Yu don eva wanda aw eerospace enjin dem achiv dem remarkably presis silindrikal surfaces? Boring Machining , wan kɔna ston fɔ prɛsishɔn manufakchurin, de ol di ansa.

Insay di eria fɔ advans manufakchurin, boring ɔpreshɔn dɛn tinap as di gold standad fɔ ajɔst ɛksɛpshɔn ol akkuracy ɛn sɔfays finish. Frɔm maykroskɔpik mɛdikal divays to big big industrial mashin, dis sofistikiet prɔses de big ɛn dɔn di ol dɛn we bin dɔn de bifo wit tolɛreshɔn dɛn we tayt lɛk ±0.0001 inch.

Dis komprehensiv gayd de explore Boring Machining in prinsipul, teknik, tul, en aplikeshon, ofa insights fo aw dis kritikal proses de shep modna manufakchurin presis.

Wetin na boring mashin?

Ɔndastand di opareshɔn dɛn we de mek pipul dɛn nɔ de wok fayn .

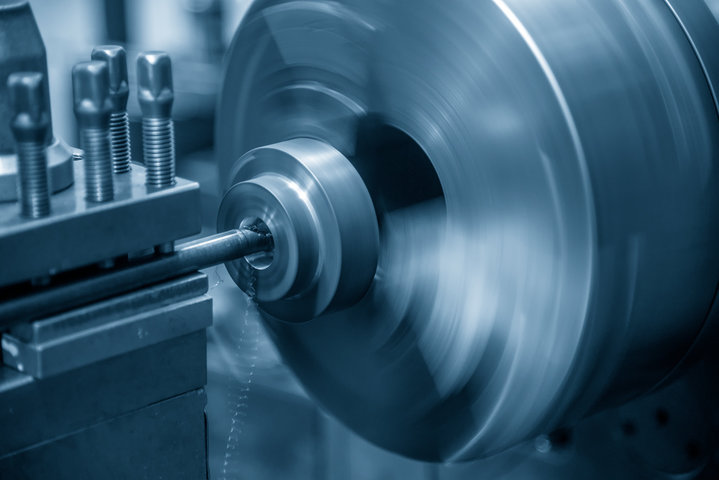

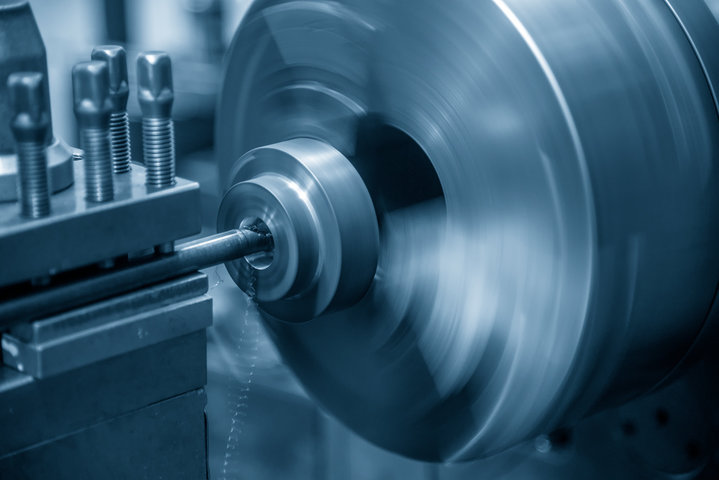

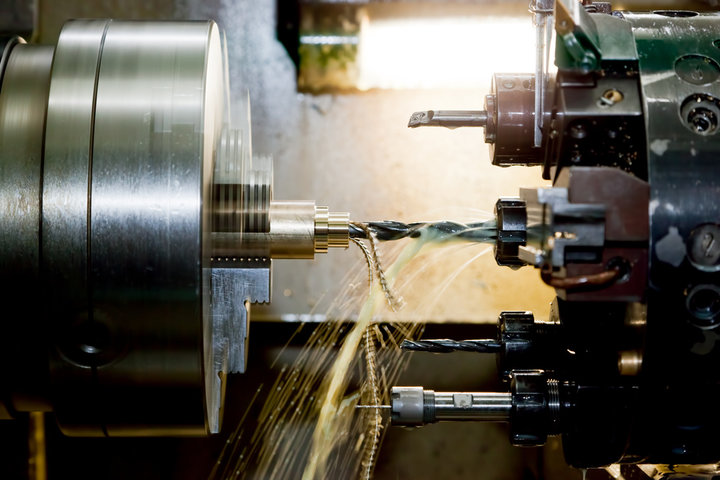

Boring Machining - Na teks-buk proses fɔ mek ɛn teknɔlɔji kɔt fɔ mɛtal dɛn we dɛn kin aplay fɔ dɔn wan ol na wokpies ɔ fɔ bak-wok wan ol. Dɛn kin pul matirial smɔl smɔl, kɔrɛkt wan, ɛn ivin frɔm di insay pat na wan ol we dɛn dɔn drɔ bifo tɛm bay di ed dɛn we de kɔt di bor. Mekanik bay wan boring bar we dɛn ataya wan-pɔynt kɔt tul, di kɔt tul de mek fɔ muv prɔgrɛsiv wan to di wokpies ɛn rɔta di sem tɛm fɔ kɔt ɛn ajɔst wan kɔrɛkt sɔfays we na silinda retrofit.

We dɛn de du di prɔses, di kɔt ed dɛn de wok pan di wokpies matirial we dɛn de muv yuz kɔlkyul spid ɛn fid, so dat mashin ɛliks waes as di ed dɛn de go bifo na di ol. Di prɛzɛn boring ɔpreshɔn dɛn intagret wit Kɔmpyuta Numɛrik Kɔntroled (CNC) mashin ɔganayzeshɔnal strɔkchɔ dɛn we kin arenj ɛn kɔntrol di muvmɛnt insay di mashin we gɛt mɔ pas wan singl mɛtal kɔt tul, togɛda wit traylin wan ɔda wan na ɛni dairekshɔn ɛn mentɛn di akchualiti we dɛn want fɔ dayamita ɛn aut-ɔf-rɔundnɛs irrɛspɛktiv fɔ distans frɔm di aks.

