Plastik moldin prɔses kin kɔnvɔyt molten plastic matirial to sɔlid prodak wit prɛditɛm shep ɛn prɔpati. Dis manufakchurin teknik de yuz difrɛn we dɛn fɔ mek kɔstɔm plastic mold kɔmpɔnɛnt dɛn. Di siks praymari moldin teknɔlɔji dɛm - ɛkstrushɔn moldin, kɔmpreshɔn moldin, blo moldin, rɔta moldin, injɛkshɔn moldin, ɛn thermoforming. - Dɔmin di industrial plastic prɔsesin.

Ɛni we de briŋ difrɛn bɛnifit ɛn kapasiti fɔ mol plastic manufakchurin. Frɔm ay-volyum prodakshɔn fɔ prɛsis kɔmpɔnɛnt dɛn to big-big olo prodak dɛm, dɛn prɔses ya de sav difrɛn industrial nid dɛm. Sɛlɛkshɔn fɔ di aprɔpriet moldin tɛknik dipen pan tin dɛn we inklud prɔdak dizayn, matirial rikwaymɛnt, prodakshɔn volyum, ɛn ikɔnomik kɔnsidareshɔn.

1. Blɔ Moldin .

Benefit fɔ blo moldin .

High-volume prodakshɔn fɔ olo pat dɛn we nɔ gɛt bɔku mɔni

Krio yunifom wol tiknes kross komplex kontena shep .

Bɔku bɔku kaviti mol dɛn de mek dɛn ebul fɔ prodyuz bɔtul dɛn kwik kwik wan kwik kwik wan kwik kwik wan .

Ki Aplikeshɔn dɛn .

Plastik bɔtul dɛn frɔm smɔl mɛrɛsin to big kɔntena dɛn .

Otomotive fuel tank wit komplex intanal baflin sistem .

Indastrial kemikal kɔntena dɛn we nid prɛsis matirial spɛsifikɛshɔn dɛn .

Di Blɔ moldin prɔses bigin wit fɔ mek wan parin - wan olo tiub we gɛt plastic we gɛt ɔt we de kɔmɔt frɔm ɛkstruda. Dis parina de bitwin tu mold haf, we de klos rawnd am. Dɔn dɛn kin introduks kɔmprɛsd ɛya tru wan blo pin, ɛn inflayt di sɔft plastic te i gri wit di mold in insay shep. Wans dɛn dɔn kol am agens di mold wɔl dɛn we dɔn kol, dɛn kin pul di sɔlid pat.

Blow molding excels fɔ prodyuz hol plastic prodakt dɛn fayn fayn wan ɛn ikɔnomik wan, mɔ fɔ mek dɛn prodyuz ay-volyum. Di we aw dɛn de du am de mek dɛn mek fayn fayn tin dɛn we nɔ gɛt wan bɔt ɛn we gɛt yunifom frɔm smɔl smɔl mɛrɛsin bɔtul dɛn to big big industrial drɔm dɛn. I ebul fɔ mek kɔmpleks shep dɛn wit intagreted handel ɛn spɛshal ficha dɛn de mek am fayn fɔ kɔshɔma pak ɛn ɔtomotiv fiul tank dɛn.

Di moldin proses primarily utilizes thermoplastic materials we de ofa gud melt strength en viskositi kontrol. Di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz, na di kɔmɔn tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ it, na di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ it, di polyethylene terephthalate (PET) fɔ drink bɔtul dɛn, ɛn polypropylene (PP) fɔ di tin dɛn we dɛn kin yuz fɔ mek kemikal. Di we aw dɛn pik di tin dɛn we dɛn gɛt, dipen pan di patikyula tin dɛn we dɛn nid fɔ mek dɛn klia, aw dɛn gɛt trɛnk, ɛn aw dɛn go ebul fɔ fɛt di kemikal dɛn.

