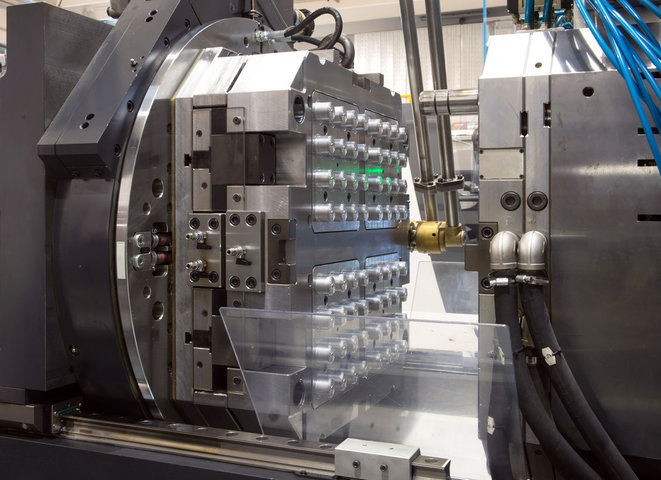

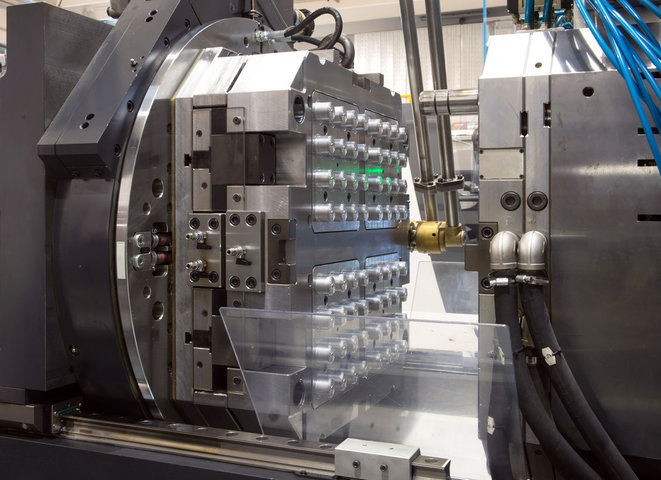

Yala i delila k’i yɛrɛ ɲininka cogo min na plastiki fɛnw bɛ bɔ ka bɔ nɔgɔw la cogo dafalen na wa? Ejector pins jɔyɔrɔ ka bon kosɛbɛ. O yɔrɔ fitininw bɛ a to yɔrɔ mɔlenw ka bɔ ka ɲɛ san 2019 kɔnɔ. Pikirili Molidali ..

Nin sɛbɛn in kɔnɔ, aw bɛna a dɔn ejector pins ye mun ye, mun na u nafa ka bon, ani u bɛ don cogo min na pikiri kɛcogo la.

Ejector pins ye mun ye?

Ejector pins nafa ka bon kosɛbɛ plastiki pikiri kɛli la. O yɔrɔ fitininw bɛ yɔrɔ mɔlenw sama ka bɔ nɔgɔ la nɛnɛ kɔfɛ. Ni ejector pins tɛ, yɔrɔw bɔli tun bɛna gɛlɛya ani a tun bɛ se ka mɔni tiɲɛ.

Ɲɛfɔli dafalen kɛra ejector pins kan .

Ejector pins ye ejector system dɔ ye moule dilanni na. U bɛ Sìgi b-yɔrɔ la min bɛ Kɛ nɔgɔ la, o min bɛ yɔrɔ min Sɔrɔ nɛnɛ kɔfɛ, o minɛ. Ni mɔni da wulila, ejector pins bɛ yɔrɔ in sama ka bɔ moule cavité kɔnɔ.

