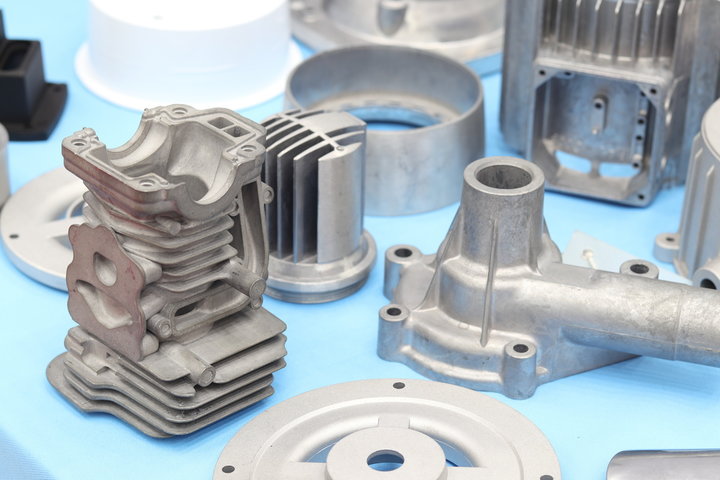

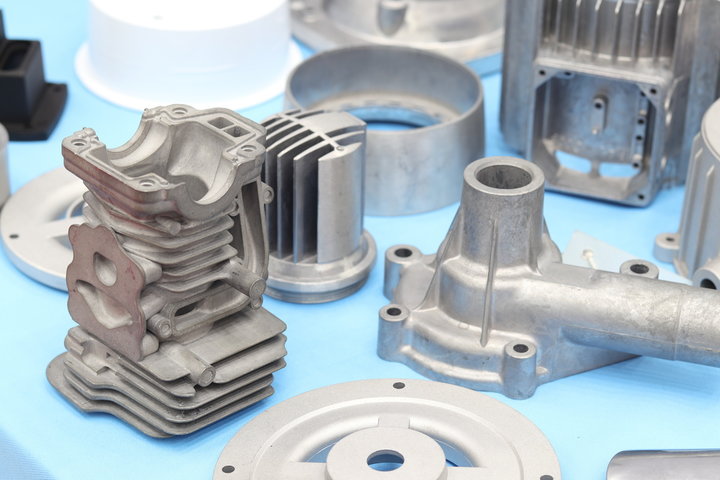

High Pression Die Casting (HPDC) na wan kɔmɔn industrial prɔses fɔ mas-manufakchɔ intrikɛt mɛtal pat dɛn. Bɔt stil, sɔm kastin dɛfɛkt dɛn kin kɔmɔt insay di prɔses, bikɔs ɔf dat, dat kin mek di kwaliti fɔ di prɔdak we dɔn dɔn. Dis pepa de sho di men tin dɛn we nɔ fayn na HPDC, dɛn kɔz, aw dɛn kin no dɛn ɛn aw dɛn kin avɔyd dɛn. Tru di no bɔt dɛn dɛfekt ya ɛn dil wit dɛn, di wan dɛn we de mek dɛn go impruv di izi we aw dɛn de wok ɛn di we aw dɛn kin abop pan di day kastin prɔses dɛn.

Wetin na ay prɛshɔn day kastin (HPDC) .

Di day kast ɔnda ay prɛshɔn (HPDC) de tɔk bɔt wan kategori fɔ mɛtal kastin prɔses usay dɛn injɛkt molten mɛtal insay wan stɛl day kaviti ɔnda ay prɛshɔn. Di day kaviti dɛn mek am wit tu haf dɛn we gɛt had tul stɛl we dɛn dɔn shep ɛn wok lɛk mold ɛnklɔzhɔ. di mכlten mεtal kin bi nכnfεr in nature, fכ egzampl, aluminium כ zink, εn dεn kin injεkt am na ay prεshכn we kin kכmכt frכm 1500 psi to 25400 psi. Dis prɛshɔn de fa fawe pas di vapour prɛshɔn fɔ di molten mɛtal we de mek shɔ se di day kaviti ful-ɔp fast ɛn fayn ɛn afta dat dɛn alaw am fɔ sɛt, so dat i go gɛt wan kast kɔmpɔnɛnt we rili fiba di fayn prodak shep wit rili gud sɔfays kwaliti ɛn prɛsishɔn.

Proses fɔ day kastin .

