CNC Milling ye bεnkan bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε b.' Yɛlɛn mansin walima milling conventionnelle ? O fɛɛrɛ fila bɛɛ jɔyɔrɔ ka bon kosɛbɛ yɔrɔ ɲumanw dilanni na, nka o fɛɛrɛ kelen-kelen bɛɛ nafa ni gɛlɛyaw bɛ ɲɔgɔn na.

Nin barokun in kɔnɔ, an bɛna CNC milling baara cogo lajɛ, ani mun na danfara min bɛ jiginni sɔgɔli ni sɛnɛcogo kɔrɔlen cɛ, o faamuyali nafa ka bon masinw fɛ. Aw bɛna fɛɛrɛ ɲuman sugandi ka da fɛnw, masinw ani fɛn dilanni kuntilenna kan walasa ka baara kɛcogo ɲuman ni fɛn dilannenw cogoya ɲɛ.

Yɛlɛn ye mun ye?

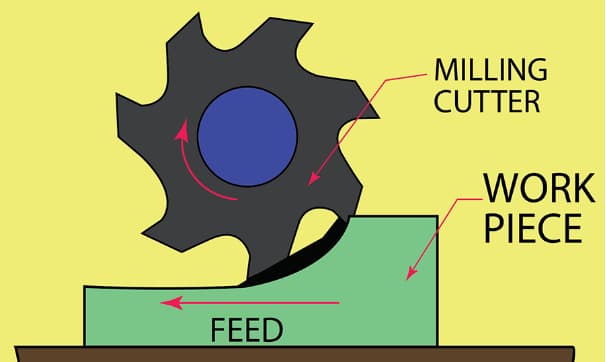

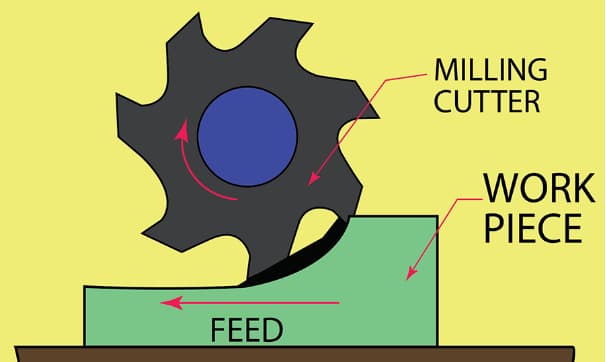

Yɛlɛn sɔgɔli, n’a bɛ fɔ fana ko Down Milling , o bɛ tali kɛ tigɛcogo la yɔrɔ min na tigɛminɛn bɛ wuli sira kelen fɛ ni balo lamagacogo ye. A bɛ a to tigɛbaga ɲinw ka se ka baarakɛminɛn in don ka bɔ sanfɛ, ka dɔ bɔ chipsw seginni na. Nin fɛɛrɛ in bɛ tigɛ saniyalenw lawuli ani a ka ɲi yɔrɔw ma minnu bɛ a ɲini ka kɛ yɔrɔ ye min bɛ kɛ ka ɲɛ.

jiginni bɛ baara kɛ cogo min na .

kɔnɔ Climb milling , chip formation bɛ daminɛ ka bonya ani ka kɛ fin ye ni tigɛbaga bɛ tɛmɛ fɛn in fɛ. O puce (puce) jɔcogo bɛ tigɛ fanga dɔgɔya, o bɛ na ni funteni dɔgɔyali ye ani ka baarakɛcogo ɲuman sɔrɔ. Tigɛ lamagacogo bɛ baarakɛminɛnw bila baarakɛminɛn kɔfɛ, ka segin-ka-bɔ mago bɔ, o min bɛ baarakɛminɛn nɔgɔya ani ka dugukolo sanfɛla fini bonya.

Chip formation : A bɛ daminɛ ka bonya ani ka dɔgɔya dɔɔni dɔɔni, ka degun dɔgɔya baarakɛminɛn kan.

Baarakɛminɛn sira ni lamaga : tigɛlan bɛ wuli ka taa sira kelen fɛ ni balo ye, ka baarakɛminɛn gɛrɛntɛ ka jigin, ka sabatili ɲɛ.

Yɛlɛn-sɔgɔli jogo jɔnjɔnw .

Climb Milling bɛ nafa caman di baara tigitigi ma:

Baarakɛminɛnw deflection dɔgɔyali : Baarakɛminɛn bɛ kurukuruli dɔgɔya tigɛ waati la, ka tiɲɛni ɲɛ.

Surface finish better : Baarakɛminɛnw taamasiɲɛw ka dɔgɔ ani surfaces smoother bɛ sɔrɔ chip formation contrôlée.

Tigɛ doni dɔgɔyali : doni min bɛ bila tigɛminɛn kan, o bɛ dɔgɔya, ka funteni ni sɛgɛn dɔgɔya.

Nafa minnu bɛ sɔrɔ jiginni na .

Surface Finish (Sɔrɔdasi) ɲɛnabɔli : a bɛ bɔ surface (yɔrɔ) saniyalen kɔfɛ ni a bɛ tali kɛ milling conventionnelle (sɔgɔli) la.

