Plastiki dilanni taabolo bɛ plastiki wulilenw sɛmɛntiya ka kɛ fɛn gɛlɛnw ye minnu cogoya n’u jogo latigɛra ka kɔn. Nin fɛn dilanni fɛɛrɛ in bɛ baara kɛ ni fɛɛrɛ suguya caman ye walasa ka plastiki fɛnw dilan minnu dilannen don ni plastiki ye. O fɛn fɔlɔ minnu bɛ kɛ ni fɛnw ye minnu bɛ kɛ ka fɛnw labɛn, olu ye fɛnw ye minnu bɛ se ka kɛ fɛn ye, u bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka fɛnw ye. - Ka fanga sɔrɔ izini plastiki baarakɛcogo la.

Fɛɛrɛ kelen-kelen bɛɛ bɛ nafa ni seko danfaralenw lase plastiki dilanni na. K’a ta fɛn tigitigiw dilanni na minnu bɛ se ka kɛ fɛn caman ye, ka se fɛn caman ma minnu bɛ kɛ ni kɔnɔnatumuw ye, o baara ninnu bɛ baara kɛ ni izini mago suguya caman ye. Moli-fɛɛrɛ bɛnnen sugandili bɛ bɔ fɛnw na i n’a fɔ fɛn dilanni, fɛnw wajibiyalenw, fɛn dilanni hakɛ, ani sɔrɔko jateminɛw.

1. Blow Molding .

Nafa minnu bɛ sɔrɔ fiɲɛbɔlanw na .

Yɔrɔ minnu bɛ kɛ ni kɔnɔnafɛnw ye, olu dilanni hakɛ caman bɛ sɔrɔ ni musaka dɔgɔman ye .

A bɛ kogo janya kelen dilan minɛnw cogoya gɛlɛnw cɛ .

Cavity molds caman bɛ kɛ sababu ye ka buteliw dilan teliya la .

Aplikasi jɔnjɔnw .

Plastiki buteliw bɛ bɔ furakɛli minɛn fitininw na ka taa minɛnbaw la .

Mobili fɛnɲɛnamafagalan minnu bɛ ni kɔnɔnatumuw ye minnu ka gɛlɛn .

Industriw ka kemikɛli minɛnw minnu bɛ fɛnw ɲɛfɔcogo tigitigiw de wajibiya .

E Blow molding process bɛ daminɛ ni Parisson dɔ dabɔli ye - tube hollow of plastique chauffée min bɛ bɔ extrudeur dɔ la. Nin parison in bɛ jɔ nɔgɔ tilayɔrɔ fila ni ɲɔgɔn cɛ, minnu bɛ a lamini. O kɔfɛ, fiɲɛ min bɛ digidigi, o bɛ don fiɲɛbɔlan dɔ fɛ, ka plastiki nɔgɔlen fiyɛ fo a ka bɛn foroko kɔnɔna cogoya ma. Ni a nɛnɛna ka kɛɲɛ ni nɔgɔji kogow ye minnu nɛnɛnen don, a yɔrɔ gɛlɛn bɛ bɔ.

Blow molding bɛ tɛmɛ plastiki kɔnɔna na ka ɲɛ ani ka sɔrɔ, kɛrɛnkɛrɛnnenya la, a dilanni hakɛ ka ca. O kɛcogo bɛ minɛnw dilan minnu tɛ ɲɔgɔn ta, minnu bɛ kɛ kelen ye, k’a ta furakɛli buteli misɛnninw na ka se izini dununbaw ma. A ka se ka siginiden gɛlɛnw dilan ni bololanɛgɛw ye minnu bɛ ɲɔgɔn ta ani fɛn kɛrɛnkɛrɛnnenw, o b’a to a ka ɲi kosɛbɛ feerekɛlaw ka pakew ni mobili sɛnɛfɛnw na.

Molida kɛcogo bɛ baara kɛ fɔlɔ ni fɛnɲɛnamafagalanw ye minnu bɛ fanga ɲuman ni sɔgɔli kunbɛncogo ɲuman di. Fɛn minnu bɛ kɛ ka caya, olu ye poliyetilɛni (HDPE/LDPE) ye min ka bon ani min ka dɔgɔn, du kɔnɔ minɛnw kama, poliyetilɛni terefitalati (PET) min bɛ kɛ ka minfɛnw buteliw ta, ani poliporopilini (PP) minɛnw na minnu bɛ se ka kɛ ni kemikɛli ye. Fɛnw sugandili bɛ bɔ wajibi kɛrɛnkɛrɛnnenw de la walasa ka jɛya, fanga ani kemikɛli kunbɛn.

