Yala aw delila k’aw yɛrɛ ɲininka cogo min na aerospace motɛriw bɛ se k’u ka silindaw yɔrɔ tigitigiw sɔrɔ cogo kabakoma na wa? Boring machining , n’o ye fɛn dilanni jɔnjɔn ye, o bɛ jaabi minɛ.

Fɛnw dilanni ɲɛtaa siratigɛ la, baara minnu bɛ mɔgɔ sɛgɛn, olu jɔlen bɛ i n’a fɔ sanu hakɛ min bɛ kɛ ka dingɛ tiɲɛni ni dugukolo fan laban danma sɔrɔ. K’a ta furakɛli minɛnw na minnu bɛ kɛ ni mikroskɔpi ye ka se izini masinbaw ma, o baara camanba in bɛ dingɛw bonya ani ka u ban minnu tun bɛ yen ka kɔrɔ ni muɲuliw ye minnu sirilen don fo ±0.0001 inch.

Nin gafe bɛɛ lajɛlen bɛ sɛgɛnlafiɲɛbɔlanw ka sariyakolow, u ka fɛɛrɛw, u ka baarakɛminɛnw ani u ka baarakɛcogo sɛgɛsɛgɛ, ka hakilinaw di cogo min na nin wale gɛlɛn in bɛ bi fɛn dilanni tigitigiya cogoya.

Machining min bɛ mɔgɔ sɛgɛn, o ye mun ye?

Faamuyali min bɛ mɔgɔ sɛgɛn .

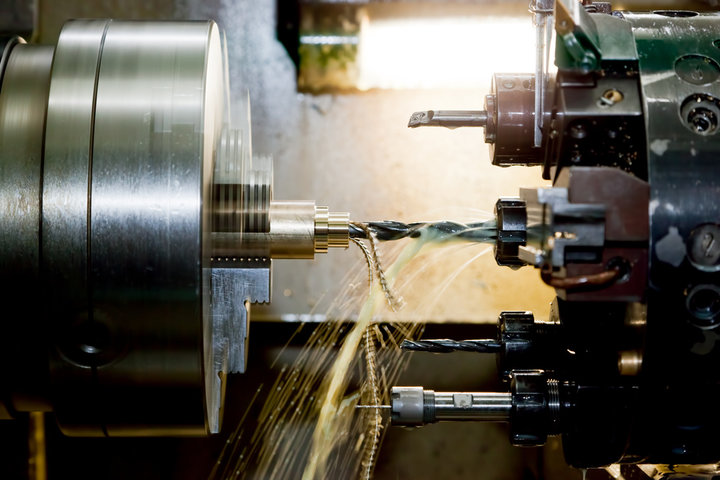

Boring machining - kalan gafe taabolo min bɛ kɛ ka nɛgɛw dilanni n’u tigɛcogo fɛɛrɛw tigɛ minnu bɛ kɛ ka dingɛ dɔ ban baarakɛminɛn dɔ kɔnɔ walima ka kɔ-baara kɛ dingɛ kɔnɔ. Fɛn bɛ bɔ dɔɔnin dɔɔnin, ka ɲɛ, ka kɛ cogo kelen na, ka bɔ dingɛ kɔnɔ min bɛ kɛ ka kɔn a ɲɛ, o kɔnɔna na, bɔgɔdaga tigɛyɔrɔw fɛ. Aw bɛ masina kɛ ni barajuru tigɛlan ye min bɛ sɛgɛn, tigɛminɛn bɛ dilan walasa ka taa dɔɔnin dɔɔnin ka taa baarakɛminɛn fan fɛ ani ka wuli waati kelen na walasa ka yɔrɔ tigitigi tigɛ ani ka se sɔrɔ min ye silinda kɔfɛla ye.

O baara senfɛ, tigɛdaw bɛ baara kɛ baarakɛminɛnfɛn kan k’a sɔrɔ u bɛ lamaga ni teliya jatebɔlenw ni balo ye, walasa ka helix wise masin na ni dakunw bɛ taa ɲɛ dingɛ kɔnɔ. Nin baara minnu bɛ sen na sisan, olu bɛ jɛ ni ɔridinatɛri jatebɔlenw (CNC) masinw ye minnu bɛ se ka lamaga labɛn ani k’u kɔlɔsi nɛgɛ tigɛminɛn kelen ka masin kɔnɔ, ka fara ɲɔgɔn kan sira o sira fɛ ani ka yɔrɔjan tiɲɛni negela ni a lamini cogoya jateminɛbali mara ka bɔ aksidan na.

Dingɛw bonya sariyakolow .

Borer baara la, jateminɛ tigitigi bɛ mara ni politiki ye min tɛ wuli ka bɔ a nɔ na, n’o ye ka fɛnw bɔ yen ni tiɲɛni ye. Tiɲɛ na, o b’a ɲini ka tigɛ fanga hakɛ bɛɛ lajɛlen sɔrɔ ani baarakɛminɛn ka gɛlɛya min bɛ jatebɔ nafa jateminɛ ka ɲɛsin overhang ratio ma, o nafa ka bon kosɛbɛ tiɲɛ na. Tigɛda in ɲɛsinnen bɛ ka jɛɲɔgɔnya kɛ ni baarakɛminɛn ye tigɛyɔrɔba yɔrɔba latigɛlen na min bɛ nɔ bila chip flow ni surface quality la.

Ka ɲɛsin dimension (hakilila) tiɲɛni ma, funteni sabatili bɛ roll (bololanɛgɛ) nafama dɔ fɔ. baarakɛminɛn ni baarakɛminɛn ka Baarakɛminɛn cɛmancɛw ni fitininw na, fɛn minnu bɛ i n’a fɔ nɛnɛbɔlanw, olu bɛ dɛmɛ ka funteni min bɛ sɔrɔ tigɛyɔrɔ la, o ɲɛnabɔ, o cogo la, o ye ka funteni bonya kofɔlenw ni jateminɛcogo caman ɲɔgɔnna caman bali. Yɛrɛyɛrɛli kɔlɔsili bɛ nafa dɔ Fàra a kan ni dingɛ sɛgɛnnen hakɛ bɛ caya, tigɛ paramɛtɛrɛ dɔgɔyali ɲinini, tigɛcogo ani baarakɛminɛnw jateminɛcogo walasa ka yɛrɛyɛrɛli balili Sɔrɔ ani ka dugukolo sanfɛla cɛɲi cogoya bɛɛ Dafa.

