Masini bɛ tali Kɛ fɛn dilanni na yɔrɔ min na fɛn bɛ Bɔ baarakɛminɛn dɔ la walasa k’a Kɛ cogo ɲininen na. Nin bɔli fɛɛrɛ in bɛ baara kɛ ni tigɛminɛnw walima sɔgɔlifɛnw ye, o bɛ na ni fɛn tigitigi ni fɛn dafalen ye. A nafa ka bon kosɛbɛ yɔrɔw dilanni na iziniw kɔnɔ i n’a fɔ mobili, aerospace ani ɛntɛrinɛti. A ka c’a la, masinw bɛ baara suguya caman kɛ i n’a fɔ fɛnw tigɛli, u sɔgɔli, u sɔgɔli, ani u sɔgɔli, o bɛ kɛ sababu ye ka fɛn dilannikɛlaw bila ka yɔrɔ gɛlɛnw dilan ka ɲɛ.

Masini nafa ka bon fɛn dilanni na .

Masini jɔyɔrɔ ka bon bi fɛn dilanni na. A bɛ se ka kɛ sababu ye ka yɔrɔw dilan minnu ka ɲi kosɛbɛ, minnu bɛ dilancogo kɛrɛnkɛrɛnnenw dafa. Sosiyetew bɛ u jigi da masinw ka baarakɛcogo kan walasa ka a dɔn:

Masina yɔrɔw dilanni ka ɲi kosɛbɛ.

Tolerances sirilenw ani tiɲɛniw ka ɲɛsin ɲɔgɔn ma ani ka baara kɛ.

ladamuni ka ɲɛsin prototypes ma walima sɛnɛfɛnw bɔli hakɛ dɔgɔman ma.

Yɔrɔ minnu bɛ kɛ ka kɛɲɛ ni sariya ye, olu dilanni masala baara la, minnu bɛ kɛ izini suguya caman na.

Ni masinw ma kɛ, ka se ka tiɲɛni ni bɛnkan wajibiyalen sɔrɔ fɛn suguya caman na, o bɛna kɛ gɛlɛya ye.

Subtractive Manufacturing Process Overview .

Masina ye fɛn dilanni taabolo ye min bɛ Bɔ a la, o kɔrɔ ye ko a bɛ fɛnw Bɔ yen walasa ka cogoya ɲininen dɔ Dabɔ. O bɛ danfara Bɔ ni farali-walew ye i n’a fɔ 3D sɛbɛnni, yɔrɔ min na fɛn bɛ Fàra ɲɔgɔn kan layini fɛ. Masini bɔli bɛ kɛ ni fɛɛrɛ suguya caman ye ka kɛɲɛ ni baarakɛminɛn ye min bɛ kɛ ani fɛn min bɛ tigɛ. Baara minnu bɛ Kɛ ɲɔgɔn fɛ olu ye 'yɔrɔ-yɔrɔ-ko ye, baarakɛminɛn dɔ bɛ Yɛlɛma-yɛlɛma tigɛ-minɛn dɔ kan, ani sɔgɔli, o min bɛ Kɛ ni tigɛ-tigɛlan ye min bɛ Kɛ ni 'yɔrɔ caman ye walasa ka fɛnw Bɔ.

Subtractive process bɛ nin wale caman in kɛ:

Baarakɛminɛn dɔ bɛ sugandi (nɛgɛ, plastiki, walima fɛn min bɛ kɛ ka fɛnw kɛ ɲɔgɔn fɛ).

Fɛn bɛ bɔ ni tigɛ ye, ka a sɔgɔ, walima ka a sɔgɔ.

A yɔrɔ bɛ nɔgɔya walasa ka se ka cogoya laban ni a hakɛw sɔrɔ.

Nin wale in nafa ka bon walasa ka yɔrɔw dilan yɔrɔ minnu na muɲuli sirilenw ni fini ɲumanw bɛ ɲini yɔrɔ minnu na.

Laɲini jɔnjɔnw bɛ sɔrɔ bi masinw na .

1. Tiɲɛni cogoya ni a bonya .

Laɲini fɔlɔ bɛ sinsin jateminɛcogo tigitigiw sɔrɔli kan:

Siginiden gɛlɛnw dilanni min tɛ se ka dilan ni fɛn dilanni fɛɛrɛ wɛrɛw ye .

Tolerances dimensions sirilenw marali ka tɛmɛn fɛn caman dilanni kan .

ka a jira ko bɛnkan bɛ sɔrɔ yɔrɔ hakɛ la jamalajɛ wajibiyalenw kama .

ka jaabiw di minnu bɛ se ka segin-ka-bɔ .

2. Dimensional tiɲɛni .

Modern Machining Processes bɛ sumanikɛlan tigitigiw bila jɔyɔrɔ fɔlɔ la:

| Accuracy level | typical application | commun processus . |

| Ultra-précision . | Optical components . | Grinding précision . |

| Precision (Jɛkabaara) ka bon . | Avion yɔrɔw . | CNC Milling . |

| Sariya | Mobili yɔrɔw . | Laadalata jiginni . |

| Zenerali | Yɔrɔw jɔli . | Masini basigilen . |

3. Surface Quality Enhancement .

Surface finishing kuntilenna dɔw ye:

Ka se ka surface roughness requirements scients for functionals components .

Baarakɛminɛnw taamasiyɛnw bɔli ani u dilanni dafabaliya ka tɛmɛ kunnafoni tigitigiw kan .

ka ɲɛnajɛko wajibiyalenw dafa fɛn yetaw yɔrɔw la .

Ka dugukolo cogoya ɲumanw dilan fɛn dilanni taabolo nataw kama .

4. Fɛnw bɔli ka ɲɛ .

Strategic Material Removal Processes Aw ye a lajɛ ko:

Tigɛcogo ɲumanw walasa ka fɛn dilanni nafa bonya .

Tiɲɛni minnu ka dɔgɔn baarakɛminɛnw sira labɛnni tigitigi fɛ .

fanga dɔgɔyali min bɛ kɛ fɛn dilanni na .

Baarakɛminɛnw ɲɛnamaya janyalen tigɛcogo ɲuman fɛ .

Masini kɛcogo kɔrɔlenw .

Masini kɔrɔlen bɛ tali kɛ laadala baaraw la minnu bɛ fɛnw bɔ baarakɛminɛn dɔ la ni masinw ye. O fɛɛrɛw bɛ tali kɛ ɲɔgɔnkanu tilennen na tigɛminɛn ni baarakɛminɛn cɛ ka kɛɲɛ ni u cogoya, u bonya ani u laban yɔrɔw ye. U bɛ baara Kɛ kosɛbɛ fɛn dilanni na k’a sababu Kɛ u ka tiɲɛni n’u ka fɛn caman ye. Masina-taamacogo kɔrɔlenba dɔw ye fɛnw tigɛli, u sɔgɔli, u sɔgɔli ani u sɔgɔli ye, ani fɛn wɛrɛw.

Turning .