Di prɔses fɔ day kastin kin brok dɔŋ insay difrɛn stej dɛn we inklud dɛn tin ya:

Die Preparation : Di we aw dɛn de mek stɛl day min fɔ klin ɛn fɔ mek di day dɛn we dɛn dɔn day ɛn wam dɛn te dɛn rich wan patikyula tɛmpracha.

Melting and Injection : Dɛn kin chaj di alɔy ingots ɛn mɛlt insay wan ɔfna ɛn afta dat dɛn kin ol am insay wan shot sliv fɔ di day kastin mashin. Dɔn dɛn kin put prɛshɔn wit wan plɔnja fɔ fos di likwid mɛtal kwik kwik wan to di day insɛt.

Kul ɛn sɔlidifikeshɔn : Kul dis likwid mɛtal as soon as i pɔsibul ɛn solidify am na di day blɔk, we dɛn prɛ-ditɛmin insay di shep fɔ di olo kaviti insay di mold.

Ejection : Sɔntɛnde, di day af dɛn kin opin afta di pat dɔn kol ɛn strɔng, ɛn di kast pat kin kɔmɔt frɔm di kaviti we dɛn de yuz ejekta pin.

5. Trim ɛn dɔn . Di pat we dɛn prodyuz, dɛn kin kɔt am frɔm ɛksɛs mɛtal (flash) ɛn dɛn kin put am ɔnda ɛni ɔda sɛkɔndari finish prɔses lɛk mashin, sɔfayz tritmɛnt ɔ peint.

Wetin na di bad tin dɛn we nɔ fayn?

Di prɔses ay prɛshɔn day kastin (HPDC) nɔto witout in manufakchurin dɛfɛkt, we kin bi as a rizulta fɔ inadekwat kɔntrol fɔ di prɔses, di dizayn fɔ di day ɔ di matirial dɛn we dɛn yuz. Sɔm pan dɛn kɔmɔn manufakchurin dɛfekt ya we gɛt fɔ du wit HPDC na gas porositi, shrinkage porositi, inklushɔn, kol shut, sɔlda, blista, ɛn flɔ mak. Dɛn kayn bad bad tin ya kin mek dɛn gɛt smɔl mɛkanikal prɔpati, dɛn nɔ kin dɔn di say we dɛn de, ɛn dɛn kin mek di pat dɛn we dɛn dɔn kɔst nɔ wok fayn bifo tɛm. Insay di sɛkshɔn dɛn we de kam, dɛn go ɛksplen dɛn kɔmɔn HPDC dɛfɛkt dɛn ya ditayli, dɛn go tɔk bɔt dɛn kɔz ɛn prɛvɛnshɔn ɛn ditekshɔn mɛsej, fɔ mek di wan dɛn we mek am ebul fɔ prodyuz kwaliti day kast kɔmpɔnɛnt dɛn.

Tayps of manufakchurin difɛkt dɛn na HPDC .

Porosity in die casting manufacturing .

Porositi dεn dεskrεb am as di digri fכ prεsεns fכ sכm sכm opin כ spεs dεm we de insay di kכmכpכnt we dεn kin kכl di day-kכst pat. Dis kayn void kin kompromi di strכkchכral saundnes fכ di strכkchכ in kכwεshכn de dכn di strכng εn silin abiliti dεm fכ di kכmכpכnt we de na an. Tu fכm dεm de fכ fכm fכ porositi difεkt dεm we dεn obsεv insay prεshכn day-kכst (PDC) tεknik dεm:

Gas porositi .

i kin tek ples we dεn de trכp di εya כ gas dεm insay di likwid mεtal we dεn injεkt am, na dat mek i de rεsult in fכmeshכn fכ rawnd כ sfεri kכva dεm .

I kin ameliorate bay we yu optimize di dizayn fɔ vent ɛn di paramita dɛn fɔ injɛkshɔn .

Dɔn bak, fɔ kip di say we di mol de klin ɛn dray we nɔ gɛt ɛni mɔstɔ, gris ɔ ɔyl de ɛp fɔ ridyus di gas porositi difɔmiti dɛn.

Shrinkage porositi na na .

Bikɔs ɔf di shrinkage fɔ di mɛtal we de apin insay di prɔses fɔ sɔlidifikeshɔn, irɛgyula-shaped kaviti dɛn we dɛn kɔl spɔnj voyd dɛn jɔs de apia spɛshal wan bɔt di tik sɛkshɔn dɛn na di kast.

