Yu dɔn ɛva wɔnda aw manifakta dɛn de mek kɔmpleks pat dɛn wit di pafɛkt blɛnd fɔ trɛnk ɛn prɛsishɔn? Ɛntay kabɔn DLS (dijital layt sɛntesis), wan grɔn-brɛkin 3D printin teknɔlɔji we de transfɔm mɔdan manufakchurin. Nɔ lɛk tradishɔnal we, kabɔn DLS de kam togɛda dijital layt projɛkshɔn wit ɔksijɛn-permiabl ɔptik ɛn programmabl rɛsin fɔ mek ɛksɛpshɔn rizɔlt.

Tru in rivɔlɔshɔnari klip prɔses, dis teknɔlɔji de brij di gap bitwin prototyping ɛn prodakshɔn manufakchurin. Frɔm ɔtomotiv pat to mɛdikal divays, Carbon DLS nɔ jɔs de print difrɛn we – i de mek bɛtɛ prɔdak. Lɛ wi fɛn ɔndastand aw dis inovashɔn de rishɛp di manufakchurin pɔsibiliti.

Join wi fɔ wan dip div insay Kabon DLS teknɔlɔji! Wi go ɛksplɔrɔ ɔl di impɔtant aspek dɛm - frɔm besik ɔpreshɔn to matirial chus, plus di prɔs ɛn kɔns fɔ dis rivɔlɔshɔnari 3D printin mɛtɔd.

Wetin na Kabon DLS?

Kabon Dijital Layt Sintesis (DLS) de ripresent wan grɔn-brɛkin lip insay 3D printin teknɔlɔji. I de kam togɛda dijital layt projɛkshɔn, ɔksijɛn-permeable optics, ɛn programmable liquid resin fɔ mek ay kwaliti, prodakshɔn-grɛd pat dɛn. Dis inovativ teknɔlɔji de sɛt insɛf apat bay we i de prodyuz kɔmpɔnɛnt dɛn wit ɛksɛpshɔn durabiliti, prɛsishɔn, ɛn supia sɔfays finish.

Aw kabon DLS difrɛn frɔm ɔda 3D printin we dɛn de yuz?

Kɔmpia wit di stereolithography (SLA)

Kɔmpiashɔn wit PolyJet 3D printin .

Kɔmpiashɔn wit Fused Deposition Modeling (FDM)

Aw Kabon DLS de wok?

