Koya ta yi mamakin yadda masana'anta ke ƙirƙirar sassan da ke da cikakkiyar ƙarfi da daidaito? Shigar da Carbon DLS (Hasken Haske na dijital), wata ƙirar bugaawa ta 3D 3d mai canzawa masana'antu na zamani. Ba kamar hanyoyin gargajiya ba, carbon dls ya haɗu da tsinkayar hasken dijital tare da fitsari na oxygen da shirye-shiryen resins don ƙirƙirar sakamakon na musamman.

Ta hanyar tsarin shirin na juyi na juyi, wannan fasaha tana da rata tsakanin sahihiyar masana'antu da masana'antu. Daga sassan motoci zuwa na'urorin likita, carbon dls ba kawai da yawa daban - yana ƙirƙirar ingantattun samfura ba. Bari mu bincika yadda wannan bidi'a ke sake resarfin masana'antu.

Kasance tare da mu don wani zurfi cikin fasahar DLS! Zamu bincika duk mahimman bangarorin - daga ayyukan yau da kullun zuwa zaɓin kayan aiki, ƙari da ribobi da kuma ƙungiyar buga takardu na 3.

Menene carbon dls?

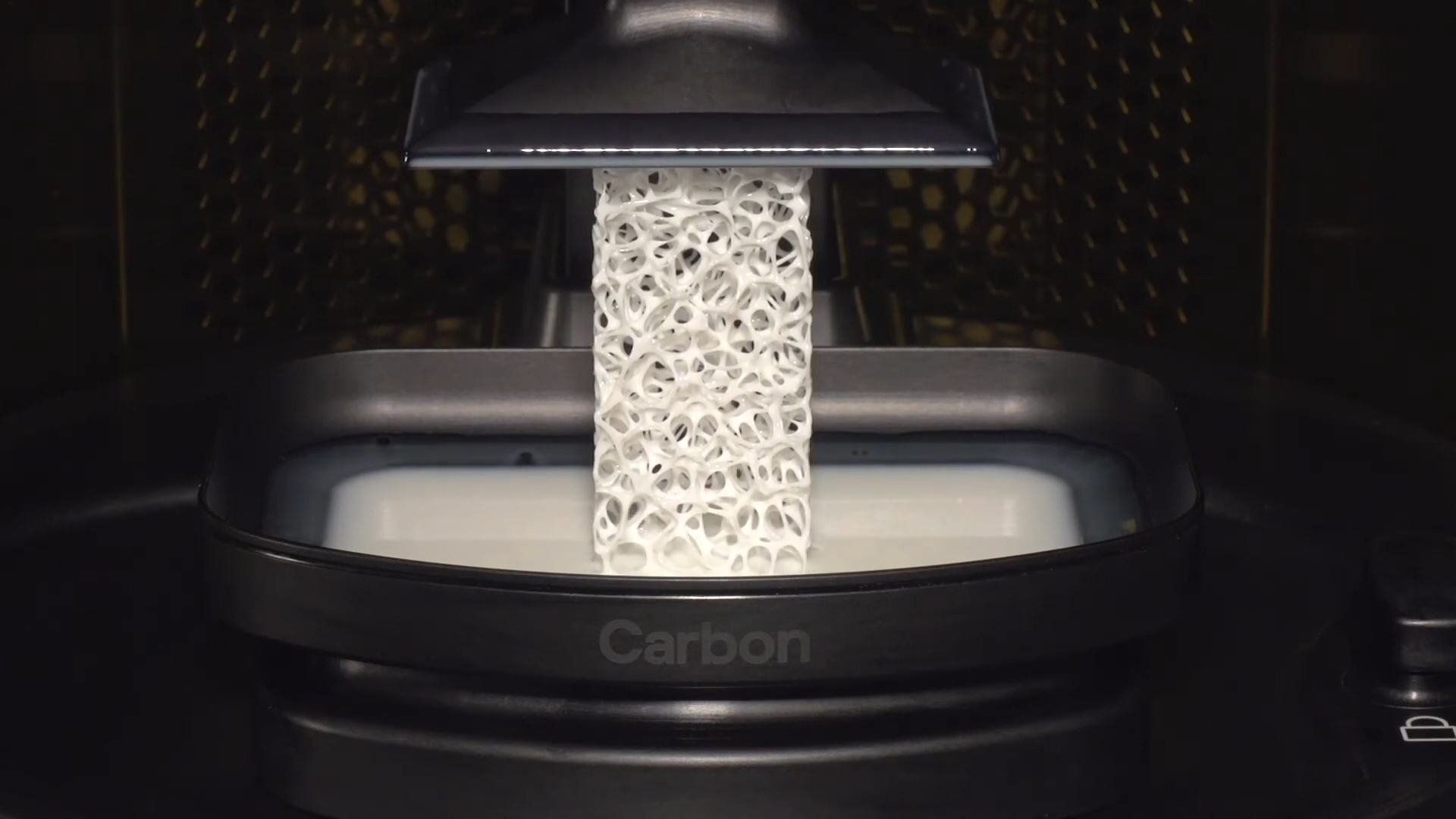

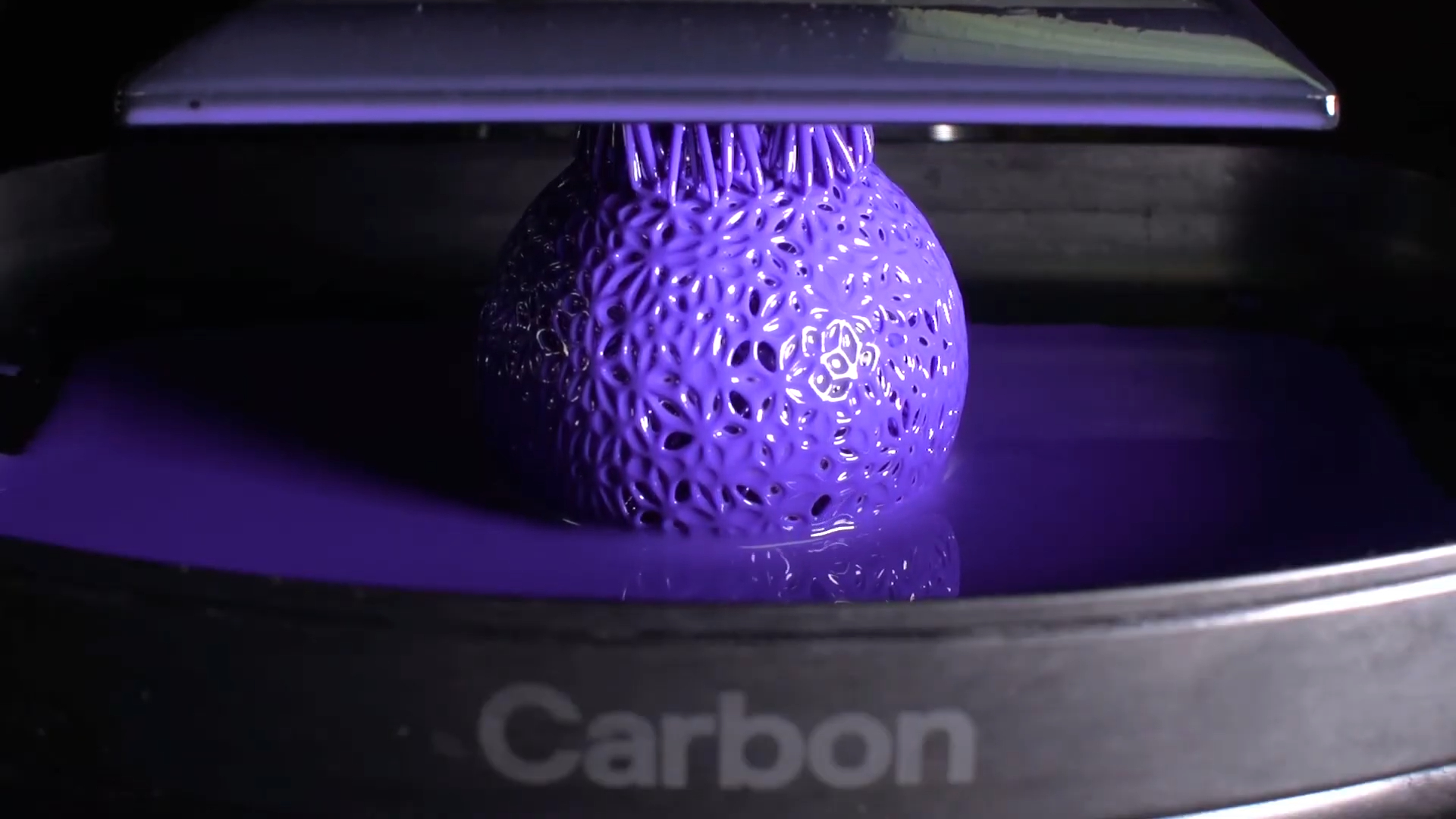

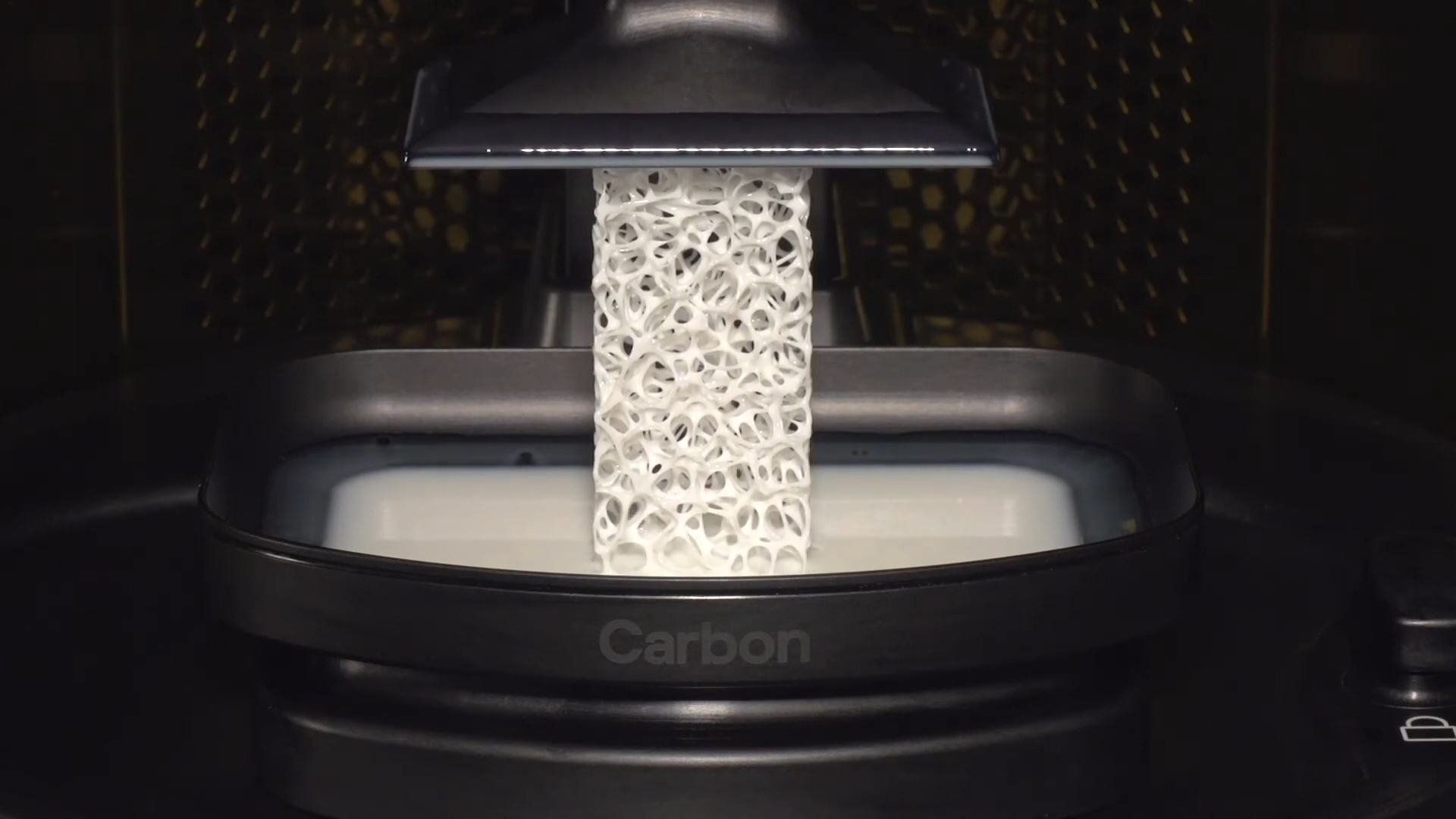

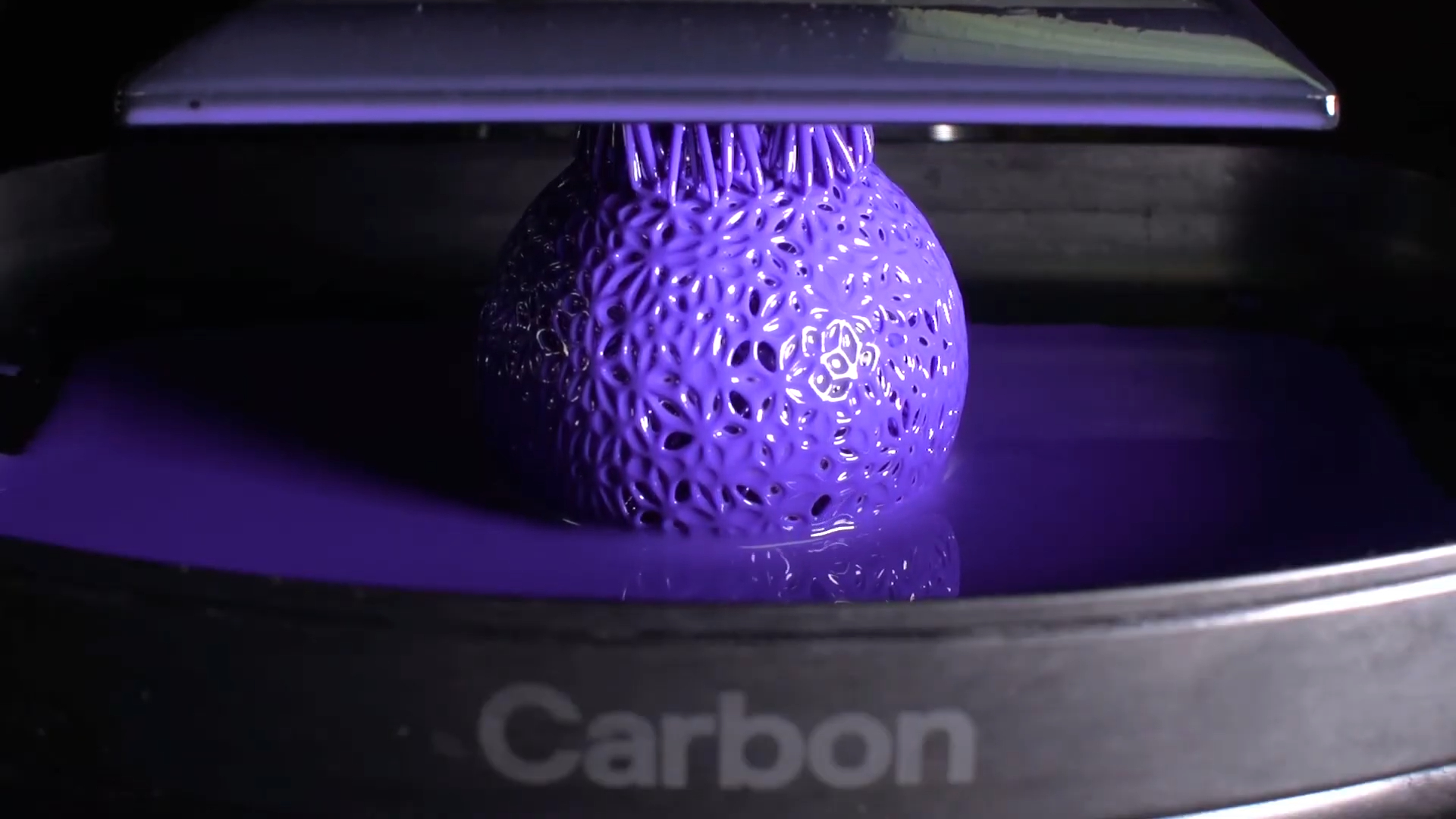

Carbon Digital Hasken Gynthesis (DLS) yana wakiltar tsalle-tsalle a Fasaha na Fasaha a Fasahar Buga ta 3D. Ya haɗu da hangen nesa mai haske na dijital, da opygen-perminabai na ofics, da kuma shirye-shiryen ɗakunan ruwa ya resins don ƙirƙirar manyan sassan saiti. Wannan nau'in halittar yana haifar da kanta ta hanyar samar da abubuwan da aka gyara tare da ƙa'idar, daidai gwargwado, da kuma mafi girman ƙasa.