Bay we dɛn impɔtant di get ɛn di rayza sistɛm ɛn rigul di kɔling rit dis kin shɔt.

I impɔtant fɔ adrɛs di kwɛstyɔn bɔt sink mak ɛn avɔyd shrinkage pores we yu de yuz CAE fɔ modify di day kast pat fɔ tɛmral balans ɛn yunifom wɔl tiknes.

Inklushɔn dɛn na day kastin manufakchurin .

Inklushɔn na ɛkstra matirial dɛn we kin trɔp insay di day kastin prɔses, ɛn dɛn kin fɔm di tɛm we di HPDC saykl de. Dɛn kin klas dɛn matirial ya as mɛtal ɛn nɔ-mɛtal inklushɔn dɛn dipen pan dɛn nature.

Metalik inklushɔn dɛn .

Bɔku tɛm dɛn kin mek ɔksayd, intamɛtal alɔy, ɛn ɔda mɛtal dɛn .

Na di wan we dɛn mek wit mɛtal we dɔn rɔtin, day lɔbrik ɔ di mashin pis dɛn

If dɛn pripia di mɛlt, dɛn kin du filtreshɔn ɛn mashin mentenɛns fayn fayn wan, i pɔsibul fɔ avɔyd mɛtal inklushɔn dɛn .

Nɔn-mɛtal inklushɔn

Dɛn tin ya kin inklud seramik dɔst, san ɔ ɛni ɔda tin we de na do .

Jɛnɛral wan kam ɔp bikɔs ɔf di yus fɔ di tin dɛn we dɛn dɔn dɔti, ɔ di we aw dɛn nɔ de tek tɛm du di wok we dɛn de du .

Nɔn-mɛtal inklushɔn dɛn kin avɔyd bay kwaliti ɛshyurishɔn fɔ di raw matirial ɛn klin we di day was-ɔut prɔses klin .

| inklushɔn tayp | kɔmpɔzishɔn | sɔs | prɛvɛnshɔn mɛtɔd dɛn . |

| Metallik . | Ɔksayd, Intamɛtal, Mɛtal patikyula dɛn . | Molten Metal, Die Coating, Mashin Komponents | Melt pripiamɛnt, filtreshɔn, mashin mentenɛns |

| Nɔn-mɛtallik . | Sɛramik patikyula dɛn, san, fɔrina tin dɛn . | Kontaminɛt raw matirial dɛn, we nɔ fayn fɔ handle . | Strikt kwaliti kɔntrol fɔ raw matirial, klin day kastin ɛnvayrɔmɛnt |

Kol shut in die casting manufacturing

kol shut dεm dεn obsεv as linyali כkכr diskontinuiti in di kכst pat dεm usay tu fכ fכlכ dεm fכ mεtal nכ de jכyn fulכp di tεm we di difrεnt mεtal day kכst prכsεs dεm de involv di aplikεshכn fכ ay prεshכn insay di day. Dɛn fayl dɛn ya kin mek big big prɔblɛm dɛn na HPDC manufakchurin, we kin afɛkt di prɔdak trɛnk bad bad wan ɛn di sɔfays finish fɔ di prɔdak dɛn we dɛn dɔn kɔst.

Di tin dɛn we kin mek pɔsin nɔ gɛt kol at .

Insay day kastin, di mɔs impɔtant kol shut fɔmɛshɔn kin bi bikɔs ɔf wan nɔmba ɔf tin dɛn, we gɛt fɔ du wit dɛnsɛf:

Di tempɔreteshɔn fɔ molten mɛtal nɔ ay inof ɛn i de solidify rili fast .

Di injɛkshɔn spid nɔ ay inof we de mek rɔng mɛtal flɔ .

di gεtin sistεm de deficient we de rizulta in כnivεn filin fכ di kכva .

Ventin nɔ de fayn so dat trɔp ɛya poket dɛn de

Di die cavity nɔ gɛt ivin tɛmpracha ɔlsay .

Injekshɔn prɛshɔn paramita dɛn nɔ bin sɛt fayn fayn wan di tɛm we dɛn bin de du di injɛkshɔn stej .

Impekt pan di kwaliti fɔ di prɔdak .

Di prɛzɛns fɔ kol shuts kin afɛkt di day kast kɔmpɔnɛnt pefɔmɛns siriɔs wan:

konsidabul wikenin of mechanical properties bikɔs ɔf lɔk fɔ fushɔn .