Pinɛw bɛ taa tilennen na ka taa nɔgɔbɔlan sanfɛla la. O bɛ a to yɔrɔ bɔli ka ɲɛ k’a sɔrɔ a ma a kɔnɔna yɔrɔ tiɲɛ. Ejector pins bɛ sɔrɔ suguya caman na i n’a fɔ pinɛ gɛlɛnw, nitride H13 pins, ani black ejector pins. suguya kelen-kelen bɛɛ bɛ sugandi ka da fɛn kɛrɛnkɛrɛnnenw kan minnu bɛ kɛ ka ɲɛsin fɛnw dilanni ma.

Nafa min bɛ pikiri kɛcogo la .

Ejector pins nafa ka bon kosɛbɛ ka ɲɛsin a dilanni ma ka ɲɛ. U bɛ yɔrɔw bali ka nɔrɔ nɔgɔ la, ka bɔli kɛcogo nɔgɔya ani ka a teliya. O bɛ dɛmɛ ka yɔrɔ mɔlenw jogo sabati ani ka mɔli ka ɲɛnamaya janya.

Ejector pins bilali ka ɲɛ, o nafa ka bon kosɛbɛ. Pinɛ minnu bɛ bila yɔrɔ jugu la, olu bɛ se ka kɛ sababu ye ka fiɲɛw sɔrɔ i n’a fɔ pinɛ taamasiɲɛw walima pinɛw impressions (pinɛw) yɔrɔ la. O nɔgɔw bɛ nɔ bila fɛn dilannen in sanfɛla cogoya n’a cogoya la. Ni fɛn caman bɛ sɔrɔ, hali ni u bɛ mɛn walima ni u ka fiɲɛw bɛ se ka kɛ sababu ye ka bɔnɛba lase u ma.

Fɛn minnu bɛ kɛ ka caya ejector pins kama .

Ejector pinw ka kan ka funteni caman muɲu ani ka segin u kan. Fɛn minnu bɛ kɛ tuma caman na, olu ye nɛgɛ gɛlɛn, H13 baarakɛminɛn nɛgɛ ani nɛgɛ ye min tɛ sɔgɔ. Nɛgɛdaga gɛlɛnw bɛ a to a bɛ se ka muɲu ani a bɛ se ka a yɛrɛ tanga. H13 Tool Steel Pins bɛ dɔn u ka funteni kunbɛncogo la, o b’a to u ka ɲi kosɛbɛ funteni caman dilanni na. Inox pinɛw bɛ sɔgɔli kunbɛn, ka ɲɛnamaya jan sɔrɔ fɛn dilanni sigida suguya caman na.

Ejector pins suguyaw .

Pins de ejector through-gɛlɛn .

jogo ni baarakɛcogo .

Ejector through-hard pins bɛ dilan ni fɛnw ye minnu ka gɛlɛn u cɛmancɛ bɛɛ la. O gɛlɛya kelen in b’a to u bɛ degunba muɲu u dilanni senfɛ. U ka ɲi kosɛbɛ pikiri kɛli la plastiki la, yɔrɔ minnu na a ka ɲi kosɛbɛ ani a bɛ mɛn cogo min na.

O pinɛw bɛ kɛ ka caya baarakɛyɔrɔw la, yɔrɔ minnu na, fɛn dilanni bɛ baara kɛ 200°C duguma. U ka gɛlɛya basigilen b’a to u bɛnnen don yɔrɔw dilanni na ni jateminɛ gɛlɛnw ye, ka a to u ka sɛgɛn ani ka u sɛgɛn dɔɔni.

Nafaw ni dɛsɛw .

Pin minnu ka gɛlɛn kosɛbɛ, olu bɛ nafa caman di:

Durability : Ni gɛlɛya kelen bɛ u la, u bɛ deformation (dɔgɔyali) kɛlɛ.

Precision : A ka ɲi kosɛbɛ molds ma kosɛbɛ, a bɛ a to a ka yɔrɔ dɔw bɔ cogo bɛnnen na.