Ta yaya carbon dls daban da sauran hanyoyin buga 3D?

Kwatanta da Storeolitography (Samu)

Tsarin shakatawa

Ci gaban ƙarfi

Saurin samar

Kwatantawa da Polyjet 3D Fitar

Abubuwan kayan abu

Ingancin ƙasa

Samarwa

Kwatanta da kayan aikin da aka yi amfani da shi (FDM)

Ingantacciyar amincin

Cikakken tsari

Zaɓuɓɓukan Abinci

Ta yaya carbon dls aiki?

Carbon dls suna ɗaukar madaidaitan tsari na uku don ƙirƙirar wadatattun sassa 3D. Bari mu rushe kowane bangare da kuma matakin wannan sabuwar fasahar.

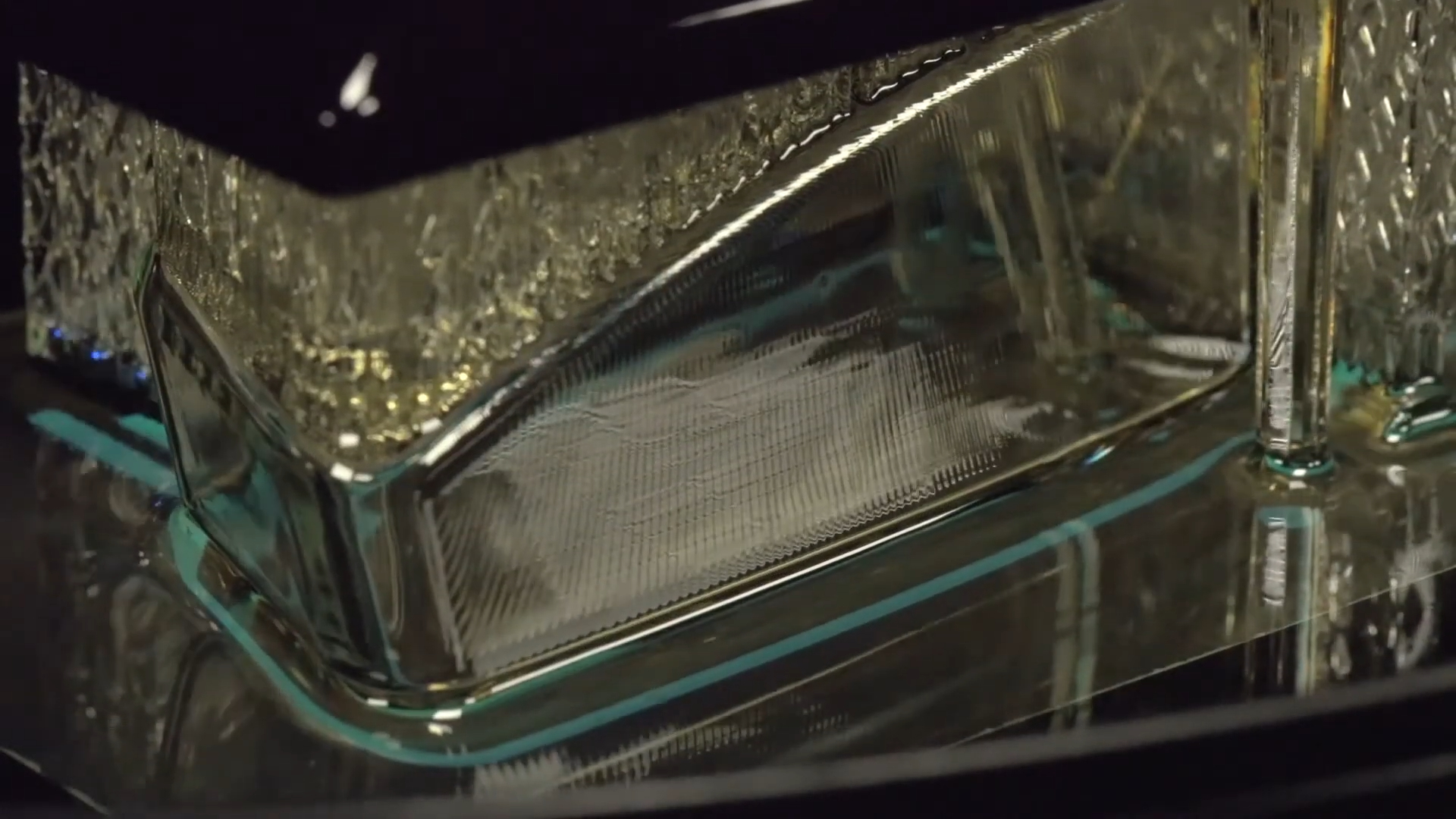

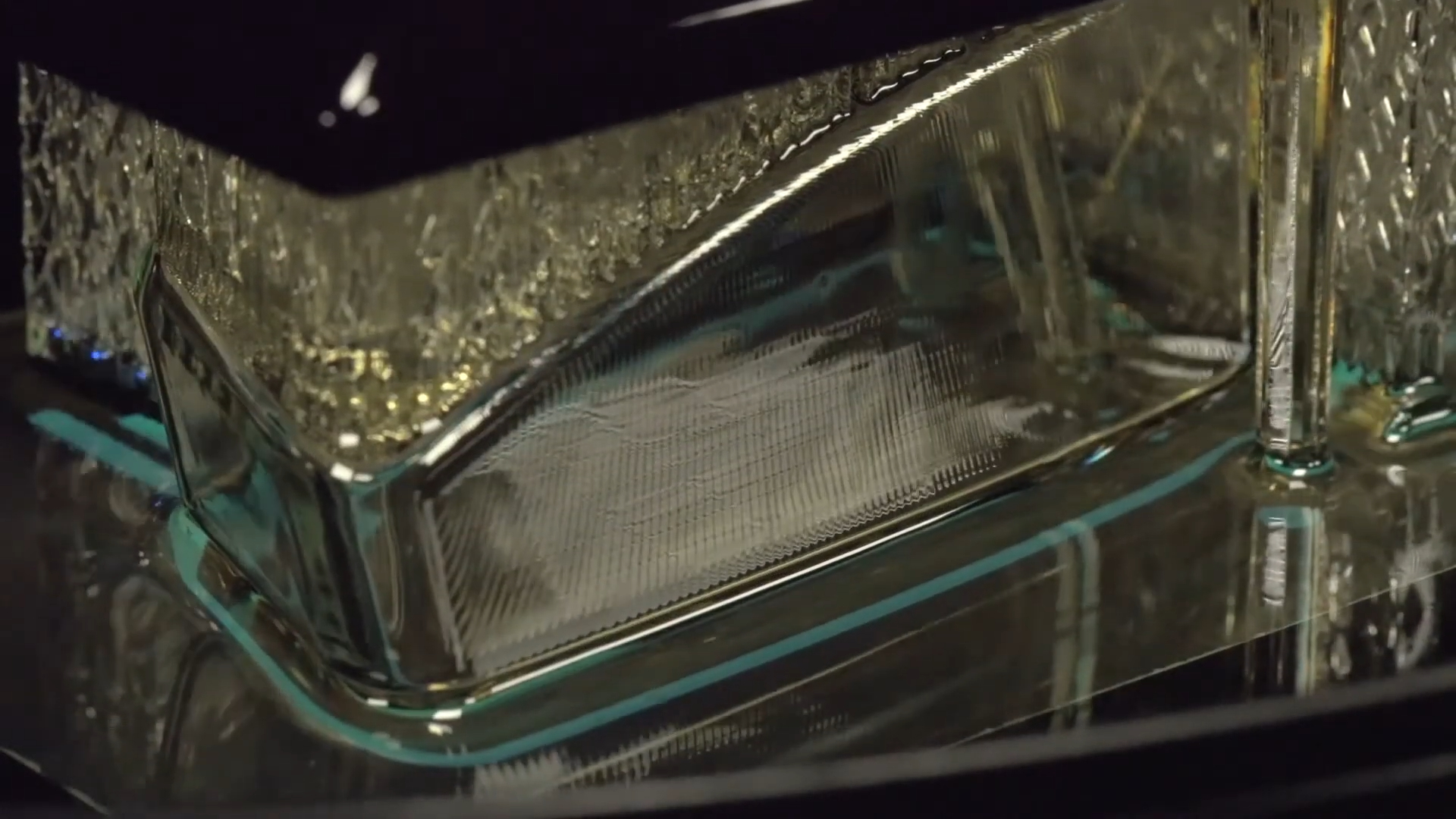

Tsarin tsinkaya na Digital

Sourla mai ruwa

Dijital ming

Tsarin shirin (ci gaba da tsarin sarrafa ruwa)

Mataki na 1: Saitin farko

Liquin resin ya cika dakin ginin

Gina matsayin dandamali a farkon

Oxygen-permetle taga yana shirya don tsari

Mataki na 2: Cigaba da Samuwa

Yancin Yankin Halitta

Gina tsari

Mataki na 3: Jarraba mai zafi

Key tsari

Oxygen-permeable Ofitic:

Ci gaba da samar da fa'idodi:

Sakamakon sakamako na karshe:

Bayanin Fasaha:

