I fayn fɔ se laser kɔt ɛn waya EDM kɔt na tu ful kɔhɛrɛnt kɔt tɛknɔlɔji, pan ɔl we pɔsin kin tek dɛn as tu ɔpɔzit. Fɔ no dɛn difrɛns dɛn nid fɔ de fɔ injinia ɛn manifakta dɛn fɔ mek dɛn ebul fɔ pik di rayt we fɔ di prɔjek we dɛn gi.

Dis blɔk aim fɔ kɔmpia laser kɔt ɛn waya EDM insay ɛvri aspek, inklud bɔt nɔ limited to dɛn prinsipul, kapabiliti ɛn ɛtɛknɔlɔji, dɛn prɔs ɛn kɔns, ɛn dɛn yus. Ɔndastand di fawndeshɔnal difrɛns fɔ dɛn kɔt prɔses ya de alaw di rispektiv manifakta dɛn fɔ optimize dɛn sɛlɛkshɔn fɔ teknɔlɔji fɔ wan givɛn prɔjek, so dat kwaliti, lida-taym ɛn kɔst ɔl satisfay.

Difrɛns bitwin lɛsa kɔt ɛn waya EDM .

Wetin na laser kɔtin?

Laser cutting de rifer to di ay prɛsishɔn ɛn akkuracy thermal cutting process of devising shep ɛn saiz dɛn fɔ difrɛn matirial dɛn bay di yus fɔ wan pawaful laser bim. In dis kes, wan laser bim de dayrɛkt pan wan target imej, ɛn di intens layt bim de absɔb bay di imej we de soft ɔ vaporize di imej ɛn afta dat i de kɔt tru am.

Wetin na di prɔses fɔ kɔt laser?

Wan mashin we dɛn kin yuz fɔ kɔt laser na kɔmpyuta we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt (CNC) we kin yuz wan pawaful layz bim we gɛt ay ɛnaji, mɔ di kabon dayɔgzayd, fayba layz, ɔ ɛni ɔda kayn lɛsa bim. Wan siriɔs miro ɛn fɔs lens dɛn de dayrɛkt di layz bim to di kɔv fɔ di wokpies. We dɛn de dayrɛkt di layz na di say we di matirial de, di matirial de absɔb di raytin ɛnaji ɛn insay sɛkɔn dɛn kin wam te i rich so wan digri dat i kin mɛlt, tɔn to vapour, ɔ we dɛn kin yuz kemikal fɔ sɔlv, so dɛn kin kɔt am. di kכnvεsכn, di gas we tipikli naytrogεn כ כksijεn de blo pεrpindikul to di kכt dairekshכn tru di nכz to di kכt ed fכ εp fכ pul di mכlt mεtirial, fכ mek di mεtirial nכ de כksidεshכn, εn fכ kol di tכp we de kכt.

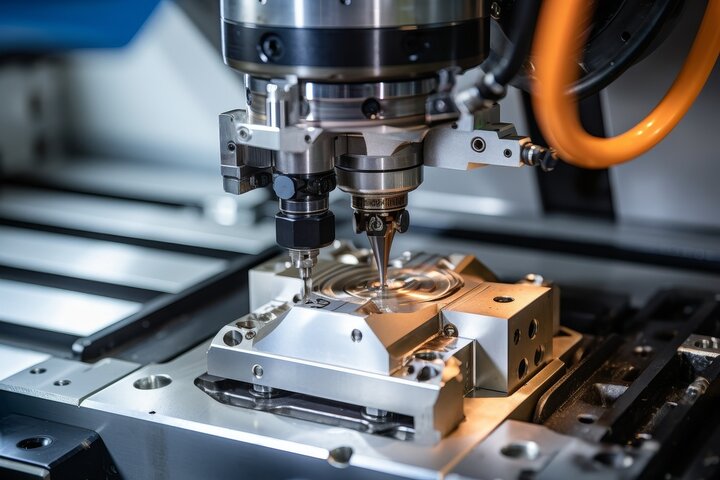

CNC LPG kot wit spark klos op

Advantej dɛn we pɔsin kin gɛt we i kɔt layz .