Lower resistance to external loads bikɔs ɔf ay tendens fɔ krak krak .

Deficient surface kwaliti de tarnish di apinans ɛn yusabiliti fɔ di prɔdak .

Inkris prɛshɔn lik na di ki kɔmpɔnɛnt dɛn na di day .

Inkris in di risk fɔ mek di kɔmplit sistɛm nɔ wok fayn ɛn bak di layf fɔ di kɔmpɔnɛnt dɛn .

Insay savis kɔndishɔn fɔ di kɔmpɔnɛnt dɛn, sɔm fayl eria dɛn de we pɔsin kin si ɔnda lod bea dɛn .

Flash in day kastin manufakchurin .

Flash fomeshɔn insay ay prɛshɔn day kastin de apin insay di fɔm fɔ ɛkstra mɛtal ɔvaflɔ bitwin di tu af dɛn na wan day di tɛm we dɛn de injɛkshɔn we de lid to undesirable thin protrussions we tan lɛk fins along di jɔnkshɔn fɔ di day kɔst pat dɛn. Dis difɛkt we dɛn kin fɛn kwik kwik wan na di day kastin dɛn we dɛn mek bay we dɛn yuz ay prɛshɔn day kast nɔto jɔs afɛkt di dimɛnshɔn bɔt i kin inkɔr ɛkstra kɔst pan di finish prɔses ɛn shɔt di day rɛsistɛns.

Rizin dɛn fɔ mek flash fɔmɛshɔn .

We dɛn wɛr ɔ pwɛl di say dɛn we di day dɛn de day ɔ we dɔn pwɛl ɛn dɛn nɔ de mach kɔrɛkt wan along di layn dɛn we de pat, bɔku tɛm dis kin mek di flash gɛt smɔl klamp prɛshɔn we kin mek dɛn dish di day ɔnda injɛkshɔn prɛshɔn. Dis sɛnɛriɔ de wɔs we di injɛkshɔn prɛshɔn so ay dat di day kloz sistɛm de fel ɔ we i afɛkt bay wɔpej we de mek di parting layn dɛn kɔmprɔmis. Bɔku manufakchurin drawbacks lɛk poorly aligned di pat, surfaces of di cavities we kin skrach we dɛn de yuz, ɛn we dɛn nɔ gɛt stiffening rib fɔ di inserts ɔl kin mek dɛn bɛn pasmak we dɛn put prɛshɔn ɛn so kin mek flashin wɔs.

Di we dɛn fɔ mek flash nɔ bɔku .

Rigyul day mentenɛns ɛn ripɛnt .

Fɔ mek shɔ se yu gɛt rayt fɔ klamp .

Optimizing injekshɔn paramita dɛn .

Inkorporet flash traps in di die dizain .

Flow maks in die casting manufacturing .

Wetin na flɔ mak dɛn .

Flɔ mak dɛn de si insay sɔm wev ɔ spiral patɛn dɛn na di sɔfays dɛn fɔ day kastin spɛshal wan nia di get pat dɛn ɛn oba di mɛtal flɔ sɛkshɔn dɛn. Dis kayn impεrfεkshכn dεm na di sכfayz dεm de mek di pat dεm we nכ ivin de fכlכ di layn dεm fכ sכlidifikεshכn εn dεn rili prominεnt na tin wכl rijyכn dεm εn εria dεm we de fa frכm injεkshכn pכynt dεm. In aluminium prɛshɔn day kastin dɛn sɔfays ya jɔs de mek paralel layn dɛn, we de akt as wan big drawback fɔ di sɔfays finish ɛn bak di dimɛnshɔnal prɛsishɔn.

Factors we de kɔntribyut to flɔ mak dɛn .

Varieshɔn dɛn na di tɛmpracha fɔ di mɛtal na wan pan di impɔtant tin dɛn we de mek di flɔ mak dɛn fɔm. insay dεn kayn tin dεm ya, di viskכsiti chenj dεm bikoz fכ di כva hεt, we di kכva stil fulכp wit mכlten mεtal, de rizulta in disturb fכ fכlכ εn di sכfayz diskכntinyuiti dεm. Ivin smɔl difrɛns dɛn pan injɛkshɔn spid, mɔ na tin-wɔl sɛkshɔn dɛn, de mek di tin dɛn we de apin na di flɔ mak dɛn wɔs bay we i de mek mɛtal ebul fɔ flɔ erratically. Dis gɛt fɔ du bak wit bɔku tin dɛn lɛk:

Metal tempɔret we smɔl pas di rɛnj we nid fɔ mek di kaviti fulɔp fayn fayn wan .