2. Pikirili Molidali .

Nafa minnu bɛ sɔrɔ pikiri kɛli la .

A bɛ plastiki yɔrɔ gɛlɛnw dilan ni u hakɛ tiɲɛni ye .

A ka baara hakɛ caman bɛ sɔrɔ ka tɛmɛn fɛnɲɛnamafagalan caman kan .

A ka fisa ni a ka baara ye ni a ka baara ye .

Aplikasi jɔnjɔnw .

Elektroniki so minnu bɛ fitininw ni fɛn caman de wajibiya .

Furakɛyɔrɔw bɛ sariyaw ni jogoɲumanya sariyaw labato minnu ka gɛlɛn .

Mobili yɔrɔw bɛ fanga ni cɛɲi jogo caman ɲini .

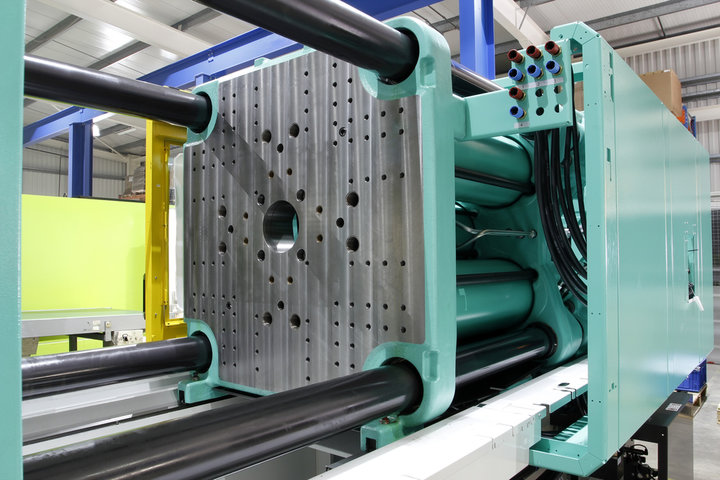

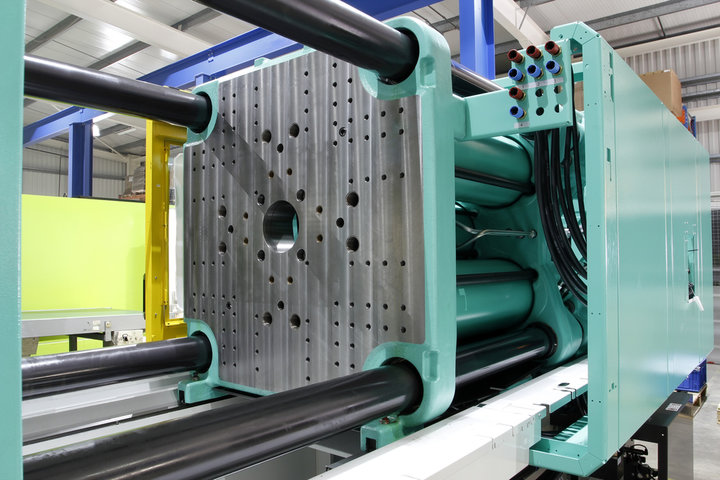

Pikiri kɛli bɛ baara kɛ ni plastiki wulilenw wajibiyali ye ka kɛ nɔgɔbɔlan datugulen ye degunba la. O kɛcogo bɛ daminɛ ni plastiki kurukuruw bɛ balo barajuru sumayalen na min kɔnɔ, fɛn min bɛ wuli ka wuli. Ni juru bɛ wuli, a bɛ fɛn in wuli ka a kɛ kelen ye k’a sɔrɔ a bɛ degunw jɔ. Ni fɛn caman dalajɛra, o kuru bɛ kɛ fɛn ye min bɛ kɛ ka fɛnw sɔgɔ, ka plastiki wulilen pikiri teliya la nɔgɔ la.