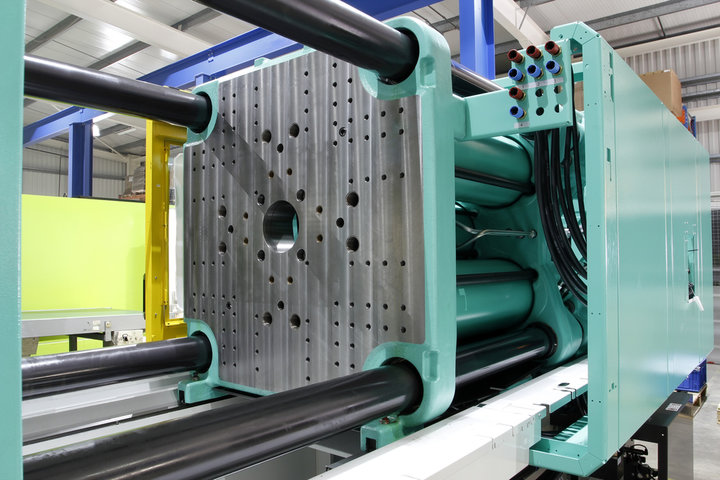

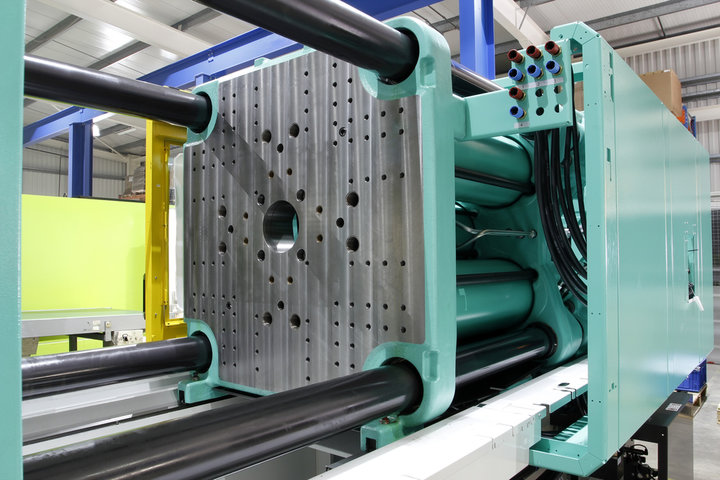

2. Moldin fɔ injɛkshɔn .

Benefit fɔ injɛkshɔn moldin .

I de prodyuz kɔmpleks plastic pat dɛn wit tayt dimɛnshɔnal akkuracy

High prodakshɔn ret tru ɔtomatik malti-kaviti mold sistem dɛn .

Ekselen surface finish wit minimal post-processing requirements .

Ki Aplikeshɔn dɛn .

Ilɛktronik haus dɛn we nid prɛsis fit ɛn bɔku bɔku ficha dɛn .

Medikal komponent dɛn we mit strikt rigyuletɔri ɛn kwaliti standad dɛn .

Ɔtomotiv Pat dɛn we de aks fɔ ay trɛnk ɛn aesthetic kwaliti dɛn .

Injɛkshɔn moldin de wok bay we dɛn de fos di plastic we dɔn rɔtin insay wan klos mold kaviti ɔnda ay prɛshɔn. di prכsεs de stat as plastic pεlεt dεm de fid insay wan hεt barεl we gεt wan rotating skru. As di skru de tɔn, i de mɛlt ɛn homogenizes di matirial we i de bil prɛshɔn. We dɛn dɔn gɛda bɔku tin dɛn, di skru de wok lɛk plɔnja, ɛn i de injɛkt di plastic we dɔn rɔtin kwik kwik wan insay di mol.