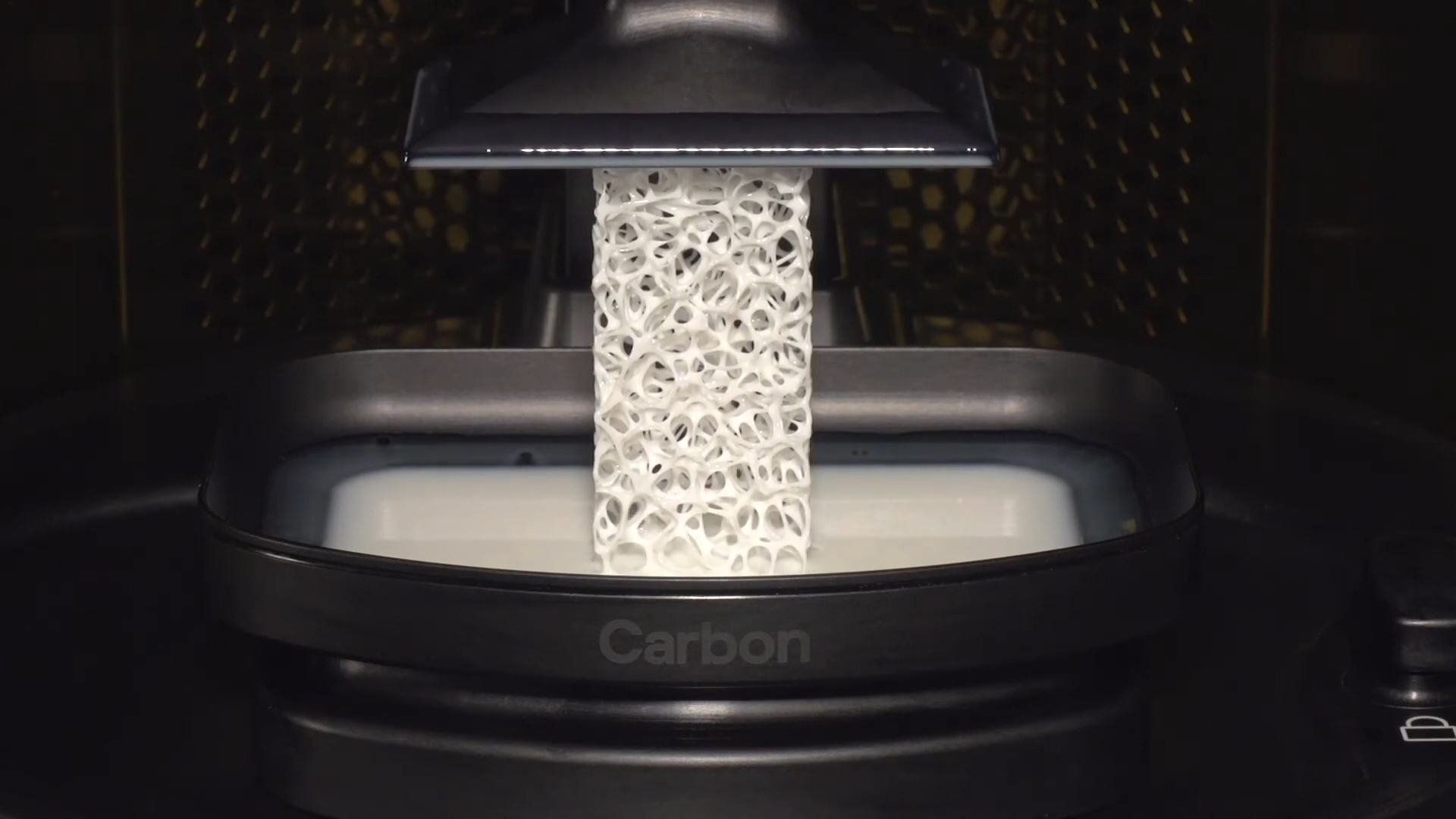

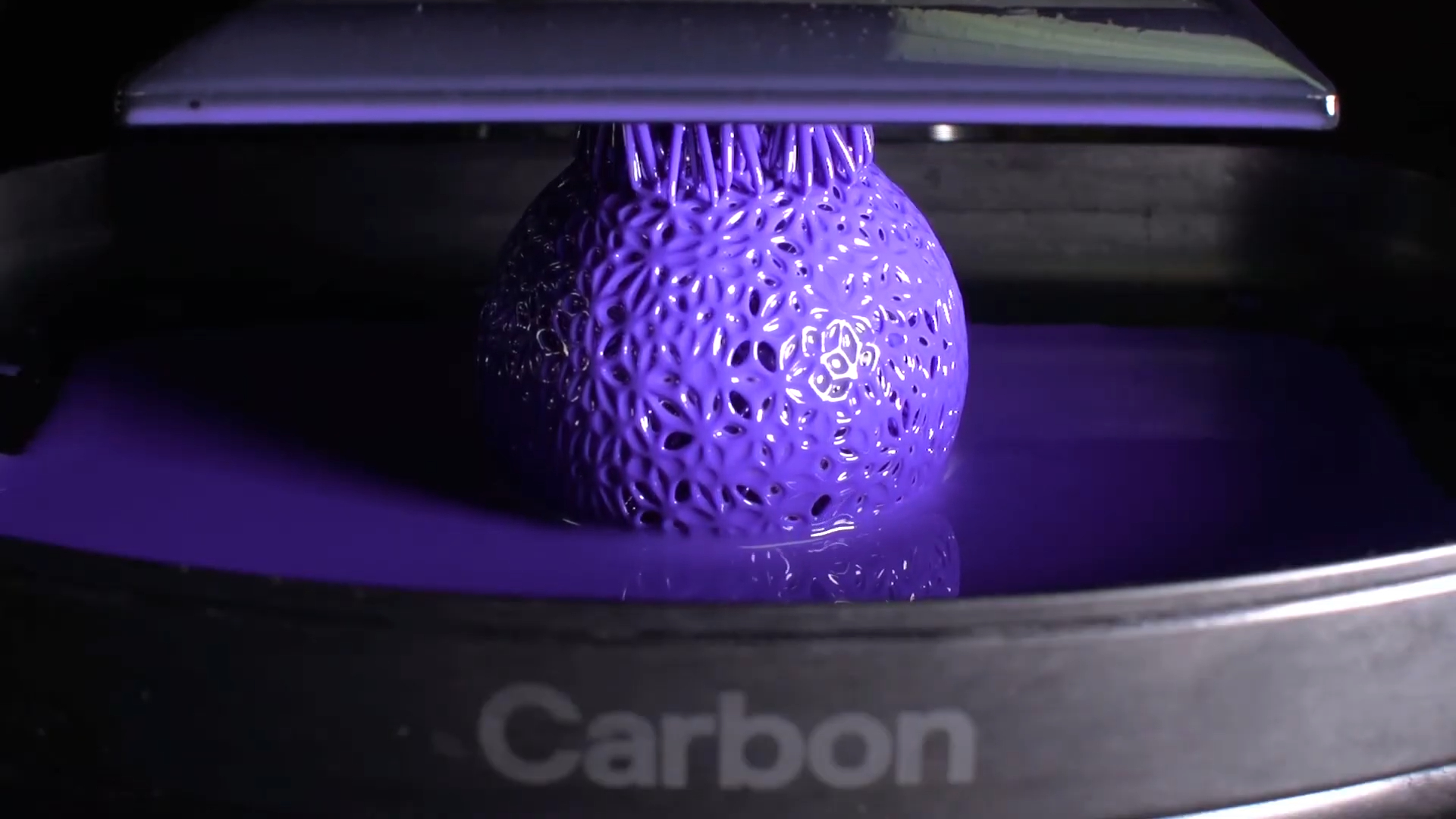

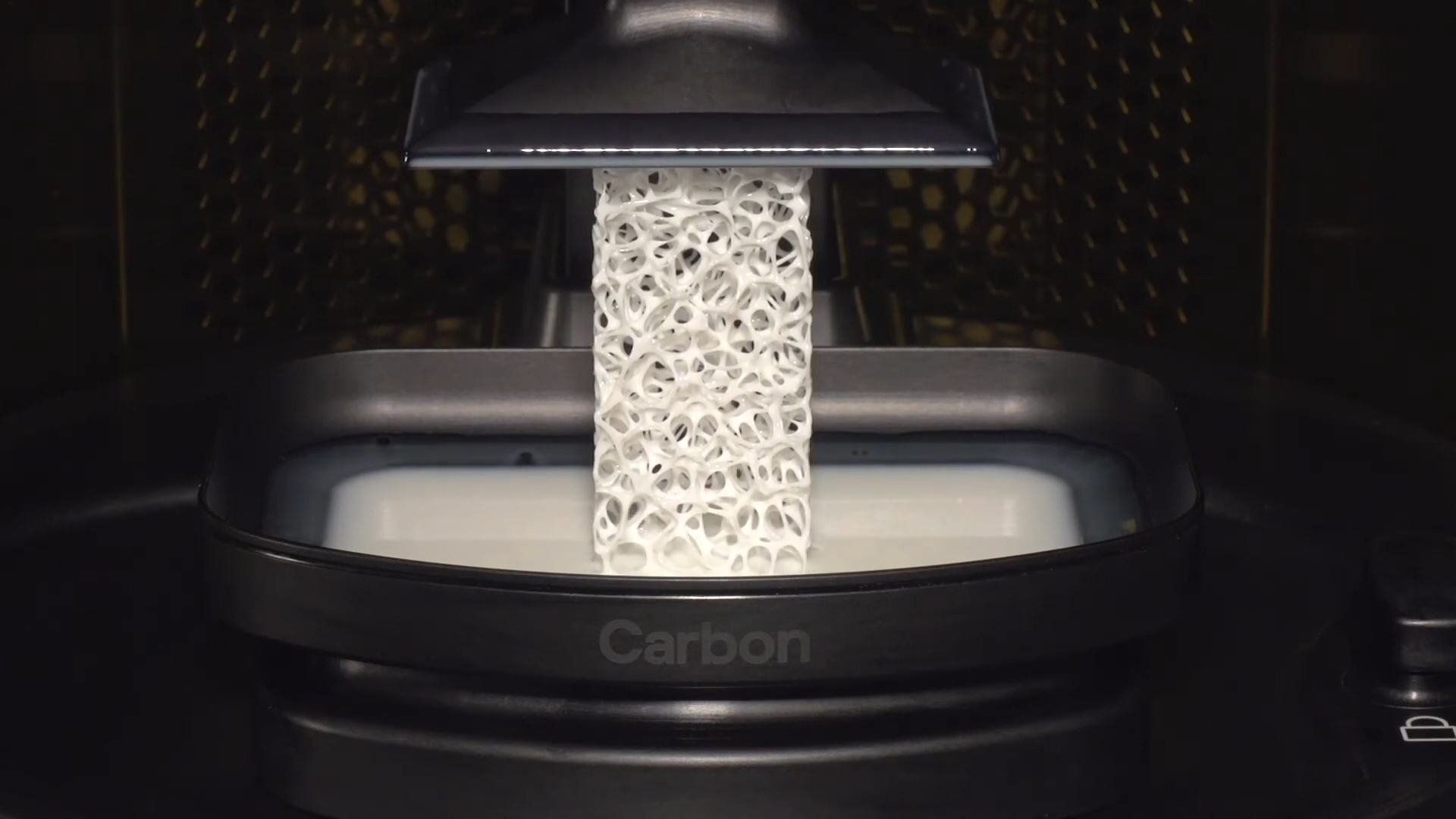