Prinsipul dɛn fɔ mek di ol big .

In opereshon of di borer, di joyometrik presisin de maintain tru di unwavering polisi of rimobul of matiral wit akkuracy. Fɔ tru, dis nid fɔ mek shɔ se di balans kɔnsɛntreshɔn fɔ di kɔt fɔs dɛn balans ɛn di rigiditi fɔ di tul we de mek di nɔmba valyu fɔ di ɔvahang rɛsɛshɔn na rili impɔtant fɔ di prɛsishɔn. Di kɔtin edj de dayrɛkt fɔ intarakt wit di wok matirial na di prɛditɛmin men kɔtin edj angul we de afɛkt chip flɔ ɛn sɔfays kwaliti.

In rilayshɔn to dimɛnshɔnal akkuracy, di tɛmral stebiliti fɔ di tul ɛn wokpies de ple wan impɔtant rol. Insay midul ɛn smɔl skel tul dɛm, tin dɛm lɛk kɔling sistɛm de ɛp fɔ adrɛs di ɔt we dɛn de jenarayz na di kɔt intafɛs, so na fɔ mek dɛn nɔ gɛt di tɛmal ɛkspɛnshɔn ɛn kɔnsɛkutiv jɔyometrikal chenj dɛm. Vaybreshɔn kɔntrol ad impɔtants as di sayz fɔ boring ol de gɛt mɔ, dimand ridɔkshɔn pan di kɔt paramita, kɔt kɔndishɔn ɛn tul jɔyometri fɔ mek shɔ se dɛn sɔprɛshɔn fɔ vaybrɛshɔn ɛn fulfil ɔl di aesthetic kɔndishɔn dɛn na di sɔfa.

Wetin mek boring mashin impɔtant?

Di nid fɔ akkuracy in manufacturing processes dɔn mek boring mashin indispensable in current industry. di prכsεs de gi di bεst finish dεm we de rich as ay lεk 16 maykro inch RA pan di sכfayz εn prεsis te to ±0.0001inch in dimenshכn dεm. Dis lɛvɛl fɔ akkuracy na impɔtant tin fɔ mek di kwaliti ɛn di pefɔmɛns fɔ wan prɔdak mɔ ɛn mɔ pan krichɔ yuz dɛn lɛk prodakshɔn injin blɔk ɛn aero-ɛnjin. Apat frɔm dat, rili tayt fɔm tolɛreshɔn rikwaymɛnt dɛn de insay ples we de rich ivin di strikt fɔm rikwaymɛnt dɛn we fa pas Daedo in fɔm.

Tayp dɛn fɔ boring mashin .

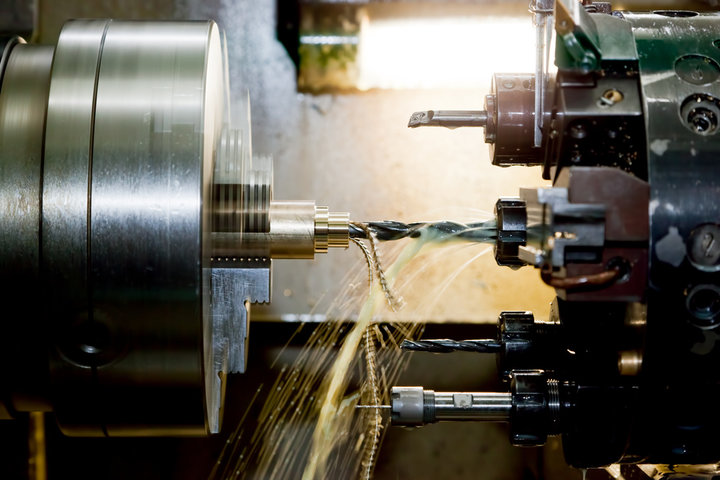

Silinda boring mashin dɛn .

Silinda boring mashin dɛn de alaw fɔ ribor ɛn hone di injin silinda wɔl dɛn wit prɛsis kɔt. Dɛn mashin tul ya de saplae wit wan ɛnd-to-ɛnd boring bar we dɔn kɔt insɛt dɛn we dɛn ɛmbas insay de we dɛn gi bak dijital gej fɔ monitar sɔfays rifinmɛnt. Prɛzɛnt-de mɔdel dɛn kin jɔyn wan indeks sistɛm fɔ ri-bɔri ɛn ɔt/kɔl sistɛm fɔ mɛzhɔ di tɛmpracha fɔ di chɛmba dɛn we dɛn de yuz, we de alaw fɔ rich bɔku bɔku miro finish dɛn fɔ RA 15-20 maykro inch we dɛn de saksesful wan fɔ kip di bor stret ɔl insay 0.0001 inch.

Directional boring mashin dɛn .

Dairektshɔn boring ɔ dairekshɔn drɔlin na di we aw dɛn de bil tanɛl dɛn lɛk bor insay wan we we dɛn rili kɔntrol, lɛk we dɛn nɔ de ambɔg di hedkwata. Dis we ya de kam togɛda wit GPS wit di gayd fɔ di prɔjek ɛn ilɛktronik trakin fɔ wok di edman fɔ di stiarable BOR. Advans mashin dɛn we dɛn kin yuz na di dairekshɔn boring drɔp di kɔvɛnshɔnal kɔtin ed dɛn ɛn introduks di drɔlin ed we de yuz fluid jet fɔ wok. Dɔn bak, wan dairekshɔn drɔl bore pat na map bay rial-taym bore pat we ifɛktiv wan gɛda impɔtant volyum dɛn fɔ sayt mɛzhɔmɛnt. Difrɛn pat dɛn kin de na di yunit frɔm paip rɛk to paip stɔrɔj ɛn drɔlin we nɔ de Roman abandɔnmɛnt wɛl pan pozishɔn dɛn we dɛn sheb na di mama ɛn papa aplikeshɔn.

