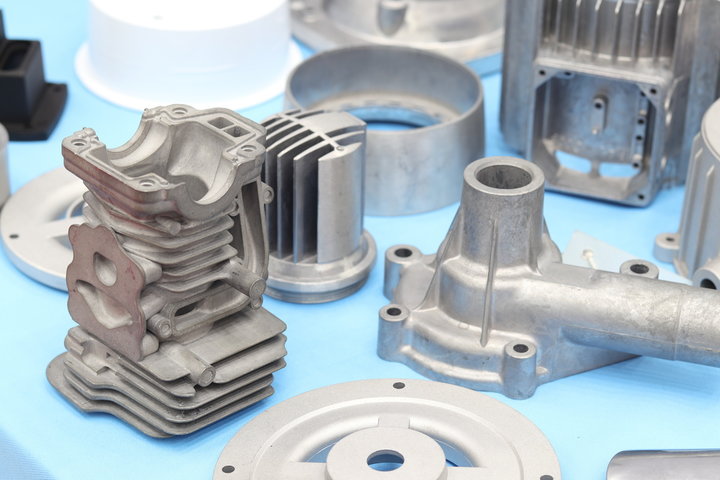

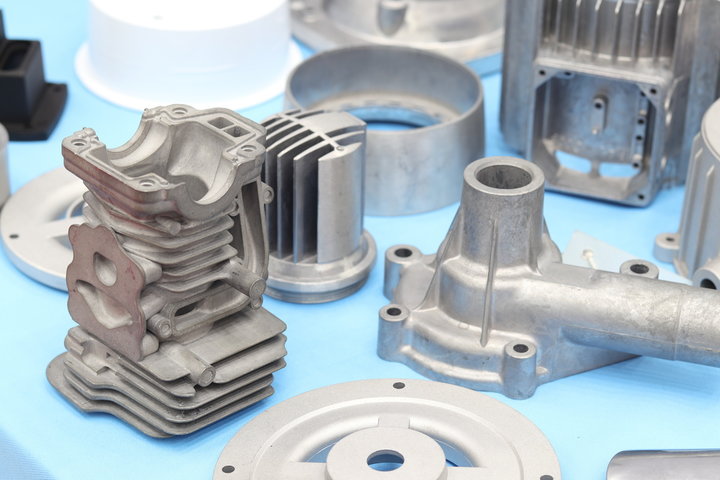

Tansiyɔnba die casting (HPDC) ye izini baara ye min bɛ kɛ tuma caman na ka kɛɲɛ ni mass-massi-massicate nɛgɛ yɔrɔw ye. O bɛɛ n’a ta, fili dɔw bɛ se ka bɔ kɛnɛ kan o kɛcogo kɔnɔ, o de kosɔn u bɛ fɛn dilannen ka jogo tiɲɛ. Nin sɛbɛn in bɛ HPDC ka fɛn dilanni nafa kunbabaw jira, u sababuw, u bɛ se ka dɔn cogo min na ani u bɛ se ka bali cogo min na. O fiɲɛw dɔnni fɛ ani u ɲɛnabɔli fɛ, fɛn dilannikɛlaw bɛna die casting taabolo nɔgɔyacogo n’a dannaya yiriwa.

Mun ye tansiyɔnba die casting (HPDC) ye .

Die casting under high pressure (HPDC) bɛ tali kɛ nɛgɛ tigɛcogo suguya dɔ la min kɔnɔ nɛgɛ wulilen bɛ pikiri kɛ nɛgɛ die kɔnɔna na tansiyɔnba kɔrɔ. Die cavity bɛ dilan ni baarakɛminɛn nɛgɛ gɛlɛn tilancɛ fila ye minnu cogoya kɛra ani minnu bɛ baara kɛ i n’a fɔ nɔgɔbɔlan. A ka c’a la, nɛgɛ min bɛ wuli, o tɛ nɛgɛ ye a cogoya la, misali la, aliminiyɔmu walima zinki, wa a bɛ pikiri kɛ ni tansiyɔnba ye min bɛ se ka kɛ 1500 psi ye ka se 25400 psi ma. O degun bɛ nɛgɛ wulilen ka lafiɲɛbɔ degun sanfɛ kosɛbɛ k’a lajɛ ko die cavity bɛ fa teliya la ani ka ɲɛ ani ka sɔrɔ ka a to a ka se ka sigi, o la, a bɛ sɔrɔ ka fɛn dɔ sɔrɔ min bɛ i n’a fɔ fɛn laban cogoya ni a ɲɛda cogoya ɲuman ani a tiɲɛni kosɛbɛ.