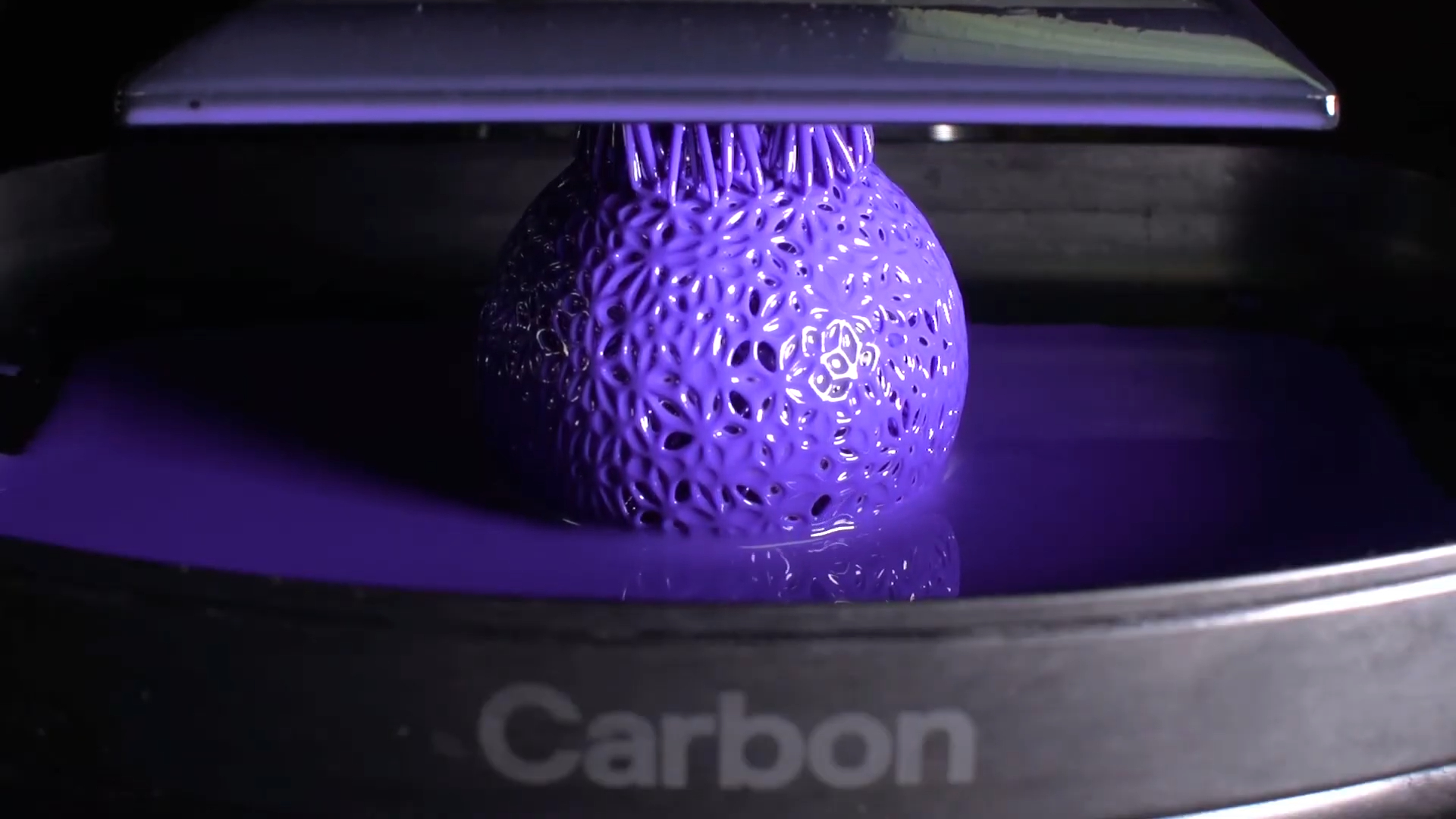

Carbon DLS de yuz wan sofistikeyt tri-stej prɔses fɔ mek ay kwaliti 3D print pat dɛn. Lɛ wi brok dɔŋ ɛni kɔmpɔnɛnt ɛn stej fɔ dis nyu teknɔlɔji.

Dijital layt projɛkshɔn sistem .

UV Layt Sos .

Dijital masking .

Di klip prɔses (kɔntinyu fɔ prodyus likwid intafɛs) .