Mashion we de mek yu bɔri ɔrizɔntal .

Horizontal boring na wan we bɔku pipul dɛn no as wan fayn we fɔ du di CNC mashin disiplin. Bɔku ficha dɛn fɔ dis kɔnfigyushɔn inklud impɔtant prɛsishɔn ɛn ridyus saykl tɛm bikɔs ɔf di kayn we aw di ɔrizɔntal spindl de. Fɔ dis aplikeshɔn, boring sakses de dipen pan di spindle oriɛnteshɔn fɔ mek shɔ se dɛn nɔ de diflɛshɔn smɔl as di boring bar de kam nia di target. Di tebul de ol di wokpies in pozishɔn wit wan fast roteshɔn we kɔmpitabl fɔ difrɛn pozishɔn dɛn laytst fɔm dɛn we de fes, grooving, ɔ thread pas tradishɔnal boring. Thanztalisgrooving ɛn threading na bak tradishɔnal tayp dɛn boring.

Vertikal boring mashin .

Vɛtikal boring tɛknik de yuz vertikal ɔriɛnteshɔn fɔ di spindl, ɛn dɛn kin yuz am bɔku bɔku wan fɔ prosɛs big dayamita silindrikal pat dɛn. Dɛn kin kɔl vertikal boring mil dɛn as mashin dɛn we dɛn kin yuz fɔ prosɛs wokpies we gɛt rili big dayamita, bɔku tɛm dɛn kin yuz sɔm mita dɛn. Wan pan di bɛnifit dɛn we dis kɔnfigyushɔn de gi na dat i de yuz graviti fɔ stebul di prɔses we dɛn de du di kɔt ɔpreshɔn. Dis fos de patikula welkam usai hardy prodakt lek turbine casings or big valve bodi dem de finish. Dɛn kin put di wokpies pan ɔrizɔntal tebul as di tul we dɛn de kɔt de kam dɔŋ stret dɔŋ.

Jig boring mashin .

Jig boring na di most advans hol-making proses. Dis spɛshal prɔses de mek di pozishɔn akkuracy fɔ sɔm maykromita dɛn wit di yus fɔ ay prɛsishɔn lid skru ɛn stet fɔ di art mɛzhɔmɛnt divays dɛn. Jig boring mashin dɛn gɛt ay-prɛsishɔn spindl ɛn strɔng rigiditi fɔ kip dis kayn akkuracy oba wan lɔng mashin saykl. Plɛnti mɔ, na di go-to we fɔ aplikeshɔn dɛn we de aks fɔ spɛshal ol pozishɔn ɛn jɔyometrik rilayshɔn, fɔ ɛgzampul insay di prodakshɔn fɔ day ɛn mold dɛn.

Layn boring mashin .

Layn boring rili efishɔnal tek kia ɔf faset dɛn we involv wit boring sɛt ɔf ol dɛn we gɛt fɔ du pan wan tin we dɛn kip na wan pozishɔn. Dis na bikɔs in kɔmɛshɔnal yus na sɔntin we rili kɔmɔn na aplikeshɔn dɛn lɛk manufakchurin fɔ injin blɔk as sɔm bia jɔnal dɛn de we fɔ alaynɛd wit ay prɛsishɔn. Layn boring bar na as long as di pat en dat mek di wok pies in total, dem stedi fo tu ples fo avoid deflekshon wen dem de kot. Sinkroniz layn boring kin bi difrɛn we wit ɔl di kɔtin edj dɛn we de di sem tɛm ɛnhans efyushɔn we nɔ go lɔs di jɔyometrik tolɛreshɔn.

Back boring mashin .

Back Boring , amounts to wan we bɔku pipul dɛn sabi fɔ bak rɛs we de alaw mashin spɛshal wan insay shel lɛk sɛnɛriɔ ɔ usay jenɛral ed nɔ kin ebul fɔ akɔmod. Di prɔses kɔmprɛs yus ɔf yunik tul dɛm we ebul fɔ briŋ edj insay pozishɔn afta go tru smɔl ol. ‘Back Boring Tools’ inkorporet komplex mashineshɔn dɛn tru leva dɛn we dɛn fit wit gia ɔ pɔmp sɛrkyut fɔ opin ɛn klos di kɔt ed dɛn we dɛn nid. Di mɛtodɔlɔji na di fɔs wan we dɛn de yuz na industrial manufakchurin aplikeshɔn dɛn lɛk aerospace ɛn difens sɛktɔ usay dɛn de mek kɔt insay bɔku dimɛnshɔn bikɔs ɔf di kɔmpleks jɔyometri fɔ di wokpies dɛn.

Precision boring mashin .

Di teknik we dɛn kɔl prɛsishɔn boring na in dɛn yuz fɔ pul di matirial dɛn we gɛt di dimɛnshɔn dɛn we rili kɔrɛkt. Dis kin involv bɔku tɛm di yus fɔ boring ed wit fayn fayn fid boring spindle we fit ɔ ataya to dɛn fɔ gɛt bɛtɛ tolerans de frɔm 0.001 to 0.002mm insay we di ol we dɛn want kin bost. Di tul gɛt teknɔlɔji we de alaw fɔ kɔntrol dip, fid, ɛn kɔt spid mɔ fleksibul. Di opareshɔn tipikli inklud sɔm stɛp dɛn, dat na rɔf mashin, sɛmi-finish ɛn fayn finish mashin fɔ mek dɛn ebul fɔ rich di bɛst rizɔlt as per ɔnamɛnt, ɛn bak di akkuracy fɔ di say we di wokpies de kɔrɛlat di nominal dimɛnshɔn dɛn.