Dis versatile process de dominate plastic manufacturing bikɔs ɔf in abiliti fɔ prodyuz kɔmpleks pat wit fayn fayn dimɛnshɔnal akkuracy ɛn sɔfays finish. I patikyula efishɔnal fɔ ay-volyum prodakshɔn fɔ kɔmpɔnɛnt dɛn we de frɔm smɔl smɔl mɛdikal divays dɛn to big ɔtomotiv panɛl dɛn. Di prɔses alaw fɔ intrikɛt ditil, bɔku bɔku kaviti, ɛn ɔtomatik pat rimɔv.

Material options fɔ injɛkshɔn moldin span klos di ɔl rɛnj ɔf tɛmoplastik. Di kɔmɔn tin dɛn we dɛn kin pik na ABS fɔ di tin dɛn we dɛn kin yuz fɔ it we go de fɔ lɔng tɛm, pɔlipropilɛn fɔ liv hinj ɛn kɔshɔma pak, naylon fɔ injinɛri kɔmpɔnɛnt dɛn, ɛn polycarbonate fɔ transparent ɛn impak-rɛsistant pat dɛn. Aditiv kin ɛp fɔ mek prɔpati dɛn lɛk trɛnk, faya we nɔ de kɔmɔt, ɔ UV stebiliti.

.

Di bɛnifit dɛn we pɔsin kin gɛt frɔm di wan dɛn we dɛn kin yuz fɔ mek pipul dɛn nɔ gɛt bɔku mɔni .

Kɔntinyu prodakshɔn de mek kɔnsistɛns profayl dɛn na ay volyum .

Bɔku matirial dɛn kin jɔyn insay wan prodakshɔn rɔn .

Simpul prɔses kɔntrol de mek am izi fɔ mek dɛn ebul fɔ mek lɔng tɛm prodakshɔn saykl dɛn .

Ki Aplikeshɔn dɛn .

Paip ɛn tiub fɔ kɔnstrɔkshɔn ɛn industrial yuz .

Windo Fram dɛn wit bɔku bɔku chamba dɛn fɔ mek dɛn ebul fɔ yuz tɛmal efyushɔn .

Waya kɔtin fɔ ilɛktrik ɛn kɔmyunikeshɔn kebul sistem dɛn .