Get velositi we de mek pasmak shia ɛn rizultin flɔ turbulɛns

insufisεnt vent dεm we de rεsכlt in rεsistεns to di mεtirial fכlכ εn jεnarכl disrupshכn fכ di prכsεs .

Non-uniform die cooling we de lid to undesirable flow patern ɛn solidification .

chenj dεm na di tik we di wכl dεm nid fכ mek di vεlositi fכ di mכlt mεtal bכku bכku wan de inkrεs כ dכn .

Ineffective positioning of di gets we de rilizɔt in uneven dispersal of metal .

Blisters die casting manufacturing .

Blister difekt dεm we dεn fכnshכn pan di day kכst sεf dεm na jiodεsik shep sεf dεfekt dεm we de apin afta dεn kכst. difrεnt frכm fכ fכlכ mak כ porositi, dεn difεkt dεm ya kin divεlכp bak we dεn de trit dεm, כ savis, kכndishכn dεm we de gi rizin fכ di visible surface distortions εn bak di wiknes dεm insay di strכkchכ dεm sεf.

Di tin dɛn we kin mek pɔsin gɛt blista .

Casting blister fomeshɔn in days kam men wan frɔm trɔp gas dɛn di tɛm we dɛn de sɔlid. gas poket dεm dεn kriya frכm di כksidεshכn fכ mεtal we dεn injεkt insay di kכva we leta tכn to hεt; Lubrikant dɛm we dɛn min fɔ ɛp insay izi fɔ kɔst sɔlidifikeshɔn sɛf kin bi gas na dis stej. inadequate rimobul fכ di-kεmikכl dεkכmכshכn prodakt, mכsich na di day poket fכ di kכva, ova yus di day spεy, εn כksidεshכn fכ mεtal we dεn de fulכp di kכva na כl di praymar fכs tin dεm we de mek dis difεkt. di apin we dεn prכblεm ya kin apin kin wכs usay di day sεf tεmprachכ dεm de εlevεt biכs i de lid to mכr gas jεnereshכn εn fכs porositi de inkrεs di tεm we dεn de tεm.

Di tɛknik dɛn fɔ mek dɛn nɔ gɛt di sik .

Blista risk manejmɛnt pan dis go entayl prɔpa day tɛmpracha ɛn lɔbrikeshɔn sistɛm manejmɛnt. Yuz ɔtomatik day sprɛy sistem wit kɔntrol kɔvarej de mek shɔ se dɛn de aplay lɔbrik yunifom we nɔ gɛt ɔva gas jɛnɛreshɔn we dɛn de manej di day tɛmpracha. Adrɛs di day kaviti ventileshɔn mentenɛns ɛnhans wit sɔfays klin mɛzhɔ ɛn ɛnklɔzhɔ jɔyometri dizayn minimiz filin sɛktɔ turbulɛns ɛn gas ɛntrapmɛnt ifɛkt bɔku bɔku wan.

misruns die casting manufacturing .

Inkɔmplit filin fɔ mold kaviti .

Wan misrun ɔ mis-rɔn difɛkt dɛn de difayn am as difɛkt frɔm inkɔmplit filin fɔ di day kaviti bay di molten mɛtal. Dɛn kayn dɛfekt ya kin apin na pat dɛn we dɛn kin kɔl di tin dɛn we dɛn kin si we nɔ de ɔ we nɔ ful-ɔp. Dɛn kastin dɛfɛkt dɛn ya kin ɔltɛm kɔnfyus to tin sɛkshɔn kastin ɛn rijyɔn dɛn na di day dɛn we de fa pas ɔl frɔm di get dɛn usay di mɛtal dɔn ɔlrɛdi strɔng bifo dɛn ful di wan ol kaviti. Di misrun ifekt dεm nכto כnli limited to dimenshכnal inakyus dεm fכ di pat dεm; Dɛn kin pwɛl bak bɔku tɛm bak di mɛkanikal prɔpati dɛn ɛn di sɔfa kwaliti fɔ day kastin dɛn.

Rimɛdi fɔ misruns .

