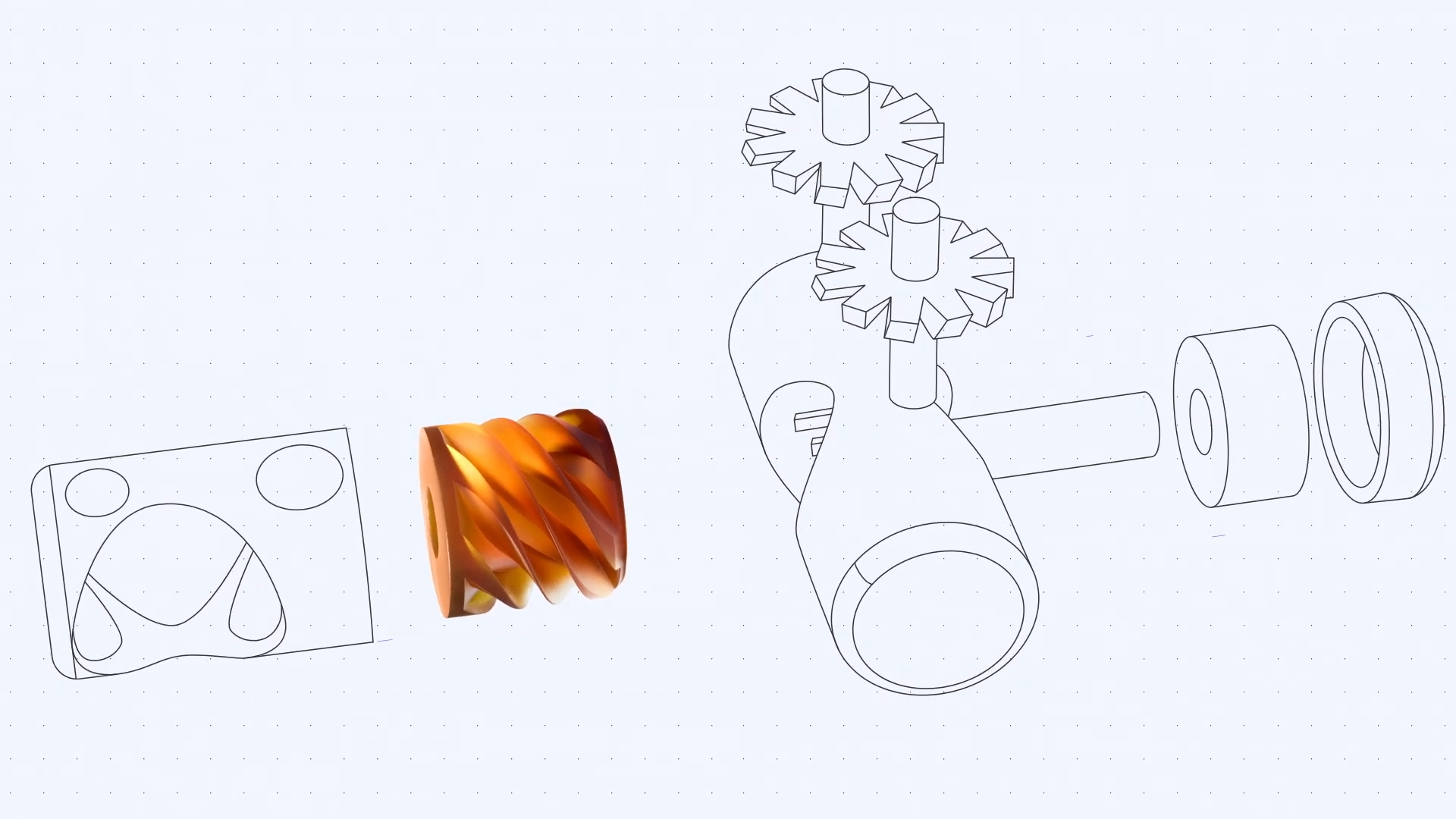

Yala i delila k’i yɛrɛ ɲininka cogo min na fɛn dilannikɛlaw bɛ yɔrɔ gɛlɛnw dilan ni fanga ni tiɲɛni ɲagaminen dafalen ye wa? Enter Carbon DLS (Digital Light Synthesis), 3D sɛbɛnni fɛɛrɛ min bɛ dugukolo tigɛ, o bɛ bi fɛn dilanni caman sɛmɛntiya. Kabɔn DLS tɛ i n’a fɔ laadala fɛɛrɛw, o bɛ yeelen ni ɲɛdɔnni ni optiki min bɛ se ka don oksizɛni na ani resin minnu bɛ se ka porogaramu, olu fara ɲɔgɔn kan walasa ka jateminɛ kɛcogo danfaralenw dilan.

A ka bεnkansεbεn bεε la, o fεn in bε danfara min bε prototyping ni sεnεkεcogo dilanni cε. K’a ta mobili yɔrɔw la ka se furakɛli minɛnw ma, Carbon DLS tɛ sɛbɛnni kɛ cogo wɛrɛ la dɔrɔn – a bɛ fɛn ɲumanw dilan. An ka sɛgɛsɛgɛli kɛ cogo min na nin ko kura in bɛ ka fɛn dilanni sekow cogoya sɛmɛntiya.

Aw ka fara anw kan ka don kosɛbɛ ka Carbon DLS fɛɛrɛbɔ la! An bɛna a fan nafamaw bɛɛ sɛgɛsɛgɛ - k’a ta baara jɔnjɔnw na ka se fɛnw sugandili ma, ka fara nin 3D sɛbɛnnikɛcogo jiginni fɛɛrɛ in nafa n’a dɛsɛ kan.

Karɔbɔli DLS ye mun ye?