| Tsarin sigogi | na hali |

| YADDA AKE CIKIN SAUKI | ~ 0.001mm |

| UV haske shawarwari | 0.005 'square |

| Gini | 7.4 'x 4.6 ' x 12.8 ' |

| Mafi qarancin kauri | 0.030 ' |

Abubuwan da aka yi amfani da su a Carbon DLS 3D Fitar

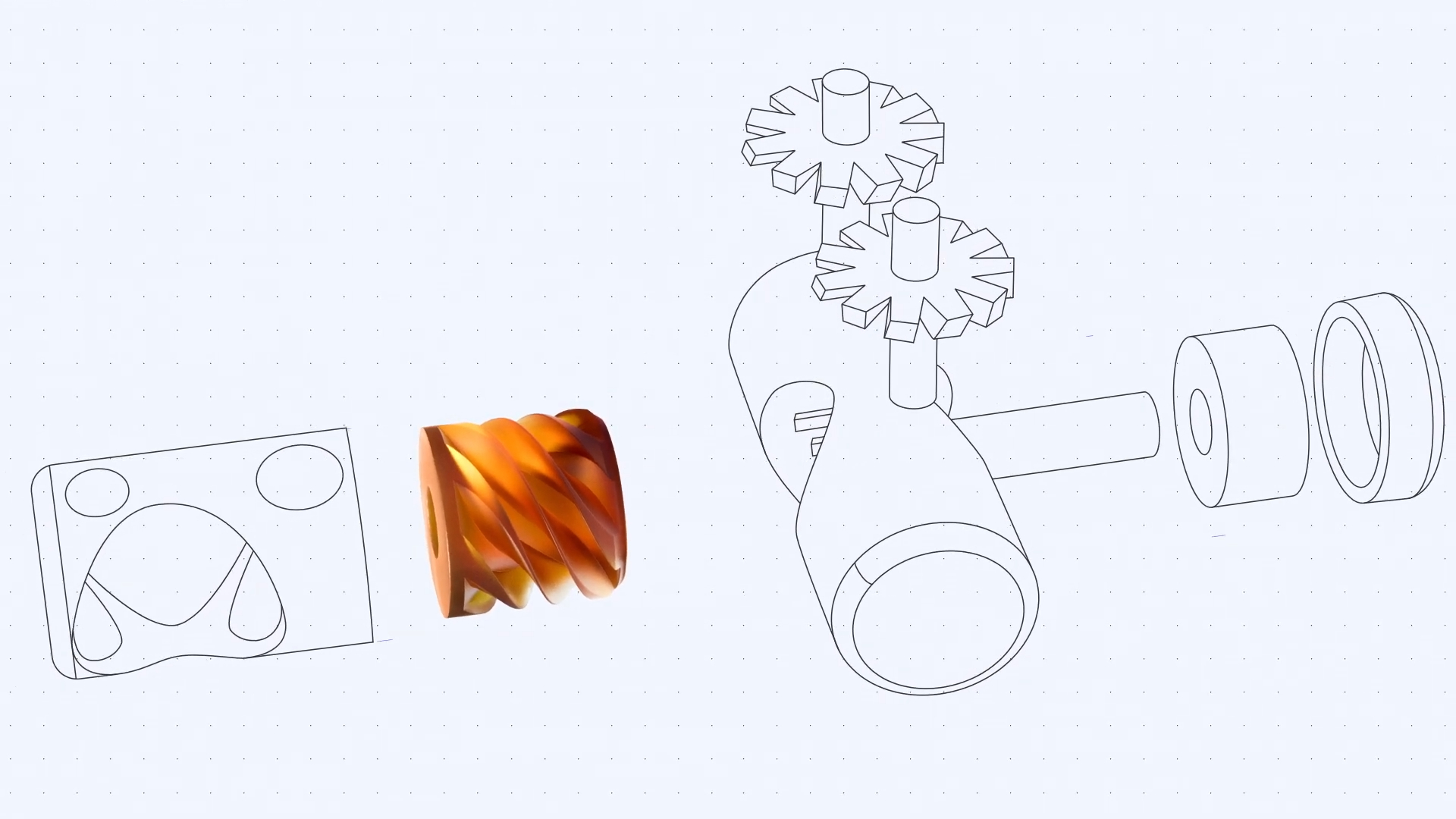

Carbon dls Fasaha yana ba da zaɓuɓɓukan abubuwa daban-daban don biyan bukatun masana'antu daban-daban. Wadannan kayan fada cikin manyan rukuni biyu: robobi masu tsauri da kayan roba.

Rikicin Robigs

Ib 221 (Cayinate ester)

Uma 90 (dalilai na da yawa)

Halaye

Kama da sl sl resins

Ikon launi iri-iri

Kyakkyawan farfajiya

Mafi kyawun amfani

Masana'antu

Samar da jig

Abubuwan da ke gani

EPX 82 (Epoxy)

Fasas

Gilashin kamar wuta

Babban karkara

Tasirin tasiri

Aikace-aikace

Abubuwan tsari na tsari

Mai haɗawa

Kaya mai ɗaukar nauyi

Roba-kamar kayan

EMU 40 (polasomeric polyurethane)

Kaddarorin

Amfani gama gari

Sil 30 (silicone)