Nin wale caman bɛ kɛ plastiki dilanni na k’a sababu kɛ a seko ye ka yɔrɔ gɛlɛnw dilan ni hakɛ ɲuman ye ani ka kɛ ni dugukolo ye. A bɛ baara kɛ kosɛbɛ kɛrɛnkɛrɛnnenya la walasa ka fɛnw dilan minnu bɛ bɔ furakɛli minɛn misɛnninw na ka se mobili pannew ma. O kɛcogo bɛ sira di kunnafoni gɛlɛnw ma, fɛn caman ma, ani yɔrɔ minnu bɛ bɔ otomatiki la.

Fɛn minnu bɛ kɛ ka pikiri kɛ, olu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka fɛnw ye. Common choices include ABS for durable consumer goods, polypropylene for living hinges and consumer packaging, nylon for engineering components, and polycarbonate for transparent and impact-resistant parts. Fɛn minnu bɛ fara a kan, olu bɛ se ka fɛnw bonya i n’a fɔ fanga, tasumafagalan, walima UV sabatili.

3. Extrusion Molding .

Nafa minnu bɛ sɔrɔ extrusion molding .

Fɛn dilanni min bɛ kɛ ka taa a fɛ, o bɛ profiles basigilenw dilan ni hakɛ caman ye .

Fɛn caman bɛ se ka fara ɲɔgɔn kan ka kɛɲɛ ni fɛn kelen ye min bɛ kɛ .

Taabolow kɔlɔsili nɔgɔman bɛ se ka kɛ sababu ye ka baara kɛcogo kuntaalajanw kɛ ka ɲɛ .

Aplikasi jɔnjɔnw .

Pipew ni tubabukanw ka ɲɛsin jɔli ni izini baara ma .

Fenɛtiriw karamɔgɔya ni so caman ye funteni nafama kama .

Fire coating ka ɲɛsin kuran ni kumaɲɔgɔnya kabɔliw ma .

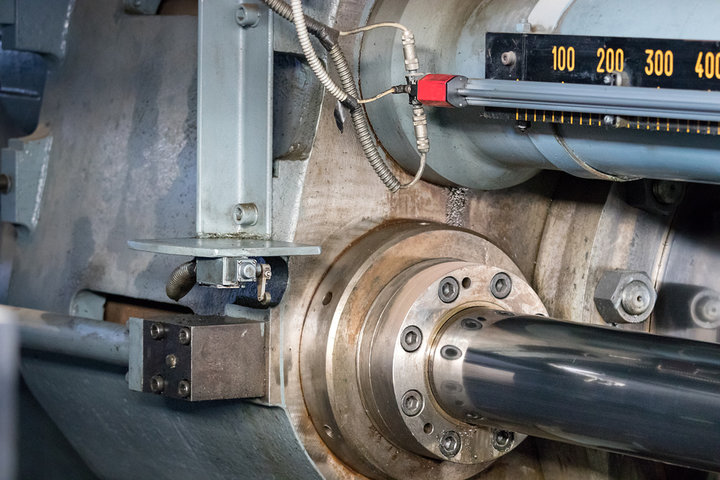

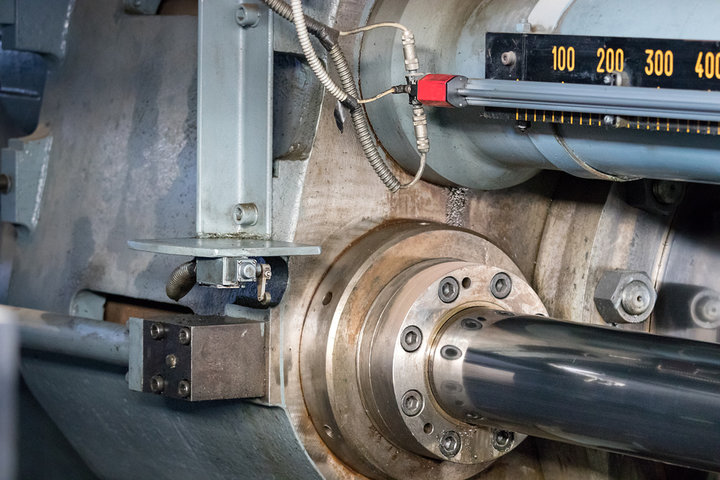

Extrusion molding ye baara ye min bɛ kɛ ka taa a fɛ, min kɔnɔ, plastiki fɛn bɛ jagoya ni die cogoya ye min bɛ kɛ ka fɛnw dilan minnu bɛ kɛ ni fɛnw ye minnu bɛ kɛ tuma bɛɛ. Plastiki kuru kɛnɛw bɛ balo barajuru sumayalen kɔnɔ min kɔnɔ, fɛn dɔ bɛ wuli, ka a ɲagami, ka a degun. Ni juru bɛ wuli, a bɛ plastiki wulilen gɛrɛn ka tɛmɛ die fɛ min bɛ fɛn in cogoya a ka profile laban cogoya la.