Baarakɛminɛnw sɛgɛn dɔgɔyali : Baarakɛminɛn bɛ sɔgɔsɔgɔ dɔɔnin sɔrɔ, k’a si hakɛ caya ani ka sɛgɛn dɔgɔya.

Sumaya dɔgɔyali : A bɛ funteni dɔgɔya, ka tigɛcogo ɲuman sabati ani ka baarakɛminɛnw sumaya kojugu.

Baarakɛcogo nɔgɔman : Jiginni fanga bɛ dɛmɛ ka baarakɛminɛn lakana, ka sirili wajibiyalenw nɔgɔya.

Nafa minnu bɛ sɔrɔ jiginni na .

Nka, jiginni-minɛn fana bɛ ni dɛsɛw ye, kɛrɛnkɛrɛnnenya la, fɛn dɔw ni masinw sigicogo dɔw la:

A ma bɛn yɔrɔ gɛlɛnw ma : a man ɲi fɛnw ma i n’a fɔ nɛgɛ gɛlɛn, o bɛ se ka baarakɛminɛn tiɲɛ.

Yɛrɛyɛrɛko koɲɛw : Balo kɔfɛla bɛ se ka kɛ sababu ye ka yɛrɛyɛrɛli kɛ tigɛ waati la.

Masina wajibiyalenw : A bɛ masinw de wajibiya minnu bɛ bɔ kɔfɛ walima minnu bɛ sara walasa ka baarakɛminɛnw tiɲɛ.

Milling conventionnel ye mun ye?

Ɲɛfɔli dafalen kɛra mansinko kɔrɔlen kan (ka u wuli) .

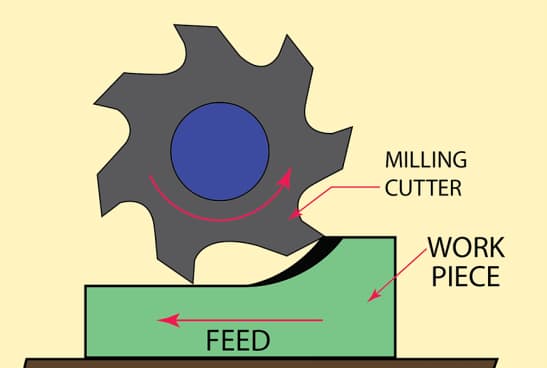

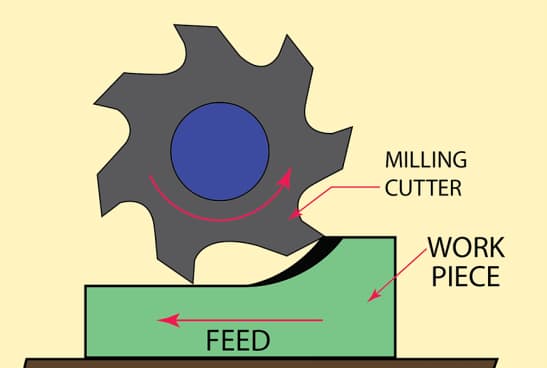

Milling conventionnelle, n’a bɛ fɔ fana ko UP milling, o ye laadala masin-fɛɛrɛ ye, tigɛminɛn bɛ wuli ka taa baarakɛminɛn in balocogo la. O fɛɛrɛ in bɛ baara kɛ kosɛbɛ fɛn dilanni na kabini san tan caman k’a sababu kɛ a jogo ni a nafa kɛrɛnkɛrɛnnenw ye baara kɛrɛnkɛrɛnnenw na.

Milling sira kɔrɔlen ani a nɔ min bɛ tigɛcogo la .

Milling conventionnel kɔnɔ:

Tigɛbaga bɛ wuli ka kɛ baarakɛminɛn ye min bɛ baara kɛ ni baarakɛminɛn ye .

ɲinw tigɛcogo bɛ fɛn in siri ka bɔ duguma , ka taa san fɛ .

chip thickness bɛ daminɛ zeru la ka bonya ka se a dan na tigɛ laban na .

O sanfɛla lamaga-lamagali bɛ nɔ danfaralenw Di masinw dilanni na, ka nɔ bila chip (puce) dilancogo la, baarakɛminɛnw sɛgɛnni na, ani surface (yɔrɔ) fini na.

Milling conventionnelle jogo ni a jogo .

Chip Formation : chip modèle fin-to-thick .

Tigɛ fanga : Sanfɛla fanga ka teli ka baarakɛminɛn kɔrɔta .

Baarakɛminɛnw ka baara : tigɛ doni bɛ caya dɔɔni dɔɔni ni ɲin bɛ taa ɲɛ .

Funteni bɔli : Sumaya hakɛ ka ca tigɛyɔrɔ la .

Nafa minnu bɛ sɔrɔ mansinw na minnu bɛ kɛ ka caya .

Sumaya sabatili : Baarakɛminɛnw ka baara kɛcogo ɲuman bɛ se ka kunbɛn ka ɲɛ, kɛrɛnkɛrɛnnenya la fɛn gɛlɛnw kama .

Backlash Elimination : Sanfɛ fanga bɛ bɔ masin kɔkanna na cogo la min bɛ bɔ a yɛrɛ la .