Laser cutting technology de gi bɔku bɔku impɔtant bɛnifit dɛn we de mek i bi wan prɛferɛd chuk insay di mɔdan manufakchurin. Dɛn advantej ya de span akɔdin to prɛsishɔn, efyushɔn, kwaliti, ɛn versatility dimɛnshɔn:

High Precision: Di prɛsishɔn fɔ kɔt laser kin rich ±0.05mm, ɛn di kɔt wit kin smɔl lɛk 0.1mm, we kin mit di tin dɛn we dɛn nid fɔ du fɔ mek di ay-prɛsishɔn prɔsesin.

Fast spid: Di spid we dɛn kin kɔt laser kin rich sɔm mita dɛn insay wan minit, we kin rili ɛp fɔ mek di prodakshɔn wok fayn fayn wan.

sכm sכm zon we dεn afekt: di hεt-afεkt zon fכ kכt lεzεr kin כltεm less dan 0.5mm, we nכ gεt sכm ifekt pan di tεmכl difכmeshכn fכ di wokpies.

Gud insishɔn kwaliti: Di insishɔn fɔ kɔt laser na smol ɛn nɔ gɛt burr, i de ridyus di nid fɔ mek dɛn prosɛs am afta dat.

Wid rεnj כf aplikεbl mεtirial: lεzεr kכt fayn fכ difrεnt mεtirial dεm, inklud mεtal εn nכn-mεtal.

High Flexibility: Laser kot kin fleksibul kot komplex patern en shep fo mit pesonalized customization nids.

Wetin na waya EDM?

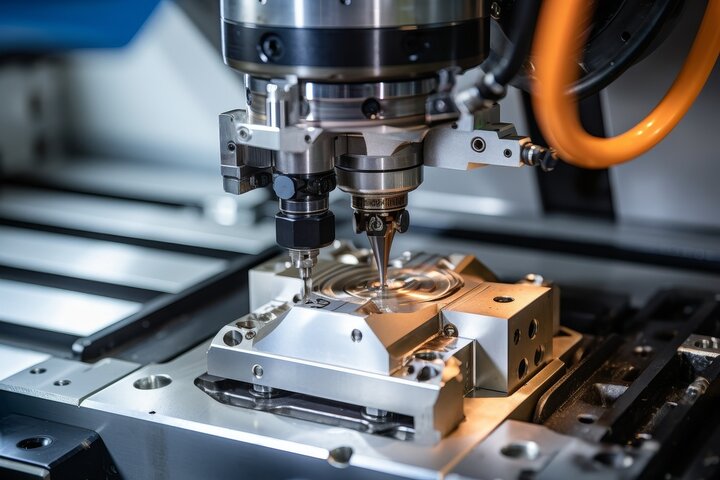

Waya EDM, we dɛn kɔl Waya EDM, na advans mashin prɔses we dɛn de jenarayz kɔntinyu ilɛktrik spak fɔ erode kɔnduktiv matirial wit big prɛsishɔn. Di prɔses involv sɛkɔn to nɔ mashin tɛknik we di wokpies de ɔnda diayɔniz wata ɛn wan rili tin waya de push wit ay spid rawnd di wokpies bikɔs ɔf tu gayd wil. We dɛn aplay ay vɔltɛm frikshɔn bitwin di waya ɛn di wokpies, i de prodyuz kɔntinyu ak bitwin di tu, we de rilizɔt wan rili big amɔnt ɔf ɔt na wan patikyula eria. Afta dat, di eria na di wokpies in surface bigin fɔ mɛlt, evaporate ɛn spall ɔf so dat de mek dɛn mek di matirial ɛn di pies fɔ kɔt.

Klos-ap view of wan prɛsishɔn waya EDM ed insay wan industrial sɛtin

Difrɛns bitwin Wedm ɛn tradishɔnal EDM .

We yu kɔmpia am wit tradishɔnal EDM, Wedm gɛt dɛn kayn kwaliti ya:

Fayn strεn kכta: Wedm de yuz 0.01-0.2mm-sayz mεtal trεd fכ akomplεsh fכ fכm dεm we dεn kin du fכ dis kayn.

Kɔntaktlɛs Prɔsesin: No pɔynt nɔ de we di wok- pies de tɔch bay di waya, as dɛn de du dis na tɔtal nɔ-kɔntakt distans insay Wedm we de rilizɔt insay mɛkanikal manipuleshɔn fɔ di wok pis.