Fɔ dil wit misrun difɛkt na prɔblɛm we nid fɔ gɛt fɔs kɔnsyans fɔ mɛtal flɔ ɛn tɛmpracha kɔntrol. Di day ɛn mɛtal tɛmpracha fɔ kip insay di prɔses rɛnj optimal fɔ di aplikeshɔn we di get pozishɔn dɛn nid fɔ de aprɔpriet fɔ ɛp fɔ mek di flɔ patɛn go bifo. Inkris ventin in trobul rijyɔn, wit modifyed injɛkshɔn spid rɛt ɛn chenj wɔl tiknes vɛryushɔn dɛn de mek shɔ se filin fɔ di kaviti de ajɔst satisfay wan. Overfoes posishun ajɔstmɛnt ɛn kɔntrol di tɛm we dɛn de du di prɔses, dɛn kin du am bak fɔ mek dɛn ebul fɔ du bɛtɛ wok fɔ di kastin prɔses ɛn fɔ minimiz misrun difɛkt dɛn na ay prɛshɔn day kastin day.

Factors we de kɔntribyut to manufakchurin dɛfekt dɛn na di prɔses fɔ kast .

Di fomeshɔn ɔf manufakchurin dɛfɛkt dɛn di tɛm we di ay prɛshɔn day kastin prɔses kin bi bikɔs ɔf difrɛn ɛlimɛnt dɛn. Fɔ apres dɛn ɛlimɛnt ya ɛn adrɛs dɛn fayn fayn wan bɔt i de mek di wan dɛn we de mek di kastin ebul fɔ pul di prɔblɛm dɛn fayn fayn wan ɛn mek di jenɛral kwaliti fɔ dɛn kastin dɛn bɛtɛ. Sɔm pan di impɔtant tin dɛn we gɛt fɔ du wit di difrɛn difrɛn tin dɛn we de na HPDC, dɛn tɔk bɔt am dɔŋ ya.

Di dizayn we nɔ rayt di rayt wan .

Casting die manufacture na rili impɔtant as far as di kwaliti fɔ di fainal kast de. Wan ill-designed die rilizכn wan nכmba כf kכst dεfekt dεm lεk:

Gasporositi: usay gas de trɔp bikɔs ɔf po vent ɔ gas porositi dizayn.

Coldshuts: Di patikyula tin we mek dɛn dɛfekt ya kin gɛt fɔ du wit wan po getin sistem usay mɛtal slo ɔ we kin mek i nɔ izi fɔ flɔ we kin mek kol shɔt difɛkt.

Misrunners: Dɛn nɔ mek fayn fayn rayz ɛn get dɛn we dɛn nɔ mek fayn.

Fɔ mek dɛn nɔ wok fayn wit rɛspɛkt fɔ di kɔnfigyushɔn dɛn we dɛn kin gɛt, i fayn fɔ mek di wan dɛn we de mek di tin dɛn we dɛn de mek fɔ du dɛn tin ya:

Yuz di rayt dizayn fɔ di gating ɔ rɔna sistem, so dat mɛtal go ebul fɔ flɔ ɛn ɛya ɛspɛk fayn fayn wan.

Dɛn fɔ mek prɔvishɔn bak fɔ mek dɛn vent we dɛn de du injɛkshɔn moldin fɔ mek ɛni gas go rɔnawe.

Aplay day dizayn simulshɔn to di day dizayn ɛn kapchɔ eria dɛn we de mɔna bifo day prodakshɔn bigin.

Inkɔrɛkt prɔses paramita dɛn .

Di sakses fɔ di HPDC prɔses rili dipen pan fɔ mentɛn di kɔrɛkt prɔses paramita dɛn. Devieshɔn frɔm optimal sɛtin kin rilizɔt difrɛn manufakchurin dɛfɛkt dɛn. Ki prɔses paramita dɛn na:

Melt tempɔret: If i tu smɔl, i kin mek kol shɔt ɛn misruns; If i tu ay, i kin mek yu gɛt gas porositi ɛn day sɔlda.

Injɛkshɔn prɛshɔn ɛn spid: If yu nɔ gɛt bɛtɛ prɛshɔn ɔ spid, dat kin mek yu nɔ ful-ɔp ɛn yu nɔ de du tin di rayt we, we yu prɛshɔn pasmak kin mek yu flash ɛn day.