Mun na masinw bɛ mɔgɔ sɛgɛn, olu nafa ka bon?

Mako min bɛ tiɲɛni na fɛn dilanni taabolo la, o y’a to masinw dilanni min bɛ mɔgɔ sɛgɛn, o nafa ka bon kosɛbɛ sisan baarakɛyɔrɔw la. O kɛcogo bɛ fini ɲumanw di minnu bɛ se ra 16 ma RA kan a sanfɛla la ani ka se ±0,0001inches tigitigi ma a hakɛw la. Nin tiɲɛni hakɛ in ye baarakɛminɛn ye ka dɔ fara fɛn dɔ ka ɲumanya n’a ka baarakɛcogo kan kɛrɛnkɛrɛnnenya la baara gɛlɛnw na i n’a fɔ fɛn dilanni motɛri blokiw ani aero-ɛntɛriw. Ka fara o kan, cogoya muɲuni wajibiyalenw ka gɛlɛn kosɛbɛ minnu bɛ se hali cogoya wajibiyalenw na minnu ka gɛlɛn kosɛbɛ ka tɛmɛ Daedo cogoya kan.

Masini suguya minnu bɛ mɔgɔ sɛgɛn .

Silindri boring machines .

Silindri boring machines bɛ sira di motɛri silinda kogow seginni ma ani u sɔgɔli ma ni tigɛ tigitigi ye. O masinw bɛ dilan ni bar bar laban-ni-ban ye min ye inserts tigɛ a kɔnɔ minnu fana bɛ dilan ni numérique gauges ye walasa ka surface reginements kɔlɔsi. Sisan misaliw bɛ index (sɛgɛsɛgɛli) kɛcogo dɔ fara ɲɔgɔn kan walasa ka segin-ka-bɔ ani ka funteni/nɛnɛ kɛ walasa ka so minnu bɛ baara la, olu ka funteni sumani kama, o min bɛ sira di ka RA 15-20 micro inch (mikɔrɔ-mikɔrɔ-mikɔrɔ-sɛrɛ) filɛli-finiba sɔrɔ k’a sɔrɔ a bɛ se ka kɛ sababu ye ka bore bɛɛ to 0,0001 inch kɔnɔ.

Machines de boring directionnelle .

Direction boring walima directional drilling ye tunɛriw jɔcogo ye i n’a fɔ bore cogo la cogo la min bɛ kɔrɔsi kosɛbɛ, i n’a fɔ k’a sɔrɔ a ma ɲɛmɔgɔso tiɲɛ. Nin fɛɛrɛ in bɛ GPS ni porozɛ ɲɛminɛni ni ɛntɛrinɛti nɔfɛtaama fara ɲɔgɔn kan walasa ka baara kɛ ni BOR ɲɛmɔgɔ ye. Masina kɔrɔlen minnu bɛ kɛ ka caya siratigɛ sɛgɛn na, olu bɛ tigɛyɔrɔw la minnu bɛ kɛ cogo kɔrɔ la ani ka drilling head don min bɛ baara kɛ ni ji jets ye ka baara kɛ. Ani fana, bore sira min bɛ sɔgɔ sira fɛ, o bɛ karti ni waati yɛrɛ la bore sira ye min bɛ yɔrɔ sumani hakɛ kabakomaw lajɛ koɲuman. A yɔrɔ yɔrɔ caman bɛ se ka kɛ ka bɔ pipe rack la ka taa pipe marayɔrɔ ni drilling na minnu tɛ Romɛkaw bila jɔyɔrɔw la minnu bɛ tila bangebagaw ka ɲinini na.

Machine boring horizontale .

Boring horizontal bɛ dɔn kosɛbɛ ko a ye fɛɛrɛ ɲuman ye CNC masinko kalan na. O cogoya in na, fɛn caman bɛ yen minnu bɛ se ka kɛ ka ɲɛ ani ka cycle waati dɔgɔya k’a sababu kɛ spindle horizontale cogoya ye. Nin baara in kama, ɲɛtaa sɛgɛn bɛ tali kɛ spindle ɲɛsincogo la walasa ka a jira ko deflection fitinin bɛ a la ni bar bar bɛ gɛrɛ laɲini na. Tabali bɛ baarakɛminɛn minɛ a jɔyɔrɔ la ni jiginni teliya ye min bɛ bɛn jɔyɔrɔ suguya wɛrɛw ma minnu bɛ ɲɛ, ka kɛ fɛn ye, walima ka fɛnw siri fo ni laadala sɛgɛn tɛ. Thanztalisgrooving ni threading ye laadala suguyaw sɛgɛn ye tugun.

Machine de boring verticale .

vertical boring technique bɛ baara Kɛ ni spindle (spindle) ɲɛsincogo jɔlen ye, wa a bɛ Kɛ ka caya ka ɲɛsin yɔrɔba silindalenw ma. Boring mansinw jɔlenw bɛ dɔn ko masinw minnu bɛ kɛ ka baarakɛminɛnw baara min cɛmancɛ ka bon kosɛbɛ, a ka c’a la, a bɛ mɛtɛrɛ caman bɔ. Nin cogoya in bɛ nafa minnu Di, olu dɔ ye ko a bɛ baara Kɛ ni girinya ye walasa ka tigɛ-tigɛ baara kɛcogo sabati. O fanga in bɛ Sɔ̀rɔ kɛrɛnkɛrɛnnenya la yɔrɔ min na fɛn gɛlɛnw i n’a fɔ turbine casings walima valve farikolo belebelew bɛ ka Ban. A ka c’a la, baarakɛminɛn bɛ bila tabali kan min bɛ wuli ni tigɛminɛn bɛ jigin ka taa duguma.

jig boring machine .