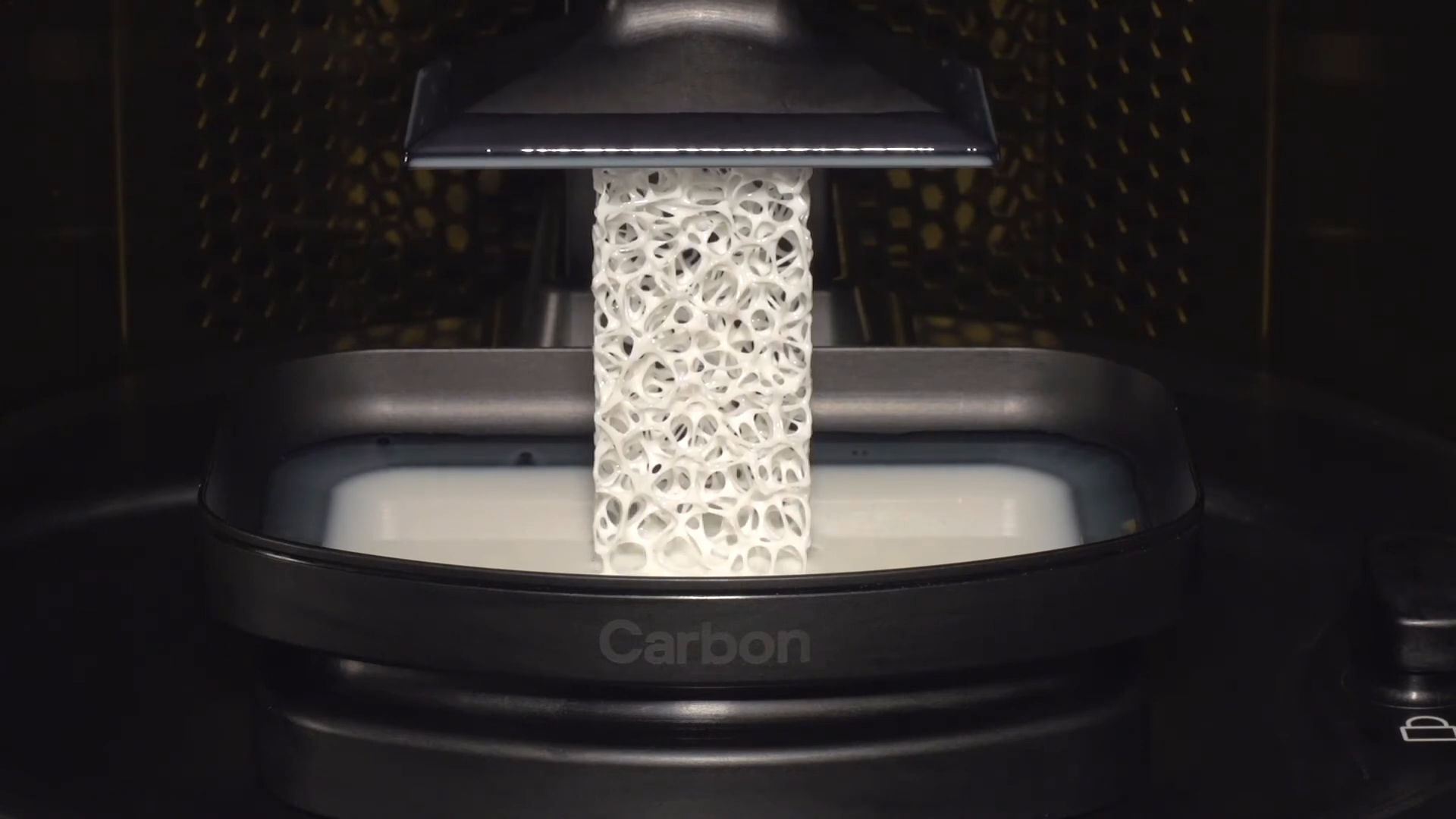

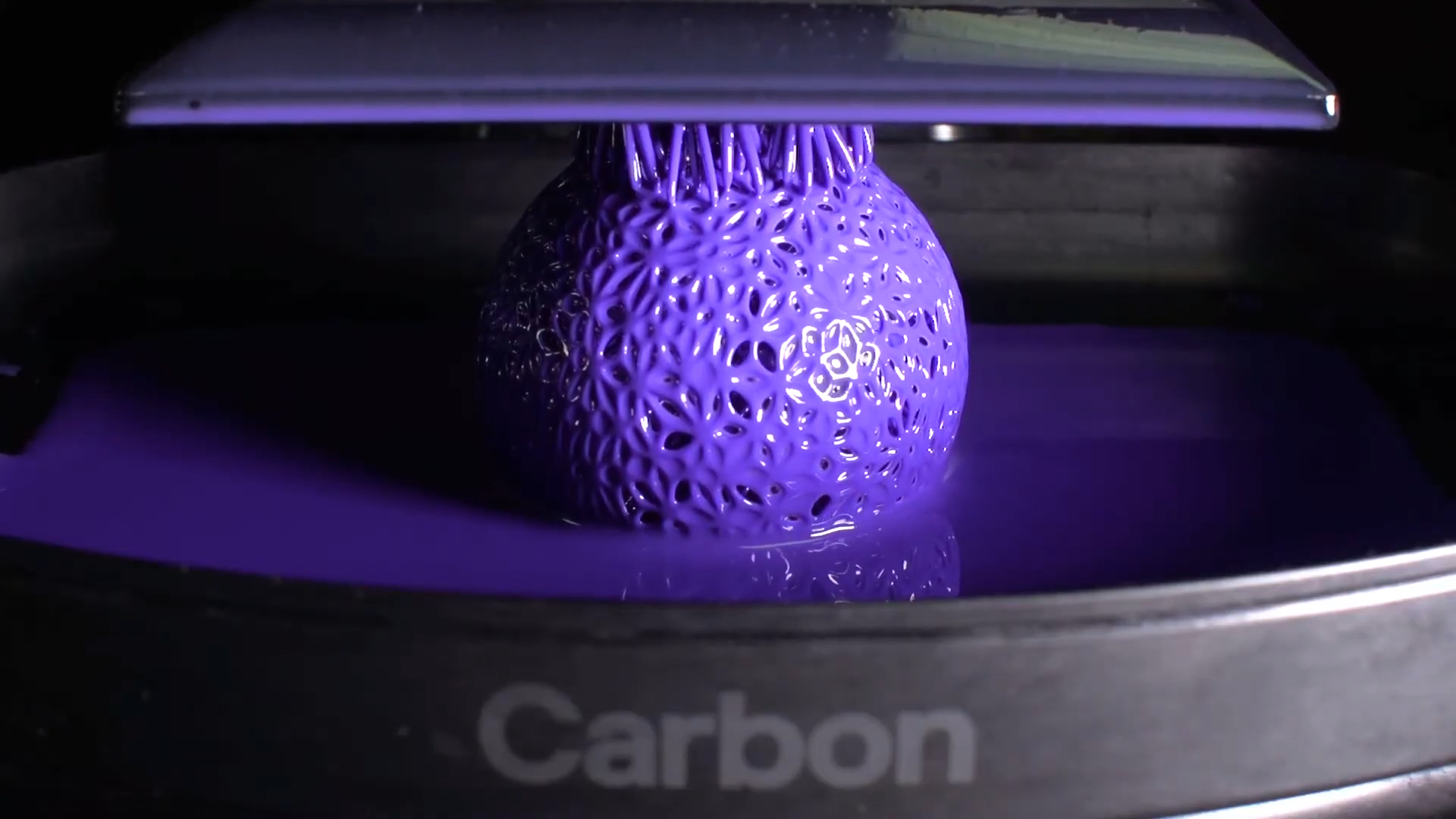

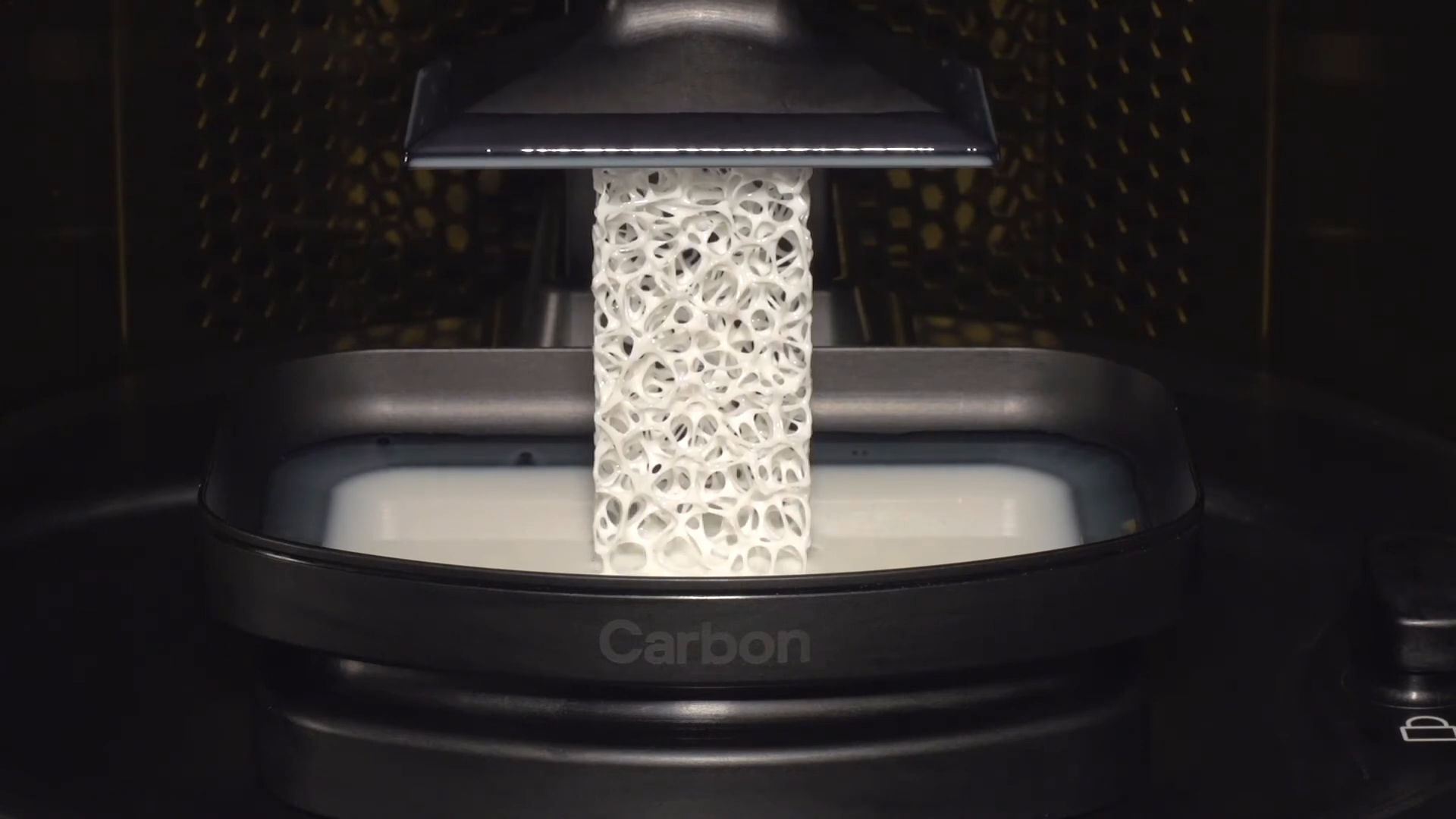

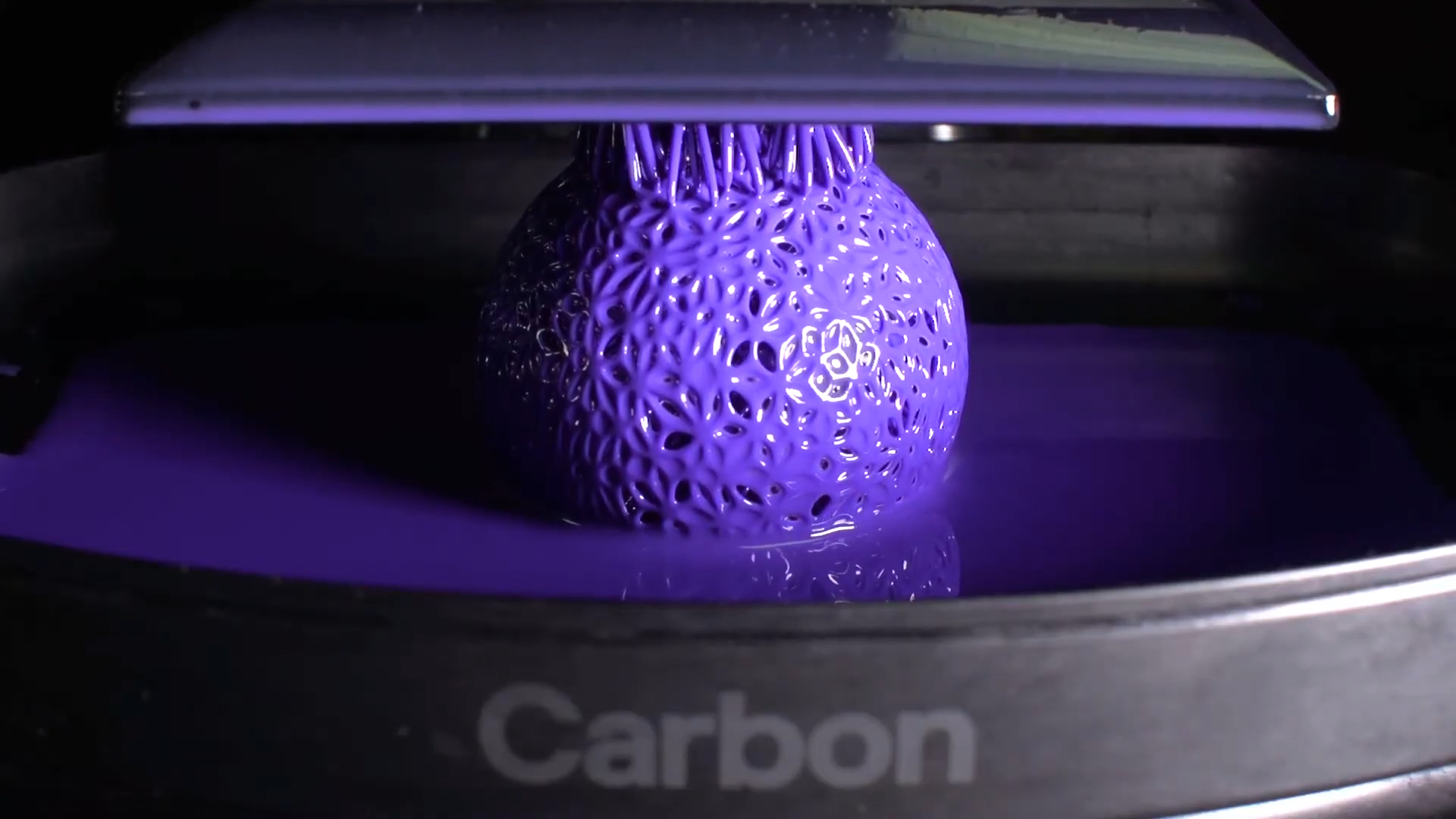

Carbon numérique light synthesis (DLS) bɛ 3D sɛbɛnnikɛcogo kura jira min bɛ dugukolo tigɛ. A bɛ yeelenbɔlan nimɔrɔma, oksizɛni sɔrɔ optiki la, ani jilama resin minnu bɛ se ka porogaramu, olu fara ɲɔgɔn kan walasa ka yɔrɔw dilan minnu ka ɲi kosɛbɛ, minnu bɛ se ka kɛ fɛn dilanni ye. Nin fɛɛrɛ kura in b’a yɛrɛ bɔ ɲɔgɔn na ni fɛnw dilanni ye minnu bɛ se ka muɲu cogo kɛrɛnkɛrɛnnen na, ni u bɛ tiɲɛ, ani minnu bɛ kɛ ka ɲɛ.

Karɔbɔli DLw ni 3D sɛbɛnnikɛcogo tɔw tɛ kelen ye cogo di?

Aw bɛ a suma ni stereolitografi ye (SLA) .

Kɛnɛyako taabolo .

Fanga yiriwali .

Production Speed .

A bɛ tali kɛ PolyJet 3D sɛbɛnni na .

Material Propriétés .

Surface Quality .

Sɛnɛfɛnw dilanni nafa .

Aw bɛ a suma ni deposition modelling fused (FDM) ye .

structurel integrité .

Detail resolution .

Material Options .

Carbon DLS bɛ baara kɛ cogo di?

Carbon DLS bɛ baara kɛ ni fɛɛrɛ saba ye minnu bɛ kɛ ni fɛn saba ye walasa ka 3D sɛbɛnnenw dilan minnu ka ɲi kosɛbɛ. An ka nin fɛɛrɛ kura in yɔrɔ kelen-kelen bɛɛ tiɲɛ.

Numérique yeelen projection system .

UV yeelenbɔlan .

Porozɛw yeelencogo tigitigiw .

Kontrɔliw yɔrɔ jateminɛ .

A bɛ se ka kunnafoni caman di .

Masque numérique .

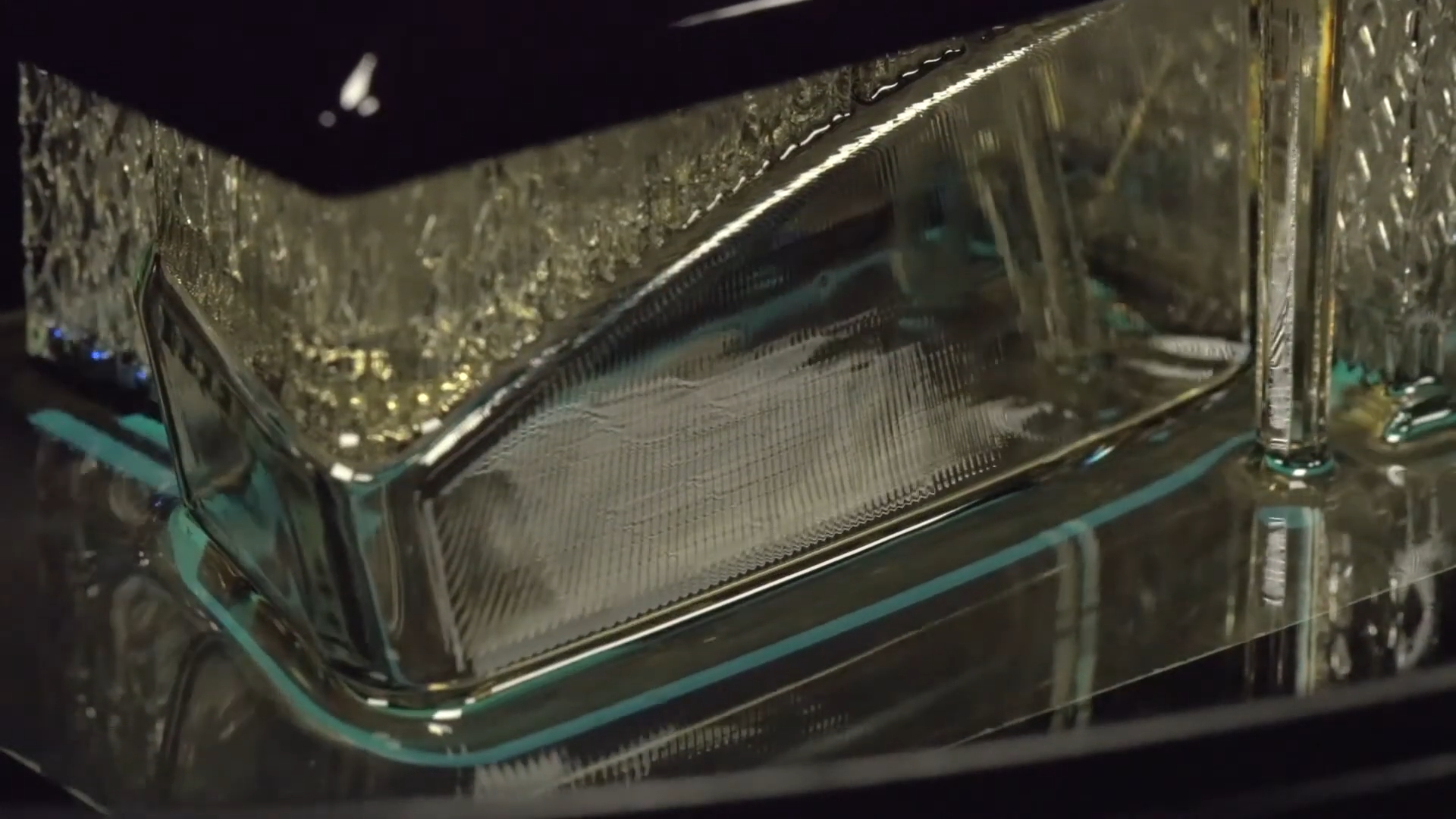

Clip processus (continuous liquid interface production) .