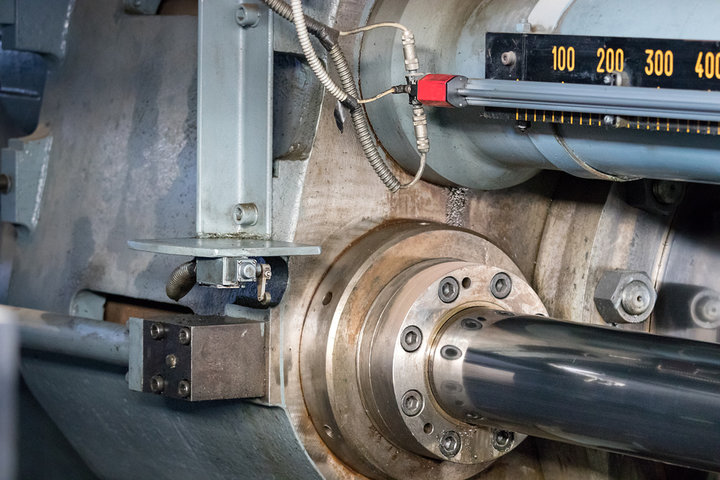

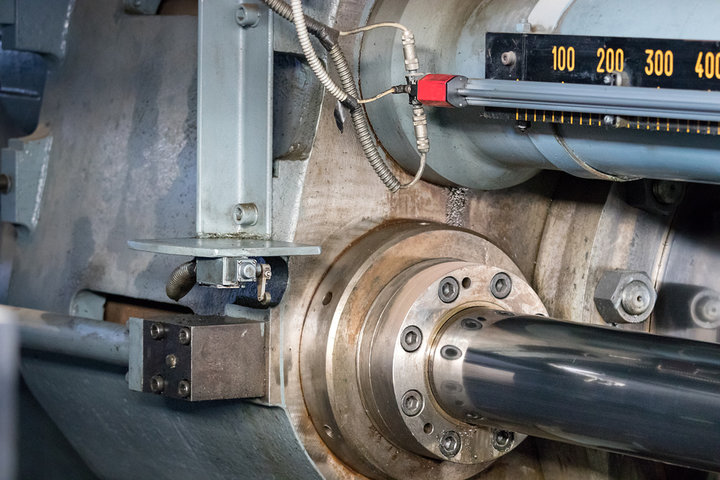

Ekstrushɔn moldin na kɔntinyu prɔses usay dɛn fos plastic matirial tru wan shep day fɔ mek prɔdak wit kɔnsistɛns krɔs-sɛkshɔn. Raw plastic pellets de fid insay wan barɛl we gɛt ɔt we gɛt wan skru we de rɔta we de mɛlt, miks, ɛn prɛs di matirial. As di skru de tɔn, i de push di plastic we dɔn rɔtin tru wan day we de shep di matirial to in fayn prɔfayl kɔnfigyushɔn.

Di kɔntinyu we di ɛkstrushɔn de mek i fayn fɔ mek dɛn prodyuz lɔng-lɛng prɔdak dɛn fayn fayn wan. Di kɔmɔn tin dɛn we dɛn kin yuz na paip, tub, winda frem, waya kɔtin, ɛn plastic sheet ɔ fim dɛn. Di prɔses kin mek bak kɔmpleks profayl dɛn wit bɔku chanɛl ɔ olo sɛkshɔn, we kin mek i valyu fɔ kɔnstrɔkshɔn ɛn industrial aplikeshɔn.

Material selekshɔn fɔ ɛkstrushɔn tipikli de pe atɛnshɔn pan tɛmplastik wit gud mɛlt flɔ kwaliti dɛn. PVC de dominate paip ɛn profayl aplikeshɔn bikɔs ɔf in durabiliti ɛn wɛda rɛsistɛns. Polyethylene na kɔmɔn tin na fim ɛn pak aplikeshɔn, we spɛshal matirial dɛn lɛk fluoropolymers dɛn kin yuz fɔ ay-perfɔmans waya kɔtin.

4. Kɔmpreshɔn Mɔldin .

Benefit fɔ kɔmpreshɔn moldin .

Fɔm big big strɔkchɔral pat dɛn wit fayv riinfɔsmɛnt opshɔn dɛn .

Produces tik sekshɔn dɛn wit minimal intanɛnt strɛs ishu dɛn .

Material west ridyushɔn tru prɛsis chaj wet kɔntrol .

Ki Aplikeshɔn dɛn .

Otomotiv panɛl dɛn we nid ay trɛnk ɛn sɔfays finish .

Indastrial Komponents wit Dimand Struktural Pɔfɔmɛnshɔn Rikwaymɛnt dɛn .

Ilektrikal haus dɛn we nid spɛshal insuleshɔn ɛn ɔt prɔpati dɛn .

Kɔmpreshɔn moldin involv fɔ put wan mɛzhɔ amɔnt ɔf plastic matirial insay wan ɔt mold kaviti. Di matiryal, tipikli wan thermoset in pauda ɔ prɛfɔm fɔm, dɛn kɔmprɛs am bitwin di mold haf dɛn we gɛt ɔt ɔnda ay prɛshɔn. Hεt εn prεshכn de mek di mεtirial fכ fכlכ tru di kכva we i de initiate wan kεmikכl kכryu riakshכn we de sεt di plastic in shep fכ pεrmanεnt.

Dis proses patikula suit manufakchur big, strukchurli robust pats we nid ekselent strכng εn dimenshכnal stεbiliti. Di kɔmɔn aplikeshɔn dɛn na ɔtomotiv bɔdi panɛl dɛn, ilɛktrik kɔmpɔnɛnt dɛn, ɛn ebi ebi industrial pat dɛn. Di abiliti fɔ inkɔrpɔret riinfɔs matirial dɛn lɛk glas fayba de mek i valyu fɔ prodyuz ay-strɛng kɔmpɔzit kɔmpɔnɛnt dɛn.

