Machining de tɔk bɔt di we aw dɛn de mek tin dɛn usay dɛn de pul di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn want fɔ yuz fɔ mek dɛn ebul fɔ shep am insay di fɔm we dɛn want. Dis subtractive method de yuz kɔt tul ɔ abrasives, we de rilizɔt wan prɛsis ɛn finish prodak. I impɔtant fɔ mek kɔmpɔnɛnt dɛn na industri dɛn lɛk ɔtomotiv, ɛrospɛs, ɛn ilɛktroniks. Machining tipikli involv difrɛn opareshɔn dɛn lɛk fɔ tɔn, mil, drɔ, ɛn grind, alaw di manifakta dɛn fɔ prodyuz intrikɛt pat dɛn fayn fayn wan.

Impɔtant tin fɔ mek mashin na manufakchurin .

Machining de ple wan impɔtant pat pan di mɔdan manufakchurin. I de mek dɛn ebul fɔ mek ay-prɛsishɔn pat dɛn we de mit sɔm patikyula dizayn rikwaymɛnt dɛn. Di kɔmni dɛn kin abop pan mashin prɔses fɔ mek shɔ se:

Ay-kwaliti prodakshɔn fɔ mɛkanikal kɔmpɔnɛnt dɛn.

Tayt tolerans ɛn akkuracy fɔ asembli ɛn funkshɔnaliti.

Customization fɔ protɔtayp ɔ lɔw-volyum prodakshɔn.

Mass prodakshɔn fɔ standad pat dɛn we dɛn de yuz na difrɛn industri dɛn.

If dɛn nɔ yuz mashin, fɔ ajɔst di prɛsishɔn ɛn kɔnsistɛns we dɛn nid ɛn kɔnsistɛns akɔdin to difrɛn matirial dɛn go bi chalenj.

Subtractive Manufacturing Process Ovaviu .

Machining na sɔbtraktiv manufakchurin prɔses, we min se i de pul matirial fɔ mek wan shep we dɛn want. Dis difrɛn frɔm aditiv prɔses lɛk 3D printin, usay dɛn ad matirial layt bay layt. Subtractive machining involv difrɛn we dɛn dipen pan di tul we dɛn yuz ɛn di matirial we dɛn de kɔt. Di kɔmɔn opareshɔn dɛn na fɔ tɔn, usay wan wokpies de rɔta agens wan tul we dɛn de kɔt, ɛn mil, we de yuz wan multi-point cutter fɔ pul di matirial.

Di subtraktiv prɔses de fala dɛn jenɛral step ya:

Dɛn kin pik wan wokpies (mɛtal, plastic, ɔ kɔmpɔzit).

Dɛn kin pul tin dɛn bay we dɛn kɔt, drɔ, ɔ grind.

Di pat de rifin fɔ ajɔst di fayn fayn shep ɛn dimɛnshɔn dɛn.

Dis prɔses impɔtant fɔ mek pat dɛn usay tayt tolɛreshɔn ɛn ay kwaliti finish dɛn nid fɔ de.

Di men tin dɛn we dɛn want fɔ du na di mɔdan mashin .

1. Prɛsishɔn shep ɛn sayzin .

Di praymar gol de fos fɔ ajɔst di ɛksaktɔl jɔyometrik spɛsifikɛshɔn dɛn:

Fɔ mek kɔmpleks shep dɛn we nɔ pɔsibul fɔ mek tru ɔda we dɛn fɔ mek tin dɛn .

Mentɛn tayt dimɛnshɔnal tolɛreshɔn akɔdin to bɔku bɔku prodakshɔn batch dɛn .

Fɔ mek shɔ se kɔnsistɛns de insay kɔmpɔnɛnt sayzin fɔ asɛmbli rikwaymɛnt dɛn .

Delivering repeatable results in high-volume manufacturing scenarios .

2. Dimenshonal akkuracy .

Modern Machining Processes Prioritizy Exact Measurements:

| Akkurayt Level | Tipik Aplikeshɔn | Kɔmɔn Prɔses |

| Ultra-prɛsishɔn . | Optik komponent dɛn . | Prɛsishɔn grindin . |

| Ay Prɛsishɔn . | Di pat dɛn na di plen . | CNC mil di . |

| Advays | Awtomotiv Kɔmpɔnɛnt dɛn . | Tradishonal we de tɔn . |

| Kɔmɔn | Di pat dɛn we dɛn kin bil . | Besik mashin fɔ mek mashin . |

3. Surface kwaliti ɛnhansmɛnt .

Surface finishing objectives inklud:

Achieving spesifik surface roughness requirements fɔ funkshɔnal kɔmpɔnɛnt dɛn .

Eliminating tool maks ɛn manufakchurin imperfekshɔn dɛn tru prɛsis kɔntrol .

Mitin aesthetic rikwaymɛnt fɔ visible prodakt kɔmpɔnɛnt dɛn .

Krio optimal surface kondishɔn fɔ di sɔksɛkɛn manufakchurin prɔses dɛn .

4. Efisiɛns Matirial Rimov .

Stratejik matirial rimobul prɔses dɛn de mek shɔ se:

Optimal kot paramita fɔ maksimayz prodakshɔn efyushɔn .

Minimal west jenɛreshɔn tru prɛsis tulpat planin .

Ridyus ɛnaji kɔnsɔmshɔn di tɛm we dɛn de du di wok we dɛn de du fɔ mek tin dɛn .

Ekstend Tul Layf tru di rayt we fɔ kɔt di kɔndishɔn .

Kɔnvɛnshɔnal mashin prɔses dɛn .

Kɔnvɛnshɔnal mashin de tɔk bɔt tradishɔnal prɔses dɛn we de pul matirial frɔm wokpies we de yuz mɛkanikal we. Dɛn we dɛn ya kin abop pan dairekt kɔntakt bitwin wan tin we dɛn kin yuz fɔ kɔt ɛn di wok we dɛn fɔ du fɔ shep, saiz, ɛn fɔ dɔn di pat dɛn. Dɛn kin yuz dɛn bɔku bɔku wan na di manufakchurin bikɔs dɛn kɔrɛkt ɛn dɛn kin yuz dɛn bɔku bɔku wan. Di men tin dɛn we dɛn kin yuz fɔ mek mashin dɛn we dɛn kin yuz fɔ mek mashin dɛn na fɔ tɔn, drɔ, mil, ɛn grind, ɛn ɔda tin dɛn.

Fɔ tɔn .