Extrusion (bɔli) cogoya min bɛ to sen na, o b’a to a ka ɲi kosɛbɛ ka fɛn janyalenw dilan ka ɲɛ. Baara minnu bɛ kɛ tuma caman na, olu ye pibilikiw, tubabukanw, finɛtiriw, nɛgɛw, ani plastiki sɛbɛnw walima filimuw ye. O kɛcogo bɛ se fana ka profil gɛlɛnw dilan ni kan caman ye walima yɔrɔ minnu bɛ kɔnɔna na, o b’a to a nafa ka bon jɔli ni izini baarakɛcogo la.

Material selection for extrusion bɛ sinsin a ka c’a la thermoplastiques kan ni melt flow jogo ɲumanw ye. PVC bɛ fanga sɔrɔ pipe ni profile baarakɛcogo la k’a sababu kɛ a ka muɲuli n’a ka waati kɛcogo ye. Poliyetilɛni bɛ sɔrɔ filimu ni pakew dilanni na, ka sɔrɔ fɛn kɛrɛnkɛrɛnnenw i n’a fɔ fluoropolimɛriw bɛ kɛ ka nɛgɛw datugu minnu bɛ se ka baara kɛ kosɛbɛ.

4. compression molding .

Nafa minnu bɛ sɔrɔ compression molding .

A bɛ kɛ yɔrɔbaw ye minnu bɛ kɛ ni fibre barika bonya ye .

A bɛ dakunw dilan minnu kɔnɔna ka dɔgɔn ni kɔnɔna degunko gɛlɛyaw ye .

Fɛnw tiɲɛni dɔgɔyali ka tɛmɛ chargement de chargement tigitigi kan .

Aplikasi jɔnjɔnw .

Mobili pannew minnu bɛ fanga ni surface fini don .

Industriw ka yɔrɔ minnu bɛ ni baarakɛcogo wajibiyalenw ye minnu bɛ ɲini .

Kuranko so minnu mago bɛ fɛn kɛrɛnkɛrɛnnenw na minnu bɛ se ka kɛ u la ani minnu bɛ funteni sɔrɔ .

Degun mouling ye plastiki hakɛ sumanlen dɔ bilali ye mouli kɔnɔ min bɛ funteni na. O fɛn in, a ka c’a la, a bɛ kɛ mugu walima a cogo la min bɛ kɛ ka ɲɛ, a bɛ degun ka kɛɲɛ ni mɔli sumalenw ye degunba la. Funteni ni degun bɛ kɛ sababu ye ka fɛn in bɔ ka bɔ a kɔnɔna bɛɛ la ka sɔrɔ ka furakɛli kɛcogo dɔ daminɛ min bɛ plastiki cogoya sigi kudayi.

Nin wale in bɛ bɛn kɛrɛnkɛrɛnnenya la yɔrɔbaw dilanni ma minnu barika ka bon, minnu bɛ fanga ni hakɛ sabatili ɲuman de wajibiya. Baara minnu bɛ kɛ tuma caman na, olu ye mobili farikolo pannew ye, kuran yɔrɔw, ani izini yɔrɔw. Se min bɛ se ka kɛ ka barikalanw don a kɔnɔ i n’a fɔ gilasi fiyɛw, o b’a to a nafa ka bon walasa ka fɛnw dilan minnu fanga ka bon kosɛbɛ.

thermoset materials bɛ fanga sɔrɔ compression molding kan k’a sababu kɛ u ka furakɛlicogo ɲɔgɔn tɛ. Bulk molding compounds (BMC) ani Sheet Molding Compounds (SMC) bɛ kɛ ka caya, u bɛ poliyesitɛri walima epoxy resinw ni fibres fanga bonyalenw fara ɲɔgɔn kan. Fenɔli resinw bɛ sugandi ka kɛ funteni caman ye, ka sɔrɔ melamini furakisɛw bɛ sɔrɔ dumunikɛminɛnw na.