Jig Boring ye dingɛ dilanni baara ye min ka bon kosɛbɛ. Nin wale kɛrɛnkɛrɛnnen in bɛ kɛ sababu ye ka mikromɛtiri caman jɔyɔrɔ tiɲɛ ni baara kɛli ye ni plɔmuw ye minnu bɛ se ka kɛ ni fɛn ye min bɛ se ka kɛ ni fɛn ye min bɛ se ka kɛ ni fɛn ye min bɛ se ka kɛ ni fɛn ye min bɛ se ka kɛ ni fɛnw ye minnu bɛ se ka kɛ ni fɛnw ye minnu bɛ se ka kɛ fɛn ye. Jig boring machines (jig boring machines) bɛ ni spindles (spindles) ye minnu bɛ se ka kɛ ni hakili ye kosɛbɛ ani minnu ka gɛlɛn kosɛbɛ walasa ka o tiɲɛni suguw mara masinw ka waati jan kɔnɔ. Ka fara o kan, o ye taa-ka-segin fɛɛrɛ ye baarakɛminɛnw na minnu bɛ dingɛ jɔyɔrɔ ni jateminɛ jɛɲɔgɔnya kɛrɛnkɛrɛnnenw ɲini, misali la diew ni mɔbiliw dilanni na.

Machine de boring line .

Layini sɛgɛnnen don kosɛbɛ, o bɛ kɛ sababu ye ka fanw ladon minnu bɛ kɛ ni dingɛw ye minnu bɛ sɛgɛn, minnu ka kan ka kɛ fɛn dɔ kan min maralen bɛ jɔyɔrɔ kelen na. O bɛ Kɛ k’a sababu Kɛ a ka jago baara bɛ Kɛ kosɛbɛ baarakɛminɛnw na i n’a fɔ motɛri blokiw dilanni bawo biriki-sɛbɛn damadɔ bɛ yen minnu ka kan ka Labɛn ni tiɲɛniba ye. Layini boring bars bɛ janya i n’a fɔ a yɔrɔ ani o la baarakɛminɛn bɛɛ lajɛlen, ninnu bɛ jɔ yɔrɔ fila la walasa ka u tanga deflection ma ka sɔrɔ ka tigɛ. Sinsinnan sinsinni bingɛ bɛ se ka kɛ cogoya wɛrɛw la ni tigɛda bɛɛ bɛ sɔrɔ waati kelen na ka baarakɛcogo ɲɛ ka sɔrɔ ka jateminɛ muɲuli ma bɔnɛ.

Back Boring Machine .

Back Boring , o bɛ kɛ kɔfɛlabɔ wale dɔnnen ye min bɛ kɛ sababu ye ka masinw kɛ kɛrɛnkɛrɛnnenya la shell i n’a fɔ scenarios walima yɔrɔ min na general head tɛ se ka ladon. O baara in bɛ Kɛ ni baarakɛminɛn kɛrɛnkɛrɛnnenw ye minnu bɛ Se ka dakunw Dòn u jɔyɔrɔ la dingɛ fitinin tɛmɛnen kɔ. ‘Back Boring Tools’ bɛ machinations gɛlɛnw don a kɔnɔ ni leverages ye minnu bɛ ni gears walima pompe circuits ye walasa ka tigɛdaw da ani ka u datugu ni a mago bɛ a la. Fɛɛrɛ in bɛ baara kɛ fɔlɔ iziniw dilanni baarakɛyɔrɔw la i n’a fɔ aerospace ani lafasali seko ni dɔnko siratigɛ la, tigɛw bɛ kɛ yɔrɔ caman na k’a sababu kɛ baarakɛminɛnw ka jateminɛ gɛlɛn ye.

Machine de boring précision .

Fɛɛrɛ min bɛ wele ko precision boring, o bɛ kɛ ka fɛnw bɔ yen minnu hakɛw bɛ tiɲɛ kosɛbɛ. O bɛ kɛ tuma caman na ni kunkolo sɛgɛnnenw ye minnu bɛ ni balofɛn finmanw ye minnu bɛ don u la walima minnu sirilen don u la walasa ka muɲuli ɲumanw sɔrɔ ka bɔ 0,001 na ka se 0,002mm ma, dingɛ ɲininen bɛ se ka sɛgɛn min kɔnɔ. Baarakɛminɛn in bɛ ni fɛɛrɛ kuraw ye minnu bɛ se ka kɛ sababu ye ka juguya, balo ani tigɛ teliya kunbɛn ka ɲɛ. A ka c’a la, opereli in bɛ kɛ ni sen caman ye, n’o ye masinw ye minnu bɛ kɛ ni masinw ye minnu bɛ se ka kɛ fɛn kelen ye ani minnu bɛ kɛ ni fini ɲumanw ye walasa ka se ka nɔ ɲuman sɔrɔ i n’a fɔ fɛn masirilenw, ani baarakɛminɛn yɔrɔ min bɛ tɔgɔlafɛnw hakɛw ni ɲɔgɔn cɛ, o tiɲɛni fana.

Boring process bɛ baara kɛ cogo di?

Precision adjustment programme ye daminɛyɔrɔ kɛ ani ka taabolo daminɛ – ka bore cɛmancɛ la ka se masin ka spindle ma, ni chambre jatebɔlen don ani ka bore redated at a relagirment abignment approprié pour le piece de service. Yan, baara bɛ kɛ ni hakɛ dɔ ye, o bɛ kɛ sababu ye ka jateminɛ kɛ ni jateminɛfɛn caman ye i n’a fɔ dial gauges ani elektɔriki sensɛriw jɔyɔrɔ (kuran otomatikiw) walasa ka zeru coordinates (cɛmancɛ jateminɛ jɔyɔrɔ) sigi sen kan ani paralɛli hakɛ min bɛ boring ni sr sɛgɛnnenw cɛ.

Baara bɛna kɛ k’a sɔrɔ i bɛ tɛmɛn o sɛgɛsɛgɛli kɛcogo kɛrɛnkɛrɛnnen caman fɛ. yɛrɛ la, Tigɛda binkannikɛlaw minnu bɛ ka dugukolo sanfɛla sɛgɛn, olu bɛ ɲɔgɔn sɔrɔ ni baarakɛminɛn dɔ ka fɛn ye waajulikɛyɔrɔ la min bɛ di ni fɛɛrɛ kuraw ni tigɛcogo caman ye. Abrasive tools bɛ ni rake nɔgɔman ye ɲɛfɛ walima ɲɛda baarakɛta la min b’a to u bɛ se ka fɛn min lamini ka dingɛ kɛnɛma lamini, o bɛ dingɛ di a ma ka kɛ fɛn ye min bɛ kɛ ka fɛn dɔ dilan. Boring ka paramɛtɛrɛw - jiginni teliya miniti kelen kɔnɔ ani tigɛ teliya insitiri walima milimɛtɛrɛ kelen kɔnɔ, olu bɛ sugandi ka ɲɛsin baarakɛminɛn ma ani a bɔli hakɛ ɲininen ma ka bɔ baarakɛminɛn na.