Nka, u fana ye nafa dɔw sɔrɔ:

Nitride H13 Ejector Pins (Pins ka case-hardenés) .

Propriétés ani baarakɛcogo bɛnnenw .

Nitride H13 ejector pins, n’a bɛ fɔ fana ko pinɛ minnu bɛ gɛlɛya ni case ye, olu ɲɛda ka gɛlɛn ani u kɔnɔna ka gɛlɛn. O dilancogo bɛ balansi di gɛlɛya ni fɛn caman sɛgɛsɛgɛli cɛ. O pinɛw bɛ se ka funteni muɲu fo ka se 600°C ma, o b’a to u bɛnnen don funteni caman sɛnɛcogo ma.

U ka ɲi kosɛbɛ baarakɛcogo la minnu bɛ kɛ ni fɛnw ye minnu bɛ kɛ ka fɛnw sɔgɔ walima minnu bɛ kɛ ka fɛnw sɔgɔ. A yɔrɔ gɛlɛn bɛ sɛgɛn kunbɛn, ka sɔrɔ a kɔnɔna gɛlɛn bɛ a biri walima a kari.

Aw bɛ a suma ni pinɛ gɛlɛnw ye .

Ni aw ye a suma ni pinɛw ye minnu ka gɛlɛn, Nitride H13 Pins bɛ o dilan:

Nka, a ka c’a la, u sɔngɔ ka gɛlɛn, wa u bɛ se ka gɛlɛya ka tɛmɛ masin kan.

Pins de ejetaire noir .

Fɛnw ni nafaw .

Ejector pins noirw bɛ furakɛ ni finimugu kɛrɛnkɛrɛnnen ye min bɛ u ka baara kɛcogo ɲɛ. Nin finimugu in, a ka c’a la, a bɛ kɛ DLC suguya dɔ ye (diamond-like carbon), o bɛ tulumafɛnw ni sɛgɛnbaliya ɲuman di. O pinɛw bɛ se ka baara kɛ funteni na fo ka se 1000°C ma, o b’a to u ka ɲi kosɛbɛ baara minnu ka gɛlɛn kosɛbɛ.

Funteni caman bɛ sɔrɔ .

K’a sababu kɛ u ka funteni ka bon, ejector pins noirw dafalen don walasa ka baara kɛ ni u ye mobili ni aerospace iziniw kɔnɔ, yɔrɔ minnu na yɔrɔw ka kan ka funteni jugumanba muɲu. U bɛ dɛmɛ don ka dugukolo sanfɛla nɔgɔya ani ka a jogo ɲuman mara, hali ni a ka gɛlɛn.

musaka jateminɛw .

Hali ni black ejector pins bɛ baara kɛcogo ɲuman di, u bɛ na ni musaka caman ye. O dacogo ɲuman ni funteni furakɛli bɛ u sɔngɔ gɛlɛya ka tɛmɛ H13 pinɛw kan minnu ka gɛlɛn walima minnu ka ɲi. Nka, u ka ɲɛnamaya jan n’u ka baarakɛcogo nafaw bɛ jo di tuma caman na ka wari bila fɛn dilanni taabolo la min bɛ kɛ ni wari caman ye.

Ejector pins bɛ baara kɛ cogo min na pikiri kɛli la .

Ejector pinw nafa ka bon kosɛbɛ pikiri kɛcogo la, nka u bɛ baara kɛ cogo di tiɲɛ na? An k'a Tigɛ ka Kɛ dakun jɔnjɔn saba ye:

Pikiri fasa .

Nin yɔrɔ in de la, maaɲɛmaaya bɛ daminɛ. Plastiki wulilen bɛ pikiri kɛ nɔgɔbɔlan kɔnɔ degunba la. O fɛn bɛ mɔni yɔrɔ bɛɛ fa, k’a cogoya ta.

Fasa nɛnɛman .