Taabolo min bɛ die casting .

Die casting taabolo bɛ se ka tila ka kɛ taabolo suguya caman ye minnu bɛ ninnu na:

DIE PAREGARE : Dies die dilanni bɛ tali kɛ diew saniya ni u tulu la ani ka u sumaya fo ka se funteni hakɛ latigɛlen ma.

Melting and Injection : Alloy ingots bɛ charge ani u bɛ wuli foro kɔnɔ ka sɔrɔ ka u minɛ ni shot sleeve ye die casting machine la. O kɔfɛ, degun bɛ kɛ ni pilon ye walasa ka nɛgɛ jilama fanga teliya ka se die insert ma.

Nɛnɛ ni solidifikasiyɔn : Aw bɛ nin nɛgɛ jilama in nɛnɛ joona ka a gɛlɛya die bloki kɔnɔ, o min bɛ kɔn ka latigɛ ka kɛɲɛ ni kɔnɔnatumu kɔnɔna ye min bɛ kɛ nɔgɔ kɔnɔ.

Ejection : Tuma dɔw la, die tilancɛw bɛ da wuli yɔrɔ nɛnɛnen kɔfɛ ani ka a sabati, ka sɔrɔ ka a yɔrɔ bɔ ka bɔ kɔnɔna na ni ejector pins ye.

5. Trimming ani finidoncogo . A yɔrɔ min bɛ Bɔ o bɛ Tigɛ ka Bɔ nɛgɛ tɛmɛnen na (flash) wa a bɛ Kɛ ni finiko filanan wɛrɛw ye i n’a fɔ masinw, surface treatment walima ja.

casting defects ye mun ye?

Taabolo High Pressure Die casting (HPDC) tɛ ni a dilanni nafama ye, o bɛ se ka kɛ sababu ye ka baara in kunbɛn cogo dafalen na, ka die dilanni walima fɛn minnu bɛ kɛ. O fɛn dilanni nafama dɔw minnu bɛ sɔrɔ HPDC fɛ, olu dɔw ye gazi porosity, shrinkage porosity, inclusions, cold shuts, soldering, blisters, ani flow marks ye. O fiɲɛ suguw bɛ kɛ sababu ye tuma caman na ka masinw ka jogo dɔgɔya, ka u ɲɛda cogoya jugu sɔrɔ, ani ka u ka yɔrɔw tiɲɛ joona. Nin yɔrɔ nataw la, nin HPDC nafamafɛn minnu bɛ sɔrɔ ɲɔgɔn fɛ, olu bɛna ɲɛfɔ ka ɲɛ, u sababuw n’u kunbɛnni fɛɛrɛw bɛna ɲɛfɔ, walasa ka se ka dilanbagaw dɛmɛ u ka se ka die cast yɔrɔ ɲumanw dilan.

A dilanni nafama suguya minnu bɛ HPDC kɔnɔ .

Porosity in die casting dilanni .

Porosité (porosity) bɛ Fɔ ko dakun walima yɔrɔ misɛnninw bɛ yen minnu bɛ yen yɔrɔ min bɛ Weele tuma caman na ko die-cast (die-cast) yɔrɔ. O yɔrɔ lakolonw bɛ se ka sigida min kofɔlen bɛ, o jɔcogo mankan tiɲɛ o cogo la ka dɔ bɔ a yɔrɔ fanga n’a sigili seko la min bɛ bolo kan. Fɔlɔ, porozɛw ka dɛsɛ suguya fila bɛ yen minnu bɛ kɔlɔsi degun die-casting (PDC) fɛɛrɛw la:

Gazi porosity .

A bɛ kɛ ni fiɲɛ walima gaziw minɛna nɛgɛ jilama kɔnɔ k’a sɔrɔ a pikirila, o de bɛ kɛ sababu ye ka lamini walima bɔgɔmuguw dilan .

A bɛ se ka nɔgɔya ni fiɲɛbɔlanw dilanni n’u kɛcogo ɲuman ye .

Ani fana, ka nɔgɔ in sanfɛla saniya ani ka a ja k’a sɔrɔ ji, tulu walima tulu si tɛ a la, o bɛ dɛmɛ ka gazi porosiyɔmu tiɲɛniw dɔgɔya.

shrinkage porosité .

K’a sababu Kɛ nɛgɛ min bɛ Kɛ solidifikasiyɔn baara la, o bɛ Kɛ ‘yɔrɔ la min bɛ Kɛ i n’a fɔ ‘fɛnɲɛnɛma-yɔrɔ minnu bɛ Weele ko spongy voids (sɔgɔsɔgɔninjɛ) bɛ Bɔ kɛrɛnkɛrɛnnenya la kɛrɛnkɛrɛnnenya la, a bɛ Kɛ ‘fɛnɲɛnɛmaw yɔrɔ minnu ka bon.