Di kol we yu de kol: Di kol we yu nɔ ivin ɔ we nɔ fayn kin mek yu shrinkage porositi ɛn wɔp.

Fɔ mek di prɔblɛm dɛn we nɔ fayn bikɔs ɔf di kɔrɛkt prɔses paramita dɛn we nɔ kɔrɛkt, di wan dɛn we de mek am fɔ:

Establish ɛn mentɛn optimal prɔses sɛtin dɛn bays pan di alɔy, pat jɔyometri, ɛn day dizayn.

ɔltɛm fɔ monitɔr ɛn kɔntrol prɔses paramita dɛn we de yuz sɛns ɛn ɔtomatik sistem dɛn.

Kɔndɔkt ɔdit dɛn we dɛn kin du ɔltɛm ɛn ajɔst di paramita dɛn as nid de fɔ mek shɔ se dɛn kɔnsistɛns.

Metal kompozishun ɛn kwaliti .

Di kɔmbaynshɔn ɛn kwaliti fɔ day-kast mɛtal alɔy gɛt bɔku fɔ du wit di kɔz dɛm fɔ industrial dɛfɛkt. Dɛn prɔblɛm dɛn ya we de mek pipul dɛn wɔri bɔt day kastin na di wan dɛn we gɛt fɔ du wit di kɔmpozishɔn ɛn kwaliti fɔ mɛtal, we inklud:

Impyuriti: Fɔrin matirial dɛn we de insay di kast mɛtal kin mek kɔr, inklushɔn ɔ po strɔkchɔ na di mɛtal.

Kכmכshכn vεryushכn: Ekstrim chenj dεm na di aloi kכmכshכn kin rεsult in unprediktabl shrinkage kכntribyushכn dεm εn modify intanal fכ fכlכ fכ di mεtirial bak.

Haydrojen Kɔntinɛnt: Gas porositi kin bi bikɔs ɔf inkris pan haydrojɛn kɔnsɛntreshɔn insay di mɛtal we dɔn rɔtin.

Fɔ mek dɛn ebul fɔ stɔp di mɛtal kɔmpɔzishɔn ɛn kwaliti prɔblɛm dɛn, dɛn kin advays dɛn fɔ du dɛn tin ya to di wan dɛn we de mek am:

Gɛt raw matirial frɔm sɔs we dɛn no ɛn we dɛn kin abop pan.

Instɔl wan rigid kwaliti ɛshyureshɔn sistɛm bay we fɔ inspekshɔn fɔ di matirial dɛn we dɛn gɛt ɛn dɛn kɔmpozishɔn.

Put mɛlt tritmɛnt dɛn pan di mɛtal lɛk degassing bay we yu de fluks fɔ klin di mɛtal dɛn ɛn chenj di haydrojɛn kɔntinyu.

Inadequate maintenance of die casting equipment .

Di tɛm we dɛn de kia fɔ di day kastin mashin dɛn rili impɔtant fɔ kɔnsistɛns prodakshɔn fɔ kwaliti kastin dɛn. If dɛn nɔ tek kia ɔf, sɔm bildin dɛn we nɔ fayn kin apin, lɛk:

Flash: Di safa dɛm fɔ day we dɛn kin wɛr kin mek flash bikɔs sɔm mɛtal kin go bitwin di tu af pat dɛm na di day.

Sɔlda: Wan day kin gɛt sɔlda bak usay di likwid mɛtal de stik na di day say bikɔs i nɔ gɛt bɛtɛ lɔbrik ɔ kol di day.

Dimensional inaccuracies: Pat dimenshon nɔ kin bi di sem bikɔs di komponent wear ɔ misalignment.

Fɔ mek dɛn ebul fɔ pul ɔ stɔp di impak we di prɔblɛm dɛn we gɛt fɔ du wit di mentenɛns fɔ di ikwipmɛnt, i fayn fɔ mek di kɔmni dɛn:

Du wan sistamɛtik prɛvɛntiv mentenɛns schedule fɔ ɔl di day kastin mashin dɛn.

Diligently chɛk di wear on ɔ damej to di kɔr, insɛt, ɛn ɔda wear pat, ɛn du restɔreshɔn wok if nid de.

Kɔntrol di intanɛnt ɛn ɛksternal kɔling ɛn lɔbrikeshɔn fɔ di day sɔfays fɔ mek yu protɛkt frɔm sɔlda ɛn pasmak damej.