Yɛlɛma ye masina ye min bɛ Kɛ ni baarakɛminɛn ye ka sɔrɔ tigɛminɛn dɔ bɛ fɛn Bɔ a la. O kɛcogo in bɛ kɛ ka caya lathe machine kan. Tigɛminɛn bɛ to a jɔyɔrɔ la ni baarakɛminɛn bɛ wuli, o bɛ kɛ sababu ye ka kunnafoni tigitigi di fɛn in cogoya laban kan.

Aplikasi kunbabaw:

Silindriki yɔrɔw dilanni i n’a fɔ jirisunw, piniw, ani bololanɛgɛw .

Yɔrɔw dabɔli minnu bɛ kɛ ni jiri ye .

Fabrication of conical shapes .

Gɛlɛyaw:

Ka se ka fɛn caman ɲɛfɔ ka ɲɛ ani ka fini don .

Ka ɲɛsin yɛrɛyɛrɛw ni kumakanw ma .

Baarakɛminɛnw ɲɛnabɔli ni u kari .

Drilling .

Drilling ye wale ye min bɛ baara kɛ ni drill bitiki wulibali ye walasa ka silinda dingɛw dilan baarakɛminɛn kɔnɔ. O ye masinw ka baara dɔ ye min ka ca kosɛbɛ, wa a nafa ka bon kosɛbɛ ka dingɛw da sirilanw, pibilikiw ani fɛn wɛrɛw kama.

Aplikasi kunbabaw:

Dingɛw dilanni bololanɛgɛw, juruw ani fɛn wɛrɛw kama .

Dingɛw bɛ dilan pibilikiw ni kuranw kama .

Baarakɛminɛnw labɛnni masinko baara wɛrɛw kama .

Gɛlɛyaw:

Dingɛw ka tilennen ni u lamininen marali .

Ka drill kari ni a doncogo bali .

chip evacuation ani heat generation ɲɛnabɔli .

Taabataaba

Boring ye masina kɛcogo ye min bɛ dingɛw bonya ani ka u labɛn ka ɲɛ walasa u ka se ka u cɛmancɛ tigitigi sɔrɔ ani ka kɔnɔna yɔrɔw nɔgɔya. A ka ca a la, a bɛ kɛ sɔgɔli kɔfɛ walasa ka dingɛ tiɲɛni ni a labancogo ɲɛ.

Aplikasi kunbabaw:

A bɛ dingɛ tigitigiw dilan birikiw, bushingw ani fɛn wɛrɛw kama .

A bonya ani a laban dingɛw walasa ka bɛn ni baara kɛcogo ɲɛ .

Kɔnɔnatumuw ni fɛnw dilanni .

Gɛlɛyaw:

Concentricité ni alignment marali ni dingɛ fɔlɔ ye .

Contrôle de vibration et chatter pour la haute précision .

Baarakɛminɛn min bɛ se ka sɛgɛn, o sugandili ka ɲɛsin a kɛcogo ma ani a kɛcogo ma .

Reaming .

Reaming ye masina kɛcogo ye min bɛ baara Kɛ ni tigɛminɛn ye min da caman bɛ yen min bɛ Weele ko reamer walasa ka dingɛ dɔ sanfɛla ni a janya tiɲɛni ɲɛ ka ɲɛ. A ka ca a la, a bɛ kɛ sɔgɔli walima sɛgɛn kɔfɛ walasa ka muɲuli gɛlɛnw sɔrɔ ani ka yɔrɔw nɔgɔya.

Aplikasi kunbabaw:

Finishing Holes Walasa ka pinɛw, bololanɛgɛw ani fɛn wɛrɛw bɛn tigitigi .

Dingɛw ka dugukolo sanfɛla labɛnni ka ɲɛ walasa u ka baara kɛcogo ɲuman ni u yecogo .

Dingɛw labɛnni tapping ani threading operations .

Gɛlɛyaw:

Dingɛw ka tilennen ni u lamininen marali .

Reamer sɛgɛnni ni a kari bali .

Reamer bɛnnen sugandili ka ɲɛsin a kɛcogo ma ani a kɛcogo ma .

Milling .

Mili ye masinw ye minnu bɛ baara Kɛ ni fɛn caman tigɛli-minɛn ye min bɛ Yɛlɛma-yɛlɛma walasa ka fɛnw Bɔ baarakɛminɛn dɔ la. Baarakɛminɛn bɛ balo ni sɔgɔlilan ye min bɛ wuli ka wuli, o bɛ fɛn dɔw bɔ walasa ka cogoya ɲininen dilan.

Aplikasi kunbabaw:

A bɛ kɛ yɔrɔ fla ye, jirisunw, yɔrɔw, ani kontoronw .

Siginidenw ni fɛn gɛlɛnw dilanni .

Gesew, jiriw ani yɔrɔ wɛrɛw masinw dilanni masinw .

Gɛlɛyaw:

Dimensional accuracy ani surface finish .

Yɛrɛyɛrɛli ni kumakanw ɲɛnabɔli walasa ka tiɲɛniba sɔrɔ .

Milling tigɛlan bɛnnenw ni paramɛtiriw sugandili ka ɲɛsin fɛnw ni baarakɛcogo ma .

Grinding .

Grinding ye masina ye min bɛ baara kɛ ni abrasif wheel ye walasa ka fɛn fitininw bɔ baarakɛminɛn dɔ la. A ka ca a la, a bɛ kɛ finidoncogo ye walasa ka dugukolo sanfɛla finiko ɲɛ, a bonya tiɲɛni, ani ka buruburu walima dafabaliya fɛn o fɛn bɔ yen.

Aplikasi kunbabaw:

Finishing of flat ani silindaw .

Tigɛminɛnw nɔgɔyali n’u cogoya kura .

Surface Defects bɔli ani ka surface texture ɲɛ .

Gɛlɛyaw:

Sumaya ni funteni tiɲɛniw kɔlɔsili .

Ka wotoro balansi sabati ani ka yɛrɛyɛrɛli bali .

Abrasive wheel and paramètres bɛnnenw sugandili ka ɲɛsin a kɛcogo ma ani a kɛcogo ma .

Tapping .

Tapping (Tapping) ye kɔnɔna-fila-minɛnw dilanni taabolo ye ni baarakɛminɛn ye min bɛ Weele ko tap. Pompi bɛ wuli ka don dingɛ dɔ kɔnɔ min bɛ kɛ ka kɔn, ka jiriw tigɛ ka don dingɛ kɔnɔ.

Aplikasi kunbabaw:

ka dingɛw dilan minnu bɛ kɛ ni jiribolow ye, minnu bɛ kɛ ka fɛnw siri, ani ka fɛn wɛrɛw dilan .

Kɔnɔna jiriw dilanni fɛn suguya caman na, nɛgɛw ni plastikiw bɛ minnu na .

Fila tiɲɛnenw dilan .

Gɛlɛyaw:

Ka jiri tiɲɛni mara ani ka cross-threading bali .

ka pɔnpe kari bali, kɛrɛnkɛrɛnnenya la fɛn gɛlɛnw na .

ka a lajɛ ni dingɛ labɛnni bɛnnen don ani ni a bɛ se ka kɛ ni pɔnpe ye .