Ni dakunw ni wulilanw sigicogo ɲɛ ani ka nɛnɛ hakɛ labɛn o bɛ se ka dɔgɔya.

A nafa ka bon ka sinkɔrɔkɛrɛdimi taamasiɲɛw ko ɲɛnabɔ ani ka aw yɛrɛ tanga shrinkage pores ma ni aw bɛ CAE kɛ ka die cast part ladilan walasa ka balansi sɔrɔ funteni na ani kogo janya kelen na.

inclusions in die casting dilanni .

Fɛn minnu bɛ don a kɔnɔ, olu ye fɛn wɛrɛw ye minnu bɛ siri die casting process kɔnɔ, wa u bɛ dilan HPDC cycle waati la. O fɛnw bɛ jate nɛgɛ ni nɛgɛ tɛ minnu na ka kɛɲɛ n’u cogoya ye.

Metallic ka don .

A ka c’a la, a bɛ kɛ ni ɔkisizɛni ye, nɛgɛw ni ɲɔgɔn cɛ, ani nɛgɛ wɛrɛw .

min bɛ sɔrɔ nɛgɛ wulilen fɛ, die tulu walima masin yɔrɔw .

Ni labɛnni, filɛtiri ani masin ladonni kɛra ka ɲɛ, a bɛ se ka kɛ ka nɛgɛw bali .

Non-metallic inclusions

Olu bɛ se ka kɛ seramiki buguri ye, cɛncɛn walima kɛnɛmafɛn o fɛn .

A ka c’a la, a bɛ na ka da fɛn nɔgɔlenw kɛli kan, walima ɲɛnabɔli min tɛ kɛ ni ɲɛmajɔ ye .

Nɛgɛ minnu tɛ nɛgɛ ye, olu bɛ se ka bali ni u ka fɛnw ye minnu bɛ se ka kɛ sababu ye ka u ka fɛnw ko ani ka u saniya.

| inclusion type | composition | sources | vente méthodes . |

| Metallic . | oksizɛni, nɛgɛw ni ɲɔgɔn cɛ, nɛgɛmafɛnw . | Metal molten, die coating, machine components . | Melt labɛnni, filɛri, masin ladonni . |

| Non-metallic . | Seramiki fɛnɲɛnamafagalanw, cɛncɛn, dunanfɛnw . | Fɛn minnu nɔgɔlen don, u minɛcogo man ɲi . | qualité de qualités qualités critiques, clean die casting environnement . |

Nɛnɛ bɛ don die casting dilanni na .

Nɛnɛ dafalenw bɛ Kɔlɔsi i n’a fɔ ɲɔgɔndan minnu bɛ Kɛ 'sèn na die cast yɔrɔw la yɔrɔ min na nɛgɛ woyocogo fla tɛ Jὲ ka ɲɛ nɛgɛ die casting kɛcogo suguyaw la minnu bɛ Kɛ ni degunba kɛli ye die la. O dɛsɛw bɛ gɛlɛyaba lase HPDC dilanni ma, o bɛ nɔ jugu bila fɛn dilannenw fanga la ani fɛn dilannenw sanfɛla la.

Nɛnɛ bɛ dabila sababuw .

Die casting kɔnɔ, nɛnɛba min nafa ka bon kosɛbɛ, o bɛ se ka kɛ sababu ye ka fɛn damadɔw sɔrɔ, minnu bɛ tali kɛ ɲɔgɔn na:

nɛgɛ mɔlen funteni man bon kosɛbɛ wa a bɛ sabati joona kosɛbɛ .

Pikiri teliya man bon ka tɛmɛ nɛgɛ bɔli jugu kan .

gating system (gating system) dɛsɛra min bɛ na ni kɔnɔna facogo ye min tɛ kelen ye .

Venting bɛ bila yɔrɔ jugu la o la fiɲɛbɔlanw bɛ yen minnu sirilen don .

Die cavity tɛ hali funteni sɔrɔ a bɛɛ kɔnɔ .

Pikiri tansiyɔn paramɛtiriw tun ma sigi ka ɲɛ pikiri kɛtuma na .

A bɛ nɔ min bila fɛn dilannenw ka ɲumanya la .

Nɛnɛ sɔgɔli sɔrɔli bɛ nɔba bila die cast component performance la:

masinw ka baarakɛcogo fanga dɔgɔyaliba ka da a kan u ye ɲɔgɔn sɔrɔ .

