion.

Tasiri na FLALER da ƙari akan Shirin da Yin haƙuri

Flers da ƙari na iya shafar ƙyallen. Misali, zargin gilashin suna rage shrinkage da inganta kwanciyar hankali. Wannan yana inganta madaidaicin madaidaicin sassan. Filin filastik yana ƙaruwa sau da yawa amma na iya canza farashin shrinkage.

Misalai na abubuwan da suka dace

Gilashin gilashin : Rage shrinkage, yana inganta ƙarfi.

Filastik filastik : yana ƙaruwa sassauƙa, na iya canza shrinkage.

Wuta Rowards : Inganta juriya na kashe gobara ba tare da ya shafi shrinkage da yawa ba.

Binciken Ruwan Mold don Tsinkayen Shrinkage

Binciken tsintsaye na ƙira yana taimakawa hango yadda kayan zai rushe kayan. Wannan kayan aikin siminti yana ba masu tsara masu zanen kaya don ganin abubuwan da ke gudana da sanyaya. Yana kan ingantawa cikin tsarin ƙirar mold don cimma makar haƙuri da ake so.

Matakai a cikin Binciken Ruwan Mold

Tsarin kirkirar : haɓaka samfurin 3D na ɓangaren.

Saita na siminti : Papport abu kaddarorin da sarrafa sarrafawa.

Gudun siminti : bincika, sanyaya, da tsarin shrinkage.

Review sakamako : daidaita ƙira bisa kan bayanan siminti.

Ta amfani da bincike na kwastomomi na tsintsaye, masana'antu na iya hango maƙasusuwa masu ƙarfi. Wannan yana tabbatar da cikakken haƙuri da sassa masu inganci. Don abubuwa masu ci gaba tare da takamaiman halayen shrinkage, kamar peek, la'akari da karanta labarinmu a kan Peok allurar gyada.

Kayan aiki da yarda da haƙurin motsa jiki

Designirƙirar ƙira da tasirinsa ga haƙuri

Tsarin mold kai tsaye yana tasiri hakorar jijiya da jijiya. Mold-da aka tsara mold yana tabbatar da sassa daidai da daidaito da daidaito. Tsarin talakawa yana haifar da rashin daidaituwa game da rashin tsaro da lahani. Don fahimta cikin ƙirar ƙirar maɓallin keɓaɓɓen, duba Jagorarmu akan tsara farantin tsere a cikin allurar gyara.

Sananniyar tashar tashar jirgin ruwa da kuma sanyin sanyi

Madaidaiciyar sananniyar tashar sanyaya tana da mahimmanci. Uniform sanyaya yana hana warping da shrinkage. Ya kamata a sanya tashoshi kan layi don ko da diski mai zafi.

Gateofar Gateofar Gateofa da Ejector Pin wurare

Gateofar Gateofar Gateofar Gateofa da Ejection wurare suna shafar wani inganci. Gates ya kamata a cikin wuraren farin ciki-walled don tabbatar da cikakken shiryawa. Ejeshin Pins dole ne a sanya su don guje wa lalata.

Tebur: Gateofi da Ejector PIN

| TOVEPIONA |

TOVE |

| Gateofar da ke cikin farin ciki |

Yana tabbatar da kwararar kayan da ya dace |

| Dabarun PIN |

Yana hana warping da nakasa |

Don cikakken bayani game da pins na musamman, ziyarci jagora namu akan Ejeshin fil a cikin allurar m.

Mummunan abu da haƙurinsu

Zabi na mold abu yana tasiri hakoran injin. Abubuwan da ke da inganci suna ba da damar yin haƙuri da kyau. Tsarin Motoci na tabbatar da mold ɗin yana kiyaye daidaitonsa akan lokaci.

Lissafi: Halayen Kayan Abu

Sarrafa sarrafawa don kiyaye hakuri

Mahimmancin daidaitattun sigogi

Sigogin aiwatar da tsari suna da mahimmanci a cikin allurar da aka gyara. Sun tabbatar da ingancin da kuma kula da hankali. Bambance-bambancen a sigogi na iya haifar da lahani da girma ba.

Matsin allurar rigakafi da tasirinsa akan hakuri

Matsakaicin allura kai tsaye yana shafar kayan abu. Babban matsin yana tabbatar da cikakkiyar matsala. Matsakaicin matsi na iya haifar da voids da shrinkage, mai tasirin haƙuri. Don ƙarin koyo game da batutuwan da suka shafi cikawa, duba jagorarmu a Short Shots a cikin allurar m.

Rike lokaci da zazzabi

Lokaci mai dacewa da kyau yana hana kayan abu. Yana tabbatar da sassan riƙe sifar su da girma. Lokaci ba daidai ba yana haifar da warping da alamun alamun ruwa. Motsauki zazzabi yana aiki daidai. Tsarin zazzabi yana tabbatar da sanyaya sutura da rage damuwa na ciki.

Tebur: Kyakkyawan lokutan riƙe da yanayin zafi da kuma

| yanayin zafi |

kaɗan |

| Rike lokaci |

5-15 seconds |

| Zazzabi na mold |

75-105 ° C |

Hanyar kimiyya ta kimiyya

Maganar kimiyya ta inganta tsarin allura. Yana amfani da bayanai don sarrafa canji kamar matsin lamba, lokaci, da zazzabi. Wannan hanyar tana tabbatar da maimaitawa da daidaito, rike m hakuri a kan samarwa.

Matakai a cikin ilimin kimiyya

Tarin bayanai : Taro bayanan tsari.