5. Molding rotational .

Nafa minnu bɛ sɔrɔ fɛnw jiginni na .

A bɛ yɔrɔw dilan minnu tɛ degun sɔrɔ ni kogo janya ye kelen ye .

Yɔrɔ caman dilanni masin kelen kɔnɔ .

Dilancogo caman bɛ sira di cogoya gɛlɛnw ma ni welda layiniw tɛ .

Aplikasi jɔnjɔnw .

Fɛnmarayɔrɔbaw minnu bɛ kɛ ka ɲɛsin iziniw ni sɛnɛko ma .

Tulonkɛyɔrɔ minɛnw bɛ mɛn minnu bɛ se ka to sen na ni yɔrɔ kurulenw ye minnu ka gɛlɛn .

Fɛn minnu bɛ kɛ ka fɛnw minɛ ni fɛnw ye minnu bɛ se ka kɛ ni u jɔcogo ye .

Yɛlɛma bɛ daminɛ ni plastiki mugu doni ye ka kɛ bɔgɔmugu ye min bɛ wuli ni biɲɛ ye so funteniman kɔnɔ. Ni nɔgɔ bɛ wuli, mugu bɛ a kɔnɔna yɔrɔw wuli ka u datugu cogo kelen na. Yɛlɛma min bɛ kɛ ka taa a fɛ nɛnɛ waati la, o bɛ kɛ sababu ye ka kogo janya tilali kɛ. A yɔrɔ dafalen bɛ bɔ ni a nɛnɛna kosɛbɛ.

O kɛcogo kɛrɛnkɛrɛnnen in bɛ tɛmɛ yɔrɔbaw dilanni kan minnu kɔnɔna ka bon, u kogo janya bɛ kɛ kelen ye, wa u kɔnɔna degun tɛ. A bɛnnen don kɛrɛnkɛrɛnnenya la ka fɛnmarayɔrɔw dilan, izini minɛnw, tulonkɛyɔrɔw, ani kayakiw. O kɛcogo bɛ sira di cogoya gɛlɛnw ma minnu bɛ ni fɛnw ye minnu bɛ ɲɔgɔn ta ani minnu bɛ dilancogo hɔrɔnya di fɛnw ma minnu kɔnɔna ka bon.

Poliyetilɛni bɛ wuli ka wuli ka bɔ a la k’a sababu kɛ a ka baarakɛcogo finɛtiri ka bon ani a sabatili ɲuman funteni waati. Poliyetilɛni (LLDPE) min bɛ kɛ ni line ye, o de ka fisa ni fɛn caman sɛgɛsɛgɛli ye ani ka se ka fɛnw minɛ, ka sɔrɔ ka poliyetilɛni min bɛ ɲɔgɔn cɛ, o bɛ fanga ni funteni fanga bonya di. PVC plastisols ni nylon fana bɛ kɛ ka baara kɛrɛnkɛrɛnnenw kɛ.

6. thermoforming .

Nafa minnu bɛ sɔrɔ thermoforming na .

A bɔli teliya la dugukolo yɔrɔbaw yɔrɔbaw la .

Baarakɛminɛn minnu musaka ka dɔgɔ, olu bɛ se ka kɛ sababu ye ka sɔrɔko surunw kɛ sɔrɔko siratigɛ la .

Taabolo nɔgɔman bɛ se ka fɛn caman Changements design rapides ni prototypes .

Aplikasi jɔnjɔnw .

Dumuniw forokoni min bɛ kɛ ni a juguya ye tuma bɛɛ ani kogo janya .

Mobili pannew ni surface texture wajibiyalenw kɛrɛnkɛrɛnnenw .

feerekɛyɔrɔw bɛ jira ni kurufew ye minnu ka gɛlɛn ani u ka fɛn dilannenw .

thermoforming bɛ daminɛ ni plastiki sɛbɛn dɔ sumaya ye fo a ka kɛ pliable ye. O kɔfɛ, sɛbɛn nɔgɔlen bɛ dilan walima ka don bɔgɔ la walima ka don ni fɛnɲɛnamafagalan ye, fiɲɛ min bɛ digidigi, walima ni fanga ye min bɛ kɛ ni masin ye. Plastiki bɛ nɛnɛ ni a bɛ maga mɔni yɔrɔ la, ka a cogoya ɲininen mara. Yɛlɛma minnu bɛ taa ɲɛ, olu ye fila-fila-sɔgɔli ni degunw dilanni ye walasa ka jateminɛ gɛlɛnw kɛ.

