Ekikuta ky’obuveera mu kulongoosa obuveera kikwata ekifo ekikulu ennyo, omutindo gw’okukola ekikuta n’obusobozi bw’okukola nabyo biraga omutindo gw’amakolero mu ggwanga. Mu myaka egiyise, okukola ekibumbe ky’obuveera n’omutindo gw’enkulaakulana kwa mangu nnyo, okukola obulungi ennyo, okukola otoma, okunene, okutuufu, obulamu obuwanvu obw’ekikuta kyakola ekitundu ekyeyongera ku bino wammanga okuva mu nteekateeka y’ekikuta, enkola z’okulongoosa, ebyuma ebikola, okulongoosa kungulu n’ebintu ebirala okufunza embeera y’enkulaakulana y’ekibumbe.

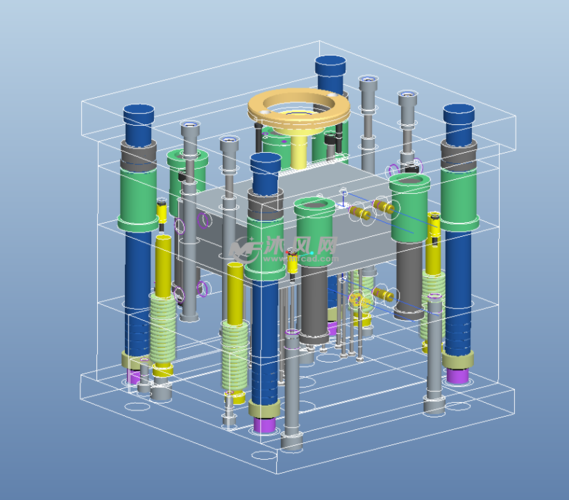

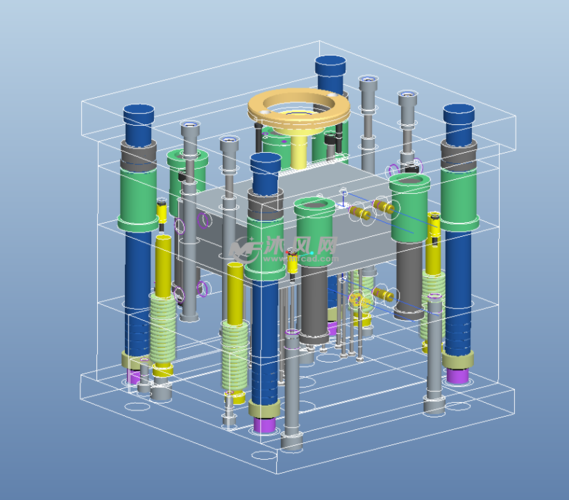

Enkola z’okubumba obuveera n’okukola dizayini y’ebibumbe .

Okubumba nga tuyambibwako ggaasi, okubumba okuyambibwako ggaasi si tekinologiya mupya, naye mu myaka egiyise wabaddewo enkulaakulana ey’amangu n’okujja kw’enkola ezimu empya. Empiso eziyambibwa omukka oguyambibwako omukka gwe mazzi ag’enjawulo agasooka okubuguma agafukibwa mu kaveera okuva mu kifuuyira, amazzi gabuguma mu kisenge ky’ekikuta ne gagaziwa nga gafuuwa omukka, ekifuula ekintu ekituli ne kisika ekisaanuuse ku ngulu w’ekisenge ky’ekibumbe, enkola eno esobola okukozesebwa ku thermoplastic yonna. Empiso eyambibwako ggaasi okukankana kwe kusiiga amaanyi g’okukankana ku kiveera ekisaanuuse nga kiwuguka omukka ogunyigirizibwa okutuuka ku kigendererwa ky’okufuga microstructure y’ekintu n’okulongoosa omulimu gw’ekintu. Abamu ku bakola ebintu bakyusa omukka ogukozesebwa mu kubumba nga guyambibwako ggaasi ne gukola ebintu ebigonvu, era ne bakola n’ebintu ebinene ebirimu ebituli.

Push-pull molding mold, okuggulawo emikutu ebiri oba okusingawo okwetoloola ekikuta, era nga kiyungiddwa ku byuma oba pisitoni bbiri oba okusingawo eziyinza okutambula okudda n’okudda, nga tebannaba kusaanuuka nga bawonya empiso, ekyuma ekikuba empiso sikulaapu oba pisitoni etambula okudda n’okudda okusika n’okusika ekisaanuuse mu kituli, tekinologiya ono ayitibwa dynamic pressure-holding technology its ekigendererwa kyayo ekigendererwa kyayo ekigendererwa kyakyo kibeera kibumba ekizimba.