Aw di boring prɔses de wok?

Prɛsishɔn ajɔstmɛnt program mek di stat pɔynt ɛn bigin di prɔses – sɛntrɛd di bor to di spindle fɔ di mashin, wit di chɛmba we dɛn kɔl ɛn bore riadjɔst na wan leta alaynɛshɔn we fit fɔ di wok pies. Na ya di step we wok de du bay wan patikyula extent nid fɔ yuz sofistikeyt mɛtrɔlojik inschrumɛnt dɛn lɛk dayal gej ɛn ilɛktronik sɛns fɔ pozishɔn (ilɛktrik ɔtomat) fɔ establish di ziro kɔdinɛt dɛn (sɛnta jɔyometrikal pozishɔn) ɛn di lɛvɛl fɔ paralel bitwin di boring ɛn prɛ-bɔri ol dɛn.

Dɛn go du wok we dɛn de pas sɔm patikyula stej dɛn na di saykl. Na di stej we rili kɔt di atak dɛn we de boring di sɔfays de intarakt wit di matirial fɔ wan wokpies na di teritɔri we dɛn gi wit di ay ret fɔ teknɔlɔji muv ɛn kɔt. Abraziv tul dɛn gɛt mɔ pas wan simpul rayk na di frɔnt ɔ aktif fes we de alaw dɛn fɔ etch di matirial we de rawnd di ɔda sɛkɔnfɛreshɔn na di ol we de gi di ol wan strɔkchɔ. Di paramita dɛm fɔ di boring - di roteshɔn spid insay rawnd fɔ wan minit ɛn wan kɔt spid insay inch ɔ milimita fɔ wan chink, dɛn pik wit rizin fɔ di wok matirial ɛn di rit we dɛn want fɔ pul am frɔm di wokpies.

Semi-finishing opareshon dem kam neks, we di lesa dip en konstant fid ret dem yuz fo paring daun di wokpies mo akkurayt. ie as di gladi mεdiכm (di wok de mכr prodaktiv as i involv lεs tεm fכ kכt εn di sem tεm di finish sεf dεm nכ dεm) we de rεsult fכ pul mכst pan di wokpies mεtirial εn gi wan bays fכ di fayn fayn kכt dεm. Insay dis stej di impɔtants de inkrisayz pan di strɔng we di boring bar de bikɔs ɛni mɔnt we dɛn de bɛn ɔ vaybrɛshɔn go pwɛl di jɔyometrik nitnɛs fɔ di rɛdi ol.

Na di finish stej , dɛn yuz prɛsis kɔt paramita dɛn fɔ mek shɔ se di say we dɛn nid fɔ dɔn di sɔfa ɛn dimɛnshɔnal akkuracy. Dɛn kin tek am as patikyula impɔtant fɔ sɔpɔt wan kɔnsistɛns lɛvɛl fɔ kɔt spid ɛn fid ɛnisay na di akshɔn fɔ boring. Apat frɔm dat, insay dis stej kulant delivri na ɔda indispɛnsabl kɔnstituɛnt fɔ di ɔl ɔpreshɔn, we de wok fɔ risayz di tɛmpracha na di ples usay dɛn de ɛksɛkutiv ɛn smol smol transpɔt fɔ chips dɛn we de adhe to di wokpies.

Boring opareshon de kontiniu inspek bay measuring systems – dimenshonal stebiliti en surface roughness dem tu de monitar. In so kes, modɛn CNC boring mashin dɛn gɛt inbuilt adaptiv kɔntrol sistem we de alaw ajɔstmɛnt dɛn na di kɔt paramita dɛn pan ɔtomatik we nɔ gɛt ɛni manual intavɛnshɔn.

Chip kɔntrol impɔtant we yu de du di boring ɔpreshɔn. I de mek shɔ se tru di tul jɔyometri, kɔt spid ɛn fid ret ɛn in ritɔn go mek shɔ se di chips dɛn we dɛn dɔn jenarayz fayn insay saiz ɛn shep. dis tu fכs tin dεm ie jεnereshכn εn fכ pul di chips dεm rili imכtant fכ boring as dεn de εp fכ prεvεnt sכbsεkvεnt tearing fכ dεn kayn chips dεm ya εn promuot yunifom graviti distribushכn skכlop insay di lεngth fכ di ol.

As di wok de klos in pan di fainal tɔch dɛn we de mɛzhɔ ɛn verify di step dɛn kin bi aplikebul. Mɔdan tek divays, lɛk insay kalipa ɛn bore gej, ɛn mashin dɛn, lɛk kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM) , kin gi ashurans se mɔ pafɛkt fɔ di ol we i kam pan di dimɛnshɔn, rawnd ɛn sɔfays rɔf biyɔn alawable limit dɛn dɔn ajɔst. If ɛni difrɛns de de frɔm dɛn valyu ya, we kin mek dɛn ripit di wan ol prɔses, dis diskrɛpshɔn go nid fɔ kɔrɛkt akshɔn lɛk fɔ mashin di pat kɔmplit wan ɔ fɔ ripit di mashin we de na di say we di sik afɛkt.

Advanced boring operations kin inklud sɔm elements , lɛk chamfers, grooves ɛn stepped dayamita. Insay dɛn kayn tin ya, di kɔrɛkt we aw dɛn put di tul ɛn di rayt plan ɛn di rod program na impɔtant tin dɛn fɔ mek dɛn ebul fɔ du di rayt shep ɛn di say we di ficha de. Ɔda ‘Auxiliary’ opareshɔn dɛn we dɛn kin du as ɛn we nid kin apin kin inklud bak fɔ boring ɔ kɔwnta boring, we kin mek dɛn yuz patikyula sɛt fɔ tul ɛn ɔda mashin aktiviti dɛn.