Ni fɛn in bɛ foroko kɔnɔ, a ka kan ka nɛnɛ ani ka a gɛlɛya. Nin yɔrɔ in de la, muɲuli bɛ na baara la. Nɛnɛ waati bɛ bɔ a fɛn na ani a yɔrɔ janya la.

Yɔrɔ min bɛ bɔ yɔrɔ la .

Sisan, Grand Finale kama – ka yɔrɔ in bɔ a la! Nin yɔrɔ in de la ejector pins bɛ yeelen bɔ. Fɛɛrɛba fila de bɛ yen:

Manuel ejection systèmes .

Operatɛri bɛ yɔrɔ in bɔ bolo la .

A ka ca a la, a bɛ kɛ ka kɛɲɛ ni fɛn caman ye walima ka kɛ fɛn ye min bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye .

A bɛ sira di a ma ka a kunbɛn tigitigi ani ka a minɛ .

Otomatiki bɔli siraw .

ejector pins walima fɛɛrɛ wɛrɛw bɛ yɔrɔ in sama ka bɔ a yɛrɛma .

A ka ɲi kosɛbɛ ka ɲɛsin fɛn caman dilanni ma .

A bɛ a to a ka yɔrɔw bɔ ɲɔgɔn na cogo basigilen na ani cogo ɲuman na .

Otomatiki sitɛmuw kɔnɔ, ejector pinw bɛ baara kɛ ni mold da yera. U bɛ Taa fo ka Se 'kɔnɔna ma, k'u Gɛn ka Bɔ yɔrɔ jɔlen na. O yɔrɔ bɛ Bɔ o kɔ fɛ k'a Lajɛ ni 'fɛn ye min bɛ Kɛ 'fɛn ye min bɛ Se ka Kɛ 'fɛn ye walima ni 'sèn wɛrɛ ye min bɛ Kɛ ni 'sèn ye.

Pikiri molding design jateminɛw ka ɲɛsin ejector pins ma .

Angles de draft .

Nafa min bɛ draft angles la yɔrɔ dɔw bɔli la .

Angles de draft nafa ka bon pikiri kɛli la. U bɛ yɔrɔ mɔlenw bɔli nɔgɔya ka bɔ nɔgɔbɔlan kɔnɔ. Ni yɔrɔw tɛ, yɔrɔw bɛ se ka nɔrɔ nɔgɔ la, ka tiɲɛni ni fiɲɛ bila u la. Draft angles bɛ yɔrɔ bɔli nɔgɔya ani ka fanga dɔgɔya min ka kan ka kɛ walasa ka yɔrɔw bɔ.

Angle draft draft recommended .

Angle de draft recommendée bɛ danfara ka kɛɲɛ ni fɛn ye ani a yɔrɔ dilanni. A ka c’a la, 1 fo 2 degere kelen-kelen bɛɛ bɛ se ka kɛ. Yɔrɔ minnu bɛ ni sɛbɛnni ye, u bɛ se ka kɛ degere 3 fo 5 ye. Angles draft ɲumanw bɛ dɛmɛ ka yɔrɔ mɔlenw ka surface quality mara.

Uniform mur thickness .

ka a lajɛ ko fɛnw bɛ woyo ka ɲɛ ani ka u nɛnɛ .

Kogo janya kelen nafa ka bon kosɛbɛ walasa ka fɛn in boli ka ɲɛ ani ka a nɛnɛ. A bɛ nɛnɛ hakɛ basigilenw sabati ani ka fiɲɛw farati dɔgɔya i n’a fɔ kirinni ni dɔgɔyali. Kogo janya basigilen bɛ dɛmɛ ka se ka dugukolo sanfɛla fini ɲuman sɔrɔ ani ka a jɔcogo dafalen sɔrɔ.

Fura minnu bɛ kɛ ka kogow janya uniforme (kari ani gussets) .