High pressure molding thin shell products, thin shell products are generally long process ratio products, more multi-point gate mold, but multi-point into the pouring will cause melt joints, for some transparent products will affect its visual effect, single point into the pouring and not easy to fill the cavity, so you can use high-pressure molding technology to molding, such as the US Air Force, the cockpit of the F16 fighter aircraft is produced with this technology, has adopted this technology to produce PC Auto Okutwalira awamu puleesa y’okukuba empiso y’okubumba endabirwamu, eya puleesa ey’amaanyi esukka 200MPa, kale ekintu ekibumba nakyo kisaana okulonda modulo y’omuvubuka ow’amaanyi ow’amaanyi amangi, okubumba kwa puleesa eya waggulu kye kisumuluzo okufuga ebbugumu ly’ekibumbe, nga kwotadde n’okufaayo ku kikuta ekifulumya ekikuta ekifulumya ekikuta kirina okuba nga kiweweevu. Bwe kitaba ekyo, okukuba empiso ey’amaanyi kivaako omukka omubi kijja kwokya akaveera.

Hot Runner Mold: Mu kibumba eky’ebidduka ebingi okweyongera okukozesa tekinologiya w’omuddusi ayokya, amaanyi gaayo mu tekinologiya w’ekitundu kye kikulu ennyo mu tekinologiya w’ekikuta. Kino kitegeeza nti okutambula kw’obuveera kutereezebwa vvaalu y’empiso, eyinza okuteekebwawo okwawukana ku buli kikomera ku budde bw’okukuba empiso, puleesa y’okukuba n’ebipimo ebirala, ekisobozesa okukakasa okw’omutindo era okulungi okw’omutindo gw’empiso. Sensulo ya puleesa mu mukutu gw’okukulukuta ewandiika buli kiseera omutindo gwa puleesa mu mukutu, ekisobozesa ekifo kya vvaalu y’empiso okufugibwa ne puleesa y’okusaanuuka okutereezebwa.

Ebibumbe by’okukuba empiso z’omutwe (core injection molding): Mu nkola eno, omusingi ogukwatagana ogukoleddwa mu aloy y’okusaanuuka eya wansi guteekebwa mu kibumbe ng’ekintu ekiyingizibwamu okubumba empiso. Olwo omusingi ogukwatagana guggyibwawo nga gufumbisa ekintu ekirimu omusingi ogukwatagana. Enkola eno ey’okubumba ekozesebwa ku bintu ebirina ebifaananyi ebizibu ebirimu ebituli, gamba nga payipu z’amafuta oba payipu ezifulumya emmotoka, n’ebitundu ebirala eby’obuveera eby’omusingi ebibeera mu ngeri enzibu. Ebintu ebirala ebikoleddwa n’ekika ky’ekibumbe kino bye bino: Omukono gwa Tennis racket, Pampu y’amazzi ey’emmotoka, ppampu y’amazzi agookya aga centrifugal n’ekyuma ekikola amafuta mu bwengula, n’ebirala.

Okukuba empiso/okunyigiriza ebibumbe: Okubumba okukuba empiso/okunyigirizibwa kuyinza okuvaamu situleesi entono. Optical properties of good products, the process is: okuggalawo ekibumbe (naye ekibumbe ekinywevu ekikyukakyuka tekiggalwa ddala, kireka ekituli okunyigirizibwa oluvannyuma), okukuba empiso y’okusaanuuka, okuggalawo ekibumbe eky’okubiri (kwe kugamba, okunyigirizibwa olwo ekisaanuuse ne kinywezebwa mu kibumbe), okunyogoza, okuggulawo ekibumbe, n’okuggyamu omusaayi. Mu nteekateeka y’ekibumbe, kisaana okumanyibwa nti olw’okuba ekibumbe tekiggaddwa ddala ku ntandikwa y’okuggalawo ekibumbe, ensengekera y’ekibumbe erina okukolebwa okuziyiza okujjula kw’ebintu mu kiseera ky’okukuba empiso.