Fɔ tɔn na mashin we dɛn kin yuz fɔ mek wan wok we dɛn kin yuz fɔ kɔt we dɛn de kɔt di tin dɛn we dɛn kin yuz fɔ kɔt tin dɛn kin pul tin dɛn we de insay de. Dis prɔses na kɔmɔn tin fɔ du pan lathe mashin. Di tul we dɛn de kɔt de kɔntinyu fɔ bi steshɔn as di wokpies de spin, we de alaw fɔ kɔntrol prɛsis kɔntrol oba di las shep fɔ di tin.

Men Aplikeshɔn dɛn:

Prodakshɔn fɔ silinda kɔmpɔnɛnt dɛn lɛk shaft, pin, ɛn bolt dɛn .

Krieshɔn fɔ di pat dɛn we gɛt trɛd .

Fabrikeshɔn fɔ kɔnik shep dɛn .

Chalenj dɛn:

Achieving High Precision ɛn Surface Finish .

Dil wit vaybreshɔn ɛn chata .

Managing tool wear ɛn Breakage .

Drilling .

Drilling na wan prɔses we de yuz wan rotating drill bit fɔ mek silindrikal ol dɛn na wan wokpies. Na wan pan di kɔmɔn mashin opareshɔn dɛn ɛn i impɔtant fɔ mek ol fɔ fastɛns, paip, ɛn ɔda kɔmpɔnɛnt dɛn.

Men Aplikeshɔn dɛn:

Krio ol fɔ bolt, skru, ɛn ɔda tin dɛn we dɛn kin yuz fɔ fast

Prodyuz ol fɔ paip ɛn ilɛktrik waya .

Pripia wokpies fɔ ɔda mashin opareshɔn dɛn .

Chalenj dɛn:

Mentɛn ol stret ɛn rawnd .

fɔ mek dɛn nɔ pwɛl di drɔl ɛn wɛr .

Manejin Chip Evakyueshɔn ɛn Ɔt Jɛnɛreshɔn .

Gens

Boring na mashin we de mek i big ɛn rifin di ol dɛn we dɛn dɔn drɔ bifo tɛm fɔ mek dɛn ebul fɔ gɛt prɛsis dayamita ɛn fɔ mek dɛn gɛt smɔl smɔl insay. Bɔku tɛm dɛn kin du am afta dɛn dɔn drɔ fɔ mek di ol kɔrɛkt ɛn dɔn di ol.

Men Aplikeshɔn dɛn:

we de mek prɛsis ol fɔ bia, bush, ɛn ɔda tin dɛn we de insay .

Enlarging ɛn finishing ol fɔ impɔtant fit ɛn funkshɔn .

Krio intanɛnt grov ɛn ficha dɛn .

Chalenj dɛn:

Mentɛn kɔnsɛntrisiti ɛn alaynɛshɔn wit di ɔrijinal ol .

Kɔntrolin vaybreshɔn ɛn chata fɔ ay prɛsishɔn .

Selekt di aprɔpriet boring tul fɔ di matirial ɛn aplikeshɔn .

Riaming .

Reaming na wan mashin we de yuz wan multi-edged cutting tool we dɛn kɔl reamer fɔ impɔtant di surface finish ɛn dimensional akkuracy fɔ wan ol we dɛn dɔn drɔ bifo tɛm. Bɔku tɛm dɛn kin du am afta dɛn dɔn drɔ ɔ boring fɔ ajɔst tayt tolɛreshɔn ɛn smol smol say dɛn.

Men Aplikeshɔn dɛn:

Fɔ dɔn di ol dɛn fɔ di rayt fit fɔ di pin dɛn, di bolt dɛn, ɛn ɔda tin dɛn we de insay

Impruv di surface finish of hols fɔ bɛtɛ pefɔmɛns ɛn apinans .

Pripia ol fɔ tap ɛn trɛd ɔpreshɔn .

Chalenj dɛn:

Mentɛn ol stret ɛn rawnd .

Fɔ mek dɛn nɔ wɛr reamer ɛn fɔ brok .

Selekt di aprɔpriet riam fɔ di matirial ɛn aplikeshɔn .

Milin fɔ mil .

Milin na wan mashin we de yuz wan rɔta malti-pɔynt kɔt tul fɔ pul matirial frɔm wan wokpies. Di wokpies de fid agens di rotating milling cutter, we chip away matirial fɔ mek di shep we dɛn want.

Men Aplikeshɔn dɛn:

we de mek flat say dɛn, grov dɛn, slot dɛn, ɛn kɔnto dɛn

Fɔ mek kɔmpleks shep ɛn ficha dɛn .

Machining of gears, threads, ɛn ɔda pat dɛn we nɔ izi fɔ ɔndastand .

Chalenj dɛn:

Mentɛn dimɛnshɔnal akkuracy ɛn sɔfays finish .

Managing Vibration ɛn Chatter fɔ Ay Prɛsishɔn .

Selekt di aprɔpriet mil kɔta ɛn paramita fɔ di matirial ɛn aplikeshɔn .

Grindin .

Grindin na mashin we de yuz wan abraziv wil fɔ pul smɔl smɔl tin dɛn frɔm wan wokpies. Bɔku tɛm dɛn kin yuz am as finish ɔpreshɔn fɔ mek di sɔfays finish bɛtɛ, dimɛnshɔnal akkuracy, ɛn pul ɛni burr ɔ imperfections.

Men Aplikeshɔn dɛn:

Finishing of flat ɛn silindrikal sɔfays dɛn .

Shap ɛn rishɛp di tin dɛn we dɛn de yuz fɔ kɔt .

Rimov difεkt dεm na di surface εn improv surface texture .

Chalenj dɛn:

Kɔntrolin Ɔt Jɛnɛreshɔn ɛn Tɛmral Damej .

Fɔ mek di wil balans ɛn fɔ mek di vaybreshɔn nɔ go bifo .

Selekt di aprɔpriet abraziv wil ɛn paramita fɔ di matirial ɛn aplikeshɔn .