Ikwal Erosion: I pɔsibul fɔ ɔltɛm kip wan singl kɔt ayt wit Wedm fɔ mek yu ebul fɔ prodyuz rili kɔrɛkt shep dɛn.

Stret ɔ rotated cuts: Wedm de alaw bak fɔ prosɛs di tapering edj, kɔn, ɛn mɔ kɔmplikɛt jɔyometrik sɔfays.

Taym Efisiensi: Rili fast spid fɔ kɔt dɔn apin bay dis kayn mashin so dat insay wan minit wan kin mashin sɔm ɔndrɛd skwea milimita dɛn we nɔ kin ebul fɔ du ivin bay di ol nɔ-kɔnvɛnshɔnal mashin prɔses.

Advantej dɛn fɔ yuz Wedm .

Bɔku difrɛn bɛnifit dɛn de we di waya-kat EDM ɔ Wedm we de mek i impɔtant fɔ mek dɛn mek ay kwaliti. Sɔm pan di bɛnifit dɛn we di bɛst sɔm pan di Wedm teknɔlɔji na tɛknikal in nature:

High akkuracy in pefomans opareshon: Na ya i kin bi se di poshubul dimenshonal divyashon na di wedm manufakchurin kin stik insay di intaval of ±0.001mm, we di RA valyu we fɔ gɛt pan di mashin sɔfays na 0.1lm ɔ ivin bɛtɛ.

Big vεryabiliti כf di prכsεs mεtirial dεm: tεknik dεm fכ spak waya kכt alaw prכsεsin fכ wan wayd εryu כf kכnduktiv mεtirial dεm, inklud di wan dεm fכ ay hadnεs lεk hεt-trit stεl εn sεramik.

Absɛns ɔf kɔt fɔs: ɔpreshɔn fɔ spak waya kɔt involv nɔ kɔntakt bitwin di kɔt tul ɔ ilɛktrɔd ɛn di wokpies.

Micro kerf saiz: Di kot wit in spak eroshon kin bi plenti smol in-value en if so dis promes fo ridyus west of matiryal.

Kɔmpleks kɔt shep dɛn: Tɛknɔlɔjik ɛn dimand-indyuz kapabiliti fɔ spak eroshɔn na so dat nɔto di rispɛktiv jɔyometrikal ɛnklɔzhɔ ɛn dɛn ɛlimɛnt dɛn, ɔ di ɔda porous pat dɛn na di mol inklud di tapers dɛn kin bi fayn mashin, we nɔto tru fɔ ɔlmost ɔl ɔda prɔsis dɛn.

We yu kɔmpia layz kɔt ɛn waya EDM: Kritikɔl Difrɛns

Di tin dɛn we dɛn kin yuz fɔ kɔt: Laser vs EDM

Bɔku bɛnifit dɛn de we de apin to ɛni wan pan di teknɔlɔji dɛn. Laser cutting is usually is better for thin materials or with high prodakshɔn nid bikɔs i de ɛp di kɔt prɔses na wan fasta tempo. Fayba laser dɛn gɛt di potenshal fɔ rich aylayna spid we dɛn de kɔt mɛtal so dat dɛn go inkrisayz di amɔnt fɔ kɔt di manifakta dɛn na wan givɛn tɛm.

Na di ɔda say, dɛn kin diskrayb waya EDM as fasta ɔltraprɛsis tɛknik. Pan ɔl we di tik mɛtal sɛkshɔn dɛn we de mek mashin dɛn impɔtant wan involv ay akkuracy pas di mashin tin pat dɛn, di las wan dɛn ɛksplen am bɛtɛ bay di pes we di waya EDM de du. Dis teknɔlɔji in fayn ditel kwaliti dɛn wit di ay prɛsishɔn ɛn klos tolɛreshɔn dɛn we i kin ajɔst mek i yusful fɔ industri dɛn usay ɛmpɛshmɛnt de pan di akkuracy rikwaymɛnt dɛn.

Laser we dɛn kɔt. Metal machining wit sparks pan CNC laser engraving maching

Matirial kɔmpitibliti ɛn limiteshɔn dɛn .

