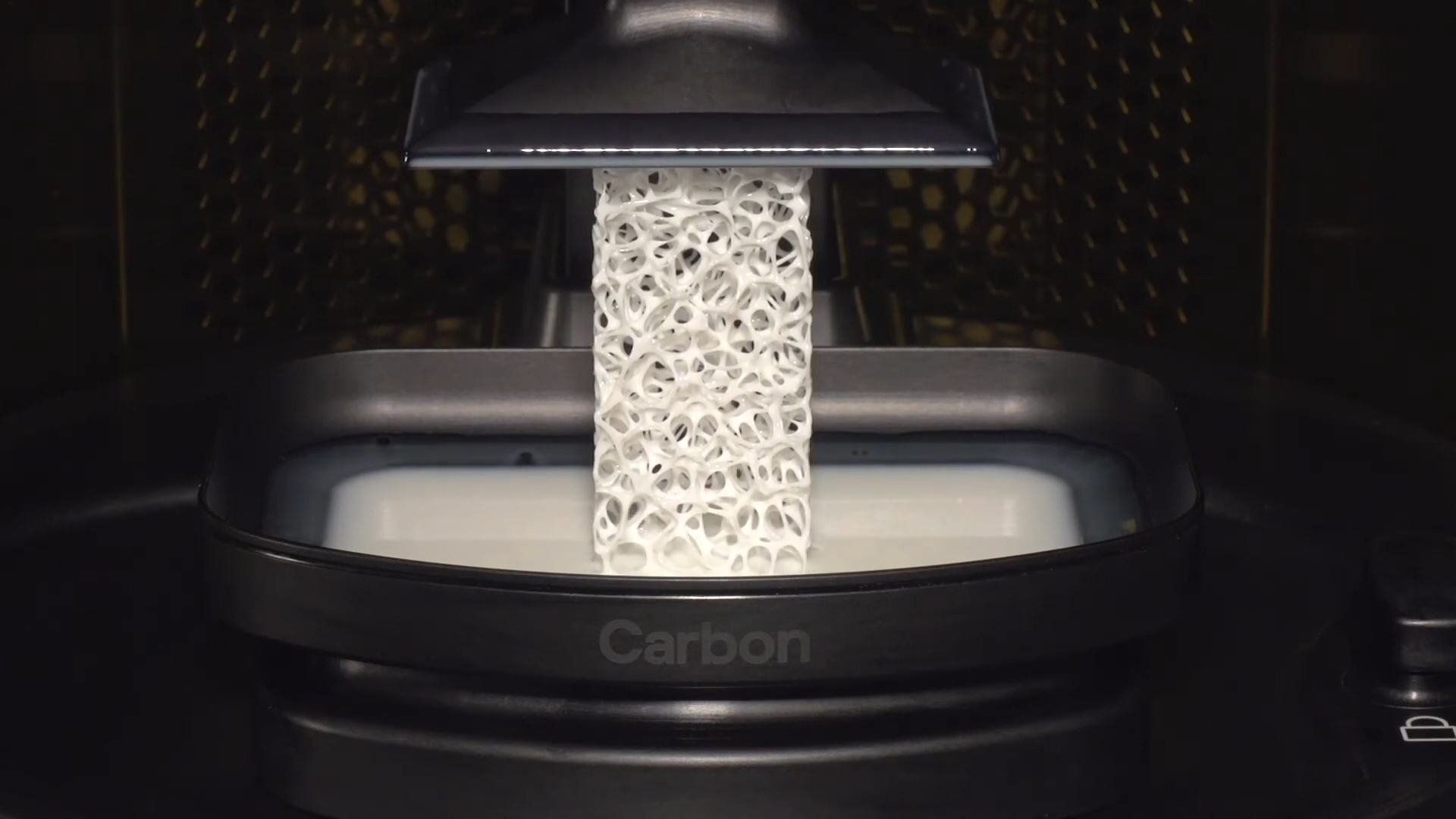

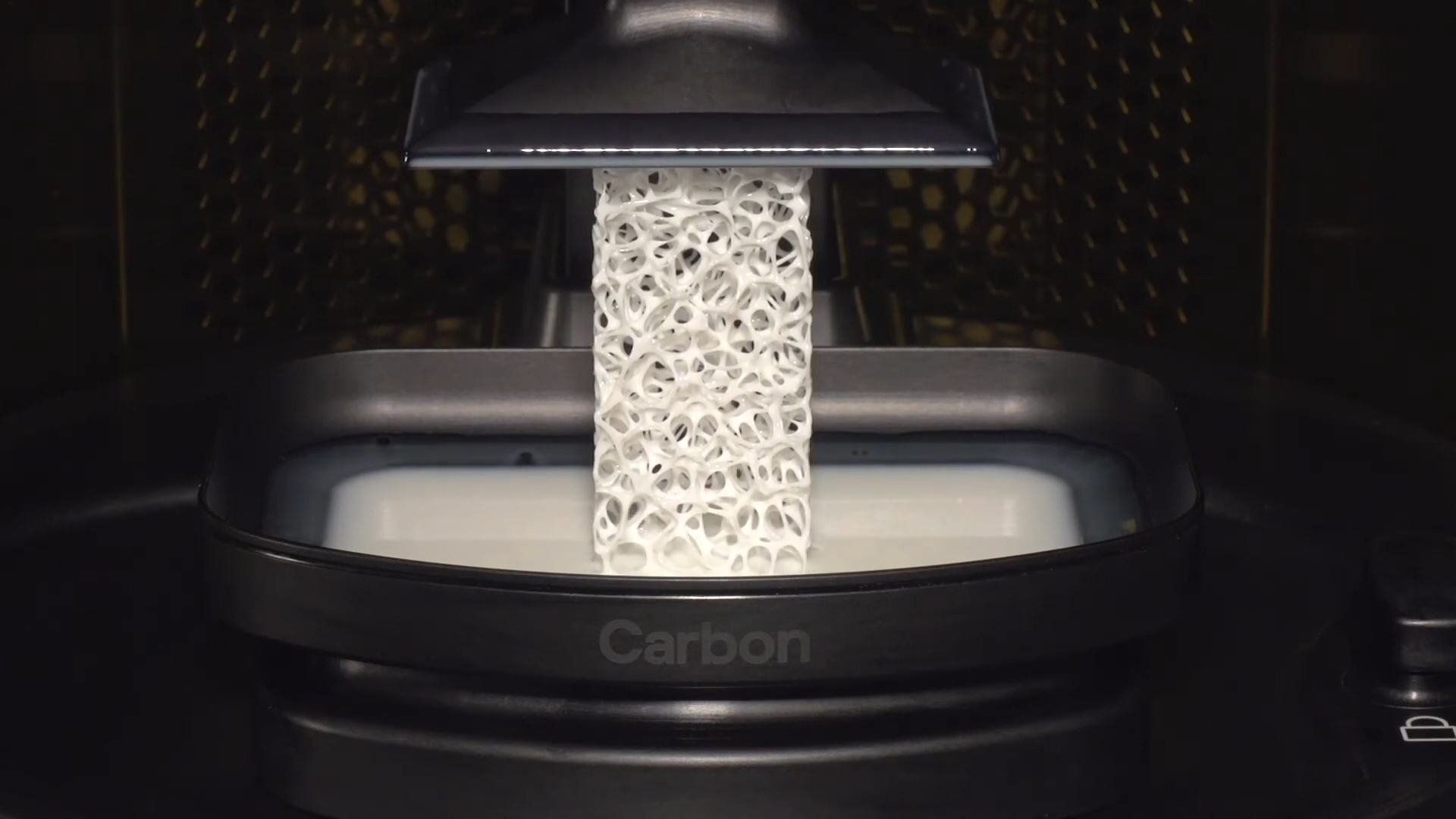

Umquam mirati quomodo manufacturers creare complexu partes cum perfecta miscetur virtutis et praecisione? Intra Carbon DLS (Digital Lux synthesis), a groundbreaking 3D printing technology transformans modern vestibulum. Dissimilis traditional modi, carbonis dls combines digital lux proiectura cum oxygeni-permeable optics et programmable resinam ad partum eximia praecessi.

Per suum novos tonde processus, hoc technology pontes gap inter prototyping et productio vestibulum. Ex automotive partes ad medicinae cogitationes, carbonis dls non solum printing aliter - suus creando melius products. Sit scriptor explorarent quomodo hoc innovation est reshaping vestibulum possibilities.

Iungere nos in altum dive in ipsum DLS technology! Nos te explorarent omnes essentialis facies - ex basic operationes ad materiam electiones, plus in pros et cons de hac re 3D printing modum.

Quid est Carbon DLS?