Dɔgɔyali ka ɲɛsin kɛnɛma doni ma ka da a kan a ka teli ka kari .

Deficient surface quality bɛ fura in cogoya n’a baarakɛcogo nɔgɔya .

tansiyɔn jiginni ka caya Die yɔrɔ kolomaw la .

Dɔ farali farati kan min bɛ sɔrɔ sigida dafalen dɛsɛ la ka fara a yɔrɔw ka ɲɛnamaya kan .

A yɔrɔw ka baarakɛcogo la, dɛsɛyɔrɔ dɔw bɛ ye doni ursi jukɔrɔ .

Flash in die casting dilanni .

Flash formation in high pressure die casting bɛ Kɛ nɛgɛ dafalen wɛrɛ cogo la die tilancɛ fla ni ɲɔgɔn cɛ pikiri waati la min bɛ Nà ni bɔli finmanw ye minnu man ɲi minnu bɛ Kɛ i n’a fɔ finw die cast yɔrɔw ka ɲɔgɔndɛmɛ sira kan. O fiɲɛ min bɛ sɔrɔ tuma caman na die castings la minnu bɛ dilan ni pressure die casting ye, o tɛ nɔ bila dimension dɔrɔn na, nka a bɛ musaka wɛrɛw fana don finidoncogo la ani ka die resistance surunya.

Kun minnu b’a jira ko flash formation .

Ni diew yɔrɔw bɛ don walima ni u tiɲɛna ani ni u tɛ bɛn ɲɔgɔn ma ka ɲɛ ka kɛɲɛ ni farali siraw ye, o bɛ se ka kɛ sababu ye tuma caman na ka flash sɔrɔli daminɛ kɛrɛnkɛrɛnnenya la ni degun dɔgɔyali ye min bɛ na ni die dishing ye pikiri degun na. Nin ko in bɛ juguya ni pikirijikɛlan tansiyɔn ka bon fo ka se die dadoncogo ma walima ni WarPage bɛ a nɔ na min bɛ kɛ sababu ye ka farali siraw tiɲɛ. Fɛn caman dilanni nafa i n’a fɔ die yɔrɔw minnu ma ɲɔgɔn sɔrɔ kosɛbɛ, die cavities surfaces minnu bɛ sɔgɔsɔgɔ u kɛli senfɛ, ani ribs stiffening sɔrɔbaliya die inserts kama, olu bɛɛ bɛ se ka kɛ sababu ye ka biri kojugu ni degun bɛ a la ani o cogo la ka flash (fiɲɛ) juguya.

Fɛɛrɛ minnu bɛ kɛ ka flash dɔgɔya .

Die ladonni ni a dilan tuma bɛɛ .

ka a lajɛ ko fanga bɛ se ka kɛ fanga la cogo bɛnnen na .

Pikiri paramɛtiriw ɲɛnabɔli .

Flash traps donna die design kɔnɔ .

Flow marks in die casting dilanni .

Flow taamasiyɛnw ye mun ye .

Flow taamasiyɛnw bɛ ye wavy walima spiral pattern dɔw la die castings sanfɛ kɛrɛnkɛrɛnnenya la da yɔrɔw kɛrɛfɛ ani nɛgɛ jibɔyɔrɔw kan. O dafabaliya suguw bɛ kɛ sababu ye ka cogoya bɛnbaliw kɛ minnu bɛ tugu solidifiyeli siraw la ani minnu bɛ ye kosɛbɛ kogo finmanw na ani yɔrɔ minnu yɔrɔ ka jan pikirikɛyɔrɔw la. Aluminiyɔmu tansiyɔn die casting nin surfaces ninnu bɛ caman da parallèles la, minnu bɛ kɛ dɛsɛba ye surface finish la ka fara dimensionnel précision kan.

Fɛn minnu bɛ dɛmɛ don jibɔ taamasiyɛnw na .

Yɛlɛma minnu bɛ kɛ nɛgɛ funteni na, olu ye fɛn nafamaba dɔ ye jibɔ taamasiɲɛw sɔrɔli la. O ko ninnu na, fɛn caman bɛ ɲɔgɔn falen ka da a sumaya kojugu kan, k’a sɔrɔ a kɔnɔna bɛ fa hali bi nɛgɛ wulilen na, o bɛ na ni ji bɔli ye min bɛ tiɲɛ ani a sanfɛla la. Hali ni danfara misɛnw bɛ pikiri teliya la, kɛrɛnkɛrɛnnenya la, yɔrɔ minnu kogow ka fin, olu bɛ jibɔ taamasiɲɛw ko kɛlenw juguya, u kɛtɔ ka nɛgɛw dɛmɛ u ka se ka taa yɔrɔ la min tɛ bɛn. O fana bɛ tali kɛ fɛn caman na i n’a fɔ:

nɛgɛ funteni min ka dɔgɔn ni a hakɛ ye min ka kan ka kɛ walasa ka a kɔnɔna fa ka ɲɛ .

da teliya min bɛ kɛ sababu ye ka sɛgɛn kojugu ani ka jibɔ wulibali sɔrɔ .

fiɲɛbɔlanw dafabaliya min bɛ na ni fɛnw bɔli ye ani taabolo tiɲɛni caman .