Semi-finishing operations (baarakɛ-minɛnw) bɛ Nà o kɔ fɛ, yɔrɔ min na dunuya dɔgɔyali ni balo hakɛ basigilenw bɛ Kɛ ka baarakɛminɛn in Dòn ka ɲɛ. O kɔrɔ ye ko nisɔndiya-minɛn (baara bɛ nafa sɔrɔ kosɛbɛ bawo a bɛ tigɛ waati dɔɔnin na ani o waati kelen na, a labanyɔrɔw bɛ tiɲɛ dɔɔnin) o bɛ na ni baarakɛminɛnfɛn fanba bɔli ye ani ka basigi di tigɛ finman labanw ma. O waati la, nafa bɛ bonya bara sɛgɛnbali jɔli la bawo biri walima yɛrɛyɛrɛ waati o waati, o bɛna dingɛ labɛnnen jateminɛcogo jɛlen tiɲɛ.

A laban na , tigɛcogo tigitigiw bɛ baara kɛ walasa ka dakun labanko wajibiyalen ni a hakɛ tiɲɛni wajibiyalen sɔrɔ. A jatera ko a nafa ka bon kɛrɛnkɛrɛnnenya la ka tigɛ teliya ni balo hakɛ basigilen sabati yɔrɔ o yɔrɔ sɛgɛnbaliya wale la. Ka fara o kan, nin waati in na, nɛnɛmadalan jiginni ye baara bɛɛ lajɛlen nafamafɛn wɛrɛ ye, min bɛ baara kɛ walasa ka tigɛ bɛ kɛ yɔrɔ min na, o yɔrɔ funteni hakɛ caman tigɛli ani ka pucew tacogo nɔgɔya minnu bɛ tugu baarakɛminɛn na.

Baara min bɛ kɛ ni sɛgɛn ye, o bɛ to ka sɛgɛsɛgɛ ni sumanikɛlanw ye – a hakɛ sabatili ni a sanfɛla gɛlɛya fila bɛɛ bɛ kɔlɔsi. O cogo la, bi CNC boring masinw bɛ ni adaptive control system ye min bɛ don a kɔnɔ min bɛ se ka ladilanni kɛ tigɛcogo paramɛtɛrɛw la otomatiki kan k’a sɔrɔ bololabaara si ma kɛ.

Chip control nafa ka bon ka sɔrɔ ka baara kɛ min bɛ mɔgɔ sɛgɛn. A bɛ sabati baarakɛminɛnw jateminɛ fɛ, tigɛ teliya ni balo hakɛw ani o kɔfɛ, o bɛna a to chips minnu bɛ dilan, olu bɛ bɛn u bonya n’u cogoya ma. Nin ko fila in i n’a fɔ chips bɔli ani u bɔli nafa ka bon kosɛbɛ sɛgɛn na bawo u bɛ dɛmɛ don ka o chips suguw tigɛ kɔfɛ ani ka girinya tilali scallop kelen sabati dingɛ janya kɔnɔ.

Ni baara bɛ daminɛ ka maga labanw na sumani ni sɛgɛsɛgɛli fɛɛrɛw bɛ se ka kɛ. Bi tekinolojiminɛnw, i n’a fɔ jateminɛfɛnw ni jatebɔlanw, ani masinw, i n’a fɔ koorilenw sumani masinw (CMM) , olu bɛ se ka hakilisigi di ko dingɛ dafalen wɛrɛ ka ɲɛsin hakɛw, lamini ani dugukolo sanfɛla gɛlɛya ma ka tɛmɛ dan hakɛ kan min bɛ se ka kɛ. Ni danfara dɔw bɛ yen ni nin nafaw ye, minnu bɛ se ka kɛ sababu ye ka taabolo bɛɛ kɛ ka segin a kan, o danfara in mago bɛna kɛ wale latilenni na i n’a fɔ ka yɔrɔ in kɛ masin ye pewu walima ka segin a yɔrɔ la min bananen don.

Boring operations ɲɛtaa bɛ se ka kɛ fɛn dɔw ye , i n’a fɔ chamfers, grooves ani stepped diamètres. O cogo la, baarakɛminɛn jɔyɔrɔ tigitigi ani bolodacogo ɲuman ni sirako porogaramu ye fɛn nafamaw ye walasa ka se ka fɛn in cogoya n’a jɔyɔrɔ tigitigi sɔrɔ. ‘Axiliaire’ baara wɛrɛ minnu bɛ se ka kɛ i n’a fɔ ani waati min na magoɲɛfɛnw bɛ se ka kɛ, olu fana bɛ se ka kɛ kɔ sɛgɛn walima counter sɛgɛn ye, o min bɛ na ni baarakɛminɛn kɛrɛnkɛrɛnnenw ni masinko baara wɛrɛw ye.

Nafaw ni dɛsɛw bɛ sɔrɔ masinw na minnu bɛ mɔgɔ sɛgɛn .

Nafa minnu bɛ sɔrɔ boring technique la .

K’a sababu kɛ kɔrɔsili ni tiɲɛni ye , butiki bɛ se ka masin dingɛw ni yɔrɔw kɛ ni muɲuli ye fo ka se ±0,0001 inch ma. O bɛ Bɔ tigɛyɔrɔ kelen-kelen bɛɛ jɔli n’a sigicogo tigitigi la minnu bɛ Kɛ nɛgɛ tigɛcogo la min bɛ tigɛda in 'kɔnɔ 'sèn Bɔ a la wa a b'a Jira ko dingɛ bɛ Lamini tuma bɛɛ.