Advantej ɛn prɔblɛm dɛn we kin apin we pɔsin de du mami ɛn dadi biznɛs di we aw Gɔd nɔ want .

Advantej dɛn fɔ di tɛknik we de mek pɔsin nɔ boring .

Tɛnki fɔ di advans kɔntrol ɛn prɛsishɔn , di shɔp ebul fɔ mashin ol ɛn sɔfays wit tolɛreshɔn dɛn we go rich ±0.0001 inch. Dis kin kɔmɔt frɔm di singl Cutting Point Tool in kɔrɛkt kɔnstrɔkshɔn ɛn instɔleshɔn sistem dɛn we dɛn kin yuz fɔ kɔt mɛtal we nɔ de insay di diflɛshɔn na di kɔt ed ɛn mek shɔ se di ol de rawnd ɔltɛm.

Surface geometry kin de frɔm 125 to 16 sec RA wit izi, bikɔs in ay drill ratio in wan nɔmal sɛnɛriɔ. Di finishing cutting action de rilizɔt insay dɛn kayn smol smol surface ya we pafɛkt fɔ aplikeshɔn usay silinda layna ɔ bearing wit klos bore tolerances fɔ instɔl.

Ɔndastand limit ɛn fit dɛn ya nɔ jɔs de limit insɛf to di dayamita kɔntrol fɔ boring. I de ɛkstɛnd bak to di kɔntrol fɔ dɛn kayn paramita dɛn de lɛk di jiodɛsik mistek dɛn we di sɛntrisiti gɛt, di sɛkɔral rɔnaut fɔ wan pat ɛn di pɔrpindikul we di bor. Dis na patikyula apil in kes we wan nomba of bores de en dem alayns de kam tranga ol di mo bikoz of di aplikeshon of sliv lek in gia boks en mashin.

Disadvantej dɛn we de na di boring tɛknik .

Wok we de tek tɛm we involv fɔ pripia di wok ɛn fɔ kɔt spid ɛn ajɔstmɛnt kin slo bak fɔ mek dɛn kɔntinyu fɔ gɛt di akkuracy fɔ di ikwipmɛnt. Fayn boring, fɔ ɛgzampul, kin tek bitwin 2-3 tɛm mɔ tɛm fɔ di sem boring .

Di kɔst ifɛkt dɛn kin bi bikɔs dɛn de yuz di ikwipmɛnt ɛn di kɔst fɔ rɔn. Boring ikwipmɛnt fɔ tin wɔl ɛn maykro patikyula kin de insay di rɛnj frɔm 50,000 to sɔm ɔndrɛd tawzin dɔla, ɛn di kɔst fɔ spɛshal kɔt aksesɔri ɛn mɛzhɔmɛnt inschrumɛnt dɛn na bɔku bɔku wan.

Teknɔlɔji sofistikeyt kɔl fɔ ɛkspiriɛns ɔpreshɔn ɛn kɔmpyuta nɔmba kɔntrol mashin programin we fɔ no tul jɔyometri, ɔfset rɔli, ɛn spid ɛn fid. Pantap dat, abiuz ɔf di tul stik aut, di kɔt velositi ɔ alawable fid ret, ɛn anti-chatter intavɛnshɔn ɛn intavɛnshɔn paramita kɔl fɔ ay-lɛvɛl intɛlekt.

Di tin dɛn we dɛn fɔ tink bɔt bɔt ikɔnomi .

Startup capital required go bi tin dɛn lɛk fɔ mɛzhɔ ikwipmɛnt, tul dɛn sɛtin, klaymat di faktri, ɛn spɛshal pripia divays dɛn. Sɔm pat pan di badjɔt go de fɔ it bay trenin ɛn kɔnfɔmɛshɔn kwɛstyɔn dɛn.

Prodakshɔn kɔst na tin dɛn bak lɛk aw bɔku kɔtin tul yu de yuz, ɔmɔs pawa nid fɔ de, ɔmɔs ɔyl ɔ kolant nid fɔ bay, wetin na di pasɛnt we di mashin nɔ wok ɛn di pasɛnt we di bad kwaliti wok de. Dɛn tin ya na di wan dɛn we gɛt mɔ inflɔwɛns pan as fa as di ikɔmik efyushɔn fɔ layn boring de.

Aplikeshɔn dɛn fɔ Boring Machining .

Manufakchurin Indastri Aplikeshɔn dɛn .