Non-Uniform die cooling min bɛ na ni flow patterns ye min man ɲi ani solidification .

Yɛlɛma minnu bɛ kɛ kogow bonya la minnu bɛ dɔ fara walima ka dɔgɔya yɔrɔnin kelen nɛgɛ wulilen teliya la .

Dabaw jɔyɔrɔ min tɛ nafa sɔrɔ min bɛ na ni nɛgɛ jɛnsɛnni ye cogo bɛnbali la .

Blisters die casting dilanni .

Blister defauts minnu bɛ sɔrɔ die cast surfaces kan olu ye geodesic shaped surface defects ye minnu bɛ kɛ casting kɔfɛ. Danfara bɛ jibɔ taamasiɲɛw walima porosiyɔmuw ni ɲɔgɔn cɛ, o fiɲɛw bɛ se ka sɔrɔ fana funteni furakɛli waati la, walima baara la, cogoyaw la minnu bɛ kɛ sababu ye ka dugukolo yɔrɔw tiɲɛni yetaw lawuli ka fara barikantanya kan fɛnw yɛrɛ kɔnɔ.

Blisters sababuw .

Casting blister formation in dies bɛ bɔ kɛrɛnkɛrɛnnenya la gazi minɛlenw na solidifié waati. Gazi-bɔrɔw bɛ Dabɔ ni nɛgɛ-oxydation (oxydation) ye min bɛ pikiri Kɛ kɔ̀ in na min bɛ Yɛlɛma kɔfɛ ka Kɛ funteni ye; Tumu minnu kun ye ka dɛmɛ don nɔgɔya la ka bɔ kaburudo la, olu fana bɛ kɛ gazi ye nin waati in na. Die-chimique decomposition produits bɔli dafabaliya, ji min bɛ die pocket de la cavité la, die sprays baara caya kojugu, ani nɛgɛw ka oxydation k’a sɔrɔ a bɛ fa kɔnɔna fa, o bɛɛ ye fɛn fɔlɔw ye minnu bɛ o fiɲɛ bila. A ka c’a la, o gɛlɛyaw sɔrɔli ka jugu yɔrɔ min na die sanfɛ funteni bɛ kɔrɔta bawo a bɛ na ni gazi bɔli ye ka caya ani ka dɔ fara porosite kan funteni sɔrɔli waati.

Banakunbɛn fɛɛrɛw .

Blister risk management o siratigɛ la, o bɛna kɛ die température ni lubrication systems management ɲuman ye. Baara kɛ ni otomatiki die spray systems ye ni contrôlée coverage bɛ a to tulu bɛ kɛ cogo kelen na ni gazi bɔli tɛ tɛmɛ k’a sɔrɔ a bɛ die funteni ɲɛnabɔ. Die cavity ventilation maintenance ɲɛnabɔli min bɛ bonya ni surface cleaning measures ani enclosure geometry design ye, o bɛ fasa secteur turbulence ani gas entrapment effect dɔgɔya kosɛbɛ.

Missruns die casting manufacturing .

Mold cavity fa dafabali .

misrun walima mis-run defect bɛ ɲɛfɔ iko defaut (dɛsɛ) min bɛ sɔrɔ die cavity (die cavité) falen dafabaliya fɛ nɛgɛ wulilen fɛ. O fiɲɛ suguw bɛ sɔrɔ yɔrɔw la minnu bɛ dɔn ni fɛnw ye minnu tɛ yen walima minnu ma dilan ka ɲɛ. A ka c’a la, o filiw bɛ dan tilayɔrɔ finmanw ni u maraw ma minnu ka jan daaw la, nɛgɛ bɛ gɛlɛya kaban yɔrɔ minnu na ka kɔn kɔnɔna bɛɛ fa. misrun nɔw tɛ dan yɔrɔw ka danfarabaliya dɔrɔn ma; U bɛ to ka masina cogoyaw ni die castings surface quality tiɲɛ.

Fura minnu bɛ kɛ ka kɛɲɛ ni ko jugu ye .