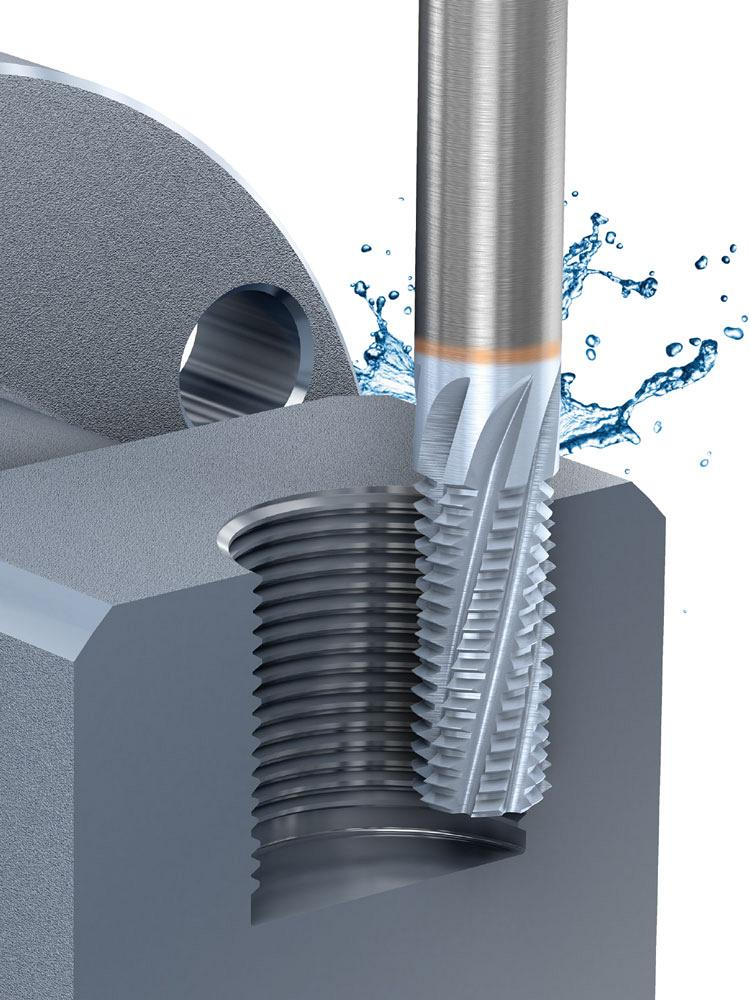

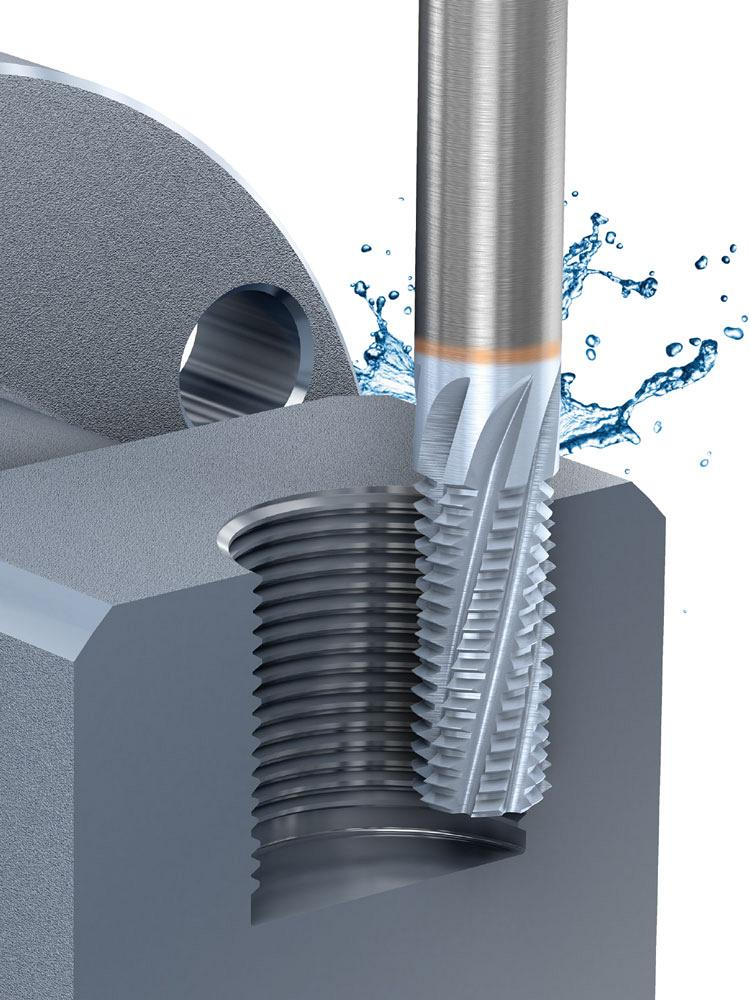

Tapping fɔ tap .

Tapping na di prɔses fɔ mek intanɛnt trɛd dɛn we yu de yuz wan tul we dɛn kɔl tap. Dɛn kin rɔta di tap ɛn drɛb am go insay wan ol we dɛn dɔn drɔ bifo tɛm, ɛn kɔt di trɛd dɛn na di ol in fes.

Men Aplikeshɔn dɛn:

Fɔ mek ol dɛn we gɛt trɛd fɔ bolt, skru, ɛn ɔda tin dɛn we dɛn kin yuz fɔ fast

we de mek intanɛnt trɛd dɛn na difrɛn tin dɛn, lɛk mɛtal ɛn plastic .

Ripairing Threads we dɔn pwɛl .

Chalenj dɛn:

Fɔ mek di trɛd kɔrɛkt ɛn fɔ mek dɛn nɔ krɔs-thrɛd .

Fɔ mek tap nɔ brok, mɔ na di had matirial dɛn .

Fɔ mek shɔ se dɛn pripia di ol ɛn tap di alaynɛshɔn fayn fayn wan ɛn tap .

Planin .

Planing na mashin opareshɔn we de yuz wan singl-pɔynt tul fɔ mek flat sɔfays pan wokpies. Di wokpies de muv linya agens di steshɔnari kɔt tul, pul matirial fɔ ajɔst di flat ɛn dimɛnshɔn dɛn we dɛn want.

Men Aplikeshɔn dɛn:

prodyuz big, flat surface lek mashin bed en ways

Machining fɔ Dovetail Slides ɛn Grooves .

Squaring of wokpies ɛnd ɛn edj dɛn .

Chalenj dɛn:

Achieving high flatness and parallelism ova big surfaces .

Managing Vibrations ɛn Chatter fɔ smol smol sɔfays finish .

Fɔ handle big ɛn ebi wokpies dɛn .

Knurling .

Knurling na wan mashin we de mek patɛn we gɛt stret, angul, ɔ krɔs layn dɛn na di say we dɛn de wok. Bɔku tɛm dɛn kin yuz am fɔ mek di grip, di fayn fayn tin dɛn we de de apin fayn fayn wan, ɔ fɔ mek dɛn gɛt bɛtɛ say fɔ ol lɔbrik.