Laminated Mold: Ebituli ebingi bisengekebwa ebikwatagana mu ludda oluggalawo mu kifo ky’ebituli ebingi mu nnyonyi y’emu, ekiyinza okuwa okuzannya okujjuvu eri obusobozi bw’okufuula ekyuma ekikuba empiso mu bujjuvu, era okutwalira awamu ekikuta kino kikozesebwa mu bibumbe by’omuddusi ebibuguma, ekiyinza okulongoosa ennyo obulungi.

layer products injection mold: layer products okukuba empiso okubumba byombi co-extrusion molding ne injection molding characteristics, bisobola okutuuka ku buwanvu bwonna obw’ebintu eby’enjawulo ku product multi-layer combination, obuwanvu bwa buli layer buyinza okuba obutono nga 0.1 ~ 10mm layer number esobola okutuuka enkumi n’enkumi. Die eno mu butuufu eba ya kugatta dieti ya mpiso n’okufa awamu okw’emitendera mingi.

Mold slip molding (DSI): this method can be molded hollow products, but also molding a variety of materials composite products, the process is: closed mold (for hollow products, the two cavity halves are in different positions), respectively, injection, mold movement to the two cavity halves together, in the middle of the injection combined with the two cavity halves of the resin, this method of molding products compared with blow molding products, have good surface obutuufu, obutuufu obw’ekipimo ekiwanvu, obuwanvu bw’ekisenge obufaanagana, eddembe ly’okukola dizayini. Obugumu bw’ekisenge obumu, eddembe ly’okukola dizayini n’ebirungi ebirala.

Aluminiyamu ekibumbe: Ekifo ekimanyiddwa mu tekinologiya w’okukola obuveera kwe kukozesa ebintu bya aluminiyamu, Corus eyakolebwa Aluminium Alloy Obulamu bw’ekikuta busobola okutuuka ku 300,000, Pechineyrhenalu Company ne Mi-600 Aluminium Manufacturing Plastic, obulamu busobola okutuuka emirundi egisukka mu 500,000

High-speed milling: At present, high-speed cutting has entered the field of precision machining, its positioning accuracy has been improved to {+25UM}, the use of liquid hydrostatic bearing high-speed electric spindle rotary accuracy of 0.2um or less, machine tool spindle speed up to 100.000r/min, the use of air hydrostatic bearing high-speed electric spindle rotary up to 200. 00R/min Omuwendo gw'emmere ey'amangu gusobola okutuuka ku 30 ~ 60m/min. 60m/min, singa okukozesa guide ennene ne sikulaapu y’omupiira ne servo motor ey’amaanyi, linear motor ne precision linear guide, sipiidi y’okuliisa esobola n’okutuuka ku 60 ~ 120m/min. Obudde bw’okukyusa ebikozesebwa bukendeezeddwa okutuuka ku 1 ~ 2S okukola kwayo obukaluba RA < 1um. Okugatta n’ebikozesebwa ebipya (ebikozesebwa eby’ekyuma eby’ekika kya ceramic, ebikozesebwa mu PCBN, ebikozesebwa eby’enjawulo ebikaluba ne zaabu, n’ebirala), nabyo bisobola okukolebwa obukaluba bwa 60HRC. Ebikozesebwa. Ebbugumu ly’enkola y’okukola ebyuma lirinnya diguli 3 zokka, era ekifaananyi ky’ebbugumu kitono nnyo, naddala nga kisaanira okukola ebintu ebiwuliziganya n’okukyukakyuka kw’ebbugumu mu bbugumu (nga magnesium alloy, n’ebirala). Sipiidi y’okusala ku sipiidi ey’amaanyi mu 5 ~ 100m / s, esobola okutuuka mu bujjuvu okukyuka kw’endabirwamu ku ngulu n’okusiiga endabirwamu kungulu kw’ebitundu by’ekibumbe. Okugatta ku ekyo okusala mu maanyi agasala kutono, kuyinza okukola ku bitundu ebigonvu ebirina ebisenge ebigonvu era ebikaluba.

Laser Welding: Ebikozesebwa mu kuweta laser bisobola okukozesebwa okuddaabiriza ekibumbe oba okusaanuusa layeri y’ekyuma okwongera ku buziyiza bw’okwambala kw’ekibumbe, obukaluba bw’oluwuzi olw’okungulu olw’ekibumbe luyinza okutuuka ku 62 hrc oluvannyuma lw’enkola ya laser welding. Obudde bw’okuweta obutonotono (microscopic welding time) bwa sikonda 10-9 zokka, bwe kityo ne kyewala okutambuza ebbugumu mu bitundu ebiriraanyewo eby’ekiyungo kya weld. Enkola ya general laser welding ekozesebwa. Kino tekireeta nkyukakyuka mu nteekateeka y’ebyuma n’eby’obugagga by’ekintu, era tekireeta kuwuguka, kukyukakyuka oba okukutuka, n’ebirala.