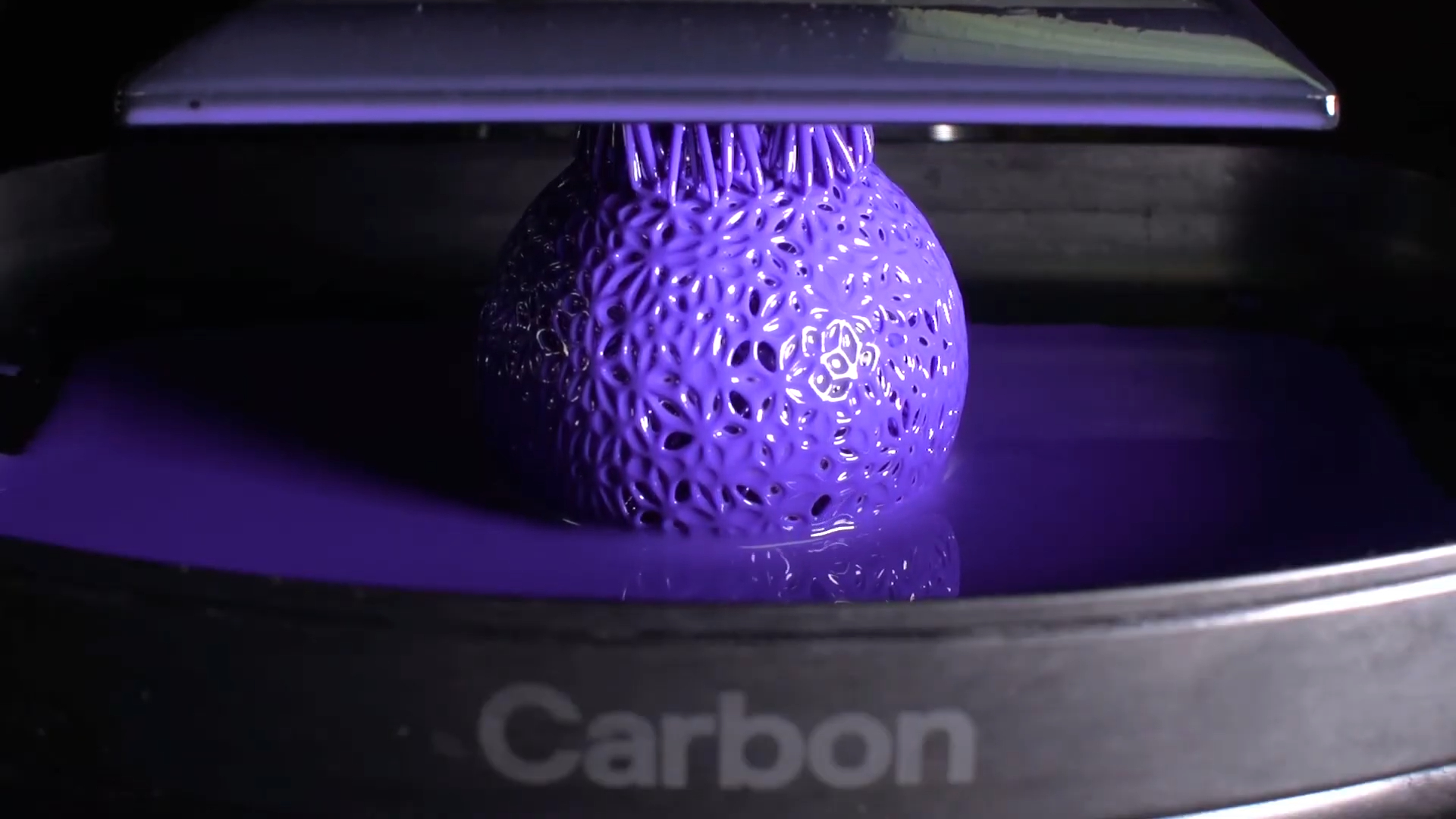

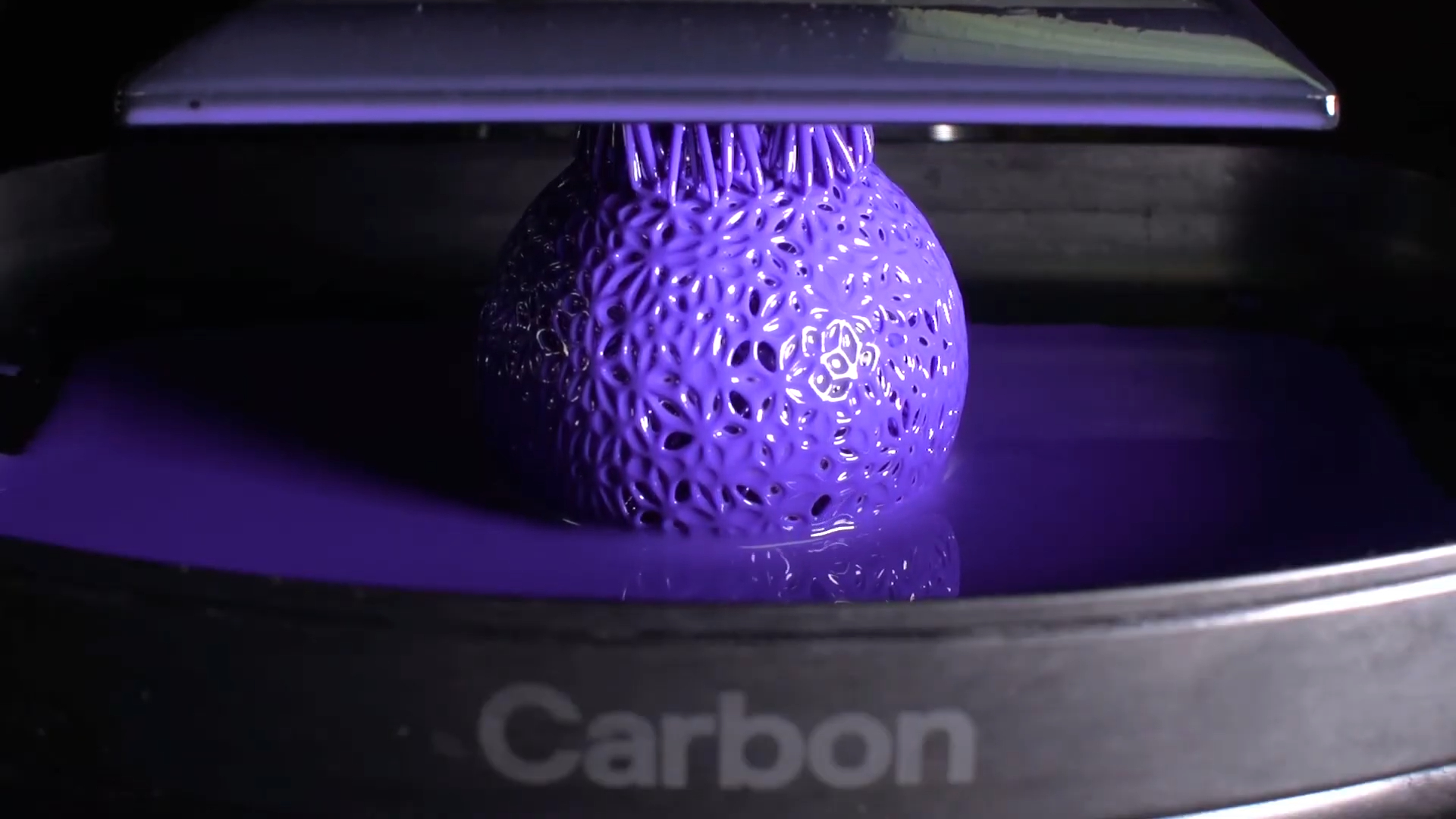

Carbon Digital Lux synthesis (DLS) repraesentat groundbreaking saltu in 3D printing technology. Hoc combines digital lux proiectura, oxygeni, permeable optica, et programmable liquorem resinam ad partum summus qualitas, productio-gradu partes. Hoc innovative technology se seorsum producendo components cum eximia diuturnitatem, praecisione et superior superficiei metam.

Quid est Carbon DLS diversis ab aliis 3D printing modos?

Comparison Stereolithography (SLA)

Comparison Polyjet 3D printing

Materia proprietatibus

Superficiem species

Polyjet: visibilia iacuit lineas

Carbon DLS, lenis, iniectio-fingunt, sicut metam

Productio efficientiam

Comparatio cum Pellentesque depositionem Modeling (FD)

Structural integritas

Detail resolutio

Material optiones

Quid facit Carbon DLS opus?

Carbon DLS utitur sophisticated tria scaena processus creare summus qualitas 3D typis partis. Sit scriptor conteram in se pars et scaena huius innovative technology.