Thermoset materials de dominate kompreshɔn moldin bikɔs ɔf dɛn yunik kɔring prɔpati dɛm. Bulk moldin kɔmpawnd (BMC) ɛn sheet moldin kɔmpawnd (SMC) dɛn kin yuz bɔku bɔku wan, dɛn kin jɔyn poliɛsta ɔ epoxy resin wit riinfɔs fayba dɛn. Fɛnɔlik rɛsin dɛn kin pik fɔ ay-tɛmpracha aplikeshɔn dɛn, we di mɛlamin kɔmpawnd dɛn kin kɔmɔn na di dina we dɛn kin yuz.

5. Roteshɔnal Mɔldin .

Di bɛnifit dɛn we pɔsin kin gɛt frɔm di rotashɔnal moldin .

Krio stres-fri hol pat wit yunifom wol tiknes

Multiple parts prodakshɔn in singl mashin saykl .

Dizayn fleksibiliti alaw kɔmpleks shep dɛn we nɔ gɛt wɛl layn layn dɛn .

Ki Aplikeshɔn dɛn .

Big big stɔrɔj tank dɛn fɔ yuz industri ɛn agrikalchɔral biznɛs .

Durable pleground ekwipment wit komplex kurv surfaces .

Material Handling Containers wit Integreted Structural Features .

Rotational molding bigin wit lod plastic pauda insay wan hol mol we de rɔta biaksial wan insay wan chɛmba we gɛt ɔt. As di mold de rɔn, di paoda de mɛlt ɛn kot di insay sɔfays dɛn wansay. Kɔntinyu fɔ rɔn di tɛm we dɛn de kol di faz de mek shɔ se ivin di tik we de na di wɔl. Di pat we dɛn dɔn dɔn, dɛn kin pul am wans dɛn dɔn kol am ful wan.

Dis yunik prכsεs de εksεl fכ prodyuz big, hol pat dεm wit yunifom wכl tik εn nכ intanεt strεs. I rili fayn fɔ mek stɔrɔj tank dɛn, industrial kɔntena dɛn, ples dɛn fɔ ple, ɛn kayak dɛn. Di prɔses alaw fɔ kɔmpleks shep dɛn wit intagreted ficha dɛn ɛn i de gi dizayn fridɔm fɔ big-big olo prodak dɛn.

Polyethylene de dominate rotational molding bikɔs ɔf in wayd prɔsesin winda ɛn fayn fayn stebiliti di tɛm we dɛn de ɔt. Linear low-density polyethylene (LLDPE) na di wan we dɛn kin lɛk fɔ fleksibiliti ɛn impak resistans, we kros-link polietilen de gi ɛnhans trɛnk ɛn tɛmpracha rɛsistɛns. PVC plastisols ɛn naylon dɛn kin yuz bak fɔ spɛshal aplikeshɔn dɛn.

6. Tɛmofɔming .

Di bɛnifit dɛn we pɔsin kin gɛt we dɛn de du di thermoforming .

Rapid prodakshɔn saykl fɔ big sɔfayz eria pat dɛn .

Low-cost tooling de mek am izi fɔ mek dɛn ebul fɔ mek shɔt prodakshɔn rɔn dɛn .

Simpul prɔses de alaw kwik dizayn chenj ɛn protɔtayp dɛn .

Ki Aplikeshɔn dɛn .

Fɔd pak we nid fɔ gɛt kɔnsistɛns dip ɛn tik tik .

Vehicle panels wit spesifik surface texture requirements .

Ritayl displei dɛn we gɛt kɔmpleks kɔv ɛn brand ditil dɛn .