EDM Milling: era emanyiddwa nga EDM Technology. Ye nkozesa y’okuzimbulukuka okw’amaanyi ennyo okw’ekyuma ekikuba enkokola eky’amaanyi eky’okukola ensengekera y’ebitundu bibiri oba bisatu, era n’olwekyo tekikyetaagisa kukola buziba bwa kubumba buzibu.

Tekinologiya wa Micromachining (DEM) ow’ebitundu bisatu: Tekinologiya wa DEM awangula ebizibu by’enzirukanya y’ebyuma empanvu era ey’ebbeeyi eya tekinologiya wa Liga ng’agatta enkola ssatu enkulu: deep etching, micro electroforming ne micro replication. Kisoboka okukola ebibumbe by’ebitundu ebitonotono nga ggiya ezirina obuwanvu bwa 100UM zokka.

Precise forming of three-dimensional cavities and mirror electro-fire processing integration only technology: the method of adding solid microfine powder to the ordinary kerosene working fluid is used to increase the inter-pole distance of finishing, reduce the electro-vacancy effect and increase the dispersion of the discharge channel, which can lead to good chip removal, stable discharge, improved processing efficiency and effective reduction of the roughness of the processed surface. Mu kiseera kye kimu, okukozesa amazzi agakola aga pawuda agatabuddwa nakyo kisobola okukola oluwuzi lw’okusiiga akakaluba aka waggulu ku ngulu w’ekintu ekikolebwamu ekibumba okulongoosa obugumu n’okwambala obuziyiza bw’ekikuta ky’ekibumbe kungulu.

Okulongoosa ku ngulu kw’ekikuta .

Okusobola okulongoosa obulamu bw’ekikuta, ng’oggyeeko enkola eza bulijjo ez’okulongoosa ebbugumu, bino wammanga bye bimu ku bikozesebwa ebya bulijjo eby’okulongoosa ku ngulu w’ekikuta n’okunyweza.

Enkola y’eddagala, enkulaakulana yaayo eva ku kuyingira kw’ekintu ekimu okutuuka ku bintu bingi, okutuuka ku kuyingira awamu okw’ebintu ebingi, okukulaakulanya okuyingira kw’ebirungo, okuva mu kugaziwa okwa bulijjo, okuyingira okusaasaana okutuuka ku kusengejja omukka gw’eddagala (PVD), okuteekebwawo kw’omukka gw’eddagala (PCVD ogulinda ion vapor deposition).

ION Okuyingira .

Laser surface treatment: 1 Kozesa laser beam okufuna sipiidi y’okubuguma ey’amaanyi ennyo okutuuka ku kuzikira kw’ebyuma ku ngulu. Mu ngulu okufuna kaboni omungi ennyo nga crystals ennungi ennyo, obugumu okusinga layeri eya bulijjo ey’okuzikiza 15% ~ 20% waggulu, ate entegeka y’omutima tejja kukyuka, 2, omulimu gwa laser surface remelting oba surface alloying okufuna high-performance surface hardening layer. Okugeza, oluvannyuma lw’obutakola nalloy ne CRWMN composite powder, okwambala kwayo mu bunene bwa 1/10 ku kwa CRWMN ezizikiddwa, era obulamu bwayo obw’obuweereza bwongerwako emirundi 14.

Laser melting treatment is the use of high energy density of the laser beam to melt the surface of the metal cooling treatment organization, so that the metal surface layer to form a layer of liquid metal cooling organization, due to the heating and cooling of the surface layer is very rapid so the organization obtained is very fine, if the cooling rate through the external medium to achieve high enough, it can inhibit the crystallization process, and the formation of amorphous state, so also known as laser melting an Amorphous treatment, also known Nga Laser Glazing.

Ebirungo by’ettaka ebitali bimu Okunyweza kungulu: Kino kiyinza okulongoosa ensengekera y’okungulu, eby’omubiri, eby’eddagala n’ebyuma eby’ekyuma, n’ebirala.Kisobola okwongera ku muwendo gw’okuyingira ebitundu 25% ku 30% n’okukendeeza ku budde bw’okulongoosa ebitundu ebisukka mu 1/3. Ebiseera ebisinga, waliwo ekirungo kya kaboni ekitatera kulabika, kaboni ow’ettaka atatera kulabika ne nayitrojeni awamu, okugatta ettaka eritali lya bulijjo, boron ow’ettaka obutatera kulabika n’okugatta kwa aluminiyamu, n’ebirala.