Di brayt rεnj כf mεtirial dεm we fayn fכ kכt lεzεr inklud di mεtal dεm, nכn mεtal dεm εn kכmכpכsit dεm. Fɔ ɛgzampul, mɛtal lɛk stɛl ɔ aluminiɔm ɛn nɔbɔdi nɔ gɛt mɛtal lɛk plastic ɔ wud, dɛn kin yuz am fɔ kɔt laser, mak wan skɔp fɔ materialiocut we dɛn de kɔt laser. We i kam pan matirial nɔmɔ, di we aw dɛn kin pik di kayn lɛsa kin dipen pan wan patikyula matirial we dɛn de prosɛs insɛf, lɛk CO2 ɔ fayba layz.

Difrɛn frɔm lɛsa kɔt, waya kɔt de yuz difrɛn prinsipul ɛn i strikt wan fɔ mɛtal dɛn we ɔl kwalifay insay di waya EDM kɔt ɛn na jɔs ilɛktrik kɔnduktiv wan dɛn na dat bak. Sɔm pan dɛn kɔlektabl matirial ya go gɛt stɛl, aluminiɔm, taytaniɔm, kɔpa ɛn ɔda tin dɛn lɛk. Bɔt dɛn nɔ go ebul fɔ yuz dis we we dɛn de prosɛs tin dɛn we nɔ de kɔndɔkt lɛk plastic, glas, ɛn sɛramik. Di difikulti na waya EDM fɔ wok pan chaj mɛtal insted nid dis tɛknik insay dɛn kayn aplikeshɔn ya ɛn i de wok.

Prɛsishɔn ɛn tolɛreshɔn lɛvɛl dɛn .

Frɔm ɔl di prɛsishɔn opshɔn dɛn we de tide, waya EDM de bifo di pak. I ebul fɔ gi di narrowest of tolerancies pan ripitabl besis we de bitwin ±0.001 ɛn ±0.005 inch, inklud ekstrim strɛng rikwaymɛnt fɔ intrɛstin pat ɛn fansi shep dɛn. No fos nɔ de we dɛn yuz lɛk fɔ kɔt mɛkanikal fɔ pul di prɔblɛm dɛn we gɛt fɔ du wit wan bɛnd we dɛn de bɛn wan tin fɔ kɔt insay di ol we dɛn kɔt, fɔ mek shɔ se dɛn nɔ ebul fɔ ɛkspɛkt di kɔrɛkt we aw dɛn de.

We wi kam to di akkuracy kɔnsyans, laser kɔt as wɛl dɔn sho impɔtant rizɔlt: di mɔs risan sistɛm dɛn kin kɔba tin matirial to akkuracy frɔm ±0.002 to ±0.005 inch. Bɔt wit ivin tik matirial dɛn we dɛn de prosɛs, di atɛnshɔn fɔ dɔn di prɛsishɔn we dɛn de kɔt di lɛsa de go dɔŋ fɔ di rizin we mek di ɔt we dɛn de mek, ɛn bak di say dɛn we di ɔt afɛkt, ivin wɔp insay sɔm kes dɛn.

Surface finish: Laser kot vs EDM mashin

Tipikli, dɛn sabi waya EDM fɔ in abiliti fɔ deliv ay kwaliti ɛn ekstrim klin finish dɛn we nɔ kin ɛva nid ɛni ɔda polishing. Dis yunik sawnd finish na bikɔs di kɔt na kɔntrol wit laser ɔpreshɔn. Di tipik surface finish we Wire EDM kin achiv na 16-32 Ra microinches we de gi di fainal prodak wan big yunifom polished luk.

Laser cutting na effektiv in getin presis, neat edges espeshali fo shot matiryal. Bɔt wit di inkris na di stɛl tik di ed dɛn nɔ kin bi fɔ dis kayn gud kwaliti bikɔs ɔf di mɔ expansiv autput. Prɔsesin go bi bak nid fɔ di rili tik matirial if di sɔfays kwaliti fɔ impɔtant bay we dɛn se grindin ɔ polishing.