Etape 1: Setup fɔlɔ .

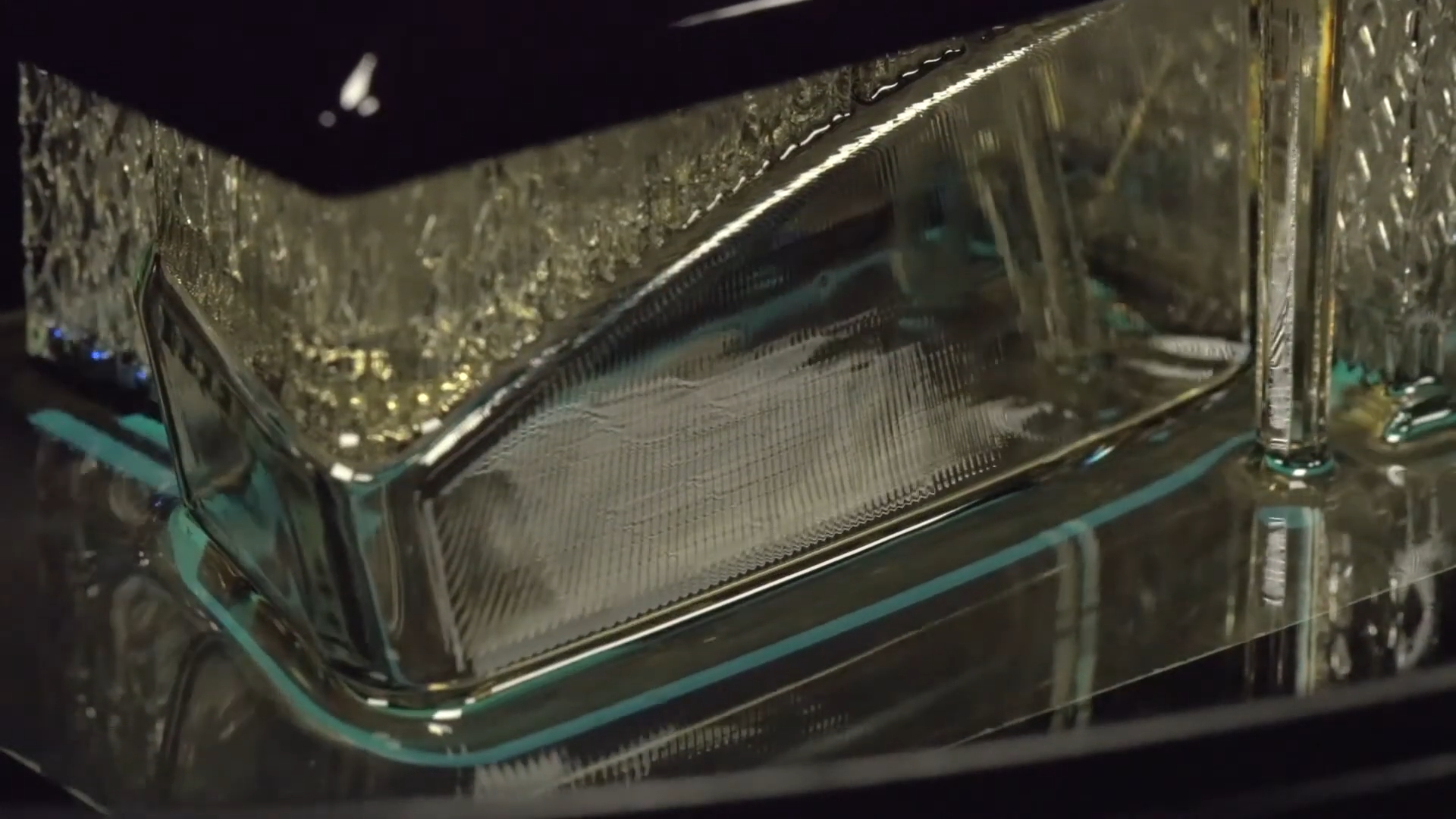

Resin jilama bɛ jɔli so fa .

jɔ plateforme jɔyɔrɔw daminɛ janya la .

Fenɛtiri min bɛ se ka don oksizɛni na, o bɛ labɛn ka ɲɛsin projɛsiyɔn ma .

Etape 2: A bɛ kɛ cogo min na .

Zoni salenw dabɔli .

Oksizɛni finman (0,001mm a ka bon) .

A bɛ resin nɔrɔli bali finɛtiri la .

A bɛ se ka sɛbɛnni kɛ ka taa a fɛ .

Build processus .

Plateforme bɛ wuli ka taa a fɛ .

Resin bɛ woyo a yɔrɔ jukɔrɔ .

Layɛrɛ danfara tɛ mago ɲɛ .

Etape 3: Furakɛli sumaya .

Fɛn minnu bɛ kɛ ka baara kɛ ni ɲɔgɔn ye .

Oksizɛni bɛ se ka don oksizɛni na cogo min na:

A bɛ zone salen basigilenw da .

A bɛ jilamaw ka ɲɔgɔndan mara .

A bɛ a yɔrɔ dɔw nɔrɔli bali .

Nafa minnu bɛ sɔrɔ a la, olu bɛ to ka kɛ:

Furakɛli labanw jaabiw:

Technical specifications:

| Process parameter |

typique value . |

| Zone de zone de zone . |

~0.001mm . |

| UV yeelen ɲɛfɔli . |

0,005' kɛnɛ . |

| Build volume . |

7,4' x 4,6' x 12,8'. |

| Minimum kogo janya . |

0,030'. |

Fɛn minnu bɛ kɛ kabon DLS 3D sɛbɛnni na .

Carbon DLS fɛɛrɛ bɛ fɛn suguya caman di walasa ka fɛn dilanni mago suguya caman ɲɛnabɔ. O fɛnw bɛ don kuluba fila la: plastiki gɛlɛnw ani fɛn minnu bɛ i n’a fɔ lastikuw.

Plastiki gɛlɛnw .

CE 221 (Siyanati ɛsitɛri) .