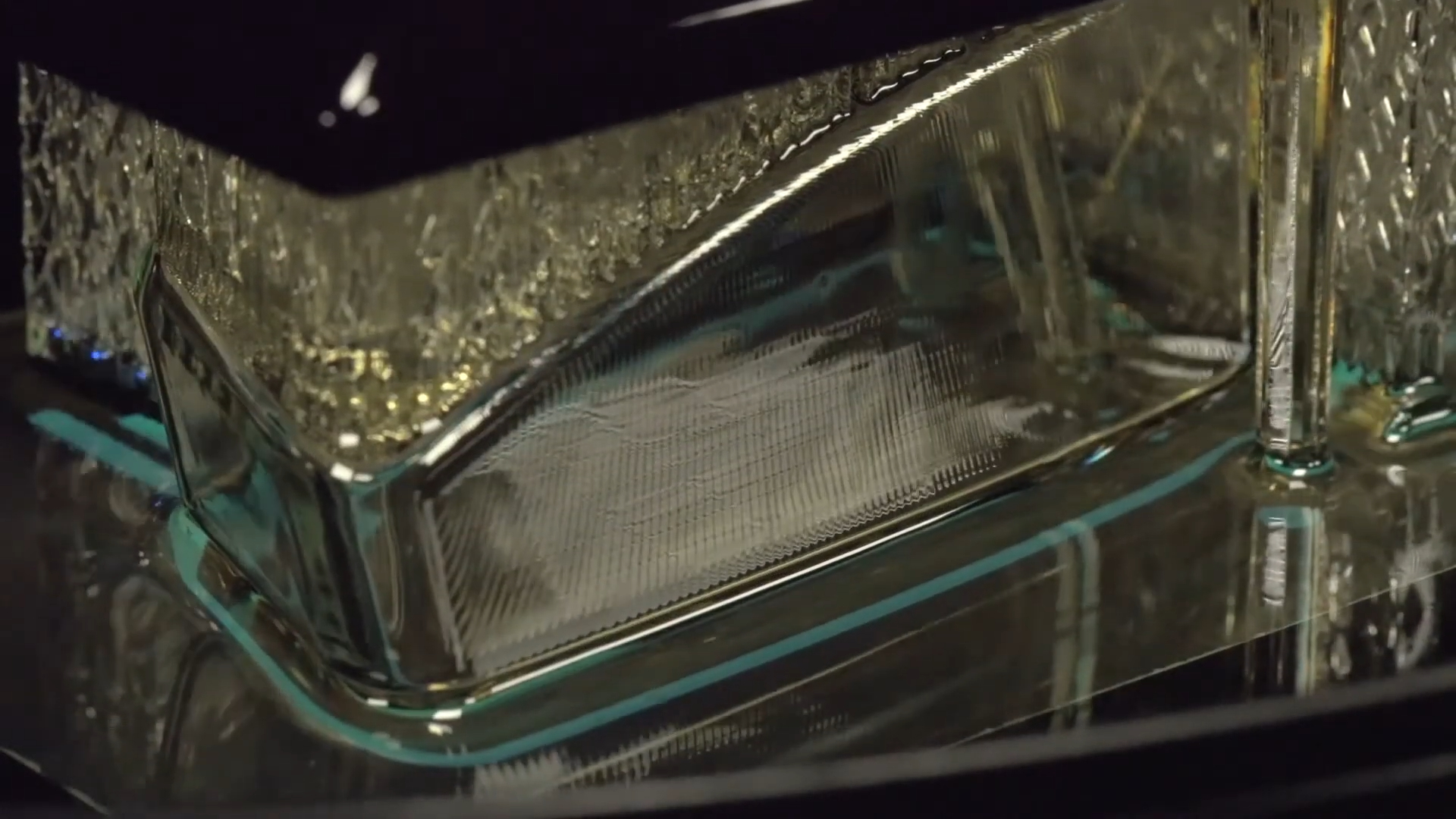

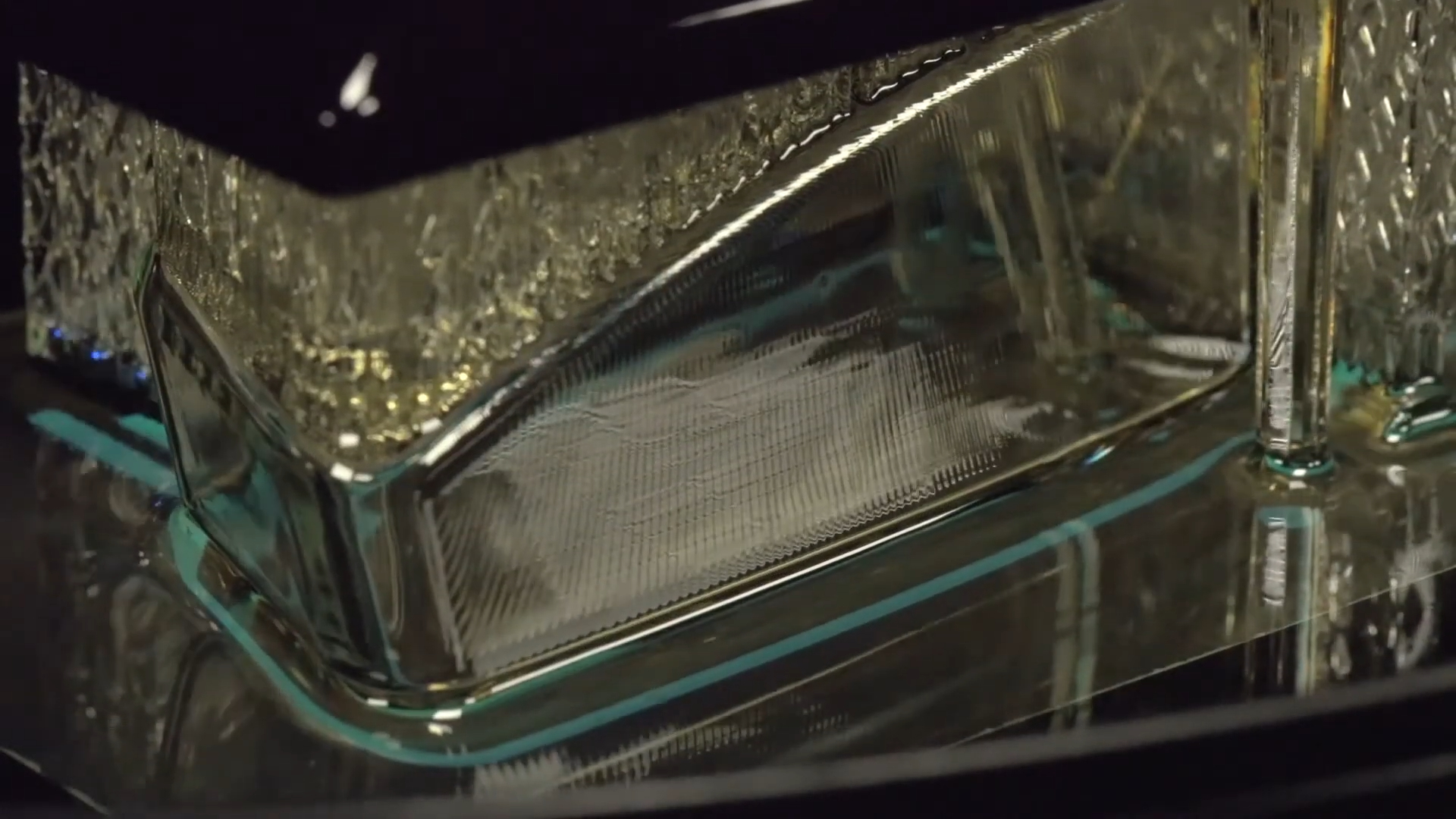

Digital Lux Projection System

UV lux Source

Digital masking

Et clip processus (continua liquida interface productio)