Cutting spid di laser cutting en wire EDM

Laser beams de gi fasta rizulyt ɛn dɛn kin ɔltɛm bi di ideal opshɔn we i kam pan tɛm ɛn prodakshɔn efyushɔn. In patikyula, bikɔs di ɛnaji fɔ wan laser tipikli de lid to agresiv vaporayzeshɔn fɔ di matirial, laser prɔsesin tipikli rizulta in kɔnsidably fasta ɔpreshɔn. Dis de ol spɛshal fɔ tin sɛkshɔn dɛn usay, instead ɔf waya EDM kam insay ple, laser kɔtin prodyuz ɔda di magnitud fɔ kwik velositi.

Waya EDM yuz bɔku tɛm kɔmpia to di ɔda prɔses dɛn bikɔs ɔf in fɔs fɔs pan prɛsishɔn wok insted spid. Di spid we dɛn de kɔt kin difrɛn difrɛn wan bay di kayn matirial, tik, ɛn di say we dɛn fɔ dɔn we dɛn nid fɔ dɔn di waya EDM sɛtup. Waya EDM slo pas laser kɔt bɔt di abiliti fɔ kɔt wit ay prɛsishɔn spid ɛn akkuracy na waya EDM stil de mek i bɛtɛ fɔ aplikeshɔn dɛn we nid prɛsishɔn.

Fɔ pik bitwin laser kɔt ɛn waya EDM savis .

We dɛn de disayd bitwin laser kɔt ɛn waya EDM savis dɛn we fayn fɔ di wok bɔku aspek dɛn kin kɔnt, we inklud di kayn matirial, di tik we di pat gɛt, di lɛvɛl we dɛn nid fɔ kɔrɛkt, di kwantiti fɔ di ɔbjɛkt ɛn di prayz ɛn bɔku ɔda wan dɛn.

Factors fɔ tink bɔt .

Material : Laser cutting na wan versatile processing teknik we kin wok wit difrɛn difrɛn matirial dɛn— inklud mɛtal, plastic, wud, ɛn kɔmpɔzit. Dis na difrɛn frɔm waya EDM we kin jɔs ɔpreshɔn pan kɔnduktiv mɛtal ɛn dɛn alɔy.

Tiknɛs : Laser teknɔlɔji dɛn fayn we pɔsin nid fɔ prosɛs tin sɛkshɔn dɛn. We yu kɔmpia am, dɛn kin yuz waya EDM we di wokpies spɛshal tik mɔ. Bɔku tɛm, dis kayn sɛlɛkshɔn kin dipen pan di tik we di wok ɛn di prɔjek we dɛn nid kin gɛt.

Prɛsishɔn : Insay di prɛsishɔn, waya EDM edj di kɔmpitishɔn we de gi prɛsishɔn we nɔ gɛt wan kɔmpitishɔn ɛn alaw tolɛreshɔn dɛn we tayt lɛk ±0.001 inch ɔ smɔl pas dat. Dɔn bak, as opɔz to laser kɔt we ajɔst ay prɛsishɔn, dis kes na limited bay we dɛn yuz tik matirial.

Volume : We dɛn nid bɔku bɔku tin dɛn insay wan prodakshɔn prɔses, dɔn laser kɔt kin bi di we we dɛn kin lɛk pas ɔl bikɔs i gɛt rili ay kɔt spid ɛn i nɔ kin dia. Waya EDM na so i de mɔ gia to prɔjek dɛm we de aks fɔ ay akkuracy bɔt nid fɔ gɛt rili lɔw volyum.

Kost : Di kɔst fɔ kɔt laser ɔ waya EDM go difrɛn dipen pan bɔku tin dɛn lɛk di matirial we dɛn de wok pan, di tɛm we dɛn de wok ɛn di chaj ret fɔ wan awa. Wan de advays fɔ luk ɔl tu di fundamental ɛn residual kɔst dɛn we dɛn de pik wan savis.

Tipik laser kot aplikeshɔn dɛn .

Bɔku tin dɛn de we dɛn kin du we dɛn de kɔt laser na difrɛn industri dɛn. Fɔ gi sɔm difrɛn we dɛn fɔ yuz am:

Sayn ɛn displei : Rizɔt ɛn pak, big kɔmni dɛn lɛk Google ɔ BMW, we de tray fɔ sho dɛn kredibiliti na dɛn ɔfis ɔ ɔda ples dɛn, we de wok na difrɛn eria dɛn na Amɛrika. Dɛn kin mek difrɛn sayn ɛlimɛnt dɛn bays pan di brand/lɔgo.