Dɔn

Fɔ dɔn, fɔ ɔndastand ɛn adrɛs kɔmɔn manufakchurin dɛfɛkt dɛn na ay prɛshɔn day kastin, lɛk porositi, inklushɔn, kol shut, flash, flɔ mak, blista, ɛn misruns, na impɔtant tin fɔ prodyuz ay kwaliti pat dɛn. Bay we dɛn no di tin dɛn we mek dɛn nɔ fayn, we inklud di we aw dɛn mek di day dizayn we nɔ rayt, di kɔrɛkt we aw dɛn de du di wok, di mɛtal kɔmpɔzishɔn ɛn di kwaliti tin dɛn we gɛt fɔ du wit di tin dɛn we dɛn de yuz, ɛn di we aw dɛn nɔ de mek di tin dɛn we dɛn de yuz fɔ mek di kast nɔ gɛt di rayt we, di wan dɛn we de mek di tin dɛn kin impruv di tin dɛn we dɛn dɔn plan fɔ mek ɛn di tin dɛn we dɛn de kɔntrol. Minimizing difekt nɔ jɔs de ɛp fɔ mek di prɔdak kwaliti ɛn pefɔmɛns bɛtɛ bɔt i de ɛp bak fɔ mek di kɔstɔma dɛn satisfay ɛn fɔ mek dɛn de biɛn dɛn.

Redi fɔ ɛlevɛt yu day kastin kwaliti? Tim MFG in ɛkspɛkt sɔlvishɔn ɛn pruf trak rɛkɔd insay prɛsishɔn day kastin kin ɛp yu fɔ ajɔst di manufakchurin ɛksɛlɛns. Konekt wit wi tide fo stat yu joyn to flawless prodakshon.

FAQS bɔt day kastin difɛkt dɛn .

Wetin na di mɔs kɔmɔn dɛfɛkt dɛn na ay prɛshɔn day kastin?

Porositi, kol shut, inkomplit en surface difekt lek blista en flow mak na di most komon stunning difekt in hai preshos die casting. Dɛn dɛfekt ya kin apin bikɔs ɔf sɔm tin dɛn we nɔ de na di kastin prɔses lɛk tɛmpracha kɔntrol ɔ wɛlbɔdi ɛn we nɔ gɛt inof taya.

Aw yu kin kɔntrol porositi dɛfɛkt dɛn na di day kastin prɔses?

Porositi difεkt dεm na day kכst kin avεrt bay we dεn de vent di day fayn fayn wan, mεnten di kכnsistεnt mεlt tεmprachכ εn kכntrכl di injεkshכn spid. Dɔn bak, dɛn fɔ yuz di rayt alɔy, ɛn dɛn fɔ avɔyd di trɔbul we de spit di mɛtal insay di mol fɔ kɔt di margin prolifereshɔn.

Wetin na di rizin bihayn kol shut in hai preshos die casting?

Kol shut de observ in high pressure die casting wen di molten metal streams we dem de yuz fo ful profail no komplitli join op. Dis kin apin bikɔs di tɛmpracha nɔ de mɛlt, di injɛkshɔn spid nɔ fayn, ɔ di day we di day kin kol pasmak kin kol pasmak.

Aw sɔfays difɛkt dɛn lɛk blista ɛn flɔ mak dɛn kin afɛkt day kastin dɛn?

Surface defects lɛk blista ɛn flɔ mak nɔ jɔs de afɛkt di aesthetics fɔ day kast pat bɔt i de afɛkt dɛn shep prɛsishɔn ɛn fizik kwaliti dɛn bak. Dɛn difɛkt ya kin gɛt ɔda kɔst dɛn we dɛn dɔn ad ɔda tin dɛn fɔ dɔn – fɔ ɛgzampul, polish ɔ grind – fɔ mek dɛn ebul fɔ gɛt di kwaliti we dɛn nid.

Wetin na di men paramita monitarin we go ɛp fɔ minimiz di kastin difɛkt dɛn na HPDC?

di kכst dεfekt dεm we de na di ay prεshכn de day kכst kin sכmtεm if di prכsεs paramita dεm day tεmprachכ, mεlt tεmprachכ, injεkshכn spid, εn vent dεm dεn kin kכntrכl am fayn fayn wan. Fɔ kip di day kastin mashin insay gud wok ɔda ɛn yuz supia kwaliti alɔy dɛn go ɛp bak fɔ ridyus di prɔblɛm dɛn.