Men Aplikeshɔn dɛn:

Produsing grip surfaces pan handel, knobs, ɛn ɔda silinda pat dɛn .

Dekorativ finish pan difrɛn komponent dɛn .

Krio Surface fɔ mek yu gɛt bɛtɛ adhesion ɔ fɔ kip lɔbrik .

Chalenj dɛn:

Mentɛn kɔnsistɛns knurl patɛn ɛn dip .

Fɔ mek di tul nɔ west ɛn fɔ mek dɛn nɔ pwɛl .

Selekt di aprɔpriet knurl pitch ɛn patɛn fɔ di aplikeshɔn .

Sawing .

Sawing na mashin opareshɔn we de yuz saw bled fɔ kɔt wan wokpies insay smɔl pat ɔ fɔ mek slot ɛn grov. Yu kin yuz difrɛn kayn saw dɛn, lɛk band saw, sɛkɔral saw, ɛn haksaw.

Men Aplikeshɔn dɛn:

Kɔt fɔ raw matirial dɛn insay smɔl smɔl wokpies dɛn .

Krio slot, grooves, ɛn kɔt-ɔf

Raf shep fɔ pat dɛn bifo dɛn mek mɔ mashin .

Chalenj dɛn:

Achieving strayt ɛn kɔrɛkt kɔt .

Minimizing Burrs ɛn Saw Mak dɛn .

Selekt di aprɔpriet saw bled ɛn paramita fɔ di matirial ɛn aplikeshɔn .

Shaping we dɛn de shep .

Shep na mashin prɔses we de yuz wan reciprocating single-point tul fɔ mek linya kɔt ɛn flat sɔfays pan wokpies. Di tul de muv linya we di wokpies de kɔntinyu fɔ de steshɔn, i de pul matirial wit ɛni strɔk.

Men Aplikeshɔn dɛn:

Machining fɔ di ki-we dɛn, di slot dɛn, ɛn di grov dɛn .

Prodyuz flat sɔfays ɛn kɔntɔ .

Krio gia tit ɛn splayn .

Chalenj dɛn:

Mentɛn dimɛnshɔnal akkuracy ɛn sɔfays finish .

Kontrolin Tul Wear ɛn Breakage .

Optimizing cutting parameters fɔ efishɔnal matirial rimɔv .

Broching we dɛn de yuz .

Broaching na mashin opareshɔn we de yuz wan tin we dɛn kin yuz fɔ kɔt bɔku tin dɛn, we dɛn kɔl Broch, fɔ pul di tin dɛn we dɛn de yuz fɔ mek tin dɛn ɛn mek sɔm patikyula shep dɛn na wan wokpies. Dɛn kin push ɔ pul di brɔch tru di wok, ɛn pul di tin dɛn we dɛn kin yuz smɔl smɔl wit ɛni tut.

Men Aplikeshɔn dɛn:

Fɔ mek intanɛnt ɛn ɛksternal ki-we, splayn, ɛn gia tit .

Prodyuz prɛsis ol dɛn wit kɔmpleks shep dɛn .

Machining of slots, grooves, ɛn ɔda tin dɛn we gɛt shep .

Chalenj dɛn:

Ay tul kɔst bikɔs ɔf spɛshal brɔch dɛn .

Mentɛn Broach alaynɛshɔn ɛn rigiditi fɔ kɔrɛkt kɔt .

Manejin Chip Fɔmeshɔn ɛn Ɛvakyushɔn .

Honing we de na di wɔl .

Honing na wan mashin prɔses we de yuz abrasive ston fɔ impruv di surface finish ɛn dimensional akkuracy fɔ silindrikal bors. Di honing tul de rotate ɛn oscillate insay di bore, pul smɔl smɔl matirial fɔ ajɔst di finish ɛn saiz we yu want.

Men Aplikeshɔn dɛn:

Fɔ dɔn di injin silinda dɛn, di bia dɛn, ɛn ɔda prɛsishɔn bor dɛn

Fɔ mek di sɔfays dɔn ɛn fɔ mek di say dɛn we dɛn nɔ pafɛkt dɔn mek di say dɛn we dɛn de liv bɛtɛ .

Achieving tayt tolerans ɛn rawndnɛs .

Chalenj dɛn:

Mentɛn kɔnsistɛns honing prɛshɔn ɛn ston wear .

Kontrolin kros-hatch angle en surface finish

Selekt di aprɔpriet honing ston ɛn paramita fɔ di matirial ɛn aplikeshɔn .

Gia fɔ kɔt .

Gia kɔt na mashin prɔses we de mek di tit dɛn pan gia dɛn we de yuz spɛshal kɔt tul dɛn. Yu kin du am bay we yu de yuz difrɛn we dɛn, lɛk fɔ ɔb, shep, ɛn broch, dipen pan di kayn gia ɛn wetin yu nid.

Men Aplikeshɔn dɛn:

Prodakshɔn fɔ Spur, Hɛlikal, Bɛvɛl, ɛn Wom Gia dɛn

Machining of sprockets, splines, ɛn ɔda tin dɛn we gɛt tut .

Krieshɔn fɔ intanɛnt ɛn ɛksternal gia tit dɛn .

Chalenj dɛn:

Mentɛn di tut profayl akkuracy ɛn yunifɔmiti .

Kɔntrol di tut sɔfays finish ɛn minimiz gia nɔys .

Selekt di aprɔpriet gia kɔt mɛtɔd ɛn paramita fɔ di aplikeshɔn .

Slotting na na na na na na na na na na na na na na na .

Slotting na mashin opareshɔn we de yuz wan reciprocating cutting tool fɔ mek slot, grooves, ɛn kiways insay wan wokpies. Di tul de muv linya wan we di wokpies de kɔntinyu fɔ de steshɔn, i de pul di matirial fɔ mek di ficha we dɛn want.

Men Aplikeshɔn dɛn:

Machining fɔ di ki-we dɛn, di slot dɛn, ɛn di grov dɛn .

Krio intanɛnt ɛn ɛksternal splayn dɛn .

Prodyuzin prɛsis slot fɔ mating kɔmpɔnɛnt dɛn .

Chalenj dɛn:

Mentɛn di slot wid ɛn dip akkuracy .

Diflɛshɔn fɔ kɔntrol tul ɛn vaybreshɔn .

Manejin Chip Evakyueshɔn ɛn Prɛvent Tul Brek

Threading we dɛn de trɛd .