Hard Surface Compatibility : A ka ɲi ka kɛ masinw ye yɔrɔ gɛlɛnw walima fɛn minnu bɛ fɛnw sɔgɔ .

Chatter Reduction : A ka dɔgɔn ka yɛrɛyɛrɛ setup dɔw la .

Milling conventionnelle nafa .

Inferior Surface Finish : Sanfɛ chip evacuation bɛ se ka kɛ sababu ye ka re-cutting ani surface marring .

Accelerated Tool Wear : ka dɔ fara ɲɔgɔnkanu kan ani ka funteni sɔrɔ ka baarakɛminɛnw ɲɛnamaya dɔgɔya .

Sumaya degun : Tigɛ doni ni funteni ka bon, o bɛ se ka kɛ sababu ye ka baarakɛminɛnw tiɲɛ .

Baara gɛlɛn : Kɛrɛkili barikama min ka kan ka kɛ walasa ka wuli fanga kɛlɛ .

Yɛlɛn milling vs milling conventionnelle: danfara jɔnjɔnw .

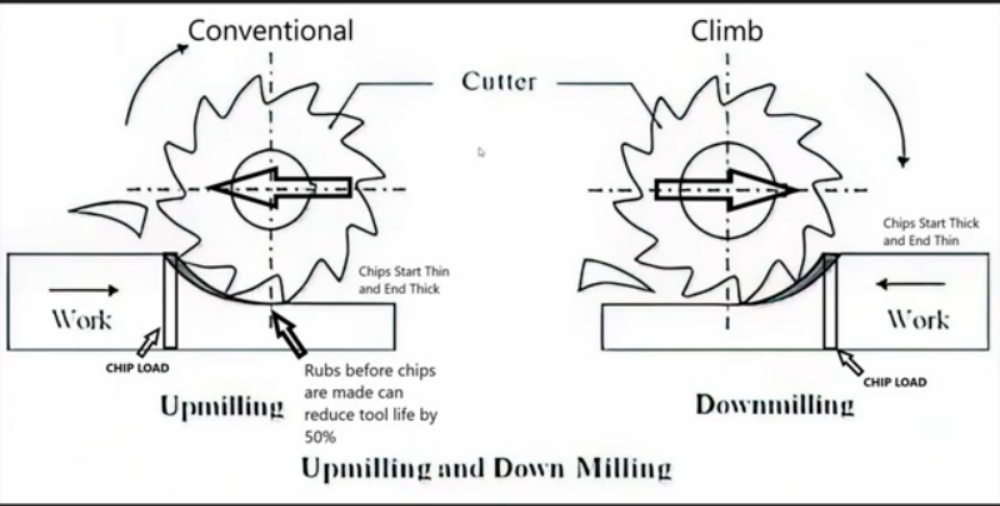

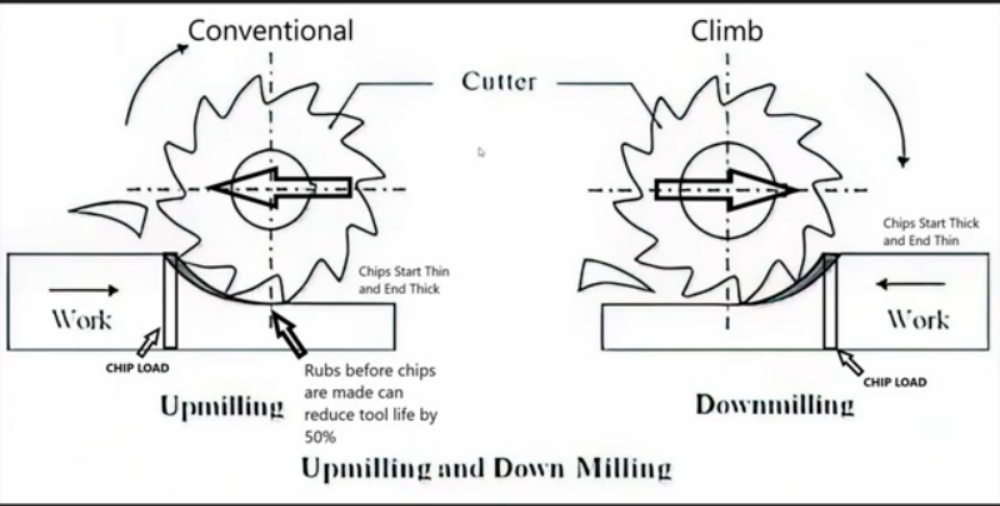

chip formation ani direction

| aspect | jiginni milling | conventionnelle . |

| chip thickness . | A ka bon fo ka se a finman ma . | A ka fin fo ka se a ka bon . |

| Sumaya tilali . | Funteni jiginni nafama ka taa chips . | funteni hakɛ min bɛ tigɛyɔrɔ la . |

| Baarakɛminɛnw degun . | A daminɛ na, a bɛ se ka kɛ ko a bɛ se ka kɛ . | Dɔ farali dɔɔnin dɔɔnin tigɛ doni kan . |