Kogo kelen-kelen min tɛ kelen ye, o bɛ se ka ko dɔw lase molding (muli) kɛcogo la. Coring ye fura kelen ye, yɔrɔ min na fɛn bɛ bɔ yɔrɔmuguw la walasa kogow ka kɛ kelen ye. GUSSETS farali bɛ se ka dɛmɛ fana kɛ ni dɛmɛ ni dɔgɔyali ye a girinya caman ɲɔgɔnna dili la. O fɛɛrɛw bɛ a to hali ka nɛnɛ ani ka degunw dɔgɔya yɔrɔw la minnu dilannen don.

Edges ronds .

Nafa minnu bɛ sɔrɔ nkɔni bulama na yɔrɔ dɔ bɔli la .

Nkɔni bulama nafa ka bon yɔrɔ dɔw bɔli la. U bɛ dɔ bɔ degunw hakɛ la ani ka plastiki wulilenw bɔli ɲɛ ka taa nɔgɔ la. O bɛ na ni bɔli nɔgɔyali ye ani fiɲɛ dɔgɔyali. A dakunw fana bɛ tiɲɛni bali ka kɛ nɔgɔbɔlan kɔnɔ.

Gɛlɛya minnu bɛ sɔrɔ nkɔni nɔgɔlenw na .

Nkɔni nɔgɔlenw bɛ se ka kɛ sababu ye ka ko caman kɛ. U bɛ plastiki bɔli bali, o bɛ na ni nɔgɔ facogo dafabali ye. Nkɔni nɛrɛmugumaw fana bɛ dɔ fara degunw hakɛ kan, o bɛ kɛ sababu ye ka a yɔrɔw kɛ fɛn ye min ka teli ka kari. Ka fara o kan, u bɛ se ka nɔgɔ tiɲɛ, o bɛ na ni ladonni musakaw ye.

Undercut Reduction .

Undercuts (Dɔgɔya) nɔfɛkow yɔrɔ dɔ bɔli la .

A bɛ yɔrɔ bɔli taabolo gɛlɛya. U bɛ balilanw Dabɔ minnu bɛ yɔrɔ in bali ka Bɔ ka ɲɛ. O bɛ se ka kɛ sababu ye ka fiɲɛw sɔrɔ i n’a fɔ pinɛ taamasiɲɛw walima pin impressions. Dugukolo jukɔrɔla tigɛw fana bɛ dɔ fara nɔgɔ dilanni gɛlɛya n’a musaka kan.

Fɛɛrɛ minnu bɛ kɛ walasa ka fɛnw dɔgɔya minnu bɛ se ka kɛ .

Undercuts dɔgɔyali nafa ka bon yɔrɔ bɔli nafama na. Fɛɛrɛ dɔ ye ka yɔrɔ in labɛn kokura walasa ka tiɲɛni kunntanw ban. Fɛɛrɛ wɛrɛ ye ka baara kɛ ni kɛrɛfɛwalew ye walima ka fɛnw kɔrɔta mɔli kɔnɔ walasa ka u jukɔrɔla tigɛ minnu ka kan. Nin fɛɛrɛ ninnu bɛ dɛmɛ don ka fiɲɛw farati dɔgɔya ani ka bɔli kɛcogo ɲɛ.

Gate yɔrɔw .

Dabaw bilali ani u nɔfɛkow bɔli pinɛ taamasiyɛnw na .

Gate bilali bɛ nɔ bila yɔrɔ mɔlenw ka jogo la. Da minnu ma bila ka ɲɛ, olu bɛ se ka kɛ sababu ye ka pinɛ taamasiɲɛw walima pin indentations kɛ. Dadoncogo ɲuman bɛ a to hali nɔgɔ fa ani ka fiɲɛw dɔgɔya. Dabaw ka kan ka bila yɔrɔw la minnu bɛ se ka fɛnw bolicogo nɔgɔya ani ka yɔrɔw bɔ nɔgɔya la.

Baara kɛ ni Edge Gates ani Ejector PIN extensions ye .