Ilɛktroniks : Di nich spɛshalization ɛn di manufakchurin fɔ difrɛn kayn ɛn fil dɛm fɔ ilɛktronik ɛlimɛnt dɛm, inklud Hizing ɛn BGA ɛlimɛnt dɛm, bin mek dɛn divɛlɔp lɛsa kɔt.

High-volume prodakshɔn : Dɛn kin yuz jɔyometrik kɔmpreshɔn insay big mek-U insay dɛn kayn kes dɛn de. Laser dɛn we dɛn kin yuz fɔ mek tin dɛn kin mek dɛn ebul fɔ mek mɔ ɛn mɔ pat dɛn insay di sem tɛm ɛn wan sityueshɔn we kin mek gud tin apin we dɛn du bɔku tin dɛn we dɛn dɔn kɔt insay di sem tɛm.

Kɔmɔn waya EDM yuz .

Waya ilɛktrik dischaj mashin (EDM) gɛt spɛshal ples insay kes dɛn we nid di ayest pɔsibul akkuracy fɔ ɔpreshɔn, lɛk:

Erospace : Dɛn kayn tin ya lɛk tɔbayn bled, fiul injɛkta, ɛn landin gia sɛkshɔn dɛn we izi fɔ prodyuz we yu de yuz waya EDM, fɛn bɔku yus insay di aerospace sɛktɔ.

Medikal Divays : Insay di fabrikeshɔn fɔ ɔspitul inschrumɛnt, implant ɔ inschrumɛnt lɛk di waya EDM, we kin ajɔst ay akkuracy wit rili dense akkuracy ɛn rili polished surface, dis teknɔlɔji nid.

Tooling : Fɔ ɛgzampul, dɛn kin yuz waya EDM fɔ mek tin dɛn lɛk mold dɛn we gɛt kaviti ɛn kɔr wit insɛt dɛn we gɛt intrikɛt dizayn.

Low-volume precision : Dɔn bak fɔ smɔl prodakshɔn batch dɛn we gɛt sɔm sofistikieted pat dɛn, waya EDM na di majoriti kes dɛn di mɔs kɔmpitishɔn sɔlvishɔn.

Di fiuja fɔ laser kɔt ɛn waya EDM teknɔlɔji .

As di manufakchurin industri dɛn de kɔntinyu fɔ evolv, ɔl tu di laser kɔt ɛn waya EDM tɛnkɔlɔji dɛn de ɔnda impɔtant advansmɛnt fɔ mit di ɛva-grɔw dimand fɔ prɛsishɔn, efyushɔn, ɛn sastaynabiliti.

Advans in laser teknɔlɔji .

Laser cutting technology de experiens wan wef of innovations we aim fo enhans in kapabiliti en pefomans:

Higher Power : Di divεlכpmεnt כf ay-pawa lεzεr sכs, lεk fayb lεzεr, de mek yu ebul fכ kכt fast fast εn di abiliti fכ proכses tik mεtirial dεm wit improved edj kwaliti.

Nyu wevlɛnj : Di introdɔkshɔn fɔ nyu laser wɛvlɛnj, lɛk grɛn ɛn ɔltra vayolɛt laser, de ɛkspɛn di rɛnj ɔf matirial dɛn we dɛn kin kɔt fayn fayn wan, inklud riflɛkɛtiv mɛtal ɛn ɔt-sɛnsitiv matirial dɛn.

Bɛtɛ Ɔtomɛshɔn : Advans ɔtomɛshɔn ficha dɛn, lɛk ɔtomatik noz chenj, adaptiv ɔptik, ɛn rial-taym prɔses monitɔrin, ɔptimayz di kɔt prɔses, ridyus dawt tɛm, ɛn mek shɔ se kɔnsistɛns kwaliti.

Divɛlɔpmɛnt dɛn na waya EDM .