Fɛn minnu bɛ se ka kɛ .

Funteni hakɛ dantɛmɛnen .

Resistance de chimique de la chimique supérieur .

Tolerance de pressure (tansiyɔnba) .

Aplikasiɔn ɲumanw .

Fluide manifolds .

Komɛsi yɔrɔw .

Kimiw tali yɔrɔw .

UMA 90 (Multi-Porpose) .

Kɛcogow

Baarakɛcogo ɲumanw .

EPX 82 (Epoxy) .

Fɛn minnu bɛ i n’a fɔ lastikuw .

EPU 40 (poliyuritani elelamɛri) .

Bolo fɛnw

Elasticité sanfɛ .

A ka fisa ni ɲɛji ye .

Fanga segincogo ɲuman .

Baarakɛcogo caman .

Seals .

Vibration dampeners .

Flexible components .

SIL 30 (Silikoni) .

Attributs .

Aplikasi .

Furakɛcogo minɛnw .

Fɛn minnu bɛ se ka don .

fari-ɲinifɛnw .

Matériel proprétés comparison

| matériel |

durabilité |

flexibilité |

resistance chimique |

resistance resistance . |

| CE 221 . |

Ɲuman ɲuman |

Fɛ́gɛn |

Ɲuman ɲuman |

Jamanjan |

| UMA 90 . |

Duman |

Ka bɛrɛbɛn |

Duman |

Ka bɛrɛbɛn |

| EPX 82 . |

Ɲuman ɲuman |

Fɛ́gɛn |

Duman |

Duman |

| EPU 40 . |

Duman |

Jamanjan |

Ka bɛrɛbɛn |

Ka bɛrɛbɛn |

| SIL 30 . |

Ka bɛrɛbɛn |

Kosɛbɛ sanfɛ . |

Duman |

Duman |

CARBO DLS ka fɛn kɛrɛnkɛrɛnnenw .

Nafa minnu bɛ sɔrɔ karɔbɔli DLS fɛɛrɛbɔ la .

1. Mun na aw bɛ Carbon DLS sugandi ka ɲɛsin dilancogo gɛlɛnw ma?

Jateminɛ seko ni dɔnko ɲɛtaa .

Diɲɛ kɔnɔ baarakɛcogo lakikaw .

sennasanbara midsoles replacement .

Automotive Component Consolidation .

Aerospace yɔrɔ nɔgɔmanw .

Dɔgɔtɔrɔso minɛnw ka ladamu .

2. DLS karɔbɔli yɔrɔw ka masina jogo .

Nafa minnu bɛ sɔrɔ isotropi la .

Uniforme properties .

Baarakɛcogo jateminɛw .

Nafa minnu bɛ sɔrɔ furakɛli fila la .

UV curing stage .

A daminɛ cogoya ye .

Dimensional tiɲɛni .

kunnafoni tigitigiw .

thermal curing stage .

A bɛ baara kɛ ni chimie sunɔgɔlen ye .

A bɛ fanga di molekiyɔmuw ka jɛɲɔgɔnyaw ma .

A bɛ fɛn bɛɛ lajɛlen ka muɲuli ɲɛ ka taa a fɛ .

3. Surface Finish quality .

Surface characteristics .

Quality Metrics .

Glass-like smoothness .

Layini fitininw .

Professionnel yecogo .

ɲɛnabɔli sekow .

Size-based performance

| Parts Size |

Resolution |

Surface Quality . |

| A ka dɔgɔ (<2') . |

Ultra-high . |

Mirror-like . |

| Medium (2-6') . |

Jamanjan |

Ɲuman ɲuman |

| belebele (>6') . |

Sariya |

Baarakɛla |

Nafa minnu bɛ sɔrɔ fɛn dilanni na .

mugu bɔli ma kɛ fura ye .

Minimal post-processing .

A bɛ se ka kɛ ka baara kɛ ni yɔrɔ ye min bɛ se ka baara kɛ .

Jateminɛw bɛ kɛ cogo basigilen na batchw kɔnɔ .

nafa wɛrɛw .

Sɛnɛfɛnw dilanni nafa .