Edge gates nafa ka bon ejector pin taamasiyɛnw dɔgɔyali la. U bɛ fɛnw bolicogo ɲɛsin dakunw ma, ka dɔ bɔ pin sɛbɛnniw sɔrɔli la yɔrɔ yetaw kan. Ejector pin extensions fana bɛ se ka dɛmɛ ni yɔrɔ in gɛrɛgɛrɛ ka bɔ yɔrɔw la minnu tɛ ye kosɛbɛ, o bɛ kɛ sababu ye ka dugukolo sanfɛla dafalen sɔrɔ.

Ejector Pin bilali ani a labɛncogo .

Ejector pin bilali ɲuman nafa ka bon kosɛbɛ yɔrɔ la min bɛ bɔ a la ani ka a tanga fiɲɛw ma. Nka, i bɛ se k’u bila yɔrɔ min na, i b’o dɔn cogo di? Fɛn caman bɛ na ni u ye.

Fɛn minnu bɛ nɔ bila ejector pin bilali la .

Parts complexité et de conception .

Yɔrɔ minnu ka gɛlɛn kosɛbɛ, olu bɛ se ka kɛ ni pinɛ caman ye .

Mold design bɛ pin yɔrɔw dictate minnu bɛ se ka kɛ .

Fɛn minnu bɛ kɛ ni fɛnw ye .

Fɛn dɔw ye 'stickier' ye ani a bɛ se ka kɛ ko u mago bɛ ejection force caman na .

Fɛn minnu ka nɔgɔn, olu bɛ se ka kɛ sababu ye ka pin tilatilali ka caya walasa ka tiɲɛni bali .

Ejector pin bilayɔrɔw .

Yɔrɔ janya pinɛw ni nɛnɛbɔlanw cɛ .

Pinɛw bilali yɔrɔ gɛlɛnw kan .

Focus pin bilali yɔrɔw kan i n’a fɔ dondaw, jɔlanw, ani kɔkiliw .

o yɔrɔw bɛ se ka fanga muɲu ka ɲɛ .

Aw bɛ aw yɛrɛ tanga bilali ma kuluw walima senw kan .

Nin ye tabali teliya ye min bɛ tali kɛ pin bilali la:

| Yɔrɔ min bɛ | pin bila yɔrɔ la |

| Yɔrɔ gɛlɛnw (inserts, ribs) . | I ka bila jɔyɔrɔ fɔlɔ la . |

| Surfaces fla . | Yɔrɔ ɲuman . |

| Sloped or step surfaces . | Aw bɛ aw yɛrɛ tanga ni aw bɛ se . |

| Kɛrɛfɛ nɛnɛ kanw . | Aw ye aw jija ka yɔrɔ janya . |

Nafa minnu bɛ sɔrɔ tuma caman na ani fura minnu bɛ tali kɛ ejector pins la .

I n’a fɔ ejector pins nafa ka bon cogo min na, u bɛ se ka fiɲɛ bila yɔrɔw la tuma dɔw la minnu dilannen don. Nka, aw kana aw hakili ɲagami! O koɲɛw bɛ se ka ɲɛnabɔ ni fɛɛrɛ ɲuman ye.

Ejector Pin Marks .

O denti fitininw bɛ i fan fɛ wa? A ka c’a la, u bɛ sɔrɔ ejector pins fɛ. Nin ye ko ye min bɛ se ka kɛ:

A sababuw:

Fɛn minnu bɛ ɲɛnabɔ:

Optimiser pin placement ka distribute fanga kelen na .

Aw bɛ bɔli fanga ladilan ka se a hakɛ fitinin ma .

Aw bɛ aw jija ka nɛnɛ waati bɛnnen sɔrɔ sani a ka bɔ .

Ejector pin kari .

Pinɛ karilenw bɛ se ka na ni sɛnɛfɛnw bɔli ye ka jɔ. Mun na u bɛ kari?