Planing .

Labɛnni ye masinko baara ye min bɛ baara kɛ ni baarakɛminɛn kelen ye walasa ka yɔrɔ fla dilan baarakɛminɛn dɔ kan. Baarakɛminɛn bɛ lamaga cogo la min bɛ tigɛtigɛminɛn jɔlen kan, ka fɛnw bɔ yen walasa ka flakɛli ni a hakɛw sɔrɔ minnu ka di.

Aplikasi kunbabaw:

A bɛ yɔrɔbaw dilan minnu ka bon i n’a fɔ masinw ani siraw .

Machining de dovetail slides et grooves .

Baarakɛminɛnw dakunw ni u dakunw sɔgɔli .

Gɛlɛyaw:

Ka se ka flakɛli ni paralɛliba sɔrɔ yɔrɔbaw kan .

Yɛrɛyɛrɛli ni kumakanw ɲɛnabɔli walasa ka surface finish smooth .

Baarakɛminɛn belebelebaw ni baarakɛminɛn girinmanw minɛni .

Knurling .

Knurling ye masina kɛcogo ye min bɛ layini tilennenw, kɛrɛw, walima tigɛlilenw cogoyaw dilan baarakɛminɛn dɔ sanfɛ. A ka ca a la, a bɛ kɛ ka a minɛcogo ɲɛ, ka a ɲɛnajɛcogo ɲɛ, walima ka yɔrɔ ɲuman di tulumafɛnw minɛni ma.

Aplikasi kunbabaw:

A bɛ grip surfaces (minɛyɔrɔw) dilan bololanɛgɛw kan, nɛgɛberew kan, ani yɔrɔ wɛrɛw silindaw kan .

Dekoratif finiw kan yɔrɔ suguya caman .

Ka yɔrɔw dilan walasa ka nɔrɔli walima tulumafɛnw marali ɲuman sɔrɔ .

Gɛlɛyaw:

Knurl ka misali ni a juguya sabatili sabatili .

Baarakɛminɛnw sɛgɛnni ni u kari .

Knurl ka pitch ni pattern bɛnnen sugandili ka ɲɛsin application ma .

Sawing .

Sɔgɔsɔgɔninjɛ ye masina baara ye min bɛ kɛ ni jirimugu ye walasa ka baarakɛminɛn dɔ tigɛ ka kɛ yɔrɔ fitininw ye walima ka slotw ni jirisunw dilan. A bɛ se ka kɛ ni jiri suguya caman ye, i n’a fɔ bandiw, jirisunw sɛrɛkiliw, ani hacksaw.

Aplikasi kunbabaw:

Fɛn minnu bɛ kɛ ka fɛnw tigɛ ka kɛ baarakɛminɛn misɛnninw ye .

Slots, grooves, ani cut-offs .

A yɔrɔw cogoya gɛlɛn sani u ka kɛ masin wɛrɛw ye .

Gɛlɛyaw:

Tigɛ tilennenw ni tilennenw sɔrɔli .

Minimizing burrs ani saw marks .

Saw blade ni paramɛtiri bɛnnenw sugandili ka ɲɛsin fɛnw ni baarakɛcogo ma .

Shaping .

Labɛnni ye masinko ye min bɛ baara kɛ ni baarakɛminɛn ye min bɛ ɲɔgɔn sɔrɔ yɔrɔ kelen na walasa ka tigɛcogo tilennenw ni yɔrɔ fla dilan baarakɛminɛn dɔ kan. Baarakɛminɛn bɛ Taa 'yɔrɔ la k'a sɔrɔ baarakɛminɛn bɛ To a jɔyɔrɔ la, ka fɛnw Bɔ ni 'sèn kelen-kelen bɛɛ ye.

Aplikasi kunbabaw:

Machining of keyways, slots, ani grooves .

A bɛ yɔrɔ fla ni kontoronw dilan .

Gear ɲinw ni splines (jiriw) dabɔli .

Gɛlɛyaw:

Dimensional accuracy ani surface finish .

Baarakɛminɛn minnu bɛ don ani ka kari .

Tigɛ paramɛtɛrɛw ɲɛnabɔli ka ɲɛ walasa ka fɛnw bɔ ka ɲɛ .

Broaching .

Broaching ye masina baara ye min bɛ baara kɛ ni tigɛminɛn ye min bɛ kɛ ni fɛn caman ye, n’o bɛ wele ko Broach, walasa ka fɛnw bɔ yen ani ka cogoya kɛrɛnkɛrɛnnenw dilan baarakɛminɛn kɔnɔ. Broach bɛ gɛrɛ walima ka sama ka tɛmɛ baarakɛminɛn fɛ, ka fɛn dɔw bɔ a la dɔɔnindɔɔnin ni ɲin kelen-kelen bɛɛ ye.

Aplikasi kunbabaw:

Kɔnɔna ni kɛnɛma fɛnw, splines, ani gear ɲinw dilanni .

A bɛ dingɛ tigitigiw Bɔ ni cogoya gɛlɛnw ye .

Slots, grooves, ani fɛn wɛrɛw minnu bɛ kɛ ni u ye, olu dilanni .

Gɛlɛyaw:

Baarakɛminɛnw musaka ka bon ka da broaches kɛrɛnkɛrɛnnenw kan .

Broach alignment ani rigidité marali walasa ka tigɛ tigitigiw sɔrɔ .

chip formation ani evacuation ɲɛnabɔli .

Honing .

Honing ye masinw ye minnu bɛ baara kɛ ni kabakurunw ye minnu bɛ kɛ ka fɛnw kɛ ka ɲɛ ani ka silindaw ka fɛnw sanfɛla dafa ani u hakɛ tiɲɛni. Honing baarakɛminɛn bɛ wuli ka wuli ka bɔ bore kɔnɔ, ka fɛn hakɛ fitininw bɔ walasa ka se ka laban ni a bonya ɲininen sɔrɔ.

Aplikasi kunbabaw:

Motɛri silindaw, birikiw, ani fɛn wɛrɛw minnu bɛ se ka kɛ fɛn wɛrɛw ye, olu laban .

Surface finish ɲɛnabɔli ani surface dafabaliya bɔli .

ka se ka muɲuli gɛlɛnw ni laminiw sɔrɔ .

Gɛlɛyaw:

ka to ka degun ni kabakurunw don .

Contrôle de cross-hatch angle ani surface fini .

ka kabakurunw ni paramɛtɛrɛw bɛnnenw sugandi minnu bɛ kɛ ka ɲɛsin fɛnw ni baarakɛcogo ma .

Gear tigɛcogo .

Gear tigɛ ye masinw dilanni ye min bɛ ɲinw dilan gesew kan ni tigɛminɛn kɛrɛnkɛrɛnnenw ye. A bɛ se ka kɛ ni fɛɛrɛ suguya caman ye, i n’a fɔ hobbing, shaping ani broaching, ka kɛɲɛ ni gear suguya ye ani a wajibiyalenw.

Aplikasi kunbabaw:

Spur, helical, bevel ani kɔnɔw dilanni .