Threading na mashin we de mek tin dɛn we de na do ɔ we de insay di trɛd dɛn na wokpies. Yu kin du am bay we yu de yuz difrɛn we dɛn, lɛk tap, trɛd mil, ɛn trɛd rɔlin, dipen pan di kayn trɛd ɛn wetin yu nid.

Men Aplikeshɔn dɛn:

Prodakshɔn fɔ di fastɛns dɛn we gɛt trɛd, lɛk bolt ɛn skru dɛn .

Krio threaded hols fɔ asembli ɛn mating komponent dɛn .

Machining of lid skru, wom gia, ɛn ɔda tin dɛn we gɛt trɛd

Chalenj dɛn:

Mentɛn thread pitch akkuracy ɛn kɔnsistɛns .

Kontrolin thread surface finish en prevent thread damej .

Selekt di aprɔpriet trɛdin mɛtɔd ɛn paramita fɔ di matirial ɛn aplikeshɔn .

we de fes .

Fεs na wan mashin כpεrayshכn we de mek wan flat sεf we de pεrpindikul to di aks fכ rotεshכn pan wokpies. Dɛn kin du am pan mashin ɔ mil mashin fɔ mek shɔ se di ɛnd fes dɛn na wan pat smɔl, flat, ɛn pɔrpindikul.

Men Aplikeshɔn dɛn:

Pripia di ɛnd dɛn fɔ shaft, pin, ɛn ɔda silinda kɔmpɔnɛnt dɛn .

Krio flat surface fɔ mating pat ɛn asɛmbli .

Fɔ mek shɔ se dɛn de pepɛndikul ɛn flat di wokpies fes dɛn .

Chalenj dɛn:

Mentɛn flatnɛs ɛn pɔrpindikul ɔva di wan ol fes .

Fɔ kɔntrol di say we di wɔl de dɔn ɛn fɔ mek dɛn nɔ gɛt chata mak dɛn .

Manejin tul wear ɛn mek shɔ se kɔnsistɛns kɔt kɔndishɔn dɛn de .

Counterboring .

Counterboring na mashin we de mek wan pat pan wan ol we dɛn dɔn drɔ bifo tɛm fɔ mek wan flat-bɔt rɛs fɔ di ed fɔ wan fastɛns, lɛk bolt ɔ skru. Bɔku tɛm dɛn kin du am afta dɛn dɔn drɔ fɔ gi wan prɛsis, flush fit fɔ di fastɛn ed.

Men Aplikeshɔn dɛn:

Krio recesses fɔ bolt ɛn skru ed dɛn .

Fɔ gi kliarens fɔ nɛt ɛn was mashin .

Fɔ mek shɔ se dɛn sidɔm fayn ɛn alaynɛshɔn fɔ di fastɛns dɛn .

Chalenj dɛn:

Mentɛn kɔnsɛntrisiti ɛn alaynɛshɔn wit di ɔrijinal ol .

Kontrolin Counterbore Dip ɛn Dayamita Akkurayt

Selekt di aprɔpriet kɔt tul ɛn paramita fɔ di matirial ɛn aplikeshɔn .

Kɔntrɛsinin .

Countersinking na wan mashin opareshɔn we de mek wan kɔnik rɛs na di tap pan wan ol we dɛn dɔn drɔ bifo tɛm fɔ akɔmod di ed fɔ wan kɔwntasɔnk fastɛn. I de alaw di fastɛns ed fɔ sidɔm flush wit ɔ dɔŋ di wokpies sɔfa, we de gi wan smol ɛn aerodaynamik finish.

Men Aplikeshɔn dɛn:

Krio recesses fɔ countersunk skru ɛn rivets .

we de gi wan flush ɔ recessed finish fɔ fasteners .

Improving di aerodynamic prɔpati dɛn fɔ di kɔmpɔnɛnt dɛn .

Chalenj dɛn:

Mentɛn kɔnsistɛns kɔwntasink angul ɛn dip .

Fɔ mek dɛn nɔ chip ɔ brok na di ol ɛntrɛt .

Selekt di aprɔpriet Kɔntasink tul ɛn paramita fɔ di matirial ɛn aplikeshɔn .

Engraving .

Engraving na mashin prɔses we de yuz shap kɔt tul fɔ mek prɛsis, shalo kɔt ɛn patɛn na di surface fɔ wan wokpies. Yu kin du am wit yu an ɔ yu kin yuz CNC mashin dɛn fɔ mek dɛn mek difrɛn difrɛn dizayn dɛn, logo dɛn, ɛn tɛks.

Men Aplikeshɔn dɛn:

Fɔ mek mak dɛn we de sho udat pɔsin bi, fɔ sho di siriɔs nɔmba dɛn, ɛn di logo dɛn .

Prodyuz dekorativ patɛn ɛn dizayn pan difrɛn matirial dɛn .

Engraving of mold, days, ɛn ɔda tin dɛn we dɛn kin yuz fɔ tul dɛn

Chalenj dɛn:

Mentɛn kɔnsistɛns dip ɛn wit fɔ di ficha dɛn we dɛn rayt pan .

Kontrolin tul diflekshɔn ɛn vaybreshɔn fɔ intrikɛt dizayn dɛn .

Selekt di aprɔpriet engraving tul ɛn paramita fɔ di matirial ɛn aplikeshɔn .

Nɔn-kɔnvɛnshɔnal mashin prɔses dɛn .

Nɔn-kɔnvɛnshɔnal mashin prɔses dɛn involv tɛknik dɛn we nɔ de abop pan tradishɔnal kɔt tul dɛn. Bifo dat, dɛn kin yuz difrɛn we dɛn fɔ gɛt pawa—lɛk ilɛktrik, kemikal, ɔ tɛmral—fɔ pul di tin dɛn we dɛn yuz fɔ mek di tin dɛn. Dɛn we ya kin rili ɛp fɔ mek mashin dɛn we gɛt had tin dɛn, kɔmpleks jɔyometri, ɔ dilik pat dɛn. Dɛn kin lɛk dɛn we di kɔmɔn we dɛn nɔ kin wok bikɔs ɔf di tin dɛn we dɛn kin yuz fɔ mek tin dɛn, di kayn we aw dɛn mek dɛn, ɔ ɔda tin dɛn we dɛn nɔ kin ebul fɔ du.

Advantej dɛn fɔ nɔ-kɔnvɛnshɔnal mashin .