Ka ɲɛsin bolibaliya nafamabaliya ma, o ye gɛlɛya ye min bɛ nɛgɛ bolicogo ni funteni kɔlɔsili haminanko sinsinnen de wajibiya. Die ni nɛgɛ funteni ka kan ka mara baarakɛcogo yɔrɔ la min ka ɲi kosɛbɛ ka sɔrɔ dakun jɔyɔrɔw ka kan ka sɔrɔ cogo bɛnnen na walasa ka jibɔcogo ɲɛ. Fiɲɛ bilali ka caya yɔrɔ gɛlɛnw na, ka fara pikiri teliya hakɛ caman sɛmɛntiyalenw kan ani kogo janya caman ɲɔgɔnna caman b’a to kɔnɔna facogo bɛ se ka sɔrɔ cogo la min bɛ mɔgɔ wasa. Overfoes position adjustment and contrôle est processus fana bɛ kɛ walasa ka casting processus kɛcogo ɲuman sɔrɔ ani ka misrun defects (boli kɛcogo jugu) dɔgɔya degunba die casting die la.

Fɛn minnu bɛ kɛ sababu ye ka fɛn dilanni nafa sɔrɔ casting taabolo la .

Fɛn dilanni nafamafɛnw sɔrɔli degunba die casting baara senfɛ, o bɛ se ka kɛ sababu ye ka fɛn suguya caman sɔrɔ. O fɛnw waleɲumandɔn ani k’u ɲɛnabɔ ka ɲɛ o bɛɛ n’a ta, o bɛ kɛ sababu ye ka die casting dilannikɛlaw dɛmɛ ka fiɲɛw ban ka ɲɛ ani ka u ka fɛnw bɛɛ lajɛlen cogoya bonya. Fɛn nafama dɔw bɛ yen minnu bɛ tali kɛ HPDC ka fɛn dilanni nafama na, olu bɛ ɲɛfɔ jukɔrɔ.

Die de conception improper .

Casting die manufacture nafa ka bon kosɛbɛ fo ka se a laban na cast ma. Die min ma dila, o bɛ na ni fili damadɔ ye i n’a fɔ:

Gasporosité : Gazi bɛ minɛ yɔrɔ min na ka da a kan ventilateur walima gazi porosity dilancogo man ɲi.

Coldshuts: A ka c’a la, o fiɲɛw sababu kɛrɛnkɛrɛnnen bɛ tali kɛ gating kɛcogo jugu la, nɛgɛ bɛ sumaya walima ka wuli ka bɔ ji la min bɛ kɛ sababu ye ka fiɲɛ nɛnɛma da.

Mɔgɔ minnu tɛ se kosɛbɛ: wulilanw ni dabaw minnu ma labɛn ka ɲɛ.

Walasa ka baarakɛbaliya bali ka ɲɛsin die cogoyaw ma, a bɛ fɔ ko fɛn dilannikɛlaw ka ninnu kɛ:

Aw bɛ baara kɛ ni gating walima runner system dilancogo ɲuman ye, walasa nɛgɛ ka se ka woyo ani ka fiɲɛ bɔ ka ɲɛ.

Labɛn ka kan ka kɛ fana walasa ka fiɲɛ bila ni pikiri kɛli bɛ kɛ walasa ka gazi suguya o suguya boli.

Aw bɛ die design simulation kɛ die designs ani ka haminankow minɛ ka sɔrɔ ka die dilan daminɛ.

Taabolo paramɛtiriw minnu tɛ tiɲɛ .

HPDC taabolo ɲɛtaa bɛ tali kɛ kosɛbɛ taabolo paramɛtɛrɛw tiɲɛni na. Yɛlɛma minnu bɛ bɔ sigida ɲumanw na, olu bɛ se ka kɛ sababu ye ka fɛn dilanni nafama suguya caman sɔrɔ. Taabolo jɔnjɔnw ye : .

Funteni wulilen : Ni a ka dɔgɔn kojugu, a bɛ se ka kɛ sababu ye ka farigan ni kurukuruni kɛ; Ni a ka ca kojugu, a bɛ se ka kɛ sababu ye ka gazi porosity ani ka sa solder.

Pikiri tansiyɔn ni a teliya: Tansiyɔn walima teliya dɔgɔyali bɛ se ka kɛ sababu ye ka fasa ni bolibaliya dafa, ka sɔrɔ degun kojugu bɛ se ka kɛ sababu ye ka flash ni die sɛgɛn.

Nɛnɛ hakɛ: Nɛnɛ kɛcogo tɛ kelen ye walima min tɛ se ka kɛ, o bɛ se ka kɛ sababu ye ka porosity ni warping dɔgɔya.