Sprockets, splines, ani ɲinfɛn wɛrɛw dilanni masin na .

Kɔnɔna ni kɛnɛma minɛnw dabɔli .

Gɛlɛyaw:

ɲin ɲɛfɔli tiɲɛni ni a kelennasigi marali .

Aw bɛ ɲinw sanfɛla fini don ani ka girinw mankan dɔgɔya .

Gear tigɛcogo bɛnnen ani paramɛtiriw sugandili baarakɛcogo la .

Slotting .

Slotting ye masinko baara ye min bɛ baara kɛ ni tigɛminɛn ye min bɛ ɲɔgɔn ta walasa ka slots, grooves ani keyways dilan baarakɛminɛn dɔ kɔnɔ. Baarakɛminɛn bɛ Taa 'yɔrɔ la k'a sɔrɔ baarakɛminɛn bɛ To a jɔyɔrɔ la, ka fɛnw Bɔ yen walasa ka Kɛ fɛn ɲininen ye.

Aplikasi kunbabaw:

Machining of keyways, slots, ani grooves .

Kɔnɔna ni kɛnɛma splinew dabɔli .

A bɛ slots tigitigiw Bɔ ka ɲɛsin furuɲɔgɔnya yɔrɔw ma .

Gɛlɛyaw:

Slot width ani a juguya tiɲɛni marali .

Baarakɛminɛnw deflection ani yɛrɛyɛrɛli .

chip evacuation ɲɛnabɔli ani baarakɛminɛnw tiɲɛni bali .

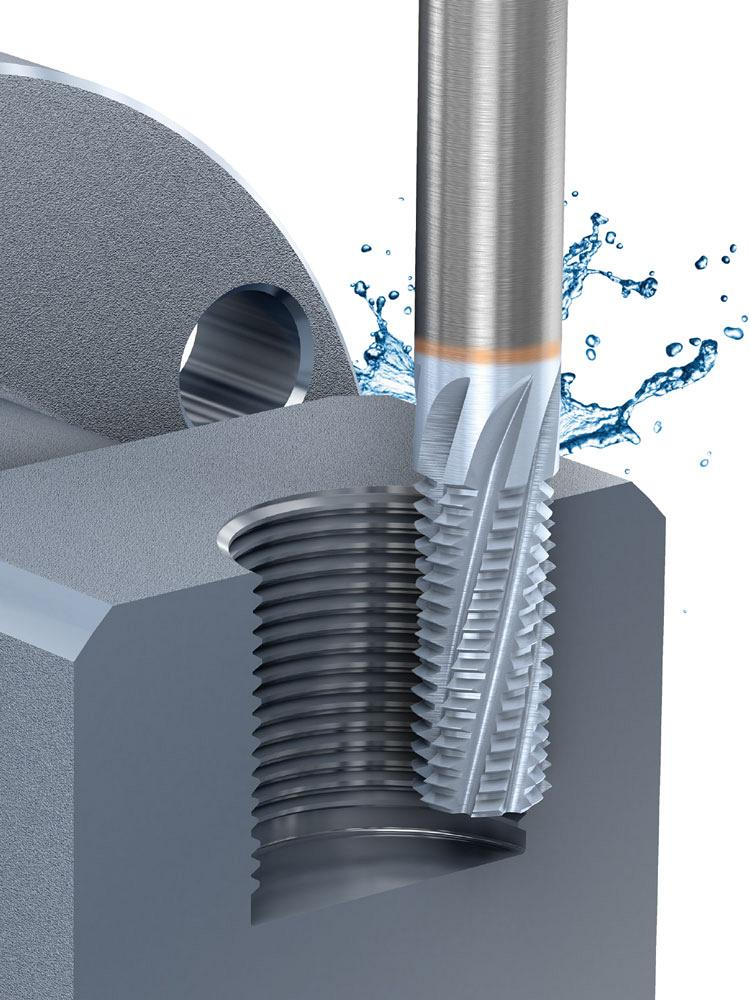

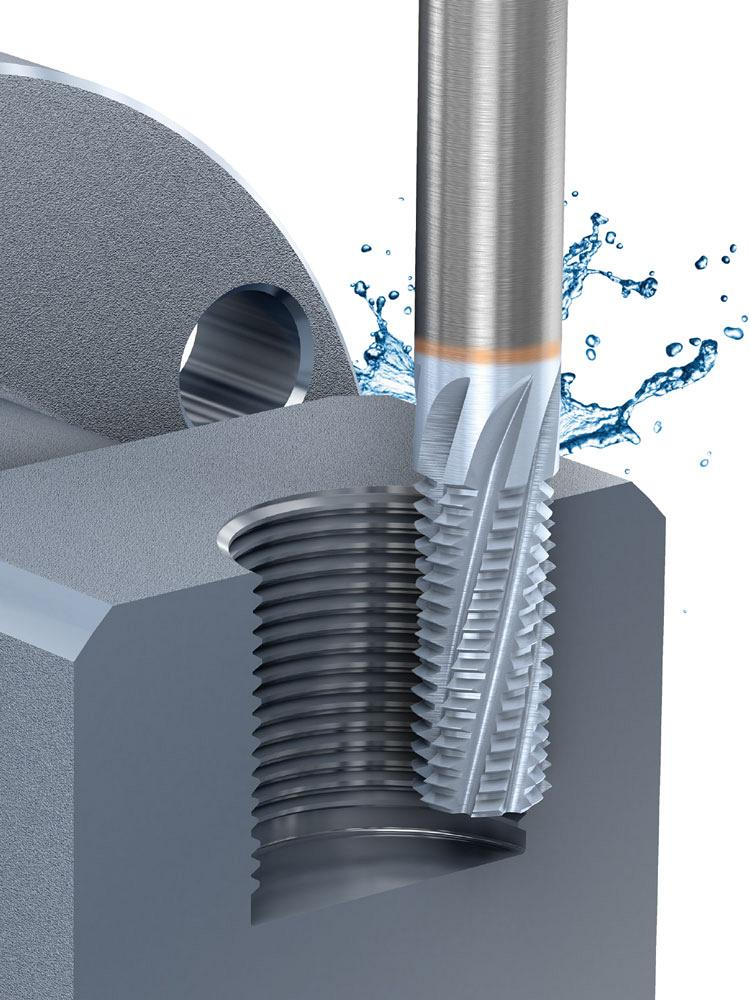

Threading .

Threading ye masina kɛcogo ye min bɛ kɛnɛma walima kɔnɔna jiriw Dabɔ baarakɛminɛn dɔ kan. A bɛ se ka kɛ ni fɛɛrɛ suguya caman ye, i n’a fɔ tapping, thread milling, ani thread rolling, ka kɛɲɛ ni jiri suguya n’a wajibiyalenw ye.

Aplikasi kunbabaw:

Fɛn minnu bɛ siri ni jiri ye, olu dilanni, i n’a fɔ bololanɛgɛw ni juruw .

Dingɛw dilan minnu bɛ siri ɲɔgɔn na walasa ka ɲɔgɔn lajɛ ani ka ɲɔgɔn sɔrɔ .