Surface geometry bɛ se ka kɛ sec 125 fo 16 ye RA la ni nɔgɔya ye, bawo a ka drill ratio caman bɛ sɔrɔ cogoya la min bɛ kɛ cogoya la. Finishing cutting action bɛ na ni o yɔrɔ nɔgɔlenw ye minnu dafalen don ka kɛ yɔrɔ la silinda liners walima bearings with close bore tolerances bɛna sigi sen kan.

Faamuyali danw ni bɛn yan tɛ dan a yɛrɛ ma ka ɲɛsin sɛgɛnlafiɲɛbɔ ma. A fana bɛ Taa fo o paramɛtɛrɛ suguw kɔlɔsili la i n’a fɔ geodesiki filiw, yɔrɔ dɔ ka runout circular ani bore perpendicularité. O bɛ mɔgɔ ɲɛnajɛ kɛrɛnkɛrɛnnenya la ko minnu na sɛgɛn damadɔ bɛ yen ani u ka ɲɔgɔndɛmɛ bɛ gɛlɛya ka tɛmɛn fɔlɔ kan k’a sababu kɛ bolokɔniw ka baarakɛcogo ye i n’a fɔ girin kɛsu ni masinw.

Nafa minnu bɛ sɔrɔ fɛɛrɛ sɛgɛnnenw na .

Baara min bɛ kɛ waati kɔnɔ, n’o bɛ baara labɛnni ni tigɛ teliya n’a ladilanni senfɛ, o fana bɛ se ka kɛ dɔɔnin dɔɔnin walasa ka minɛnw tiɲɛni sabati. Misali la, sɛgɛn ɲuman bɛ se ka ta siɲɛ 2-3 cɛ o sɛgɛn kelen in na .

Muɲu nɔ bɛ bɔ minɛnw ni baara musakaw la. Kogo finmanw ni fɛn fitininw bɛ se ka kɛ dɔrɔmɛ 50.000 fo kɛmɛ caman na, ani tigɛlan kɛrɛnkɛrɛnnenw ni sumanikɛminɛnw musakaw bɛ se ka kɛ kosɛbɛ.

Fɛɛrɛko sɛgɛsɛgɛli bɛ wele bila baarakɛlaw ma minnu bɛ se kosɛbɛ ani ɔridinatɛri minnu bɛ kunnafoni di masinw kan minnu bɛ baara kɛ ni baarakɛminɛnw ye, minnu ka kan ka baarakɛminɛnw jateminɛcogo dɔn, ka ɲɔgɔn lajɛw kunbɛn, ani ka teliya ni balo sɔrɔ. Ka fara o kan, baarakɛminɛn in tiɲɛni bɛ bɔ kɛnɛ kan, tigɛ teliya walima balo hakɛ min bɛ se ka kɛ, ani anti-chatter intervention ani intervention paramètres bɛ hakili sanfɛ.

Sɔrɔko jateminɛw .

Daminɛ kapitalu wajibiyalen bɛna kɛ fɛnw ye i n’a fɔ sumanikɛminɛnw, baarakɛminɛnw sigicogo, waati cogoya izini, ani kɛrɛnkɛrɛnnenya la minɛnw. Baarakɛnafolo yɔrɔ dɔw bɛna dun ni kalan ni dantigɛli koɲɛw ye.

Fɛn dilanni musakaw fana ye fɛnw ye i n’a fɔ i bɛ baara kɛ ni tigɛminɛn hakɛ min ye, fanga hakɛ min ka kan, tulu walima nɛnɛ hakɛ min ka kan ka san, masin dɛsɛ kɛmɛsarada la ani baara jugu kɛmɛsarada la. O ko ninnu de ye fanga sɔrɔ kosɛbɛ line boring ka sɔrɔko nafa sɔrɔli la.

Machining boring (masinw) baarakɛcogo .

Fɛn dilanni industriw ka baarakɛminɛnw .