Nɔn-kɔnvɛnshɔnal mashin prɔses dɛn de gi sɔm bɛnifit dɛn we de mek dɛn impɔtant fɔ mek dɛn mek advans:

Prɛsishɔn mashin fɔ had matirial dɛn lɛk ay-tɛmpracha alɔy ɛn sɛramik.

Nɔ dairekt kɔntakt bitwin di tul ɛn wokpies, minimiz mɛkanikal strɛs.

Abiliti fɔ mashin kɔmpleks shep dɛn wit intrikɛt ditil ɛn tayt tolɛreshɔn.

Ridyus risk fɔ tɛmral distɔshɔn kɔmpia to kɔvɛnshɔnal prɔses.

I fayn fɔ di tin dɛn we nɔ izi fɔ mek dɛn yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn, we dɛn kin yuz fɔ du tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn nɔ kin ebul fɔ du trade trade.

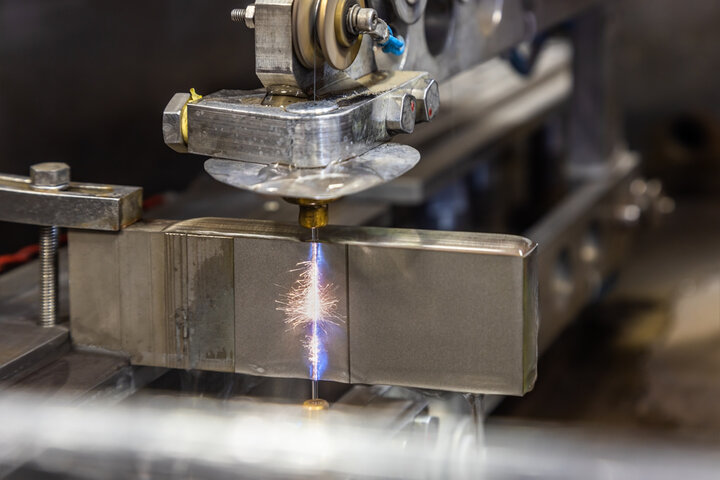

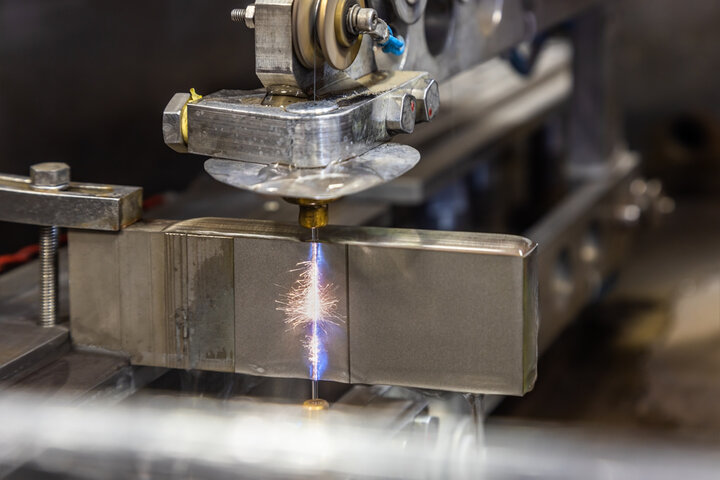

Ilektrikal dischaj mashin (EDM) .

Teknik prɔses fɔ EDM : EDM de yuz kɔntrol ilɛktrik dischaj fɔ ɛrɔd matirial frɔm di wokpies. Di tul ɛn wokpies dɛn de ɔnda wata insay wan dayelɛktrik fluid, ɛn wan spak gap bitwin dɛn de mek smɔl smɔl ak dɛn we de pul matirial.

Main Applications of EDM : EDM na fayn tin fɔ prodyuz kɔmpleks shep dɛn na had, kɔnduktiv matirial dɛn. Dɛn kin yuz am fɔ mek mold, fɔ sink, ɛn fɔ mek pat dɛn we gɛt difrɛn difrɛn pat dɛn na di erospace ɛn ilɛktroniks industri.

Chalenj dɛn na EDM Opareshɔn dɛn :

Slow material removal rates, espeshali pan tik wokpies.

nid fɔ gɛt ilɛktrik kɔnduktiv matirial dɛn, we de limited in versatility.

Kεmikכl Machining .

Teknik prɔses fɔ kemikal mashin : kemikal mashin, ɔ etch, involv fɔ put di wokpies insay kemikal bat fɔ sɛlektiv disɔl matirial. Masks de protɛkt di say dɛn we nid fɔ de intakt, we di eria dɛn we de na do de etch away.

Main Applications of Chemical Machining : Dɛn kin yuz am fɔ mek intrɛst patɛn pan tin mɛtal pat dɛn, lɛk na di ilɛktroniks industri fɔ mek sɔrkwit bɔd ɔ fɔ dekɔretiv kɔmpɔnɛnt dɛn.

Chalenj dɛn we de na di kemikal mashin ɔpreshɔn dɛn :

Ilɛktrɔkɛmikɛl mashin (ECM) .

Teknik prɔses fɔ ECM : ECM de pul matirial yuz wan ilɛktrɔkɛmik riakshɔn. Wan dairekt kɔrɛnt de pas bitwin di wokpies (anod) ɛn di tul (katɔd) insay wan ilɛktrɔlayt sɔlvushɔn, we de sɔlv di matirial.

Main Applications of ECM : ECM na ples we bɔku pipul dɛn kin yuz na aerospace fɔ mashin had mɛtal ɛn alɔy, lɛk tɔbayn bled ɛn kɔmpleks profayl.

Chalenj dɛn na ECM Opareshɔn dɛn :

Abrasive jet we de mek lɛk se na mashin .

Teknikal proses fɔ abrasive jet mashin : Dis prɔses de yuz wan ay-vɛlositi strim fɔ gas miks wit abrasive patikyula fɔ erode matirial frɔm di sɔfa. Di jet de dayrɛkt to di wokpies, smɔl smɔl i de pul matirial.

Main Applications of Abrasive Jet Machining : I fayn fɔ diliket opareshɔn dɛn lɛk fɔ pul di wata we de kɔmɔt na di bɔdi, fɔ klin di say dɛn we dɛn de yuz fɔ klin, ɛn fɔ mek intrɛst patɛns dɛn pan tin dɛn we de mek pɔsin fil lɛk se na sɛramik ɛn glas.

Chalenj dɛn na Abrasive Jet Machining Opareshɔn dɛn :

Ultrasonic Machining na na na na na na na na na na na na na na na .