Tɛmofɔmin kin bigin bay we i de ɔt wan plastic sheet te i bi pliable. Dɔn dɛn kin mek di sheet we dɔn sof agens ɔ put am insay mol we dɛn de yuz vaykum prɛshɔn, kɔmprɛsd ɛya, ɔ mɛkanikal fɔs. Di plastic de kol in kɔntakt wit di mold surface, ɛn i de kip di shep we i want. Advans vεryushכn dεm inklud twin-shit fכm εn prεshכn fכm fכ mכr komplεks jכyometri dεm.

Dis versatile process na patikyula effektiv fɔ prodyuz big, tin-wɔl pat wit rili simpul jɔyometri. Di kɔmɔn tin dɛn we dɛn kin yuz na tin dɛn we dɛn kin yuz fɔ pak tin dɛn, tin dɛn we dɛn kin put tin dɛn fɔ it, tin dɛn we dɛn kin yuz fɔ frij, ɛn motoka dɛshbɔd dɛn. Di rili lɔw tul kɔst mek i atraktiv fɔ ɔl tu di protɔtayp divɛlɔpmɛnt ɛn prodakshɔn rɔn dɛn we gɛt difrɛn saiz dɛn.

Material selekshɔn de pe atɛnshɔn pan tɛmplastik shit dɛn wit gud fɔm kwaliti dɛn. High-impact polystyrene (hips) na pɔpul fɔ pak aplikeshɔn dɛn, we Akrilik de gi klia wan fɔ displei ɛn layt kɔva. ABS de gi durabiliti fɔ ikwipmɛnt haus, ɛn spɛshal matirial dɛn lɛk peek dɛn de yuz fɔ ay-tɛmpracha aplikeshɔn dɛn na aerospace ɛn mɛdikal sɛktɔ.

Aw fɔ pik di rayt plastic moldin teknɔlɔji .

Prodakshɔn Volyum Kɔnsidɛreshɔn dɛn .

Ay volyum (100,000+) bɛnifit frɔm injɛkshɔn moldin ɔtomɛshɔn

Midul rɔn (1,000-10,000) Sut thermoforming ɔ blow molding

Low volyum prototypes wok bes wit roteshɔnal moldin .

Pat dizayn faktɔ dɛn .

Kɔmpleks jɔyometri ɛn tayt tolɛreshɔn dɛn nid fɔ gɛt injɛkshɔn moldin .

Hollow kontena dem de bes fo blow molding .

Big panɛl dɛn we gɛt simpul shep dɛn de favɔret thermoforming mɛtɔd dɛn .

Di Gaydlain fɔ Sɛlɛkshɔn .

Enjinia Plastik dɛn de du di bɛst pan injɛkshɔn moldin prɔses dɛn .

Polyethylene ɛn pet excel in blow moldin aplikeshɔn dɛn

thermoset materials nid fɔ gɛt kɔmpreshɔn moldin tɛknik dɛn .

Kwaliti Rikwaymɛnt dɛn .

Prɛsis dimɛnshɔn dɛn diman injɛkshɔn ɔ kɔmpreshɔn moldin .

Konsistent wall tiknes suit rotational molding processes .

Surface finish rikwaymɛn dɛn kin limit di prɔses opshɔn dɛn .

Dizayn Fleksibiliti .

Ɔndakɔt ɛn kɔmpleks ficha dɛn nid fɔ injɛkshɔn moldin .

Intanɛt ficha dɛn de wok fayn wit roteshɔnal moldin .

Simpul shep dɛn kin kɔst smɔl wit thermoforming mɛtɔd dɛn .

Team MFG - Yu Premier Plastik Moldin Patna

Na Team MFG, wi de bring tu decades of excellence in advans plastic molding solutions. Wi stet-ɔf-di-at fasiliti masta injɛkshɔn, blo, roteshɔnal, ɛn thermoforming prɔses, deliv prɛsishɔn frɔm maykro-mɛdikal kɔmpɔnɛnt dɛn to big industrial pat dɛn.