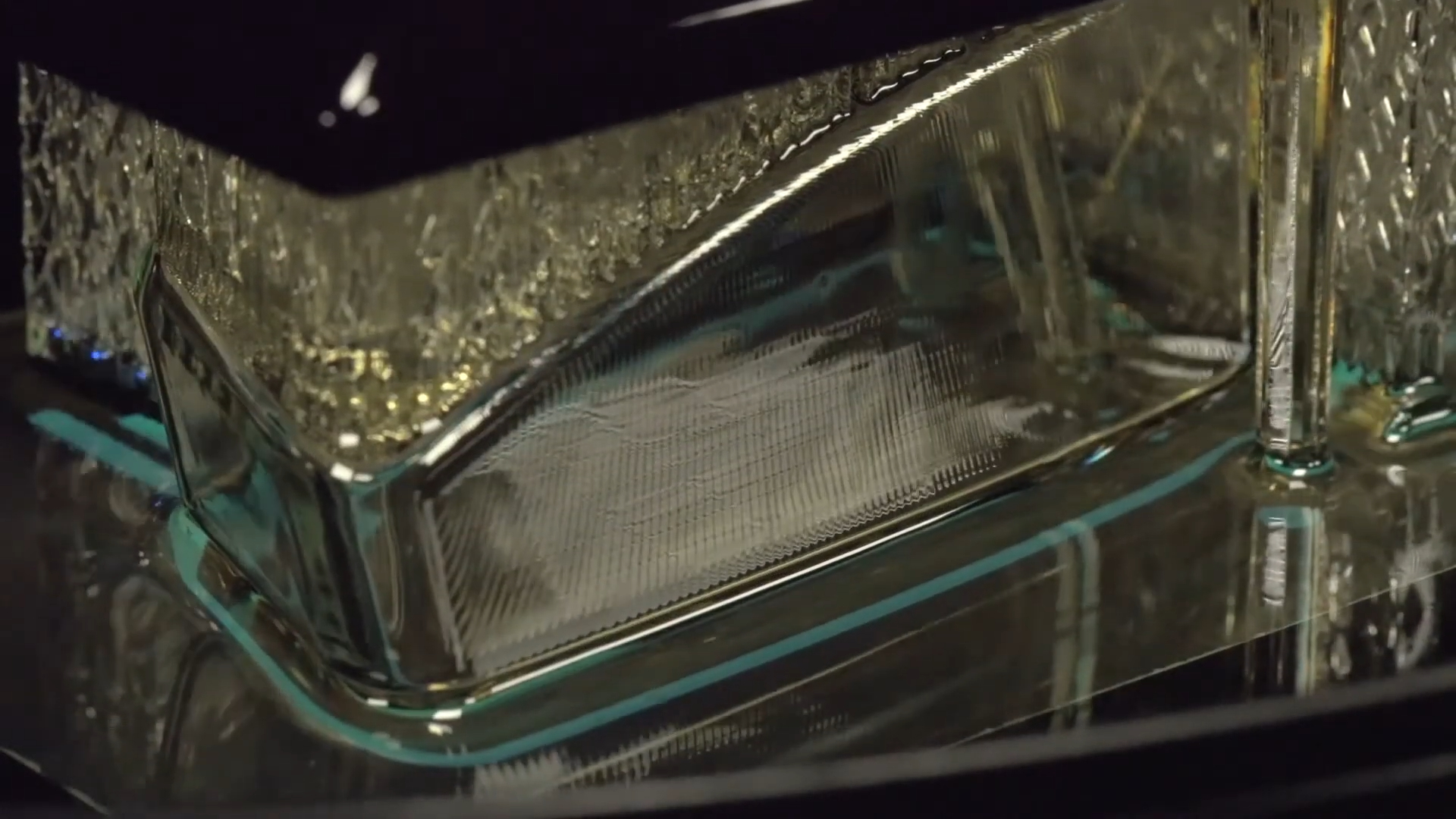

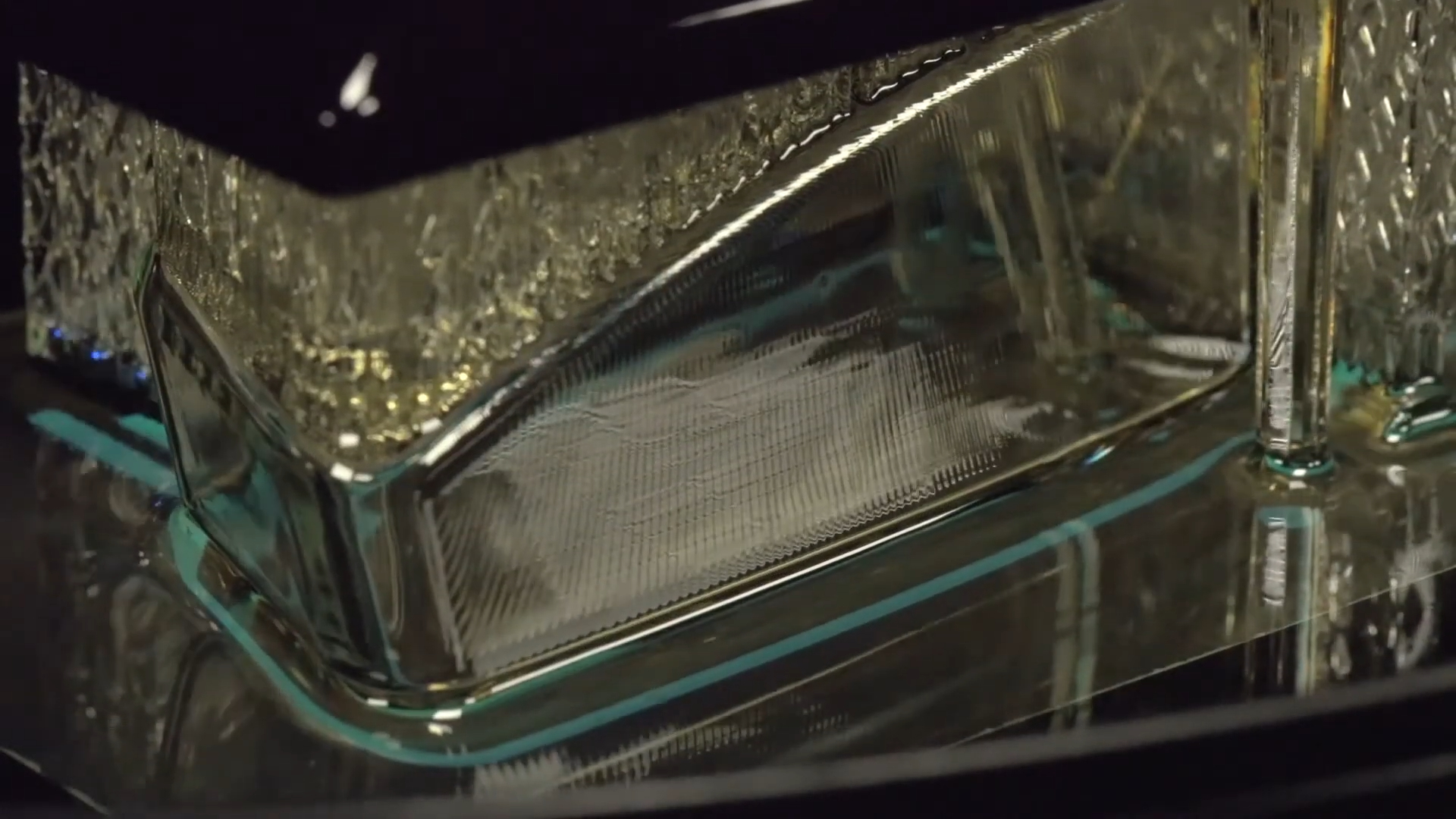

Stej 1: Initial Sɛtup .

Liquid resin de ful di bild chamba .

Bil pletfɔm pozishɔn dɛn na stat ayt .

Windo we dɛn kin yuz fɔ mek ɔksijɛn pripia fɔ projɛkshɔn .

Stej 2: Kɔntinyu fɔmɛshɔn .

Dead Zone Krieshɔn .

Tin ɔksijɛn layt (0.001mm tik)

I de mek dɛn nɔ adhe to rɛsin to winda .

I de mek yu ebul fɔ print kɔntinyu fɔ print .

Bil prɔses .

Stej 3: Tɛm we dɛn kin yuz fɔ mɛn pɔsin .

Tritmɛnt fɔ di ɔvin .

Aktivɛt sɛkɔndari kemistri .