Kun minnu na:

Furakɛcogo:

Aw bɛ PIN material ani a hakɛ bɛnnen sugandi a kɛcogo la .

Aw bɛ bɔli fanga ladilan ani ka a lajɛ ni a tilali bɛ kɛ .

Aw bɛ to ka nɔgɔ yɔrɔw lajɛ ani ka u mara .

Jetting .

Jetting defauts bɛ sɔrɔ ni fɛn sɔgɔlen ma woyo ka ɲɛ ka don bɔgɔ la. O nɔ na, a 'jets' in, o bɛ kɛ sababu ye ka jibɔ siraw ye walima ka dugukolo dafabaliya.

A sababuw:

Labɛnni fɛɛrɛw:

Aw bɛ dɔ fara da hakɛ kan walasa ka se ka fɛnw bolicogo ɲuman sɔrɔ .

Aw bɛ pikiri teliya ni tansiyɔn ladilan .

Optimiser gate yɔrɔ hali fɛnw tilatilali .

Ejector Pins kinin fɛ sugandi i ka application kama .

Ka ejector pins dafalenw sugandi, o bɛ se ka kɛ i n’a fɔ i b’a ɲini ka pikirijikɛlan dɔ sɔrɔ binkɛnɛ na. Nka, aw kana aw hakili ɲagami! An bɛ yan walasa k’aw dɛmɛ ka sugandiliw kɛ.

Pin diamètre ani a bonya .

Bonya nafa ka bon ni ejector pins ye. Aw ye nin ko ninnu jateminɛ:

Diamètres belebelebaw bɛ fanga caman di ejection ma .

hakɛ fitininw bɛ pinɛ taamasiɲɛw yecogo dɔgɔya .

Aw bɛ pin hakɛ ni aw ka yɔrɔ wajibiyalenw bɛn .

Fanga wajibiyalenw .

Aw ka pinɛw ka kan ka barika sɔrɔ walasa ka bɔli kɛcogo ɲɛnabɔ k’a sɔrɔ u ma tiɲɛ. Aw ye aw hakili to a la ko:

Material Selection .

Ejector pin materials bɛɛ tɛ da ɲɔgɔn na. An ka sugandiliw dɔw suma ɲɔgɔn na minnu bɛ kɛ tuma caman na:

| Material | Tensile Strength (MPa) | nafaw . |

| inox . | 1900-2000 . | resistance de corrosion, durabilité . |

| Baarakɛminɛn nɛgɛ . | 1500 | Aw bɛ resistance don, toughness . |

| Teliyaba . | 3900 | Extreme wear resistance, ɲɛnamaya jan . |

Inox bɛ fanga ni sɔgɔli kɛcogo ɲuman di. Baarakɛminɛn nɛgɛ bɛ balansi di sɛgɛn ni gɛlɛya ma. Nɛgɛ teliyaba, n’a fanga tɛ se ka da a la, o ka ɲi kosɛbɛ baarakɛcogo caman na, minnu bɛ kɛ ni fɛn caman ye.

A laban na, ejector pin material right bɛ bɔ i mago kɛrɛnkɛrɛnnenw de la. Aw ye jateminɛ kɛ fɛn dilanni sigida la, fɛn min bɛ kɛ ka fɛn dilannenw kɛ, ani fɛn min bɛ kɛ ka fɛnw labɛn.

Ejector suguya wɛrɛw pikiri kɛli la .

Hali ni ejector pins ye ejector suguya caman ye, u dɔrɔn tɛ tulonkɛlaw ye tulon in na. An ka ejector suguya wɛrɛw lajɛ minnu bɛ se ka dɛmɛ don ka i ka mouding kɛcogo ɲɛ.

Ejector Manches .

Ejector sleeves bɛ i n’a fɔ ejector pins brothers (boli pinɛw) minnu bɛ lakana kojugu. U bɛ Kɛ kɛnɛma-bolo gɛlɛn ye ani pinɛ min bɛ Dòn a kɔnɔ.