Nin wale caman bɛ se ka kɛ kɛrɛnkɛrɛnnenya la walasa ka yɔrɔbaw dilan minnu kogow ka fin, minnu ka jateminɛ ka nɔgɔn. Baara minnu bɛ kɛ tuma caman na, olu ye pakew, dumunikɛminɛnw, frigow, ani mobili dashboardw ye. Baarakɛminɛnw musaka minnu ka dɔgɔ kosɛbɛ, olu b’a to a bɛ mɔgɔ ɲɛnajɛ prototype yiriwali ni a dilanni boliw bɛɛ la minnu bonya tɛ kelen ye.

Material Selection bɛ sinsin thermoplastique sɛbɛnw kan minnu dilacogo ka ɲi. Polisitiri (HIP) min bɛ nɔba bila mɔgɔ la, o ka di a ye ka kɛɲɛ ni a foroko dilanni ye, ka sɔrɔ akiriliki bɛ jɛya di a jirali ni a yeelen datugulanw ma. ABS bɛ muɲuli di minɛnw so ma, ani fɛn kɛrɛnkɛrɛnnenw i n’a fɔ Peek bɛ kɛ ka funteni caman sɔrɔ aerospace ani furakɛli siratigɛ la.

Aw bɛ se ka plastiki mɔli kɛcogo ɲuman sugandi cogo min na .

Production volume jateminɛw .

Volume caman (100.000+) Nafa minnu bɛ sɔrɔ pikiri kɛli la otomatiki la .

medium runs (1 000-10.000) bɛ bɛn thermoforming walima blow molding ma .

Prototypes hakɛ dɔgɔmanw bɛ baara kɛ ka ɲɛ ni jiginni ye .

Yɔrɔw labɛncogo fɛnw .

Geometries complexes ani tolerances sirilenw bɛ pikiri kɛ ni pikiri ye .

Minɛnw kɔnɔna bɛ bɛn fiɲɛ dilanni ma kosɛbɛ .

Panɛri belebelebaw ni u cogoya nɔgɔmanw bɛ thermoforming fɛɛrɛw fɛ .

Material Selection Guidelines .

Ɛntɛrinɛti plastikiw bɛ baara kɛ ka ɲɛ pikiri kɛcogo la .

Poliyetilɛni ni sokɔnɔbaganw ka fisa ni fiɲɛ ye .

thermoset materials bɛ compression moulding techniques de wajibiya .

Jogoɲumanya wajibiyalenw .

Dimensions tigitigiw bɛ pikiri walima compression molding ɲini .

Kogo janya basigilen bɛ bɛn jiginni kɛcogo ma .

Surface Finish wajibiyalenw bɛ se ka dan sigi baarakɛcogo suganditaw la .

Dilancogo sɛgɛsɛgɛli .

Undercuts and complex features mago bɛ pikiri kɛli la .

Kɔnɔnafɛnw bɛ baara kɛ ka ɲɛ ni jiginni ye .

Siginiden nɔgɔmanw musaka ka dɔgɔ ni thermoforming fɛɛrɛw ye .

Ekipu MFG - Aw ka PREMICE PLASTIQUE MOLDING PARTON .

Team MFG la, an bɛ na ni san tan fila ye ka ɲɛtaa sɔrɔ plastiki dilanni fɛɛrɛw la minnu bɛ taa ɲɛ. An ka baarakɛyɔrɔ kura bɛ pikiri kɛ, fiɲɛ, wuli, ani funteni hakɛ, ka tiɲɛni kɛ ka bɔ furakɛli fitininw yɔrɔw la ka taa izini yɔrɔbaw la.

An ka baara minnu kɛra ni ISO ye ani dɔnnikɛlaw ka jɛkulu, olu bɛ se ka jogo ɲuman sɔrɔ, ka sɔngɔko kɛ ɲɔgɔndan na, ani ka fɛn caman tigɛli teliya. I mago bɛ yiriwali prototype la walima fɛn caman dilanni na, Team MFG bɛ i ka hakilinaw sɛmɛntiya ka kɛ tiɲɛ ye.