Walasa ka fiɲɛw dɔgɔya minnu bɛ sɔrɔ baarakɛcogo paramɛtiriw fɛ minnu tɛ tiɲɛ ye, dilanbagaw ka kan ka:

Ka taabolo ɲumanw sigi sen kan ani k’u mara ka da alloy, part geometry ani die dilancogo kan.

Aw bɛ to ka taabolo paramɛtiriw kɔlɔsi ani k’u kɔlɔsi ni sensɛriw ni otomatiki sitɛmuw ye.

Aw bɛ jateminɛw kɛ waati ni waati ani ka paramɛtiriw ladilan i n’a fɔ a mago bɛ cogo min na walasa ka bɛnkan sɔrɔ.

nɛgɛw labɛncogo ani u jogo .

Nɛgɛmugu die-casting faralen ɲɔgɔn kan, o bɛ caman kɛ ni izini nafamabaliya sababuw ye. Nin gɛlɛya minnu bɛ die casting haminankow la, olu ye minnu bɛ tali kɛ nɛgɛw labɛncogo n’u jogo la, olu dɔw ye:

Nɔgɔw : Dunanfɛn minnu bɛ nɛgɛ fililen na, olu bɛ se ka kɛ nɛgɛw ye, u bɛ don u kɔnɔ walima u bɛ kɛ nɛgɛ jɔcogo jugu ye.

Furakɛcogo caman ɲɔgɔnna: Yɛlɛmaba minnu bɛ kɛ fɛn caman na, olu bɛ se ka kɛ sababu ye ka fɛnw dɔgɔyacogo jira minnu tɛ se ka fɔ ka ɲɛ ani ka fɛnw kɔnɔna taabolo sɛmɛntiya fana.

Hydrogène hakɛ : Gazi porozɛri bɛ se ka sɔrɔ hidrɔzɛni hakɛ caya fɛ nɛgɛ wulilen kɔnɔ.

Walasa ka nɛgɛw labɛncogo n’u jogo gɛlɛyaw nɔgɔya, nin wale ninnu bɛ kɛ ka ɲɛsin dilanbagaw ma:

Aw bɛ fɛnɲɛnamafagalanw sɔrɔ sɔrɔyɔrɔw la minnu dɔnna ani minnu bɛ se ka da u kan.

Aw bɛ jogoɲini sira gɛlɛn dɔ sigi sen kan, ka kɛɲɛ ni fɛnw sɛgɛsɛgɛli ye minnu sɔrɔla ani u labɛncogo.

Aw bɛ furajiw kɛ nɛgɛ la i n’a fɔ ka u bɔ u la ni u bɛ wuli ka nɛgɛw saniya ani ka hidrɔzɛni hakɛ Changer.

Die casting minɛnw ladonni dafabaliya .

Die casting masinw ladonni waati bɛnnen na, o nafa ka bon kosɛbɛ casting ɲumanw dilanni na cogo basigilen na. Ni a ma ladon, sow jɔli nafama dɔw bɛ se ka kɛ, i n’a fɔ:

Flash: Die minnu bɛ sɛgɛn, olu sanfɛlaw bɛ flash sababuya bawo nɛgɛ dɔw bɛ taa die tilancɛ fila cɛ.

Soldering: Die fana bɛ se ka solder sɔrɔ yɔrɔ min na nɛgɛ liquit bɛ die surface kan ka da a kan lubrication walima cooling of the die.

Dimensionnel inaccuracies: Yɔrɔ hakɛw tɛ se ka kɛ kelen ye k’a sababu kɛ u yɔrɔw sɛgɛnni walima u kɛcogo jugu ye.

Walasa ka fiɲɛ minnu bɛ sɔrɔ minɛnw ladonni na, olu bɛ se ka bɔ walima ka dɔ bɔ u la, a ka ɲi kosɛbɛ ko tɔnw ka kɛ:

Aw bɛ ladonni kunbɛncogo bolodalen sigi sen kan die casting masinw bɛɛ la.

Aw bɛ aw hakili to a la ko aw bɛ a sɛgɛn walima ko a bɛ a tiɲɛ, a bɛ don a kɔnɔ, ani a yɔrɔ wɛrɛw la, ani ka seginkanni baara kɛ ni a mago bɛ o la.

Aw bɛ die yɔrɔw kɔnɔna ni kɛnɛma nɛnɛ ni u tuluma kɔlɔsi walasa ka u tanga solder ni tiɲɛni kojugu ma.