Bolo bɛ pinɛ tanga sɛgɛn ni sɛgɛn ma, o b’a to u ka ɲi kosɛbɛ fɛnw dilanni na minnu bɛ kɛ ka fɛnw sɔgɔ. Ka fara o kan, bolokɔni dɛmɛ min bɛ fara a kan, o bɛ sira di pinɛ dilanni janya ma, min ka nɔgɔn.

Ejector plates .

Ni ejector pins ye sɔrɔdasiw ye, ejector plates ye jeneraliw ye. O platiw bɛ ejector pins caman minɛ u nɔ na, k’a lajɛ u bɛɛ bɛ baara kɛ ɲɔgɔn fɛ bɛnkan dafalen na.

Ejector plates nafa ka bon kɛrɛnkɛrɛnnenya la moule belebelebaw la minnu bɛ ni ejector pins caman ye. U bɛ basigi sabatilen di pinɛw ma ani ka dɛmɛ don ka bɔli fanga tila ɲɔgɔn na.

Ejector Blades .

Ejector blades bɛ i n'a fɔ ninjas ka ejection diɲɛ. U ye nɛgɛmugu finmanw ye minnu bɛ sɔgɔ ka don yɔrɔ sirilenw na, pinɛ basigilenw tɛ se ka taa yɔrɔ minnu na.

O nɛgɛw dafalen don yɔrɔw la minnu kɔkiliw ka surun walima minnu kɔnɔna ka dun. U bɛ bɔli fanga Kɛ yɔrɔba dɔ kan, o bɛ dɔ Bɔ a yɔrɔ tiɲɛni walima a tiɲɛni farati la.

Nin ye tabali teliyalen ye:

| Ejector suguya | Key Benefit . |

| Manches . | A bɛ pinɛw tanga sɛgɛn ma . |

| Plates . | A bɛ pinɛ caman minɛ a nɔ na . |

| Blades . | A bɛ bɛn yɔrɔ sirilenw na . |

Miirili laban .

Ejector pins nafa ka bon kosɛbɛ pikiri kɛli la. U bɛ yɔrɔ nɔgɔlenw bɔli sabati, ka yɔrɔ mɔlenw jogo n’u dafalen mara.

Fɛn minnu bɛ kɛ ka fɛnw dilan ani ka baara kɛ ni u ye, olu ye fɛnw ye minnu bɛ se ka kɛ ka fɛnw bɔ u la ani ka baara kɛ ni u ye, olu ye ka u bila yɔrɔ bɛnnen na, ka kogo janya kɛ kelen ye, ani ka baara kɛ ni pinɛ suguya ɲumanw ye. Angles draft, ka dɔ bɔ undercuts (dafalenw) la, ani strategic gate (gate) yɔrɔw fana bɛ ejection (bɔli) nafa bonya.

Baarakɛlaw minnu bɛ se kosɛbɛ, olu jɔyɔrɔ ka bon kosɛbɛ ejector pin dilancogo ɲuman na. U ka dɔnniya bɛ dɛmɛ don ka fɛn dilannenw sɔrɔ minnu ka ɲi kosɛbɛ, ni fiɲɛ bɛ sɔrɔ u la. Ejector pin dilanni ni a bilali ka ɲɛ, o nafa ka bon pikiri kɛcogo ɲuman na, min ka ɲi kosɛbɛ.

Aw mago bɛ pikiri kɛcogo la min bɛ se ka da a kan wa? Aw bɛ se ka jɛkulu MFG sɔrɔ yɔrɔ ɲumanw na sɔngɔw la minnu bɛ se ka ɲɔgɔn sɔrɔ. An ka jɛkulu min bɛ se kosɛbɛ, o bɛ jaabiw di waati kɔnɔ, waati bɛɛ. Aw ye aw bolo bɔ bi walasa ka baro kɛ aw ka poroze magow kan.