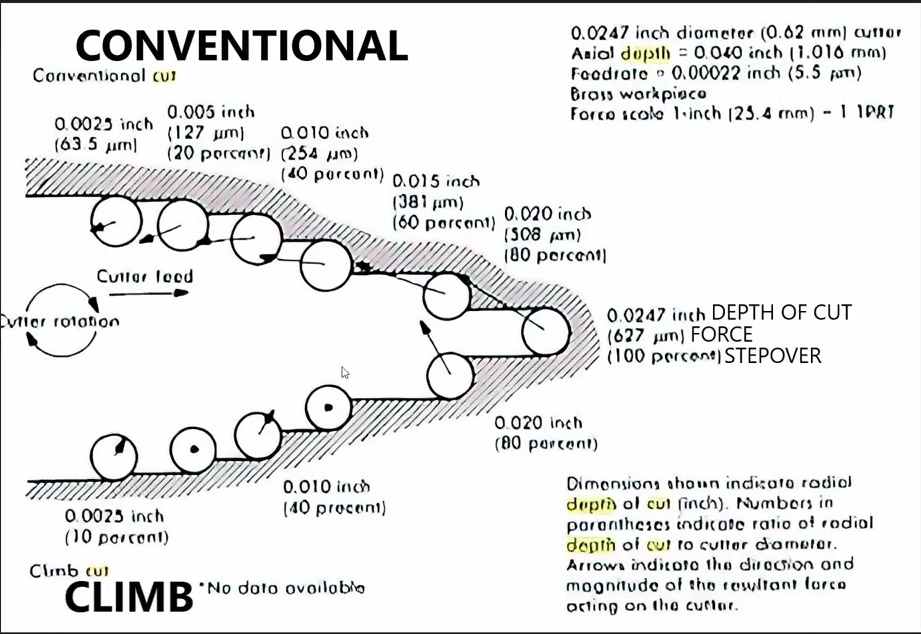

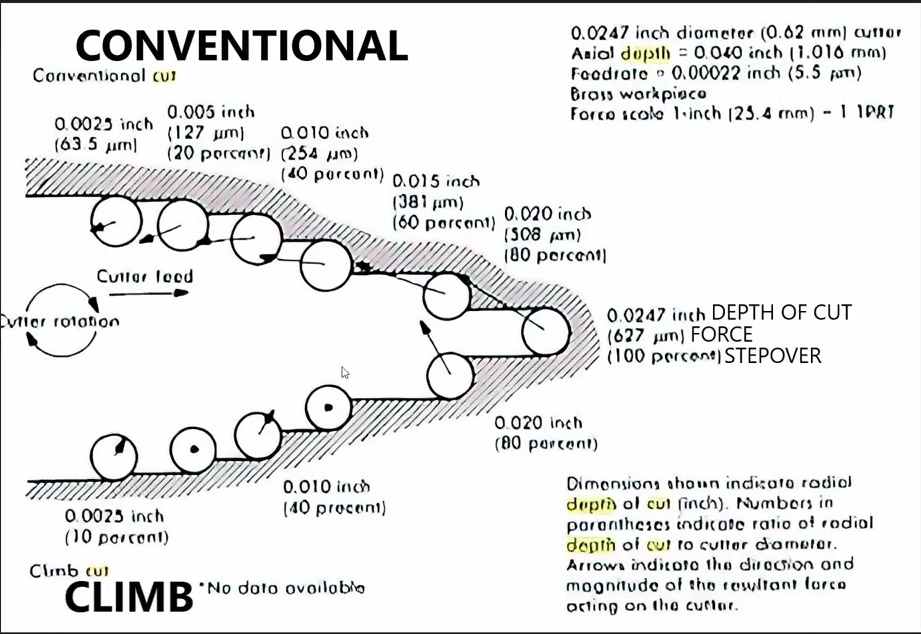

Puce (puce) dilancogo bɛ nɔba bila funteni sɔrɔli la ani baarakɛminɛnw doncogo la. Climb Milling ka puce (puce) minnu ka bon fo ka se u dan ma, olu bɛ funteni bɔli nɔgɔya, ka funteni degunw dɔgɔya baarakɛminɛn ni baarakɛminɛn kan.

Baarakɛminɛnw deflection ani tigɛcogo ɲuman .

Baarakɛminɛnw deflection direction bɛ nɔ bila masinw ka tiɲɛni na. Deflection parallèle dans la conventionnel milling bɛ a to a bɛ se ka kunbɛn ka ɲɛ, kɛrɛnkɛrɛnnenya la ni a bɛ baara kɛ ni fɛn gɛlɛnw ye walima ni a bɛ baara kɛ ni fɛn gɛlɛnw ye.

Yɛlɛn mansin bɛ kɛ cogoya la min bɛ kɛ ka ɲɛ ka ɲɛ ka da a kan:

chip evacuation efficace .

Dɔgɔyali ka se ka kɛ chip recutting .

Jiginni fanga minnu bɛ baarakɛminɛnw kɔrɔtacogo dɔgɔya .

Milling conventionnelle bɛ se ka kɛ sababu ye ka yɔrɔ gɛlɛnw sɔrɔ minnu bɛ sɔrɔ chip flow sanfɛ ani chips seginni seko la.

Baarakɛminɛnw ɲɛnamaya ani u doncogo .