Tempus I: Initial Setup

Liquid resina implet aedificare camera

Aedificare Platform Positions in Satus Altitudo

Oxygeni-permeable fenestram praeparat pro proiectura

Scaena II: continua formation

Mortuus zona creaturae

Processum aedificare

Platform surge constantly

Resina influit infra partem

Nec iacuit separationem opus

Scaena III: scelerisque curing

Furnae curatio

Actorum secundarium Quaestiones

Enhances materia proprietatibus

Ensures uniformis viribus

Key processus features

Oxygeni-permeable Optics:

Gignit consistent mortuis zona

Maintains liquida interface

Perspicuum est adhaesionem

Continua productio beneficia:

Final curing results:

Technical Specifications:

| Processus parameter | typical valorem |

| Mortuus Zone Crassitudo | ~ 0.001mm |

| UV lux resolutio | 0.005 'platea |

| Aedificate volumine | 7.4 'X 4.6 ' x 12.8 ' |

| Minimum murum crassitudine | 0.030 ' |

Materials in Carboni DLS 3D printing

Carbon DLS technology offert diverse material optiones in occursum variis vestibulum necessitates. Hae materiae cadunt in duo genera: rigidas plastics et Flexilis, sicut materiae.

Rigidum plastics

CE CCXXI (Cyanate Esther)

Clavem proprietatibus

Extreme temperatus resistentia

Superior chemical resistentia

Princeps pressura tolerantia

Specimen applications

Uma XC (multi-proposito)

Characteres

Similia SLA resins

Multi-color facultatem

Bonum Superficies metam

Optimus usus

Fixtures vestibulum

Productio Jigs

Visual prototypes

Epx LXXXII (epoxy)

Features

Vitulum, sicut vires

DIGNUS

Impulsum repugnans

Applications

Structural components

Connexiones

Onus-afferentem uncis

Flexilis, sicut materiae

Epu XL (elastomeric polyurethane)

Proprietatibus

ELECTRUM

Lacrima

Optimum Energy Redi

Communis usus

Sigilla

Vibrationis dampe

Flexibilia components

SIL XXX (Silicone)

Attributio

Applications

Medicinae cogitationes

Wearable products

Cutis, contactus items

Material proprietatibus collatio

| materiae | diuturnitatem | flexibilitate | eget resistentia | æstus resistentia |