Sifofin

Na biocadder

Low m

Babban juriya

Aikace-aikace

Abubuwan ke cikin kayan abu Kwatanta

| kayan daki | daki | - | na kayan maye | da |

| Ib 221 | M | M | M | M |

| Uma 90 | M | Matsakaici | M | Matsakaici |

| EPX 82 | M | M | M | M |

| EPU 40 | M | M | Matsakaici | Matsakaici |

| Sil 30 | Matsakaici | Sosai babba | M | M |

Abubuwan Musamman na Carbo DLS

Abvantbuwan amfãni na Carbon DLS Fasahar Carbon

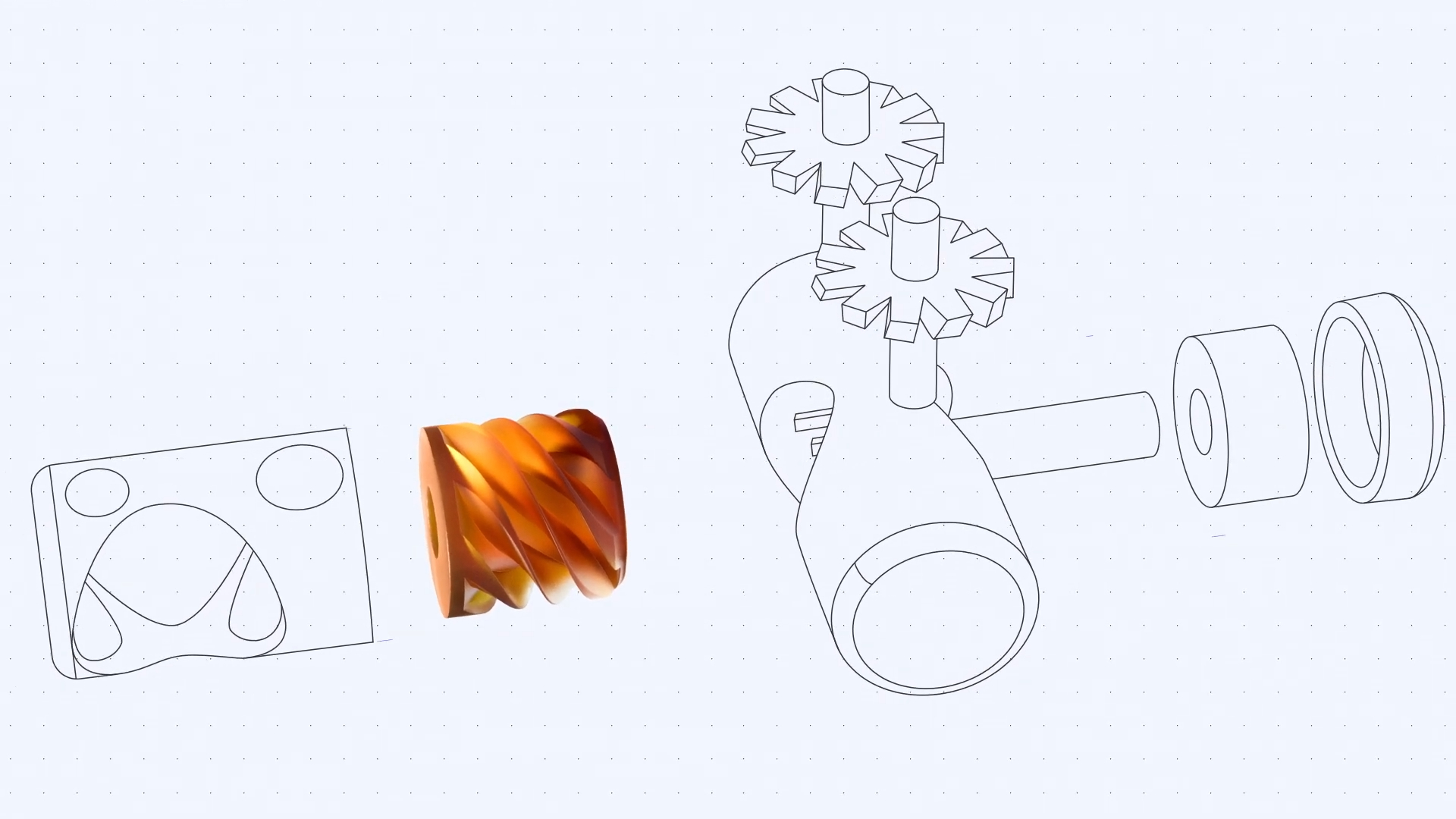

1. Me yasa zaba carbon dls ga hadaddun zane?

Babban ikon Kayayyaki

'Yancin ƙirar ƙira

Fa'idodin lattice

Aikace-aikace na Gaskiya

2. Kaddarorin injin na sassan carbon dls

Isasropic karfi taimako

Kayan kwalliya

Ayyukan Aikin

Dual-curing fa'idodi

UV kwalliya

Farko na farko

Daidaito daidai

Littafi Mai Tsarki

Mataki na Tsaro

Yana kunna Dormant Chemistry

Karfafa shaidu masu kwayar cuta

Inganta tsauraran tsauraran gaba daya

3. Ingancin gama

Halaye na farfajiya

M awo awo

Gilashin-kamar sassauya

Karancin Layer Layer

Bayyanar ƙwararru

Ƙuduri

0.005 'Square Pixel

Cikakken daki daki

Ma'anar fasalin fasalin

Girman girman kai na

| girman girman | girman | girman |

| Karami (<2 ') | Matsanancin-babba | Madubi-kamar |

| Matsakaici (2-6 ') | M | M |

| Babba (> 6 ') | Na misali | Gwani |

Masana'antu

Babu cirewa da ake buƙata

Minimal Post-sarrafawa

Shirya-da-amfani da ingancin yanayi

Rashin sakamako a duk faɗin batir

Ƙarin fa'idodi

Samarwa

Rage sharar gida

Mai sauri juya

BUKATAR-AIKI

'Yancin Yanayi

Babban taro

Ingantaccen geometries

Hadewar aiki

Tabbacin inganci

Sakamakon maimaitawa

Abubuwan da ake iri

Abin dogara masana'antu

La'akari da iyakance na carbon dls

Abubuwa masu tsada

Zuba jari na farko: Kayan aiki na Premium, Abubuwan Musamman, da Saita na musamman suna buƙatar babban birnin kasar.

Kudin aiki: resins na mallaka da ci gaba da haɓaka kudaden samarwa fiye da hanyoyin gargajiya.

Post-Production: ƙarin matakan gamawa yana ƙaruwa farashin kuɗi da lokacin samarwa.

Kayan Aiki

Zaɓin ƙarancin: kayan gini 8 kawai akwai, ƙuntatawa ƙira da zaɓuɓɓukan aikace-aikace.

Zaɓuɓɓukan Launi: Zaɓuɓɓukan launi na launi a cikin daidaitattun kayan. Canjin launi na buƙatar ƙarin aiki.

Abubuwan kayan abu: kewayon ƙa'idojin kayan injin da aka kwatanta da masana'antar gargajiya.

Yaushe za a yi la'akari da hanyoyin

Mai sauƙaƙawa mai sauƙi: FDM ko na asali SLA suna ba da sauri, mafi ƙarancin tsada don gwajin gaske.

Babban samarwa: Sls ko allurar rigakafi suna ba da ingantacciyar tattalin arziƙi na sikelin babban kundin.

Ayyukan kasafin kuɗi: Hanyoyin masana'antar gargajiya suna ba da ƙarin zaɓuɓɓukan tattalin arziki don:

Garkunan Geometries

Sassa masu sauki

Babban girma

Sauƙaƙe

Ayyukan da suka dace: Tsarin bugun 3D na 3D na 3D suna ba da hanzarin sauri don zane mai sauƙi.

Carbon dls Excelels cikin hadaddun, sassa masu inganci amma ba za su dace da kowane aiki ba. Yi la'akari da takamaiman bukatunku, kasafin kuɗi, da ƙarar samarwa kafin zabar wannan fasaha.

Aikace-aikacen Carbon Dls

Aikace-aikace masana'antu na yanzu

Masana'antu mota: samar da sassan manyan ayyukan, kayan aikin al'ada, da kuma sahihan ayyuka. Yana ba da damar raba kayan haɗin gwiwa da rage nauyi.

Na'urorin likitanci: Yana ƙirƙirar kayan aikin ɓoyayyun bayanai, aikin kayan aikin al'ada, da kuma takamaiman implants. Mafi dacewa don aikace-aikacen hakori da kayan aikin likita.