Yɛlɛn milling bɛ baarakɛminɛnw ɲɛnamaya janya ka tɛmɛ:

Jiginni daminɛ degunw dɔgɔyali tigɛyɔrɔw kan .

Dɔgɔyali dɔgɔyali ni funteni sɔrɔli .

chip evacuation efficace, min bɛ abrasion (abrasion) dɔgɔya .

Milling conventionnel bɛ teli ka kɛ sababu ye ka baarakɛminɛnw sɛgɛn teliya la ka da:

Dɔ farali dɔɔnin dɔɔnin tigɛ doni kan .

Fɔɲɔba min bɛ kɛ ni baarakɛminɛn ye, o bɛ kɛ baarakɛminɛn ye .

Sumaya hakɛ cayalenba tigɛyɔrɔ la .

Baarakɛminɛn minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ

| fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se | ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye . |

| Nɛgɛ nɔgɔlenw (misali la, aluminiyɔmu) . | Yɛlɛn milling . |

| Alloy gɛlɛnw (misali la, titanium) . | Milling conventionnel . |

| Plastikiw ni Composites . | Yɛlɛn milling . |

| Baara minnu bɛ gɛlɛya . | Yɛlɛn milling . |

| Abrasif fɛnw . | Milling conventionnel . |

Fɛn minnu ka kan ka jateminɛ ni aw bɛ jiginni ni sɛnɛ kɛcogo kɔrɔlen sugandi .

Masina seko ni dɔnko .

Backlash elimination : A nafa ka bon jiginni na walasa ka yɛrɛyɛrɛli bali ani ka tiɲɛni kɛ.

Kɔrɔsili : Masina gɛlɛya ka bon, o bɛ sira di jiginni ma ka ɲɛ, kɛrɛnkɛrɛnnenya la, teliyaba la.

Contrôle system : CNC systems avancés bɛ se ka kɔkanko musaka bɔ, o bɛ se ka kɛ sababu ye ka jiginni baarakɛlaw lakana.

Baarakɛminɛnw ka fɛnw nafa

| Material characteristic | preferred milling method . |

| Soft ani ductile . | Yɛlɛn milling . |

| A ka gɛlɛn ani a bɛ kari . | Milling conventionnel . |

| Baara-kɛlɛli . | Yɛlɛn milling . |

| Abrasif . | Milling conventionnel . |

Aw ye gɛlɛya kɛrɛnkɛrɛnnenw jateminɛ minnu bɛ kɛ ni fɛn kɛrɛnkɛrɛnnenw ye i n’a fɔ puce (puce) dilancogo, funteni sɔrɔli, ani baarakɛminɛnw doncogo ni aw bɛ mansin kɛcogo sugandi.

Tigɛ baarakɛminɛn jateminɛcogo ani a dacogo .

Rake angle : rake angle ɲumanw ka teli ka baara kɛ ka ɲɛ jiginni na, ka sɔrɔ rake angles negatives bɛ bɛn milling conventionnel ma fɛn gɛlɛnw kama.

Flute design : Baarakɛminɛn minnu dilannen don jiginni kama, a ka c’a la, olu bɛ ni puce evacuation channels ye minnu bɛ baara kɛ ka ɲɛ.

Coatings : Tialn walima ticn coatings bɛ se ka baarakɛminɛnw ka baara kɛcogo ɲɛ ka ɲɛsin sɔgɔli kɛcogo fila bɛɛ ma, ka sɛgɛnbaliya ni funteni jɛnsɛnni ɲɛ.

Surface Finish ani Dimensional tiɲɛni ɲininen .

Yɛlɛn milling bɛ caman Bɔ:

Surface finiw bɛ nɔgɔya .

Dimensional accuracy ka fisa ni fɛn nɔgɔmanw ye .

Burr sɔrɔli farati bɛ dɔgɔya .

Milling conventionnelle bɛ se ka kɛ ka ɲɛ:

Baara kɛcogo gɛlɛnw .

Machining Hard Materials yɔrɔ min na surface fini bɛ dɔgɔya kosɛbɛ .

Aplikasi minnu bɛ se ka kɛ ni kunnafoni jugumanw ye tigɛ juguya kan .

Machining paramètres

| paramètres | climb milling | conventionnel millage . |

| Tigɛ teliya . | Teliya caman bɛ se ka kɛ . | Teliya dɔgɔyali bɛ se ka kɛ wajibi ye . |

| Balo hakɛ . | A bɛ se ka balo hakɛ caman minɛ . | A bɛ se ka kɛ ko balo hakɛ dɔgɔyali de bɛ kɛ . |

| Tigɛ ka juguya . | Sɔgɔsɔgɔninjɛ minnu bɛ fɔ ka ɲɛ . | Ka se ka tigɛtigɛ juguw minɛ . |

O paramɛtɛrɛw ɲɛnabɔ ka da sɔgɔli fɛɛrɛ sugandilen kan, baarakɛminɛnw, ani kɔlɔlɔ ɲininenw. Labɛnni ɲuman bɛ kɛ sababu ye ka puce (puce) dilancogo ɲuman, baarakɛminɛnw ɲɛnamaya, ani surface quality (yɔrɔ ɲuman) sabati.