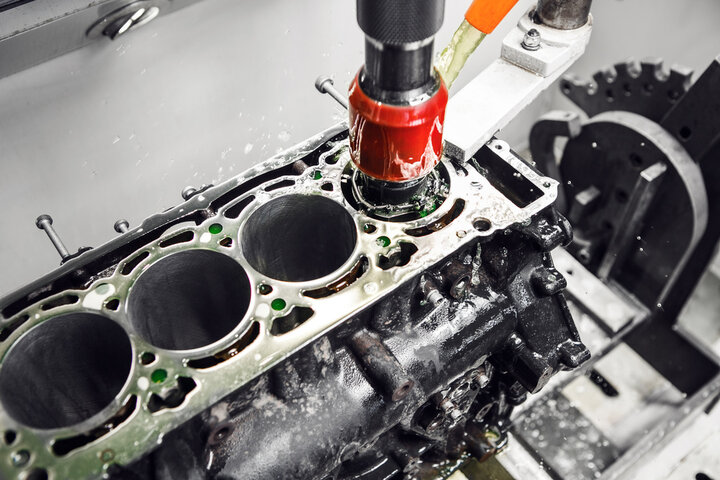

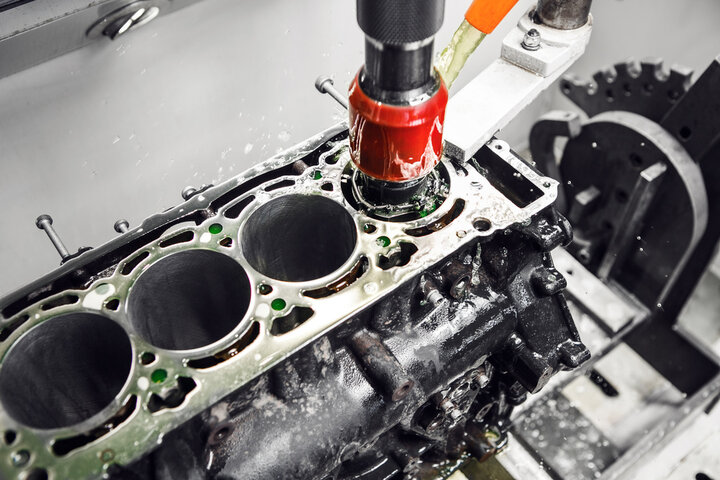

Motɛri bloki dilanni bɛ kɛ ka caya ni baarakɛcogo sɛgɛnbaliw ye minnu laɲini ye ka silinda tigitigiw sɔrɔ ka ɲɛsin pisinw ma ani ka motɛri seko caman sabati. Masina injiniyɛri baara bɛ dɔn ni baarakɛcogo caman ye minnu bɛ baara kɛ ni hakɛ caman ye minnu ka tiɲɛni hakɛ ka bon ±0,0002 inch kɔnɔ minnu bɛ baara kɛ motɛri piston bololanɛgɛw la ani tulu nege kojugu tɛ min na. Mobiliw dilannikɛlaw sisan, olu bɛ baara kɛ ni ɔridinatɛri ye min bɛ wele ko « ordinateur contrôlé n’o ye masinw ye, n’u bɛ sumani kɛ ɛntɛrinɛti kan i n’a fɔ fɛɛrɛ dɔ min b’a jira ko danfara caman tɛ u dilanni siraw cɛ ka ɲɛsin baarakɛcogo ɲuman ma.

Jibolisiraw dilanni bɛ baara kɛ kosɛbɛ ni fɛntigi fɛɛrɛ ye min bɛ kɛ ni baarakɛminɛnw ye minnu bɛ kɛ sababu ye ka sɛgɛn furakɛli kɛ kɛrɛnkɛrɛnnenya la u ka so ani hali valve farikolow sen bɛ o la. Nin fɛn sugu ninnu bɛ sɔgɔ minnu na 16-32 micro inci RA bɛna kɛ dugukolo sanfɛla gɛlɛya danma ye, ka tulu kɛ ka ɲɛ ani ka yɔrɔ in nafa bɔ. Boring operation Ni baara bɛ kɛ, o b’a to fɛn dilannikɛlaw bɛ se ka dugukolo sanfɛla cogoya mara ka dɔgɔya cogo min na min bɛ bɔ bore blank’s idealized form la kosɛbɛ ka da geometric tolerance kan min bɛ fɔ ni hydraulique system baarakɛcogo ye.

Precision engineering applications .

I n’a fɔ a yɔrɔ tɔw bɛɛ, a ka c’a la, aerospace yɔrɔw bɛ kɛ ni masinw ye walasa ka bolt holes ani bearing diamerically in the turbine housings ani structural elements wɛrɛw dilan. Baara min bɛ kɛ nin ko in na, o ye aerospace application ye min bɛna kɛ wajibi ye ka kɛ wajibi ye ka baara kɛ ni coordinate measure machine (CMM) ye walasa ka dimensions critiques suman. Dɔgɔtɔrɔso minɛnw dilanni bɛ baara kɛ ni mikro boring ye walasa ka fɛɛrɛw ni minɛnw labɛn, COT dilanni minɛnw kama. O yɔrɔ suguw la, finimugu dafalenba bɛ sɔrɔ, a dɔw la, sɛgɛnlafiɲɛbɔ baarakɛtaw ka capabilitew fana bɛ se ka kɛ ni dugukolo sanfɛla gɛlɛya hakɛw ye fo ka se 8 μin RA ma. A ka gɛlɛn k’a sɔrɔ a bɛ yɔrɔ gɛlɛnw ni masinw ka ɲininiw bɛɛ labato waati kelen na ni baara kɛli ye ni fɛnw ye i n’a fɔ opereli min bɛ kɛ ni nɛgɛ ye min tɛ sɔgɔ furakɛli titaniyɔmu kan.

Industrie baarakɛcogo gɛlɛnw .

Masina caman dilanni bɛ baara sɛgɛnbaliw don a la ka ɲɛsin fɛn dilanni yɔrɔw ma i n’a fɔ turbine casings ani izini pɔnpew. O baarakɛcogo ninnu ka teli ka kɛ ni layini sɛgɛnni baara ye min janya bɛ se sen caman ma, o bɛ kɛ sababu ye ka sɛgɛnlafiɲɛbɔlan kɛrɛnkɛrɛnnenw wajibiya ni yɛrɛyɛrɛli ye. Taabolo ka kan ka silinda muɲuni sabati janya janyalenw na k’a sɔrɔ a bɛ baara kɛ ni fɛn caman ye minnu bɛ kɛ ni fɛnw ye minnu bɛ kɛ ka fɛnw sɔgɔ.

Minɛnw dilanni bɛ tali kɛ baara sɛgɛnnenw na walasa ka fɛnw dilan i n’a fɔ kurufew ani minɛn girinmanw karamɔgɔya. O baarakɛminɛnw bɛ to ka baara gɛlɛnw kɛ walasa ka fɛnw hakɛ caman bɔ, o kɔfɛ, u bɛ se ka kɛ ni fini ye walasa ka jateminɛ kɛcogo ɲuman wajibiyalen sɔrɔ. O kɛcogo ka kan ka tigɛ tigɛtigɛlenw ni fɛnw gɛlɛya suguya caman na minnu bɛ sɔrɔ fɛn caman na minnu bɛ kɛ fɛn caman tigɛli la ka sɔrɔ ka baarakɛminɛnw ɲɛnamaya ni u ka baarakɛcogo mara.

Kɔgɔjida la, ɛntɛrinɛti baarakɛminɛnw bɛ baara kɛ ni boring operations ye ka ɲɛsin propeller shafts ani stern tube bearings ma. O yɔrɔ ninnu bɛ jateminɛ tigitigiw de wajibiya walasa ka ɲɔgɔndɛmɛ ɲuman sɔrɔ ani ka yɛrɛyɛrɛli dɔgɔya baara kɛtuma na. Boring process ka kan ka silindriki muɲuni sɔrɔ ka sɔrɔ ka baara kɛ ni a yɔrɔbaw ye, tuma caman na, a bɛ ɲini ka fixturing ni dɛmɛ sira kɛrɛnkɛrɛnnenw de wajibiya walasa ka tiɲɛni mara janya janw kɔnɔ.

Aplikasi minnu bɛ kɛ ni tiɲɛni ye kosɛbɛ .