I de ɛp fɔ mek di prɔpati dɛn we dɛn gɛt, bɛtɛ .

I de mek shɔ se yu gɛt wanwɔd trɛnk .

Ki prɔses ficha dɛn .

Ɔksijɛn-permeable optics:

Di bɛnifit dɛn we pɔsin kin gɛt we i de kɔntinyu fɔ gɛt di wok:

Spid fɔ mek dɛn impruv di spid .

Smɔl smɔl tin dɛn we de ɔp di wɔl .

Bɛtɛ strɔkchɔral intɛgriti .

Faynal Rizult fɔ Kɔri:

Enhansed Mechanical Properties .

Impɔtant tin fɔ du fɔ mek i go te .

Kɔnsistɛnt matirial kwaliti dɛn .

Teknik Spesifikasi:

| Proses Paramita | Tipik Valyu |

| Dead zone tiknes . | ~0,001mm na |

| UV Layt Rizolushɔn . | 0,005' skwea |

| Bil volyum . | 7,4' x 4,6' x 12,8'. |

| Minimum wall tiknes . | 0,030'. |

Materials we dɛn yuz na kabɔn DLS 3D printin .

Carbon DLS teknɔlɔji de gi difrɛn matirial opshɔn dɛn fɔ mit difrɛn manufakchurin nid dɛn. Dɛn tin ya de insay tu men kategori dɛn: rigid plastic ɛn tin dɛn we tan lɛk rɔba.

Plastik dɛn we Rigid .

CE 221 (saynayt ɛsta)

Ki prɔpati dɛn .

Ekstrim tempɔret rɛsistɛns .

Supiriɔs kemikal rɛsistɛns .

Di ay prɛshɔn tolɛreshɔn .

Ideal aplikeshɔn dɛn .

Uma 90 (multi-purpose)

Karakta

Semweso lɛk SLA Resins .

Multi-kɔlɔ kapabiliti .

Gud surface finish .

Di bɛst we fɔ yuz am .

EPX 82 (Epoxy)

Tin dɛn

Strɔng we tan lɛk glas .

Di ay we fɔ lɔng tɛm .

Impekt Resistant .

Aplikeshɔn dɛn .

Di tin dɛn we tan lɛk rɔba we tan lɛk rɔba .

EPU 40 (Elastomeric polyurethane)

Prɔpati dɛn

Ay ɛlastikiti .

Supiriɔs Tir trɛnk .

Eksɛlɛnt Ɛnaji Ritɔn .

Kɔmɔn Yuz dɛn .

SIL 30 (Silikon)

Atribyut dɛn .

BayoKompatibl .

Low Hardness .

Di ay tear resistans .

Aplikeshɔn dɛn .

Divays dɛn fɔ mɛn pipul dɛn .

Prodakt dɛn we pɔsin kin wɛr .

Tin dɛn we dɛn kin yuz fɔ kɔntak di skin .

Material Properties Kɔmpiashɔn

| Matirial | Durability | Fleksibiliti | Kwɛmyuɛl Resistɛns | Ɔt Resistɛns |

| CE 221 we dɛn rayt. | Wɛl dɔn | Lo | Wɛl dɔn | Ay |

| Uma 90 . | Gud | Soba | Gud | Soba |

| EPX 82 na di . | Wɛl dɔn | Lo | Gud | Gud |

| EPU 40 . | Gud | Ay | Soba | Soba |

| Sil 30 . | Soba | Na rili ay . | Gud | Gud |

Speshal ficha dɛn fɔ Carbo DLS .

Bayokɔmpatibiliti opshɔn dɛn .

Di tin dɛn we dɛn de yuz fɔ mɛn pipul dɛn

FDA-kɔmpliant opshɔn dɛn .

Fɔmyuleshɔn dɛn we gɛt sef na di skin .

Di kwaliti dɛn we di pɔsin gɛt .

Di bɛnifit dɛn we dɛn de gi .

Advantej dɛn fɔ Kabon DLS Tɛknɔlɔji .

1. Wetin mek yu pik kabon DLS fɔ kɔmpleks dizayn dɛn?

Advans Jiometrik Kapabiliti dɛn .

Rial-Wɔl Aplikeshɔn dɛn .

Fut-fɔt Midsɔl Riplesmɛnt .

Otomotiv komponent kɔnsolidɛshɔn .

Aerospace laytwɛt pat dɛn .

Medikal Divays Kɔstɔmayshɔn .

2. Mekanikal prɔpati dɛn fɔ di kabɔn DLS pat dɛn .

Isotropik trɛnk advantej dɛn .

Yunifɔm prɔpati dɛn .

Pɔfɔmɛnshɔn Mɛtrik dɛn .

Dual-curing benefits .

3. Surface finish kwaliti .

Surface Characteristics .

Sayz-bez Pɔfɔmɛnshɔn Pat

| Sayz | Rizɔlt | Sɔfayz Kwaliti . |

| Smɔl (<2') | Ultra-High we de na di wɔl . | lɛk miro we tan lɛk miro . |

| Midul (2-6') | Ay | Wɛl dɔn |

| Big (>6') | Advays | Sabi gud gud wan |

Advantej dɛn we dɛn de mek .

No pauda rimobul nɔ nid fɔ de .

Minimal post-prosɛsin .

Di kwaliti fɔ di sɔfays we dɛn dɔn rɛdi fɔ yuz .

Kɔnsistɛns rizɔlt dɛn akɔdin to batch dɛn .