Yɛlɛn-sɔgɔli ni mansin-minɛn kɔrɔlenw baarakɛcogo .

Aerospace industrie .

Aerospace sector bɛ a jigi da kosɛbɛ sɛnɛfɛnw dilanni fɛɛrɛ kɔrɔlenw kan walasa ka fɛn nafamaw dilan:

Avionw sigicogo .

Yɛlɛn milili: A ka ɲi kosɛbɛ aluminiyɔmu bɔgɔlan yɔrɔw la, a bɛ a to a ka kɛ a ɲɛda la ka ɲɛ ani a ka muɲuli ka gɛlɛn.

Milling conventionnelle : A ka fisa nɛgɛmafɛnw ma minnu ka gɛlɛn, o bɛ sabatili di masinw ma.

Motɛri yɔrɔw .

Turbine blades: Yɛlɛn ka excels (jibɔ) kɛ ka fiɲɛ-foyi cogoya gɛlɛnw dilan, ka baarakɛminɛnw doncogo dɔgɔya ni titanium alloys (titanium alloys) bɛ baara kɛ.

Combustion Chambers: Milling conventionnelle bɛ kunnafoni ɲuman di kɔnɔnafɛnw kan minnu ka gɛlɛn ani superalloys minnu bɛ se ka funteni sɔrɔ.

Landing gear yɔrɔw .

Struts: jiginni sɔgɔli bɛ surface fini ɲuman di, min nafa ka bon sɛgɛn kunbɛnni na.

Pivot pins: conventionnel milling bɛ a to dimensional accuracy ni masinw ka gɛlɛn.

Mobili industrie .

Milling techniques jɔyɔrɔ ka bon kosɛbɛ mobili dilanni na:

| Component | Climb Milling | Milling conventionnel . |

| Motɛri blokiw . | Finish passes ka silinda bores . | Machine de machine de fer blocs de cast . |

| Transmission koɲɛw . | Surface laban laban . | Fɛn fɔlɔ bɔli . |

| Silindri kunkolow . | Valve sigilan machining . | port roughing operations . |

Dɔgɔtɔrɔso minɛnw dilanni .

Precision milling critical ka furakɛli minɛnw dilan:

Orthopedic Implants .

Opereli minɛnw .

Denw ka yɔrɔw .

Implant abutments (Implant abutments) : Yɛlɛn bɛ se ka fini ɲumanw sɔrɔ titanium kan walasa ka osseointegration ɲuman sɔrɔ.

Koronawirisi ni bɔrɔw : mansincogo kɔrɔlen bɛ sira di seramiki fɛnw cogoya tigitigi ma.

Fɛɛrɛko ɲɛtaa ani u nɔfɛkow jiginni ni sɛnɛ kɛcogo kɔrɔ la .

Masini teliya (HSM) .

HSM bɛ jiginni ni sɛnɛcogo kɔrɔlenw bɛɛ sɛmɛntiya:

HSM ka baarakɛminɛnw bɛ sɔrɔ iziniw kɔnɔ .

Aerospace:

Automobile:

Furakɛli:

Tigɛminɛn minnu bɛ taa ɲɛ .

Bi baarakɛminɛnw kɔnɔfɛnw bɛ nɔba bila milling baarakɛcogo la:

| fɛnw | gɛlɛya (HV) | Best for . |

| Carbide . | 1 300 - 1 800 . | A bɛ se ka kɛ fɛn caman ye, a teliya ka bon . |

| Seramiki . | 2 100 - 2 400 . | Alli minnu bɛ se ka funteni sɔrɔ, nɛgɛ gɛlɛnw . |

| HSS . | 800 - 900 . | Fɛn minnu ka nɔgɔn, olu bɛ se ka kɛ musaka ye . |

| Diamant-coated . | >10 000 | Abrasif matériaux, ultra-précision baara . |

Nafa jɔnjɔnw:

Carbide Inserts: Baarakɛminɛnw ɲɛnamaya janyalen, baarakɛcogo ɲɛnabɔlen na sɔgɔli fɛɛrɛ fila bɛɛ la .

Seramiki dondaw: A ka ɲi kosɛbɛ masinw dilanni na minnu bɛ kɛ ni funteni ye kosɛbɛ aerospace baarakɛcogo la .

HSS baarakɛminɛnw: musaka min bɛ kɛ ka ɲɛsin fɛn bɛɛ ma min bɛ kɛ ka fɛnw tigɛ .

Diamant-coated Tools: A tɛ se ka suma ni fɛn ye min tɛ se ka suma ni fɛn ye min tɛ se ka suma .

Ɔridinatɛri dɛmɛni (CAM) porogaramu .

CAM porogaramu bɛ sɛnɛfɛnw dilanni fɛɛrɛw yiriwa ni fɛn kɔrɔw ye:

Adaptive Clearing: A bɛ baarakɛminɛnw siraw ɲɛnabɔ ka da fɛn tolenw kan, ka nafa sɔrɔ sɔgɔli kɛcogo fila bɛɛ la.

Masini teliyaba (HSM) alɔgɔridiw: A bɛ jiginni waatiw dɔgɔya ani ka dugukolo sanfɛla finiw ɲɛ ka taa a fɛ jiginni na.