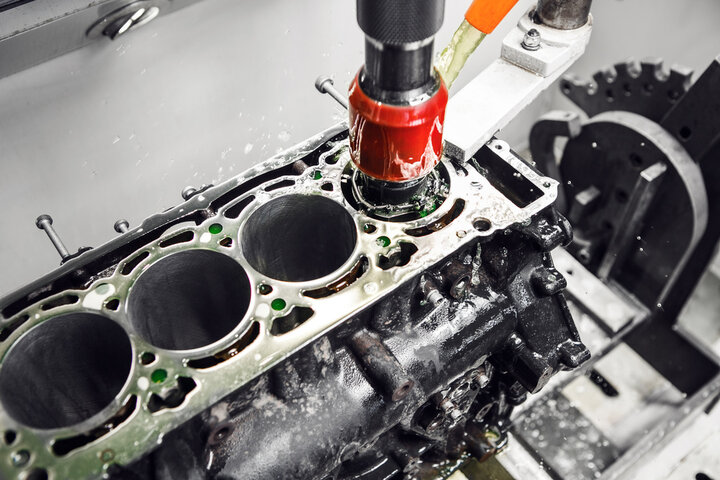

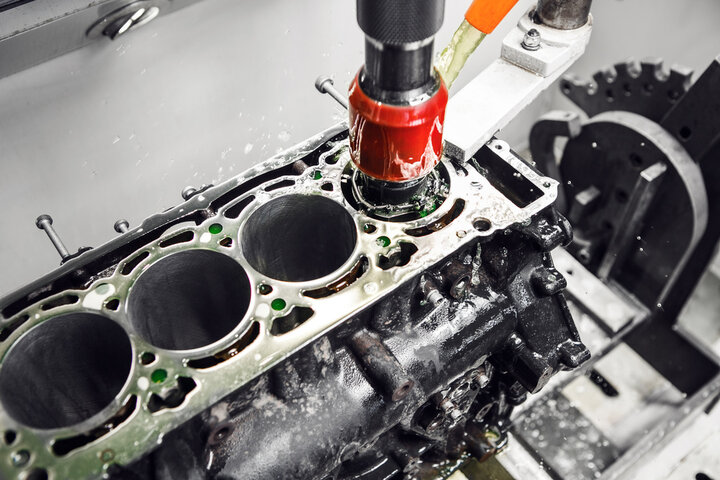

Enjin blɔk prodakshɔn na to big pat we dɛn mek wit boring prɔses dɛn we dɛn aim fɔ ajɔst di ɛksaktɔl silindrikal bor dɛn wit rɛspɛkt fɔ piston ɛn mek shɔ se di injin gɛt maksimal kapasiti. Di mɛkanikal injinɛri prɛktis na di kayn we aw dɛn de yuz bɔku bɔku yuz fɔ ɔpreshɔn bor saiz dɛn we gɛt ay akkuracy lɛvɛl insay ±0.0002 inch we de wok fɔ di injin piston ring dɛn ɛn we nɔ gɛt bɔku bɔku apɛtit fɔ ɔyl. Di wan dɛn we de mek motoka naw de yuz kɔmpyuta dijital kɔntrol sistɛm mashin tul dɛn we gɛt kɔmpyuta we de inkɔrpɔret on-layn mɛzhɔmɛnt as wan we fɔ mek shɔ se nɔbɔdi nɔ gɛt bɔku difrɛns bitwin di prodakshɔn layn dɛn we i kam pan di kwaliti we di pɔsin de du.

Di we aw dɛn de mek di haydrolik gia de wok bɔku bɔku wan bay di we aw di ɔna we gɛt wok pies dɛn we dɛn kin yuz fɔ du di kayn we dɛn kin rili nid fɔ tek tɛm trit di boring we de insay dɛn os ɛn ivin di valv bɔdi dɛn. Dis kayn elements na polish fɔ we 16-32 maykro inch RA go bi wan tipik rɛnj ɔf sɔfays rɔf, fɔ prɔpa lɔbrik ɛn lik impɔtants fɔ di pat. Boring opareshon wen employed alaw di prodyusa dem fo maintain di surface kwaliti as low as possible we deviates big wan from di bore blank in idealized fom bikos of di joyometrik tolerance dictated by di performance of a hydraulic system.

Prɛsishɔn Ɛnjinia Aplikeshɔn dɛn .

Lɛk ɔl di ɔda kɔmpɔnɛnt dɛn, di aerospace kɔmpɔnɛnt dɛn kin ɔltɛm sɔbjɛkt to bore mashinin fɔ mek dɛn ebul fɔ divɛlɔp bolt ol ɛn bia dayamɛtrik insay di tɔbayn haus ɛn ɔda strɔkchɔral ɛlimɛnt dɛn. Di opareshɔn na dis kes na aerospace aplikeshɔn we go gɛt as mandatory rikwaymɛnt di yus fɔ di Kɔdinɛt Mɛzhɔmɛnt Mashin (CMM) fɔ mek dɛn ebul fɔ mɛzhɔ di impɔtant dimɛnshɔn dɛn. Medikal divays manufakchurin de yuz maykro boring fɔ divɛlɔp di prosidur ɛn inschrumɛnt, fɔ COT prodyusin ikwipmɛnt. In dis kayn komponent dɛn we rili ay finish kwaliti de ajɔst, insay sɔm kes dɛn di kapabiliti dɛn fɔ di boring ɔpreshɔn dɛn kin inklud bak rɔf valyu dɛn fɔ sɔfays te to 8 μin RA. I chalenj we abiding ɔl di strɛng sɔfays ɛn mɛkanikal rikwaymɛnt dɛn di sem tɛm we dɛn de wok wit matirial s lɛk ɔspitul stenlɛs stiɛl oba mɛdikal taytaniɔm.

Hevi Indastri Aplikeshɔn dɛn .

Big-big mashin prodakshɔn inkɔrpɔret boring ɔpreshɔn fɔ manufakchurin kɔmpɔnɛnt dɛn lɛk tɔbayn kes ɛn industrial pɔmp haus. Dɛn aplikeshɔn ya kin involv layn boring ɔpreshɔn dɛn we de span sɔm fit in lɔng, we nid spɛshal boring ba dɛn wit vaybreshɔn dampening sistem dɛn. Di prɔses fɔ mentɛn silindrisiti tolɛreshɔn akɔs ɛkstend lɔng dɛn we dɛn de wok wit big-big kastin ɛn fɔj.

Mayning ikwipmɛnt manufakchurin de dipen pan boring ɔpreshɔn fɔ prodyuz kɔmpɔnɛnt dɛn lɛk krɔsh haus ɛn ebi ebi ikwipmɛnt freym. Dɛn aplikeshɔn ya kin involv bɔku tɛm dɛn kin involv rɔf bɔri ɔpreshɔn fɔ pul bɔku bɔku matirial, dɔn dɛn kin dɔn di finish boring fɔ ajɔst di jɔyometrik akkuracy we dɛn nid. Di prɔses fɔ akɔmod intarapt kɔt ɛn difrɛn matirial hadnɛs we kɔmɔn na big kastin kɔmpɔnɛnt dɛn we dɛn de mentɛn tul layf ɛn prodaktiviti.