Bincike : Gano mafi ƙarancin saiti.

Aiwatar : Aiwatar da saitunan a samarwa.

Kulawa : ci gaba da saka idanu da daidaitawa.

Matsayi da dabarun dubawa

Binciko na gani

Binciken gani shine matakin farko a cikin kulawa mai inganci. Yana taimaka gano ƙa'idojin ƙasa da warpage da sauri. Sufeto na neman karce, dents, da sauran ajizai.

Zane-zane: surface

Kayan aikin kayan aiki

Calipers da Micrometers

Calipers da micrometers suna da mahimmanci ga ma'aunin jagora. Suna ba da tabbatattun karatu game da girma. Yi amfani da su don auna kauri, diamita, da zurfin.

Mafi kyawun ayyukan don auna ma'auni

Yi amfani da ingantacciyar hanya don tabbatar da daidaito. Zero da caliper kafin kowane amfani. Aiwatar da matsin lamba don gujewa yanayin.

Tebur: Mita na ma'auni mafi kyau ayyukan amfani

| da kayan aikin |

amfani da kayan aiki |

| Calipers |

Sifili kafin amfani |

| Micromereters |

Aiwatar da matsin lamba |

Tsarin aiki na atomatik

Gudanar da auna injin (cmms)

Cmms suna samar da ingantacciyar daidaito don sassan sassa. Suna amfani da probes don auna daidaitawa na ɓangaren ɓangaren. Wannan hanyar tana da kyau don cikakken bincike na girma.

Tsarin hangen nesa

Tsarin hangen nesa yana amfani da kyamarori da masu aikin sirri. Sun kama hotuna da kuma nazarin girma ta atomatik. Waɗannan tsarin suna da sauri kuma mafi inganci ga manyan ayyukan girma.

Tarihin farko na farko (Fai)

FA wata cikakkiyar bincike ce ta farkon da aka samar. Hakan yana tabbatar da farkon sashi ya hadu da bayanai dalla-dalla. FIA ta ƙunshi auna duk girman girma da kuma kwatanta su da ƙirar.

Cikakken bincike na girma

FAI yana bincika kowane irin mahimmanci. Wannan nazarin ya tabbatar da cewa sashin ya dace da ƙirar.

Tabbatar da farkon sashi daidai

Cikakken labaran farko na farko saita ma'auni don samarwa. Suna taimakawa gano abubuwan da suka shafi da wuri. Wannan yana tabbatar da ingancin inganci a cikin sassan.

Tebur:

| Mataki na Fai |

Bayanin Binciken |

| Auna girma |

Kwatanta da ƙirar ƙira |

| Duba surface |

Duba don lahani |

| Tabbatar da kayan |

Tabbatar da kayan aiki daidai |

Kalubalen gama gari da mafita

Yin ma'amala da warpage da shrinkage

Gyare-gyare da zaɓuɓɓuka na abu

Warpage da shrinkage abubuwa ne na yau da kullun. Daidaita ƙirar na iya taimakawa. Yi amfani da madaidaicin bangon bango don rage warppage. Zaɓi kayan tare da ƙarancin shrinkage don mafi kyawun kwanciyar hankali.

Tebur: Kayan Kayan

| Kayan |

Sharimai |

| Abin da |

M |

| Polypropylene |

M |

| Nail |

Matsakaici |

Abubuwan da aka gyara

Gyara tsarin allura na iya rage warppage. Yi amfani da sandar sutura don hana shrinkage mara kyau. Daidaita matsarin allura don tabbatar da cika yawan mold.

Gudanar da haƙuri tarihin

Tasirin tarin abubuwa masu girma

Haƙuri mai haƙuri mataki yana faruwa lokacin da ƙananan karkacewa ƙara sama. Wannan na iya shafar dacewa da aiki na sassan. Fahimtar tasirin sakamako shine mabuɗin don sarrafa su.

Dabaru don rage batutuwan ajiya

Yawancin fasahohi suna taimakawa rage girman tarihin-UPS. Yi amfani da haƙuri mai haƙuri game da girman girma. Aiwatar da sarrafa tsarin ƙididdiga (SPC) don saka idanu. Tsara don Majalisar don tabbatar da abubuwan da suka dace da kyau.

Tebur: dabaru don Gudanar da haƙuri

| Fasali |

- |

| Mai haƙuri mai haƙuri |

Rage rikicewar tarawa |

| Ikon tsari na ilimin lissafi (SPC) |

Saka idanu da sarrafa inganci |

| Tsara don Majalisar |

Tabbatar da ingantaccen bangare ya dace |

Ƙarshe

Gwaji da sarrafa haƙurinsu na gyara yanayin rashin daidaituwa. Madaidaiciyar ibada tabbatar da sassa dace da aiki yadda yakamata. Tsara, zaɓi na abu, da sarrafa sarrafa duk irin ƙarfin tasiri. Maganar al'amura kamar warpage da shrinkage yana da mahimmanci don inganci.

Kokokin haɗin gwiwa tare da masu samar da ingantaccen kayan adon allurar rigakafi suna ba da fa'idodi da yawa. Suna kawo gwaninta da ingantaccen fasaha. Wannan yana tabbatar da ingancin sassa, ingantattu. Aiki tare da kwararru yana adana lokaci kuma yana rage farashi.

A taƙaice, sarrafa ikon yin haƙuri mai haƙuri mai haƙuri yana kaiwa ga ingantattun samfurori. Wannan yana da mahimmancin masana'antu da gamsuwa na abokin ciniki.