| CE CCXXI | Praeclarus | Humilis | Praeclarus | Altum |

| Uma XC | Bonum | Moderor | Bonum | Moderor |

| Epx LXXXII | Praeclarus | Humilis | Bonum | Bonum |

| Epu XL | Bonum | Altum | Moderor | Moderor |

| SIL XXX | Moderor | PERPREPIDUS | Bonum | Bonum |

Special features of Carbo DLS

Biocompatibility Options

Perficientur characteres

PRAESTITUTUM

Minima materia vastum

Reusable excess material

Color Aliquam options

DLS DLS Technology

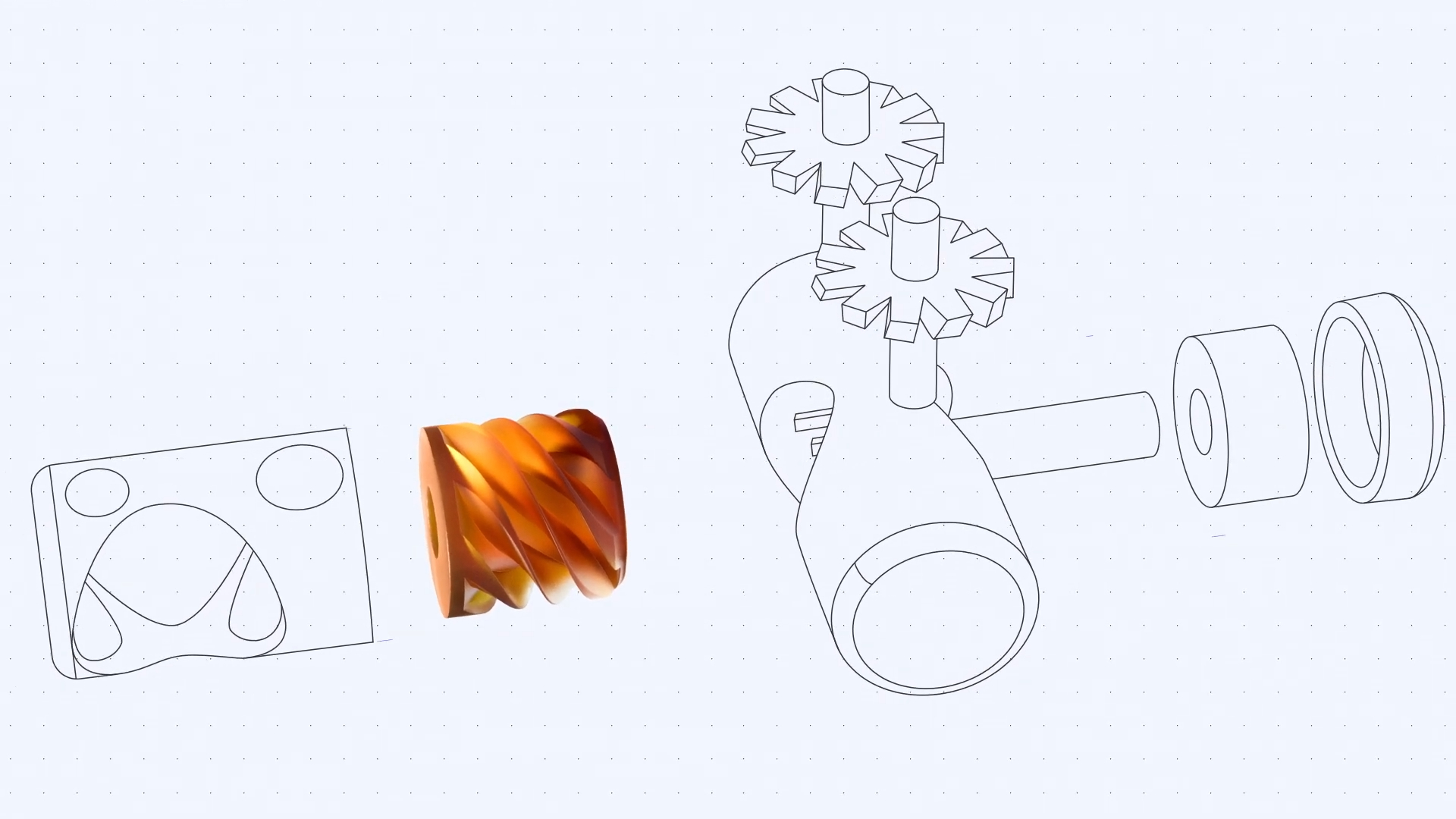

I. Quid eligere carbonis DLS ad complexu consilia?

Advanced Geometric

Real-World Applications

Calceamentis midsoles replacement

Automotive component consolidationis

AEROSPACE PARS

Medical fabrica customization

II. Mechanica proprietatibus Carbon DLS partes

Isotropic fortitudo commoda

Uniformis proprietatibus

Aequalis viribus omnibus

Consistent perficientur

Reliable diuturnitatem

Perficientur metrics

Dual-curing beneficia

III. Superficiem metam qualis

Superficies characteres

Qualis metrics

APPARATUS

Minimam iacuit lineas

Professional species

Resolutio capabilities

Size, secundum perficientur

| pars mole | resolutio | superficies qualis |

| Parvus (<II ') | ULTRA | Speculum |

| Medium (2-6 ') | Altum | Praeclarus |

| Magna (> VI ') | Vexillum | Professio |

PROPRESSUS

Non pulveris remotionem opus

Minimal Post-Processing

Promptus-ut-usu superficiem qualis

Consistent results per batches

Additional beneficia

Productio efficientiam

Design Freedom

Consolidated Convention

Optimized geometries

Functionali integration

Qualitas fide

Et limitations de carbonis DLS

Cost factors

Initial Tractatus: Premium Equipment, Propria Materials et Project Setup requirere substantial upfront capitis.

Operating costs: proprietary resinam et ongoing sustentationem coegi altius productio expensas quam traditum modi.

Post-processus: additional consummatione gradus augmentum labore costs et productio est.

Materia limitations

Limited Electio: Tantum VIII Base Materials praesto, Restricting consilium et applicationem optiones.

Color options: minimal color electiones in vexillum materiae. Consuetudo coloring requirit extra processus.

Material Properties: Rerum Reliqua Mechanica Characteristics comparari traditional vestibulum.

Cum considerare alternatives

Simple prototypes: FDM seu basic shas providere citius, magis sumptus-effective solutions pro basic temptationis.

Productio magna, aut iniectio CUMATIUM Offer OMNIBRIUM VELICUM ALIQUE SPECIE VOLES.

Donec projects: Traditional vestibulum modos providere magis frugi options ad:

Basic Geometries

Simple mechanica partes

High-Volume productio

Velox iterations

Tempus, sensitivo Projects: Latin 3D printing Technologies offerre velocius turnaround pro simplex consilia.