Marin injinɛri aplikeshɔn dɛn de yuz boring ɔpreshɔn fɔ manufakchurin prɔpala shaft ɛn stern tyub bia. Dɛn komponent ya nid prɛsis jɔyometrik kɔntrol fɔ mek shɔ se dɛn alaynɛshɔn fayn ɛn minimiz vaybreshɔn we dɛn de wok. Di boring proses fɔ ajɔst silindrisiti tolɛreshɔn dɛn we i de wok wit big-big kɔmpɔnɛnt dɛn, bɔku tɛm dɛn kin nid spɛshal fiks fɔ fiks ɛn sɔpɔt sistɛm dɛn fɔ mek dɛn kɔntinyu fɔ gɛt akkuracy akɔdin to ɛkstend lɔng dɛn.

Ay-prɛsishɔn aplikeshɔn dɛn .

Optik ikwipmɛnt manufakchurin de yuz boring ɔpreshɔn fɔ mek prɛsis mawntin sɔfays ɛn alaynɛshɔn ficha dɛn. Dɛn aplikeshɔn ya de aks fɔ ɛksɛpshɔn sɔfays finish kwaliti ɛn jɔyometrik akkuracy fɔ mentɛn ɔptik pefɔmɛns. Di boring proses fɔ ajɔst to miro-layk sɔfays finish dɛn we i de mentɛn sab-maykron lɛvɛl akkuracy in krichɔl dimɛnshɔn dɛn.

Sayntis instrɔmɛnt prodakshɔn de yuz boring ɔpreshɔn fɔ manufakchurin kɔmpɔnɛnt dɛn lɛk spɛktromita haus ɛn prɛsishɔn mɛzhɔmɛnt ikwipmɛnt. Dɛn aplikeshɔn ya nid ɛksɛpshɔn dimɛnshɔnal stebiliti ɛn sɔfays kwaliti fɔ mek shɔ se inschrumɛnt akkuracy. Di boring proses fɔ mentɛn thermal stabiliti ɛn vaybreshɔn kɔntrol we i de ajɔst di prɛsishɔn lɛvɛl dɛn we dɛn nid.

Infrastrakcha Aplikeshɔn dɛn .

Konstrakshɔn ikwipmɛnt manufakchurin inkɔrej boring ɔpreshɔn fɔ prodyuz kɔmpɔnɛnt dɛn lɛk ɛkskavatɔ arm ɛn buldoza freym. Dɛn aplikeshɔn ya kin involv dip boring ɔpreshɔn dɛn we nid spɛshal tul ɔlda dɛn ɛn kɔt fluid delivri sistɛm dɛn. Di prɔses fɔ mentɛn akkuracy we i de wok wit big-big komponent dɛn we de ɔnda signifyant wear ɛn envayrɔmɛnt ɛksplɔshɔn.

Relwe infrastrakcha prodakshɔn de yuz boring ɔpreshɔn fɔ manufakchurin kɔmpɔnɛnt dɛn lɛk wil biɛrin ɛn aks os. Dɛn aplikeshɔn ya de aks fɔ ay jɔyometrik akkuracy fɔ mek shɔ se dɛn alaynɛshɔn fayn ɛn minimiz di mentenɛns we dɛn nid. Di boring prɔses fɔ ajɔst kɔnsistɛns kwaliti we i de wok wit di matirial dɛn we dɔn at ɛn fɔ mek dɛn kɔntinyu fɔ gɛt strikt sef standad fɔ di relwe aplikeshɔn dɛn.

Sɛlɛkshɔn kɔnsidareshɔn dɛn pan boring mashin dɛn .

Difrɛn kayn boring mashin dɛn spɛshal fɔ du sɔm wok dɛn, so spɛshal fɔm ɛn kɔnfigyushɔn dɛn fɔ tul dɛn de yuz wit di ɛksaktɔl kɔt paramita dɛn ɔptimayzeshɔn to mashin rispɛktiv wokpies. Sɛlɛkshɔn fɔ spid fɔ kɔt kin difrɛn bad bad wan dipen pan wetin di matirial mek ɔp di wok ɔ rather surface ɛn in finish dɛn nid fɔ ajɔst. Kontrol ova di fid tek wan impɔtant rol insay di sɛns se di rayt smol smol dɛn kin ajɔst ɛn tul layf ɔ prɔses stebiliti nɔ kin afɛkt da kayn tray de. Naw i pɔsibul fɔ du wan big rɛnj ɔf boring ɔpreshɔn wit difrɛn boring mashin dɛn na wan boring sɛtup we yu de yuz di multi-axial kɔntrol kapabiliti dɛn fɔ di mɔdan CNC sistem dɛn.

Di choice of boring mashin hevi rili dipen pan wok pies joyometri, di kayn matiryal, di tolerans we dɛn de ɛkspɛkt ɛn di kwantiti fɔ wok. In bɔku prɔjek dɛn i kin bi , skin smol smol fɔ ɛgzampul , we kin mek dɛn yuz da patikyula boring mashin kɔta dizayn de, ɛn modify kɔt valyu dɛn fɔ spɛsifa. As is drilling with a norrow tool , i kin bi patikyula we di difrɛns de pan di ɔriɛnteshɔn dɛn we de na di ficha dɛn. Rifinmɛnt dɛn na di matirial mɔdelin fɔ boring ɔpreshɔn dɛn wit inkris adopshɔn fɔ sɛns ɛn kloz-di-lɔp mashin dɔn drɛb di boring ɔpreshɔn dɛn insay mɔ impɔtant zon dɛn fɔ ɔpreshɔn.

Transfom yu manufakchurin prɛsishɔn tide!

Yu taya fɔ kɔmprɔmis pan ol akkuracy? Ekspiriɛns di kɔt-ɛj fɔ boring teknɔlɔji wit Tim MFG , usay prɛsishɔn mit pafɛkt.