Machining of lead screws, worm gears, ani fɛn wɛrɛw minnu bɛ kɛ ni jiri ye .

Gɛlɛyaw:

Ka jirikurunw ka fɔcogo ɲuman mara ani ka u kɛ ɲɔgɔn fɛ .

Contrôle thread surface finish ani thread tiɲɛni bali .

Ka jirituru fɛɛrɛ bɛnnenw ni paramɛtɛrɛw sugandi minnu bɛ kɛ ka ɲɛsin fɛnw ni baarakɛcogo ma .

A ɲɛsinnen bɛ .

ƝƐFƆLI ye masinko baara ye min bɛ kɛ sababu ye ka yɔrɔ jɛlen dɔ da min bɛ jɔ baarakɛminɛn dɔ kan. A ka ca a la, a bɛ kɛ lathe walima milling machine kan walasa ka a dɔn ko a yɔrɔ dɔ laban ɲɛda bɛ nɔgɔya, ka kɛ fla ye, ani ka jɔ.

Aplikasi kunbabaw:

Aw bɛ jirisunw, pinɛw ani fɛn wɛrɛw dakunw labɛn minnu bɛ kɛ ni silinda ye .

Dakun flaw dabɔli ka ɲɛsin ɲɔgɔn ma yɔrɔw ni ɲɔgɔn cɛ .

Ka baarakɛminɛnw ɲɛda tilennenw ni u flakɛli sabati .

Gɛlɛyaw:

Ka flakɛli ni jɔli sabati ɲɛda bɛɛ kan .

Contrôle sur surface de surface ani ka chatter marks bali .

Baarakɛminɛnw ɲɛnabɔli ani tigɛcogo basigilenw sabatili .

counterboring .

Kɔrɔsili ye masinw dilanni ye min bɛ dingɛ dɔ yɔrɔ dɔ bonya min bɛ kɛ ka kɔn walasa ka fɛn dɔ dilan min bɛ duguma, o bɛ kɛ fɛn sirilan kun ye, i n’a fɔ bolokɔni walima kuru. A ka ca a la, a bɛ kɛ sɔgɔli kɔfɛ walasa ka a kɛ fɛn tigitigi ye min bɛ se ka kɛ fɛn ye min bɛ kɛ ka a siri.

Aplikasi kunbabaw:

Ka fɛnw dilan minnu bɛ kɛ ka bolo ni buruburuw kunw dilan .

ka clearance di nuts ni washers ma .

ka a jira ko fɛn sirilanw sigiyɔrɔ bɛnnen don ani u bɛ bɛn ɲɔgɔn ma .

Gɛlɛyaw:

Concentricité ni alignment marali ni dingɛ fɔlɔ ye .

Contrôle de contrôle de counterbore et diamètre accuratif .

Tigɛminɛn ni paramɛtiri bɛnnenw sugandili ka ɲɛsin fɛnw ni baarakɛcogo ma .

counterSinking .

counterSinking ye masinko baara ye min bɛ kɛ sababu ye ka fɛn dɔ kɛ min bɛ kɛ ni kon ye dingɛ dɔ sanfɛ walasa ka countersunk sirilan kunkolo ladon. A bɛ a to sirilan kunkolo ka sigi ni baarakɛminɛn sanfɛla ye walima a duguma, ka finimugu jɛlen ni aerodinamiki di.

Aplikasi kunbabaw:

Ka fɛnw dilan minnu bɛ kɛ ka fɛnw bila ɲɔgɔn na minnu bɛ kɛ ni fɛnw ye minnu bɛ kɛ ka fɛnw kɛ .

ka fini dɔ di min bɛ kɛ ka fɛnw falen walima ka a don a kɔnɔ.

Fɛn minnu bɛ kɛ ka aerodynamique (aerodynamique) kɛ ka ɲɛ .

Gɛlɛyaw:

A bɛ to ka kɛ countersink angle ni a juguya ye .

ka chipping walima breakout bali dingɛ da la .

Kontesink baarakɛminɛn ni paramɛtiri bɛnnenw sugandili ka ɲɛsin fɛnw ni baarakɛminɛnw ma .

Ja min bɛ kɛ .

Jala ye masinko ye min bɛ baara kɛ ni tigɛminɛn ye min bɛ kɛ ni nɛgɛ ye walasa ka tigɛcogo tigitigiw ni fɛn dɔw dilan minnu man dun, baarakɛminɛn dɔ sanfɛ. A bɛ se ka kɛ bolo la walima ka baara kɛ ni CNC masinw ye walasa ka dilanw, logow ani sɛbɛnni gɛlɛnw dilan.

Aplikasi kunbabaw:

dantigɛli taamasiyɛnw, seriyali nimɔrɔw, ani logow dilanni .

ka dekoratif patterns ni dilanw dilan fɛn suguya caman kan .

Moliw, dies ani baarakɛminɛn wɛrɛw ja .

Gɛlɛyaw:

Fɛn jalenw juguya ni u bonya basigilen marali .

Baarakɛminɛnw deflection ani vibration ka ɲɛsin dilancogo gɛlɛnw ma .

Jala-minɛn ni paramɛtɛrɛ bɛnnenw sugandili ka ɲɛsin fɛnw ni baarakɛcogo ma .

Masini kɛcogo minnu tɛ laadalako ye .

Masina-taamacogo minnu tɛ laadalako ye, olu bɛ tali kɛ fɛɛrɛw la minnu tɛ tali kɛ laadala tigɛminɛnw na. O nɔ na, u bɛ baara kɛ ni fanga suguya caman ye—i n’a fɔ kuran, kemikɛli, walima funteni— walasa ka fɛnw bɔ yen. O fɛɛrɛ ninnu nafa ka bon kɛrɛnkɛrɛnnenya la, fɛn gɛlɛnw dilanni na, jateminɛ gɛlɛnw, walima yɔrɔ nɔgɔlenw. U ka fisa ni fɛɛrɛ kɔrɔw ma ɲɛ ka da fɛnw gɛlɛya kan, u dilanni gɛlɛnw, walima dan wɛrɛw.

Nafa minnu bɛ sɔrɔ masinw na minnu tɛ laadalako ye .

Masini kɛcogo minnu tɛ laadalako ye, olu bɛ nafa caman di minnu b’a to u nafa ka bon kosɛbɛ fɛn dilanni na:

Fɛn gɛlɛn minnu bɛ kɛ ka fɛn gɛlɛnw kɛ i n’a fɔ funteni caman ani seramiki.

jɛɲɔgɔnya tilennen tɛ , min bɛ masinw ka degunw dɔgɔya. Baarakɛminɛn ni baarakɛminɛn cɛ

Se ka masinw cogoya gɛlɛnw kɛ ni kunnafoni gɛlɛnw ye ani muɲuli gɛlɛnw.

Farati min bɛ sɔrɔ funteni tiɲɛni na, o bɛ dɔgɔya ni a bɛ tali kɛ taabolo kɔrɔw la.