Optical Equipment Manufacturing bɛ baara kɛ ni sɛgɛn ye walasa ka jiginni yɔrɔ tigitigiw ni ɲɔgɔndɛmɛ cogoyaw dilan. O baarakɛminɛnw bɛ ɲini ka kɛ surface finish qualité exceptionnel ye ani ka jateminɛ kɛ ka ɲɛ walasa ka ɲɛnajɛ kɛcogo sabati. Boring process ka kan ka se ka surface finiw sɔrɔ minnu bɛ i n’a fɔ miirili ka sɔrɔ ka sub-micron nivo accuracy mara dimensions critiques kɔnɔ.

Dɔnniya minɛnw dilanni bɛ baara kɛ ni sɛgɛn ye fɛn dilanni yɔrɔw la i n’a fɔ spektromɛtiri so ani sumanikɛminɛnw. O baarakɛcogo ninnu bɛ danfaralan danfara ni dugukolo sanfɛla cogoya danfaralenw de wajibiya walasa ka minɛnw tiɲɛni sabati. Boring process ka kan ka funteni sabatili ni yɛrɛyɛrɛli kunbɛn ka sɔrɔ ka se ka fɛnw sɔrɔ minnu bɛ se ka kɛ ka ɲɛ.

Infrastructure applications .

So jɔli minɛnw dilanni bɛ baara sɛgɛnnenw don a kɔnɔ walasa ka fɛnw dilan i n’a fɔ sɛgɛsɛgɛlikɛlanw ani bulldozer frames. O baarakɛcogo ninnu bɛ kɛ tuma caman na baara juguw la minnu bɛ kɛ ni baarakɛminɛn kɛrɛnkɛrɛnnenw ye ani jibolisira tigɛcogo. O kɛcogo ka kan ka kɛ tiɲɛ ye ka sɔrɔ ka baara kɛ ni fɛn belebelebaw ye minnu bɛ sɛgɛn kosɛbɛ ani ka sigida laminiw jira.

Nɛgɛso infrastructure production bɛ baara kɛ ni boring operations ye fɛn dilanni yɔrɔw la i n’a fɔ wotoroninw ani axle sow. O baarakɛminɛnw bɛ jateminɛ kɛcogo ɲuman ɲini walasa ka ɲɔgɔndɛmɛ ɲuman sɔrɔ ani ka ladonni wajibiyalenw dɔgɔya. Boring process ka kan ka jogo sabatilen sɔrɔ ka sɔrɔ ka baara kɛ ni fɛn gɛlɛnw ye ani ka lakana sariya gɛlɛnw mara nɛgɛso baarakɛcogo la.

Sugandili jateminɛ minnu bɛ kɛ masinw kan minnu bɛ sɛgɛn .

Masina suguya wɛrɛw bɛ kɛrɛnkɛrɛnnenya la walasa ka baara dɔw kɛ, o la, baarakɛminɛnw cogoya kɛrɛnkɛrɛnnenw n’u labɛncogo bɛ baara kɛ ni tigɛcogo tigitigiw ɲɛnabɔli ye masin kelen-kelen bɛɛ la. Teliya sugandili tigɛcogo la, o bɛ se ka ɲɔgɔn ta kosɛbɛ ka kɛɲɛ ni fɛn min bɛ baarakɛminɛn walima a dakunw kɛ, o bɛ se ka kɛ fɛn ye min bɛ se ka sɔrɔ. Kɔlɔsili kɛli balo la, o bɛ jɔyɔrɔba ta k’a da a kan, nɔgɔ ɲumanw bɛ sɔrɔ ani baarakɛminɛnw ɲɛnamaya walima taabolo sabatili tɛ nɔ bila o cɛsiri sugu la. Sisan, a bɛ se ka kɛ ka baara caman kɛ minnu bɛ mɔgɔ sɛgɛn ni masinw ye minnu bɛ sɛgɛn suguya kelen na, n’u bɛ baara kɛ ni bi CNC sitɛmuw ka kunnafoniko seko caman ye.

Machine boring sugandili bɛ tali kɛ kosɛbɛ baarakɛminɛnw jateminɛcogo la, fɛn suguya, muɲuli minnu bɛ makɔnɔ ani baara hakɛ. Porozɛ caman kɔnɔ a bɛ se ka kɛ , fari nɔgɔya misali ye , o bɛ kɛ sababu ye ka o kɛrɛnkɛrɛnnen masin tigɛlan dilanni baara kɛ, ani tigɛcogo caman sɛmɛntiyalenw ka fɔ. I n’a fɔ a bɛ drilling kɛ ni baarakɛminɛn fitinin ye , a bɛ se ka sɔrɔ kɛrɛnkɛrɛnnenya la danfara min bɛ sɔrɔ a kɛcogo la min bɛ sɔrɔ. Boring operations (baarakɛbaliya baarakɛcogo) ka fɛnw modeliw labɛnni ka fara sensɛriw tali kan ani dadon-wulu-masinw, olu ye boring operations (baarakɛ-baaraw) bila ka taa baarakɛyɔrɔ kɔrɔlenw na.

Aw ye aw ka fɛn dilanni tigitigi sɛmɛntiya bi!

Sɛgɛn ka ɲɛsin bɔgɔbɔgɔ ma dingɛ tiɲɛni kan wa? Aw ye fɛɛrɛ tigɛlenw tigɛcogo dɔn ni Team MFG ye , yɔrɔ min na tigitigi bɛ dafalenya kunbɛn.

An ka fɛɛrɛ kɔrɔlenw bɛ se ka muɲuli sɔrɔ fɛn dilannikɛla tɔw dɔrɔn de bɛ sugo kɛ. K’a ta aerospace components la ka se precision furakɛli minɛnw ma, an bɛ ka danw gɛlɛya min bɛ se ka kɛ hole finishing kɔnɔ. Aw ye anw sɔrɔ bi ɛntɛrinɛti la walasa ka ladilikan caman sɔrɔ.

Ɲininkali minnu bɛ kɛ tuma caman na (FAQ) .

J: Danfaraba jumɛn bɛ sɛgɛn ni sɔgɔli cɛ?

O baara fila bɛɛ bɛ kɛ walasa ka dingɛw da nka ka se hakɛ wɛrɛw ma - kɛrɛnkɛrɛnnenya la, jirituru bɛ kɛ dingɛw ye minnu bɛ kɛ sababu ye k’u kɛ ka ɲɛ ; A bɛ ɲɛfɔli dɔ ɲɛfɔ. Boring bɛ fini ɲumanw di ani jateminɛ tiɲɛni ɲumanw ani a ka c’a la, a ka kan ka kɛ ka kɔn ninnu ɲɛ o kɔfɛ dingɛ bonya.