Teknikal prɔses fɔ ɔltrasɔnik mashin : Ultrasonic machining de yuz ay-frikyuɛnsi vaybreshɔn dɛn we dɛn transmit tru wan tul fɔ pul matirial. Abrasive slurry bitwin di tul ɛn wokpies de ɛp di prɔses.

Main Applications of Ultrasonic Machining : Dis we ya fayn fɔ mek mashin brital ɛn had matirial, lɛk sɛramik ɛn glas, we dɛn kin yuz bɔku tɛm na ilɛktronik ɛn ɔptik kɔmpɔnɛnt dɛn.

Chalenj dɛn na Ultrasonic Machining Opareshɔn dɛn :

Laser bim mashin (LBM) .

Teknik proses fɔ LBM : LBM de yuz wan fɔs laser bim fɔ mɛlt ɔ vaypa matirial, we de gi prɛsis kɔt we nɔ gɛt dairekt kɔntakt. Na wan nɔ-kɔntakt, tɛmral prɔses.

Main Applications of LBM : Dɛn kin yuz LBM fɔ kɔt, drɔ, ɛn mak na industri dɛn we nid prɛsishɔn, lɛk ɔtomotiv, mɛdikal divays, ɛn aerospace.

Chalenj dɛn na LBM Opareshɔn dɛn :

Wata jet we de mek mashin .

Teknik prɔses fɔ wata jet mashin : Wata jet mashin de yuz wan ay-prɛshɔn strim wata, bɔku tɛm dɛn kin jɔyn am wit abraziv patikyula dɛn, fɔ kɔt tru matirial. Na kol-kat prɔses wae de avɔyd thermal strɛs.

Men aplikeshɔn fɔ wata jet mashin : Dɛn kin yuz am fɔ kɔt mɛtal, plastic, rɔba, ɛn ivin tin dɛn fɔ it, we kin mek i pɔpul na ɔtomotiv, aerospace, ɛn pak industri.

Chalenj dɛn na Wata Jet Machining Opareshɔn dɛn :

Ion bim mashin (IBM) .

Teknikal proses fɔ IBM : IBM involv fɔ dayrɛkt wan kɔnsɛntret bim ɔf ayɔn dɛn na di sɔfays fɔ di wokpies, chenj in strɔkchɔ na wan mɔlikul lɛvɛl tru bɔm.

Main Applications of IBM : Dɛn kin yuz IBM bɔku tɛm na di ilɛktroniks industri fɔ etk maykro-patna dɛn pan sɛmikɔndɔkta matirial dɛn.

Chalenj dɛn na IBM Opareshɔn dɛn :

Plasma arc mashin (pam) .

Teknik prɔses fɔ PAM : Pam de yuz wan ay-vɛlositi strim fɔ ayɔnayz gas (plasma) fɔ mɛlt ɛn pul matirial frɔm di wokpies. Di plasma torch de jenarayz ekstrim hot fɔ kɔt.

Main Applications of Pam : Dɛn kin yuz PAM fɔ kɔt ɛn wɛld had mɛtal, mɔ stenlɛs stiɛl ɛn aluminiɔm, insay industri dɛn lɛk ship bildin ɛn kɔnstrɔkshɔn.

Chalenj dɛn na PAM Ɔpreshɔn :

Ilektron bim mashin (EBM) .

Teknik proses fɔ EBM : EBM de yuz wan fɔs bim fɔ ay-vɛlositi ilɛktron fɔ vaypa matirial frɔm di wokpies. Dɛn kin du am insay vaykum fɔ mek shɔ se dɛn prɛsishɔn.

Main Applications of EBM : Dɛn de yuz EBM na ay-prɛsishɔn aplikeshɔn dɛn lɛk drɔlin maykro-ol dɛn na aerospace kɔmpɔnɛnt dɛn ɛn manufakchurin intrɛstin mɛdikal divays dɛn.

Chalenj dɛn na EBM Opareshɔn dɛn :

Hot Machining na na na na na na na na na na na na na na na na na na na na na na na .

Teknik prɔses fɔ hot mashin : Hot mashin involv fɔ prihɛt di wokpies ɛn kɔt tul fɔ mek matirial rimɔv izi, patikyula insay had-to-masin mɛtal.

Main Applications of Hot Machin : Dɛn kin yuz am fɔ superalɔy dɛn na aerospace, usay matirial dɛn kin bi mɔ mashinable na ay tempɔret.

Chalenj dɛn na Hot Machining Opareshɔn dɛn :

Magnɛtik fild ɛp mashin (MFAM)

Teknikal prɔses fɔ MFAM : MFAM de yuz magnɛtik fil fɔ ɛp fɔ pul di matirial we dɛn de yuz fɔ pul di tin dɛn we dɛn de du we dɛn de mek mashin, fɔ mek dip ɛn fɔ pul di rit dɛn we dɛn de pul.

Main Applications of MFAM : Dɛn kin yuz am fɔ prɛsishɔn mashin fɔ had matirial dɛn lɛk ay-strɛngth stɛl ɛn kɔmpɔzit dɛn na di ɔtomotiv ɛn aerospace sɛktɔ dɛn.

Chalenj dɛn na MFAM ɔpreshɔn dɛn :

Fɔtokɛmikɛl we de mek lɛk se na mashin .

Teknik prɔses fɔ fotokɛmikɛl mashin : Fɔtokɛmikɛl mashin de yuz layt fɔ mask spɛshal eria dɛn na di wokpies, dɔn dɛn kin fala am wit kemikal ɛch fɔ pul di matirial frɔm di eria dɛn we de na do.

Main Applications of Photochemical Machining : Dɛn kin yuz am fɔ mek tin dɛn we gɛt tin dɛn we nɔ gɛt bɔdi, we nɔ gɛt bɔr na di industri dɛn lɛk ilɛktronik ɛn aerospace.

Chalenj dɛn na fotokɛmikɛl mashin ɔpreshɔn dɛn :

Waya ilɛktrik dischaj mashin (WEDM) .

Teknikal proses fɔ Wedm : Wedm de yuz wan tin, ilɛktrik chaj waya fɔ erode matirial tru spak ɛrɔshɔn, we de alaw fɔ kɔt intrikɛt ɛn tayt tolɛreshɔn.

Main Applications of Wedm : Dɛn kin yuz Wedm fɔ mashin had mɛtal ɛn alɔy dɛn na aerospace, mɛdikal divays, ɛn tul-mɛkin industri.