Trochoidal milling: A bɛ baara kɛ ni baarakɛminɛnw siraw ye minnu bɛ circular (circulaire) kɛ walasa ka funteni sɔrɔli dɔgɔya milling conventionnel (jibɔcogo kɔrɔ) la.

Rest Machining: A bɛ fɛn minnu tolen don baarakɛminɛnbaw fɛ, olu bɔ ka ɲɛ, ka fɛɛrɛ fila bɛɛ dafa.

CAM porogaramu minnu bɛ fɔ kosɛbɛ:

Fusion autodesk 360 .

Mastercam .

SolidCam .

HSMWORKS .

Camworks .

O porogaramuw ɲɛnabɔcogo ninnu bɛ simulatigɛ seko bɛɛ di, ka sira di masinw ma u ka se ka sɛnɛ kɛcogo ɲumanw ɲɛnabɔ ka sɔrɔ ka u dilan tiɲɛ na. U bɛ jiginni ni sɛnɛfɛnw sɛnɛcogo kɔrɔlenw don ɲɔgɔn na cogo ɲuman na walasa ka ɲɛtaa ɲuman sɔrɔ fɛn dilanni cogoya caman na.

Gɛlɛyaw ni jateminɛw jiginni ni sɛnɛ kɛcogo kɔrɔlen na .

Baarakɛminɛnw deflection ani chatter .

A sababuw ni a nɔfɛkow

| bɛ na | Kow | ni nɔw ye . |

| Baarakɛminɛnw deflection . | Materiel gɛlɛya, tigɛ juguya, baarakɛminɛnw jateminɛ . | Dimensionnel inaccuracies, surface de surface man ɲi . |

| Chatter . | Baarakɛminɛn ni masinw ka fɔkanw, tigɛ fanga tɛmɛnenw . | Yɛrɛyɛrɛli, dugukolo kan dafabaliya, baarakɛminɛnw ɲɛnamaya dɔgɔyali . |

Mitigation fɛɛrɛw .

Baara kɛ ni baarakɛminɛn surunw ye minnu ka gɛlɛn walasa ka deflection dɔgɔya .

Optimiser spindle speeds walasa ka i yɛrɛ tanga resonant frequences ma .

Baarakɛcogo ɲɛtaa fɛɛrɛw waleya walasa ka sabatili ɲɛ .

Baara kɛ ni nɛnɛmadalan ye min bɛ tansiyɔnba la walasa ka tigɛ fanga dɔgɔya .

Chip formation ani evacuation .

Comparative Analysis

| Aspect | Climb Milling | Conventionnelle Milling . |

| Chip formation . | Modèle de thick-ka-thin . | Modèle fin-to-thique . |

| evacuation direction . | yɔrɔ jan tigɛyɔrɔ la . | Ka ɲɛsin tigɛyɔrɔ ma . |

| Sumaya tilali . | Funteni jiginni nafama ka taa chips . | Sumaya hakɛ tigɛyɔrɔ la . |

Optimisation fɛɛrɛw .

Balance tigɛ paramɛtɛrɛw (teliya, balo, juguya) ka ɲɛsin chip dilancogo ɲuman ma .

Baarakɛminɛn minnu bɛ ni nɛgɛw ye minnu bɛ polisi ani helikiliw ka bon walasa ka mɔgɔw bɔ u la cogo ɲuman na .

Aw bɛ fiɲɛbɔlanw walima nɛnɛmadalan minnu bɛ tansiyɔnba la, olu waleya walasa ka chip bɔli kɛ ka ɲɛ .

Aw bɛ baarakɛminɛnw dacogo ladilan walasa ka chip nɔrɔli bali ani ka aw labɔli ɲɛ .

Baarakɛminɛnw ni jateminɛ kɛcogo .

Material Impact on Milling Technique Selection .

Fɛn nɔgɔlenw, ductile (misali la, aluminiyɔmu): Yɛlɛn sɔgɔli min ka fisa walasa ka surface fini ɲuman sɔrɔ .

Fɛn gɛlɛnw, fɛn minnu bɛ tiɲɛ (misali la, nɛgɛ gɛlɛn): Milling conventionnelle bɛ sabatili caman di .

Baara minnu bɛ kɛ ka gɛlɛya sɔrɔ: Yɛlɛli bɛ dɔgɔya, o bɛ dɔ bɔ degun gɛlɛyali farati la .

Abrasive Materials: Milling conventionnel bɛ baarakɛminɛnw ɲɛnamaya ani u kunbɛncogo ɲuman di .

Jateminɛw kɛli jateminɛw .

Kɛnɛma tigɛw: Yɛlɛn ka tɛmɛ periferi mansin baara kan .

Kɔnɔnafɛnw: Milling conventionnel bɛ se ka kunnafoni ɲuman di slots ni pockets kan .

Fɛn minnu kogo ka fin: Yɛlɛn sɔgɔli bɛ dɔ bɔ fɛnw tiɲɛni farati la .

Contours complexes : o fɛɛrɛ fila bɛɛ faralen ɲɔgɔn kan, o bɛ se ka kɛ wajibi ye walasa ka ɲɛtaa ɲuman sɔrɔ .