A bɛnnen don masinw ma minnu ka gɛlɛn , laadala fɛɛrɛw tɛ se ka minnu ɲɛnabɔ.

Kuran bɔli masin (EDM) .

EDM ka fɛɛrɛbɔ : EDM bɛ baara kɛ ni kuran bɔli ye min bɛ kɔrɔsi walasa ka fɛnw tiɲɛ ka bɔ baarakɛminɛn na. Baarakɛminɛn ni baarakɛminɛn bɛ ji la dielektriki ji la, wa spark gap bɛ u ni ɲɔgɔn cɛ, o bɛ arc misɛnninw bɔ minnu bɛ fɛnw bɔ.

EDM ka baarakɛcogo kunbabaw : EDM ka ɲi kosɛbɛ walasa ka cogoya gɛlɛnw dilan fɛn gɛlɛnw na, minnu bɛ se ka fɛnw ta. A bɛ kɛ ka caya nɔgɔ dilanni na, die jigincogo la, ani yɔrɔ gɛlɛnw dilanni na aerospace ani elekitoroniki baarakɛyɔrɔw la.

Gɛlɛyaw EDM baarakɛcogo la : .

Fɛnw bɔli hakɛ dɔɔni dɔɔni, kɛrɛnkɛrɛnnenya la baarakɛminɛnw kan minnu ka bon.

A bɛ kuran fɛ fɛnw de wajibiya, o bɛ dan sigi a caman na.

Machine de machine chimique .

Fɛɛrɛ min bɛ wele ko technique processus de machining chimique : Machinisation chimique, walima etching, o ye ka baarakɛminɛn su ji la, ka kɛ kemikaliya la walasa ka fɛn dɔw wuli ka bɔ u nɔ na. Masikiw bɛ yɔrɔw lakana minnu ka kan ka to u cogo la, ka sɔrɔ yɔrɔ minnu bɛ kɛnɛ kan, olu sɛbɛnnen bɛ ka taa yɔrɔ jan.

Machining kemikali baara kunbabaw : A bɛ kɛ ka misali gɛlɛnw dilan nɛgɛ finmanw kan, i n’a fɔ ɛntɛrinɛti baarakɛyɔrɔ la walasa ka ciriw walima fɛnw masirifɛnw dilan.

Gɛlɛya minnu bɛ sɔrɔ kemikɛli masinw baara la : .

Masina-minɛn min bɛ kɛ ni kuran ye (ECM) .

ECM ka fɛɛrɛbɔ : ECM bɛ fɛnw bɔ ni kuran-sɛnɛ ye. Kuran tilennen dɔ bɛ tɛmɛ baarakɛminɛn (Anode) ni baarakɛminɛn (katoli) cɛ elekitoroliti jilama kɔnɔ, ka fɛn in wuli.

ECM baarakɛcogo kunbabaw : ECM bɛ kɛ ka caya aerospace la nɛgɛ gɛlɛnw ni nɛgɛw dilanni na, i n’a fɔ turbine blades ani profiles complexes.

Gɛlɛyaw ECM baarakɛcogo la : .

Jet machining abrasive .

Technical process of abrasive jet machining : Nin wale in bɛ baara kɛ ni gazi teliyaba ye min ɲagaminen don ni fɛnɲɛnamafagalanw ye walasa ka fɛn dɔw tiɲɛ ka bɔ sanfɛ. Jet bɛ ɲɛsin baarakɛminɛn ma, ka fɛnw bɔ dɔɔnin dɔɔnin.

Abrasive jet machining baarakɛcogo kunbabaw : A ka ɲi baara nɔgɔlenw na i n’a fɔ deburring, saniya yɔrɔw, ani ka cogoya gɛlɛnw dilan minnu bɛ funteni sɔrɔ fɛnw kan i n’a fɔ seramiki ani gilasi.

Gɛlɛyaw bɛ sɔrɔ jet machining operations abrasive : .

Machining ultrasonic .

Fɛɛrɛ min bɛ wele ko ultrasonic machining : ultrasonic machining bɛ baara kɛ ni yɛrɛyɛrɛba ye min bɛ lase baarakɛminɛn dɔ fɛ walasa ka fɛnw bɔ yen. Abrasive slurry min bɛ baarakɛminɛn ni baarakɛminɛn cɛ, o bɛ baara dɛmɛ.

Ultrasonic machining baarakɛcogo kunbabaw : Nin fɛɛrɛ in ka ɲi kosɛbɛ masinw tiɲɛni ni fɛn gɛlɛnw na, i n’a fɔ seramiki ni gilasi, minnu bɛ kɛ tuma caman na ɛntɛrinɛti ni ɲɛkisɛw la.

Gɛlɛyaw minnu bɛ sɔrɔ ultrasonic machining operations kɔnɔ : .

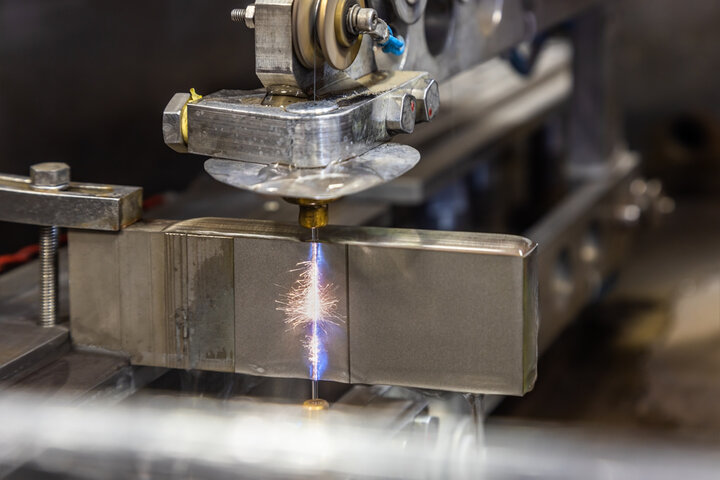

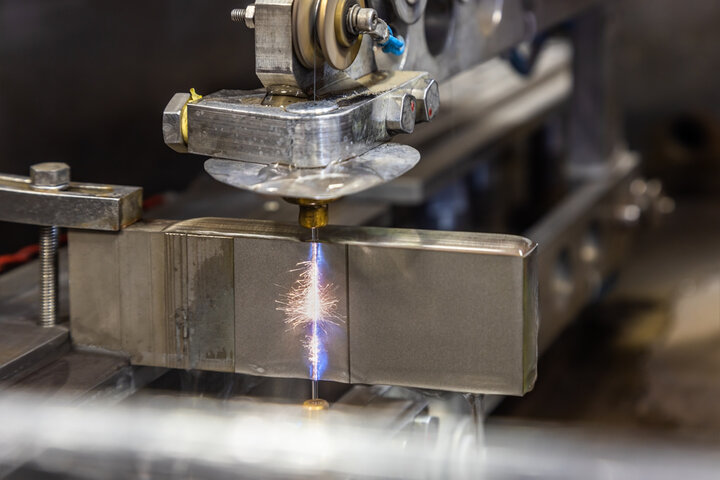

Laser beam machining (LBM) .