Products Produch: Ikon samar da kayan haɗin tekun zamani, hoodronics housings, da kayan aikin wasanni na al'ada. Excells a ƙirƙirar ƙirar Ergonomic.

Aerospace abubuwan haɗin Aerospace: yana kawo sassa na biyu, tsarin mulki na rikice-rikice, da kuma kayan aikin musamman. Yana ba da ingancin tsarin zane don rage nauyi.

Masana'antu

Saurin Prototyping: isassun ƙira da kuma gwajin gwaji a cikin awanni. Yana ba da amsa kai tsaye don inganta haɓaka ƙira.

Nasakarwa: sauyawa sauƙin canji zuwa masana'antar sikelin. Yana ba da ingancin inganci a kan samarwa.

Alamar taro: Yana haifar da samfuran musamman waɗanda aka kera su ga bukatun mutum. Ikon ƙwararrun masanan don masana'antu daban-daban.

Labarun Nasara

Aiwatar da Adidas: samar da wuri mai gudana ta hanyar tsarin lattice. Cimma tsarin samar da masana'antu a masana'antar masana'antar masana'antu.

Aikace-aikace na likita: canza yanayin mai haƙuri mai haƙuri. Rage Times Times da kashi 60% don mafita na lafiyar al'ada.

Nasara taultotive: Rage part count ta hanyar ingantawa. Cimma sakamako 40% a cikin masana'antar da aka shirya.

Abubuwan da zasu faru nan gaba

Openactomarancin Actions: Fadada Zabin kayan da haɓaka kaddarorin na inji. Gabatar da kayan halitta da kayan haɗin gwiwa.

Ci gaban fasaha: kara gina gudu da kundin. Aiwatar da tsarin sarrafa kansa.

Juyin Masana'antu: Motsi zuwa hanyoyin dijital da aka samarwa na dijital. Fadada cikin sabon sassan kasuwa.

Kammalawa: Me yasa zabi Carbon DLS don aikinku na gaba?

Carbon dls yana wakiltar ci gaba na gaba a cikin fasahar buga 3D. Haɗin sa na musamman na tsinkaye na dijital, oxygen-perminabai na ofits, da shirye-shiryen shirya suna ba da sakamako na musamman sakamakon neman aikace-aikace. Ta hanyar tsarin kirkirar sa, wannan fasaha yana ba da ƙirƙirar maharan geometries wanda ba zai yiwu ba tare da hanyoyin masana'antar gargajiya.

Yayin da Carbon DLS na iya haɗawa da farashi na farko, iyawarsa na samar da manyan sassa na aiki yana sa shi kyakkyawan zaɓi don ƙarin ayyukan da ake buƙata masu haɓaka. Kamar yadda wannan fasaha ta ci gaba da juyar da masana'antu a kan masana'antu, daga kayan aiki zuwa na'urori marasa aiki, yana ba da 'yancin lafiya da ƙarfin samarwa. Don ayyukan da ke buƙatar inganci na musamman, daidaito, da hadaddun geometries, carbon dls gabatar da ingantaccen bayani don masana'antar kerting na gaba.

Shirya don canza tsarin masana'antar ku?

Theauki cigaban samfurin ka zuwa matakin na gaba tare da fasahar MFG ta ci gaba da fasahar DLS. Ko kuna buƙatar rikitattun abubuwan da aka shirya ko sassan samfurori, ƙungiyar ƙwararrunmu ta ba da sakamako na musamman.

Takamatsu

Carbon dls 3D buga fasaha

Tambayoyi akai-akai game da Carbon DLS

Q1: Menene mafi qarancin katse bangon zai yiwu tare da carbon dls?

A: Mafi ƙarancin shawarar bangon bango shine 0.030 '(0.762mm). Wannan yana tabbatar da amincin fasalin da ya dace yayin bugawa.

Q2: Har yaushe ne carbon dls carbon dls kai?

A: Lokaci na Buga ya bambanta da girman da rikitarwa. Yawancin bangarorin da suka dace da buga bugawa a cikin sa'o'i 1-3, da ƙarin 2-4 hours don zafi mai narkewa a cikin tanda.

Q3: Carbon dls sassan za a fentin ko canza launin?

A: Ee. Carbon DLS sassa suna karɓar daidaitaccen zane da tafiyar matakai na launi. Koyaya, aiki bayan aiki don launi ƙara ƙarin lokaci da kuma kuɗin zuwa samarwa.

Q4: Menene matsakaicin girman gini don bugun carbon dls?

A: Yankin gina yanki shine 7.4 'x 4.6 ' x 12.8 '. Sarari sun wuce 4 ' x 4 'X 6 ' na buƙatar bita ta hannu don sakamakon buga takardu.

Q5: Shin kayan dls carls abinci-amintattu da bibommas.

A: Zaɓi kayan kamar sil 30 da RPU 70 masu jituwa ne kuma sun dace da aikace-aikacen Cibiyar abinci. Kowane abu yana buƙatar takamaiman takaddun shaida don amfanin da aka yi niyya.

Q6: Yaya farashin ya kwatanta da hanyoyin masana'antar gargajiya?

A: Carbon DLS yawanci yana biyan kuɗi kowace sashi don ƙananan kundin. Koyaya, ya zama mai tsada-tasiri ga hadaddun geometries da matsakaita na matsakaici yana gudana inda farashin kayan aikin zai zama haramtacce.

Q7: Wace irin aiki-aiki ake buƙata don sassan carbon dls?

A: Mafi yawan sassan suna buƙatar farfadowa da zafi bayan bugawa. Additionarin aiki bayan aiki ya dogara da aikace-aikacen - daga cire goyon baya mai sauƙi don ƙarewar sassan ado.