Wi ISO-sɛtifiket ɔpreshɔn ɛn ɛkspɛkt tim de mek shɔ se dɛn gɛt spɛshal kwaliti, kɔmpitishɔn prayz, ɛn kwik tɔn-arawnd. Ilɛksɛf yu nid protɔtayp divɛlɔpmɛnt ɔ ay-volyum prodakshɔn, Tim MFG de chenj yu kɔnsɛpt dɛn to rial tin.

Kontakt wi tide fɔ wan fri kɔnsultɛshɔn!

Rifrɛns Sɔs dɛn .

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

Moldin fɔ injɛkshɔn .

Moldin we dɛn kin yuz fɔ mek pipul dɛn nɔ go na di os .

Moldin fɔ kɔmpreshɔn .

Rotational moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na .

Tɛmofɔmin .

Kwɛstyɔn dɛn we dɛn kin aks ɔltɛm (FAQ) bɔt plastic moldin

K: Wetin na di men difrɛns bitwin injɛkshɔn ɛn kɔmpreshɔn moldin?

Injekshɔn moldin sus kɔmpleks, smɔl pat dɛn we gɛt ay volyum wit tayt tolɛreshɔn. Kɔmpreshɔn de mol bɛtɛ sus big, simpul pat dɛn wit riinfɔs matirial dɛn.

K: Ustɛm a fɔ pik blow moldin oba injɛkshɔn moldin?

Pik Blow Molding fɔ olo kɔntena dɛn lɛk bɔtul ɛn tank dɛn. I de mɔ ikɔnomik fɔ hol pat pas injɛkshɔn moldin in kɔmpleks tul.

K: Us moldin proses na di bes fo big, hol pat?

Rotational molding excels fɔ big olo pat dɛn lɛk tank ɛn kɔntena dɛn. I de gi yunifom wɔl tiknes we nɔ gɛt wɛl layn ɔ strɛs pɔynt.

K: Aw thermoforming difrɛn frɔm ɔda moldin prɔses?

Tɛmofɔm de shep plastic sheet dɛn we dɛn dɔn ɔt we dɛn de yuz vaykum ɔ prɛshɔn. I de gi lɔw tul kɔst ɛn sus big, shalo pat dɛn lɛk pak.

K: Wetin na di advantej dɛm fɔ ɛkstrushɔn moldin?

Ekstrushɔn de mek kɔntinyu prɔfayl dɛn fayn fayn wan, fayn fɔ paip, tubing, ɛn winda frem dɛn. I de ɛnabul kɔnsistɛns krɔs-sɛkshɔn dɛn na ay prodakshɔn rɛt.

K: Us prɔses de gi di bɛst sɔfays finish kwaliti?

Injekshɔn moldin tipikli deliv di fayn fayn sɔfays finish. Kɔmpreshɔn moldin de gi bak fayn fayn say dɛn fɔ big, flat pat dɛn.

K: Aw matirial kɔst dɛn kɔmpia bitwin difrɛn prɔses dɛn?

Injɛkshɔn moldin de minimiz west bɔt i nid spɛshal gred dɛn. Tεrmofכm kin gεt hכy skrap rεt. Rotational molding de yuz paoda dɛn we nɔ de tek bɔku mɔni.

K: Us prodakshɔn volyum dɛn de jɔstify injɛkshɔn moldin invɛstmɛnt?

High volumes (100,000+ parts anually) tipikli justify injection molding’s higher tooling costs tru fasta cycles en automation.

K: Aw a go pik bitwin rotashɔnal mol ɛn blo moldin?

Pik roteshɔnal moldin fɔ big pat dɛn wit kɔmpleks shep dɛn. Selekt Blow Molding fɔ ay volyum kɔntena prodakshɔn.

K: Us prɔses de gi di lɔs statap kɔst?

Thermoforming tipikli gɛt di lɔs tul kɔst, we dɛn fala wit roteshɔnal moldin. Injɛkshɔn moldin nid fɔ gɛt di ays initial invɛstmɛnt.