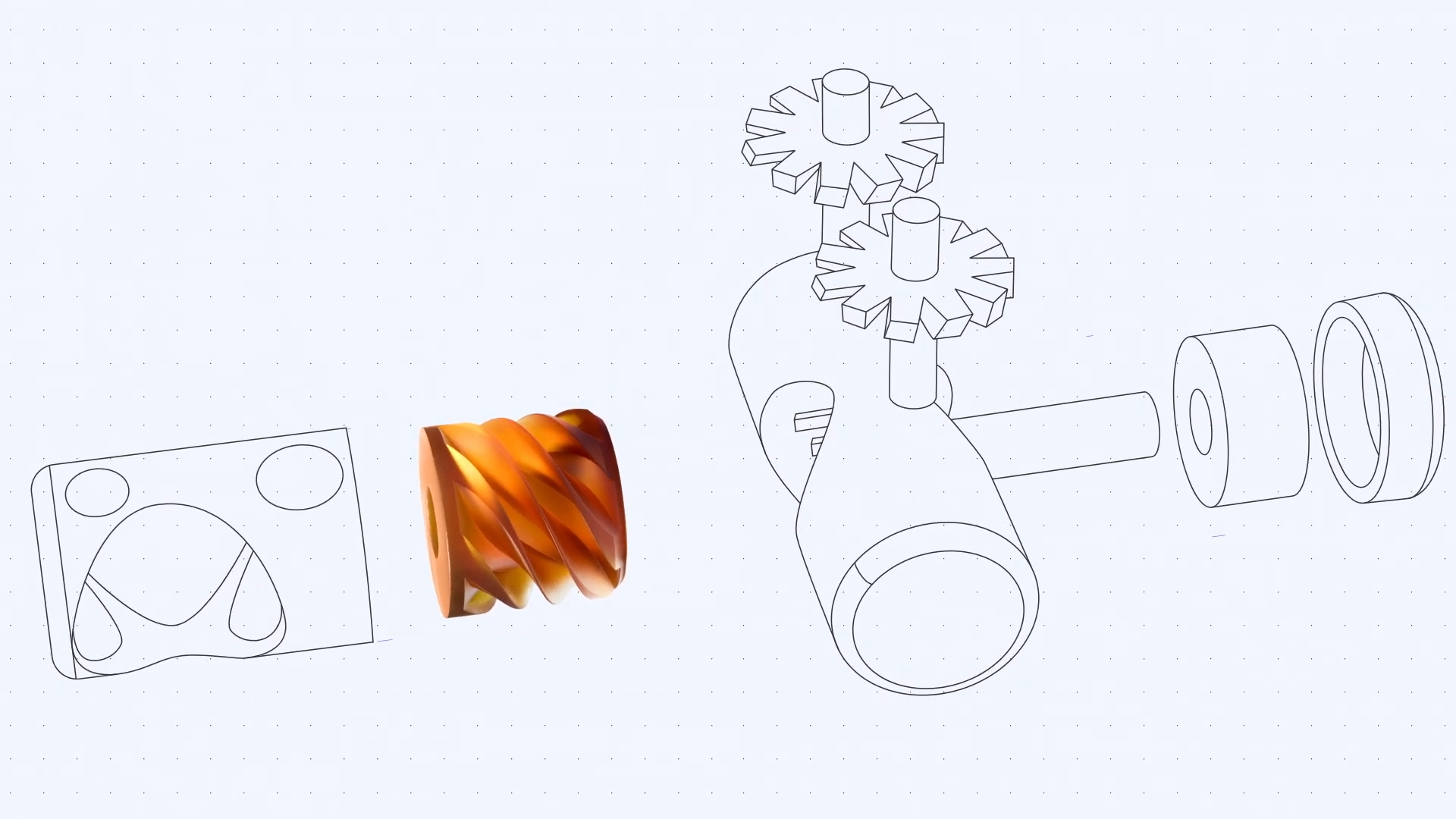

Design hɔrɔnya .

Assemblées consolidées .

Geometries optimisés .

Baarakɛcogo jɛlen .

Quality Assurance .

DLS karɔbɔli jateminɛ ni dantigɛliw .

Cost Factors .

Investissement fɔlɔ: Minɛnw, fɛn kɛrɛnkɛrɛnnenw, ani porozew sigicogo bɛ ɲini ka ɲɛsin waribonba ma min bɛ ɲɛfɛ.

Baara musakaw: Resin minnu bɛ sɔrɔ u yɛrɛ la ani ladonni min bɛ senna, olu bɛ kɛ sababu ye ka fɛn dilanni musakaw caya ka tɛmɛ laadala fɛɛrɛw kan.

Baara kɛlen kɔfɛ: finidoncogo wɛrɛw bɛ dɔ fara baara musakaw kan ani a dilanni waati.

Fɛn minnu bɛ kɛ ni fɛnw ye .

Sugandili danma: Basi fɛn 8 dɔrɔn de bɛ sɔrɔ, minnu bɛ dantigɛli kɛ u dilanni na ani u kɛcogo la.

Kulɛri suganditaw: Kulɛri sugandili fitininw bɛ sɔrɔ fɛnw na minnu bɛ kɛ ka kɛɲɛ ni sariya ye. Custom Coloring bɛ baara wɛrɛw de wajibiya.

Material Properties (Matériel propriétés): A ka kan ka kɛ ni masinw ka jogo ye ni a bɛ tali kɛ laadala fɛn dilanni na.

Waati min na i bɛ se ka fɛɛrɛ wɛrɛw jateminɛ .

Prototypes nɔgɔmanw: FDM walima SLA basigilen bɛ fura teliyalenw di, minnu musaka ka dɔgɔ sɛgɛsɛgɛli jɔnjɔnw na.

A dilanni ka bon: SLw walima pikiri kɛcogo bɛ sɔrɔ ɲumanw di hakɛ caman na.

Budjet porozew: Laadalata dilanni fɛɛrɛw bɛ nafa sɔrɔcogo caman di:

Porozɛ minnu bɛ waati jateminɛ: 3D sɛbɛnni fɛɛrɛw bɛ teliya ka fɛn caman tigɛli kɛ walasa ka dilancogo nɔgɔmanw sɔrɔ.

Carbon DLS bɛ tɛmɛ yɔrɔ gɛlɛnw kan, minnu ka ɲi kosɛbɛ nka a bɛ se ka kɛ ko u tɛ bɛn porozɛ bɛɛ ma. Aw ye aw mago kɛrɛnkɛrɛnnenw, aw ka baarakɛnafolo ani aw ka fɛn dilanni hakɛ jateminɛ sani aw ka nin fɛɛrɛ in sugandi.

DLS ka seko ni dɔnko baarakɛcogo .

Sisan izini baarakɛcogo .

Mobili dilanni: Yɔrɔ minnu bɛ se ka baara kɛ kosɛbɛ, olu dilanni, ani baarakɛcogo prototypes. A bɛ se ka kɛ sababu ye ka yɔrɔ dɔ sigi sen kan ani ka girinya dɔgɔya.

Furakɛcogo minɛnw: A bɛ minɛnw dilan minnu bɛ se ka baara kɛ ɲɔgɔn fɛ, opereli baarakɛminɛnw, ani banabagatɔ kɛrɛnkɛrɛnnenw ka fɛnw. A ka ɲi kosɛbɛ ɲinw furakɛli la ani furakɛli-sɛnɛfɛnw na.

Mɔgɔ minnu bɛ fɛnw feere: Sennasanbaraw yɔrɔ ɲumanw dilanni fanga bɛ sɔrɔ, ɛntɛrinɛti so, ani farikoloɲɛnajɛ minɛnw. A ka fisa ni ergonomi dilanw dabɔli ye.

Aerospace components (Aerospace yɔrɔw): A bɛ yɔrɔ nɔgɔmanw di, ka ducting systems (ducting systems) gɛlɛnw, ani baarakɛminɛn kɛrɛnkɛrɛnnenw di. A bɛ se ka kɛ ni dilancogo ɲuman ye walasa ka girinya dɔgɔya.

Fɛn dilanni seko .

Prototyping rapide (Prototyping rapide): teliya dilancogo iterations ani baarakɛcogo sɛgɛsɛgɛli lɛrɛ damadɔ kɔnɔ. A bɛ teliya ka hakilinaw di walasa ka dilancogo ɲɛ.

Production Scaling: Yɛlɛma-yɛlɛma ka bɔ prototyping la ka taa fɛn dilanni dafalen na. A bɛ se ka kɛ sababu ye ka jogo ɲuman sɔrɔ fɛn dilanni boliw bɛɛ kɔnɔ.

Mass Customization: A bɛ fɛn kɛrɛnkɛrɛnnenw dilan minnu bɛ bɛn mɔgɔ kelen-kelen bɛɛ magow ma. fanga minnu bɛ sɔrɔ mɔgɔ kelen-kelen bɛɛ fɛ izini suguya caman na.

Ɲɛtaa maanaw .

Adidas waleyali: A ye fɛn caman sɛmɛntiya midsole sɔrɔli la lattice structures fɛ. A ye mass customization sɔrɔ sennasanbara dilanni na.