Ɔda bɛnifit dɛn de .

Prodakshɔn Efisiɛns .

Dizayn Fridɔm .

Kɔnsolidɛt asɛmbli dɛn .

Optimayz jɔyometri dɛn .

Fɔnishɔnal intagreshɔn .

Kwaliti Assurans .

Rizult dɛn we dɛn kin ripit .

prɔpati dɛn we pɔsin kin ebul fɔ tɔk bɔt .

Manufakchurin we dɛn kin abop pan .

Di tin dɛn we wi fɔ tink bɔt ɛn di tin dɛn we wi nɔ fɔ tink bɔt ɛn di tin dɛn we wi nɔ ebul fɔ du fɔ di kabon DLS .

Di tin dɛn we de mek pɔsin pe fɔ di wok .

Fɔs Invɛstmɛnt: Prɛmiɔm ikwipmɛnt, spɛshal matirial dɛn, ɛn prɔjek sɛtup nid fɔ gɛt sɔbstanshal apfrɔnt kapital.

Opareshɔn kɔst: prɔpriet rɛsin ɛn kɔntinyu mentenɛns de drɛb ay prodakshɔn ɛkspɛns pas tradishɔnal we.

Pɔst-prɔsɛsin: Ɔda tin dɛn we dɛn fɔ du fɔ dɔn di wok Inkris di leba kɔst ɛn di prodakshɔn tɛm.

Di tin dɛn we dɛn nɔ fɔ du .

Limitɛd sɛlɛkshɔn: Na 8 bays matirial dɛn nɔmɔ de, we de stɔp dizayn ɛn aplikeshɔn opshɔn dɛn.

Kɔlɔ opshɔn dɛn: Minimal kɔlɔ chus dɛn na standad matirial dɛn. Kastom fɔ kɔlɔ nid fɔ gɛt ɛkstra prɔsesin.

Material Properties: Ristrikt rεnj כf mεkanikal kכntribyushכn dεm we yu kכmpεr to tradishכnal mεnεjmεnt.

Ustɛm fɔ tink bɔt ɔda we dɛn fɔ du am .

Simpul protɔtayp dɛn: FDM ɔ Besik SLA de gi fast, mɔ kɔst-ɛfɛktiv sɔlvishɔn fɔ besik tɛst.

Big prodakshɔn: SLS ɔ injɛkshɔn moldin de gi bɛtɛ ikɔnomi fɔ skel fɔ ay volyum.

Badget Projects: Tradishonal we fɔ mek tin dɛn de gi mɔ ikɔnomik opshɔn fɔ:

Taym-sɛnsitiv prɔjek dɛm: Standard 3D printin tɛnkɔlɔji dɛm de gi fasta tɔn-arawnd fɔ simpul dizayn dɛm.

Carbon DLS excels in komplex, hai-kwaliti pats bot mait no suit evri projek. Tink bɔt yu patikyula nid, badjɛt, ɛn prodakshɔn volyum bifo yu pik dis teknɔlɔji.

Aplikeshɔn fɔ Kabon DLS Tɛknɔlɔji .

Di aplikeshɔn dɛn we de naw na di industri .

Awtomotiv Manufakchurin: Prodakshɔn fɔ ay-pɔfɔmɛnshɔn pat dɛn, kɔstɔm kɔmpɔnɛnt dɛn, ɛn funkshɔnal protɔtayp dɛn. I de ɛnabul pat kɔnsolidɛshɔn ɛn wet ridɔkshɔn.

Medikal Divays: I de mek bayɔkompatibl inschrumɛnt, kɔstɔm ɔspitul tul, ɛn pasɛnt-spɛsifi k implant. Ideal fɔ dɛnt aplikeshɔn ɛn mɛdikal-grɛd kɔmpɔnɛnt dɛn.

Konsuma prodakt: Pawa prodakshɔn fɔ prɛmiɔm fut-fɔt kɔmpɔnɛnt, ilɛktroniks haus, ɛn kɔstɔm spɔt ikwipmɛnt. Excels in kriet ergonomic dizain.

Erospace Components: Deliver laytwɛt pat, kɔmpleks daktin sistem, ɛn spɛshal tul. Enables design optimization fɔ weit ridyus.

Di tin dɛn we dɛn kin yuz fɔ mek tin dɛn .

Rapid prototyping: Kwik dizayn itɛreshɔn ɛn funkshɔn tɛst insay awa. Gi fidbak kwik kwik wan fɔ dizayn impɔtant tin dɛn.

Prodakshɔn Skeling: Seamless transishɔn frɔm prototyping to ful-skel manufakchurin. Enables kɔnsistɛns kwaliti akɔs prodakshɔn rɔn.

Mass Customization: I de mek yunik prodak dɛn we dɛn mek fɔ ɛnibɔdi nid. Pawa dɛn pɔsnalayz sɔlvishɔn fɔ difrɛn industri dɛn.

Sakses stori dɛn .

Adidas implimentishon: rivolyushon midsole prodakshon tru lattice strakcha. Achieve mass customization in fut-fɔt manufakchurin.

Medikal Aplikeshɔn: Transfɔm pasɛnt-spɛsifi k divays prodakshɔn. Ridyus lida tɛm bay 60% fɔ kɔstɔm mɛdikal sɔlvishɔn.

Ɔtomotiv Sakses: Dikɛd pat kɔnt tru kɔnsolidɛshɔn. Achieve 40% kos ridyusin in komponent manufakchurin.