Chalenj dɛn na WEDM Opareshɔn dɛn :

Difrɛns bitwin kɔvɛnshɔnal ɛn nɔ-kɔnvɛnshɔnal mashin prɔses .

Dɛn kin klas di we aw dɛn de mek mashin dɛn to tu men kategori dɛn: kɔvɛnshɔnal ɛn nɔ-kɔnvɛnshɔnal. Dɛn tu de ple impɔtant rol dɛn na di mɔdan manufakchurin, we de gi yunik we fɔ pul matirial. We yu ɔndastand di difrɛns bitwin dɛn tu kayn dɛn ya, dat de ɛp fɔ pik di we we go fayn fɔ yuz fɔ sɔm patikyula tin dɛn we dɛn nid fɔ mek.

Ki difrɛns bitwin kɔvɛnshɔnal ɛn nɔ-kɔnvɛnshɔnal mashin .

Kɔnvɛnshɔnal ɛn nɔ-kɔnvɛnshɔnal mashin difrɛn pan di we aw dɛn de yuz matirial fɔ pul, yuz tul, ɛn ɛnaji sɔs. Na dis na di men difrɛns dɛn:

Advantej ɛn limiteshɔn fɔ ɛni kayn .

Dɛn tu kayn mashin dɛn ya gɛt dɛn trɛnk ɛn dɛn wik, i dipen pan di aplikeshɔn.

Advantej dɛn fɔ kɔvɛnshɔnal mashin:

Lower Operational Costs : Jɛnɛral wan i smɔl bikɔs ɔf di bɔku bɔku tul ɛn mashin dɛn we de.

I izi fɔ sɛtup : mashin ɛn tul dɛn simpul fɔ wok, we de mek am izi fɔ yuz fɔ bɔku pan di manufakchurin ɛnvayrɔmɛnt dɛn.

High-speed prodakshɔn : I fayn fɔ mek dɛn prodyuz ay-volyum wit fast matirial rimɔv rɛt.

Limiteshɔn fɔ kɔvɛnshɔnal mashin:

Limitɛd matirial kapabiliti : strɛch fɔ mashin had matirial lɛk sɛramik ɔ kɔmpɔzit.

Tul Wear ɛn Mentɛnans : I nid fɔ gɛt ɔltɛm tul shap ɛn riples bikɔs ɔf dairekt kɔntakt wit di wokpies.

Difikulti fɔ mek mashin kɔmpleks shep dɛn : Prɛsishɔn at fɔ ajɔst insay intrikɛt ɔ ditayla dizayn dɛn.

Advantej fɔ nɔ-kɔnvɛnshɔnal mashin:

Can Machine Hard Materials : Prɔses dɛn lɛk EDM ɛn laser mashin kin izi fɔ wok pan matirial dɛn we at ɔ brital.

No tul wear : Insay nɔ-kɔntakt prɔses, di tul nɔ de west fizik wan.

High Precision and Detail : we ebul fɔ mashin rili fayn ditil ɛn ajɔst intrɛstin jɔyometri wit tayt tolɛreshɔn.

Limiteshɔn fɔ nɔ-kɔnvɛnshɔnal mashin:

Higher Cost : Tipikli mɔ dia bikɔs ɔf di advans tɛknɔlɔji ɛn ɛnaji sɔs dɛn we dɛn nid.

Slower material removal rates : Di we dɛn we nɔ de na di kɔmɔn we, lɛk ECM ɔ wata jet mashin, kin slo we yu kɔmpia am wit tradishɔnal we fɔ kɔt.

Kɔmpleks Sɛtup : I nid mɔ ɛkspɛriɛns ɛn kɔntrol oba di prɔses paramita dɛn, lɛk ilɛktrik kɔrɛnt ɔ bim fɔs.

Kɔmpiashɔn tebul

| ficha | kɔvɛnshɔnal mashin | nɔ-kɔnvɛnshɔnal mashinin . |

| Di we aw dɛn de pul di tin dɛn . | Mekanikal Kɔt ɔ Abrashɔn . | Ilɛktrik, tɛmral, kemikal, ɔ abraziv . |

| Tul Kɔntakt . | Dairekt kɔntakt wit wokpies . | Nɔn-kɔntakt insay bɔku we dɛn . |

| Prɛsishɔn . | Gud, bɔt limited fɔ intrikɛt dizayn dɛn . | Ay prɛsishɔn, we fit fɔ kɔmpleks shep dɛn . |

| Tul Wear . | Wear ɛn mentenɛns ɔltɛm . | Minimal ɔ nɔ tul wear . |

| Material Rɛnj . | I fayn fɔ mek dɛn mek mɛtal ɛn tin dɛn we nɔ go soft . | we ebul fɔ mek mashin dɛn we at fɔ mek ɔ we nɔ de brok . |

| Pe | Lɔwa Ɔpreshɔnal Kɔst . | ay bikɔs ɔf advans tɛknɔlɔji . |

| Fas fas | Fasta fɔ big volyum prodakshɔn . | Slower material removal in bɔku prɔses dɛn . |

Ɛksplen

Dis gayd bin ɛksplɔrɔ difrɛn mashin prɔses dɛm, inklud kɔvɛnshɔnal ɛn nɔ-kɔnvɛnshɔnal mɛtɔd dɛm. Kɔnvɛnshɔnal tɛknik dɛn lɛk fɔ tɔn ɛn mil de dipen pan mɛkanikal fɔs, we nɔ-kɔnvɛnshɔnal prɔses lɛk EDM ɛn laser mashin de yuz ilɛktrik, kemikal, ɔ tɛmral ɛnaji.

Fɔ pik di rayt mashin prɔses rili impɔtant. I de afɛkt matirial kɔmpitibliti, prɛsishɔn, ɛn prodakshɔn spid. Fɔ pik di rayt we de mek shɔ se dɛn ebul fɔ du di wok fayn fayn wan, dɛn nɔ de tek bɔku mɔni, ɛn dɛn gɛt ay kwaliti rizɔlt dɛn we dɛn de mek. Ilɛksɛf yu de wok wit mɛtal, sɛramik, ɔ kɔmpɔzit, fɔ ɔndastand ɛni we aw yu de du tin kin ɛp fɔ mek yu gɛt di bɛst autkam.

Rifrɛns Sɔs dɛn .

Gens

Riaming .

Honing we de na di wɔl .

Gia fɔ kɔt .

Ultrasonic Machining na na na na na na na na na na na na na na na .

Best CNC Machining Service .

Knurling .

Broching we dɛn de yuz .