Furakɛcogo: Banabagatɔ kɛrɛnkɛrɛnnenw ka minɛnw dilanni fɛn caman tigɛli. Dɔgɔyali waati dɔw la ni 60% ye ka ɲɛsin furakɛli fɛɛrɛw ma minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye.

Mobili ɲɛtaa: Yɔrɔ jate dɔgɔyali ni jɛkafɔ ye. A ye 40% musaka dɔgɔyali sɔrɔ a yɔrɔw dilanni na.

Future Trends .

Fɛnw dilanni: Fɛnw sugandiliw bonya ani masinw ka nafaw bonya. Fɛn sabatilenw ni biyo-based fɛnw jirali.

Fɛɛrɛko ɲɛtaa: Ka dɔ fara jɔli teliya ni hakɛw kan. Otomatiki siratigɛw waleyali.

Industriw ka sɛgɛsɛgɛli: Ka taa ɲɛ ka ɲɛsin inventory solutions numériques ma ani sigida labɛnni ma. ka bonya ka don suguya kuraw la.

Kuncɛli: Mun na aw bɛ Carbon DLS sugandi aw ka poroze nata kama?

Carbon DLS bɛ ɲɛtaa jira min bɛ dugukolo tiɲɛ 3D sɛbɛnni fɛɛrɛw la. A ka yeelen ni yeelen bɔli ni oksizɛni bɛ se ka don oksizɛni na, ani resin minnu bɛ se ka porogaramu, olu faralen ɲɔgɔn kan, o bɛ nɔ bɔ baarakɛcogo caman na. A ka klip kura kɛcogo fɛ, o fɛɛrɛ in bɛ se ka kɛ sababu ye ka jateminɛ gɛlɛnw dilan minnu tun tɛ se ka kɛ fɔlɔ ni laadala dilanni fɛɛrɛw ye.

Hali ni karɔbɔli DLS bɛ se ka kɛ musaka fɔlɔ caman ye, a ka se ka yɔrɔ ɲumanw dilan, yɔrɔ minnu bɛ baara kɛ, o b’a kɛ sugandili ɲuman ye porozɛ kuraw la minnu bɛ baara kɛcogo ɲuman ɲini. Ni nin fɛɛrɛ in bɛ ka taa a fɛ ka fɛn dilanni sɛmɛntiya iziniw kɔnɔ, k’a ta mobili la ka se furakɛli minɛnw ma, a bɛ dilancogo hɔrɔnya ni a dilanni sekow di minnu ma deli ka kɛ fɔlɔ. Porozɛ minnu bɛ ɲini ka ɲɛ, ka bɛn ɲɔgɔn ma, ani ka jateminɛ gɛlɛnw kɛ, karɔbɔli DLS bɛ fura barikama jira mɔgɔw la minnu bɛ se ka fɛn wɛrɛw dilan.

Aw labɛnnen don ka aw ka fɛn dilanni taabolo sɛmɛntiya wa?

Aw bɛ aw ka fɛn dilannenw yiriwali ta ka taa se hakɛ wɛrɛ ma ni MFG ka Carbon DLS fɛɛrɛ kɔrɔlen ye. I mago bɛ prototypes complexes (prototypes) gɛlɛnw na wo, walima yɔrɔ minnu labɛnnen don fɛn dilanni na, an ka dɔnnikɛlaw ka jɛkulu bɛ nafa kɛrɛnkɛrɛnnenw di.

Reference sources .

Carbon DLS 3D sɛbɛnni fɛɛrɛ .

Ɲininkali minnu bɛ kɛ tuma caman na karɔbɔli DLS kan .

Q1: Kogo janya hakɛ fitinin bɛ se ka kɛ ni DLS karɔbɔli ye?

A: Kogo janya min ka dɔgɔn, o ye 0,030' (0,762mm) ye, o bɛ kɛ sababu ye ka sigicogo dafalen ni a kɛcogo ɲuman sabati sɛbɛnni senfɛ.

Q2: DLS sɛbɛnni baara bɛ taa waati joli kɔnɔ?

A: Sɛbɛnni waatiw bɛ danfara ka kɛɲɛ ni u bonya ni u gɛlɛya ye. Yɔrɔ fanba bɛ sɛbɛnni dafalen kɛ sanga 1-3 kɔnɔ, ka fara sanga 2-4 wɛrɛ kan funteni furakɛli la foro kɔnɔ.

Q3: Yala karɔbɔli DLS yɔrɔw bɛ se ka penta walima ka u kulɛri wa?

A: Ɔwɔ. Carbon DLS yɔrɔw bɛ sɔn ja ni kulɛri kɛcogo la min bɛ kɛ ka kɛɲɛ ni sariya ye. Nka, baara kɔfɛ kulɛriw bɛ waati ni musaka wɛrɛw fara a dilanni kan.

Q4: DLS sɛbɛnni ka bonya hakɛ min bɛ se ka kɛ, o ye mun ye?

A: A jɔli yɔrɔ min bɛ kɛ cogoya la o ye 7,4' x 4.6' x 12.8'.Yɔrɔ minnu bɛ tɛmɛ 4' x 4' x 6' bɛ bolola seginnkanni de wajibiya walasa ka sɛbɛnni ɲumanw sɔrɔ.

Q5: Yala Carbon DLS fɛnw bɛ dumuniko gɛlɛya ani u bɛ se ka baara kɛ ni u ye wa?

A: Fɛn sugandilenw i n’a fɔ SIL 30 ani RPU 70, olu bɛ se ka baara kɛ ɲɔgɔn fɛ, wa u bɛnnen don dumuniko la. Fɛn kelen-kelen bɛɛ bɛ seereyali kɛrɛnkɛrɛnnenw de wajibiya baarakɛcogo laɲininen na.

Q6: O musaka bɛ se ka suma ni laadala fɛn dilanni fɛɛrɛw ye cogo di?

A: Kabon DLS bɛ musaka caman bɔ yɔrɔ kelen na hakɛ fitininw na. Nka, a bɛ kɛ musakabɔ ye jateminɛ gɛlɛnw na ani sɛnɛfɛnw bɔli cɛmancɛ la, baarakɛminɛnw musakaw bɛna kɛ dantigɛli ye yɔrɔ minnu na.

Q7: Post-processing sugu jumɛn de ka kan ka kɛ karɔbɔli DLS yɔrɔw la?

A: A fanba bɛ furakɛli funteni de wajibiya sɛbɛnni kɔfɛ. Fɛn wɛrɛ minnu bɛ kɛ kɔfɛ, olu bɛ bɔ a kɛcogo la - k’a ta dɛmɛnan bɔli nɔgɔman na ka se surface finishing ma ɲɛnajɛ yɔrɔw la.