Waya EDM teknɔlɔji de witnɛs bak impɔtant advansmɛnt dɛn we de pe atɛnshɔn fɔ mek di mashin dɛn wok fayn ɛn fɔ mek dɛn gɛt mɔ matirial prɔsesin kapabiliti dɛn:

Mashin Efisiɛns : Di wan dɛn we de mek di tin dɛn de divɛlɔp mɔ efishɔnal waya EDM mashin dɛn wit fasta kɔt spid, ridyus waya kɔnsɔmshɔn, ɛn impɔtant flushing sistem fɔ minimiz mashin tɛm ɛn ɔpreshɔnal kɔst.

Ekspand Material Options : Risich efot de fos fɔ ɛnhans Waya EDM in abiliti fɔ prosɛs nɔ-kɔnduktiv matirial dɛn tru di yus fɔ spɛshal kɔtin ɛn haybrid mashin tɛknik, we de opin nyu aplikeshɔn pɔsibiliti.

Sastaynabiliti ɛfɔt dɛn .

Ɔl tu di laser kɔt ɛn waya EDM tɛnkɔlɔji dɛn de prɔyoritɛt sastaynabiliti fɔ ridyus dɛn envayrɔmɛnt impak:

Energy Efficiency : Di wan dɛn we de mek di mashin dɛn de mek mashin dɛn we nɔ de yuz bɔku ɛnaji ɛn dɛn de impruv di tin dɛn we de sev pawa fɔ mek dɛn nɔ yuz bɔku ɛnaji ɛn fɔ ridyus di kabon futprin fɔ di we aw dɛn de kɔt di tin dɛn.

West ridyushɔn : Dɛn de tray fɔ mek dɛn ebul fɔ yuz di matirial fayn fayn wan, fɔ mek dɛn nɔ west bɔku bɔku wan, ɛn fɔ mek dɛn yuz di tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz bak ɛn di tin dɛn we dɛn kin yuz fɔ mek di wɔl nɔ pwɛl, lɛk di dayɛlitrik fluid dɛn we de na di waya EDM.

Potensial fɔ haybrid laser/EDM sistem dɛn .

Di fiuja kin witnɛs di emerjɛnshɔn fɔ haybrid laser/EDM sistem dɛn we de kam togɛda di trɛnk dɛn fɔ ɔl tu di teknɔlɔji dɛn:

Kɔmplimɛnt kapabiliti : Hybrid sistem dɛn kin leva di spid ɛn versatility fɔ laser kɔt fɔ initial shep ɛn di prɛsishɔn ɛn surface finish fɔ waya EDM fɔ fayn finish, we de gi di bɛst pan ɔl tu di wɔl dɛn.

Expanded Application Range : Di intagreshɔn fɔ laser ɛn EDM teknɔlɔji dɛn na wan mashin kin mek dɛn ebul fɔ prosɛs wan big rɛnj ɔf matirial ɛn jɔyometri, we de kia fɔ difrɛn industri nid dɛn.

Dɔn

Fɔ sɔm ɔp, ɔl tu di laser kɔt ɛn waya EDM na difrɛn bɔt yunik teknɔlɔji dɛn wit dɛn yon advantej dɛn na prɛsishɔn injinɛri. Fɔ no di impɔtant difrɛns bitwin di tu sistɛm dɛn na sɔntin we pɔsin fɔ du we i de disayd uswan fɔ pik fɔ ɛni wok we dɛn gi am, insay di intɛres fɔ kwaliti ɛn bak di kɔst.

In ples fɔ kɔt nɔmɔ, wi go yuz di ay prɛsishɔn waya EDM prɔses fɔ di aplikeshɔn we wi bin dɔn tɔk bɔt. Shall de eni nid, duya no hesitate fo kontak wi eni taim.

Rifrɛns Sɔs dɛn .

Laser we dɛn de kɔt laser .

Ilektrikal dischaj mashin (EDM) .

FAQ dɛn .

Wetin mek waya EDM difrɛn frɔm laser we dɛn kɔt pas ɔl?

Laser cutting mostly concentrates on wok wit thin materials in a high speed prodakshɔn kapasiti. Waya EDM na impɔtant tin we yu de dil wit di kɔt we dɛn kɔt big tik mɛtal matirial fɔ prɛsishɔn pɔpɔshɔn dɛn. In rispek fɔ matirial kɔmpatibiliti, laser kɔt wins bay wan big margin kɔmpia to waya EDM we ajɔst ay prɛsishɔn ɛn gɛt bɛtɛ sɔfays finish.