Waleya ɲumanw ani laadilikanw jiginni ni sɛnɛ kɛcogo kɔrɔlen na .

Tigɛ paramɛtɛrɛw sugandili ka ɲɛ .

Optimiser milling performance ni ka nin paramètres critiques ninnu labɛn ka ɲɛ:

Tigɛ teliya: Aw bɛ ladilan ka da fɛnw cogoyaw kan ani baarakɛminɛnw seko kan .

Balo hakɛ: Balance ni tigɛ teliya ye chip formation ɲuman ye .

Tigɛ juguya: Kɔlɔsili walasa ka tigɛ fanga ni funteni sɔrɔ .

| paramètre | climb milling | conventionnel milling . |

| Tigɛ teliya . | Teliya caman bɛ se ka kɛ . | Teliya damadɔ minnu bɛ fɔ . |

| Balo hakɛ . | A bɛ se ka balo caman minɛ . | Balo dɔgɔyali ka ɲɛsin sabatili ma . |

| Tigɛ ka juguya . | tigɛcogo minnu ka dɔgɔn . | Ka se ka tigɛtigɛ juguw ɲɛnabɔ . |

Baarakɛminɛnw jateminɛcogo ɲuman ani u datugucogo .

Baarakɛminɛnw cogoya bɛnnenw sugandi baara kɛrɛnkɛrɛnnenw kama:

Rake angle: positive for climb milling, negative for convention in harders materials .

Helix angle: Angles sanfɛtaw bɛ chip evacuation ɲɛ ka taa jiginni na .

Flute design: open flutes for better chip flow in conventionnel milling .

Coatings: Tialn ka funteni caman sɔrɔ, ICN ka ɲɛsin fɛnw ma minnu bɛ kɛ ka fɛnw sɔgɔ .

Contrôlée chip formation ani evacuation .

Puce ɲɛnabɔli yiriwali nin fɛɛrɛ ninnu fɛ:

Aw bɛ nɛnɛmadalan minnu bɛ tansiyɔnba la, olu waleya walasa ka chip bɔli kɛ ka ɲɛ .

Aw bɛ fiɲɛbɔlanw kɛ walasa ka chip recuttting bali ka kɛ milling conventionnelle la .

Baarakɛminɛnw sugandi minnu bɛ ni flutes polisilenw ye walasa ka chip adhesion dɔgɔya .

Tigɛ paramɛtɛrɛw ladilan walasa ka chip thickness ɲuman sɔrɔ .

Baarakɛminɛnw deflection ni chatter min bɛ dɔgɔya .

Aw bɛ dɔ bɔ yɛrɛyɛrɛli la ani ka tiɲɛni mara:

Baara kɛ ni baarakɛminɛnw minɛcogo gɛlɛnw ye walasa ka deflection dɔgɔya .

Optimiser spindle speeds walasa ka i yɛrɛ tanga resonant frequences ma .

Baara kɛ ni baarakɛminɛn surunw ye ni a bɛ se ka kɛ .

Yɛrɛyɛrɛli damping baarakɛminɛnw waleya fɛn gɛlɛnw kama .

Ka baarakɛcogo ɲuman ni masinw ka gɛlɛya sabati .

Aw bɛ sabatili ni tiɲɛni kɛ ka caya:

Baara kɛ ni fixturing systems barikamaw ye minnu bɛnnen don milling technique ma .

Ka clamping points caman waleya baarakɛminɛnbaw kama .

Aw ye a lajɛ ni a bɛ kɛ ni vacuum ye walasa ka fɛn finmanw sɔrɔ jiginni na .

Aw bɛ to ka masinw mara ani ka u jateminɛ walasa ka gɛlɛya ɲuman sɔrɔ .

Kuncɛli

Kuma surun na, jiginni sɔgɔli ni sɔgɔli kɔrɔlen bɛ danfara Bɔ chip (puce) dilancogo la, baarakɛminɛnw deflection (minɛn) la, ani surface (yɔrɔ) la. Yɛlɛn sɔgɔli ka ɲi kosɛbɛ fɛnw na minnu ka nɔgɔn ani minnu bɛ kɛ ka ɲɛ, ka sɔrɔ mansinw bɛ bɛn fɛn gɛlɛnw ma ani u bɛ se ka u kunbɛn ka ɲɛ.

Aw bɛ jiginni kɛ ni fɛn nɔgɔmanw ye i n’a fɔ aliminiyɔmu. Aw bɛ sugandi mansin kɛcogo kɔrɔlen ni aw bɛ a yɔrɔ gɛlɛnw kɛ masinw ye i n’a fɔ nɛgɛ walima nɛgɛ min bɛ kɛ ka nɛgɛ kɛ. Masina suguya ani a mago bɛ kɔkanna musaka la, o fana bɛ nɔ bila sugandili la.

Walasa ka baara kɛcogo ɲuman sɔrɔ ani ka baarakɛminɛnw ɲɛnamaya janya, aw bɛ mansin kɛcogo bɛn ni fɛnw ni masinw ka ɲininiw ye. Fɛɛrɛ sugandili ɲuman bɛ baarakɛminɛnw sɛgɛn dɔgɔya ani ka baara kɛcogo ɲɛ.