Kuncɛli

Kuncɛli la, fɛn dilanni nafama minnu bɛ kɛ ɲɔgɔn fɛ, olu faamuyali n’u ɲɛnabɔli die caman na, i n’a fɔ porosity, inclusions, cold shuts, flash, flow marks, blisters, ani misruns, o nafa ka bon kosɛbɛ walasa ka yɔrɔ ɲumanw dilan. Ni nin fiɲɛ ninnu sababuw dɔnna, minnu ye die dilancogo bɛnbali ye, baarakɛcogo paramɛtiriw minnu tɛ bɛn, nɛgɛw labɛncogo ani u jogo koɲɛw, ani die casting minɛnw ladonni nɔgɔyali, fɛn dilannikɛlaw bɛ se ka fɛɛrɛw tigɛ minnu ɲɛsinnen don u kunbɛnni ni u kɔlɔsili ma. Ni an ye fiɲɛw dɔgɔya, o tɛ dan fɛn dilannenw ka ɲumanya ni u ka baara kɛcogo dɔrɔn ma, nka o bɛ kiliyanw wasa ni u ka kantigiya fana ɲɛ.

Yala i labɛnnen don ka i ka die casting jogo kɔrɔta wa? Ekipu MFG ka furakɛli dɔnbagaw ani taamasiyɛn minnu sɛgɛsɛgɛra Precision die casting kɔnɔ, olu bɛ se k’aw dɛmɛ ka fɛn dilanni ɲɛtaa sɔrɔ. Jɛɲɔgɔnya kɛ ni an ye bi walasa k’aw ka taama daminɛ ka taa baara dafalen na.

Ɲininkaliw bɛ kɛ die casting defects ko la .

Nafa jumɛnw de ka teli ka sɔrɔ degunba die casting la?

Porosité, shuts cold, incompletes ani surface defauts i n’a fɔ blisters ani flow marks, olu de ye fiɲɛ ye min bɛ mɔgɔ kabakoya kosɛbɛ die casting la min bɛ tansiyɔnba la. O fiɲɛw bɛ se ka sɔrɔ k’a sababu kɛ fɛn dɔw ye minnu tɛ fɛn dilanni na i n’a fɔ funteni hakɛ kunbɛnni walima kɛnɛya ani ni sɛgɛn bɛrɛ tɛ a la.

Aw bɛ porosity defects (porosité defauts) kunbɛn cogo di die casting processus kɔnɔ?

Porosité defauts in die casting bɛ se ka bali ni die fiɲɛbɔli ɲuman ye, ka funteni hakɛ basigilen mara ani ka pikiri teliya kunbɛn. Ka fara o kan, a ka kan ka kɛ ni nɛgɛbere ye, wa, nɛgɛ min bɛ nɛgɛ bɔn ka don nɔgɔ la, o ka kan ka kɔlɔsi walasa ka margin (margin margin) caya dɔgɔya.

Kun jumɛn de bɛ nɛnɛ kɔfɛ ka da a kan a bɛ kɛ ni degunba ye?

Nɛnɛ dafalenw bɛ kɔlɔsi die casting la min bɛ kɛ ni tansiyɔnba ye ni nɛgɛdaga wulilenw bɛ kɛ ka profil fa, olu tɛ fara ɲɔgɔn kan pewu. O bɛ se ka kɛ ka a sababu kɛ funteni dɔgɔyali ye, pikiri teliya man ɲi, walima die nɛnɛ kojugu.

Surface defects i n’a fɔ blisters ani flow marks bɛ nɔ bila die castings la cogo di?

Surface defects i n’a fɔ blisters ani flow marks, olu tɛ dan die cast yɔrɔw cɛɲi dɔrɔn ma, nka u cogoya fana bɛ se ka kɛ cogo min na ani farikolo cogoya. O fiɲɛw bɛ se ka musaka wɛrɛw kɛ finidoncogo wɛrɛw la – misali la, polisi walima sɔgɔli – walasa ka jogo wajibiyalen sɔrɔ.

Paramɛtiriw kɔlɔsilibaw ye jumɛnw ye minnu bɛna dɛmɛ ka HPDC ka fɛnw filili hakɛ dɔgɔya?

Casting defauts in pressure die casting bɛ se ka dɔgɔya ni taabolo paramɛtɛrɛw die funteni, funteni, pikiri teliya, ani fiɲɛbɔlan bɛ kunbɛn ka ɲɛ. Ni an ye die casting machine to baarakɛcogo ɲuman na ani ka baara kɛ ni fɛn ɲumanw ye minnu ka ɲi, o fana bɛna dɛmɛ ka fiɲɛw dɔgɔya.