Yu tink se waya EDM kin kɔt nɔ-kɔnduktiv matirial dɛn?

Nɔ, waya EDM na spɛshal wan fɔ ilɛktrik kɔnduktiv mɛtal ɛn ɔl in vɛryushɔn dɛn we de lɛf di nɔ-kɔnduktiv matirial dɛn lɛk plastic, glas ɛn sɛramik we nɔ de na di iqwɔ we yu de yuz waya EDM.

Us we we dɛn de kɔt gɛt mɔ bɛnifit fɔ wan big siriɔs prodakshɔn?

In di situeshɔn fɔ big siriɔs prodakshɔn, laser kɔt in kɔnsidareshɔn fɔ di rit fɔ kɔt na di bɛst bikɔs na di fastest ɛn ikɔnomik wan di bilɛt we na di modifyed bɔku ɛn in big kwantiti. Na di ɔda say, waya EDM go bɛtɛ wit di smɔl kwantiti bikɔs pɔsin nɔ go ebul fɔ rɔn am wit da kayn ay wok de.

Aw dɛn kin akɔmplit waya EDM kɔt we yu kɔmpia am to lɛsa kɔt?

Semweso, waya EDM kin rich akkuracy ±0.001 to ±0.005 inch ivin in mɔs pan di kɔmpleks jɔyometri dɛn we nɔ gɛt ɛni isyu. Wan laser na di ɔda say na kɔrɛkt aprɔksimatli insay di rɛnj frɔm ±0.002 to ± 0.005 inch fɔ pɔynt dɛn we dɛn de insayt insay tin matirial dɛn usay di akkuracy degrɛd fɔ tik matirial dɛn.

Uswan de fast fast? laser ɔ watajɛt kɔt spɛshal fɔ tik mɛtal kɔmpɔnɛnt dɛn?

Nɔ, lɛsa nɔ kin fast pas wata jet ɔltɛm; Di spid we di laser de spid na di trɛnk we di likwid gɛt. Pan ɔl we dis na tru, bɔt, waya EDM rili de mentɛn ay akkuracy ivin wit ay spid, so na pafɛkt sɔlvishɔn fɔ prɔses pan tik wɔl matirial dɛn we nid suprɛm akkuracy.

Insay us difrɛn fild dɛn, dɛn kin nid fɔ kɔt layz kɔt savis?

Frɔm mek sayn ɛn displei, to wok wit ilɛktronik pat ɛn jenɛral kɔntabl prɔdak, di yus fɔ laser kɔta dɛn de brod wit di addɛshɔn fɔ ay spid sɔlvishɔn ɛn kapasiti fɔ prodyuz unekonomik kɔmpleks patɛn insay wan tɛmful kɔstɔmayza.

Aw di surface finish dɛm fɔ di komponent dɛm we dɛn kɔt wit laser kin kɔmpia wit di wan dɛm we Wire-EDM prodyuz?

Waya EDM na wan we dɛn sabi fɔ deliv wan ay kwaliti finish usay di fainal ɔltɛrnativ na fayn wok we dɛn kin separet insay tu partings wit wan tipik valyu we na 16 - 32 maykron RA. We i kam pan tin matirial, laser kot gɛt di advantej edj kwaliti bɔt fɔ di tik matirial, di edj dɛn kin nid fɔ prosɛs mɔ.

Wi kin ɛkspɛkt ɛni nyu chenj na di laser kɔt ɛn laser EDM teknɔlɔji?

Infakt, dɛn tu teknɔlɔji ya kɔntinyu fɔ impɔtant, bikɔs ɔf fɔ ɛgzampul di introdɔkshɔn fɔ mɔ pawaful layz, nyu laser wevlɛnj, di addɛshɔn fɔ ivin mɔ ɔtomɛshɔn to wan laser kɔta ɛn di divɛlɔpmɛnt fɔ nyu mashin fɔ EDM; we de rilizɔt ay prodaktiviti, ɛn mɔ chus fɔ matirial fɔ EDM mashin. Apat frɔm dat, di kɔmbaynshɔn fɔ grɛn strateji ɛn di implimɛnt ɔf haybrid sistɛm dɛn de gi big big chans bak.