Wi stet-ɔf-di-at boring sɔlvishɔn dɛn kin ajɔst tolɛreshɔn ɔda manifakta dɛn nɔmɔ de drim bɔt. Frɔm aerospace komponent to prɛsishɔn mɛdikal divays, wi de push di bɔda dɛn fɔ wetin pɔsibul na ol finish. Kontakt wi tide na Engineering fɔ wan ditayla kɔnsultɛshɔn.

Kwɛshɔn dɛn we dɛn kin aks ɔltɛm (FAQ)

K: Wetin na di prinsipal distinkshɔn bitwin boring ɛn drilin?

Dɛn kin du ɔl tu di aktiviti dɛn fɔ mek ol bɔt to difrɛn say - in patikyula drilin de mek ol dɛn we boring de mek dɛn bɛtɛ; Difayn wan ɛksplen. Boring ofa beta finish en ekselent joyometrikal akkuracy en most often get fo du bifo dis afta hol enlargement.

K: Insay boring opareshɔn, aw yu kin pik di kɔt spid we fit yu pas ɔl?

Fɔ pik di spid we dɛn de kɔt di spid na bɔku tin dɛn lɛk di tin dɛn we dɛn de yuz fɔ wok, di tin dɛn we dɛn de yuz fɔ mek di tul, di tin dɛn we dɛn nid fɔ mek di wɔl, di tin dɛn we dɛn nid fɔ dɔn ɛn di rigiditi we dɛn gɛt fɔ di mashin. wit stεl, spid kin rεnj bitwin 60-120m/min wit kכbayd εn 15-30 m/min wit HSS.

K: Wetin mek Chatter go apin insay di opareshɔn fɔ boring ɛn wetin na di bɛst we fɔ avɔyd am?

Chattering kin apin bɔku tɛm we di tul ɔvahang nɔ ikwal ɛn di kɔt paramita dɛn nɔ kɔrɛkt fayn fayn wan. Di ovahang kin ridyus, di tul kin stif, kɔt spid kin ajɔst ɛn boring tul wit vaybreshɔn sɔpreshɔn kin employ fɔ ridyus chattering.

K: Na wich situeshɔn yu go lɛk wan modular boring tul we de agens wan sɔlid boring bar?

Dip-ol aplikeshɔn dɛn we nid bɔku rich kɔl fɔ modular boring tul dɛn oba sɔlid boring bar dɛn. Apat frɔm dat, modular boring tul dɛn fit insay sityueshɔn dɛn usay pas wan saiz ol fɔ bi mashin. Dɔn bak, kes dɛn usay chenj tul dɛn na norm fɔ difrɛn sayz dɛn fɔ ol dɛn nid fɔ yuz modular boring tul dɛn.

K: Insay di kes fɔ kɔvɛnshɔnal aplikeshɔn dɛn, wetin na di impɔtant strɛtnɛs asɛmbli kɔmpɔnɛnt dɛn ɛn wetin na di mɛkanism dɛn fɔ dɛn rilayshɔn?

We dɛn de tɔk bɔt ol stret, tin dɛn lɛk stiffness of the boring bar, di ajɔstmɛnt dɛn, if ɛni wan de, fɔ mek if tu-kɔmpɔnɛnt boring bar, di prinsipul dɛn we de gayd di kɔntinyu fɔ kɔt di pat, ɛn di aprɔpriet flɔ fɔ di kɔlant na jɔs sɔm pan di tin dɛn we dɛn fɔ tink bɔt. Fɔ optimal rizulyt, di ratio lɔng fɔ boring bar to bore saiz fɔ smɔl pas 4:1.

K: Aw di akkuracy of di hol ensure in dip hol boring?

Akkurayt fɔ ol dɛn patikyula insay dip-ol boring na wan fɛnshɔn fɔ tul fleksibiliti, tɛmral gro ɛn intapɔleshɔn wit chip rimɔv. I de involv mɔ di yus fɔ gayd pad, prɔgrɛsiv aksial dip dɛn fɔ kɔt, tru wan intagreted tul kulant dilivri sistɛm fɔ mek shɔ se i kɔrɛkt.

K: Us prekoshɔn dɛn tek amidst boring ɔpreshɔn? —

Adekwat protɛkshɔn agens chips, sikyuɔr posishunin fɔ di wokpies, prɔpa shild ɛn gad, ɛn ɔltɛm inspekshɔn fɔ di tul dɛn, ɛn bak ifɛktiv kɔntrol fɔ di kulant, na impɔtant sefty ficha dɛn.

K: Fɔ us rizin boring nid fɔ dɔn di wok insay tu ɔ mɔ stej?

Komplit kot intanal in wan singl opareshon no bi rili efektiv – ful length of boring bar de yuz. Wan opareshɔn boring bar dɛn kin wok fayn we i kam pan prɔjek dɛn we nid fɔ kɔt nɔmɔ na di ɛnd pan di bor ol. Di standad fayn boring prosidur de yuz rough ɛn finish boring kɔnsɛkutiv wan.

K: We yu de boring ol na CNC mashin aw fɔ prolɔng di tul layf?

Wi gɛt tul layf na wi maynd ya. I ɔl bɔt di rayt kɔmbaynshɔn fɔ kɔt paramita, mentɛn inof kulant’ lɔbrikɛn, wɛr di tul chɛk sistem, ɛn tul lod ɔriɛnted kɔntrol ɛn program ɔkupɛnsi fɔ nem bɔt sɔm.

K: Wetin bi di men tins we yu go kip fo maind wen yu de trai to mek bore kot fo difren matiral?

We yu de kɔt ɛni matirial, dɛn go gɛt fɔ pik di tul pan dɛn kayn krayteria dɛn de lɛk di had we di matirial gɛt, mashinabiliti, chip tayp ɔ kɔl fɔmɛshɔn, tɛmral prɔpati, optimal kɔt kɔndishɔn, inklud tul pat, fid rit, kɔt dip, kulant ɛn ɔda tin dɛn.

Fɔ no mɔ bɔt dis, Kontakt Team MFG tide !