Okusiiga eddagala: Kuyita mu mita y’okugezesa eddagala mu kisoolo kya Ni Pb, gamba ng’okutonnya kw’okukendeeza ku ngulu w’ekyuma, okusobola okufuna okusiiga kwa Ni-P, Ni-B, n’ebirala. Okulongoosa eby’obutonde eby’ebyuma eby’ekyuma, obuziyiza bwa kandulo n’enkola y’enkola, n’ebirala, era ebimanyiddwa nga autocatalytic reduction plating, tewali electroplating, etc.

Nanosurface treatment: ye tekinologiya eyesigamiziddwa ku nanomaterials n’ebintu ebirala ebitali bya low-dimensional non-equilibrium okumala ekiseera, okuyita mu bukodyo obw’enjawulo obw’okulongoosa, okutuuka ku bintu ebigumu eby’okungulu okumala ekiseera, okuyita mu bukodyo obw’enjawulo obw’okulongoosa, okunyweza oludda olugumu oba okuwa emirimu emipya egy’okungulu.

(1) Ekizigo kya nanocomposite kikolebwa nga kigatta ebintu bya nanoplasmonic eby’ekitundu oba eky’ekitundu kimu mu kisengejjo kya bulijjo eky’okuteeka amasannyalaze okukola ekizigo kya nanocomposite. Nanomaterials can also be used for wear-resistant composite coatings, such as n-ZrO2 nanopowder materials added to NI-WB amorphous composite coatings, can improve the high-temperature oxidation performance of the coating at 550-850C, so that the corrosion resistance of the coating increased by 2 to 3 times, wear-resistant livelihood and hardness are also significantly improved.

(2) Ebizigo bya nanostructured birina enkulaakulana ey’amaanyi mu maanyi, obugumu, okuziyiza okukulukuta, okuziyiza okwambala, okukoowa okw’ebbugumu n’ebintu ebirala eby’okusiiga, era ekizigo kisobola okuba n’eby’obugagga ebingi mu kiseera kye kimu.

Okukola ebikozesebwa eby’amangu n’okukola ebibumbe eby’amangu .

Enkola y’enkola y’okubumba empiso esaanuuse kwe kukola oluwuzi lw’ekyuma ekisaanuuse ku ngulu w’ekyokulabirako, olwo oluwuzi lw’okusaanuuka ne lunywezebwa, era ekisaanuuse ne kiggyibwamu okufuna ekibumbe ky’ekyuma, nga kiriko ekintu ekisaanuuka eky’okusaanuuka eky’amaanyi kiyinza okufuula obugumu ku ngulu w’ekibumbe bwa 63HRC.

Enkola z’ebyuma ebikoleddwa mu bwangu (DRMT) ze zino: Laser nga ensibuko y’ebbugumu ey’enkola ya laser sintering (SLS) n’enkola ya laser-based melt stacking (Lens), plasma arc, n’ebirala nga ensibuko y’ebbugumu ey’enkola ya fusion (PDM), okukuba empiso okubumba emirundi esatu okukuba ebitabo mu ngeri ey’obutuufu (3DP) n’ebyuma ebiweza tekinologiya wa lom, SLS mold making mu kulongoosa (3DP) enkola n’ebyuma ebikola ku by’okusiba ebipande, SLS Mold Making mu kulongoosa (3DP) enkola n’ebyuma ebikola ku by’okusiba ebipande, SLS Mold making mu kulongoosa (3DP) enkola n’ebyuma tekinologiya wa lom, SLS okubumba. Okukendeera kukendeezeddwa okuva ku 1% eyasooka okutuuka wansi wa 0.2%, ebitundu ebikola lenzi n’ebintu eby’ebyuma okusinga enkola ya SLS nnongoosereza nnyo, naye wakyaliwo ebitundu nga 5% eby’obuziba, kisaanira okukola geometry ennyangu yokka ey’ebitundu oba ekibumbe.

Enkula y’okukola enkola y’okukola (SDM) , nga tukozesa enkola ya welding okusaanuusa ekintu ekiweweeza (wire), n’enkola y’okufuuyira ebbugumu okukola ultra-high temperature molten droplets deposited layer by layer forming, okutuuka ku inter-layer cure bonding.