Carbon DLS excellit in universa, summus qualitas partes sed non sectam omni project. Considerans vestri specifica necessitates, budget, et productionem volumen ante eligens hoc technology.

Applications of Carbon DLS Technology

Current industria applications

Automotive vestibulum productionem summus perficientur partes, consuetudo components et eget prototypes. Dat partis consolidationis et pondus reductionem.

Medical cogitationes: gignit biocompatible instrumenta, Custom chirurgicam instrumenta et patientes estote-speciei implantatorum. Specimen enim dentalis applications et medicinae-gradus components.

Consumer products: Potestates Premium Footwear components, electronics housings, et mos ludis apparatu. Excedit in creando ergonomic consilia.

Aerospace components: delivers Partes, complexu ducting systems, et specialized tooling. Designatis optimization ad pondus reductionem.

Manufacturing capabilities

Celeri prototyping: Velox consilio iterations et eget temptationis intra horas. Providet statim feedback pro consilio improvements.

Productio scaling: seamless transitus a prototyping ad plenus-scale vestibulum. Enables consistent qualis trans productio fugit.

Missam Aliquam: creates unique products tailored ad singula necessitates. Potestates personalized solutions pro variis industrias.

Success fabulas

Adidas exsequendam: revolutionlized midsole productio per cancellos structuras. Effectum massa customization in calceamentis vestibulum.

Medical Applications: Transformed patientes estote-speciei fabrica productio. Reducitur plumbum temporibus a LX% ad mos medical solutions.

Automotive Success: decrescebat pars numerare per consolidationem. Effectum XL% pretium reductionem in component vestibulum.

Future Trends

Material Development: Expanding Material Options et enhancing mechanica proprietatibus. Introducendis sustineri et bio-fundatur materiae.

Technical profectum: augendae constructum celeritates et volumina. Exsequendam provectus automation systems.

Industria PRAEGRESSUS: movere ad digital inventarium solutions et localized productio. Expanding in Novum Market segments.

Conclusio: Quid eligere Carbon DLS pro proximo project?

Carbon DLS represents a groundbreaking profectum in 3D printing technology. Et unique compositum de digital lux proiectura, oxygeni-permeable optics, et programmable resinam tradit eximia eventus ad postulans applications. Per suam innovative clip processus, hoc technology dat creaturae complexu geometries antea impossibile est traditum vestibulum modos.

Dum Carbon DLS ut involvere altius initial costs, sua facultatem ad producendum summus qualitas, eget partes facit optimum arbitrium pro innovative projects postulans superior perficientur. Ut hoc technology pergit revolutionise vestibulum per industries, ex automotive ad medicinae cogitationes, offert unleccecedened consilio libertatem et productionem elit. Nam projects requiring Exceptional qualis, constantia, et complexu geometries, carbonis dls praesentibus suis cogens solution pro proximo-generatione vestibulum.

Paratus transform vestri vestibulum processus?

Tolle vestri uber progressionem ad proximum gradum cum MFG scriptor Advanced Carbon DLS technology. Utrum vos postulo complexu prototypes vel productio-partis, nostri peritus quadrigis tradit eximia praecessi.

Reference Sources

Carbon DLS 3D excudendi technology

Frequenter Interrogata Quaestiones de Carbon DLS

Q1: Quid est Minimum Wall Crassitudo fieri potest cum Carbon DLS?

A: Minimum commendatur muri crassitudine est 0.030 '(0.762mm). Hoc ensures structural integritas et propria pluma formatio in printing.

Q2: Quousque facit Carbon DLS excudendi processus accipere?

A: Print tempora variantur magnitudine et multiplicitate. Pleraque partes completum printing intra 1-3 horas, plus an additional 2-4 horis ad scelerisque curantes in clibano.

Q3: can carbonis DLS partes picta vel coloratum?

A: Sic. Carbon DLS partes accipere vexillum pictura et colorantes processus. Autem, post-processus pro color adiungit extra tempus et sumptus ad productionem.

Q4: Quid est maximum constructum magnitudinem carbonis dls printing?

A: quod typical aedificare area est 7.4 'x 4.6 ' x 12.8 '. IV IV ' x IV 'x VI requirere manual ad meliorem printing results.

Q5: Sunt Carbon DLS materiae cibum-tutum et biocappatible?

A: Select materiae sicut SIL XXX et RPU LXX sunt biocappatible et idoneam cibum contactus applications. Quisque materiam requirit certis certification pro animo usus.

Q6: Quomodo enim sumptus Compare Traditional vestibulum modos?

A: Carbon dls typice costs plus per partem in parvis voluminibus. Tamen, quod fit sumptus-efficax ad universa geometries et medium-amplitudo productio fugit ubi tooling costs esset prohibitoria.

Q7: Quod genus post-processus non requiritur ad ipsum DLS partes?

A: Most partes eget scelerisque curantes post printing. Additional Post-Processing pendent applicationem - a simplex suscipio remotionem ad superficiem consummatione pro aesthetic partes.