Aw ye anw sɔrɔ bi walasa ka ladilikan sɔrɔ fu!

Reference sources .

Blow Molding .

Pikirili Molidali .

Molding extrusion .

Molding compression .

Molding rotational .

thermoforming .

Ɲininkali minnu bɛ kɛ tuma caman na (FAQS) plastiki dilanni kan .

J: Danfarabaw jumɛnw bɛ pikiri ni degunw cɛ?

Pikiri mɔli bɛ bɛn yɔrɔ gɛlɛnw ma, yɔrɔ fitininw hakɛ caman na ni muɲuli gɛlɛnw ye. compression molding bɛ bɛn yɔrɔbaw ma minnu ka nɔgɔn, ni fɛn barikamaw ye.

J: Tuma jumɛn na ne ka kan ka fiyɛlilan sugandi ka tɛmɛ pikiri kɛli kan?

Aw bɛ fiɲɛbɔlanw sugandi minɛn kɔnɔna na i n’a fɔ buteliw ni tankiw. A ka sɔrɔ ka bon yɔrɔw la minnu kɔnɔna ka bon ka tɛmɛ Injection Molding ka baarakɛminɛn gɛlɛnw kan.

J: Molidali kɛcogo jumɛn de ka fisa ni yɔrɔbaw ye minnu kɔnɔna ka bon?

Rotational molding bɛ tɛmɛ yɔrɔbaw kan minnu kɔnɔna ka bon i n’a fɔ tankiw ni minɛnw. A bɛ kogo janya kelen di ni welda layiniw walima degun yɔrɔw tɛ.

J: thermoforming ni molding processus tɔw tɛ kelen ye cogo di?

Fula minnu bɛ kɛ ni funteni ye, olu bɛ kɛ ni plastiki ye minnu bɛ sumaya ni vacuum walima pressure ye. A bɛ baarakɛminɛnw musaka dɔgɔya ani ka sutura yɔrɔbaw, yɔrɔ minnu man dun i n’a fɔ pakew.

J: Nafa jumɛnw bɛ sɔrɔ extrusion molding na?

Extrusion bɛ profile continues dilan ka ɲɛ, a ka ɲi pipew, tubing ani fenêtre frames ma. A bɛ se ka kɛ sababu ye ka fɛnw tigɛtigɛ cogo basigilen na ni sɛnɛfɛnw bɔli hakɛ caman ye.

J: Taabolo jumɛn bɛ Surface Finish cogoya ɲuman di?

A ka c’a la, pikiri kɛli bɛ kɛ sababu ye ka fini ɲumanw di. Compression mouling fana bɛ yɔrɔ ɲumanw di yɔrɔbaw ma minnu bɛ kɛ fla ye.

J: Fɛnw musakaw bɛ suma cogo di taabolo suguya caman cɛ?

Pikiri dilanni bɛ tiɲɛni dɔgɔya nka a bɛ kɛ ni kala kɛrɛnkɛrɛnnenw ye. thermoforming bɛ se ka kɛ ni scrap hakɛ caman ye. Yɛlɛma-yɛlɛmali bɛ kɛ ni mugu ye min musaka ka dɔgɔn.

J: Production volumes jumɛnw bɛ jo di Injection Molding Investment ma?

A ka c’a la, hakɛ caman (yɔrɔ 100 000+ san o san) bɛ jo di pikirijikɛlanw ka baarakɛminɛnw musaka caman ma, u ka teliya ka tɛmɛ sɛgɛsɛgɛli ni ɔtomatizi kan.

J: Ne bɛ se ka sugandili kɛ cogo di rotational molding ni blow molding cɛ?

Aw bɛ jiginni kɛcogo sugandi yɔrɔbaw kama minnu cogoya ka gɛlɛn. Aw bɛ Blow Molding sugandi walasa ka a bonya hakɛ caman sɔrɔ.

J: Taabolo jumɛn bɛ daminɛ musaka dɔgɔman di?

A ka c’a la, thermoforming bɛ ni baarakɛminɛnw musaka dɔgɔman ye, o kɔfɛ, a bɛ wuli ka wuli. Pikiri molidali bɛ wari bilali fɔlɔ de wajibiya.