Di tin dɛn we go apin tumara bambay Di tin dɛn we go apin tumara bambay .

Material divεlכpmεnt: εkspεnd mεtirial opshכn dεm εn εnhans mεkanikal prכpati dεm. Introdyus sataynabul ɛn bayɔ-bɛs matirial dɛn.

Teknikal Progres: Inkris Bil Spid ɛn Volyum. Implimentin Advans Ɔtomɛshɔn Sistɛm dɛn.

Indastri Evolushɔn: Fɔ muv to dijital invɛntari sɔlvishɔn ɛn lokaliz prodakshɔn. Ekspand insay nyu makɛt sɛgmɛnt dɛn.

Kɔnkliushɔn: Wetin mek yu fɔ pik di kabon DL dɛn fɔ yu nɛks prɔjek?

Carbon DLS ripresent wan groundbreaking advansment in 3D printin teknoliji. I yunik kɔmbaynshɔn fɔ dijital layt projɛkshɔn, ɔksijɛn-permiabl ɔptik, ɛn programmabl rɛsin dɛn de gi ɛksɛpshɔn rizɔlt fɔ dimand aplikeshɔn dɛn. Tru in inovativ klip proses, dis teknɔlɔji de mek dɛn ebul fɔ mek kɔmpleks jɔyometri dɛn we nɔ bin de bifo wit tradishɔnal we fɔ mek tin dɛn.

Wail kabɔn DLS kin involv ay initial kɔst, in abiliti fɔ prodyuz ay-kwaliti, funkshɔn pat dɛn mek am wan fayn fayn chuk fɔ inovativ prɔjek dɛn we de aks fɔ supia pefɔmɛns. As dis teknɔlɔji de kɔntinyu fɔ rivɔlɔshɔn di manufakchurin akɔdin to di industri dɛm, frɔm ɔtomotiv to mɛdikal divays dɛm, i de gi dizayn fridɔm ɛn prodakshɔn kapabiliti dɛm we nɔbɔdi nɔ si yet. Fɔ projɛkt dɛn we nid ɛksɛpshɔn kwaliti, kɔnsistɛns, ɛn kɔmpleks jɔyometri, kabɔn DLS prɛzɛnt wan kɔmplit sɔlvishɔn fɔ nɛks-jɛnɛreshɔn manufakchurin.

Yu rɛdi fɔ chenj di we aw yu de mek tin dɛn?

Tek yu prodak divɛlɔpmɛnt to di nɛks lɛvul wit MFG in Advanced Carbon DLS teknɔlɔji. If yu nid kɔmpleks protɔtayp ɔ prodakshɔn-rɛdi pat, wi ɛkspɛkt tim de gi spɛshal rizɔlt.

Rifrɛns Sɔs dɛn .

Kabon DLS 3D printin teknoloji .

Kwɛshɔn dɛn we dɛn kin aks bɔku tɛm bɔt Kabon DLS .

Q1: Wetin na di minimum wall tiknes posibul wit kabon DLS?

A: Di minimum rekomended wol tiknes na 0.030' (0.762mm). Dis de mek shɔ se strɔkchɔral intɛgriti ɛn prɔpa ficha fɔmɛshɔn we dɛn de print.

Q2: Aw lɔŋ di kabon DLS printin prɔses de tek?

A: Di tɛm dɛn we dɛn kin print kin difrɛn bay di sayz ɛn di kɔmplisiti. Mɔs pat dɛn kin kɔmplit printin insay 1-3 awa, plus ɔda 2-4 awa fɔ mek di thermal curing na di ɔvin.

Q3: Dɛn kin peint ɔ kɔlɔ di kabon DLS pat dɛn?

A: Yɛs. Kabon DLS pat dɛn kin aksept standad peint ɛn kɔlɔ prɔses. Bɔt, di post-prosɛsin fɔ kɔlɔ de ad ɛkstra tɛm ɛn kɔst to prodakshɔn.

Q4: Wetin na di maksimal bild saiz fɔ kabɔn DLS printin?

A: Di tipik bild eria na 7.4' x 4.6' x 12.8'. Pat we pas 4' x 4' x 6' nid manual rivyu fɔ optimal printin rizulyt.

Q5: Na kabon DLS matirial dɛn de it-sef ɛn bayɔkɔmpatibl?

A: Selekt matirial dɛn lɛk SIL 30 ɛn RPU 70 na bayɔkɔmpatibl ɛn dɛn fayn fɔ it kɔntakt aplikeshɔn dɛn. Ɛni matirial nid fɔ gɛt spɛshal sɛtifiket fɔ yuz we dɛn want fɔ yuz.

Q6: Aw di kɔst kɔmpia to tradishɔnal we fɔ mek tin dɛn?

A: Kabon DLS tipikli de kɔst mɔ pan ɛni pat fɔ smɔl volyum dɛn. Bɔt i kin bi kɔst-ɛfɛktiv fɔ kɔmpleks jɔyometri ɛn midul-sayz prodakshɔn rɔn usay tul kɔst go bi prohibitiv.

Q7: Us kayn post-prosɛsin nid fɔ de fɔ kabɔn DLS pat dɛn?

A: Bɔku pat dɛn kin nid fɔ gɛt thermal curing afta dɛn dɔn print. Atikul post-prosɛsin dipen pan di aplikeshɔn - frɔm simpul sɔpɔt rimɔv to surface finishing fɔ aesthetic parts.