LBM ka fɛɛrɛbɔ : LBM bɛ baara kɛ ni laser-fiɲɛ ye min sinsinnen bɛ a kan walasa ka fɛn dɔw wuli walima ka u lamaga, ka tigɛ tigitigiw di k’a sɔrɔ u ma ɲɔgɔn sɔrɔ tigitigi. O ye wale ye min tɛ ɲɔgɔn sɔrɔ, min bɛ kɛ ni funteni ye.

LBM ka baarakɛcogo kunbabaw : LBM bɛ kɛ ka tigɛ, ka fɛnw tigɛ, ani ka taamasiyɛn kɛ iziniw kɔnɔ minnu bɛ tigitigi ɲini, i n’a fɔ mobili, furakɛli minɛnw, ani aerospace.

Gɛlɛyaw LBM baarakɛcogo la : .

Ji jet machining .

Ji jet machining fɛɛrɛ fɛɛrɛ : Ji jet machining bɛ baara kɛ ni ji ye min bɛ tansiyɔnba la, a ka ca a la a bɛ fara ɲɔgɔn kan ni fɛnɲɛnamafagalanw ye, walasa ka fɛnw tigɛ. O ye farigan tigɛcogo ye min bɛ i tanga funteni degunw ma.

Ji jet machining baarakɛcogo kunbabaw : A bɛ kɛ ka nɛgɛw, plastikiw, lastikuw, ani hali dumunifɛnw tigɛ, k’a kɛ fɛn ye min bɛ diya mobili, aerospace ani pakew dilanni na.

Gɛlɛya minnu bɛ ji jet machining baara la : .

Iyon Beam Machining (IBM) .

IBM ka fɛɛrɛtigɛ taabolo : IBM bɛ tali kɛ ionw ka jiribolo camanba la baarakɛminɛn sanfɛ, k’a jɔcogo caman sɛmɛntiya molekiyɔmu taabolow la, ka tɛmɛn bombe fɛ.

IBM ka baarakɛcogo kunbabaw : IBM bɛ kɛ ka caya ɛntɛrinɛti baara la walasa ka mikro-patɛriw kɛ semikɔndukiri fɛnw kan.

Gɛlɛyaw IBM baarakɛcogo la : .

Machining (PAM) min bɛ kɛ ni plasma ye (PAM) .

PAM ka fɛɛrɛbɔ : Pam bɛ baara kɛ ni gazi ionize (plasma) teliyaba ye walasa ka fɛnw wuli ani ka u bɔ baarakɛminɛn kɔnɔ. Plasma tasuma bɛ funteni jugumanba lase tigɛ ma.

PAM baarakɛcogo kunba : Pam bɛ kɛ ka nɛgɛ gɛlɛnw tigɛ ani ka u welding, kɛrɛnkɛrɛnnenya la nɛgɛ ni aliminiyɔmu, iziniw kɔnɔ i n’a fɔ kurunbokari ni jɔli.

Gɛlɛyaw PAM baarakɛcogo la : .

Elektɔronw dilannikɛlan (EBM) .

EBM ka fɛɛrɛbɔ : EBM bɛ baara kɛ ni ɛlektrɔniki teliyaba ye min sinsinnen bɛ fɛn kan walasa ka fɛnw lafiɲɛ ka bɔ baarakɛminɛn na. A bɛ kɛ yɔrɔ la min bɛ kɛ yɔrɔ la min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka ɲɛ.

EBM ka baarakɛcogo kunbabaw : EBM bɛ kɛ baarakɛminɛnw na minnu bɛ se ka kɛ kosɛbɛ i n’a fɔ drilling micro-holes in aerospace components ani furakɛli minɛn gɛlɛnw dilanni.

Gɛlɛyaw EBM baarakɛcogo la : .

Machining ka funteni .

Masini funteniman fɛɛrɛ : masin funteni bɛ kɛ ka baarakɛminɛn ni tigɛminɛn sumaya ka kɔn walasa ka fɛnw bɔli nɔgɔya, kɛrɛnkɛrɛnnenya la nɛgɛ gɛlɛnw na minnu bɛ kɛ ni masin ye.

Machining hot (masin funteni) baarakɛcogo kunbabaw : A bɛ kɛ superalloys (superalloys) ye aerospace (aerospace) la, yɔrɔ min na fɛnw bɛ kɛ masinw ye ka caya funteni caman na.

Gɛlɛya minnu bɛ sɔrɔ masinw na minnu bɛ wele ko hot machining operations : .

Magnétique Field Assisted Machining (MFAM) .

MFAM ka fɛɛrɛbɔ : MFAM bɛ baara kɛ ni magɛnni yɔrɔw ye walasa ka fɛnw bɔli sabati masinw kɛcogo la, ka juguya ni u bɔli hakɛw ɲɛ.

MFAM baarakɛcogo kunbabaw : A bɛ kɛ ka fɛn gɛlɛnw dilan ni masinw ye minnu fanga ka bon i n’a fɔ nɛgɛw ni fɛnɲɛnamafagalanw minnu bɛ kɛ ni fanga ye mobili ni aerospace seko ni dɔnko siratigɛ la.

Gɛlɛyaw MFAM baarakɛcogo la : .

Machining fotokimiki .

Fɛɛrɛbɔcogo min bɛ kɛ ni fotokimiki ye : fotokimiki masina bɛ baara kɛ ni yeelen ye walasa ka baarakɛminɛn yɔrɔ kɛrɛnkɛrɛnnenw datugu, o kɔfɛ, kemikɛli sɛgɛsɛgɛli bɛ kɛ ka fɛnw bɔ yɔrɔw la minnu bɛ kɛnɛ kan.

Photochimique machining baarakɛcogo kunbabaw : A bɛ kɛ ka nɛgɛ yɔrɔw dilan minnu ka fin, minnu tɛ burr ye, iziniw kɔnɔ i n’a fɔ ɛntɛrinɛti ni aerospace.

Gɛlɛyaw minnu bɛ sɔrɔ fotokimika masinko baarakɛcogo la : .

Machine de la décharge de la médiaux de la machine de la machine (WEDM) .

WEDM ka fɛɛrɛbɔ : WEDM bɛ baara kɛ ni nɛgɛ finman ye, kuran bɛ min na walasa ka fɛn dɔ tiɲɛ ni sɛgɛn ye, o bɛ sira di tigɛ gɛlɛnw ma ani muɲuli gɛlɛnw ma.

WEDM ka baarakɛcogo kunbabaw : WEDM bɛ kɛ nɛgɛ gɛlɛnw ni nɛgɛw dilanni na aerospace, furakɛli minɛnw, ani baarakɛminɛnw dilanni na.

Gɛlɛyaw WEDM baarakɛcogo la : .

Danfara min bɛ masinw ni masinw taabolo kɔrɔlenw ni kɔrɔlenw cɛ .