J: Operations sɛgɛnnenw na, i bɛ tigɛ teliya bɛnnen sugandi cogo di?

Tigɛ teliya sugandili bɛ da fɛn caman kan i n’a fɔ baarakɛminɛn, baarakɛminɛn fɛn, dugukolo sanfɛla labɛnni wajibiyalen ani masin gɛlɛya. Ni nɛgɛ ye, teliya bɛ se ka kɛ 60-120m/min cɛ ni karɔbɔli ye ani 15-30 m/min ni HSS ye.

J: Mun na kumakan bɛna kɛ sɛgɛn ni a kɛcogo ɲuman na walasa ka i yɛrɛ tanga a ma?

Kumakan bɛ Bɔ tuma caman na ni baarakɛminɛn overhang tɛ kelen ye ani tigɛcogo paramɛtɛrɛw tɛ Bɛn kosɛbɛ. Overhang bɛ se ka dɔgɔya, baarakɛminɛn bɛ se ka gɛlɛya, tigɛ teliya bɛ se ka ladilan ani ka baarakɛminɛnw sɛgɛn ni yɛrɛyɛrɛli balili bɛ se ka baara kɛ walasa ka kumakanw dɔgɔya.

J: Ko jumɛnw bɛna kɛ ni modular boring tool ye min bɛ kɛlɛ ni bar bar solide ye?

Deep-hole applications minnu mago bɛ reach caman na call for modular boring outils over solid boring bars. Ka fara o kan, modulu boring baarakɛminɛnw bɛnnen don ko dɔw la minnu na dingɛ hakɛ ka ca ni masin ye. Ani fana, ko minnu na baarakɛminɛn caman yeli ye sariya ye dingɛw hakɛ danfaralenw na, olu bɛ baara kɛ ni modulu boring baarakɛminɛnw ye.

J: Baara kɛcogo kɔrɔw la, tilennenw lajɛyɔrɔ kolomaw ye jumɛnw ye ani u ni ɲɔgɔn cɛ jɛɲɔgɔnya fɛɛrɛw ye mun ye?

Ni baro bɛ kɛ dingɛ tilennen kan, fɛn minnu bɛ i n’a fɔ bar bar gɛlɛya, ni o bɛ yen, ni o bɛ yen, ni o bɛ kɛ ni fɛn fila ye minnu bɛ sɛgɛn, sariyakolo minnu bɛ yɔrɔ tigɛcogo basigilen ɲɛnabɔ, ani nɛnɛmadalan bolicogo bɛnnen ye fɛn dɔw ye minnu ka kan ka jateminɛ. Walasa ka jaabi ɲuman sɔrɔ, bar bar ni bore hakɛ hakɛ ka kan ka dɔgɔya ka tɛmɛ 4:1 kan.

J: Dingɛ tiɲɛni bɛ sabati cogo di dingɛ juguman kɔnɔ?

Dingɛw tiɲɛni kɛrɛnkɛrɛnnenya la dingɛ dunba kɔnɔ, o ye baarakɛminɛnw sɛgɛsɛgɛli baara ye, funteni bonya ani ɲɔgɔn falen-falen ka fara chip bɔli kan. A bɛ tali kɛ ɲɛjiralanw baara la, tigɛw juguya axial progressive, ka tɛmɛn baarakɛminɛnw nɛnɛma dilancogo jɛlen fɛ walasa ka tiɲɛni sabati.

J: Fɛɛrɛ jumɛnw bɛ tigɛ baara sɛgɛnnenw cɛma? — .

Lakanali bɛrɛbɛrɛ ka bɔ pucew la, baarakɛminɛn jɔyɔrɔ lakananen, kala ni garadi ɲumanw, ani baarakɛminɛnw sɛgɛsɛgɛli tuma bɛɛ, ka fara nɛnɛmadalan kɔlɔsili ɲuman kan, o ye lakanafɛn nafamaw ye.

J: Kun jumɛn de b’a to baara bɛ kɛ ka baara dafa cogo fila la walima ka tɛmɛ o kan?

Tigɛ dafalen kɔnɔna na opereli kelen na, o tɛ nafa sɔrɔ kosɛbɛ – bar bar janya dafalen bɛ baara kɛ. Opereli boring bars kelen bɛ nafa sɔrɔ ni a bɛ tali kɛ porozew la minnu bɛ tigɛ tigɛ dɔrɔn bore dingɛ laban na. Standard Fine Boring kɛcogo bɛ baara kɛ ni sɛgɛn ni fini ye ka tugu ɲɔgɔn na.

J: Ni i bɛ dingɛw sɛgɛn CNC masin kan cogo di ka baarakɛminɛnw ɲɛnamaya janya?

Baarakɛminɛnw ɲɛnamaya bɛ an hakili la yan. A bɛɛ bɛ tali kɛ tigɛcogo paramɛtɛrɛw faralen ɲɔgɔn kan cogo bɛnnen na, ka coolant’ tulu hakɛ caman mara, ka baarakɛminɛnw sɛgɛsɛgɛli kɛcogo don, ani ka baarakɛminɛnw doni oriented controlling ani program occupancy to there but a few.

J: Fɛn minnu ka kan ka to an hakili la, n’i b’a ɲini ka tigɛw kɛ fɛn suguya caman na, olu ye jumɛnw ye?

Ni fɛn o fɛn tigɛra, baarakɛminɛn bɛna sugandi sariyaw kan i n’a fɔ fɛn gɛlɛya, masinability, chip suguya walima kurukuruw dilanni, funteni cogoyaw, tigɛcogo ɲumanw, i n’a fɔ baarakɛminɛn sira, balo hakɛ, tigɛ juguya, nɛnɛmafɛn wɛrɛw, fɛn suguya wɛrɛw bɛna tigɛcogo gɛlɛnw de wajibiya tigɛyɔrɔ (insert) ka fara dacogo kɛrɛnkɛrɛnnenw kan.

Ni aw b'a fɛ ka ɲininkali wɛrɛw kɛ, Contact Team MFG bi !