Masini kɛcogo bɛ se ka tila kuluba fila ye: a bɛ kɛ cogo kɔrɔ la ani a tɛ kɛ cogo la min tɛ fɛn ye. U fila bɛɛ jɔyɔrɔ ka bon kosɛbɛ bi fɛn dilanni na, u bɛ fɛɛrɛ kɛrɛnkɛrɛnnenw di fɛnw bɔli ma. Danfara minnu bɛ nin suguya fila ninnu cɛ, olu faamuyali bɛ dɛmɛ don fɛɛrɛ ɲuman sugandili la fɛn dilanni mago kɛrɛnkɛrɛnnenw na.

Danfaraba minnu bɛ masinw ni masinw cɛ minnu bɛ kɛ ka kɛɲɛ ni u ka baara ye ani minnu tɛ laadalako ye .

Masini kɔrɔlenw ni kɔrɔlenw tɛ kelen ye u ka fɛnw bɔcogo la, baarakɛminɛnw baaracogo la, ani fanga sɔrɔyɔrɔw la. Danfara jɔnjɔnw filɛ nin ye:

Nafaw ni dantigɛliw suguya kelen-kelen bɛɛ la .

Masina suguya fila bɛɛ n’u fanga n’u barika tɛ, ka kɛɲɛ ni a kɛcogo ye.

Nafa minnu bɛ sɔrɔ masin kɔrɔw la:

Baara musakaw dɔgɔyali : A ka c’a la, a musaka ka dɔgɔ ka da baarakɛminɛnw ni masinw sɔrɔli kan yɔrɔ bɛɛ.

Setup nɔgɔya : masinw ni baarakɛminɛnw baara ka nɔgɔn, o b’a to a bɛ se ka sɔrɔ fɛn dilanni sigida fanba la.

Teliyaba sɔrɔli : A bɛnnen don sɛnɛfɛnw bɔli ma ni fɛnw bɔli teliya ye.

Dantigɛli minnu bɛ kɛ masinw na minnu bɛ kɛ ka caya:

Danmafɛnw seko danma : A bɛ kɛlɛ kɛ ni masin gɛlɛnw ye i n’a fɔ seramiki walima composites.

Baarakɛminɛnw sɛgɛnni ni u ladonni : A bɛ baarakɛminɛnw sɔgɔli ni u falenni de wajibiya tuma bɛɛ ka da a kan u bɛ ɲɔgɔn sɔrɔ ni baarakɛminɛn ye.

Gɛlɛya bɛ masinw cogoya gɛlɛnw na : tigitigi ka gɛlɛn ka sɔrɔ u dilanni na minnu ka gɛlɛn walima minnu ɲɛfɔlen don kosɛbɛ.

Nafa minnu bɛ sɔrɔ masinw na minnu tɛ laadalako ye:

Can Machine Hard Materials : Taabolow i n’a fɔ EDM ani laser machining bɛ se ka baara kɛ nɔgɔya la fɛnw kan minnu ka gɛlɛn walima minnu bɛ kari.

Baarakɛminɛnw doncogo tɛ : baarakɛcogo minnu tɛ ɲɔgɔn sɔrɔ, baarakɛminɛn tɛ sɛgɛn farikolo la.

High Precision and Detail : A bɛ se ka kɛ ni masinw ye minnu ka ɲi kosɛbɛ ani ka jateminɛ gɛlɛnw sɔrɔ ni muɲuli gɛlɛnw ye.

Dan minnu bɛ masinw na minnu tɛ laadalako ye:

A musaka ka bon : A ka c’a la, a sɔngɔ ka gɛlɛn ka da fɛɛrɛ kɔrɔlenw kan ani fanga sɔrɔyɔrɔw kan minnu ka kan.

Fɛnw bɔli hakɛ minnu ka dɔgɔn : fɛɛrɛw minnu tɛ laadalako ye, i n’a fɔ ECM walima ji jet machining, olu bɛ se ka sumaya ni u bɛ tali kɛ laadala tigɛcogo la.

Setup complexe : A bɛ dɔnniya caman ɲini ani ka baara kɛcogo paramɛtiriw kan, i n’a fɔ kuran walima beam focus.

Tabali min bɛ tali kɛ ɲɔgɔn na

| , o bɛ kɛ ni | masinw ye minnu | bɛ kɛ ka masinw kɛ cogo kɔrɔ la . |

| Fɛnw bɔli fɛɛrɛ . | Mekaniki tigɛ walima abrasion . | Kuran, funteni, kemikɛli, walima fɛn min bɛ kɛ ka fɛnw sɔgɔ . |

| Baarakɛminɛn minnu bɛ sɔrɔ . | Contact direct ni baarakɛminɛn ye . | Non-Cotact (Kɛbaliya) fɛɛrɛ caman na . |

| Tiɲɛni . | A ka ɲi, nka a dan ye dilancogo gɛlɛnw ye . | A ka kan ka kɛ cogo min na, o bɛ bɛn cogoya gɛlɛnw ma . |

| Baarakɛminɛn don . | A bɛ to ka sɛgɛn ani ka a ladon . | Baarakɛminɛn don min ka dɔgɔ walima a tɛ don . |

| Materiel range . | A bɛnnen don nɛgɛw ni fɛn nɔgɔlenw ma . | A bɛ se ka kɛ masinw ye minnu ka gɛlɛn walima minnu bɛ tiɲɛ . |

| Sɔngɔ | Baara musakaw dɔgɔyali . | sanfɛ ka da a kan fɛɛrɛ kɔrɔlenw bɛ yen . |

| Teliya | Teliya ka ɲɛsin volume caman bɔli ma . | Fɛn minnu bɛ bɔ dɔɔnin dɔɔnin cogo caman na . |

Farankan

Nin gafe in ye masinw kɛcogo suguya caman sɛgɛsɛgɛ, i n’a fɔ fɛɛrɛ kɔrɔlenw ani fɛɛrɛ minnu tɛ kɛ cogo kɔrɔ la. Fɛɛrɛ kɔrɔlenw i n’a fɔ jiginni ni sɔgɔli bɛ tali kɛ masin fanga la, k’a sɔrɔ baarakɛcogo minnu tɛ laadalako ye i n’a fɔ EDM ani laser machining, olu bɛ kuran, kemikali walima funteni fanga baara.

Ka masinw kɛcogo ɲuman sugandi, o ye ko kɔrɔba ye. A bɛ nɔ bila fɛnw na minnu bɛ bɛn ɲɔgɔn ma, ka tiɲɛni kɛ, ani ka fɛn dilanni teliya. Sugandili ɲuman bɛ kɛ sababu ye ka baara kɛcogo ɲuman, musakabɔ, ani sɔrɔ ɲuman sɔrɔ fɛn dilanni na. Ni aw bɛ baara kɛ ni nɛgɛw ye, ni seramiki ye, walima ni fɛnɲɛnamafagalanw ye, ni aw ye fɛɛrɛ kelen-kelen bɛɛ fanga faamuya, o bɛ dɛmɛ ka ɲɛtaa ɲuman sɔrɔ.

Reference sources .

Taabataaba

Reaming .

Honing .

Gear tigɛcogo .

Machining ultrasonic .

CNC machining service ɲuman .

Knurling .

Broaching .